Fisher & Paykel AeroSmart Series, AeroSmart DG62T27C, AeroSmart DE62T27C Installation Instructions And User Manual

For your the

information in this manual must be

followed to mb_imize tSe risk of fire or

or to

damage, persor_al b_jury or death°

--Do not store or use gasolir_e or other

flammable vapors and liquids ire the

vici_ri+y of this or any other appliam;e°

--WHAT TO DO IF YOU SMELL GAS

+ Do not try to l[glht a++y appliance°

+ Do not touch any electrical switch; do

not use arty phone ire your building,

+ Clear tie room, building or area of all

+ Immediately call your gas supplier from

a _eighbor's pSo_eo Follow the gas

supplier's irrstruc+ionso

+ [f you canrro+ reach your' gas supplier',

call the fire departme_+t°

and service must be

performed by a qualified installer', service

agency or tie gas supplier,

Espa ol 64 = 119

The Governor of California is required to pub/sh a list of substances known to the

state of California to cause cancer or reproductive harm and requires business to

warn customers of potentiM exposures to such substances

Gas appliances contain or produce substances, which can cause death, or serious

illness and which are known to the State of California to cause cancer, birth defects,

or other reproductive harm To reduce the risk from substances in fuel or f_om

fuel combustion, make sure this appliance is instaHed, operated, and maintained

accord[n 9 to the manufacturers instructions

_ntroductio_

_mpod:ant sa[ety insl.ructions

_nstalladon instructions

The first time you turn yo_Jr'@'yet or_

Getdng starCed quk:kly

Operating ir_strud io_s

AeroSmart controls

EasyIouch controls, The display screels

S2

S4

S4

S6

S6

S7

Sorti_g and loading

Lint bucket

Choosing your @ying cycle

Changing the @ying cycle options

Drying cycle options

Dryir_g cycle progress

Dryir_g cycles expbsi_ed

S7

S8

S9

40

41

42

4S

46

Special Care Handwash /Jeans / Fresher_ Up / Warm Up / Dryd_ an

Com[oder / Pilk)ws / AII_ rgy / Shids //-owels / _ofi Toys

Spodswear Light _,p srtswu:ar Heavy / Outdoor Wear /

/_, f" .... s.....

47

48

50

Care IabeIs 51

Lid Lock 52

Power failure 52

Settings Menu 53

Alarm Level / Screen Brightness/Key Lock Mode 53

Reminders / Hinls / Language 54

Service Contacls / _rouble Shootilsg / []eset De%ults / [:/eplay hs_ro 55

Caring For your AeroSmart: dryer' 56

BeFore yo_JcalI lot service 57

I/your Ae_oSmart dryer beeps/or help 57

Solving operating problems 58

Solving drying problems 59

Limited warranty 60

2

S

7

SAVE THESE INSTRUCTIONS

The models shown in this user guide may not be available in aJ[ markets and are subject to

change at any time. For current details about model and specification availability in your country,

please go to our website www.fisherpaykeLcom or contact your local Fisher & Paykel dealer.

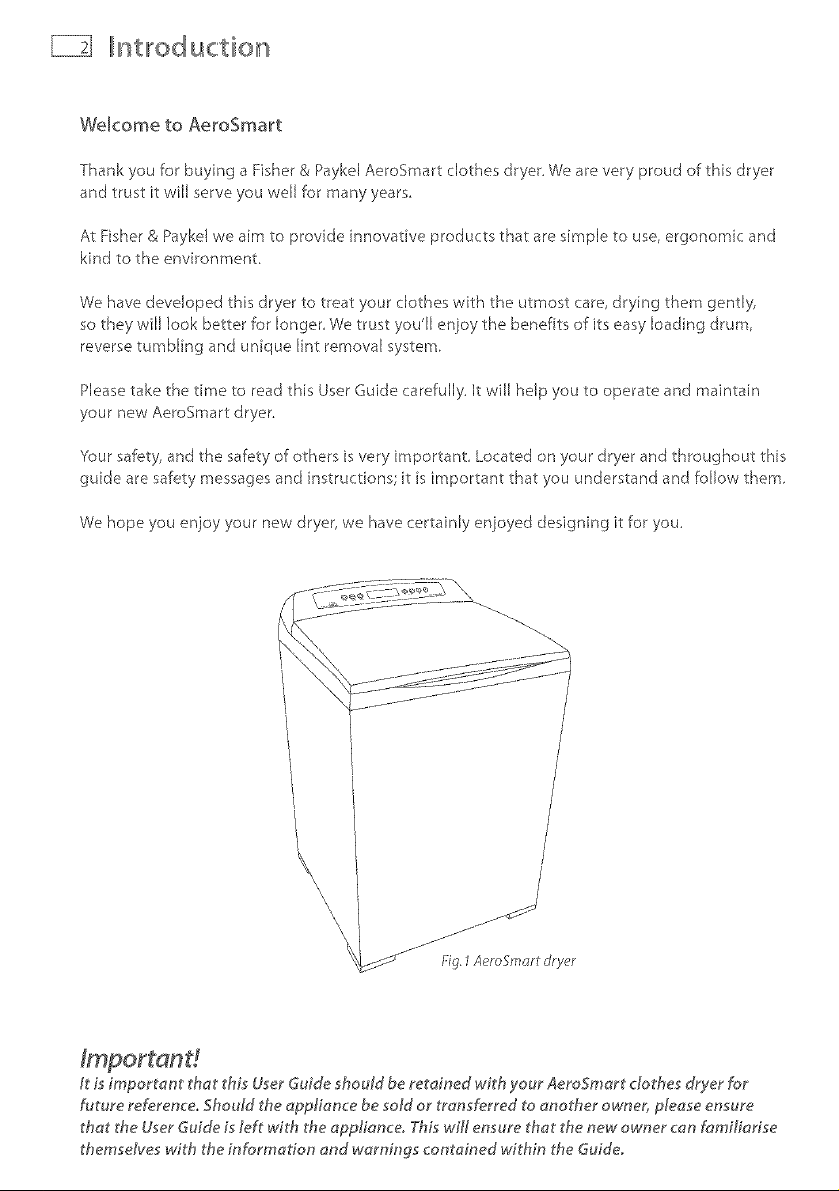

nt,roduction

Welcome to AeroSma_t

Thank you for buying a Fisher & Paykd AeroSmart clothes dryer, We are very proud of this dryer

and trust it will serve you well for many years

At Fisher & Paykd we aim to provide innovative products that are simple to use, ergonomic and

kind to the environment,

We have developed this dryer to treat your clothes with the utmost care, drying them gently,

so they will look better for longer We trust you'll enjoy the benefits of its easy loading drum,

reverse tumbling and unique lint removal system,

Please take the time to read this User Guide carefully, It will help you to operate and maintain

your new AeroSmart dryer,

'four safety, and the safety of others is very important Located on your dryer and throughout this

guide are safety messages and instructions it is important that you understand and follow them,

We hope you enjoy your new dryer, we have certainly enjoyed designing it for you,

\

\

\

\

\

it is importam' that _'hisUser Guide should be retained with your AeroSmart clothes dryer for

future reference, Should the applionce be sold or transferred to another owner, please ensure

that the User Guide is left with the oppliance_ This t,WNensure that _'henew owner can familiarise

themselves with the information end warnings contained within the Guide.

Ilmpolrtant safety instructions El}

Symbols will be used in this Guide to highlight when extra care is required, Abide by these at all

times to ensure you and your family are not harmed while operating your dryer,

It is important to always act with caution and use common sense when operating your dryer,

Use only as instructed by the User Guide,

This isthe safety alert symbol.This symbol alerts you to hazardsthat can kill

Thesafety alert symbol andthe word DANGERor WARNINGwill precede all

safety messages.Thesewords mean:

You can be killed or seriously injured if you don't

immediately, follow instructions°

You can be killed or seriously injured if you don't

follow instructions.

All safety messageswill identify the hazard,tell you how to reducethe chance of iniury,

andtell you what can happen ifthe instructions are not followed,

mportant safety inst/ uctions

Follow the safety precautions outlined in this User Guide°

Failure to do so can resutt in death or electric shock.

Read all instructions carefully before using this dty'er,

Use this dty'er on!y for its intended purpose as described in this User Guide.

To minimize the possibility of electric shock, unplug this dryer from the power supply or disconnect

the dryer at the household distribution panel (by removing the fuse or switching

off the circuit breaker') before attempting any user maintenance or cleaning.

Installations must be performed by a qualih_d or licensed contractor, plumber or gasfitter quafified

or licensed by the state, province, or region where this appliance is being installed.

This @yer must be proper!y installed and located in accordance with the Installation Instructions

before it is used.

T,_isdryer must be proper/}/grounded to conform with dill governing codes and ordinances. Follow

details in Installation Instructions.

Do not instal/ or store the do,,er where it wi/l be exposed to water or exposed to the weather.

Connect to apropedy protected, rated and sized power supply circuit to avoid electrical overload,

Do not repair or replace any part of the appliance or attempt any servicin b unless specifically

recommended in the published user repair instructions thot you understand and have the skills to

carry out,

When disconnecting the dt}¢er,puff by the plug rather than the cord orjunction of the cord plub to

avoid damage to the cord or junction of the cord plug.

Make sure the cord is located so that it will not be stepped on, tripped over or otherwise subject to

stress or damage.

Do not tamper with the controls or the lid lock.

Note: Pressing the POWER button doe_sNOT disconnect the dryer from the power supp!y, ew*n

though the lights are out.

Do not operate this dryer if it is damaged, malfunctioning, partial!y disassembled or has missing or

broken parts, including a damaged cord or plug,

T,_isdryer must be directly connected to an approved fixed electrical outlet. It cannot beplugged into

an extension cord.

mpo,rt ant safety in st,ructio ns

Fire Ha£a_d

Only dry fabrics that have been washed with water°

Do not use heat to dry articles containin 9 foam rubber or similarly textured

rubber-like materials,, Dry on the Air Dry cyc[eo

A clothes dryer produces combustible lint and must be exhausted

outdoors, Take care to prevent the accumulation of lint around the exhaust

openin 9 and in the surrour'_din 9 area°

Do not use fabric softeners or products to e_iminate £atic unmess

recommended by the manufacturer of the _abric softener* or product,,

Failure to follow these instructions can result in death or personat injury,

To reduce the risk of fire in a tumble dryer the following should be observed:

Do not place items in a tumble dryer that have previously been cleaned in, washed in, soaked

in, or spot cleaned with flammable liquids or solids They are a fire or explosion hazard

Highly flammable substances commonly used in domestic environments include acetone,

denatured alcohol, gasoline, kerosene, some brands of spot removers and dry cleaning solvents,

turpentine, waxes, wax removers, vegetable oil, fish oil, massage oil, and cooking oil

Do not leave hot oil-affected items in a pile or stack. This can prevent heat from escaping and

can create a fire hazard. Oil--affected items can ignite spontaneously, especially when exposed

to heat sources such as a tumble dryer. The items become warm causing an oxidation reaction

in the oil. This oxidation creates heat. If the heat cannot escape the items can become hot

enough to catch fire.

Do not use heat to dry terns containing rubber, foam rubber, plastic or similar materials, (such

as padded bras, bath mats, rugs, bibs, baby pants, plastic bags, pillows etc), as these materiaB

might melt or burn. Some rubber materials when heated can under certain circumstances

produce fire by spontaneous combustion. Dry only on the AIR DRY cycle.

Unless specifically recommended by their manufacturer, do not use fabric softeners or similar

products in a tumble dryer

Do not store or use gasoline or other flammable gases and liquids near this or any other

appliance.

Keep the area around and underneath your dryer free from the accumulation of combustible

materials such as lint, paper, rags, chemicals etc.

Do not store any items that may burn or melt (such as paper materials, plastics or plastic

containers etc) next to the dryer

Empty the lint bucket before the lint reaches the top of the transparent section (usually once a

week).

The dryer must be exhausted to the outside, Carefu{[y follow the venting details in the

Installation instructions.

