Page 1

Instruction Manual

D104239X012

Service Manual for Multiport Flow

™

Selector

Valve

Multiport Flow Selector

April 2022

Contents

Introduction 1.................................

Specifications 3................................

Installation 4..................................

Field Technician Commissioning Activities 5.......

Reinstallation of the Actuator Assembly 5.....

Home Port Calibration 6....................

Electric Actuator Setup 6....................

Maintenance 7.................................

Disassembly 7.................................

Assembly 8....................................

Body 8......................................

Plug 8.......................................

Bonnet 9.....................................

Plug Seal Adjustment 10........................

Troubleshooting 11.............................

Drawing Assembly 12...........................

Parts List 15...................................

Maintenance Checklist Procedure 18..............

Multiport Electric Actuator 19....................

Figure 1. Fisher Multiport Flow Selector Valve

X1398

Introduction

Scope of Manual

This instruction manual includes installation, operation, and maintenance information for the Multiport Flow Selector.

Do not install, operate, or maintain a Multiport Flow Selector without being fully trained and qualified in

valve, actuator, and accessory installation, operation, and maintenance. To avoid personal injury or

property damage, it is important to carefully read, understand, and follow all the contents of this

manual, including all safety cautions and warnings. If you have any questions about these instructions,

contact your Emerson sales office

www.Fisher.com

before proceeding.

Page 2

Multiport Flow Selector

April 2022

Instruction Manual

D104239X012

Description

The Multiport Flow Selector offers an efficient solution for oil well testing. This valve has eight inlets, one test outlet,

and one group outlet. Eight pipe lines can be connected to this valve and allows continuous flow while

sampling/testing individual oil wells.

Educational Services

For information on available courses for the Multiport Flow Selector valve, as well as a variety of other products,

contact:

Emerson Automation Solutions

Educational Services - Registration

Phone: 1-641-754-3771 or 1-800-338-8158

E-mail: education@emerson.com

emerson.com/fishervalvetraining

2

Page 3

Instruction Manual

D104239X012

Multiport Flow Selector

April 2022

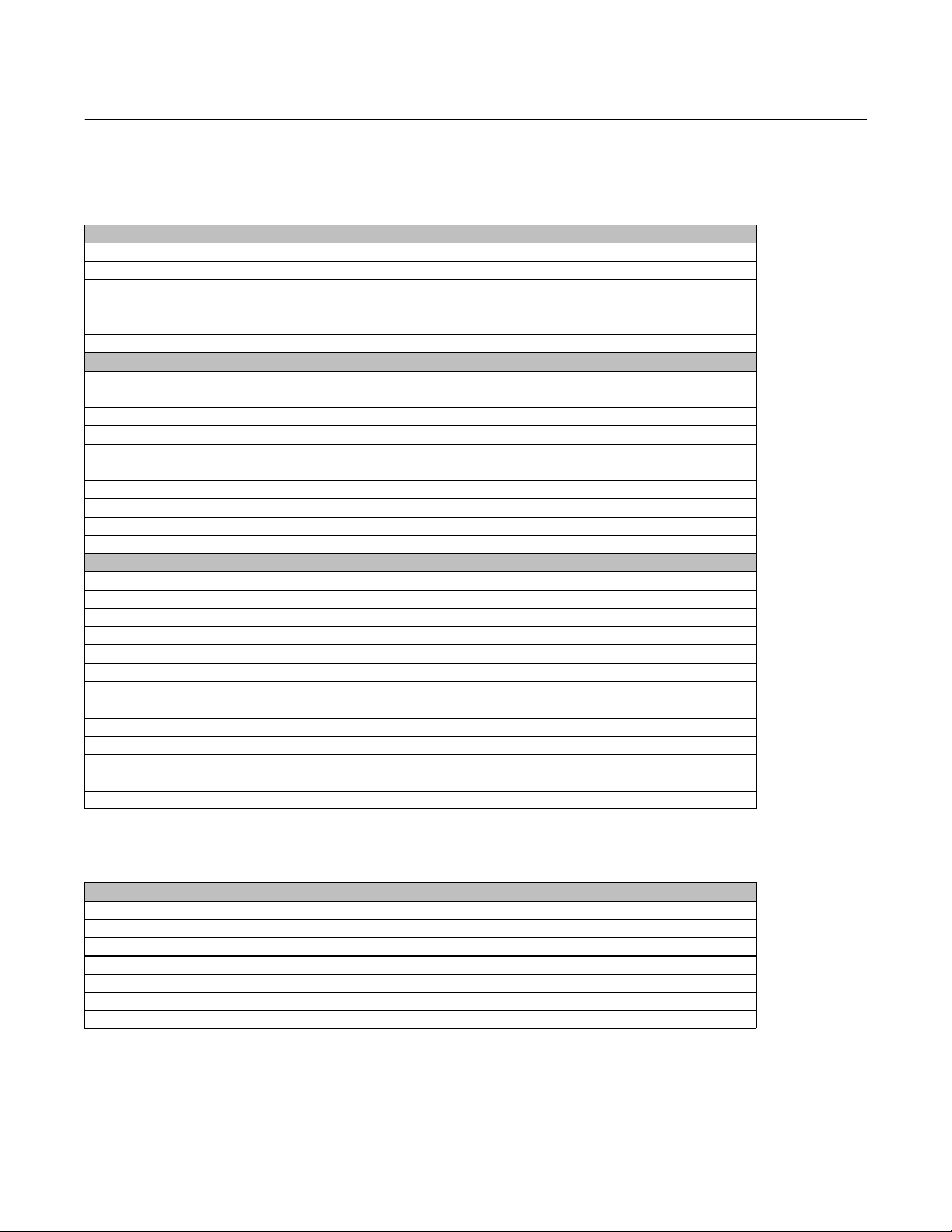

Specifications

The Multiport Flow Selector specifications are given in tables 1 through 5.

Table 1. Valve Specifications NPS 2x4 and 3x6

SPECIFICATIONS

ASME Class Rating

Weight, kg (lb) 91 (200) 91 (200) 363 (800) 553 (1220) 630 (1390) 658 (1450) 680 (1500) 968 (2135)

Inlet Ports NPS 2 NPS 3

Test Outlet Port NPS 2 NPS 3

Group Outlet Port NPS 4 NPS 6

End Connections Raised-face flanges (ASME B16.5) or threaded connections for NPS 2x4 constructions only

Temperature Range

Shutoff Class IV per ANSI/FCI70-2 and IEC 60534-4

1. The pressure/temperature limits in this instruction manual and any applicable standard or code limitation should not be exceeded.

2. Standard O-ring material established upper and lower temperature limits.

(1)

(2)

CL300 CL600 CL900 CL150 CL300 CL600 CL900 CL1500

2 x 4 3 x 6

Table 2. Valve Specifications NPS 4x8, 4x10, and 6x16

SPECIFICATIONS

ASME Class Rating CL300 CL600 CL900 CL1500 CL300 CL600 CL900 CL1500

Weight, kg (lb)

Inlet Ports NPS 4 NPS 4 NPS 6

Test Outlet Port NPS 4 NPS 4 NPS 6

Group Outlet Port NPS 8 NPS 10 NPS 16

End Connections Mates with raised-face flanges per ASME B16.5

Temperature Range

Shutoff Class IV per ANSI/FCI70-2 and IEC 60534-4

1. The pressure/temperature limits in this instruction manual and any applicable standard or code limitation should not be exceeded.

2. Standard O-ring material established upper and lower temperature limits.

(1)

959

(2115)

4 x 8 4x10 6 x 16

975

(2150)

1134

(2500)

VALVE SIZE

-1 to 204°C (30 to 400°F)

VALVE SIZE

1742

(3840)

-1 to 204°C (30 to 400°F)

1810

(3990)

2018

(4450)

3590

(7915)

5343

(11780)

Table 3. Actuator Specifications

VALVE SIZE AND ASME CLASS RATING

SPECIFICATIONS

Max Torque Output,

Nm (ftlbf)

Actuator Speed, RPM 1.0 0.5-1.0 0.5-1.0 0.5-1.0 0.3-0.5

Actuator Weight, kg (lb) 82 (180)

Plug Position Accuracy ± 1°

NPS 2 x 4

CL300/600/900

203 (150) 881 (650) 1085 (800) 1085 (800) 2034 (1500)

NPS 3 x 6

CL150/300/

600/900/1500

NPS 4 x 8

CL300/600/900

NPS 4 x 10

CL1500

NPS 6 x 16

CL300/600/

900/1500

3

Page 4

Multiport Flow Selector

April 2022

Instruction Manual

D104239X012

Installation

Minimum Tools Required

A torque wrench, socket wrench, and Allen head wrenches are required to install the Multiport Flow Selector Valve and

actuator assembly.

Table 4. Socket Size for Multiport Bonnet Studs and Nuts

VALVE SIZE, NPS ASME CLASS RATING SOCKET SIZE (in)

CL300

2 x 4

3 x 6

4 x 8

4 x 10 CL1500 2-3/4

6 x 16

CL600

CL900

CL150

CL300

CL600

CL900

CL1500 2-3/8

CL300

CL600

CL900

CL300

CL600

CL900 3-1/8

CL1500 3-7/8

1-5/8

2

2-3/16

2-9/16

Other socket sizes (inch) required: 7/16, 1/2, 9/16, 3/4, 7/8, and 1-1/8.

