Fisher & Paykel AeroSmart DE62T27CW1, AeroSmart DG62T27CW1, AeroSmart DE62T27DW1, AeroSmart DG62T27DW1 Servlce Manual

517760C

Models

DE62T27CW1

DG62T27CW1

DE62T27DW1

DG62T27DW1

Supplementary to 517760B

517760C

2

517760C - APRIL 2007 REPRINT - AUGUST 2007

Fisher & Paykel Appliances Inc

5800 Skylab Road

Huntington Beach

CA 92647

USA

Phone: 1 888 936 7872

3

The specifications and servicing procedures outlined in this manual are subject to change without

notice.

The latest version is indicated by the reprint date and replaces any earlier editions.

Note: This supplementary manual is only to be used in conjunction with service manual

517760B. It is not intended to be used on its own.

517760C

4

CONTENTS

1 SERVICING REQUIREMENTS................................................................................................5

1.1 Health & Safety...............................................................................................................5

1.2 Electrical Safety ..............................................................................................................5

1.3 Electrostatic Discharge ...................................................................................................5

1.4 Good Working Practices .................................................................................................5

1.5 Safety Test......................................................................................................................5

1.6 Sheet Metal Edges..........................................................................................................5

2 MODELS INFORMATION........................................................................................................6

2.1 Models Number...............................................................................................................6

2.2 Serial Number.................................................................................................................6

2.3 Product Code..................................................................................................................7

3 TECHNICAL OVERVIEW ........................................................................................................7

3.1 Finish ..............................................................................................................................7

3.2 Electrical Supply..............................................................................................................7

3.3 Dimensions .....................................................................................................................7

3.4 Maximum Capacity (Full Load) .......................................................................................7

4 COMPONENTS........................................................................................................................8

4.1 Control Panel Assembly..................................................................................................8

4.2 Fascia .............................................................................................................................9

5 SERVICE PROCEDURES.....................................................................................................10

5.1 Removal of Lid..............................................................................................................10

5.2 Removal of Console......................................................................................................10

5.3 Removal of Display Module ..........................................................................................10

6 DIAGNOSTICS ......................................................................................................................11

6.1 Overview – LCD Models ...............................................................................................11

6.2 Overview – LED Models................................................................................................11

6.3 Fault Code Summary....................................................................................................12

7 DIAGNOSTIC MODE – LCD MODELS .................................................................................16

7.1 Entering the Diagnostic Mode.......................................................................................16

7.2 Service Screen..............................................................................................................16

7.2.1 Fault Status Screen..............................................................................................16

7.2.2 Machine Status Screen........................................................................................17

7.2.3 Warning Status Screen........................................................................................17

7.3 Testing the Conductivity Contacts.................................................................................17

7.4 Data Download Mode....................................................................................................17

7.5 Showroom Mode...........................................................................................................18

8 DIAGNOSTIC MODE – LED MODELS .................................................................................18

8.1 Entering the Diagnostic Mode.......................................................................................18

8.2 Testing the Conductivity Contacts.................................................................................19

8.3 Show Room Mode ........................................................................................................19

8.4 Data Download Mode....................................................................................................19

9 AUTOSENSING.....................................................................................................................19

10 TEMPERATURE CONTROL .................................................................................................19

11 COOL DOWN.........................................................................................................................20

12 CYCLE CHARTS – LCD MODELS .......................................................................................21

12.1 Electric.....................................................................................................................21

12.2 Gas ..........................................................................................................................23

13 CYCLE CHARTS – LED MODELS........................................................................................25

13.1 Electric.....................................................................................................................25

13.2 Gas ..........................................................................................................................25

14 WIRING DIAGRAM – ELECTRIC MODELS .........................................................................26

15 WIRING DIAGRAM – GAS MODELS....................................................................................27

517760C

5

1 SERVICING REQUIREMENTS

1.1 Health & Safety

Note: When servicing the AeroSmartTM electronic dryer, health and safety issues must be

considered at all times. Specific safety issues are listed below to remind service people of

the health and safety issues.

1.2 Electrical Safety

WARNING! TO AVOID ELECTRIC SHOCK!

Do not attempt to service this dryer without suitable training and qualifications.

Ensure the mains power has been disconnected before servicing any part of the dryer. If the

power is required to be on for electrical fault finding, or checking the operation, then extreme care

should be taken not to make contact with electrical components other than with testing probes.

