Page 1

Instruction Manual

D103803X012

Fisher™ Z500 Severe Service Ball Valves

Z500 Valve

July 2017

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Specifications 1...............................

Installation 5

Operation 7...................................

Maintenance 8

Troubleshooting 9.............................

Packing Replacement 10.......................

Actuator Mounting 13.........................

Parts Ordering 18

Parts List 18.....................................

....................................

..................................

................................

Introduction

Scope of Manual

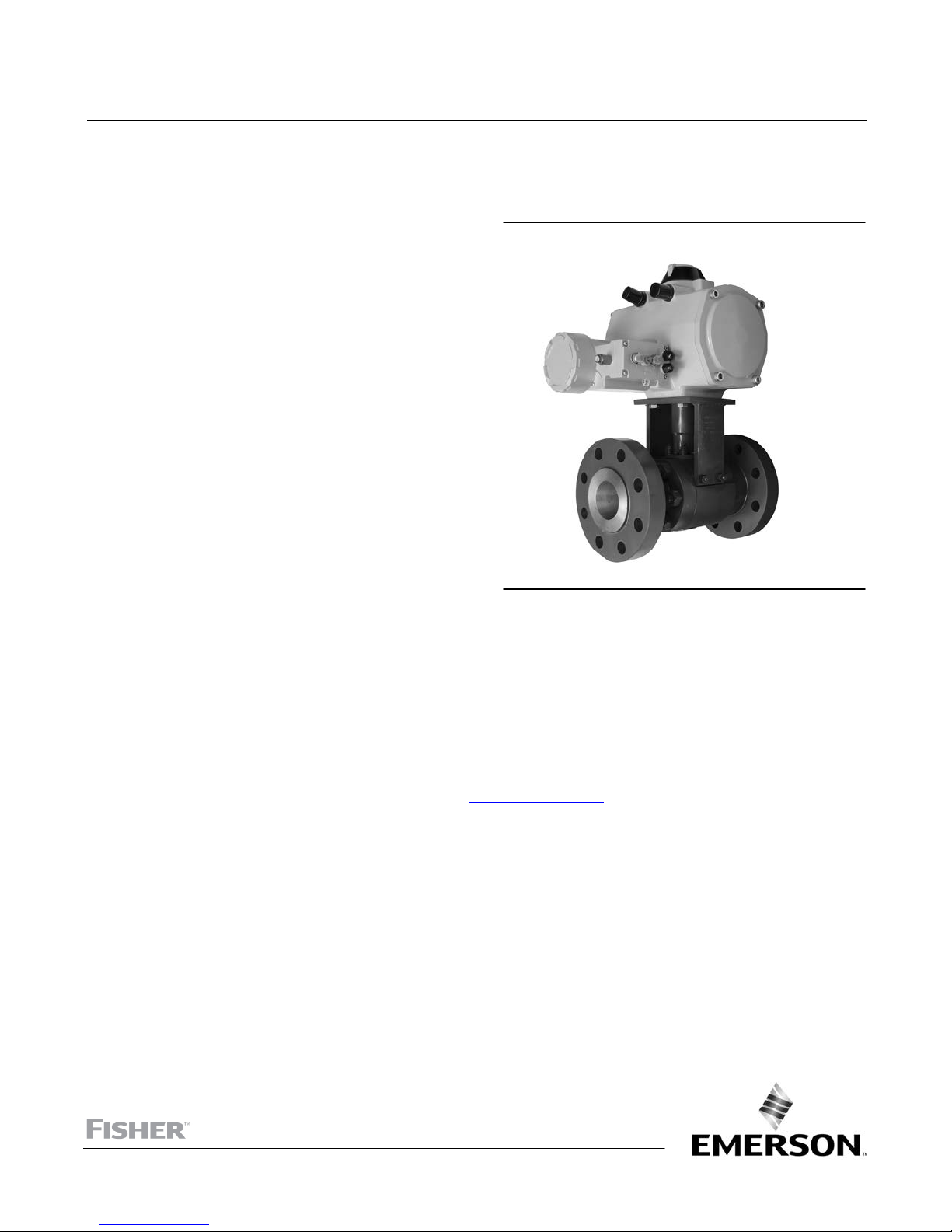

Figure 1. Fisher Z500 Severe Service Ball Valve

X1243

This instruction manual provides installation, operation, maintenance, and parts information for the Fisher Z500

Severe Service Ball Valve (see figure 1).

Do not install, operate, or maintain Z500 valves without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson sales office

proceeding.

or Local Business Partner before

Description

The Z500 severe service ball valve is a split body bolted design, full or reduced port, with a blowout proof shaft. It can

be lever operated, gear operated, or actuated. The Z500 severe service ball valve line is a simplistic two-piece floating

ball design with integral metal seat meant to provide tight metal seating shutoff in high temperature, high pressure,

corrosive, and erosive applications across all industries.

Specifications

Specifications for these valves are shown in table 1.

www.Fisher.com

Page 2

Z500 Valve

July 2017

Table 1. Specifications

Instruction Manual

D103803X012

Valve Sizes

Z500: NPS

J 1/2, J 3/4, J 1, J 1-1/2, J 2, J 3,

J 4, J 6, J 8, J 10, J 12, J 14, J 16, J 18, J 20,

J 24, J 26, J 28, J 30 and, J 36

Packing Constructions

Carbon Steel Valve Bodies: Wire reinforced graphite

packing, AISI 4130 nitrided packing gland

Stainless Steel: N06600 wire-reinforced graphite

packing, S31600 nitrided packing gland

Maximum Working Pressures

(1)

Standard Flow Direction

Forged Steel Valves: Consistent with applicable

pressure-temperature ratings in table 4 per ASME

B16.34, but do not exceed the material temperature

Preferred Flow Direction: Preferred flow for optimal

sealing is forward into the integral seat

capabilities shown below

Flow Coefficients

Shutoff Classification

Z500: Valves are tested to API 598 in the preferred

(1)

Contact your Emerson sales office or Local Business

Partner

flow direction.

