Fisher & Paykel DishDrawer DS602I, DishDrawer DS602, DS602, DS602I Installation Instructions Manual

USA

DS602 (Prefinished)

Part No. 599066/D

DS602I (Integrated)

Models DS602 DS602I

Single DishDrawer

Table of Contents

Section 1 General Information

1.1 Preparation

1.2 Product Specifications & Cavity Dimensions

1.3 Options for Installing Multiple Products

1.4 Electrical, Plumbing & Drainage Information

1.5 Product Parts

1.6 Additional Product Parts for Integrated DishDrawer

Section 2 Fitting the DishDrawer

2.1 DishDrawer Mounting Hole Locations

2.2 Connecting the Services

2.3 Flexible Extrusion Attachment for 24 Cavity

Section 3 Inserting DishDrawer Into Cavity

Section 4 Information for Cabinet Maker for Integrated DishDrawer

4.1 Integrated Drawer Front Dimensions

Section 5 Integrated Drawer Front Installation

5.1 Changing the Integrated Badge Enclosure

5.2 Disassembling the Integrated Badge Assembly

5.3 Assembling the Integrated Badge

5.4 Fitting the Badge, Handle & Mounting Panel to the Drawer Front

5.5 Fitting the Drawer Front to the DishDrawer

Section 6 Final Fitting For Single DishDrawer

Section 7 Final Checks

7.1 Installation Wet Test

7.2 Troubleshooting

Page DS_01

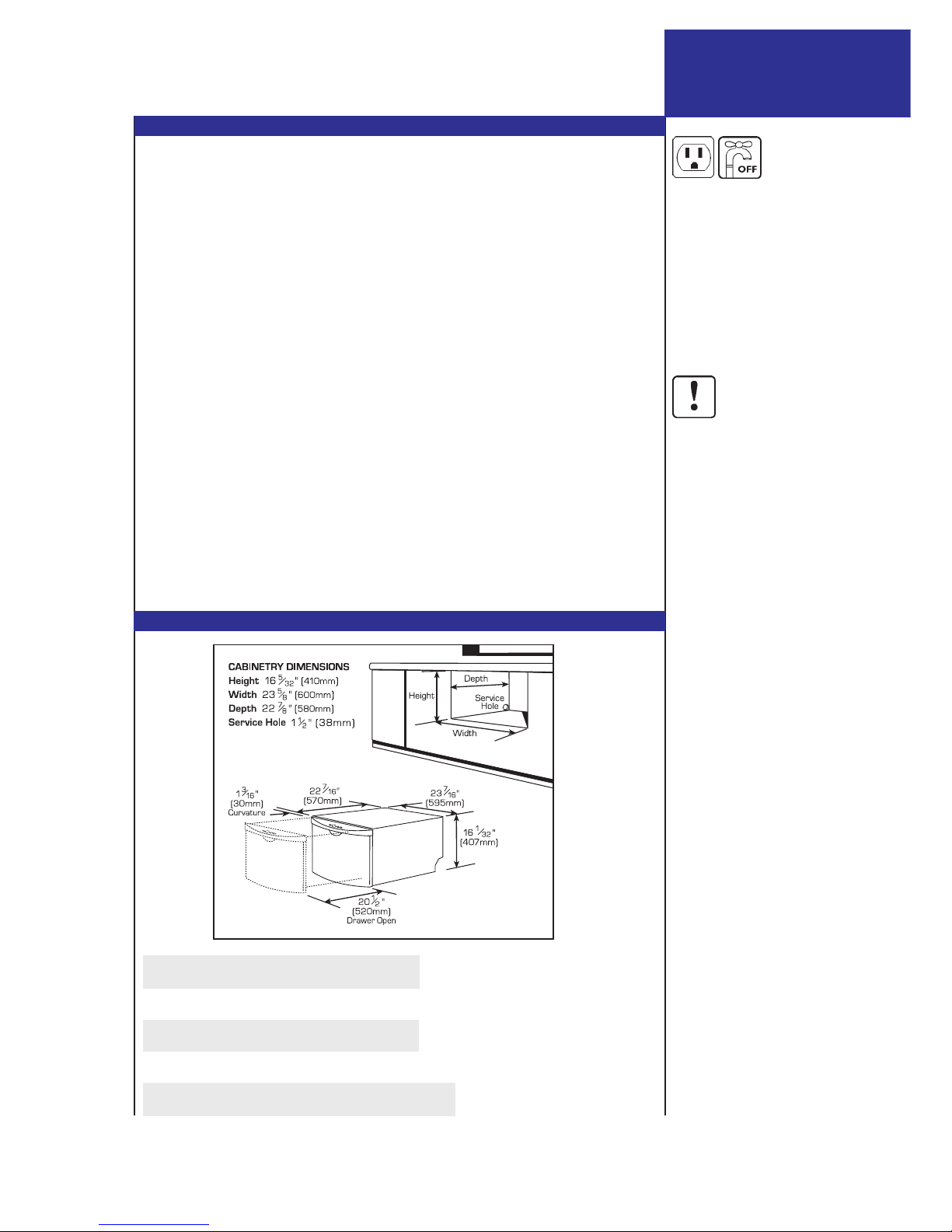

Weight - Full 93lb (42kg) Prefinished

- Empty 62lb (28kg) Prefinished

Electrical 110-120VAC

3 pin socket outlet

Drying Residual Heat &

Fan Assisted

Water Connection Recommended Hot

140°F (60°C) Max.

Water Pressure Maximum 139 p.s.i. (960 kpa)

Minimum 4.3 p.s.i. (30 kpa)

GENERAL INFORMATION

SECTION 1

The DishDrawer MUST

be installed to allow for

future removal from the

enclosure if service is

required.

Before installing the

DishDrawer, remove the

house fuse or open the

circuit breaker.

Ensure all water

connections are turned