Ensure the dryer is turned off when removing any electrical component or connection.

1.3 Electrostatic Discharge

Electronic components are prone to damage from electrostatic discharges. The electronic

modules in this product contain no user serviceable components and breaking seals to access

internal components of an electronic module may void the product warranty. Avoid contact with

PCB edge connectors when handling electronic modules.

1.4 Good Working Practices

Ensure the work areas are kept tidy and free of hazards while servicing the dryer. On completion

of the servicing, ensure the dryer and work areas are left clean and tidy.

1.5 Safety Test

On completion of any service carried out to the dryer, all safety tests as required by law must be

carried out.

1.6 Sheet Metal Edges

When working around cut sheet metal edges use appropriate gloves or protection to eliminate the

chance of receiving a laceration.

517760C

6

2 MODELS INFORMATION

The product serial plate is located on the upper rear of the cabinet and contains the following

information:

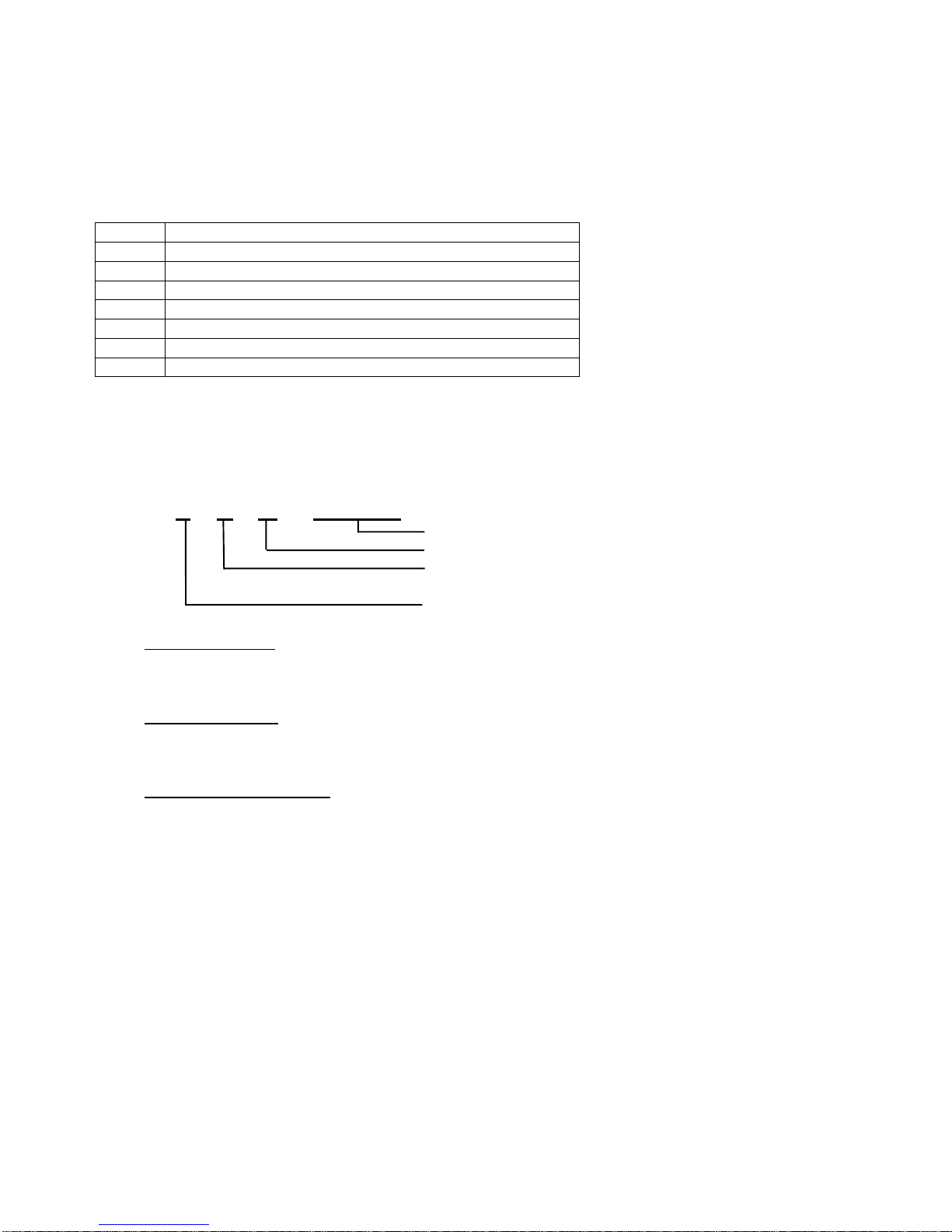

2.1 Models Number

The models number contains the following information:

D

Product Type (Dryer)

E

Heating Type (E = Electric / G = Gas)

62

Capacity cu/ft (6.2) IEC

T

Top Loading

27

Size (27 inches wide)

C

Console (C = LCD / D = LED)

W

Color (White)

1

Series (1)

2.2 Serial Number

The serial number consists of three letters and six digits and contains the following information:

Example:

L F U 123456

Sequential Serial Number

Manufacturing Plant Code

FISHERPAYKUL Code indicates month of

manufacture

CUMBERLAND Code indicates year of manufacture

Cumberland Code

Letter C U M B E R L A N D

Year 1 2 3 4 5 6 7 8 9 0

Fisherpaykul Code

Letter F I S H E R P A Y K U L

Month 1 2 3 4 5 6 7 8 9 10 11 12

Manufacturing Plant Code

F Refrigeration – New Zealand

M Range & Dishwasher

N Laundry – New Zealand

Q Refrigeration – Australia

U Laundry – U.S.A.

In the example above, the appliance was manufactured in the first month of the seventh year

(2007) at the Laundry plant in Ohio (U.S.A.).

517760C

7

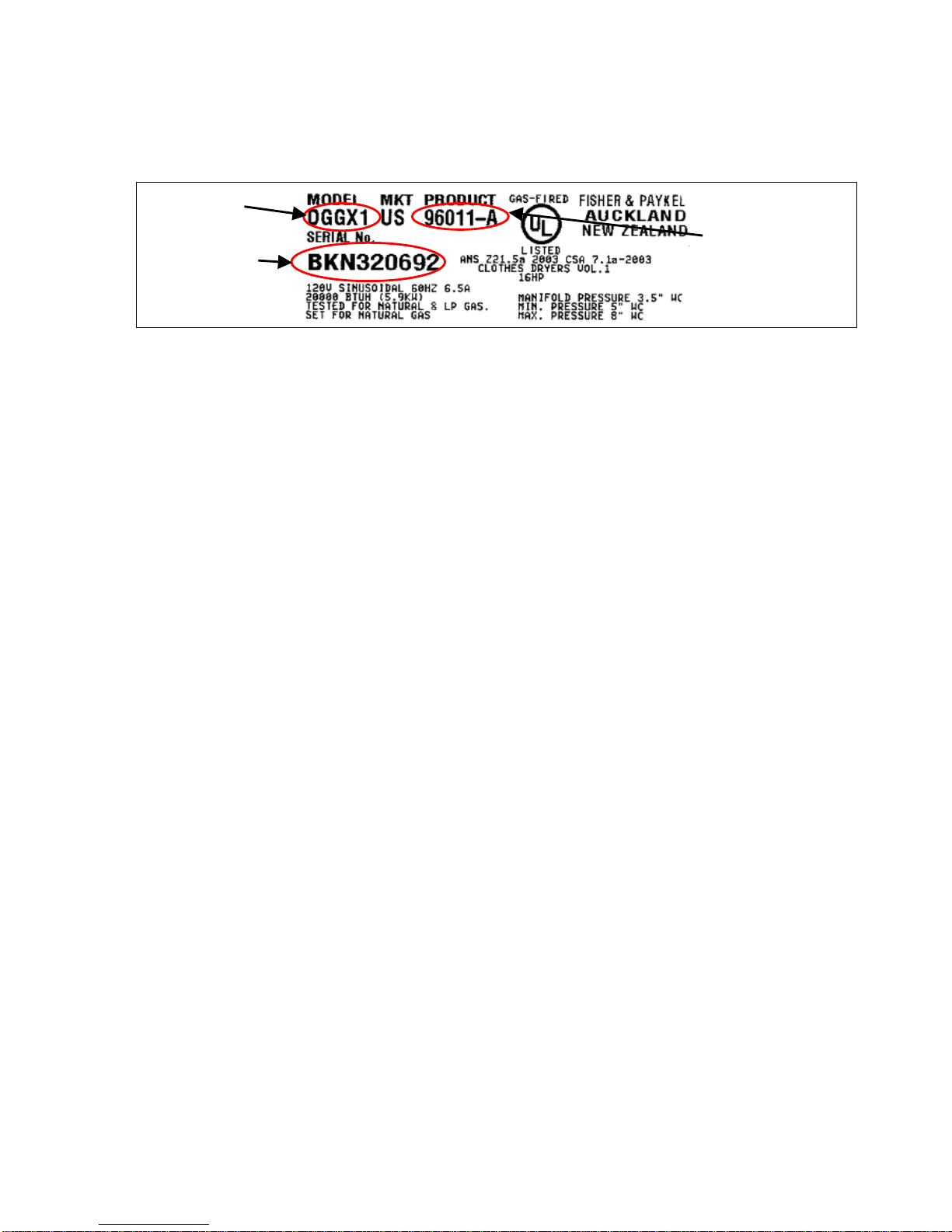

2.3 Product Code

A suffix letter has been added to the Product Code. This suffix letter will change whenever a part

is changed that is not completely retro-fittable without the need for a kit, or whenever a cosmetic

change is made.

At the same time, separate parts manuals will be produced for each product code, making it easier

for the service technician to obtain the correct part for the appliance they are servicing. The part

number of the manual will be the same as the Product Code.

It is now important that the service technician obtains the Product Code from the serial plate of the

appliance before ordering parts, then refers to the appropriate parts manual to ensure that the