Keep the floor around your dryer clean and dr},, to reduce the possibility of slipping

If }/our dryer is running and you want to unload or add clothes press START/PAUSE and wait

until the machine has unlocked the lid. Do not force it open.

mpo/rta IIr" tsafety illrsstlructions

Do not reach into the appliance if the drum is moving

Close supervision is necessary if this dryer s used by or near children, Do not alEow children to

play inside, around or with this dryer or any other appliance,

Never climb on, climb into, or stand on the dryer top, Eidor drum

Undergarments that contain metal reinforcements should not be placed directly in the dryer,

Damage to the dryer can result if the metal reinforcements come Eooseduring drying

The interior of the appliance and exhaust duct should be cleaned periodically by qualified

service personnel

Before the appliance is removed from service or discarded remove the lid and the drum door to

SAVE THESEINSTRUCTIONS

iiiii_i_iiii_@_@_@_@_@_@_@_@_@_@_@_@_@_@_i_iiiiiii_i_¸il¸lii¸ili¸iiiiiiiiiiiil,iiiii_!_!_iiiiiiiiiiiiii_iiiliiiliiiiiiiiiiiiiiiiiiiiil_i_i_iii_i_ii_iiii_iiii_iiiii_iiiii_iiiii_iiiii_iiiii_iiiii_iiiii_iiiii_iiiii_ii_i_i_i_i_i_i_ii_i_i_ii_i_i_ii_i_ii_iiii_iiii_iiiii_ii_iiii_iiiiiii_!iii_i_i_iiiiiii¸il¸ii'iiiiiiiii¸I¸I¸I¸il_il_ii_il_ii_il_I_iiiiiiiiiiiil¸ii:i'ii'iiiiill

_nstalllllationinst,ructions _iI

Read the important safety instructions on pages 3 - 6 before you start installing the dryer.

Checktomakesureyouhaveallthetoolsandpartsnecessarytocorrectly_nstallth_sappUance,

Tools required

Y4"nut driver or socket wrench

Phillips screwdriver

Fiat-blade screwdriver

Adjustable wrench B" or 10" (200 mm or 250 ram) for gas connections

Pipe joint compound (pipe dope or tape) for gas pipe connections that is resistant to

LP Propane, Butane and Natural Gas (Gas models only)

Level

Caulking gun and compound (for nstaJling new exhaust vent)

Gloves

Knife

Duct tape

Parts supplied

2feet inserts for front feet

A power supply cord issupplied already connected to the gasdryer (Gasmodels only)

Checkto make sure all parts have been supplied,

1i_.2powersupplycord

Accessories

Mobile Home Installation Kit Part No 395488

Natural Gas to LP Conversion Kit Part No 395489 (Gas models only)

LP to Natural Gas Conversion Kit Part No _95490 (Gas models only)

Kit Element 208V Part No 395500 (Electric models only)

Parts needed

If you need to purchase a power supply cord kit or power supply cable, they must meet the

requirements outlined on page 21 (power supply). Check with local codes and read dectricaJ, gas

and venting requirements before purchasing parts,

llL stallllllati© illL structior s

To the installer

The correct installation of the dryer is your responsibility.

Be sure you read the following instructions carefully before you start to install the dryer. These

instructions should be left with the home owner for future reference.

It is your respor_sibHity to:

Observe all governing codes and ordinances.

Check code requirements. Some codes limit or do not permit installation of clothes dryers in

garages, closets, mobile homes or sleeping quarters. Contact your local building inspector.

Adhere to these nstallation nstructions.

Allow for spacing requirements with side by side installations (refer page g).

Make sure you have all items necessary for correct installation.

Properly install the dryer.

Contact a qualified installer to ensure that the electrical and gas installation meets all national

and local codes and ordinances (See page 4),

Location requirements

Explosion Hazard

Keep f[ammaMe materials and vapor& such as gasoline, away from the dryer.

P_ace dryer at _east 18 inches (460 ram) above the floor for a garage

instaHationo

Failure to do so can result in death, explosion, fire. or burns.

The dryer must be installed or stored in an area which is not exposed to water or weather.

It is extremely irnportant that the dryer is installed in a well ventilated location, This dryer must

exhaust air outdoors, Do not install the dryer in any room or closet which does not permit the

free flow of replacement air,

The free area of any opening for the introduction of outside air shall not be less than twice the

area of the dryer exhaust outlet.

Before installing the dryer ensure that there is sufficient height to fully open the lid. Allow

sufficient room behind the dryer for the exhaust. The air intake is at the rear of the dryer. Ensure

that there is a sufficient air passage on each side of the dryer for intake air.

IlllnstaIIIIlationinstructions

Location requirements

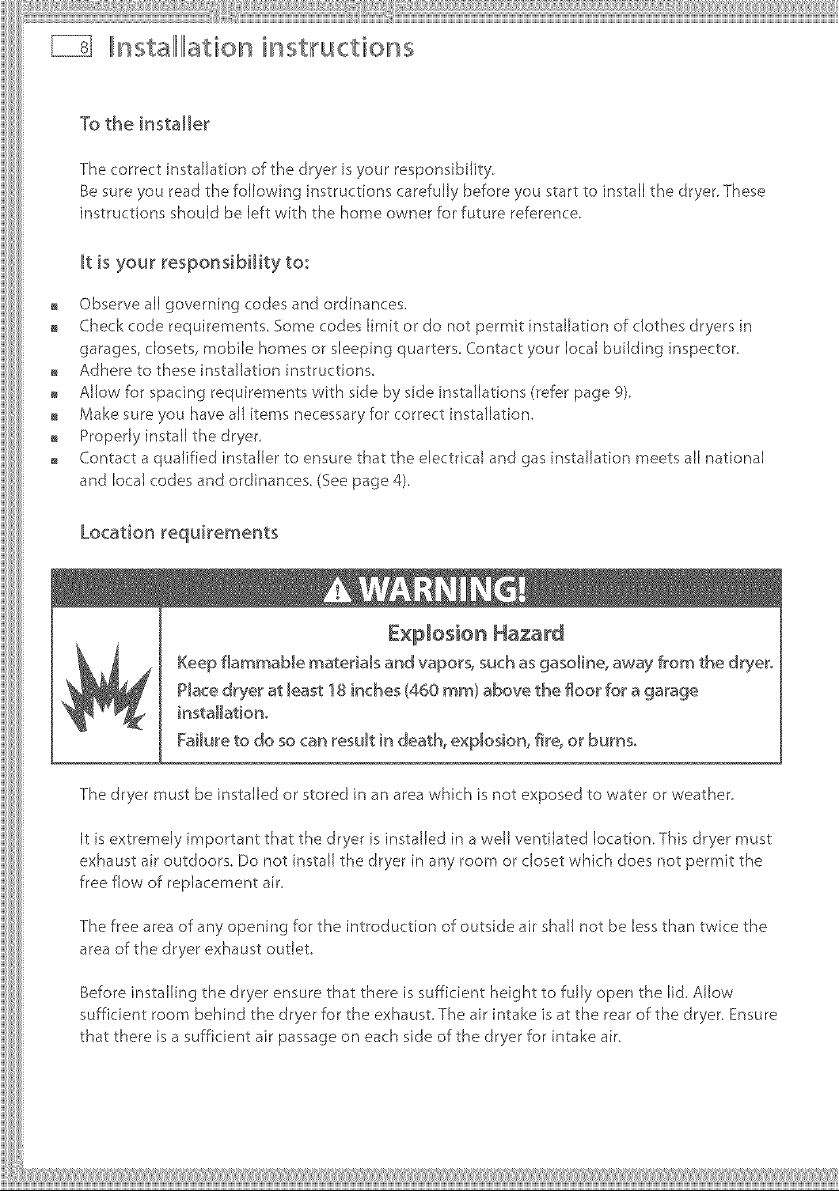

The area in which the dryer is located must be

kept clear and free from combustible materials,

gasoJine and other flammabJe vapors and

liquids. A dryer produces combustibJe [int so the

area around the dryer must be cleaned reguJarJy

to keep it free of lint. Fig.3Rearw*nting

This dryer can only be vented from the rear and must be exhausted to the outdoors.

Alcove or closet installation

When installing a dryer in a cbsedalcove it must be exhausted _o the outdoors. No other

fuel burning appliance can be installed in the same closet or a[coveo

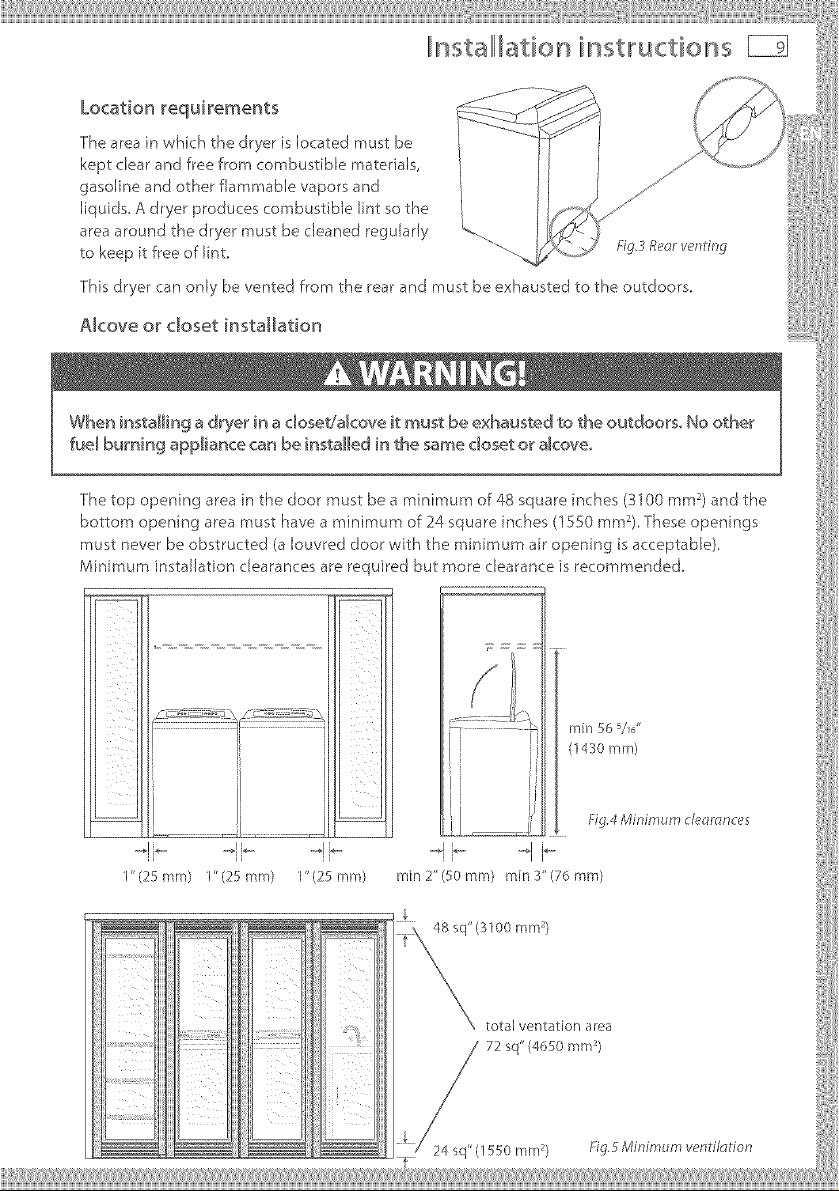

The top opening area in the door must be a minimum of 48 square inches (31 O0 mm 2)and the

bottom opening area must have a minimum of 24 square inches (1550 mm 2) These openings

must never be obstructed (a [ouvred door with the minimum air opening is acceptable).

Minimum installation cJearances are required but more cJearance is recommended.