Allen key sizes (inch) required: 5/32, and 1/4

Table 5. Wrench Sizes (Inch) for Multiport Inlet and Outlet Flanges

FLANGE SIZE, NPS

2 - - - 1-1/16 1-1/16 1-7/16 - - -

3 1-1/16 1-1/4 1-1/4 1-7/16 1-13/16

4 - - - 1-1/4 1-7/16 1-13/16 2

6 1-1/4 1-1/4 1-5/8 1-13/16 2-3/16

8 - - - 1-7/16 1-13/16 2-3/16 - - -

10 - - - - - - - - - - - - 2-15/16

16 - - - 2 2-3/8 2-9/16 3-7/8

CL150 CL300 CL600 CL900 CL1500

ASME CLASS RATING

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury. Check with your process or safety engineer for any additional measures that must be taken to protect against

process media.

Avoid personal injury and property damage by keeping hands, tools, and other objects away from the plug while operating

the valve.

Observe all WARNING decals and tags.

4

Page 5

Instruction Manual

D104239X012

Multiport Flow Selector

April 2022

Key numbers in this procedure are shown in figure 2 and 3 unless otherwise indicated.

Before installing the unit, observe all warning tags and:

1. Check for external physical damage.

2. Check for any visible leakage of gear oil from the Multiport Electric Actuator (MPA).

3. Visually inspect the inside of the Multiport through the group outlet port checking for damage, rust, and/or debris.

4. Verify the voltage requirement of the MPA (AC/DC) and connect power supply and signal circuits to test the

operation of the electric actuator and plug. Check for proper plug alignment at each port.

5. Inspect connecting piplines to be certain they are free of foreign material such as pipe scale or weld slag that could

damage the sealing surfaces fo the Multiport Flow Selector valve.

6. Provide appropriate flange gaskets and install them between the pipe flanges and valve body flanges. Tighten

flange bolting in a star pattern to ensure uniform compression of the gaskets.

Note

To prevent seal damage when hydrotesting external piping, position the plug midway between two inlet ports in order to equalize

pressure between the plug and valve body.

The Multiport Flow Selector plug/port alignment is factory adjusted when supplied with an actuator and should not require further

adjustment.

Field Technician Commissioning Activities

Refer to the Multiport Actuator (MPA) O&M Manual — Supplied by Bettis (MPA-400-0711). See page 19 for detailed

commissioning activities.

CAUTION

Replace pipe plug with breather before operating unit. The valve body may be pressurized from hydrostatic testing. Do not

remove any bolts or flanges for inspection until after the unit has been depressurized.

Circuit boards are susceptible to damage from static discharge when touched. Ensure that you ground yourself before

touching the knobs on the electric actuator.

Reinstallation of the Actuator Assembly

1. Using a manual wrench, rotate the plug (key 2) a few revolutions to verify it turns freely. Initial effort required to

rotate the plug could be high if the plug has not been rotated for an extended period of time.

2. Secure the actuator mounting bracket (key 43) to the bonnet using two cap screws (key 44), two travel indicator

studs (key 54), and four lock washers (key 56). For the NPS 2x4 construction, secure the lower plate to the bonnet

using two cap screws, two travel indicator studs and nuts, and four lock washers.

Regardless of size, apply an anti-seize lubricant (key 40) to the threaded portion of the fasteners. The cap screws

should be spaced 180 degrees apart from one another and 90 degrees apart from the travel indicator studs.

3. Secure the travel indicator plate to the travel indicator studs by tightening two cap screws (key 55). Proper

assembly has occurred if the lock washers have been placed between the travel indicator studs and travel indicator

plate and if flat washers (key 57) have been placed between the cap screws and travel indicator plate. For the 2x4

construction, place travel indicator spacers over the travel indicator studs and secure the travel indicator plate

5

Page 6

Multiport Flow Selector

April 2022

down by tightening the nuts. Proper assembly has occurred if there are flat washers between the travel indicator

spacers and travel indicator plate and travel indicator plate and nuts.

Instruction Manual

D104239X012

Regardless of size, an anti-seize lubricant (key 40) shall be applied to the threaded portion of the fasteners and nuts

4. To complete the assembly of the mounting kit for the NPS 2x4 construction, thread four spacer studs into the lower

plate and secure the upper plate to the spacer studs using four cap screws. Proper assembly has occurred if there

are lock washers between the lower plate and spacer studs and spacer studs and upper plate. An anti-seize lubricant

(key 40) shall be applied to the threaded portion of the studs and fasteners.

5. Apply grease (key 41) to the surfaces on the key slot(s) found on the shaft coupler (key 47). Insert key(s) (key 48)

into the shaft coupler key slot(s). Insert the shaft coupler with key(s) into the bottom of the Multiport Electric

Actuator and hold in place by hand.

6. Slowly lower the actuator with shaft coupler (key 47) onto the mounting bracket (key 43). Align the shaft coupler

with the square end of the plug (key 2). Position the shaft coupler such that the reference mark on the square end of

the plug remains visible between the flats of the shaft coupler. This reference mark indicates the location of the seal

assembly relative to the inlet ports of the body.

7. Attach the actuator to the mounting bracket (key 43) using four cap screws (key 45) and four lock washers (key 46).

Tighten these fasteners finger tight only.

8.

Apply an anti-seize lubricant (key 40) to the travel indicator holder (key 49) and thread on the jam nut (key 51), as

well as the travel indicator pointer (key 50) and nut (key 52). Thread this assembly into the shaft coupler (key 47).

The travel indicator pointer shall be on the same side as the reference mark found on the square end of the plug and

shall be positioned such that it will not contact any parts of the travel indicator assembly while rotating.

9. Using the electric actuator, rotate the plug (key 2) a few revolutions to establish proper alignment between the

shaft coupler (key 47) and plug. Visually check for any binding and adjust the position of the actuator as necessary.

Once the proper alignment has been established, secure the actuator to the mounting bracket (key 43) by

tightening the cap screws (key 46).

Home Port Calibration

.

Refer to the Multiport Electric Actuator (MPA) O&M Manual — Supplied by Bettis (MPA-400-0711) for detailed

instructions on how to calibrate the home port position.

Multiport Electric Actuator Set Up

Refer to the Multiport Electric Actuator (MPA) O&M Manual — Supplied by Bettis (MPA-400-0711) for detailed

instruction on:

1. Disabling port positions

2. Controller address

3. Control room MODBUS RTU operation

4. Installation and use of MPA software on laptop/PC

6

Page 7

Instruction Manual

D104239X012

Multiport Flow Selector

April 2022

Maintenance

Refer to figure 2 and 3, typical Multiport assembly and mounting drawings.

WARNING

Avoid personal injury from sudden release of process pressure. Before performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly rotate the plug.

D Use bypass valves or completely shut off the process to isolate the Multiport from process pressure. Relieve process

pressure from all parts of the valve. Drain the process media from all sides of the Multiport.

D Use lockout procedures to be sure the above measures stay in effect while you work on the equipment.

D Always wear protective gloves, clothing and eyewear when performing any maintenance operations to avoid personal

injury.

D The tapered roller bearing area may contain process fluids that are pressurized, even when the valve has been removed

from the pipeline. Process fluids may spray out under pressure when separating the bonnet from the plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

The Multiport Flow Selector valve is shipped completely greased and lubricated. Routine maintenance of this valve is

recommended, especially if it has been stored for an extended amount of time. Maintenance steps include:

1. Keeping the tapered roller bearing (key 3) greased. A high temperature silicone grease (key 39) can be injected into

the bearing housing through the lube fitting (key 28).

2. Confirming proper alignment between the plug and inlet ports.

D Verify the correct placement of the travel indicator pointer (key 50) onto the coupler (key 47).

D Align the plug (key 2) with one of the inlet ports. Confirm the travel indicator pointer is in alignment with the

selected inlet port.

3. Visual inspection of the seal insert (key 12). The sealing surface of this insert should be smooth and completely

intact.

D If the seal insert needs to be replaced, replace all o-rings (key 5, 7, 14, 20, 25, and 26), backup rings (key 6, 8, 15,

and 21), rod seal (key 4), plug bushing (key 9), and wiper seals (key 24).

4. Rotate the plug (key 2) one complete revolution using the electric actuator to confirm the assembly is functioning

properly. Check the local display unit on the electric actuator for any alarm codes.

Disassembly

Review warnings found in the Maintenance section of this manual.

Refer to figures 2 and 3 when disassembling the Multiport Flow Selector.

7

Page 8

Multiport Flow Selector

April 2022

Note

The bonnet can be removed with the Multiport Electric Actuator still attached. If this is done, ensure proper orientation has been

maintained between the actuator and valve body once the bonnet has been re-installed onto the valve body. If this orientation has

not been maintained, recalibration of the actuator is required. One way to ensure proper orientation has been maintained is to

place alignment marks between the plug (key 2) and coupler (key 47) prior to removal of the bonnet (key 19).

1. Rotate the plug (key 2) to any unused inlet port. Remove the blind flange from this inlet port to gain access to the

seal assembly. Once the adjustment tool has been secured to the seal adjuster (key 18), rotate this tool clockwise

until it stops. This action unloads the wave springs (key 11, 17) and removes the forces generated between the seal

insert (key 12), valve body (key 1) and scraper (key 12)/valve body (key 1).

2. Remove the nuts (key 32) from the bonnet (key 19), lifting lugs (key 33), and the studs (key 31) from the body (key

31). Thread eye bolts into the jack screws holes provided in the bonnet. Raise the bonnet vertically until it clears the

plug (key 2) and move it to the side.

3. Remove the plug (key 2) from the valve body (key 1). The seal components should still be installed inside of the

plug.

4. Remove the seal assembly from the plug (key 2) using the adjustment tool as follows:

D Once the adjustment tool has been inserted into the seal adjuster (key 18) and secured, rotate the tool

counterclockwise until the seal adjuster disengages from the final thread on the plug.

Instruction Manual

D104239X012

D With the adjustment tool still secured to the seal adjuster (key 18), pull it out of the plug. All components that

make up the seal assembly are now outside of the plug.