correct part numbers are obtained.

3 TECHNICAL OVERVIEW

3.1 Finish

Cabinet: Pre-paint (Polyester)

Touch-Up Paint: White #503086

Lid: ABS Co-injected, one piece

Console: ABS plastic

Facia (LCD Models): IMD (In-mould decorative) Polycarbonate/PET

Facia (LED Models): PC/PBT Printed film + clear ABS.

Drum: Stainless steel grade 430T

Top Deck: Polypropylene

3.2 Electrical Supply

Operating Voltage Maximum Current

USA Electric 220/240V AC 60Hz 24 Amps

USA Gas 110/120V AC 60Hz 6 Amps

3.3 Dimensions

Height to lid

Open 55 ½ in – 56 ¾ in 1410mm – 1440mm

Closed 36 ½ in – 37 ½ in 925mm – 955mm

Height to console 40 ¼ in – 41 ½ in 1020mm – 1050mm

Width 27 685mm

Depth 27 ½ in 700mm

Note: Exact height of the AeroSmart

TM

dryer is dependent on how far the feet are inserted

into the base of the dryer.

Weight Packed 152lbs (69kg)

Unpacked 134 lbs (61kg)

3.4 Maximum Capacity (Full Load)

Drum Volume 6.2 cubic feet (.184 cubic meters)

Model

Serial

517760C

8

4 COMPONENTS

The only visual change of major components between the G (General), I (Intuitive™) and the

AeroSmart™ dryer is with the console assembly.

The Aerosmart™ LCD models incorporates an IMD (In-mould decorative display), which uses

capacitive touch buttons that sense the user’s fingers over the buttons. It has a large LCD Display

allowing us to show graphics on the screen. The new screen allows us to present information

simply while providing a lot more detail, such as graphic icons, pop up explanations and

confirmation.

The AeroSmart™ LED models incorporates backlit buttons, with the selected button illuminated

more brightly than the others. Words indicating selections made are also illuminated.