Maximum Ball Rotation

Class V type B per FCI 70-2 in reverse flow in

bi-directional design (Must be specified). For other

90 degrees

shutoff requirements, please contact your Emerson

sales office or Local Business Partner.

Actuator Mounting

The preferred mounting orientation is vertical. Other

Construction Materials

orientations are acceptable

See tables 2 and 3

Approximate Weight

Temperature Capabilities

(1)

Contact your Emerson sales office or Local Business

Partner

Welded and Threaded Ends: SA105 - 800_F, F22

1000_F, F91 1200_F, F316 1400_F

Flanged End Connections: SA105 - 600_F, F22 800_F,

F91 1000_F, F316 1000_F

Lower Limits: Carbon steel: -29_C (-20_F),

Stainless steel: -40_C (-40_F)

1. The pressure/temperature limits in this manual, and any applicable code or standard limitation, should not be exceeded.

Options

J Reduced port, J Expanded outlet, J Scraper

seats,

sealing,

J Spray and fused coatings

J HVOF coating options, J Bi-directional

J High cycle constructions, J Lockouts,

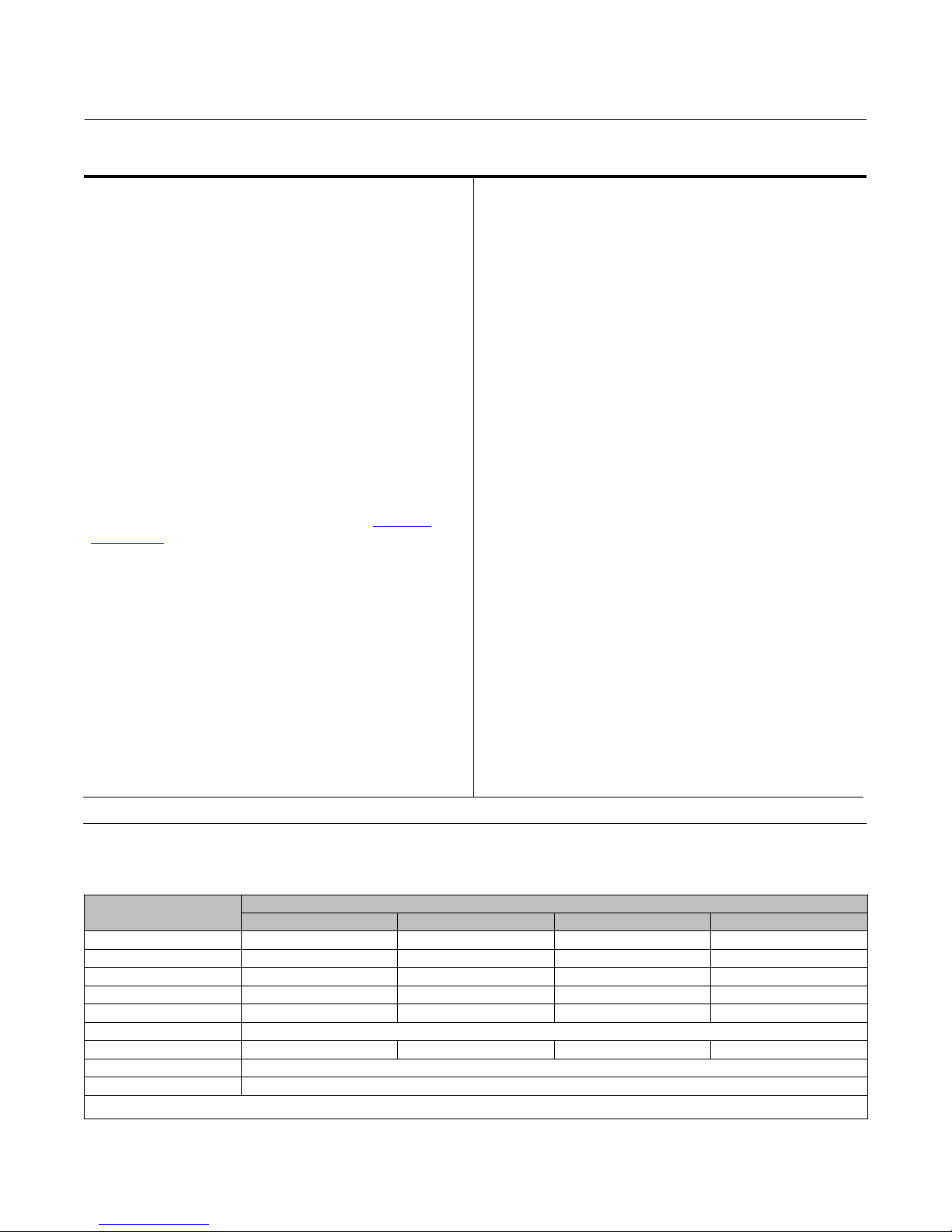

Table 2. Standard Construction Materials for NPS 1/2 through 36 Valves

PART

(1)

Ball

Upstream seat

Seat Holder

Body gasket S17400 N07718 N07718 AISI 660

Spring N07718 N07718 N07718 AISI 660

Packing Flexible graphite with wire-reinforced braided graphite and stainless steel washers

Shaft adapter AISI 4130 Nitrided, 4140 Nitrided

Coatings HVOF Chrome Carbide (standard), HVOF Tungsten Carbide, Spray and Fused Nickel-Boron

1. Part is coated (HVOF chrome carbide standard)

2. Seat holder is standard on welded and threaded end connections in 0.65, 1.15, 1.5, and 2 inch bores only. Bidirectional option must be specified for all other constructions.