5. Carefully remove the bearing cup (key 3) from the bonnet (key 19).

6. Inspect all components for damage. Replace any damaged parts and reassemble by following the Assembly

procedure in this manual.

Assembly

Refer to figures 2 and 3 when assembling the Multiport Flow Selector.

Ensure all parts are clean and in good condition before assembling the Multiport Flow Selector. Refer to figure 2 to

determine which components require lubrication.

Body (Key 1)

1. Visually inspect all internal and external surfaces and threads.

2. Install the plug bushing (key 9) into the lower section of the body.

Plug (Key 2)

1. Install the lower plug O-ring (key 8), with the correct number of backup rings (key 7). For ASME rated CL150, 300,

600, and 900 valves, install one backup ring above (on the side nearest to the bonnet) the O-ring. For CL1500 rated

Multiports, install two backup rings one on either side of the lower plug O-ring.

2. Lubricate and install the seal adjuster (key 18) by turning it clockwise (i.e. viewing toward the plug centerline) until

solid. Follow with the correct number of wave springs (key 17). For NPS 2x4, 3x6, and 6x16 constructions, install

three wave springs. For NPS 4x8 and 4x10 constructions, install four wave springs. Ensure the wave springs are

properly aligned and seated on the seal adjuster.

Note

If the wave springs are not properly aligned and seated then the seal assembly may not function properly.

8

Page 9

Instruction Manual

D104239X012

3. Install the back up plate (key 16) against the shoulder in the plug (key 2).

4. Install the O-ring (key 14) onto the seal carrier (key 13). Install the seal assembly into the plug. Hand force should

only be required for proper installation.

5. Install the correct number of wave springs (key 11) followed by the scraper (key 10) into the plug over the seal

assembly. For NPS 2x4 constructions, install two wave springs and for NPS 3x6, 4x8, 4x10, and 6x16 constructions,

install one wave spring.

both hands then letting go to see if it returns to its original position.

6. Lower the plug (key 2) into the body ensuring that the seal insert (key 12) and scraper (key 10) clear the bore of the

body (key 1). When installed, the plug rests on top of the plug bushing (key 9).

7. Lubricate the tapered bearing cone and rollers (key 3) using a high temperature silicone grease (key 39) and install

onto the plug.

Ensure the scraper fits freely into the plug. Check by pushing the scraper into the plug using

Multiport Flow Selector

April 2022

Bonnet (Key 19)

1. Lubricate and press fit the bearing cup (key 3) into the bonnet using a high temperature silicone grease (key 39).

Lubricate the bearing cup and press fit it into the bonnet.

2. Install the backup ring (key 6), O-ring (key 5), and rod seal (key 4) into the bonnet bore. Rod seal is not required for

NPS 2x4 or 3x6 CL300, 600, and 900 rated valves.

3. Install the bonnet O-ring (key 20) into the groove of the bonnet. For NPS 4x8, 4x10, and 6x16 constructions, install

the backup ring above this O-ring.

4. Install the wiper seal (key 24), lube fitting (key 28), and vent plug (key 27). For NPS 4x10 and 6x16 constructions,

install the wiper seal on an external wiper retainer (key 24) with two extra O-rings (key 25 and 26).

5. Using two eye bolts threaded into the jack screw holes found on the bonnet, slowly lower the bonnet onto the

body. Be careful not to damage any soft parts when feeding the plug through the bonnet. The bonnet has been

properly positioned onto the body when the following has been achieved:

D The bolt holes in the bonnet have been aligned with the stud holes in the body.

D The centerline of the bonnet vent port has been aligned with the centerline of the group outlet of the body.

Excessive force should not be required to properly seat the bonnet onto the body. For NPS 2x4, 3x6, and 4x8

constructions, use hoist rings or eye bolts with 1/2 UNC threads. For NPS 3x6 CL1500, 4x10, and 6x16

constructions, use hoist rings or eye bolts with 3/4 UNC threads.

6. Lubricate studs (key 31) with an anti-seize lubricant (key 40) and thread into valve body (key 1). Place the

appropriate number of lifting lugs (key 33) over these studs. The placement of these lifting lugs should be equally

spaced with one being located directly above the group outlet. The placement of these lifting lugs is as follows:

D For NPS 2x4, 3x6, 4x8, and 4x10 constructions, place two lifting lugs equally spaced with one being located

directly above the group outlet port.

D For NPS 6x16 CL300, 600, and 900 constructions, place three lifting lugs equally spaced with two of them

straddling the group outlet port.

D For NPS 6x16 CL1500 constructions, place four lifting lugs equally spaced with two of them straddling the group

outlet port.

7. Lubricate the threads and the bottom surface of the nuts (key 32) with an anti-seize lubricant (key 40) paste prior to

threading them on to the studs (key 31). Once all nuts have been threaded hand tight, tighten two nuts spaced

180-degrees apart to the recommended torque values per table 6. Rotate the plug (key 2) one complete revolution

to ensure that it rotates with minimal resistance. If the plug rotates smoothly, then proceed to tighten the

remaining nuts using an appropriate tightening pattern.

8. Using the lube fitting (key 28), fill the bearing bore with grease.

9

Page 10

Multiport Flow Selector

April 2022

Instruction Manual

D104239X012

Table 6. Bonnet Bolting Torque

VALVE SIZE,

NPS

2 x 4

3 x 6

4 x 8

4 x 10 1500 44.5 1-3/4 1356 1000

6 x 16

ASME

CLASS RATING

300

600

900

150

300

600

900

1500 38.1 1-1/2 814 600

300

600

900

300

600

900 50.8 2 2034 1500

1500 63.5 2-1/2 4203 3100

STUD SIZE TORQUE

mm Inch Nm ftlbf

25.4 1 217 160

31.8 1-1/4 441 325

34.9 1-3/8 651 480

41.3 1-5/8 1085 800

Plug Seal Adjustment

1. Prior to adjusting the seal assembly (key 12 and 13), align the plug (key 2) with an open inlet port and insert the

supplied adjustment tool. Once this tool has been secured to the seal adjuster (key 18), rotate this tool counter

clockwise until the scraper (key 10) touches the inside surface of the body (key 1). The resistance to rotate the

adjustment tool will increase once the scraper contacts the body. Remove the adjustment tool.

2. Rotate the plug (key 2) a few revolutions to check for binding or excessive turning torque. If the plug rotates

smoothly, then insert, secure, and rotate the adjustment tool counter clockwise to tighten the seal adjuster (key

18) to the appropriate torque value listed in table 7.

Note

Do not exceed the torque values listed in table 7. Exceeding these values may cause the valve to not function as intended.

Table 7. Plug Seal Torque

VALVE SIZE, NPS ASME CLASS RATING

2 x 4

3 x 6

4 x 8

4 x 10 1500 54 40

6 x 16

300

600

900

150

300

600

900

1500

300

600

900

300

600

900

1500

Nm ftlbs

TORQUE

41 30

48 35

41 30

54 40

95 70

10

Page 11

Instruction Manual

D104239X012

3. Rotate the plug (key 2) a few revolutions while checking for smooth movement. If the seal assembly is binding

during rotation, then the seal assembly or the wave springs (key 17) are not in their proper position(s). See

disassembly procedure, if required.

4. Install the appropriate amount of pipe plugs (key 27).

5. Perform any required functionality test(s).

Multiport Flow Selector

April 2022

Troubleshooting

Actuator Does Not Align Plug to Inlet Port

1. Check the shaft coupler for looseness.

2. Check the motor for stalling or overload.

3. Check the visual leakage or noisy gear.

4. Refer to the Multiport Electric Actuator (MPA) O&M Manual — Supplied by Bettis (MPA-400-0711

calibration procedures and troubleshooting.

Seal Leakage

1. Check the travel indicator plate (key 53) and travel indicator pin (key 50) to ensure the plug (key 2) is properly

aligned with the inlet ports.

2. Check the seal insert (key 12) for damage. To visually inspect the seal insert, the blind flange from an unused inlet

port needs to be removed. Prior to removing this flange, verify the Multiport Flow Selector valve has been

depressurized to a value of zero. With the blind flange removed, rotate the plug until visual inspection of the seal

insert can occur. The sealing surface of the seal insert should be smooth, completely intact, and free of deep groove

marks.

) for port

WARNING

Ensure that all pressures in the Multiport body, group outlet, and test port are ZERO before visually checking the seal.

3. If more information is required, please contact your Emerson sales office.

11

Page 12

Multiport Flow Selector

April 2022

Figure 2. Multiport Drawing Assembly

Instruction Manual

D104239X012

VIEW C

VIEW D

VIEW B

VIEW E

VIEW B

SCALE 2:1

VIEW A

VIEW D

SCALE 2:1

VIEW E

SCALE 3:1

VIEW A

SCALE 2:1

GE99805

APPLY LUB/SEALANT

PARTS NOT SHOWN: 30, 34, 35, 36, AND 37.

