Page 1

Chemical Compatibility of Elastomers and Metals

Te c h n i c a l

Introduction

This section explains the uses and compatibilities of elastomers

commonly used in Fisher® regulators. The following tables

provide the compatibility of the most common elastomers and

metals to a variety of chemicals and/or compounds.

The information contained herein is extracted from data we believe

to be reliable. However, because of variable service conditions over

which we have no control, we do not in any way make any warranty,

either express or implied, as to the properties of any materials or as to

the performance of any such materials in any particular application, and

we hereby expressly disclaim any responsibility for the accuracy of any

of the information set forth herein.

Refer to the applicable process gas service code or standard

to determine if a specic material found in the Process Gases

Application Guide is allowed to be used in that service.

Elastomers: Chemical Names and Uses

NBR - Nitrile Rubber, also called Buna-N, is a copolymer of

butadiene and acrylonitrile. Nitrile is recommended for: general

purpose sealing, petroleum oils and uids, water, silicone greases

and oils, di-ester based lubricants (such as MIL-L-7808), and

ethylene glycol based uids (Hydrolubes). It is not recommended

for: halogenated hydrocarbons, nitro hydrocarbons (such as

nitrobenzene and aniline), phosphate ester hydraulic uids

(Skydrol, Cellulube, Pydraul), ketones (MEK, acetone), strong

acids, ozone, and automotive brake uid. Its temperature range is

-60° to 225°F (-51° to 107°C), although this would involve more

than one compound and would depend upon the stress state of the

component in service.

EPDM, EPM - Ethylenepropylene rubber is an elastomer prepared

from ethylene and propylene monomers. EPM is a copolymer of

ethylene and propylene, while EPDM contains a small amount

of a third monomer (a diene) to aid in the curing process. EP is

recommended for: phosphate ester based hydraulic uids, steam to

400°F (204°C), water, silicone oils and greases, dilute acids, dilute

alkalis, ketones, alcohols, and automotive brake uids. It is not

recommended for: petroleum oils, and di-ester based lubricants.

Its temperature range is -60° to 500°F (-51° to 260°C) (The high

limit would make use of a special high temperature formulation

developed for geothermal applications).

FKM - This is a uoroelastomer of the polymethylene type having

substituent uoro and peruoroalkyl or peruoroalkoxy groups

on the polymer chain. Viton® and Fluorel® are the most common

trade names. FKM is recommended for: petroleum oils, di-ester

based lubricants, silicate ester based lubricants (such as MLO

8200, MLO 8515, OS-45), silicone uids and greases, halogenated

hydrocarbons, selected phosphate ester uids, and some acids. It

is not recommended for: ketones, Skydrol 500, amines (UDMH),

anhydrous ammonia, low molecular weight esters and ethers, and

hot hydrouoric and chlorosulfonic acids. Its temperature range is

-20° to 450°F (-29° to 232°C) (This extended range would require

special grades and would limit use on each end of the range.).

CR - This is chloroprene, commonly know as neoprene, which

is a homopolymer of chloroprene (chlorobutadiene). CR is

recommended for: refrigerants (Freons, ammonia), high aniline

point petroleum oils, mild acids, and silicate ester uids. It is

not recommended for: phosphate ester uids and ketones. Its

temperature range is -60° to 200°F (-51° to 93°C), although this

would involve more than one compound.

NR - This is natural rubber which is a natural polyisoprene,

primarily from the tree, Hevea Brasiliensis. The synthetics

have all but completely replaced natural rubber for seal use.

NR is recommended for automotive brake uid, and it is not

recommended for petroleum products. Its temperature range is

-80° to 180°F (-62° to 82°C).

FXM - This is a copolymer of tetrauoroethylene and propylene;

hence, it is sometimes called PTFE/P rubber. Common trade

names are Aas® (Asahi Glass Co., Ltd) and Fluoraz® (Greene,

Tweed & Co.). It is generally used where resistance to both

hydrocarbons and hot water are required. Its temperature range is

20° to 400°F (-7° to 204°C).