2

(1)

(2)

Shaft S17400 Nitrided N07718 Nitrided N07718 Nitrided AISI 660 Nitrided

SA105 F22 F91 F316

S41000 S41000 S41000 S31600

S41000 S41000 S41000 S31600

S41000 S41000 S41000 S31600

VALVE BODY AND END ADAPTER MATERIAL

Page 3

Instruction Manual

D103803X012

Z500 Valve

July 2017

Table 3. Spray and Fused Coating Standard Construction Materials

PART

Ball and Upstream Seat

Shaft N07718 Nitrided AISI 660 Nitrided

Spring and Body Gasket N07718 AISI 660

1. Seat holder is standard on welded and threaded end connections in 0.65, 1.15, 1.5, and 2 inch bores only. Bidirectional option must be specified for all other constructions.

2. Part is coated.

(2)

SA105 F22 F91 F316

VALVE BODY AND END ADAPTER MATERIAL

F22 S31600

(1)

Table 4. Valve Body Materials, End Connections, and Ratings

Ratings Bore (inches) Size, NPS End Connection Valve Body Materials

1/2

3/4

1

1-1/2

1

1-1/2

2

2-1/2

1-1/2

2

2-1/2

3 Buttweld, RF, RTJ

2

2-1/2

3

4

3

4

6

4

6

6

8

8

10

‐continued‐

Buttweld, Socketweld, FNPT,

RF, RTJ

Buttweld, Socketweld, FNPT,

RF, RTJ

Buttweld, RF, RTJ

RF, RTJ

SA105, F22, F91, and F316

CL150 through 1500

0.65

1.15

1.5

2

3

4

6

8

10 10

12 12

14 14

16 16

18 18

20 20

24 24

26 26

28 28

30 30

36 36

3

Page 4

Z500 Valve

July 2017

Table 4. Valve Body Materials, End Connections, and Ratings (continued)

Ratings Bore (inches) Size, NPS End Connection Valve Body Materials

1/2

3/4

1

1-1/2

1

1-1/2

2

2-1/2

1-1/2

2

2-1/2

3 Buttweld, RF, RTJ

2

2-1/2

3

4

3

4

6

4

6

6

8

8

10

1/2

3/4

1

1

1-1/2

2

1-1/2

2

2-1/2

1/2

3/4

1

1

1-1/2

2

1-1/2

2

2-1/2

CL2500

CL3200

CL4500

0.65

1.15

1.5

2

3

4

6

8

0.65

1.15

1.5

0.65

1.15

1.5

Instruction Manual

D103803X012

Buttweld, Socketweld, FNPT,

Buttweld, Socketweld, FNPT,

RF, RTJ

SA105, F22, F91, and F316

RF, RTJ

Buttweld, RF, RTJ

RF, RTJ

Buttweld, Socketweld SA105, F22, F91, and F316

Buttweld, Socketweld SA105, F22, F91, and F316

4

Page 5

Instruction Manual

D103803X012

Z500 Valve

July 2017

Installation

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

Personal injury or equipment damage caused by sudden release of pressure may result if the valve assembly is installed

where service conditions could exceed either the valve body rating or the mating pipe flange joint rating. To avoid such

injury or damage, provide a relief valve for overpressure protection as required by government or accepted industry codes

and good engineering practices.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

WARNING

When ordered, the valve configuration and construction materials were selected to meet particular pressure, temperature,

pressure drop, and controlled fluid conditions. Responsibility for the safety of process media and compatibility of valve

materials with process media rests solely with the purchaser and end‐user. To avoid possible personal injury and because

some valve/trim material combinations are limited in their pressure drop and temperature ranges, do not apply any other

conditions to the valve without first contacting your Emerson sales office

or Local Business Partner.

WARNING

The valve drive shaft is not necessarily grounded to the pipeline when installed. Personal injury or property damage could

result from an explosion caused by a discharge of static electricity from valve components if the process fluid or the

atmosphere around the valve is flammable. If the atmosphere around the valve or the process fluid is flammable,

electrically bond the drive shaft to the valve.

WARNING

Personal injury could result from packing leakage. Valve packing was tightened before shipment; however the packing

might require some readjustment to meet specific service conditions. Check with your process or safety engineer for any

additional measures that must be taken to protect against process media.

When a valve is shipped bare shaft:

a. Valve is shipped in the open position with exposed shaft

b. Valve will include two shaft keys.

When a valve is shipped with mounting kit only:

a. Valve will ship in the in open position

b. Valve will have the mounting finger-tight to the valve

c. Customer shall ensure proper mounting of the actuator

5

Page 6

Z500 Valve

July 2017

Instruction Manual

D103803X012

d. Customer shall ensure valve shaft has not been pushed or forced down into the valve

e. Customer shall ensure no binding occurs when mounting the actuator

i. Customer shall ensure the correct alignment is done when mounting the actuator

ii. No hammering or forcing down of the shaft adapter is allowed

f. Customer shall ensure all bolts are torqued down appropriately

g. Customer shall ensure the actuator mounting surface is completely flush with the mounting bracket. For

additional information on actuator mounting, refer to the Actuator Mounting section in this instruction manual

on page 13.

h. Customer shall ensure the mounting can allow for or can accommodate expansion of the shaft or adapter at high

temperatures. See table 7.

When a valve is shipped with actuator:

a. Valve will be shipped in the required fail position

b. All bolting will be torqued as required

c. Emerson recommends that the customer not remove the actuator for final installation in the line

1. Inspect the valve prior to installation into the piping system to ensure there is no shipping damage. End protectors

and shipping materials must be removed to allow a complete inspection.

2. Inspect the actuator, if included, for damage and then cycle the valve with the actuator from open (the normal

shipping position) to closed to open to ensure proper functioning.

CAUTION

Make sure the valve is installed in the correct orientation. Put the high pressure side (body side) on the upstream side. The

arrow on the valve should point from the high pressure to low pressure side when the valve is closed. The valve could be

damaged if installed incorrectly.

Weld End Valves

WARNING

Emerson Automation Solutions is not responsible for improper installation or inspection of any valve which falls outside the

criteria presented in this instruction manual. Requests for additional information on unique situations should be directed

to your Emerson sales office

CAUTION

or Local Business Partner.