12

VIEW C

SCALE 2:1

Page 13

Instruction Manual

D104239X012

Figure 3. Multiport Mounting Assembly for NPS 2x4 Constructions

Multiport Flow Selector

April 2022

GE99891

Figure 4. Multiport Mounting Assembly for NPS 3x6, 4x8, and 6x16 Constructions

GE99891

13

Page 14

Multiport Flow Selector

April 2022

Parts Kits

Seal Kits

DESCRIPTION PART NUMBER

MINOR REPAIR KIT, 316 FOR 2X4 MPFS RMPFS20409X072

MINOR REPAIR KIT, AFLAS FOR 2X4 MPFS RMPFS20409X052

MINOR REPAIR KIT, AFLAS/FLEXISEAL FOR 2X4 MPFS RMPFS20409X062

MAJOR REPAIR KIT, 316 FOR 2X4 MPFS RMPFS20409X082

MAJOR REPAIR KIT, AFLAS FOR 2X4 MPFS RMPFS20409X012

HIGH DIFFERENTIAL PLUG UPGRADE, AFLAS/FLEXISEAL FOR 2X4 MPFS RMPFS20409X042

MINOR REPAIR KIT, 316 FOR 3X6 MPFS RMPFS30609X102

MINOR REPAIR KIT, AFLAS FOR 3X6 MPFS RMPFS30609X082

MINOR REPAIR KIT, AFLAS/KALREZ FOR 3X6 MPFS RMPFS30609X092

MINOR REPAIR KIT, AFLAS/25CFT/DSS FOR 3X6 MPFS RMPFS30609X022

MINOR REPAIR KIT, AFLAS/25CFT/825 FOR 3X6 MPFS RMPFS30609X112

MAJOR REPAIR KIT, 316 FOR 3X6 MPFS RMPFS30609X132

MAJOR REPAIR KIT, AFLAS FOR 3X6 MPFS RMPFS30609X042

MAJOR REPAIR KIT, AFLAS/25CFT/DSS FOR 3X6 MPFS RMPFS30609X032

MAJOR REPAIR KIT, AFLAS/25CFT/825 FOR 3X6 MPFS RMPFS30609X122

HIGH DIFFERENTIAL PLUG UPGRADE, AFLAS FOR 3X6 MPFS RMPFS30609X062

Instruction Manual

D104239X012

MINOR REPAIR KIT, 316 FOR 4X8 MPFS RMPFS40809X112

MINOR REPAIR KIT, AFLAS/VITON FOR 4X8 MPFS RMPFS40809X102

MINOR REPAIR KIT, 718 FOR 4X8 MPFS RMPFS40809X022

MINOR REPAIR KIT, AFLAS/25CFT/825 FOR 4X8 MPFS RMPFS40809X032

MINOR REPAIR KIT, AFLAS/25CFT/SDS FOR 4X8 MPFS RMPFS40809X132

MAJOR REPAIR KIT, 316 FOR 4X8 MPFS RMPFS40809X122

MAJOR REPAIR KIT, AFLAS FOR 4X8 MPFS RMPFS40809X072

MAJOR REPAIR KIT, 4X8 MPFS RMPFS40809X082

MAJOR REPAIR KIT, AFLAS/25CFT/DSS FOR 4X8 MPFS RMPFS40809X042

MAJOR REPAIR KIT, AFLAS/25CFT/718 FOR 4X8 MPFS RMPFS40809X052

MAJOR REPAIR KIT, AFLAS/25CFT/825 FOR 4X8 MPFS RMPFS40809X062

MAJOR REPAIR KIT, AFLAS/25CFT/SDS FOR 4X8 MPFS RMPFS40809X142

HIGH DIFFERENTIAL PLUG UPGRADE, AFLAS FOR 4X8 MPFS RMPFS40809X092

Adjustment Tool Kits

DESCRIPTION PART NUMBER

ADJUSTMENT TOOL 2x4 CL 300, 600, and 900 RMP20409X012

ADJUSTMENT TOOL 3x6 CL 150, 300, 600, and 900 RMP30609X012

ADJUSTMENT TOOL 3x6 CL 1500 RMP30615X012

ADJUSTMENT TOOL 4x8 CL 300, 600, and 900 RMP41015X012

ADJUSTMENT TOOL 4x10 CL 1500 RMP41015X012

ADJUSTMENT TOOL 6x16 CL 300, 600, and 900 RMP61609X012

ADJUSTMENT TOOL 6x16 CL 1500 RMP61625X012

14

Page 15

Instruction Manual

D104239X012

Multiport Flow Selector

April 2022

Parts List

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson should not, under any

circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the performance

of the valve, and could cause personal injury and property damage.

Key Description

Note

Contact your Emerson sales office

Multiport Assembly

(see figure 2 and 3)

Key Description

1 Valve Body

2 Plug

3 Bearing

4 Rod Seal

5 O-Ring, upper plug

6 Back up Ring, upper plug

7 O-Ring, lower plug

8 Back up Ring, lower plug

9 Plug Bushing

10 Scraper

11 Wave Spring Scraper

12 Seal Insert

13 Seal Carrier

14 O-Ring

15 Back up Ring

16 Back up Plate

17 Wave Spring

18 Seal Adjuster

19 Bonnet

20 O-Ring

21 Back up Ring

22 Wiper Retainer

23 Cap Screw, Wiper Retainer

24 Wiper Seal

for part ordering information.

25 O-Ring, Wiper Retainer

26 O-Ring, Shaft

27 Pipe Plug

28 Lube Fitting

29 Pipe Bushing

30 Set Screw

31 Stud

32 Nut

33 Lifting Lug

38 White Petrolatum

39 High temperature silicone grease

40 Anti-seize lubricant

41 Grease

42 Thread sealant paste

43 Mounting Bracket

44 Cap Screw

45 Cap Screw

46 Lock Washer

47 Coupler

48 Key

49 Travel Indicator Holder

50 Travel Indicator Pointer

51 Jam Nut

52 Nut

53 Travel Indicator Plate

54 Travel Indicator Stud

55 Cap Screw

56 Lock Washer

57 Washer

58 Cap Screw

59 Bracket, Upper

60 Travel Indicator Spacer

61 Nut

62 Stud

63 Bracket, Lower

15

Page 16

Multiport Flow Selector

April 2022

Figure 5. Typical Multiport Seal Components

Instruction Manual

D104239X012

PLUG SEAL

WAVE SPRINGS

SCRAPER

X1581

SEAL

ADJUST

MENT

NUT

X1582

SEAL

ADJUSTMENT NUT

SCRAPER WAVE

SPRING

PLUG SEAL COMPONENTS

ASSEMBLY

SEAL WAVE

SPRINGS

SEAT RING/

PLATE/

O-RING/

SEAL INSERT

HIGH DIFFERENTIAL SEAL

BEARING

DIFFERENTIAL SEAL

SCRAPER

WAVE

SPRINGS

HIGH

SCRAPER

X1584

BACKUP

PLATE

X1583

O-RING

SEAT

RING

HIGH DIFFERENTIAL

SEAL ASSEMBLY

SEAL ADJUSTMENT TOOL

SEAL

INSERT

ASSEMBLY

NOTE:

1

PLUG SEAL ADJUSTMENT TOOL SHOWN WITH BASE PARALLEL TO SHANK FOR INSERTION, BASE PERPENDICULAR TO SHANK, AND ENGAGED IN SEAL ADUSTMENT NUT.

16

Page 17

Instruction Manual

D104239X012

Figure 6. Typical Multiport Seal Components

Multiport Flow Selector

April 2022

PLUG

E-60681009

NOTE:

1

PLUG (INDEX MARK CAN BE FOUND ON THE STEM FLAT THAT FACES THE SAME WAY AS THE PLUG SEAL OPENING.) PLUG SEAL ADJUSTMENT TOOL IN PLUG.

SEAL ADJUSTMENT TOOL

17

Page 18

Multiport Flow Selector

April 2022

Instruction Manual

D104239X012

Recommended Periodic Multiport Maintenance

Checklist Procedure

Half Yearly Check

1. Check the plug port position in the Local Display Module (LDM) and the mechanical indicator respectively and in

remote feedback.

2. Check the plug travel sequence for smooth operation with local/remote.

3. Lubricate the bearing through the grease nipple with high temperature silicone grease.

4. Visual Inspection of Multiport Flow Selector (MPFS) valve.

Annual Check

1. Visual Inspection of MSV.

2. Lubricate the bearing through the grease nipple with high temperature silicone grease.

3. Check the seal torque (refer chart) and seal visual condition.

4. Check the plug position in LDM and the mechanical indicator respectively and in remote feedback.

5. Check the plug travel sequence for smooth operation with local / remote.

6. Check mechanical operation (using manual override).

7. Check electrical connections of Multiport Actuator (MPA) (power and communication port).

8. Check the Torque Encoder and Position Encoder.

9. Visual check of shaft penetrations for lubrication leakage.

10. Inspect stem nut or bushing for wear / damage of Multiport Actuator.

11. Run online seal integrity test.

Visual Seal Inspection

1. Local Shutdown should be take by end user to isolate the Multiport valve.

2. Check the plug alignment visually at home port (blind flange open condition).

3. If the seal visual inspection and seal torque are deemed acceptable, then assemble the home flange and run on line

seal integrity test.

General

1. It is recommended to operate the Multiport, once in three weeks, at least one full rotation, if there is no well

testing. Not recommended to keep Multiport idle for more than 3 to 4 weeks.

2. Recommended to replace the seat ring (complete Seal Kit Assembly) and all the soft seals every 5 years.

18

Page 19

Instruction Manual

D104239X012

Multiport Flow Selector

April 2022

Multiport Actuator

O&M Manual — Supplied by Bettis

Document No. MPS-400-0711

WARNING

Use caution when working on, with, or around valves and actuators. High pressures, forces, voltages, and flammable

media can be present.

Read this manual in its entirety before installing, operating, or performing maintenance on the MPA valve actuator.

Failure to follow instructions for proper electrical wiring, storage, setup, and maintenance may cause serious injury,

damage equipment, or void the warranty. Refer to Manual E796 for instructions on storage, electrical hook-up, and

maintenance.

Ensure that the installation is carried out in accordance with EN 60079-14 and IEC 60079-14.

Regulatory information:

II 2 GD

EEx d IIB T4 or EEx d IIB 120° C (T4) Tamb -20° C to +60° C

Revision M

19

Page 20

Multiport Flow Selector

April 2022

Table of Contents

Introduction 21................................