OFF.

WARNING

WARNING

STEP 1.2 PRODUCT SPECIFICATIONS & CAVITY DIMENSIONS

STEP 1.1 PREPARATION

Page DS_02

NOTE TO THE INSTALLER

n Be sure to leave these instructions with the Customer.

n Ensure this appliance is properly grounded.

NOTE TO THE CONSUMER

n Keep these Installation Instructions with your Use & Care Manual for future

reference.

IMPORTANT

n Read these Instructions completely and carefully.

n Observe all governing Codes and Ordinances.

WARNING

n These Instructions are intended as a guide only.

n It is the responsibility of the plumber and electrician to ensure that each installation

complies with all Codes and Ordinances.

n Installation of this DishDrawer requires basic mechanical and electrical skills.

n The installer is responsible for the DishDrawer installation.

Improper installation is not covered under the Express Warranty Form.

IMPORTANT

n At the completion of the DishDrawer installation, the Installer must perform Final

Checks as per Section 7 of these Installation Instructions.

n Ensure the DishDrawer enclosure is prepared for installation.

n Remove all packaging and materials supplied with the DishDrawer.

n If you have any questions concerning the installation of this DishDrawer, contact:

Fisher & Paykel Customer Care Centre 27 Hubble

TOLL FREE 1-888-9-FNP USA Irvine

TOLL FREE 1-888-9-367 872 CA 92618

Fax (949) 829 8699 USA

WWW.FISHERPAYKEL.COM

(Water pressure below 7 p.s.i. (50 kpa)

may require the electronics to be

re-programmed by a Service Person

at the time of installation.)

Page DS_03

Where the DishDrawer is

in an under counter

situation, i.e. built into a

kitchen unit, it is

recommended that bare

wood surrounding the

DishDrawer is sealed with

an oil based paint or

polyurethane to prevent

possible steam damage.