Weld fill between the valve and pipe should never be used to correct for improper pipe installation length or misalignment.

Additional welding beyond what is required may cause the valve to reach higher temperatures and have a larger

heat-affected zone, which can cause permanent damage to the valve or its components.

For additional information, refer to ASME Boiler and Pressure Vessel Code Section IX.

6

Page 7

Instruction Manual

D103803X012

Z500 Valve

July 2017

Procedure

Initial Preparation

1. Ensure the valve is in the fully open position so that vital sealing areas of the ball are not exposed to weld spatter.

2. Never make arc strikes on the valve body or end adapter except inside the groove intended for butt welding or

inside the corner of the joint for socket welding. Arc strikes made on areas which are not intended to be welded can

cause a localized increase in hardness and micro-cracks, and can otherwise compromise the intended mechanical

properties of the material.

3. Attach the welding ground strap to the side of the valve being welded.

4. Install the valve into the piping system prior to welding in order to minimize piping loads. Orient the valve with the

shaft vertical, if possible, and install the piping such that pipe loads are minimized on the valve.

5. Weld the valve into the line using welders and procedures fully qualified per ASME Boiler and Pressure Vessel Code

Section IX.

6. Ensure that the valve body temperature always remains below 427_C (800_F).

Post-Weld Heat Treatment

CAUTION

Depending on valve body materials used, post weld heat treating may be required. If so, damage to internal parts is

possible. Do not place the entire valve in a stress relief furnace, or cover the entire valve with stress relieving blankets, as

this could damage the valve. Contact your Emerson sales office

1. Weld the valve into the line using qualified welders and procedures per Section IX of the ASME Boiler and Pressure

Vessel Code. If specific procedures are required, contact your Emerson sales office or Local Business Partner for

written guidance based on pipe and valve materials.

2. Apply post weld heat treat in accordance with valve material and code requirements. Only local post weld heat treat

on each end of the valve must be used.

or Local Business Partner for additional information.

Final Inspection after Post-Weld Heat Treatment

After post weld heat treat, verify valve body studs and packing studs are tight.

CAUTION

Before cycling the valve in the line, make sure the line is clean of weld slag and other debris that could damage the valve.

Cycle the valve after installation to ensure proper functioning.

1. Cycle the valve to verify proper operation. Ensure that the torque required to cycle the valve has remained within

acceptable limits.

2. Verify that the body and packing bolting are tightened to the correct torque per tables 5 and 6.

3. Install proper insulation as required for insulated piping systems.

Operation

1. No routine maintenance or lubrication is required. No tightening of body studs should be necessary. Packing

bolting may be retightened if a shaft packing leak is noted during operation.

7

Page 8

Z500 Valve

July 2017

Instruction Manual

D103803X012

2. Actuators supplied with the valve may require maintenance per the actuator manufacturer's recommendations. For

valves supplied with gears, the grease in the gearbox might need to be cleaned out and replaced periodically. Use

only high temperature grease recommended for gearboxes.

3. Metal-seated ball valves have high torques. Consult your Emerson sales office

or Local Business Partner for more

information.

4. Valves operate clockwise to close and counterclockwise to open. Gears and actuators are marked with arrows and

symbols to show valve position and operating direction. Lever operated valves have an integral lockplate so that

only the correct operating direction is possible. The lockplate has the “O” for open and the “C” for closed marked to

show proper position. The lever is always aligned with the ball bore for positive proof of ball position. Gears and

actuators have adjustable stops for proper ball positioning.

5. The ball is mate lapped to the end adapter seat. The top of the shaft is marked to show the proper orientation of the

lapped side of the ball.

6. This valve should be either normally open or normally closed. Throttling with this valve is not recommended for

extended periods. Throttling for brief periods during startup or shutdown is allowed.

Maintenance

Valve parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of inspection

and replacement depends upon the severity of service conditions.

WARNING

Avoid personal injury from sudden release of process pressure. Before performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations.

D The valve packing area may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

1. If valve maintenance is required, contact your Emerson sales office or Local Business Partner.

8

Page 9

Instruction Manual

D103803X012

Z500 Valve

July 2017

Troubleshooting

Operation

D Shaft adapter/actuator may be misaligned-- Remove actuator and shaft adapter, then reassemble per assembly

procedures for actuators.

D Over-tightened shaft packing-- Loosen packing to hand tight, cycle valve and retighten per procedures following

torque table 6.

D Inadequate air supply-- Increase air supply or install larger solenoid or quick exhaust valve. Refer to actuator

manufacturer's specifications.

Valve will not Rotate

D Valve body ID or bore is clogged-- Flush or clean valve ID and try to cycle valve.

D Actuator is not operating correctly or has failed-- Replace or repair actuator and try to cycle valve.

D Shaft keys have sheared-- Remove shaft adapter and determine why keys sheared, insert new keys, reassemble and

try to cycle valve.

Valve Shaft Packing Leaking

D Packing flange bolting is loose-- Tighten packing bolting. See Packing Replacement section, step 7 on page 13 of

this instruction manual.

D Packing is damaged or improperly installed-- Depressurize valve, remove old packing and replace with new

assembly per assembly instruction steps 3 to 5.

D Actuator misalignment-- Check for actuator misalignment.

Valve Body Gasket Leaking

D Body bolting is loose-- Tighten body bolting per table 5 and figure 2.

D Body gasket damaged-- Contact your Emerson sales office

Table 5. Body Bolt Torque Values

BOLT SIZE RECOMMENDED TORQUE

mm Inch lbf•ft lbf•in N•m

13 1/2 20 240 27

16 5/8 40 480 54

19 3/4 65 780 88

22 7/8 110 1320 149

25 1 165 1980 224

29 1-1/8 240 2880 325

32 1-1/4 335 4020 454

35 1-3/8 450 5400 610

38 1-1/2 600 7200 814

41 1-5/8 725 8700 984

44 1-3/4 1000 12000 1356

or Local Business Partner.