Figure 1 – Typical Well Test Application 21........

Figure 2 - MPA mounted on 6x16 MPFS 22.........

Features 23....................................

Figure 3 – MPA Features 23.....................

Figure 4 – Local Display Module (LDM) 25.........

Figure 5 – MPA with Remote Display Module (RDM)26

Mechanical and Electrical Installation 26............

Wiring 27....................................

Power Wiring 27...........................

Network Wiring 27.........................

Monitor Relay Wiring 27....................

Local ESD Wiring (Emergency Shutdown) 27...

Optional Remote Display Module (RDM) Wiring27

Local Display Module 28........................

Figure 6 – LDM 28.........................

Operation 28.............................

Figure 7 – LDM 29.........................

Local Operation 29.........................

Operational Display 29.....................

Display Blanking 30.......................

Alarms Display 30.........................

Field Setup Using DCMLink

Figure 8 – DCMLink Setup 31....................

Figures 9 – 13 DCMLink Setup 32................

User Setups Menu 33..........................

Selecting New Home Port 34....................

Figure 14 – Change Home Port Setting 34.........

Home Port LED Function 34.....................

Home Port Calibration

Figures 15 and 16 35........................

Factory Setup 35..............................

Figures 17 – 20 – Factory Setup Port Calibration 36.

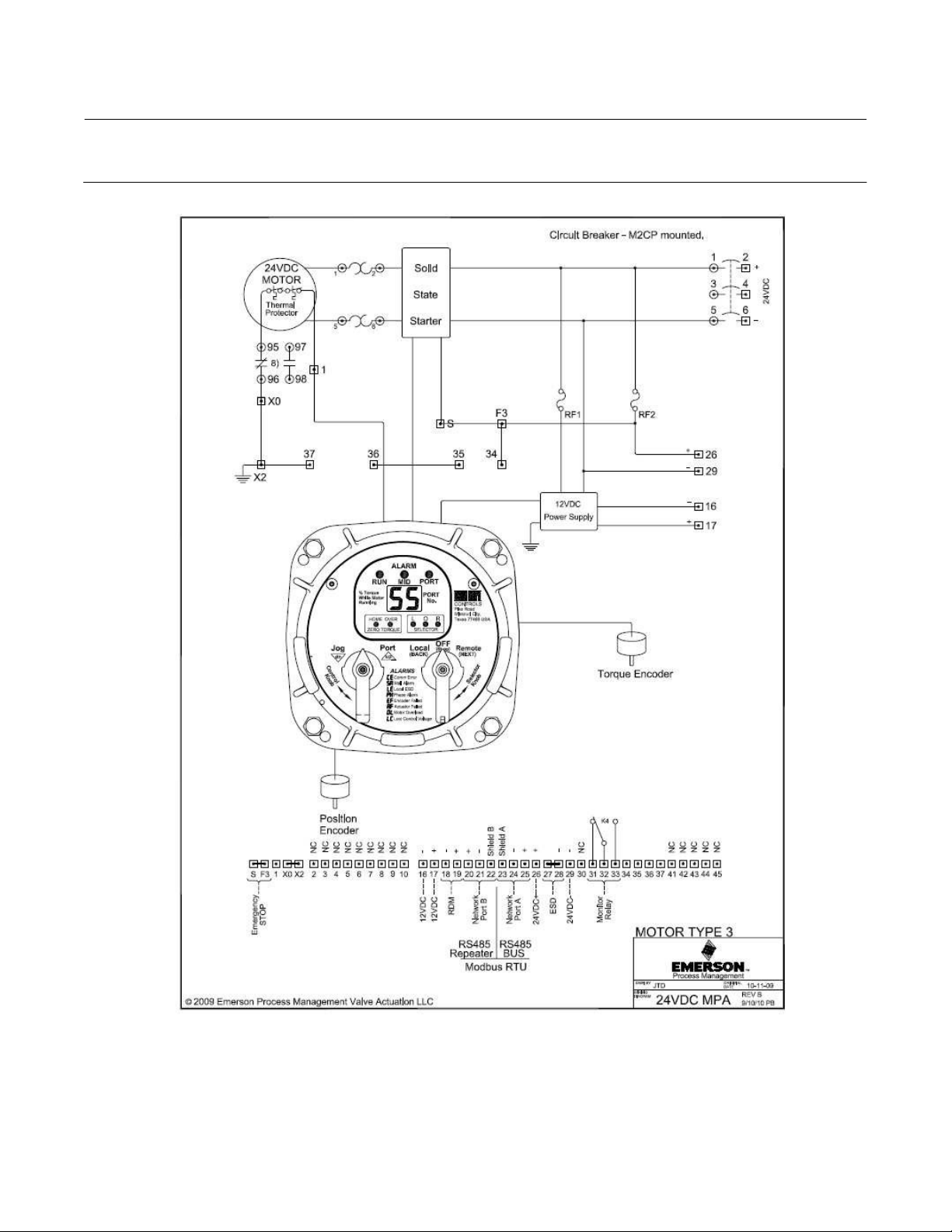

Motor Type 37............................

Figures 21 – 23 – Status Control 38...............

Field Controls 39..............................

Field Setup Using Local Controls 40................

Alarm History Display 41.......................

Setup Mode Display Sequence 41................

Field Diagnostics 44.............................

Fault Codes 44................................

Remote Control Network 45.....................

Modbus RTU 45...............................

Discrete Input Map (Valve Status and Alarms) … 45

Coil Map (Discrete Network Control) 45.......

Holding Register Map 46....................

Foundation Fieldbus (FF) 47.....................

Profibus DP Redundant Networks with Redcom 49..

DeviceNet 50.................................

EC Declaration of Conformity 51..................

Wiring Diagram – Three Phase Power 52...........

Wiring Diagram – Single Phase Power 53...........

Wiring Diagram – 24VDC Power 54................

™

Software 31...........

Instruction Manual

D104239X012

20

Page 21

Instruction Manual

D104239X012

Multiport Flow Selector

April 2022

Introduction

The Multiport Actuator (MPA) is a Bettis single turn actuator for control of Multiport Flow Selectors (MPFS) with 3 to 8

ports. A typical application is oil or gas well selection for well production testing as shown in figure 1. Typically the MPA

is the actuator of a Multiport Flow Selector as shown in figure 2. There are applications in other processes where

control of Multiport valves is required.

Figure 1. Typical Well Test Application

WELL 1

WELL 1

WELL 2

WELL 2

WELL 3

WELL 3

WELL 4

WELL 4

TO PRODUCTION

TO PRODUCTION

WELL 5

WELL 5

WELL 6

WELL 6

WELL 7

WELL 7

TO TEST SEPARATOR

TO TEST SEPARATOR

21

Page 22

Multiport Flow Selector

April 2022

Figure 2. MPA Mounted on 6”x16” MPFS

Instruction Manual

D104239X012

22

Page 23

Instruction Manual

D104239X012

Multiport Flow Selector

Features

The actuator features several assemblies as shown in figure 3. Unique features of the actuator are listed below.

April 2022

Figure 3. MPA Features

LOW VOLTAGE INTERFACES

BETWEEN CPU AND TBM

ELECTRICAL ENCLOSURE WITH MOTOR

STARTER, CONTROL TRANSFORMER,

DC POWER SUPPLIES, POWER ENTRY,

TERMINATION PANEL, USER WIRING,

I/O INTERFACES, TORQUE ENCODER

MOTOR

(NOT SHOWN)

LOCAL DISPLAY MODULE

(LDM) WITH DISPLAYS &

STATUS LEDS. SELECTOR

& CONTROL KNOBS, CPU

MODULE, NETWORK

COMMUNICATIONS,

POSITIONER ENCODER

POSITIONER

ENCODER

COUPLING TO

MPFS STEM

GEARBOX

INTEGRAL

DISCONNECT

1. MPA uses Bettis's heavy duty gearbox with capacity of 3000 ft•lbs

a. Wide range of motors available for any voltage and torque

2. Configurable for Multiport flow selectors from 3 to 8 ports

a. Any port may be selected as home port and any port(s) may be skipped

b. Actuator calibrated at factory for exact match to alignment of flow selector ports

c. Calibration parameters stored in nonvolatile memory and available to DCS

3. 12-bit magnetic encoder coupled directly to valve stem for precision position feedback

a. Provides position measurement resolution of 0.088 degrees

4. Bettis’s exclusive solid-state motor starter and control software provides precise positioning of flow selector within

+

0.26 degrees of selected port for the largest flow selector, and within +0.79 degrees for smallest flow selector,

where accuracy is less of a concern because of reduced radius

23

Page 24

Multiport Flow Selector

April 2022

Instruction Manual

5. High performance microcontroller updates motor control output every 4mS for precision motor control

6. 12-bit magnetic encoder coupled directly to torque pinion for torque feedback

a. Provides torque measurement resolution of 0.146% of full torque

7. MPA supports all network protocols available with all other Bettis actuators

D ModbusRS485 Bus or E>Net ring available

D Profibus Redundancy with Redcom

D Foundation Fieldbus

D DeviceNet

D Ethernet Modbus TCP/IP

8. I/O and alarm monitoring include:

D Integral circuit breaker/disconnect

D Motor overload and motor thermal

D104239X012

D Loss of control voltage

D Encoder failure

D Stall detection and alarming (detects mechanical faults)

D 3-Phase monitoring and phase correction to insure correct motor rotation

D ESD to send selector to home port (also goes to home port on fault)

D Monitor relay for hardwired relay contact status on fault

9. Four models support five 8-port MPFS (Also see motor type on page 33)

Table 1.