L

ii ii

1" (25 mm) 1"(25 mm) I" (25 mm)

rain 565/6"

(1430 mm)

.._1b....... .I i_m

[ J II

rain 2" (50 ram) rain 3" (76 ram)

fig.4 Minimum deomnces

_] _,L_stalllllati©,L_h_st,ructions

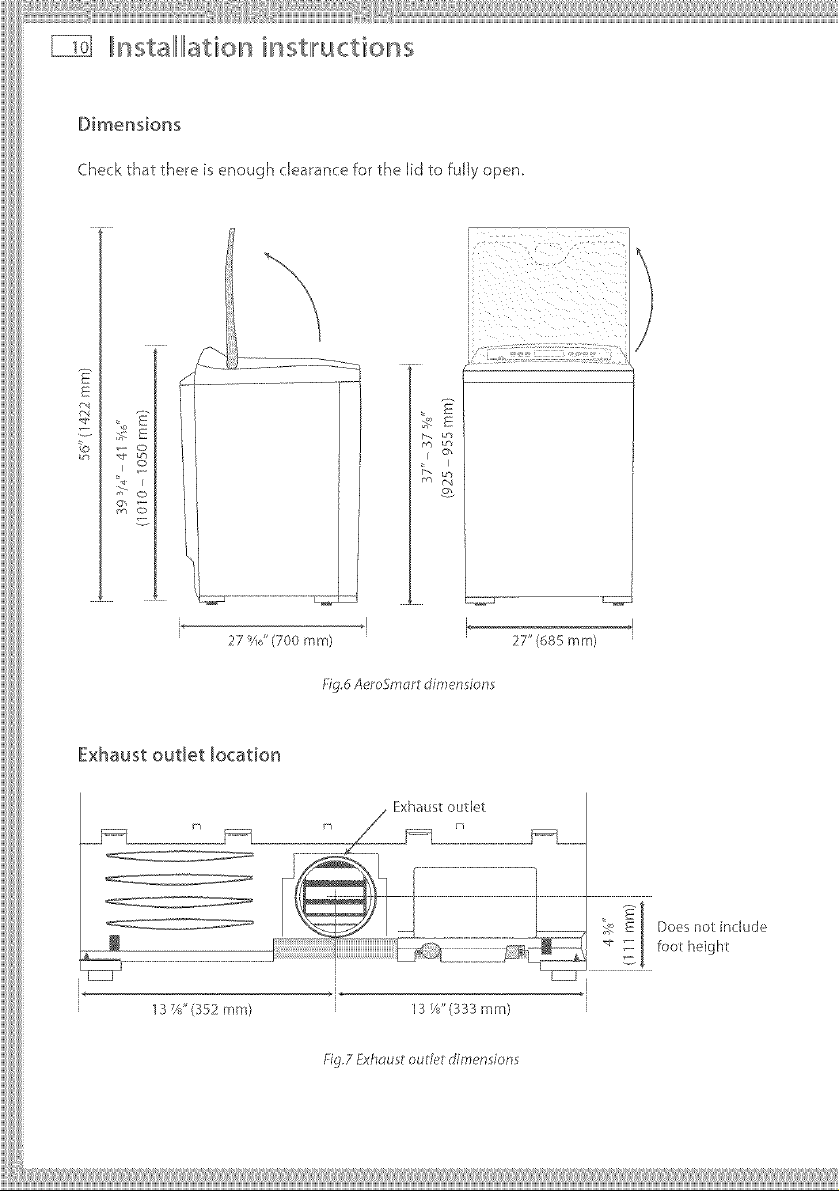

Dimensions

Checkthat there is enough clearance for the lid to fully open.

S

27'!JJ'(700 mm)

Exhaust outlet Jocation

137a" (352 mm} 13 W' (333 mm)

,2

[

L

27" (685 ram)

1:i9.6 Aero_.mor_ dimensions

Fig.7 Exhd_ sl o_d_t dir'nen io_s

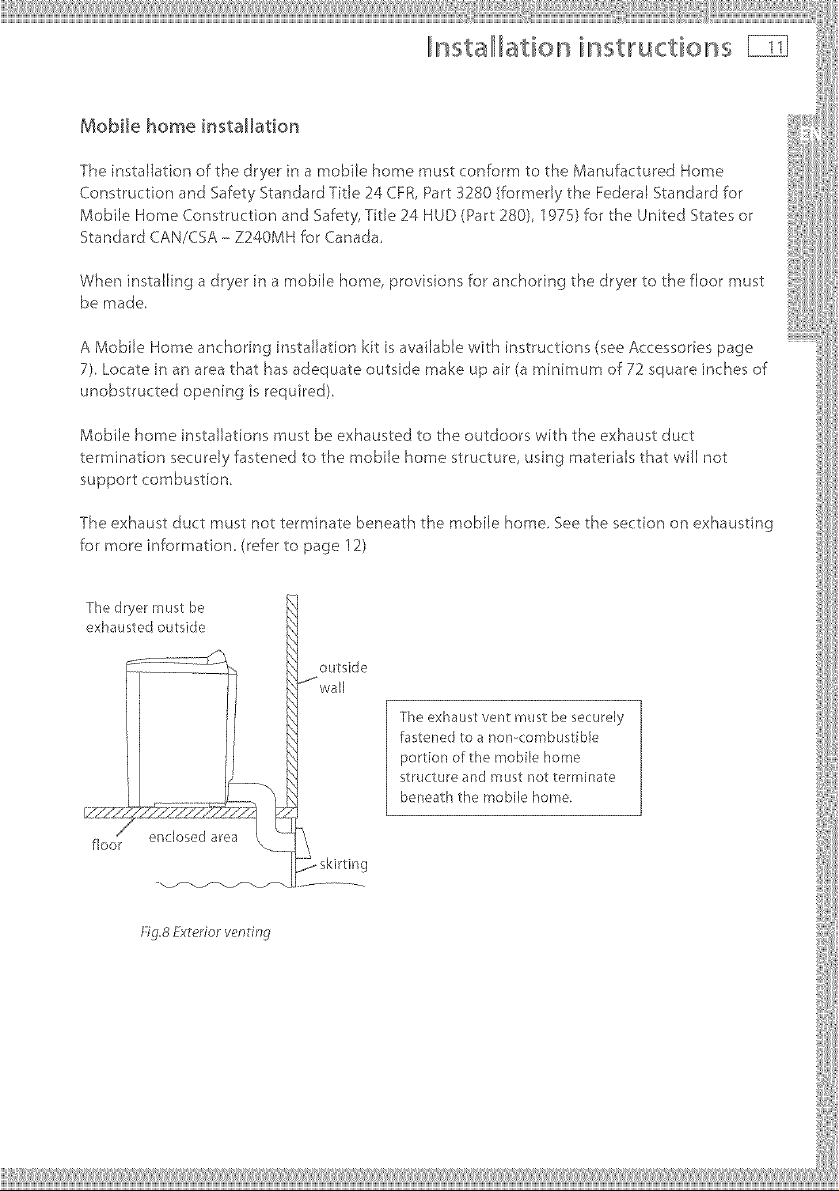

Mobile home i_stallation

The installation of the dryer in a mobile home must conform to the Manufactured Home

Construction and Safety Standard Title 24 CFR, Part 3280 {formerly the Federal Standard for

Mobile Home Construction and Safety, Title 24 HUD (Part 280), 1978} for the United States or

Standard CAN/CSA - Z240MH for Canada,

When installing a dryer in a mobile home, provisions for anchoring the dryer to the floor must

be made,

A Mobile Home anchoring installation kt is available with instructions (see Accessories page

7), Locate in an area that has adequate outside make up air (a minimum of 72 square inches of

unobstructed opening is required),

Mobile home installations must be exhausted to the outdoors with the exhaust duct

termination securely fastened to the mobile home structure, using materials that will not

support combustion,

The exhaust duct must not terminate beneath the mobile home, See the section on exhausting

for more information, (refer to page 12)

The dryer must be

exhausled outside

outside

*_wall

The exhaust vent must be securely

fastened to a noncombustible

portion of the mobile home

stR/( _ure and must not terminate

beneath the mobile home.

floor enclosed area

i

,qg.8Yxlerior vending

¸il¸liiii¸il¸liiiii¸I¸II¸iiiil¸ii i i iiiil¸il¸ii'i iiiiiii¸il¸iiiii:ii¸iliiii'liiii¸I¸ii'iii iiii¸I¸ii iiiiiiil

lnstalllllation ilnstlructions

The dryer must be ve_ed to the outdoo_s_

Ose rigid or thick wall fle×iMe metal exhaust duct,

Oo _ot use a p_astic exhaust duct,

Do not use a meta_ foi_ exhaust duct.

Failure to follow these instructions can result in death or fire.

The dryer must be exhausted to the outdoors. This will prevent the build up of lint and moisture

in the room in which it is located and reduce the risk of fire.

This appliance must always be vented to the outdoors.

Exhaust ducting products can be purchased from your local Appliance store or Hardware store.

Plastic or metal foil flexible duct can kink, sag, be punctured, reduce airflow, extend drying

times and affect dryer operation.

A minimum of 4 inch (100 ram) thick wall flexible metal or rigid galvanised metal duct must be

used. Using ducts larger than 4 inches (100 mm) diameter may result in more lint accumulating.

Using straight rigid metal ducting will minimize lint accumulation. Thick wall flexible metal

ducting may be used but care must be exercised to avoid sharp bends which may squash the

duct and cause blockages. Do not use plastic ducting or thin wall flexible metal ducting

Use duct tape to secure joints. Do not use screws as they collect lint.

Keep ducting as short and straight as possible. Do not exceed the maximum exhaust duct

lengths stated later in these nstalJation nstructions.

Do not exhaust the dryer into any other duct, chimney or gas vent, a wall, a ceiling or any

concealed space in a building Do not exhaust the dryer under a house or mobile home or a

porch, or into a window well or other area that will accumulate lint.

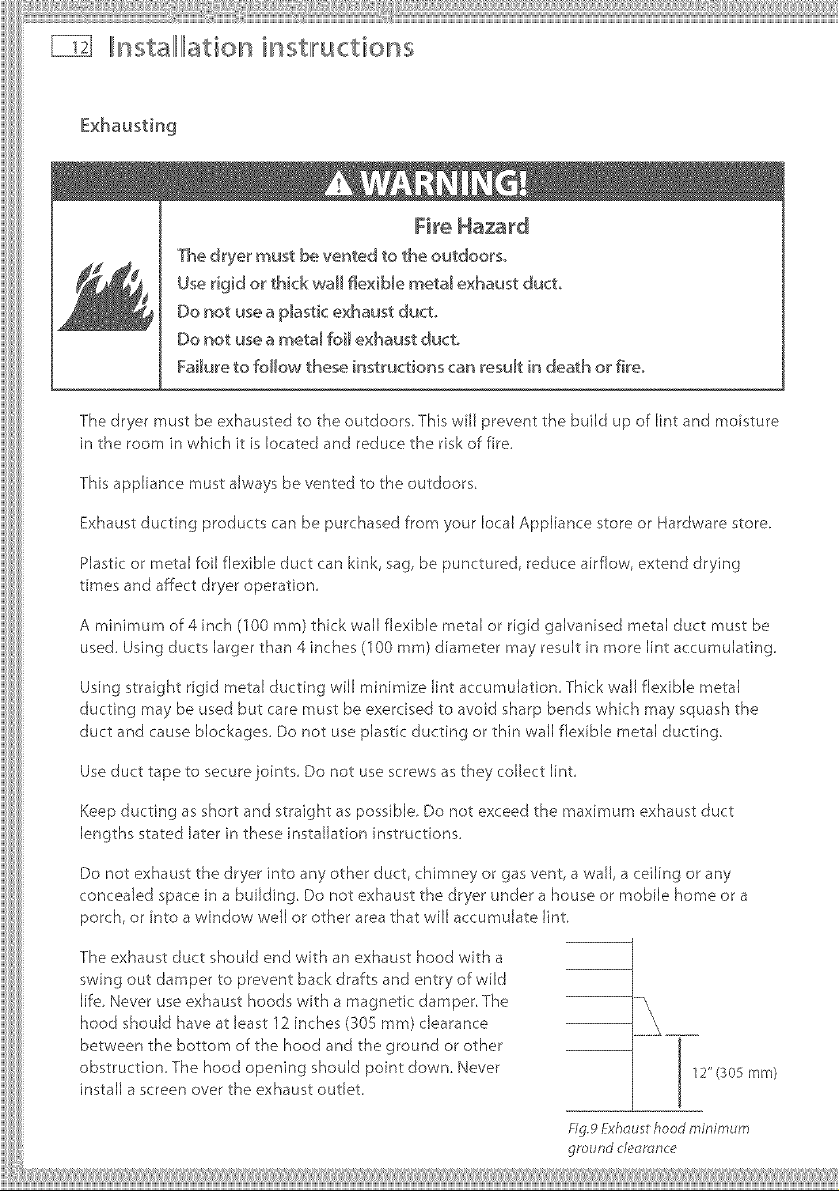

The exhaust duct should end with an exhaust hood with a

swing out damper to prevent back drafts and entry of wild

life. Never use exhaust hoods with a magnetic damper The

hood should have at least 12 inches (305 mm) clearance

between the bottom of the hood and the ground or other

obstruction The hood opening should point down. Never

install a screen over the exhaust outlet.