9

Page 10

Z500 Valve

July 2017

Figure 2. Bolting Tightening Pattern

1

3

2

1

1

44

5

3

2

6

4

5

8

3

7

2

6

Valve Leaking through Ball or Seating Area

D Valve body ID or bore is clogged-- Flush or clean valve ID and try to cycle valve.

D Valve is not fully closed-- Close valve, taking care not to over torque.

D Actuator travel stops are not set correctly-- Set stops and cycle, checking for leaks.

Instruction Manual

D103803X012

D Seat or Ball is damaged-- Contact your Emerson sales office

or Local Business Partner for repair.

D Belleville spring is collapsed — Contact your Emerson sales office or Local Business Partner for repair.

Note

If you need additional trouble-shooting assistance, please contact your Emerson sales office or Local Business Partner.

Packing Replacement

WARNING

Avoid personal injury from sudden release of process pressure. Before performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations.

D The valve packing area may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

10

Page 11

Instruction Manual

D103803X012

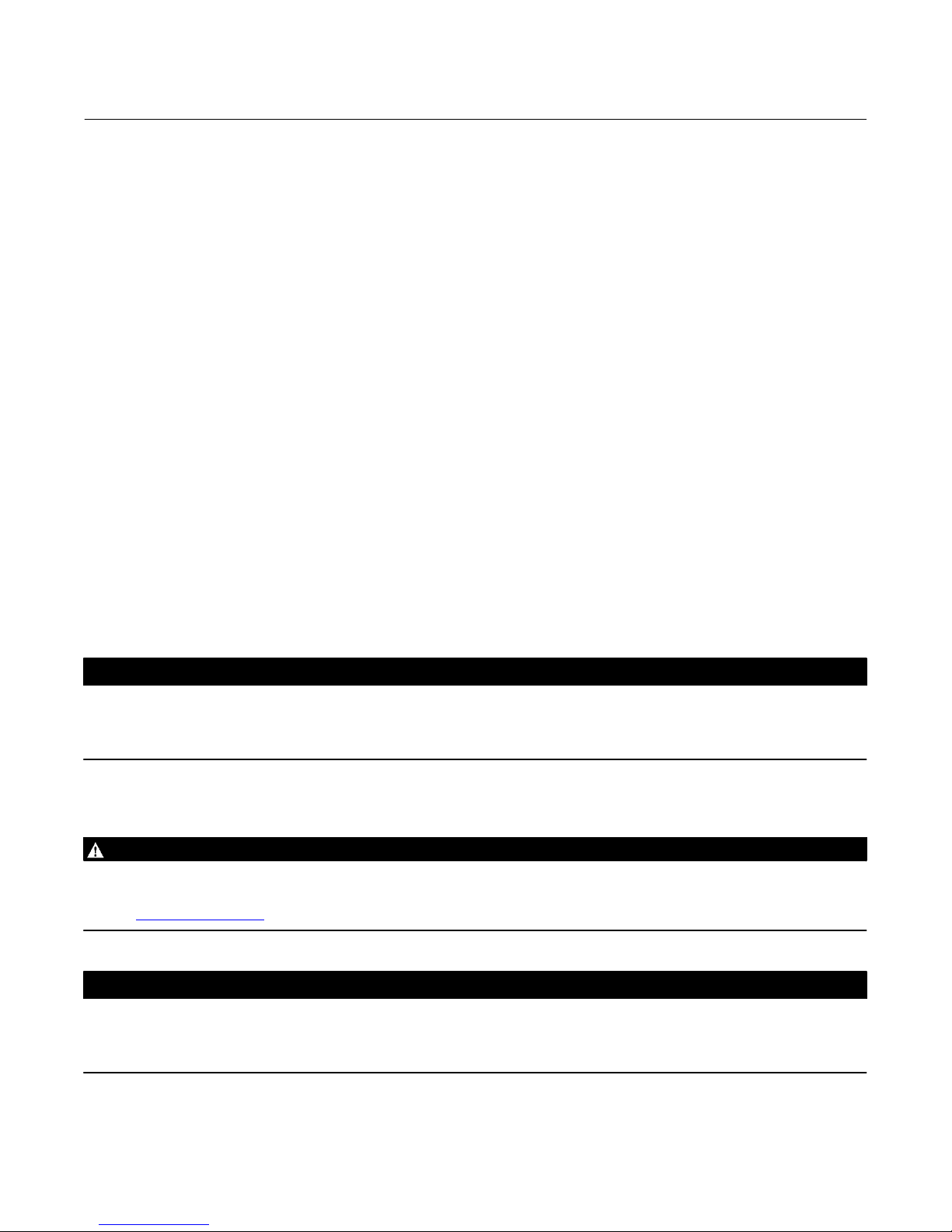

Figure 3. Z500 Construction Features

Z500 Valve

July 2017

LOCKPLATE

SUPPORT BUSHING

(HIGH CYCLE

BRACKET ONLY)

SIDE-MOUNTED

BRACKET

PACKING STUD

AND BELLEVILLE

WASHERS

PACKING GLAND

SHAFT

ADAPTER

BELLEVILLE

SPRING

PACKING SET

SEAT HOLDER

UPSTREAM

SEAT

SHAFT

METAL BODY

GASKET

1

INTEGRAL

METAL SEAT

END ADAPTER

BALL

BODY

STUD/NUT

X1207

Note:

1Seat holder is standard on welded and threaded end connections in 0.65, 1.15, 1.5, and 2 inch bores only. Bidirectional option must be specified for all other

constructions.