MODEL MPFS

MPA 150 2x4 150 203 1.0 1.0 1.0 0.79

MPA 650 3x6 650 881 0.7 1.0 0.5 0.49

MPA 800 4x8 and 4x10 800 1085 0.6 0.9 0.5 0.40

MPA 1500 6x16 1500 2034 0.3 0.4 0.3 0.26

Note: Accuracy based on worse case tests at 38% of maximum torque.

CAPACITY RPM ACCURACY

lb ft Nm 1Ph 3Ph DC Degrees

10. MPA includes local display module (LDM) standard

D Uses rugged, high visibility LED display for port number, torque, and alarms (also displays setup menus and setup

parameters)

D Multiple color LEDs display

a. Port position within 1° of port

24

Page 25

Instruction Manual

D104239X012

b. Port position within 2° of port

c. Motor running

d. Alarm

e. Over torque

f. Position within 0.25° of home port

g. Local mode 〉

h. Off mode 〉 Combined detection logic for two selector switches

i. Remote mode 〉

D Display blanking user setup option to conserve power in idle mode

D Includes Local Off Remote selector switch

D Local control knob for Port selection and Jog control when enabled by User

Multiport Flow Selector

April 2022

Figure 4. Local Display Module (LDM)

25

Page 26

Multiport Flow Selector

April 2022

11. Remote display module (RDM) option available

a. RDM displays identical information and performs identical control as LDM

b. Bettis's patented combined switch logic allows detection of selector switch position on LDM and RDM

c. Allows remote control up to 4,000 feet (1,220 meters) away

d. Alarming includes loss of communication with RDM

Figure 5. MPA with Remote Display Module (RDM)

Instruction Manual

D104239X012

Mechanical and Electrical Installation

Do not connect power until you have gone through the following checklist:

1. Does the information given on the nameplate correspond with the application?

2. Have all wire terminations and the equipotential bonding system been connected correctly?

3. EEx d applications: are the cable entries, plugs and adaptors EEx d approved?

4. Are all cable entries of the correct internal diameter providing a good seal around the cable?

5. Do the ambient and process temperatures correspond to the ratings on the nameplate as shown below?

26

Page 27

Instruction Manual

D104239X012

Multiport Flow Selector

April 2022

Wiring

All user wiring terminations are made inside the Electrical Enclosure shown in figure 3. Refer to wiring diagram located

at the back of this manual for wiring connections. High voltage power connections are made to the disconnect/circuit

breaker located inside the electrical enclosure. All low voltage connections, including network wiring, are made to the

Termination Board Module (TBM) located inside the electrical enclosure. Use conduit and seals in accordance with

National Electric Code (NEC) and local codes for all wiring entering the electrical enclosure.

Power Wiring

Connect power voltage leads to the circuit breaker located in the main electrical enclosure. Power wires must enter

the electrical enclosure at the conduit entry on the lower right side of the enclosure to prevent water from entering.

The controller provides automatic phase correction in case three-phase power is connected in the wrong phase

rotation.

Network Wiring

If a single bus network connection, such as Foundation Fieldbus, is being made, connect to Network Port A at TBM

terminals 24 (-) and 25 (+). If the cable is shielded, connect shield to TBM terminal 23. If redundant or repeater

network connections such as Bettis E>Net are being made, connect the second network to Network Port B at TBM

terminals 23 (+) and 24 (-). Connect cable shield of Port B to TBM terminal 25. Cable shields are isolated from earth in

the actuator. Connect shields to only one earth ground point in the network, normally the host location.

Monitor Relay Wiring

The Monitor Relay is used for hardwiring an indication of availability of the actuator for remote control. When the

selector switch is placed in the Remote mode and if there are no alarms present that prevent operation, the Monitor

Relay is energized. If an alarm occurs or the selector switch is moved from the Remote position, the relay is

deenergized. The Monitor Relay is a Form C relay with both normally open (N.O.) and normally closed (N.C.) contacts.

Wire to either TBM terminals 31 and 32 if N.O. contacts are desired. Wire to TBM terminals 32 and 33 if N.C. contacts

are desired. The relay is shown on the wiring diagram in the deenergized state, meaning that the actuator is not

available for remote control.

Local ESD Wiring (Emergency Shutdown)

Remove jumper between TBM terminals 27 and 28. Connect Normally Closed (N.C.) dry contacts to terminals 27 and

28. When the contacts open, ESD is activated, causing the actuator to go to Home Port. The actuator will remain at the

Home Port until the ESD contacts are closed and a new command is received from either Local or Remote control. The

ESD circuit is a closed loop failsafe circuit. It the circuit is opened for any reason, broken wire, bad contact, 24VDC

power supply failure, etc., the ESD function is activated. The closed loop circuit is powered by 24VDC from the

actuator.

Optional Remote Display Module (RDM) Wiring

Connect twisted pair RS485 cable from the RDM to TBM terminals 18 (-) and 19 (+). If the RDM is being powered from

the actuator 12VDC supply, wire the power wires from the RDM to TBM terminals 16 (-) and 17 (+). The RDM is polarity

protected, preventing damage, but will not operate if polarity is reversed.

27

Page 28

Multiport Flow Selector

April 2022

Instruction Manual

D104239X012

Local Display Module

Contains microprocessor controller, position encoder, and network interface. This is the main controller used to setup

and operate the actuator.

This module displays operating parameters, port position, torque, and alarms. It also provides a means to configure

the actuator by using the local controls.

To use the Local Control and Selector:

Note

Actuator moves in only the counterclockwise position.

Figure 6. Local Control and Selector

SELECTOR KNOB (right) ROTATE

OFF (Stop) [return position] Stop movement Prevents motor operation

REMOTE (Auto) Clockwise Remote control Allows control from remote location

LOCAL (Hand) Counter-clockwise Hand Operation

SELECTOR KNOB (left)

(while selector is in LOCAL

(hand)mode)

Spring return Neutral position No operation

PORT (up) Clockwise

Jog (dn) Counter-clockwise

ROTATE FUNCTION RESULTS

FUNCTION RESULTS

Allows Control from the local control knob or the

control knob of the RDM, if connected.

Releases a local command when Local control is

used

Local command

to go to next port

Local command

to micro-step

Commands actuator to move to the next port.

Momentary knob control

Commands actuator to move only

while knob is being held , i.e. maintained knob

control.

Operation

Place the “Selector Knob” in the desired operating position –

28

Page 29

Instruction Manual

D104239X012

Multiport Flow Selector

April 2022

LOCAL – hands on operation at the actuator by manipulation of Control Knob.

REMOTE – used within the context of plant operation, i.e. Remote Control Panel, PLC, DCS, etc. See wiring diagram for

typical user wiring for remote control.

OFF (Stop) – to prevent local or remote operation.

Figure 7.

Local Operation

Place the “Selector Knob” in the “Local” position. If a remote display is connected, the remote selector switch must not

be in the “Off” position. Verify that the selector “L” amber light is on. The actuator may now be operated using the

port and jog Control Knobs. Jog control is normally disabled and must be enabled in the setup menu.

To jog or micro-step the actuator toward the next port, rotate the control knob in the counterclockwise direction. Jog

to position and release when the desired position is reached. When using jog for calibrating the actuator, always stop

short of the desired port and use the hand wheel to complete accurate positioning to center of the port.

To move only to the next port, momentarily rotate the control knob in the clockwise direction to the Port position and

release.

To Stop or prevent actuator movement, move Selector knob to the OFF (Stop) position.

Operational Display

Operational indicators for RUN / ALARM / PORT position use long lasting LED’s. Run torque and port position are

shown on the digital readout during normal operation. Torque in percent of maximum is displayed as a 2-digit number

only while the motor is running. Port position is displayed as a single digit when the motor stops. If the actuator stops

between two ports, the two corresponding port numbers will alternate. Torque less than 10% is displayed as 0%.

RUN LED flashes Green while the actuator is moving to the next port and flashes Red while running within 2° of the

selected port position.

29

Page 30

Multiport Flow Selector

April 2022

Instruction Manual

D104239X012

PORT LED flashes Green when the actuator is within 2° and outside 1° prior to the setpoint of the selected port. The

port LED flashes Red when within 2° and outside 1° beyond the setpoint. The port LED illuminates steady Green while

within 1° of the selected port position.

ALARM (Yellow) LED flashes when any alarm is present. The LED is on solid when stopped between ports, otherwise it is

off.

OVER TORQUE alarm condition is indicated when a torque alarm occurs in mid-travel. The over torque LED will flash so

long as the over torque condition exists.

HOME PORT LED will light when the actuator is within 0.25° of the user selected Home Port position.

Selector switch LEDs are also made available for operational use in the bottom right corner. The selector LEDs are

important when using a Remote Display Module (RDM) because these LEDs indicate the combined logic of the two

selector switches, i.e. the selected mode of operation of the actuator. All three LOR LEDs flash while the actuator is in

setup mode.

Display Blanking

The user has the option to have the display blank out (turn off) when not in use. This is a very important feature for

solar power applications because power consumption is minimized. Option to enable or disable display blanking

timeout is available by setup using MPA Config or the control knobs. See the field setup section for selecting the

option. When control knobs are used for setup, the parameter is C9 as shown in the table on page 38. The default

setting is display blanking timeout enabled for 24VDC versions and disabled for AC versions. If display blanking is

enabled, the display will blank out after 60 seconds when left unattended while the selector switch is in Remote mode.

The display will blank out after 3 minutes when left unattended while the selector switch is in Local mode. The display

will not blank out while in setup mode. When selected, display blanking applies to both local (LDM) and remote (RDM)

displays.