ECO - This is commonly called Hydrin® rubber, although that is a

trade name for a series of rubber materials by B.F. Goodrich. CO

is the designation for the homopolymer of epichlorohydrin, ECO is

the designation for a copolymer of ethylene oxide and chloromethyl

oxirane (epichlorohydrin copolymer), and ETER is the designation

for the terpolymer of epichlorohydrin, ethylene oxide, and an

unsaturated monomer. All the epichlorohydrin rubbers exhibit

better heat resistance than nitrile rubbers, but corrosion with

aluminum may limit applications. Normal temperature range is

(-40° to 250°F (-40° to 121°C), while maximum temperature ranges

are -40° to 275°F (-40° to 135°C) (for homopolymer CO) and

-65° to 275°F (-54° to 135°C) (for copolymer ECO and

terpolymer ETER).

FFKM - This is a peruoroelastomer generally better known as

Kalrez® (DuPont) and Chemraz® (Greene, Tweed). Peruoro

rubbers of the polymethylene type have all substituent groups on

the polymer chain of uoro, peruoroalkyl, or peruoroalkoxy

groups. The resulting polymer has superior chemical resistance

and heat temperature resistance. This elastomer is extremely

expensive and should be used only when all else fails. Its

temperature range is 0° to 480°F (-18° to 249°C). Some materials,

such as Kalrez® 1050LF is usable to 550°F (288°C) and

Kalrez® 4079 can be used to 600°F (316°C).

FVMQ - This is uorosilicone rubber which is an elastomer that

should be used for static seals because it has poor mechanical

properties. It has good low and high temperature resistance and

is reasonably resistant to oils and fuels because of its uorination.

Because of the cost, it only nds specialty use. Its temperature

range is -80° to 400°F (-62° to 204°C).

VMQ - This is the most general term for silicone rubber. Silicone

rubber can be designated MQ, PMQ, and PVMQ, where the Q

designates any rubber with silicon and oxygen in the polymer

chain, and M, P, and V represent methyl, phenyl, and vinyl

substituent groups on the polymer chain. This elastomer is used

only for static seals due to its poor mechanical properties. Its

temperature range is -175° to 600°F (-115° to 316°C) (Extended

temperature ranges require special compounds for high or

low temperatures).