VALVE BODY

11

Page 12

Z500 Valve

July 2017

Instruction Manual

D103803X012

1. Loosen the packing studs.

2. Remove the packing rings from the packing box, being careful not to damage the packing box.

3. Inspect the clean packing box to ensure all surfaces are clean and undamaged.

4. Insert the zero clearance washer. Us the packing flange to press the washer into position.

5. Insert the bottom end ring of the shaft packing. Use the packing flange to press the bottom end ring into position.

6. Insert the die formed rings. Use the packing flange to press the ring into position.

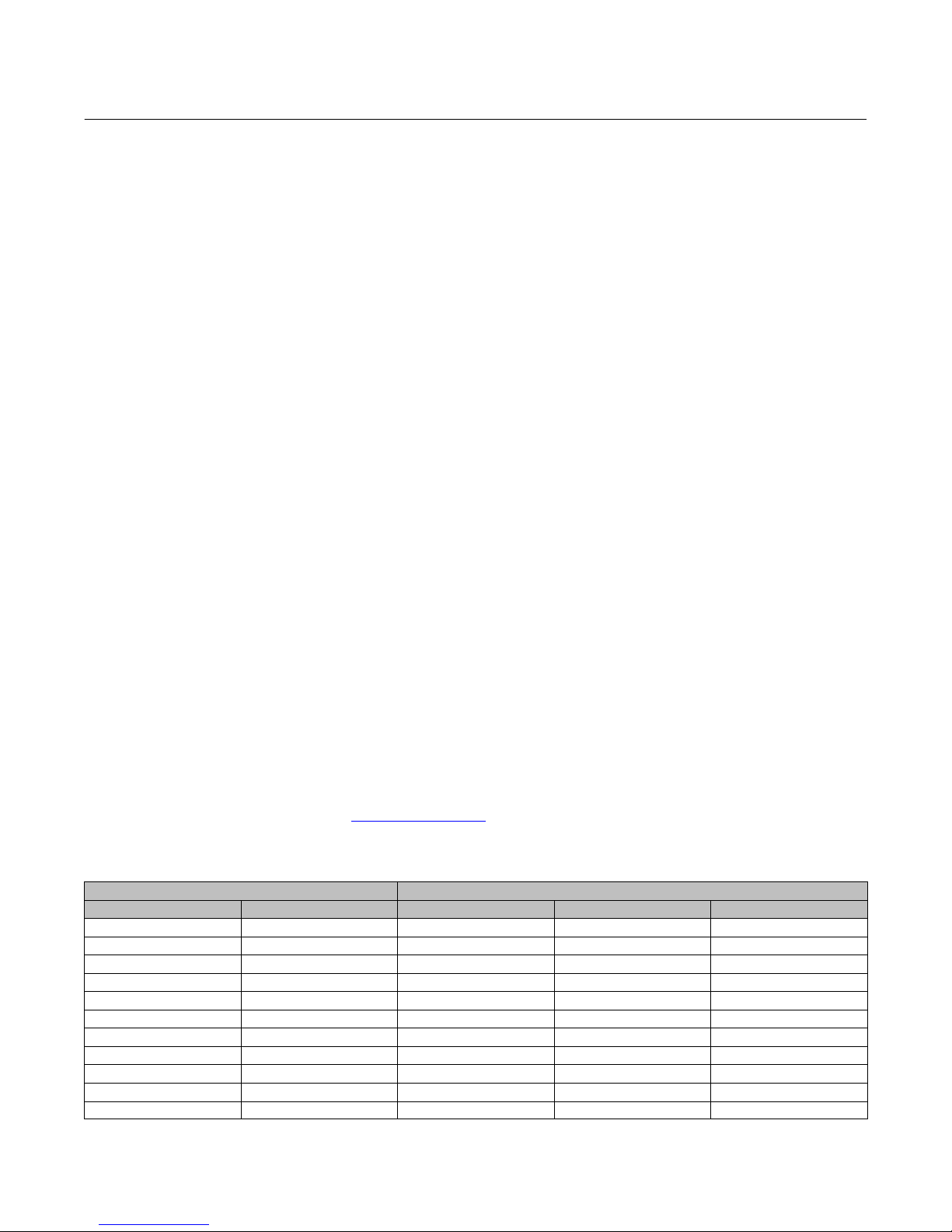

Figure 4. Assembly Steps

Figure 5. Insert Top End Ring

7. Insert the top end ring of shaft packing. Use the packing flange to press the top end ring into position.

12

Page 13

Instruction Manual