IMPORTANT

IMPORTANT

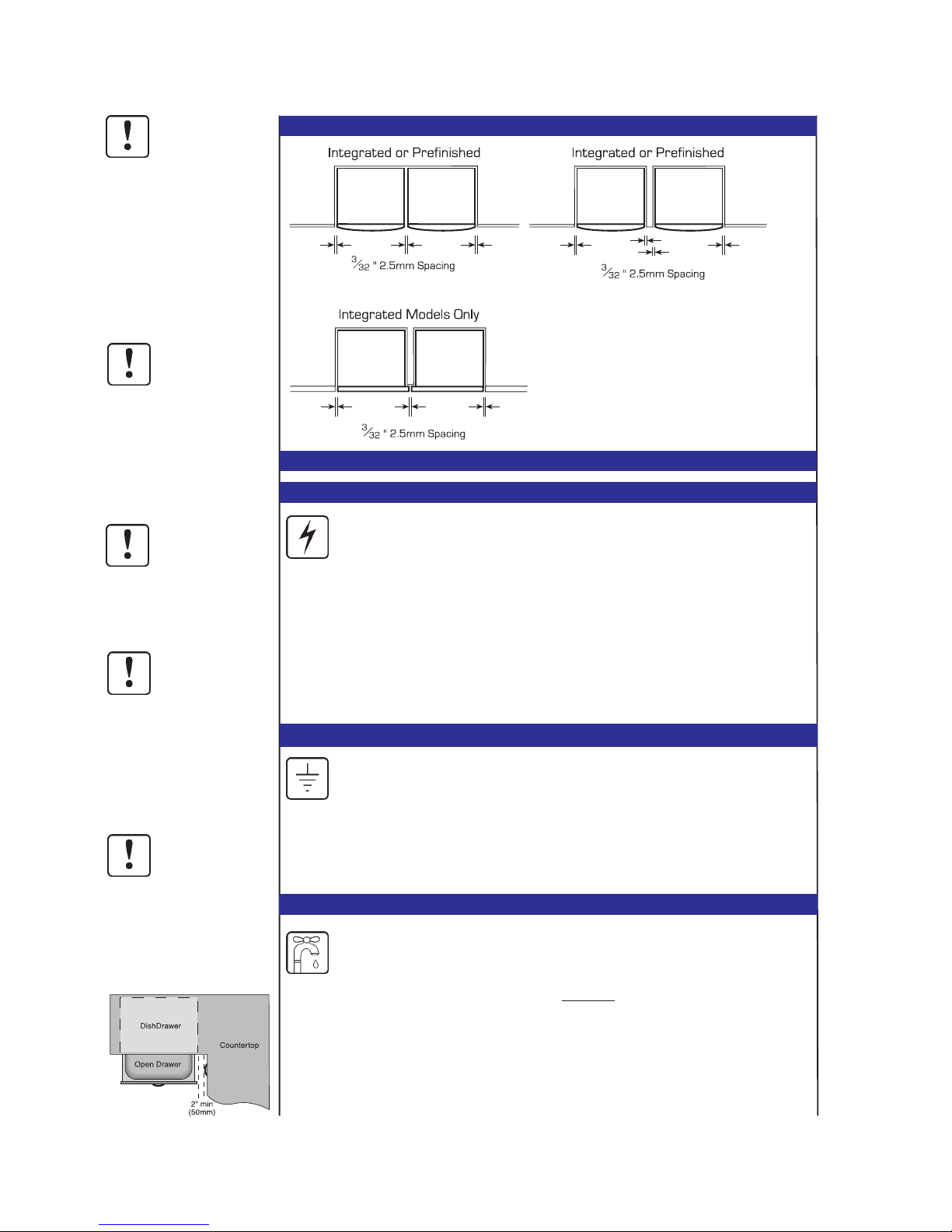

STEP 1.3 OPTIONS FOR INSTALLING MULTIPLE PRODUCTS

IMPORTANT

IMPORTANT

IMPORTANT

If mounting the

DishDrawer near the

bottom of the cabinet,

ensure there is adequate

room underneath the

supporting cabinet to

tighten bolts.