659

Page 2

Chemical Compatibility of Elastomers and Metals

Te c h n i c a l

660

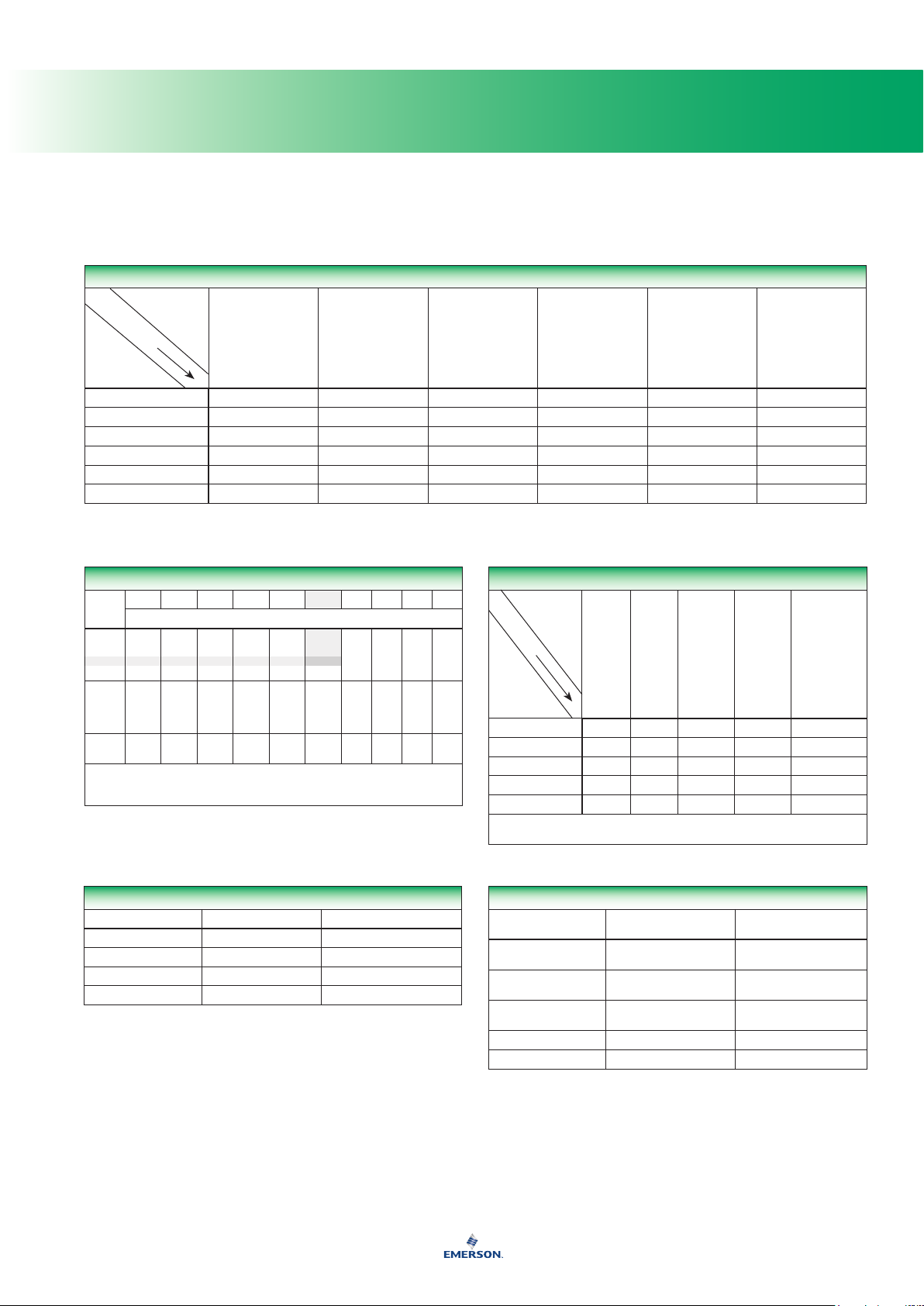

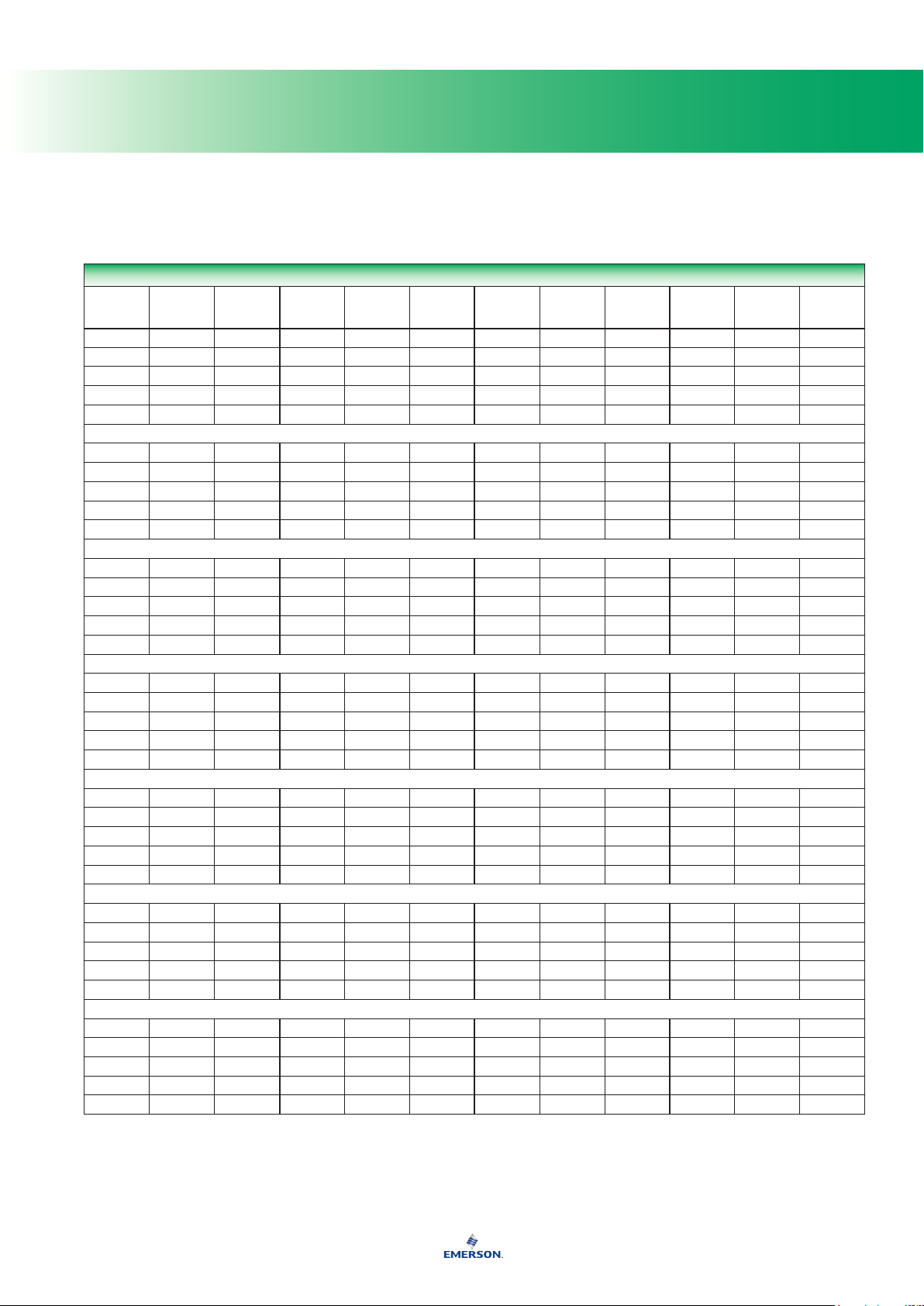

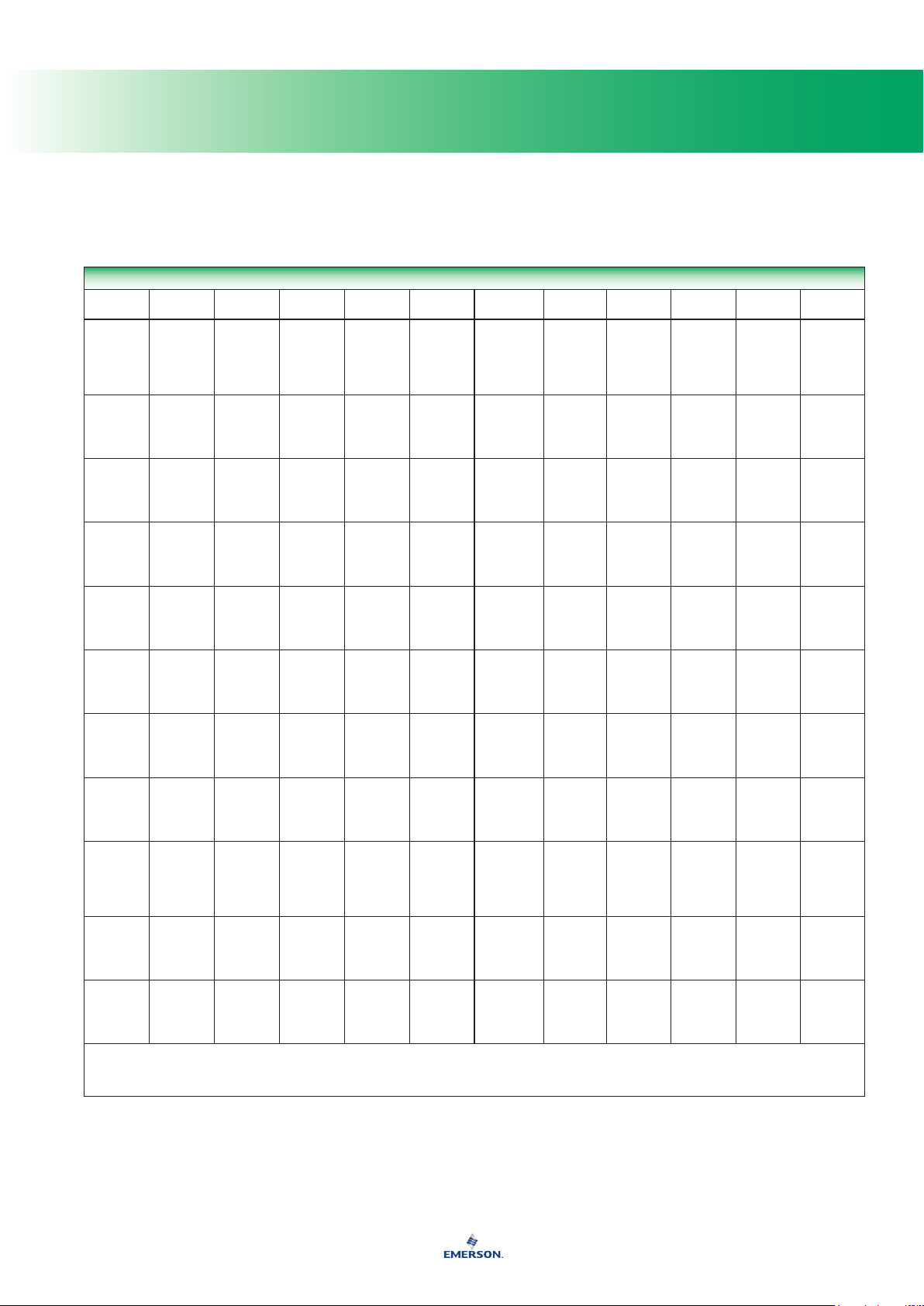