Alarms Display

When an alarm occurs, it is automatically displayed by the two character LED display. The yellow ALARM LED will flash

while any alarm is present. The display will alternate between the current port position and the active alarm(s) except

when stopped between parts. If more than one alarm is active, the display will cycle through a sequence of Port

Position, newest alarm, Port Position, next oldest alarm and so on until all active alarms are displayed. The cycle is

continuously repeated until all alarms are cleared. Each alarm is recorded in an Alarm History. The alarm history may

be viewed by entering setup mode (see next section).

All possible alarms that may be displayed are listed on the name plate of the Local Display Module (LDM). Following are

definitions of the listed alarms.

CE Communication Error Lost communication with the Remote Display Module (RDM) when configured.

SA Stall Alarm Actuator failed to move within 8 seconds after commanded by either local or remote

LE Local ESD Hardwired Local Emergency Shut Down is active.

PH Phase Alarm Loss of one phase when configured for 3-Phase.

EF Encoder Failed Failure of either the position or torque encoders.

AF Actuator Failed A fault is detected by hardware electronics fault monitor. This is a non-recoverable

OL Motor Overload Motor thermals or motor overload relay has tripped.

LC Lost Control Voltage

Note

Over torque alarm is displayed by dedicated LED. See Operational Display section above.

controls.

condition that requires actuator service.

Loss of power to the motor control circuits. The control voltage supply has an

automatic resetting fuse.

30

Page 31

Instruction Manual

D104239X012

Multiport Flow Selector

April 2022

Field Setup Using DCMLink Software

DCMLink is an application for configuration, calibration, test, and operation of the MPA DCMLink is a licensed product.

It is a Windows-based program. Compatible Windows Operating Systems are listed in the DCMLink IOM,

DCM-402-0317.

Connection to the MPA to utilize DCMLink requires a RS485 link. The MPA supports several network protocols so it may

be necessary to use a USB to RS485 converter for connection of a PC to the RDM port of the actuator. RDM port is at

TBM terminals 18 (-) and 19 (+). DCMLink Software loaded to a laptop or other compatible PC device can connect the

RS485 link to the TBM in the electrical enclosure. If opening the enclosure is undesirable, configuration may be

performed using the local control knobs of the actuator as described in the next section of this manual. If the system is

configured for Modbus networking, the PC may be connected to the local area network at any location in the network

after disconnecting the Host system communication. The MPFS factory uses this software to configure and calibrate

the MPA and saves the configuration to a “.mpa” file by MPFS serial number. Should loss of factory configuration or

port calibration occur due to failure of a CPU module or user error, a copy of the file may be obtained from the MPFS

factory and loaded to the actuator using DCMLink program.

DCMLink SetUp

HELP: Clicking the Menu Bar Help Tab button at the

top of the screen will open linked documents or

information. Passing the cursor across the Icons or

Navigation Pane tabs will cause a description of that

item to be displayed.

To setup communication and DCMLink Display

Preferences, select the DCMLink Setup Tab in the

Menu Bar as shown in figures 8b and 8c. To configure

the network communication link select the

Communication Tab in Preferences per figure 9.

Figure 8a.

Figure 8b.

Figure 8c.

31

Page 32

Multiport Flow Selector

April 2022

Communications Setup

If connected to the RDM port, set the computer Baud

Rate to 9600, Parity None and Stop Bits to 1. Set the

Slave Address to 99. The RDM port configuration of the

MPA is fixed at 9600,N,8,1 and may not be changed by

the user.

If connected to a Modbus local area network, the baud

rate and slave address configured for the actuator

must be known in order to setup the computer

communication port. Default configuration for the

MPA network port is 19,200 baud and default address

is 99.

Select the configured Com Port in Navigation Pane and

Right Click to Scan for Devices. Set address and Start

Scan. When device is detected stop scan and close the

window .

Instruction Manual

D104239X012

Figure 9.

Figure 10.

32

Figure 11.

Page 33

Instruction Manual

D104239X012

User Setup Menus

To configure the actuator, select (highlight) the Device

Tag in the Navigation Pane per figure 12. Then Right

Click or use the Icon in the Menu Bar to select Detailed

Setup as shown in figure 13. The current Actuator

configuration and the default MPA settings or opened

Dataset settings are displayed. A Dataset is a file on

DCMLink based on the Device type and Displayed

Device Tag. A yellow Tab indicates there are

differences between the displayed Actuator

configuration and the displayed Dataset.

Configuration can be changed between the Actuator

and the Dataset and the actuator Configuration File

and Dataset can be saved to the PC. No passcode is

required to change User Configuration Settings

(Detailed Setup & Home Port Calibration) when using

DCMLink.

The Network Tab allows changes in configuration only

for the network ports. It does not affect the RDM port.

The Control Tab allows unused/unconnected Ports of

the MPFS to be bypassed. If a pipeline is not connected

to any one or more ports, or if it is desirable to skip any

one or more ports, click on the “Delete Port” number.

The deleted ports will be skipped when a next port

command is issued in either local or remote control

modes.

Multiport Flow Selector

April 2022

Figure 12.

Figure 13.

Notice: When configuration changes are made,

clicking the Blue arrows “Writes” the configuration to

the Actuator or Dataset. If there are no differnces

between the Actuator and Dataset, the arrows will be

grey. Using the dropdown box arrow of the Dataset

allows for parameter change selections to be made.

The “Read” button may be used to refresh the screen

to verify the parameters have been properly written for

storage in the actuator. You can read or write entire

configuration or just the opened page using the

Arrows or tab in upper right hand of the page. Values

are written to EEPROM when the Setup page or Device

Tag is closed. On the MPA LDM, within several seconds

of writing the configuration, the 3 LOR LEDs will

simultaneously flash slowly. This slow flash is a signal

that all new values were successfully written to

EEPROM.

33

Page 34

Multiport Flow Selector

April 2022

Instruction Manual

D104239X012

Selecting New Home Port

The user may select any port as the new “Home Port”

in the field. When a new home port is selected, the

new home port is identified as Port 0 or 8 and the MPA

reassigns all other port numbers (1-7) in a

counterclockwise sequence around the MPFS. The

MPA recalculates the exact calibrated port position

based on factory calibration values so no accuracy is

lost.

To select a new home port, click on the desired

selection in Detailed Setup for User Home Port and

Label (0 or 8) as shown in figure 14.

Note

When a new home port is selected, it must be a port without piping

connected and must be fitted with a blind cover to allow for future seal

inspection and visual port alignment. Selecting a new home port will

cause the MPA to recalculate all calibration parameters based on the

factory calibration and store the new values to EEPROM.

Home port may be identified as either Port 0 or Port 8. The desired

designation may be selected by the CA configuration parameter as

shown on page 38.

Home Port LED Function

The home port LED on the LDM will now identify the

newly selected home port position. This LED is on

when the actuator is within 0.25 degrees of the

selected home port. When the blind cover of the home

port is removed in the field to inspect the seals, the

home zero may be verified and corrected if an error is

detected.

Figure 14.

34

Page 35

Instruction Manual

D104239X012

Multiport Flow Selector

April 2022

Home Port Calibration

If maintenance is performed on the actuator that can

cause loss of calibration, the home port must be

recalibrated. Examples of maintenance that affect

calibration are removal of the actuator from the MPFS

and replacement of the position encoder. If a MPA is

removed from one MPFS and installed on another or if

a CPU module is replaced, the factory configuration

(.mpa) file for the MPFS must be loaded to the new

actuator and the selected home port calibrated.

To calibrate the home port position, remove the blind

cover from the selected home port. Use the hand

wheel of the MPA to position the plug seal over the

port as precisely as possible. Open DCMLink and

connect to Device. Right click Device Tag or select

Calibration button on the Menu Bar. Select the “Home

Port Calibration” as shown in Figure 15. To avoid

accidental setting of a new home port, the user is

required to enter a passcode of 43 to gain access. A

Pop-Up will appear as shown in figure 16 providing a

warning and allow entry of the passcode. The Port Raw

Value should be displayed in the Home Port Calibration

Box. Select Calibrate Home Port and review the value

before closing. The Home Port should be indicated on

the MPA LDM as the MPA is aligned with the Home

Port.

Figure 15.

Figure 16.

Factory Settings

Factory Settings are only accessible by Factory

Authorized Technicians with DCMLink License

authorization. Factory Setup contains protected

configuration items defining the application and

motor control as well as the User Password and Port

Calibration. These items are in the “.mpa”

configuration file saved by the Factory and can be

loaded to or saved from a PC during any service or CPU

Replacement. See figure 17.

Factory Settings Items are displayed in figure 18.

Figure 17.

35

Page 36

Multiport Flow Selector

April 2022

Instruction Manual

D104239X012

Factory Settings - Port Calibration

Port Calibrations are made by Factory Authorized

Technicians through the Factory Menu only accessible

by Factory Authorized Technicians with DCMLink

License authorization.

Select Port Calibration from the Factory Menu Options.

See figure 19.

For precise MPFS port alignment, the factory calibrates

each actuator to each of the ports of the mated MPFS.

These items are in the “.mpa” configuration file saved

by the Factory and can be loaded to or saved from a PC

during any service or CPU replacement.

The calibrated values are displayed on the Port

Calibration screen and may be compared to the

current position (Encoder Feedback) to determine

accuracy. When a new home port is selected by the

user, these calibration values are recalculated and

stored to EEPROM. See figure 20.

Figure 18.

Figure 19.

36

Figure 20.

Page 37

Instruction Manual

D104239X012

Multiport Flow Selector

April 2022

Motor Type

Motor Type is entered at the factory for the type of MPFS, power supply and motor horse power rating as shown in the

table below. Motor type is displayed on the MPA Config Factory Setup Menu. If the motor type is changed, it is

necessary to cycle power to the actuator after existing factory setup to ensure proper initialization.