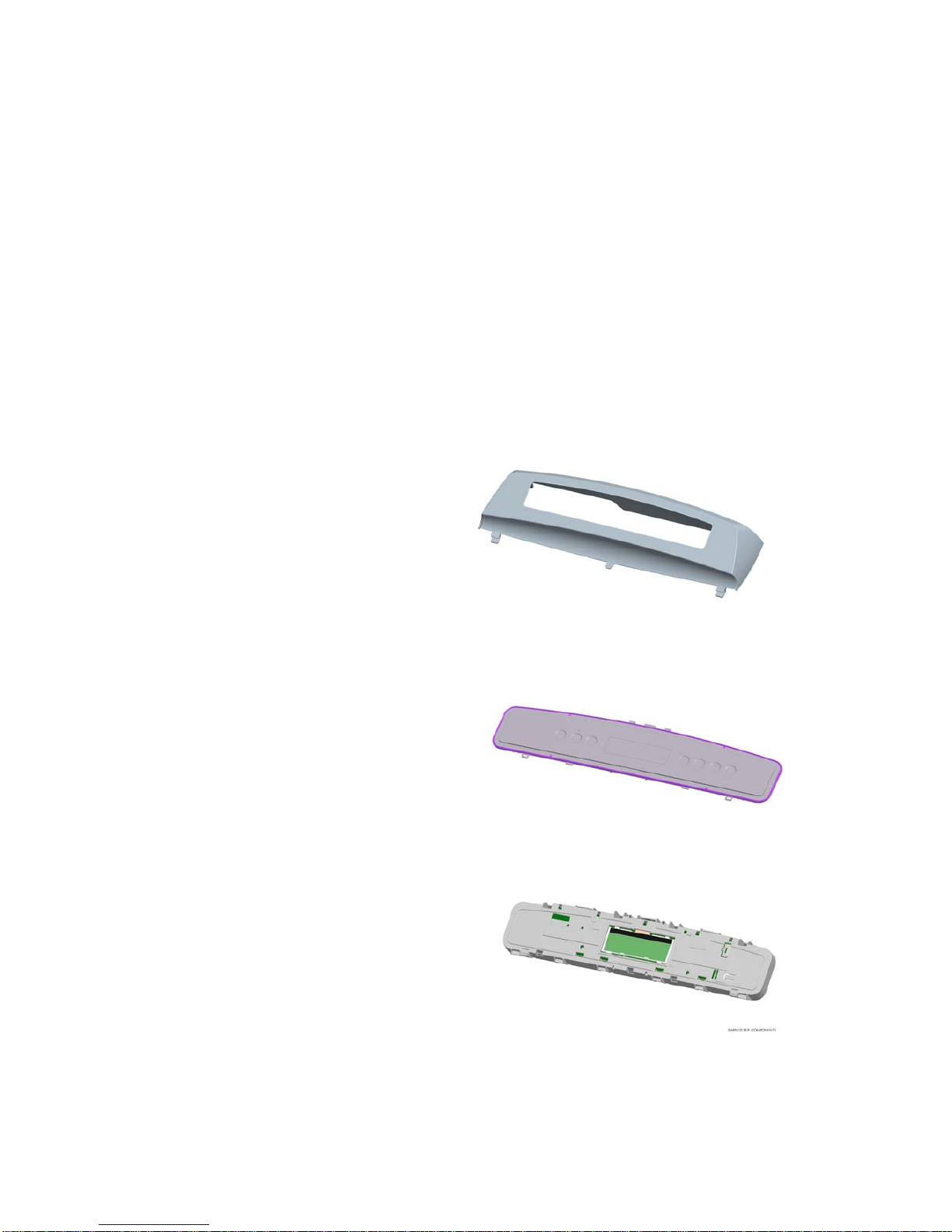

4.1 Control Panel Assembly

The three core components of the control panel assembly are the console, the fascia, and the PCB

and housing.

Console

The console, which is made from ABS is the

housing to which the fascia and PCB housing

attaches. Lugs at the base of the console

locate into the top deck. The console is secured

to the rear of the top deck by two screws.

Fascia

The fascia will be one of either the IMD fascia

for LCD models or the touch panel for LED

models.

PCB and Housing

The PCB, which contains the electronics, is

mounted within a plastic housing. The PCB

housing is clipped into the console at the

bottom, and secured with four screws along the

top.

517760C

9

4.2 Fascia

LCD Models

1. Power On/Off button.

2. Wrinkle Free On/Off. When the LED is on the wrinkle free option is turned on.

3. Wrinkle Free LED used also for data download (Refer to Section

7.4).

4. Start/Pause button.

5. LCD Screen.

6. Left arrow (used when scrolling through options on the LCD screen).

7. Right arrow (used when scrolling through options on the LCD screen).

8. Select button – Use to confirm setting.

9. Back button – Use to cancel setting.

LED Models

1. Power button. 10. Bulky button.

2. Auto Sensing button. 11. Air Dry button.

3. Time Dry button. 12. Sheets button.

4. Dryness Level button. 13. Delicate button.

5. Temperature. 14. Heavy button.

6. Progress. 15. Regular button.

7. Start/Pause button. 16. Lid Lock icon.

8. Wrinkle Free button. 17. Service Spanner icon.

9. Easy Iron button.

1

2

5

6

7

8

9

3

4

1

2 3 4 5 6

7

15 14 13 12 11 10 9 8 17 16

Loading...

Loading...