D103803X012

Z500 Valve

July 2017

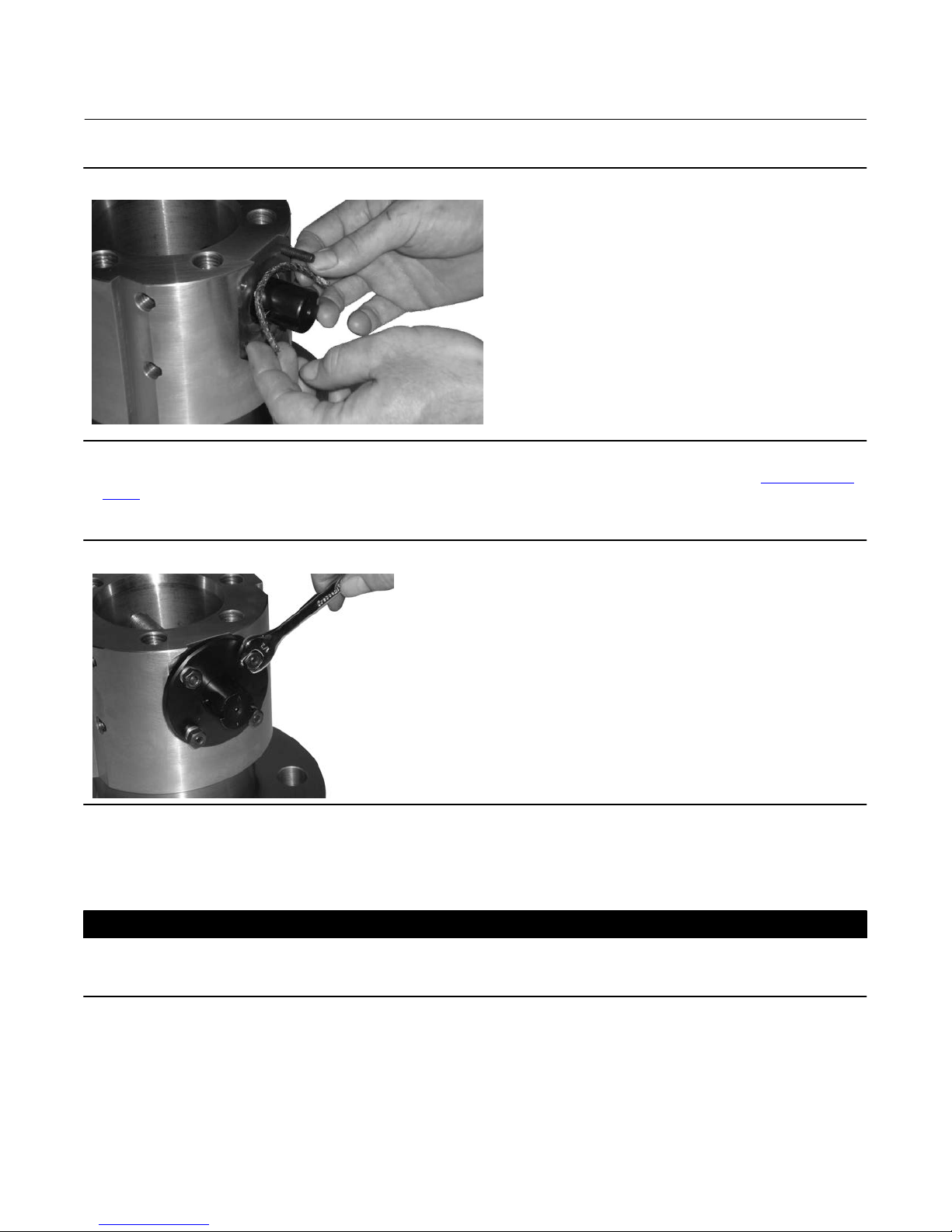

Figure 6. Use Packing Flange

8. Bolt up the packing flange. Use Belleville washers in the same orientation as removed. Contact your Emerson sales

office or Local Business Partner for additional information. Make sure that the markings on the studs and nuts are

facing out. Tighten the nuts in a star pattern (figure 2). Tighten the nuts with applicable torque (table 6).

Figure 7. Bolt Up the Packing Flange

Actuator Mounting

CAUTION

Never use a hammer or excessive force to install the shaft adapter on the valve. Improper installation can cause permanent

damage to the valve.

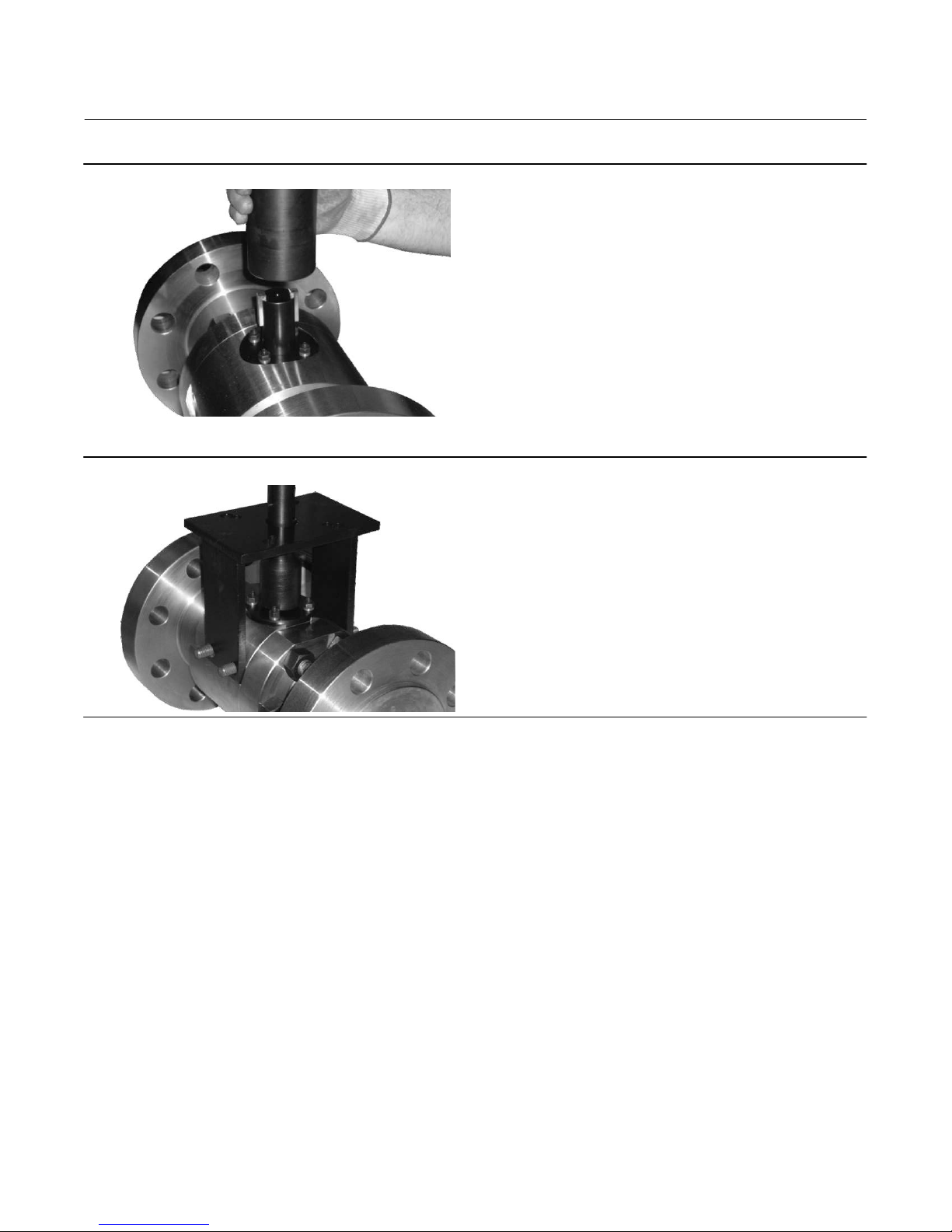

1. Mount the shaft adapter on top of the shaft with the two keys. Make sure it fits onto the shaft easily without

hammering.