Table 2. Motor Type

MPFS

2 x 4 1/12 2 6 10 14 18 22 26 --2 x 4 1/6 --- --- --- --- --- --- --- 30

3 x 6 1/6 3 7 11 15 19 23 27 31

4 x 8 /

4 x 10

6 x 16 1/6 5 9 13 17 21 25 29 33

Motor HP

1/6 4 8 12 16 20 24 28 32

1 Ph

115

VAC

Note

The user is not required to select motor type unless qualified to download firmware upgrade to the MPA. If a new HEX file for

firmware upgrade is loaded to the MPA in the field, the motor type must be configured before the actuator will operate. When

power is first applied to the MPA after a firmware upgrade, in order to know how to initialize the electronics, the Motor Type stored

in the EEPROM will be examined. If a new HEX file was just downloaded, it will not yet have a Motor Type (it will be ZERO).

When firmware sees that the Motor Type is ZERO, firmware will immediately go to the display entry in the Factory Setup Menu for

Motor Type. The user will NOT have to move the left control knob back and forth to go to Setup Mode or enter a passcode. The

user will see alternate display of "F1" and "0". The "F1" is the abbreviation for Motor Type in the factory setup menu, and the current

value is 0. Then the user (who just now completed the hex file download) will have to use the left hand control knob to increment

the display number to the correct Motor Type (from 1 to 33 shown in the table above). Then a move of the right hand selector

knob either left or right will force an exit out of the Setup Menu in this unusual one-time circumstance after a HEX file download.

1 Ph

230

VAC

3 Ph

220/230

VAC

3 Ph

380

VAC

3 Ph

415

VAC

3 Ph

460

VAC

3 Ph

575

VAC

24

VDC

Now the firmware will examine the Motor Type and know how to initialize the electronics. Normally when power is

applied to the MPA, if it is NOT after a new download of the HEX file, the Motor Type will already be non-ZERO so the

firmware will know how to initialize the electronics without forcing the user to use the knobs.

Table 3. MPA Model Selections and Capacities

Valve Size

and Max

Torque

2 x 4

150 ft•lb

3 x 6

650 ft•lb

4 x 8 / 4 x 10

800 ft•lb

6 x 16

1500 ft•lb

Note: All valve torques are run torques.

Power

Supply

24 VDC 37RK-FJ 1/6 50 6.5 11.7 2000 2.58 0.42 0.76

115/1/60 35RK-6J 1/12 4.4 2 3.6 1725 0.74 0.37 0.67

230/3/60 35RK-2J 1/12 2.32 0.64 1.2 1725 1.07 0.35 0.63

415/3/50 35RK-9J 1/12 0.94 0.32 0.6 1400 1.41 0.34 0.61

460/3/60 35RK-3J 1/12 1.16 0.32 0.6 1725 1.4 0.33 0.59

24 VDC 37LK-FJ 1/6 50 6.5 11.7 2000 2.58 0.42 0.76

115/1/60 37OK-6J 1/6 6.8 3.9 7.0 1725 1.43 0.53 0.95

230/3/60 37RK-2J 1/6 3.8 1.1 2.0 1725 2.57 0.52 0.94

415/3/50 37RK-9J 1/6 1.54 0.54 1.0 1400 2.61 0.64 1.15

460/3/60 37RK-3J 1/6 1.9 0.55 1.0 1725 2.48 0.53 0.95

24 VDC 37MK-FJ 1/6 50 6.5 11.7 2000 2.58 0.42 0.76

115/1/60 37MK-6J 1/6 6.8 3.9 7.0 1725 1.43 0.53 0.95

230/3/60 37QK-2J 1/6 3.8 1.1 2.0 1400 2.57 0.52 0.94

415/3/50 37QK-9J 1/6 1.54 0.54 1.0 1400 2.61 0.64 1.15

460/3/60 37QK-3J 1/6 1.9 0.55 1.0 1725 2.48 0.53 0.95

24 VDC 37DK-FJ 1/6 50 6.5 11.7 2000 2.58 0.42 0.76

115/1/60 37DK-6J 1/6 6.8 3.9 7.0 1725 1.43 0.53 0.95

230/3/60 37JK-2J 1/6 3.8 1.1 2.0 1725 2.57 0.52 0.94

415/3/50 37DK-9J 1/6 1.54 0.54 1.0 1400 2.61 0.64 1.15

460/3/60 37JK-3J 1/6 1.9 0.55 1.0 1725 2.48 0.53 0.95

Model

Size

Nominal

Size (HP)

Start Current

(amps)

Run Current

15 min

(amps)

MOTOR DATA

5 min

(amps)

Speed

(rpm)

Start

(ftwlb)

Motor Torque

15 min

(ftwlb)

15 min

(ftwlb)

37

Page 38

Multiport Flow Selector

April 2022

Valve Status Monitor

The Status Monitor is a valuable tool for monitoring

and commissioning the system. It provides a

Dashboard for quick visual indication of status and

provides tab for review of Alarm and ESD Status, as

well as Device Info. This screen may be used to

determine command and position status troubleshoot

any problems should they occur. Red Tabs indicate an

active alarm or event exists. Field diagnostic code or

Alarms are displayed in the Monitor Tab. All active

alarms may be viewed at a glance in the Alarms tab.

See figures 21 through 23.

Mode displays the mode selected by the selector

switch of the LDM or combined logic of both LDM and

RDM selector switches.

Monitor provides a snapshot of the active conditions

and and Logs displays the last 9 Alarms.

Instruction Manual

D104239X012

Figure 21.

Figure 22.

At Port displays the port number position of the

actuator and whether the MPA is at the port within 1

degree or within 2 degrees.

Torque is displayed as percentage of the full torque

rating of the actuator. Torque is displayed from 10% to

99% in 1% increments. Torque less than 10% is

displayed as zero because torque between 0% and 10%

cannot be accurately measured.

Tracking and trend graphics display Setpoint, Position,

and Torque over travel time.

Encoder Value is the 12-bit raw data from the position

encoder in the range of 0 to 4095. This value is the

same as the value displayed during Port Calibration in

the Factory on the Factory Setup screen so it can be

compared to port calibration value of each port.

Figure 23.

38

Page 39

Instruction Manual

D104239X012

Valve Control

Valve Control allows all functions of the system to be

tested prior to commissioning with the DCS. It

provides for a Dashboard for Controlling the MPA and

providing Host ESD. It also includes a tab for Alarm

Status.

Valve Control can be used to command the actuator to

go to the next port or go to a desired port number. “Go

to Port” is the new setpoint in the range of 0 to 8 for

the 8 ports (including the Home Port).

Based on selections for general display preferences in

DCMLink™ Setup, the Dashboard can display Digital

indication of Setpoint, Port Position, and Torque.

Figure 24.

Multiport Flow Selector

April 2022

Figure 25.

Figure 26.

Figure 27.

39

Page 40

Multiport Flow Selector

April 2022

Instruction Manual

D104239X012

Field Setup Using Local Controls

Use the Local Control (left) knob and Selector (right) knob to enter setup mode and to execute Setup functions. The

table below outlines the knob functions for Setup mode.

To access the Field SETUP mode of operation ensure the Selector Knob is placed in the OFF (Stop) position. Once set,

rotate the Control Knob to the “UP” and then to the “DOWN” position in right to left succession three times. Keep the

knob in each position for at least ½ second but not more than 3 seconds. The display module will flash the (3) amber

LOR selector LED’s when the SETUP mode is enabled.

Figure 28.

SELECTOR KNOB (right) SETUP FUNCTION RESULTS

OFF (Stop) [return position] Neutral position

Clockwise (REMOTE) (Auto) NEXT

Counter-clockwise

(LOCAL) (Hand)

CONTROL KNOB (left) SETUP FUNCTION SETUP RESULTS

Spring return to Center Neutral position

Clockwise (CLOSE) UP Increments displayed data

Counter-clockwise (OPEN) DOWN Decrements displayed data

40

BACK Backs up to the last menu item

Allows entry to SETUP mode. Completes NEXT, or

BACK entry cycle, except when knob is held for

scrolling through various menus

Advances to the next menu item. Displayed data is

accepted

Completes UP or Down entry Cycle except when

knob is held for continuous data entry update

Page 41

Instruction Manual

D104239X012

When the actuator LDM is placed in SETUP mode of operation it first displays the Field Diagnostics (Fd) menu item. The

second menu item Alarm History (AH) menu. The field diagnostics and alarm history may be viewed without entering

a passcode (See Field Diagnostics and Alarm History Display section).

Note

On any setup menu, use up/down to change a parameter and back/next to accept the displayed parameter. All menus and all

parameters are wrap around, meaning they will advance from the highest or last value to the lowest or first value.

To view or change setup parameters of the actuator, Rotate the Selector Knob to the right or NEXT position to cycle

through the alarm history display A1 through A8 until P1 is displayed. Alarm history (A1-A8) may be skipped by

changing AH(1) to AH(0) and go directly to passcode menu. Passcode menu is displayed as two, 2-digit entries, P1 and

P2. The actuator is shipped from the factory with the passcode disabled, meaning that the passcode is 00 00. Until the

passcode is changed by the user, the passcode of 00 00 may be accepted by using the NEXT selector knob sequence to

accept the passcode and continue to the setup menus. You will now be able to display and/or edit setup data. If you

forget your configured passcode, factory trained technicians can reset the passcode back to 00 00.

Multiport Flow Selector

April 2022

Note

While in the SETUP mode the actuator will not turn on the motor control circuits and disables all control of discrete outputs until

exiting the Setup Mode.

Alarm History Display

Setup always enters the main menu at the Field Diagnostics (Fd) and the next menu item is Alarm History (AH). The