_ig.9Yxh_usthood minimum

ground deoro,nce

,,,,,,,,,,,,,,,,,,,,,,i)

Toreducecondensation,insulateanyductingwhichpassesthroughunheatedareas.Slopethe

ductgentlydownwardstothehood,todraincondensationandreducelintbuildup,Avoidsag

orloopsintheductastheymaycollectandstorewaterandaccumulatelint.

Beforeusinganexistingexhaustductsystemforadryerensurethat:

NopEasticorotherpotentiallycombustibEeductorflexiblemetalfoilductinghasbeenused.

Theductisnotpierced,kinkedorcrushed.

Theductdoesnotexceed the maximum recommended length for the new dryer.

The exhaust hood damper opens and closes freely and with sufficient movement.

Static pressure in the exhaust ducting does not exceed 1 inch (250Pa), or s not less than 0

inches of water column fie. negative pressure), when measured with a manometer in the first 6

inches of the duct, wth the dryer running on Air Dry (no heat) setting.

The exhaust duct system meets aJ[ relevant local, state and national codes.

All ducting should be inspected and cleaned at least once a year to remove accumulated lint.

Frequently check that the damper on the exhaust hood moves sufficiently and opens and

Mobile Home Installations

A Mobile Home Installation Kit is available (see Accessor es page 7).

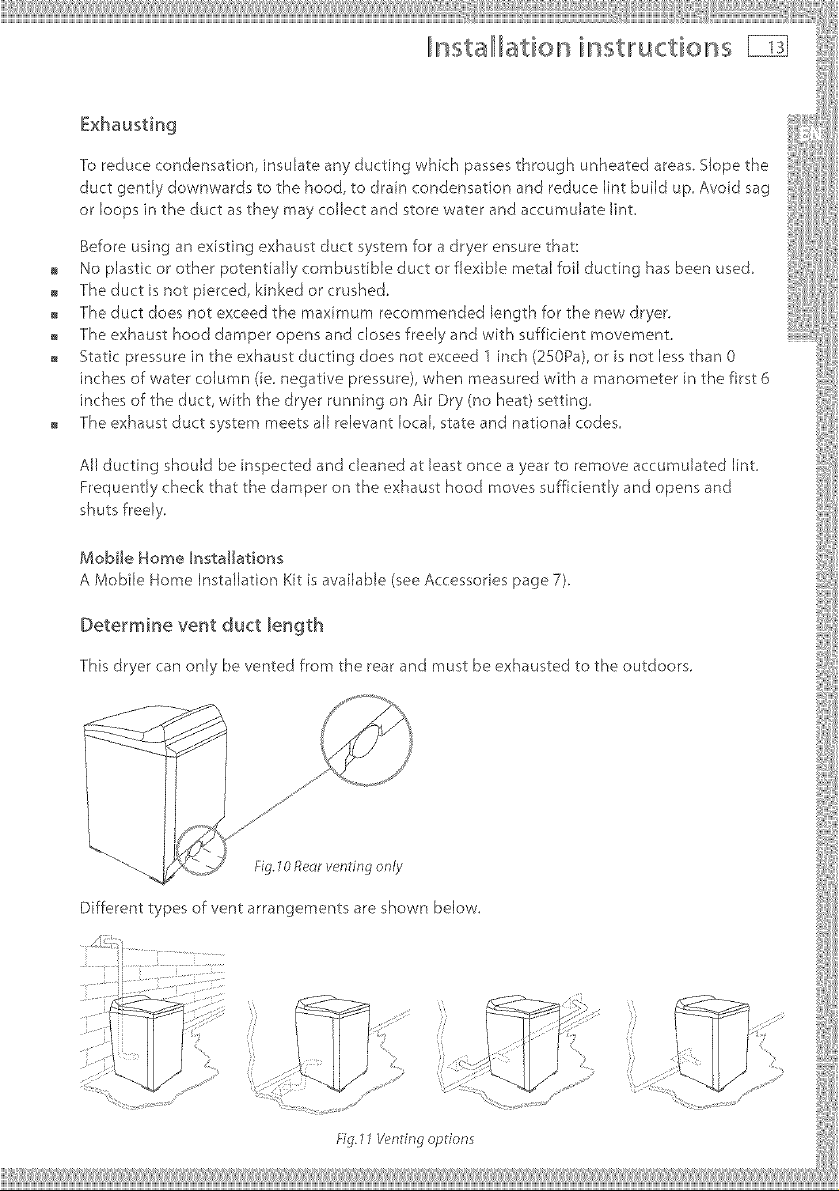

Determine vent duct length

This dryer can only be vented from the rearand must be exhausted to the outdoors,

...._ Fig.70Reclrvenling only

Different types of vent arrangements are shown below.

i

fig. 11V_'ndngoptions

nstallllation instlructions

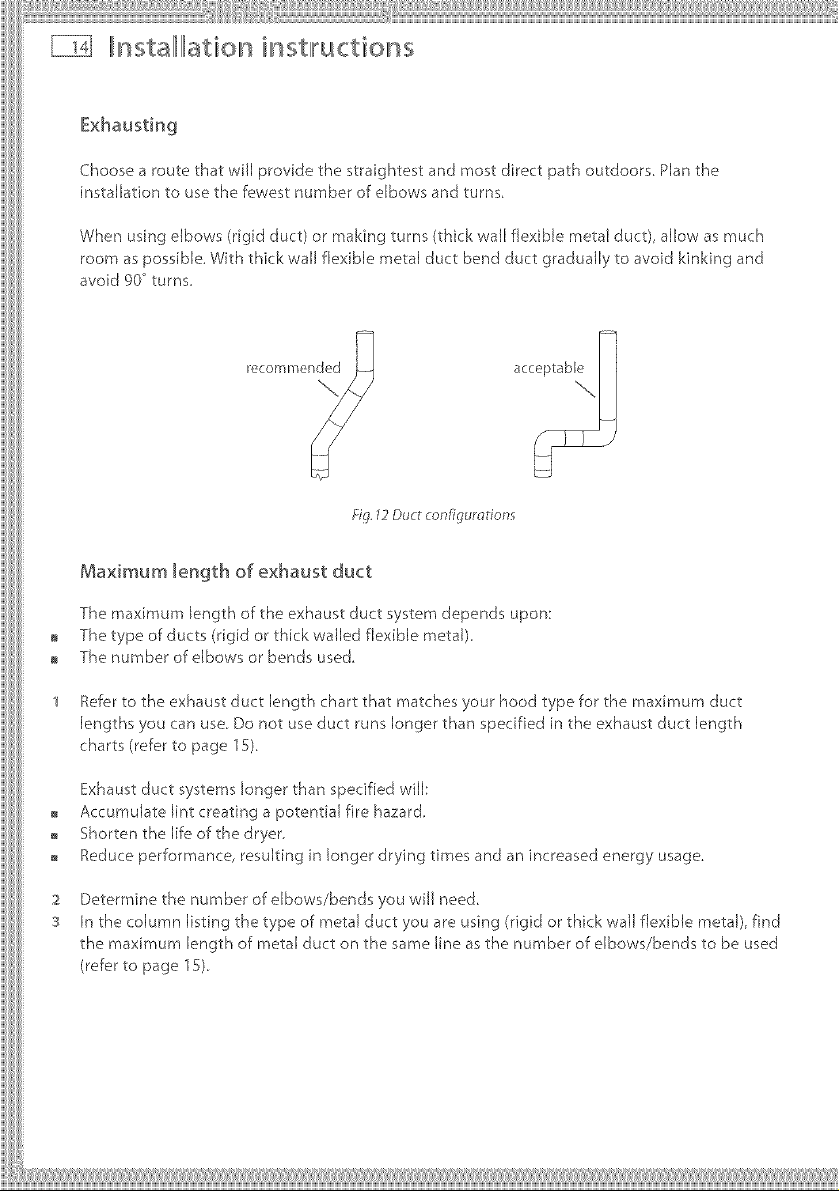

Choose a route that will provide the straightest and most direct path outdoors, Plan the

installation to use the fe__westnumber of elbows and turns,

When using elbows (rigid duct) or making turns (thick wall flexible metal duct), allow as much

room as possible, With thick wall flexible metal duct bend duct gradually to avoid kinking and

avoid 90 °turns,

Fig.12Dud configumfion_

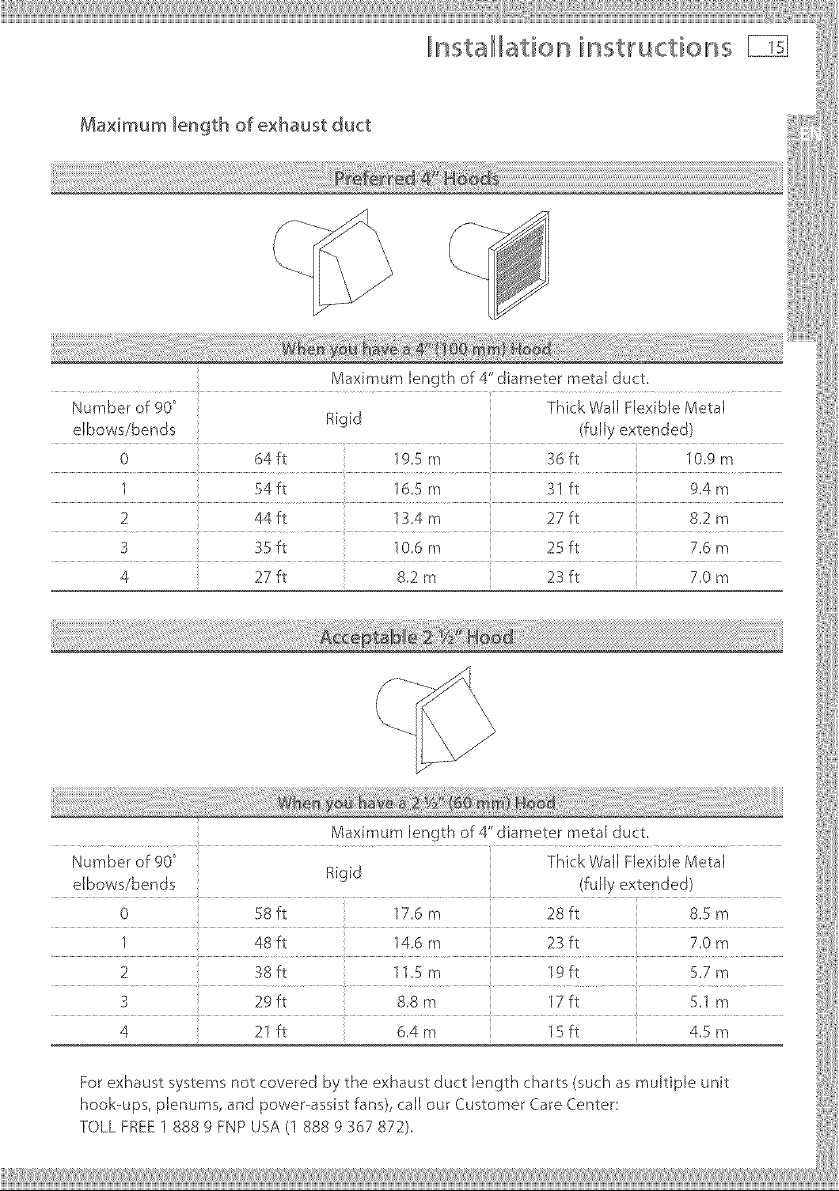

Maximum length of exhaust duct

The maximum length of the exhaust duct system depends upon:

The type of ducts (rigid or thick walled flexible metal),

The number of elbows or bends used

Refer to the exhaust duct length chart that matches your hood type for the maximum duct

lengths you can use. Do not use duct runs longer than specified in the exhaust duct length

charts (refer to page 1S),

Exhaust duct systems longer than specified will:

Accumulate lint creating a potential fire hazard,

Shorten the life of the dryer.