Ensure the cavity sides are

plumb (vertical) as this will

assist with leveling the

DishDrawer.

Ensure the Services Hole is

as close as possible to the

rear corner of the cabinet.

The hole can be located

on either side depending

on the location of the

services.

On corner installations

ensure that there is a gap

of 2" (50mm) minimum

between the adjacent

cabinetry and sides of

drawers.

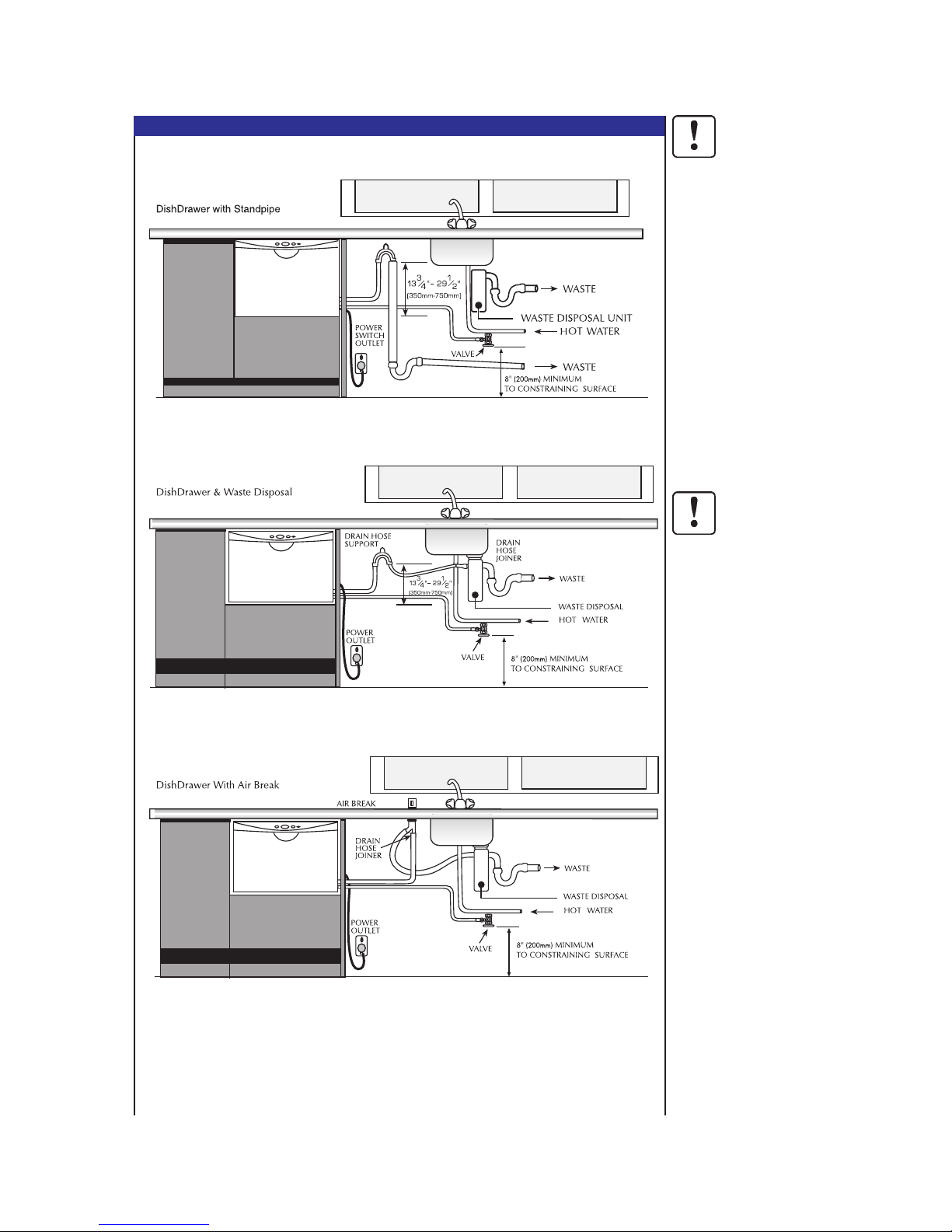

STEP 1.4 ELECTRICAL, PLUMBING & DRAINAGE INFORMATION

ELECTRICAL

GROUNDING INSTRUCTIONS

PLUMBING - WATER SUPPLY

a) The water connection is to be made to a hot water supply only. Ensure the water

temperature is not greater than 140°F (60°C).

b) A readily accessible shut off valve must be installed in the supply pipe.

c) The water supply pressure is to be between 4.3 p.s.i. minimum and

139 p.s.i. maximum.

d) The inlet supply hose must be connected to the water supply using a 3/8"

compression type water supply fitting.

e) Ensure sealing washer supplied with connection hose is fitted.

This appliance must be grounded. In the event of malfunction or breakdown,

grounding will reduce the risk of electric shock by providing a path of least

resistance for electric current.

This appliance is equipped with a cord having an equipment-grounding conductor and a

grounding plug. The plug must be plugged into an appropriate outlet that is installed and

grounded in accordance with all local Codes & Ordinances.