2. Position the mounting bracket onto the body. Use anti-seize lubricant on the bracket studs and nuts. Make sure the

markings on the studs and nuts are facing out. Leave the nuts.

13

Page 14

Z500 Valve

July 2017

Figure 8. Mount the Shaft Adapter

Figure 9. Position the Mounting Bracket

Instruction Manual

D103803X012

3. Place the actuator on top of the mounting bracket and shaft adapter, in the fail position. Make sure the actuator is

properly aligned with the shaft adapter. If not, loosen the mounting bracket to assure proper alignment and

retighten the mounting bracket. Use anti-seize lubricant on the actuator studs and nuts. Ensure the markings on

the studs and nuts are facing out. Ensure the mounting can allow or can accommodate expansion of the shaft or

adapter at high temperature. Reference table 7.

4. Tighten the actuator and mounting bracket studs to the applicable torque after everything is aligned properly.

5. Install the actuator hand wheel, if present, with key and retention plate. Install the indicator plate on top of the

actuator.

14

Page 15

Instruction Manual

D103803X012

Figure 10. Place the Actuator on Top of the Mounting Bracket

Figure 11. Install the Handwheel

Z500 Valve

July 2017

Hand Lever

6. Position the mounting bracket onto the body. Use anti-seize lubricant on the bracket studs and nuts. Make sure the

markings on the studs and nuts are facing out. Leave the nuts finger tight.

7. Insert the support bushing into the allotted slot of the mounting bracket.

8. Mount the shaft adapter on top of the shaft with the two keys. Make sure it fits onto the shaft easily without

hammering. Make sure the mark is facing the lapped side of the ball/end adapter.

15

Page 16

Z500 Valve

July 2017

Instruction Manual

D103803X012

Figure 12. Shaft Adapter

9. Place the lock plate on top of the mounting bracket. Note the orientation of the open “O” and closed “C”

markings.

Figure 13. Lock Plate

10. Thread on the socket head cap screws, using anti-seize lubricant, from the underside of the mounting bracket.

11. Tighten the mounting bracket and lockplate bolting to the applicable torque after everything is aligned properly.

Figure 14. Handlever Assembly

12. Insert the lever through the hole on the shaft adapter. Thread in the set screw on top of the shaft adapter to hold

the lever in place.

16

Page 17

Instruction Manual

D103803X012

Table 6. Packing Flange Bolt Torque Values

BOLT SIZE RECOMMENDED TORQUE

mm Inch lbf•ft lbf•in N•m

6 1/4 4 50 6

8 5/16 6 75 8

10 3/8 8 100 11

11 7/16 15 180 20

13 1/2 21 250 28

16 5/8 38 450 50

19 3/4 58 700 79

22 7/8 100 1200 135

25 1 150 1800 203

Z500 Valve

July 2017

Table 7. Assembly Stand Off

NOMINAL BORE SIZE

mm Inch mm Inch mm Inch

17 0.65 0.38 0.015 0.89 0.035

29 1.15 0.38 0.015 0.89 0.035

38 1.5 0.38 0.015 0.89 0.035

51 2 0.38 0.015 0.89 0.035

76 3 0.64 0.025 1.14 0.045

102 4 0.89 0.035 1.40 0.055

152 6 1.02 0.040 1.52 0.060

203 8 1.27 0.050 1.78 0.070

254 10 1.52 0.060 2.03 0.080

305 12 1.78 0.070 2.54 0.100

356 14 2.92 0.115 3.68 0.145

406 16 3.43 0.135 4.19 0.165

457 18 2.67 0.105 3.43 0.135

1. Contact your Emerson sales office or Local Business Partner for additional sizes.

(1)

STANDOFF - MINIMUM STANDOFF - MAXIMUM

17

Page 18

Z500 Valve

July 2017

Instruction Manual

D103803X012

Parts Ordering

A serial number is assigned to each valve and stamped on the nameplate. Always refer to the valve serial number when

corresponding with your Emerson sales office

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Automation Solutions should

not, under any circumstances, be used in any Fisher valve, because they will void your warranty, might adversely affect the

performance of the valve, and could give rise to personal injury and property damage.

or Local Business Partner regarding spare parts or technical information.

Parts List

Note

Contact your Emerson sales office or Local Business Partner for part

number information.

Key Description

1 If you need a valve body as a replacement part, order by valve

size, serial number, and desired valve body material. Contact your

Emerson Automation Solutions sales office for assistance.

2 Mounting Bolts

3 Mounting Nuts

4 Belleville Spring

5 Upstream Seat / Guide

6 Ball

Key Description

7 Valve Body Gasket

8 End Adapter

9 Body Bolts

10 Body Nuts

11 Shaft

12 Shaft Key

13 Mounting Bracket

14 Support Bushing

15 Shaft Adapter

16 Handle Lever

17 Lever Cap Screw

18 Lock Plate

19 Plate Cap Screw

20 Packing Nuts

21 Belleville Washer

22 Packing Bolts

23 Packing Gland

24* Shaft Packing

Seat Holder for Bidirectional Shutoff (not shown)

18

*Recommended spare parts

Page 19

Instruction Manual

D103803X012

Figure 15. Fisher Z500 Valve Assembly

Z500 Valve

July 2017

19

Page 20

Z500 Valve

July 2017

Instruction Manual

D103803X012

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

20

E 2015, 2017 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...