Reduce performance, resulting n longer drying times and an increased energy usage,

Determine the number of elbows/bends you wiJJ need

In the column listing the type of metal duct you are using (rigid or thick wail flexible metal), find

the maximum length of metal duct on the same line as the number of elbows/bends to be used

(refer to page 1S).

Maximum length of exhaust duct

Maximum length of 4" diameter metal duct.

Number of 900 Thick Wall Flexible Metal

elbows/bends Rigid

0 64 ft 195 rn 36 ft 10,9 m

1 54 ft 165 m 31 ft 9.4 m

2 44 ft 13.4 m 27 ft 8.2 m

3 35 ft 106 m 25 ft 7.6 rn

4 27 ft 8.2 m 23 ft 7.0 m

Maximum length of 4" diameter metal duct.

Number of 900 Thick Wall Flexible Metal

elbows/bends Rigid

0 58ft 176 m 28ft 8.5 m

1 48 ft 14.6 m 23 ft 7.0 m

2 38ft 115m 19ft 5.7m

3 29 ft 8.8 m 17 ft 5.1 m

4 21 ft 6.4m 15ft 4.5 m

For exhaust systems not covered by the exhaust duct length charts (such as multiple unit

hook-ups, plenums, and power assist fans), call our Customer Care Center

TOLL FREE 1 888 g FNP USA (1 888 g 367 872).

nstallilation instlructioss

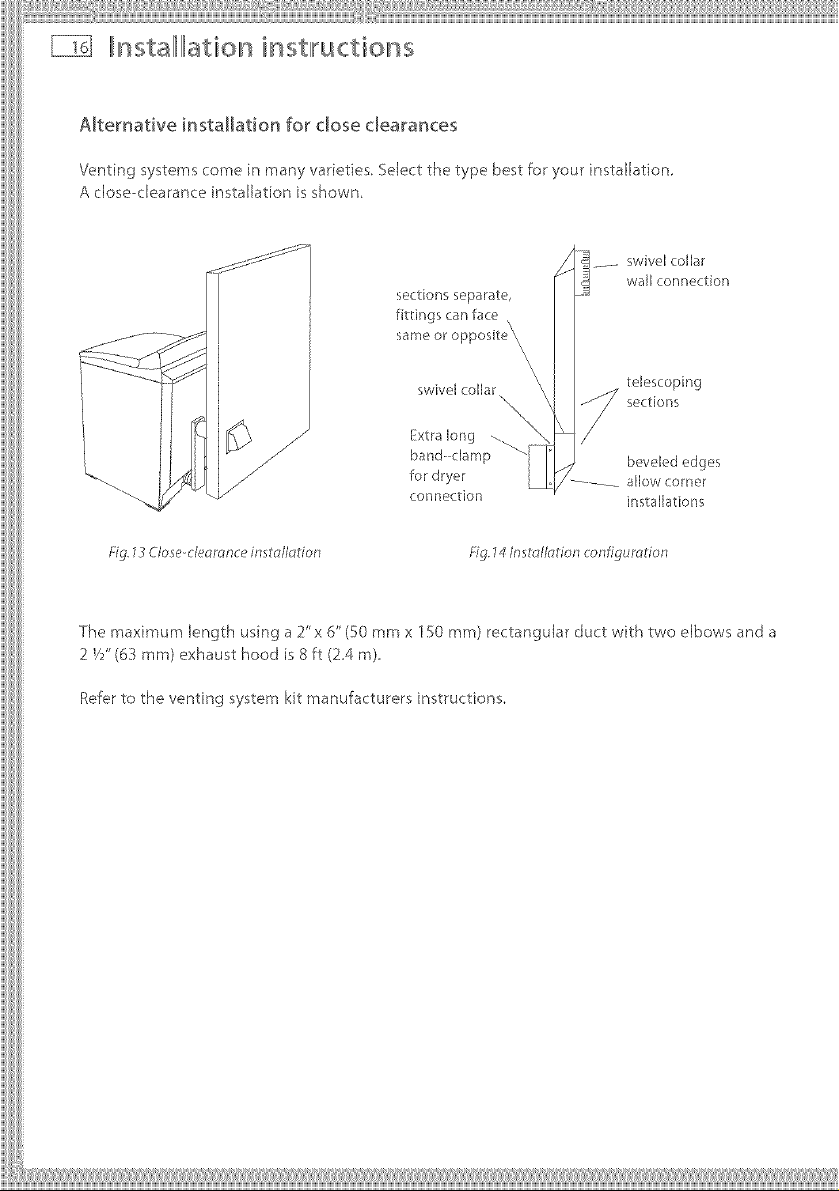

Alternative installation for close dearances

Venting systems come in many varieties. Select the type best for your instaNation,

A dose--clearance instalhtion is shown.

SSS_ _S_

sections separate,

(onnection

Fig. 73 C/ose c/eomnce insto//olion Fig. 14/nstd_//odon configumdon

il ...... swivel collarwall connection

telescoping

s(sctions

beveled edges

.......... allow corner

installations

The maximum length using a 2"x 6"(50 mmx 150 mm) rectangular duct with two elbows and a

2 V/'(6_ ram) exhaust hood is 8 ft (24 m),

Refer to the venting system kit manufacturers insWuctions,

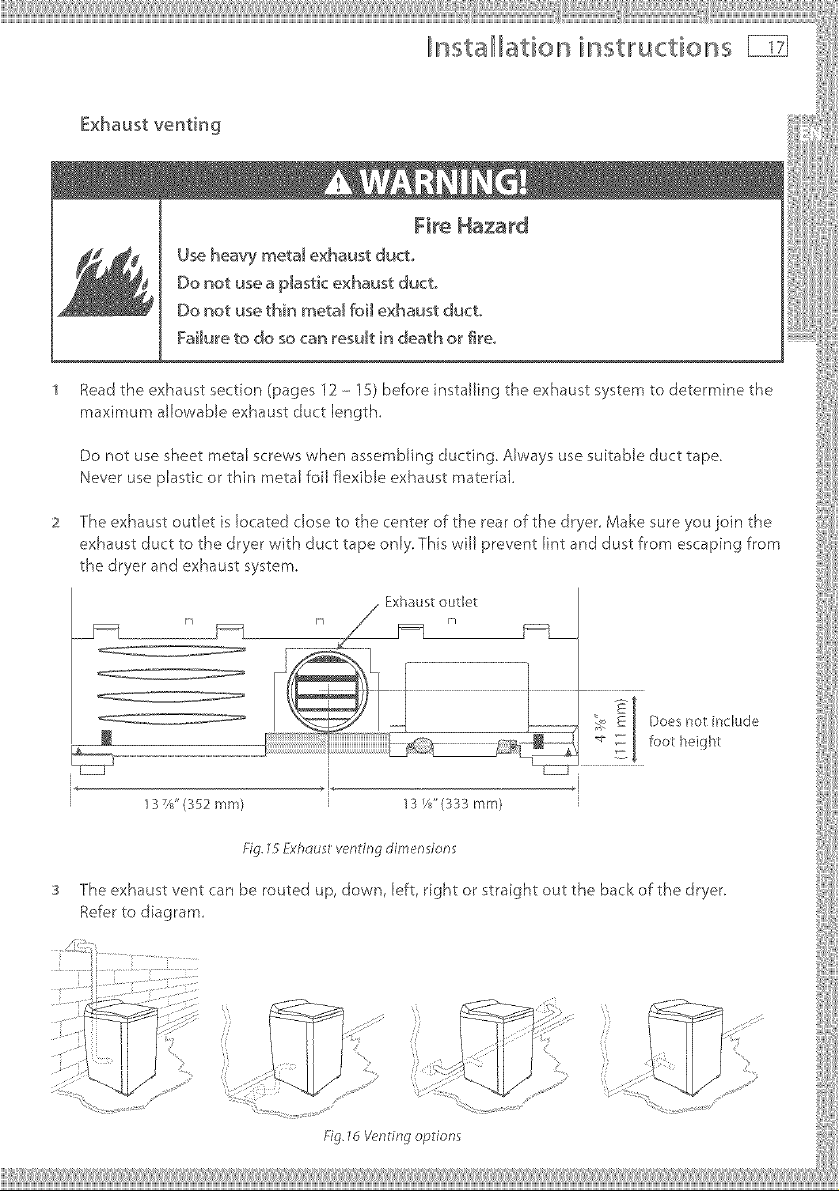

_,L_sta/111atio n i,L_st,ructio ns _z]

Fire Haza_'d

Use heavy meta_ exhaust duct,,

Do not use a p_astk exhaust duct.

Do not use thin metam foi_ exhaust duct

Failure to do so can resutt in death or _eo

Read the exhaust section (pages 12 - 15) before installing the exhaust system to determine the

maximum allowable exhaust duct length,

Do not use sheet metal screws when assembling ducting. Always use suitable duct tape,

Never use plastic or thin metal foil flexible exhaust material

The exhaust outlet is located close to the center of the rear of the dryer, Make sure you join the

exhaust duct to the dryer with duct tape only, This will prevent lint and dust from escaping from

the dryer and exhaust system,

13%" (352 ram) 13 f/8"(333 mm)

Fig. 75 Fxhdusl venting dimendons

The exhaust vent can be routed up, down, left, rght or straight out the back of the dryer,

Refer to diagram

\\

//

Fig, 76 Vendng options

lnsta llation instllructior' s

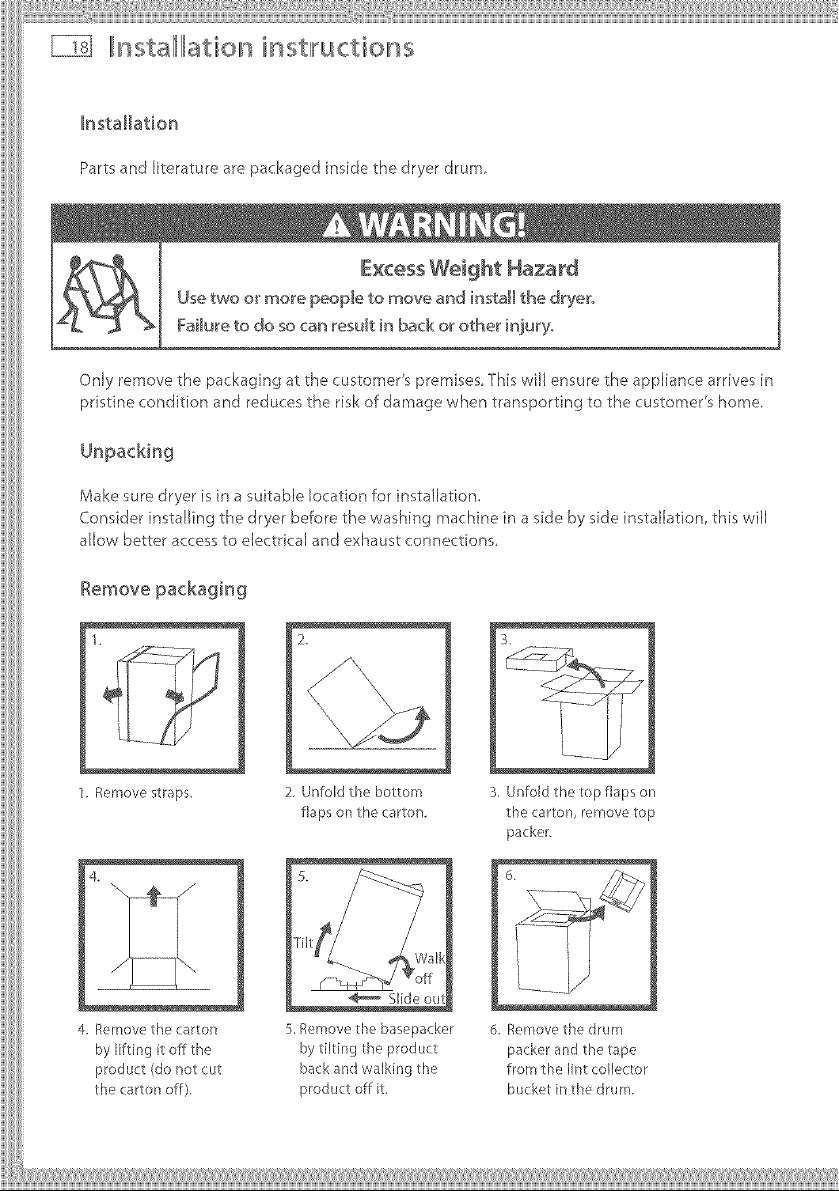

Installation

Partsand literature are packaged inside the dryer drum,

Only remove the packaging at the customer's premises This will ensure the appliance arrives in

pristine condition and reduces the risk of damage when transporting to the customer's home.