Care should be exercised when the appliance is installed or removed, to

reduce the likelihood of damage to the power supply cord.

If the power supply cord is damaged, it must be replaced by the Manufacturer, its Service

Agent or a similarly qualified person, in order to avoid a hazard.

The power supply receptacle for the appliance should be installed in a cabinet or on a wall

adjacent to the under counter space in which the appliance is to be installed.

The power supply receptacle should be positioned between 6" and 18" (150mm and

450mm) from the cabinet opening of the DishDrawer.

Note: DS602 Prefinished Model is shown. There is no variation in

plumbing between DS602 Prefinished Model and DS602I

Integrated Model.

Options 1 and 2 are the preferred options.

PLUMBING - DRAINAGE OPTIONS

Improper connection of

the equipment-grounding

conductor can result in a

risk of electric shock.

Check with a qualified

electrician or service

representative if you are

in doubt as to whether the

appliance is properly

grounded.

Do not modify the plug

provided with the

appliance - if it will not fit

the outlet, have a proper

outlet installed by a

qualified electrician.

The Drain Hose Support

must be at least 133/4"

(350mm) above the base

of the DishDrawer to

prevent siphoning of the

water during the wash

cycle.

It is recommended that

the Drain Hose Support is

secured in place using the

screw tab.

Ensure that the drain

hoses are fully extended.