Make sure dryer is in a suitabEe location for installation.

Consider installing the dryer before the washing machine in a side by side installation, this will

allow better access to electrical and exhaust connections.

1.

1. Remove straps.

4

4 Remove the carton

by lifting it off the

product (do not cut

the carton off).

2,

2. Unfold the botlom

flaps on the carton.

Slide

S,Remove the basepacker

by tilting the product

back and walking the

product off it.

S.Unfold the top flaps on

the carton, remove top

packer.

6.

d. Removethe drum

packer and the tape

from the lint collector

bu ket in the drum.

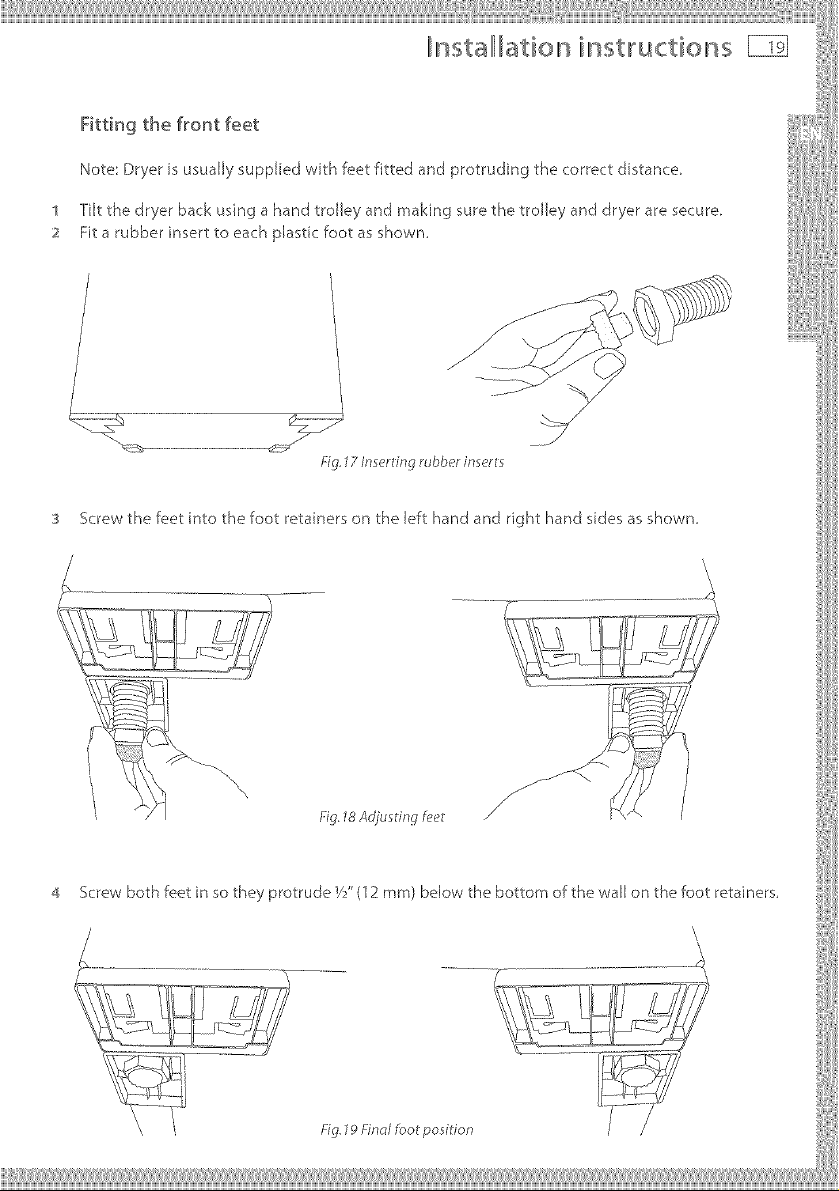

4 ScrewbothfeetinsotheyprotrudeVY'(12ram)bdowthebottomofthewaJJonthefootretainers,

Fig.19Fincdfool posidon

lnstalllLation instlructions

Grounding instructions for gas and electric dryers

EWectrka_ Shock Ha_rd

Make sure appliance is wired or plugged into a grounded out_et,,

Do not use an adaptor.

Do not use an extension cord.

Failure to follow these instructions can result in death, fire, or electrica_

shock

E_ectrka_ Shock Hazard

Check with a qualified e_ectrician or serviceperson if you a_e in doubt as to

whether the appliance is property grounded.

Do not modify the plug if it will not fit the out_et.

Have the proper outlet installed by a qualified electriciano

Failure to follow these instructions can result in death, fire. or e_ectrical

shock.

Grounding for a cord<onnected appliance

This appliance must be grounded. In the event of malfunction or breakdown, grounding will

reduce the risk of electric shock by providing a path of least resistance for electric current.

When this appliance is equipped with a cord having an equipment-grounding conductor and a

grounding plug, the plug must be plugged into an appropriate outlet that is properly installed

and grounded in accordance with all local codes and ordinances, or in their absence, with the

National Electrical Code ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.1. Do not cut or

remove the grounding prong from this plug.

Improper connection of _he equipmentogrounding

conductor can result in a risk of e_ectric shock. (beck with

a qualified electrician or service representative if you are in

doubt as to whether the appliance is properly grounded.

Refer to pages 21 - 27 for wiring details for electric dryers.

Illnstalllllation instlructions E]

Electrical requirements for electric models only

Use a new UL approved 30-ampere power cord or direct wire came°

Use a UL approved strain relief.

Disconnect power before making e_ectrica_ connections,

Connect neutra_ wire (white or center wire) to center terminal

On aH four wire [ns_Hat[ons remove the grounding _ink and connect the

ground wire to the green ground connecting screw.

Connect remaining 2 supply wires to remaining 2 terminalso

Securely tighten a_me_ectrica_ connections,,

Failure to do so can result [n death, fire, or electrical shock.

Note: The wiring diagram is located in the control console.

The dryer must be plugged into or connected to an individual branch circuit, do not use an

extension cord.

The power supply must be 220/240V or 208V, 60 Hz approved alternating current electrical

service.The electrical service requirements can be found on the data label that is located on the

splash back. A 30-ampere fuse or circuit breaker is required on each of the lines.

If a power cord is used, the cord must be plugged into a 30-ampere receptacle.

The power cord is NOT provided with U.S. electric model dryers.

This dryer is supplied with the cabinet grounded through the neutral on the terminal block.

If the dryer is to be nstaJled in (1) a new branch circuit installation, (2) a mobile home, (3) a

recreational vehicle, (4) an area where local codes do not permit grounding through the neutral

conductor, the appliance grounding link must be removed and a 4-wire power cord/cable or a

separate grounding wire must be used.

Do not reuse a power supply cord/cable from an old dryer.The power cord/cable electric supply

wiring must be retained at the dryer cabinet with a suitable ULlisted strain relief.

208V requirements

if your power supply is 208V 60 Hz, a new element kit rnust be fitted by a qualified electrician or

service representative (see Accessories page 7 for kit part number).

nstalllBtion inst,ructions

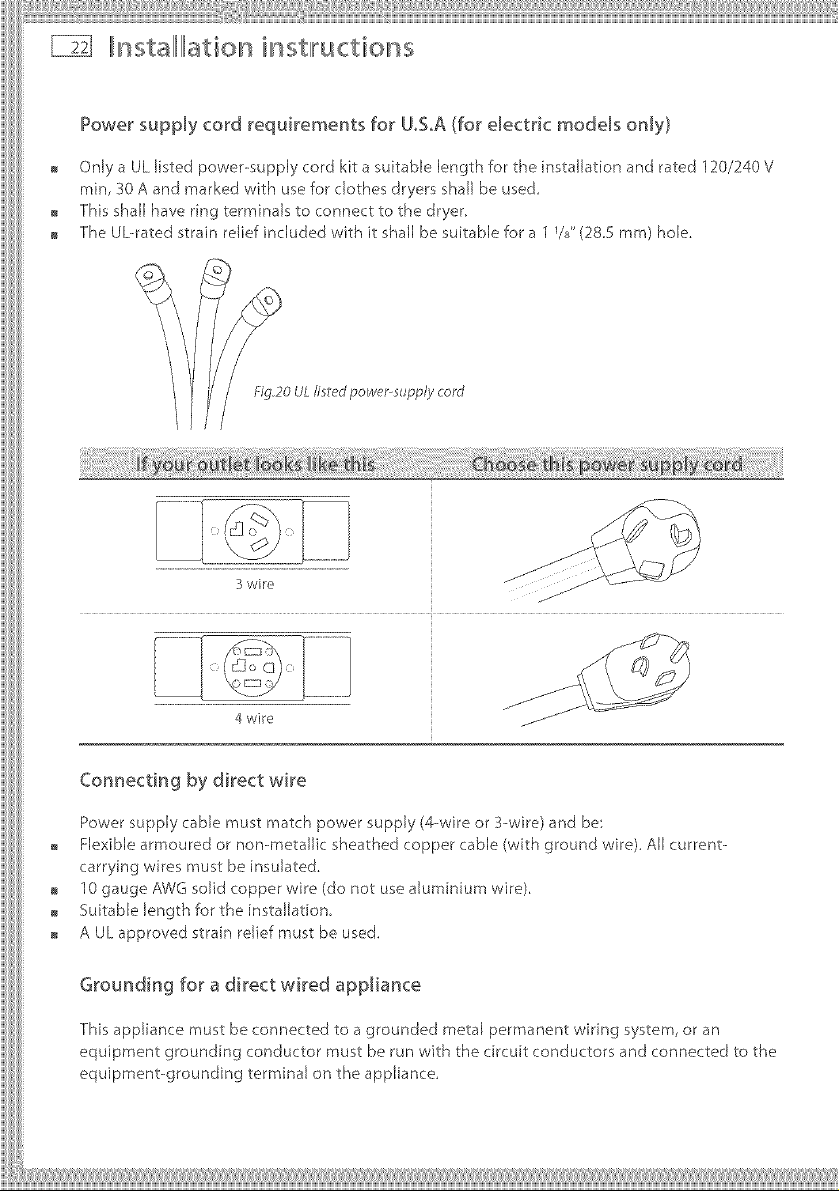

Power supply cord requirements for U°SA (for electric models only)

Only a UL listed power--supply cord kit a suitable length for the installation and rated 120/240 V

rain, 30 A and marked with use for dothes dryers shall be used.

This shall have ring terminals to connect to the dryer.

The Ubrated strain relief included with it shall be suitable for a 1 1/8"(28.S mm) hole.

Fig_20 ULIi£€*d power-supply cord

..................................lJ

3wire _ f

4 wire

Cormecdng by direct wire

Power supply cable must match power supply (4--wire or 3--wire) and be:

Flexible armoured or non--metallic sheathed copper cable (with ground wire), All current-

carrying wires must be insulated.

10 gauge A3b/Gsolid copper wire (do not use aluminium wire).

Suitable length for the installation,

A UL approved strain relief must be used.

Grounding for a direct wired appliance

This appliance must be connected to a grounded metal permanent wMng system, or an

equipment grounding conductor must be run with the circuit conductors and connected to the

equipment-grounding terminal on the appliance.

iiii}iilliiii ¸ii'ii¸ii'iiiiill¸iiilliiiii'}}}iillliii!i

IIInstalllllation insWuctions

Electrical connections (electric models only)

Please read Electrical requirements and grounding instructions on pages 20 - 21 fkst_

Electric models of the dryer are manufactured for a 3-wire connection system, The dryer frame

is grounded by a link to the neutral conductor on the dryer terminal block If local codes do

not permit grounding through the neutral, the grounding link from the terminal block must be

removed and a separate ground wire must be used,

The grounding link on the dryer must be removed for all &wire installations including new

remodelled construction, or mobile homes,

These Electrical Connection instructions provide for installing the dryer in the following

situations:

3--wire connection where local codes permit grounding through the neutral.

3-wire connection plus separate grounding connector where local codes do not permit

grounding through the neutral.

&wire connection.

Each of the above connections can be made with an approved power supply cord or by direct

wiring. Each connection instruction identifies the appropriate Power Supply Cord and covers

requirements for direct wiring.

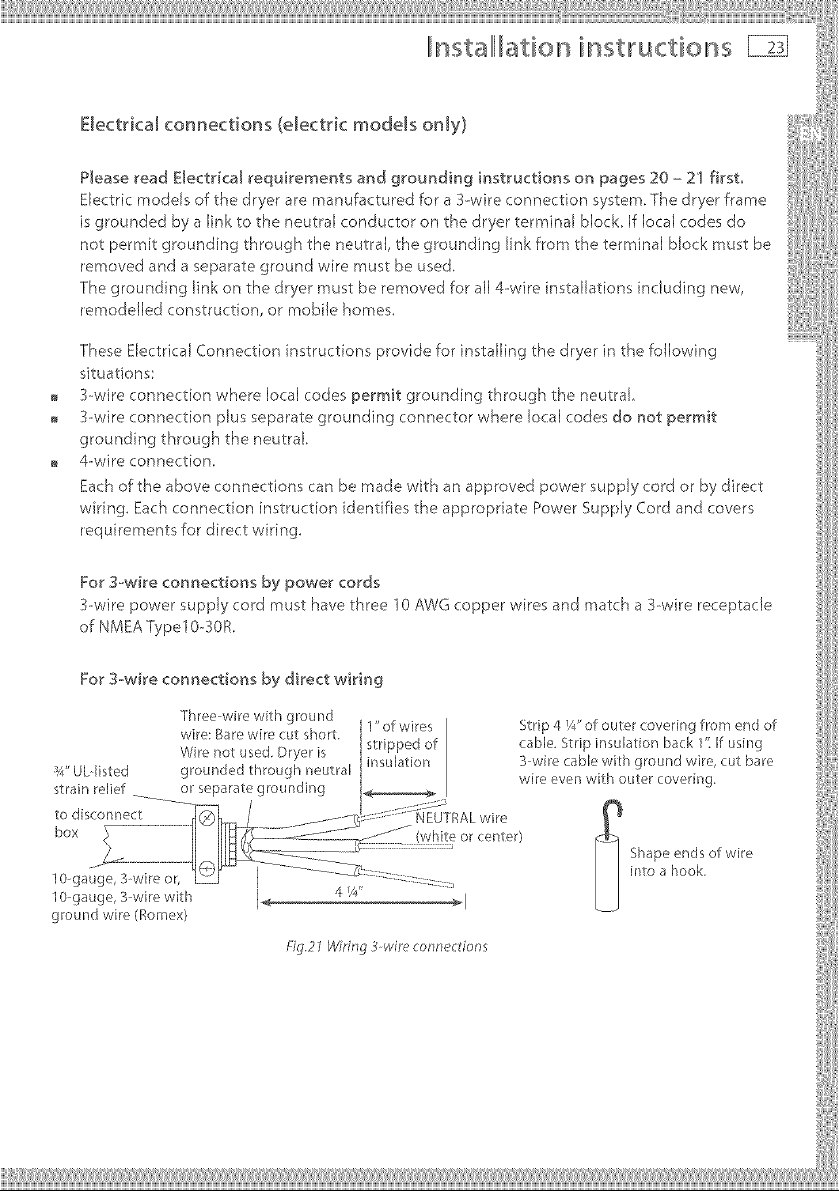

For 3_-wire connections by power cords

3-wire power supply cord must have three 10 AWG copper wires and match a 3-wire receptacle

!

For 3owire connections by direct wiring

1O-gauge, 3wire with

ground wire (Romex)

14

,Ng.21 Wiring 3wire conneclions

i!iii_!_!_i!i!_li_l_lii_iiiiiiii_ii_li_i_iiii!iiii!i!ii!ili_iiil¸il¸il_iii_ii_iiii:iiii¸I¸iiiiiiii¸ii'lii¸iiiiiiiii'ii_iiliiiiiil¸il_ii_iii_li_i_liiiiiiiiil¸il¸ii'liiiii¸iiiiiiiiiiHi_i_iii_iii_i1i@iiiw@iii_iiii_ii@@;iiiiii_i_ii_i_i_i_i_ii_iiii1i_¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸iiiil¸i_ili_li_i_iiii:iiiil¸liiiliiliiliiliiliiliiliiliiliiliiliiliiliiliiliiliiliiliiliiliiliiliiiiil

_t _nstalllati©n inst_ucti©ns

Electrical connections (electric models only}

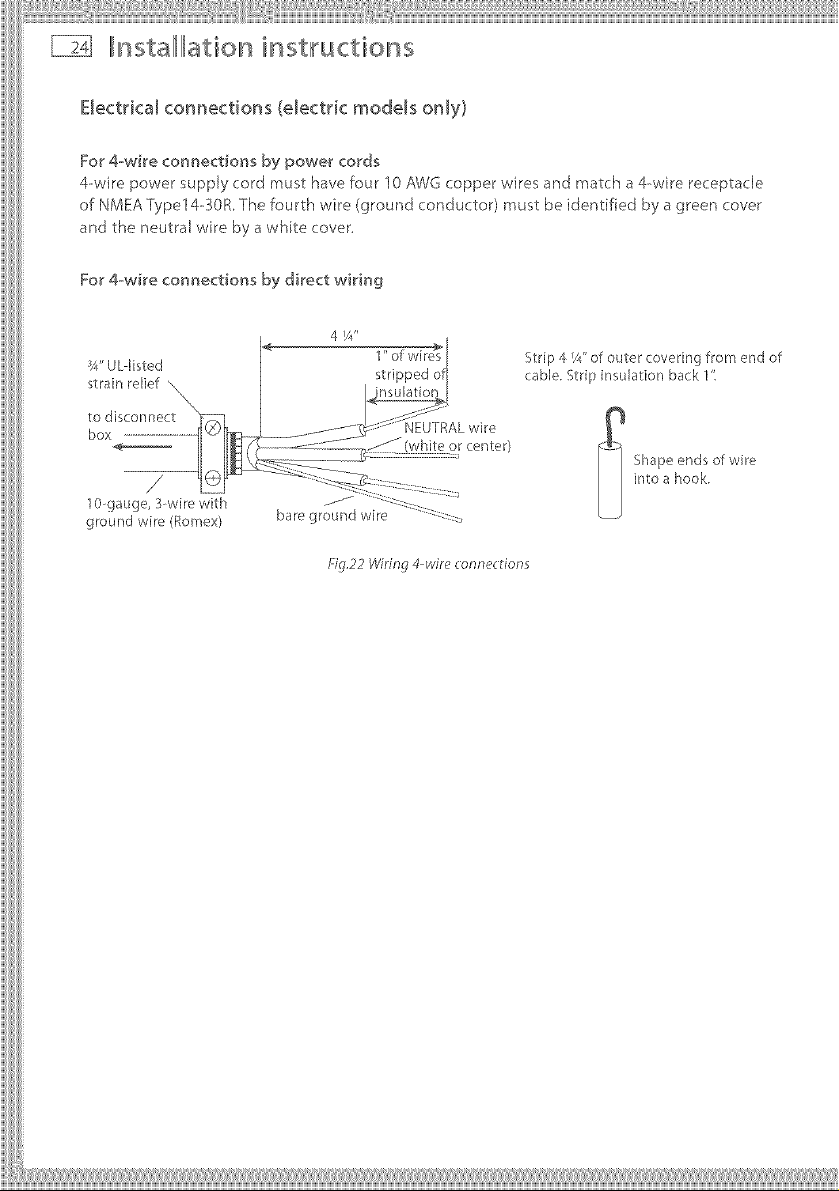

For #wire connections by power cords

4-wire power supply cord must have four 10 A}fTGcopper wires and match a 4-wire receptacle

of NMEA Type14--SOR The fourth wire (ground conductor) must be identified by a green cover

and the neutral wire by a white cover,

For 4wire connections by direct wiring

4 I/4"

Strip 4 ¼"of outer covering from end of

cable. Strip insulation back 1':

Shapeends of wire

into a hook.

ground wire (Eomex)

f:/g.22 Wiring 4wire connedions

Illnstallllationinst,ructions E]

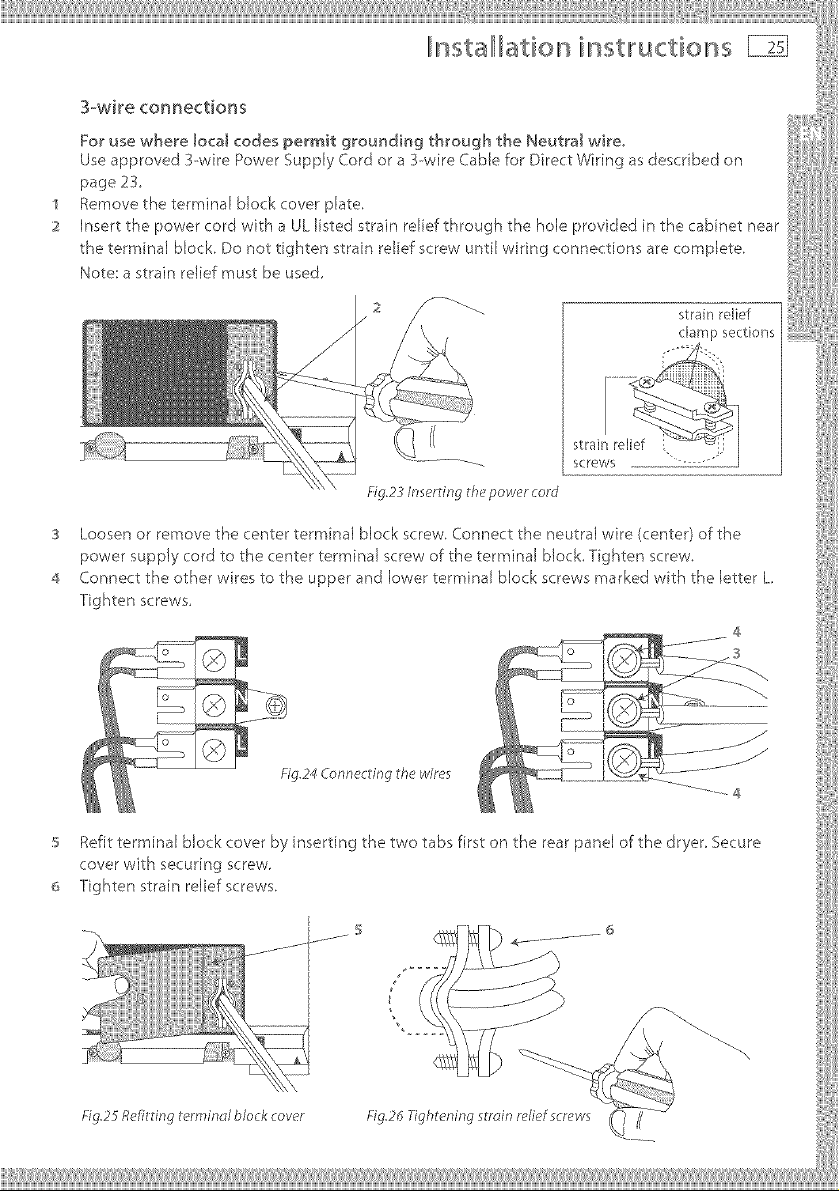

3_wi_e connections

For use where [oca[ codes permit grounding through the Neutra[ wire°

Use approved I--wire Power Supply Cord or a 3--wire CaNe for Direct Wiring as described on

page 23,

Remove the terminal block cover plate.