WARNING

WARNING

Page DS_04

Option 1

Option 2

Option 3

Page DS_05

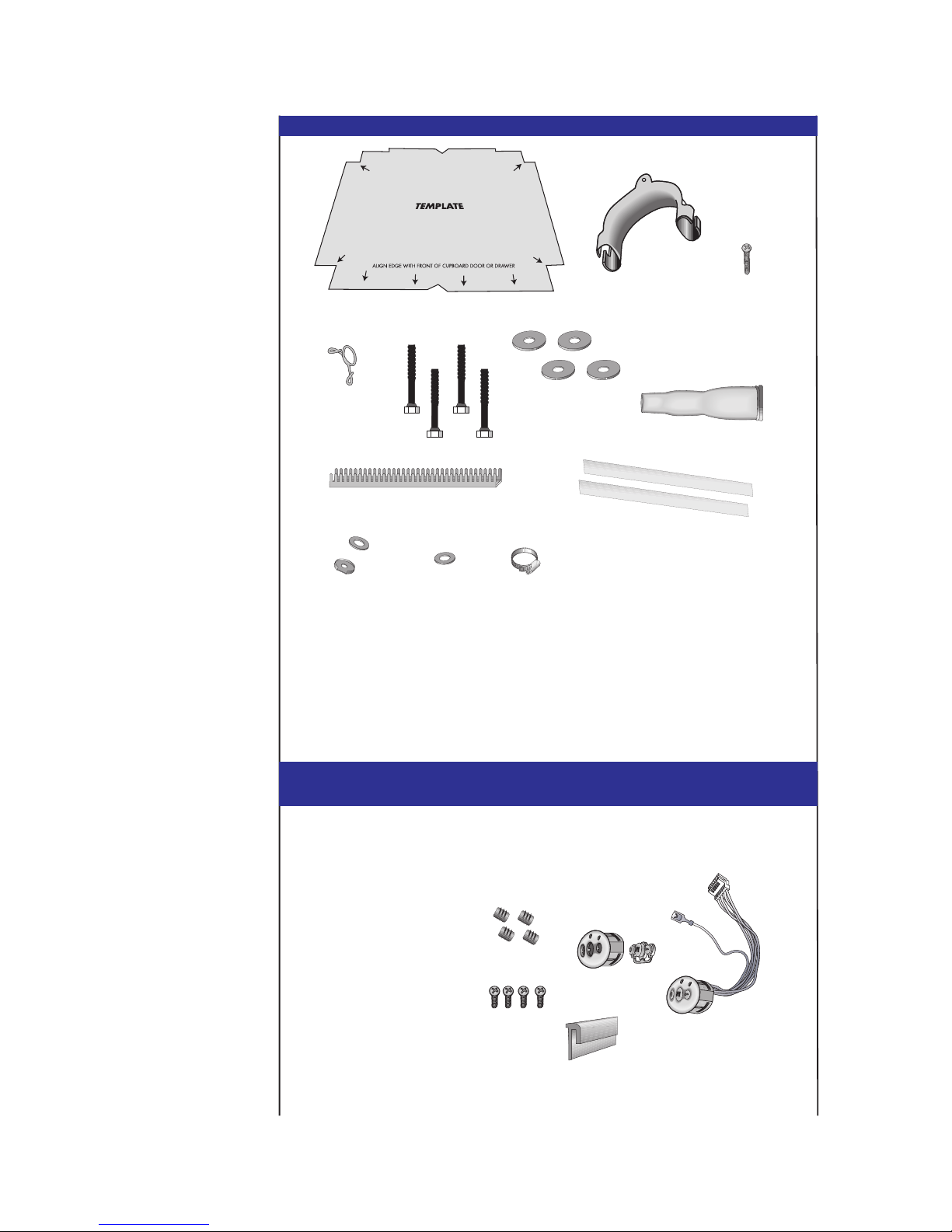

STEP 1.5 PRODUCT PARTS

Tools Needed To

Install DishDrawer

Wooden Chopping Board

Level

Safety Glasses

Utility Knife

Pencil

Drill & Drill Bits

(3/32", 9/16" & 11/32")

(2.5mm, 12mm, 14mm)

Sandpaper

Tape Measure

Square

Ruler

Phillips Screwdriver

Pliers

Adjustable Wrenches(x2)

7/32" (6mm) Allen Key

(Integrated Models)

Router (Integrated Models)

Jigsaw (Integrated Models)

STEP 1.6 ADDITIONAL PRODUCT PARTS FOR INTEGRATED

DISHDRAWER

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

1. Template (Single 1)

2. Drain Hose Support (1)

3. Screw (1)

4. Wire Clip (1)

5. M8 Bolts (4)

6. Washers (4)

12.

7. Single Connector (1)

8. Edge Protector (1)

9. Flexible Extrusion 2)

10. Solderless Lug & Washer (1)

11. Inlet Hose Washer (1)

12. Hose Clamp (1)

13. Mounting Bracket Nuts (4)

14. Seal (1)

15. Door Screws (4)

16. Badge Kit (2)

13.

14.

15.

16.

Loading...

Loading...