Insert the power cord with a UL listed strain relief through the hole provided in the cabinet near

the terminal block. Do not tighten strain relief screw until wiring connections are complete,

Note: a strain relief must be used,

strain relief

damp sections

SCreWS - --

3

Loosen or remove the center terminal block screw, Connect the neutral wire (center) of the

power supply cord to the center terminal screw of the terminal block, Tighten screw.

4

Connect the other wires to the upper and lower terminal block screws marked wth the letter L

Tighten screws,

4

3

Fig.24 Conneding lhe wires

_ Refit terminal block cover by inserting the two tabs first on the rear panel of the dryer, Secure

cover with securing screw.

6 Tighten strain relief screws,

Fig.25 Ref'ildng terminol blo k cover Fig.J* Tightening s_min relief screws

lnsta[lllati©n inst 'uctions

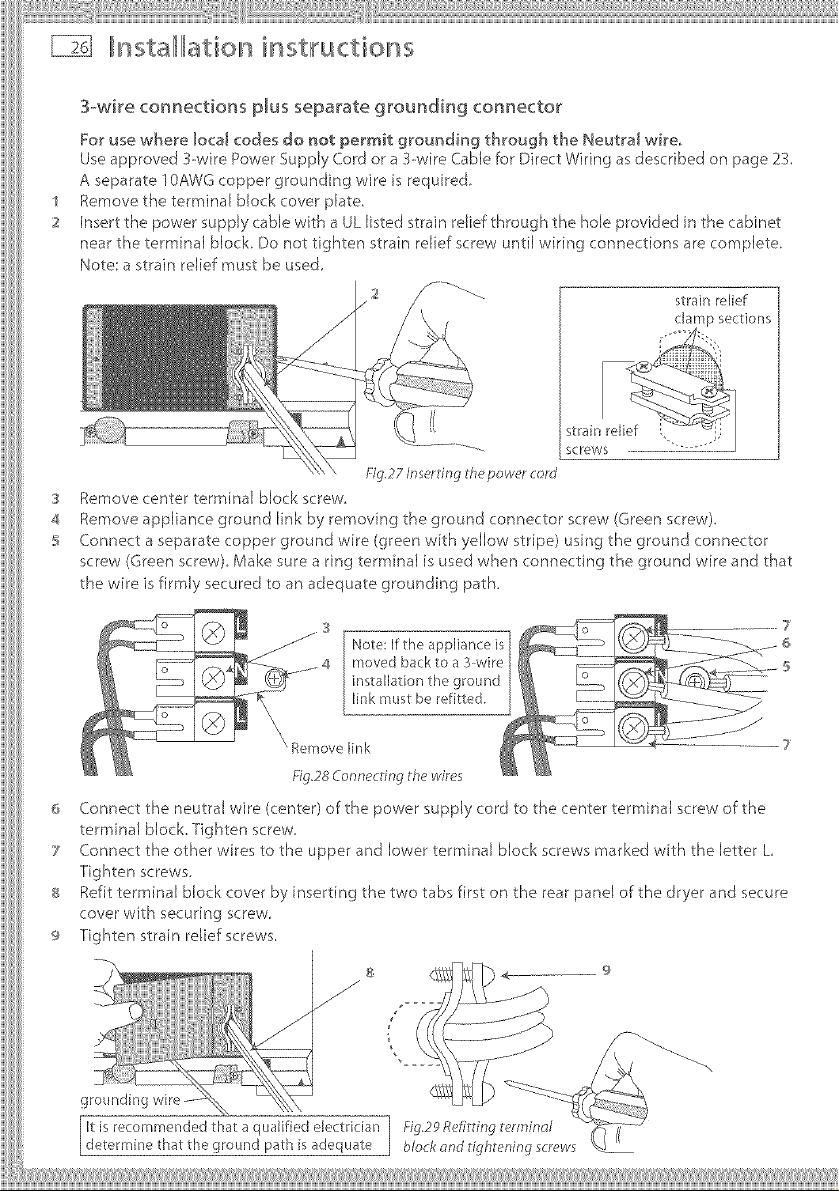

3-wire connections plus separate grounding connector

For use where local codes do not permit grounding through the Neutral wire.

Useapproved 3wife PowerSupply Cordor a 3--wireCablefor DirectWiring asdescribed on page 2X

Aseparate ]0AWGcopper grounding wire isrequired,

Removethe terminal block cover plate,

Insert the power supply cable wkh a ULlisted strain relief through the hob provided inthe cabinet

near the terminal biocL Do not tighten strain relief screw until wiring connections are complete.

Note astrain relief must be used

strain relief

clamp sections

Fig.27 Inserling 8hepowercord

Removecenter terminal block screw.

3

4

Removeappliance ground link by removing the ground connector screw (Greenscrew).

S

Connect a separate copper ground wire (green with yellow stripe) using the ground connector

screw (Greenscrew).Make sure a ring terminal is usedwhen connecting the ground wire and that

the wire isfirmly secured to an adequate grounding path.

S

Note: If the appliance is

moved back to a 3wire

installation the ground

link must be refitted,

\ Remove link 7

FYg,28Connecting th_ wir_*s

Connect the neutral wire (center) of the power supply cord to the center terminal screw of the

terminal block.Tighten screw.

7 Connect the other wires to the upper and lower terminal block screws marked with the letter L

Tighten screws.

8 Refit terminal block cover by inserting the two tabs first on the rear panel of the dryer and secure

cover with securing screw

9 Tighten strain relief screws

8

.//j/

J

/

It is recommended that a qualified ,4ectriclan 1 ig.2g R_filting _ennind

delermine that the ground path is adequate ] block ond tightening screws

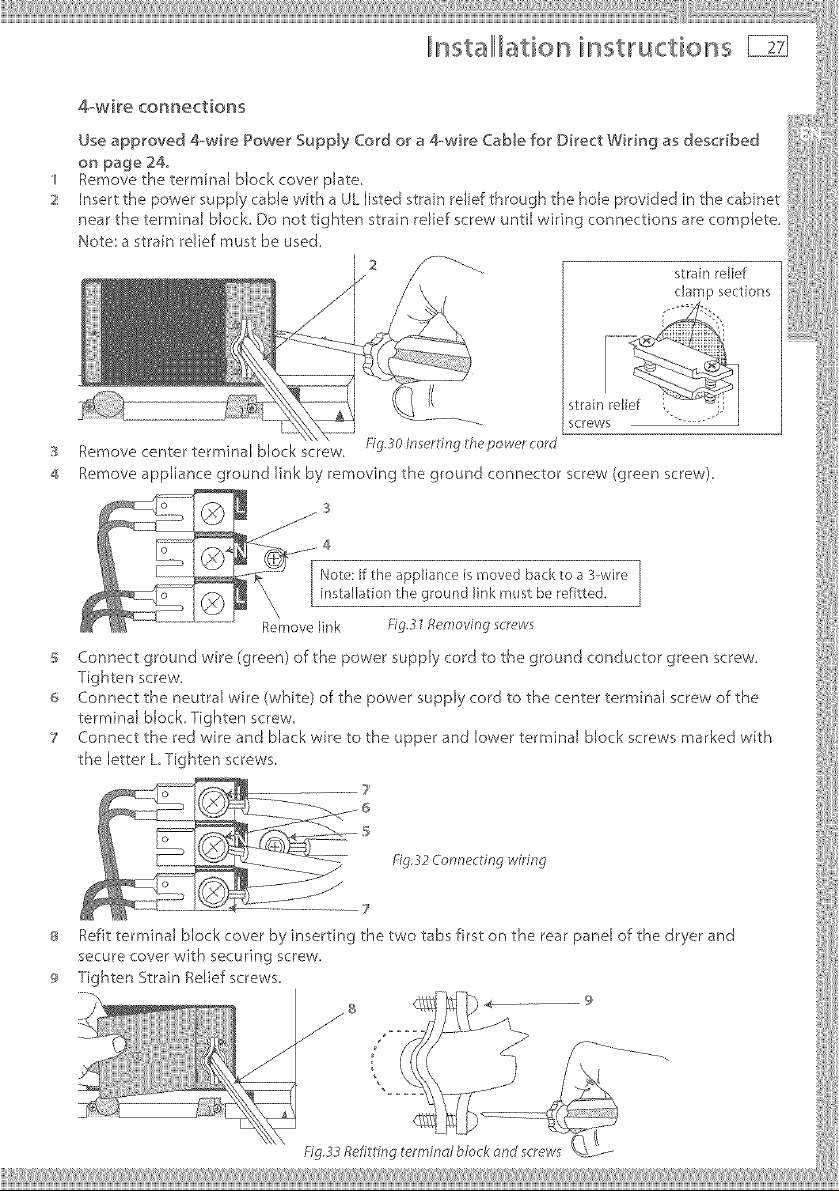

4,_wi_e co_ectio_s

Remove the terrninal block cover plate. _ 'i

Insert the power supply cable with a UL listed _train relief through the hole provided in the cabinet

near the terminal block Do not tighten strain relief screw until wiring connections are complete,

Note', a strain relief must be used,

sorrows

Remove center terminal block screw, ig._o Inserling lhe power cord

Remove appliance ground link by removing the ground connector screw (green screw),

3

4

I No_e:lf_he appliance is moved backtoa 3wire ]

lns_aJlationtha ground link must be lefi_ted.

Remove link ig._'/Removing screws

S Connect ground wire (green) of the power supply cord to the ground conductor green screw,

Tighten screw,

_ Connect the neutral wire (white) of the power supply cord to the center terminal screw of the

terminal block Tighten screw,

7 Connect the red wire and black wire to the upper and lower terminal block screws marked with

the letter L Tighten screws

]

Fig._;2 Connect ng wiring

7¸

_ Refit terminal block cover by inserting the two tabs first on the rear panel of the dryer and

secure cover with securing screw,

(_ Tighten Strain Relief screws,

Fig,33Refitdng terminal block_nd screws

_t

,L stalllatio ilnst 'uctior s

Gasrequiremertts (gas models ordy}

The installation must conform with Local Codes, or in the absence of Local Codes, to the

National Fuel Gas Code ANSI Z223,1/NFPA 54 or the Canadian Natural Gas and Propane

Installation Code, CSA B14g.l.

Explosion Ha_rd

_nstaHations must be performed by a qualified or _icensed contractor,

p_umber, or gasfitter qualified or _icensed by the state, province, or region

where this appliance is being instaHedo

Use a new AGA or CSA approved gas supply _ineo

Install a shut-offva[ve in an a<cessib[e p[aceo

Only use a gas shut-off valve approved for u_ within the state, province, or

region where this appliance is being instaHedo

Securely tighten aH gas connections.

_fconnecting to LP Gas, have a qualified person make sure gas pressure

does not exceed 13"(330 ram} water co_umno

Failure to follow these instructions can result in death, explosion, or fire.

Gas type

'four dryer must have the correct burner for the type of gas in your home. Burner information

is ocated on the rating plate located on the rear of the console. [f this information does not

agree with the type of gas available in your home, contact your local Fisher & Paykel supplier or

service center.

This dryer is supplied ready for use with Natural Gas.

It is design certified by UL International for LP (Propane or Butane) Gases with the appropriate

conversion,

LPgas conversion

If the dryer is to be operated on LP (Liquid Propane or Butane) Gas, the dryer must be

converted. To do so, use only the approved Fisher & Payke[ conversion kit listed in Accessories

on page 7. Do not use with a different gas without consulting the serving gas supplier.

The dryer must be converted for safe and proper performance by qualified service or installation

personek

Conversion kits for Natural and LPGas are available from your local Fisher & Payke[ Dealer

(see Accessories page 7) If other conversions are required, check with your local gas utility for

specific information concerning conversion requirements.

Loading...

Loading...