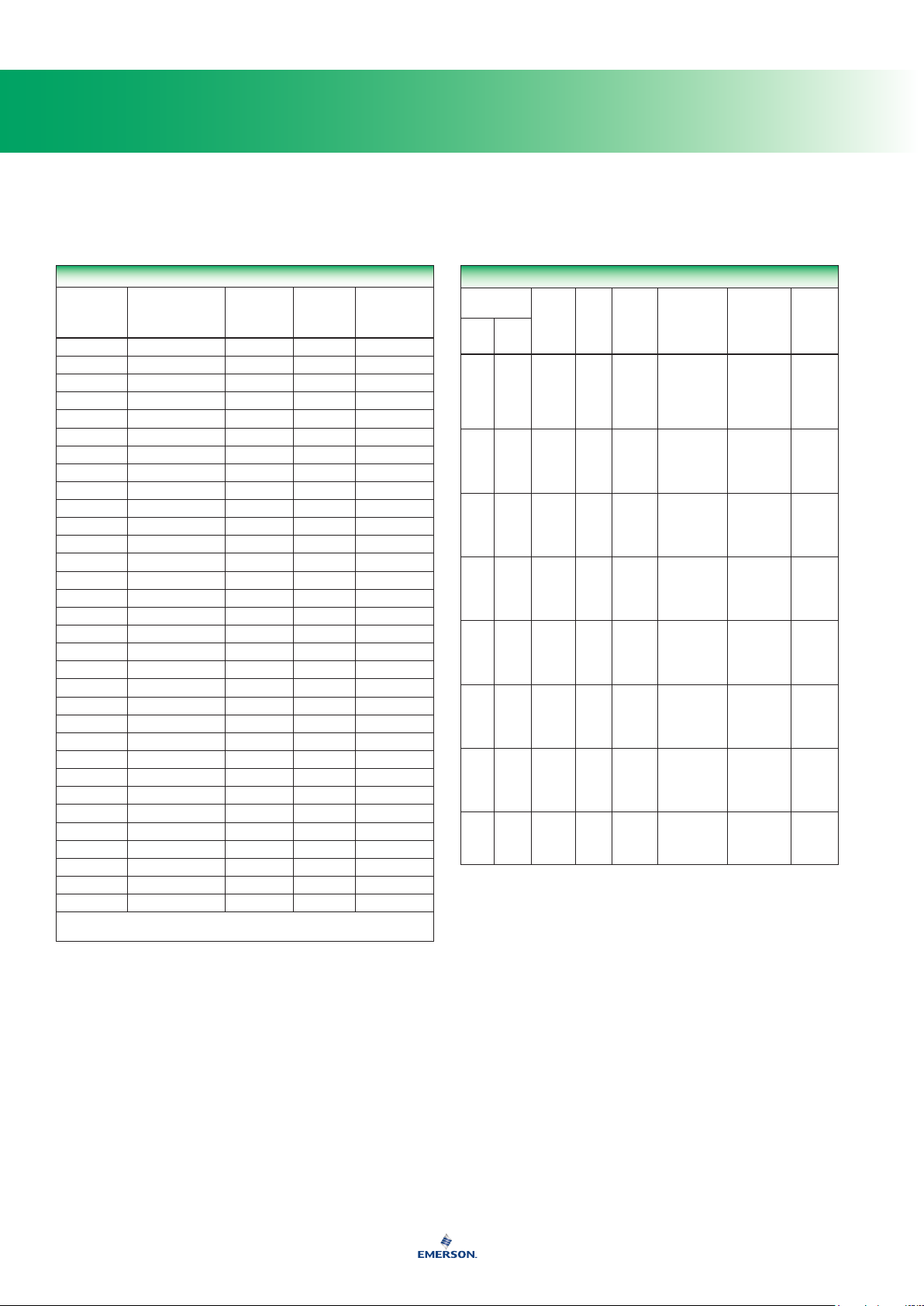

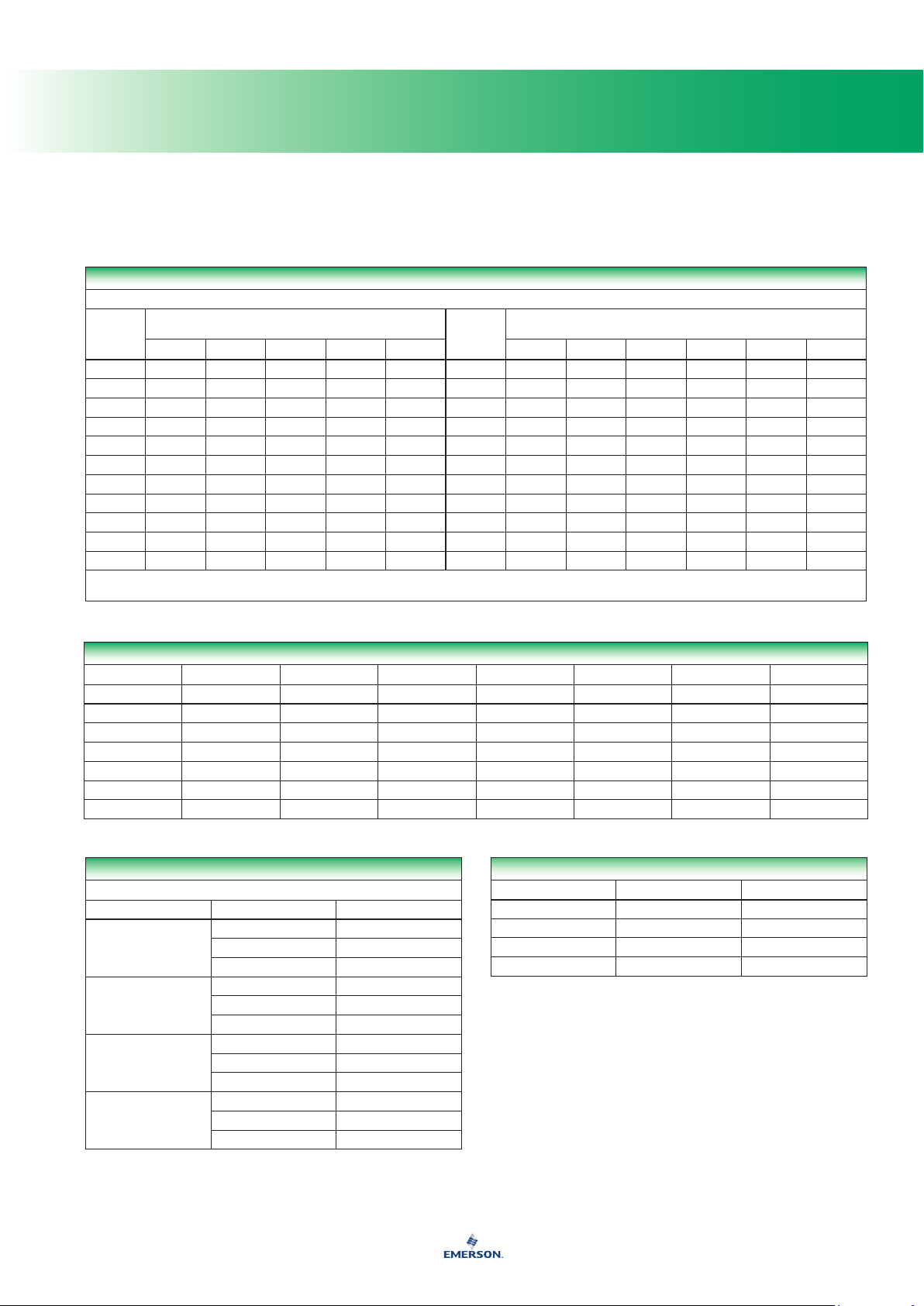

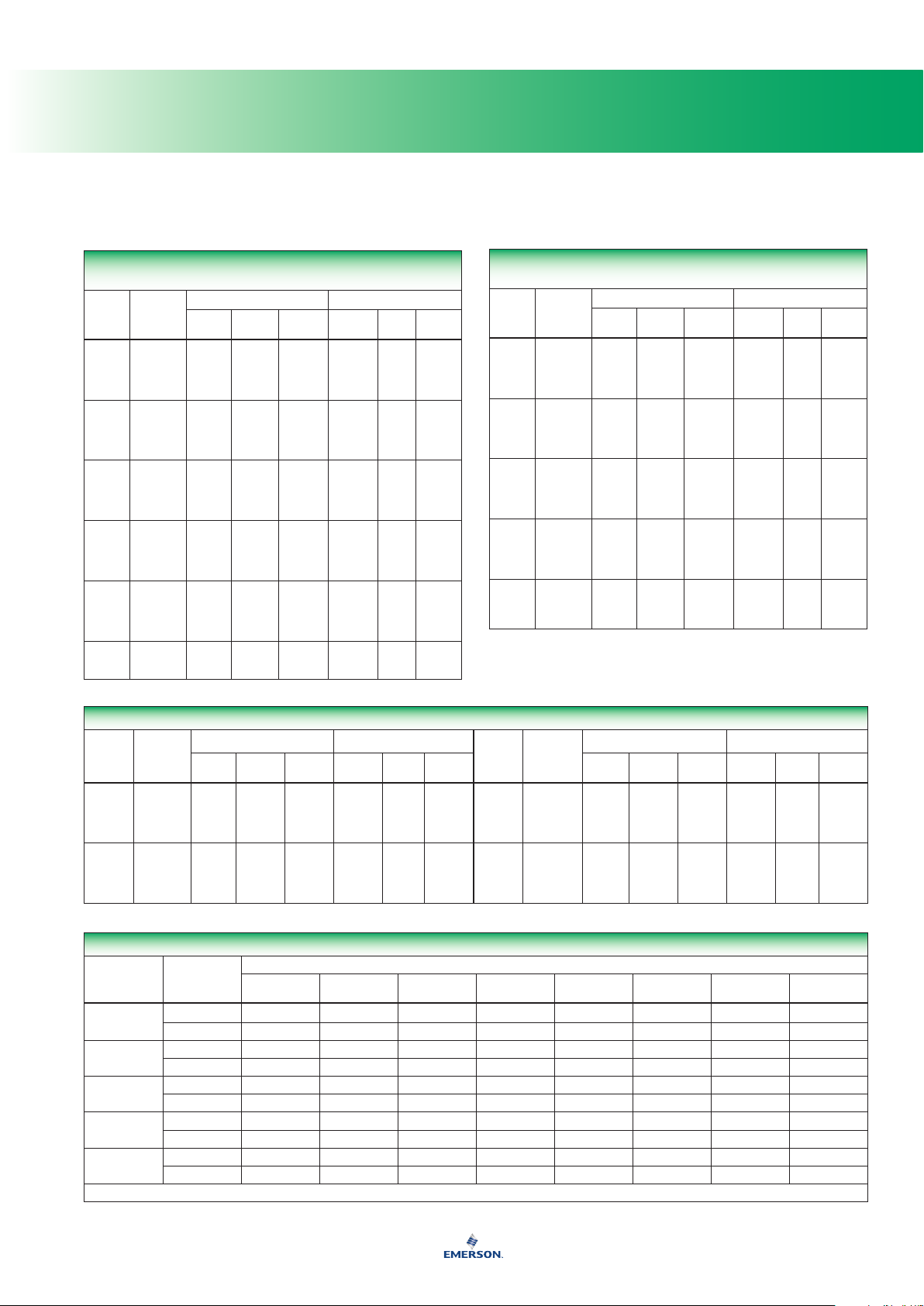

General Properties of Elastomers

PROPERTY

Tensile

Strength,

Psi (bar)

Abrasion Resistance Excellent Good Good Excellent Fair Poor Poor Excellent Very Good Excellent Good Good

Cracking Resistance

Solvent Resistance:

Aliphatic Hydrocarbon

Aromatic Hydrocarbon

Oxygenated Solvent

Halogenated Solvent

Low Aniline Mineral Oil

High Aniline Mineral

Synthetic Lubricants

Organic Phosphates

Gasoline Resistance:

Diluted (Under 10%)

Flexibility (Maximum)

Permeability to Gases Fair Fair Fair Very Good Very Good Good Fair Very Good Good Good Good Good

Diluted (Under 10%)

Elongation (Maximum) 700% 500% 500% 500% 700% 400% 300% 300% 425% 625% 200% 500%

1. Do not use with steam.

2. Do not use with ammonia.

3. Do not use with petroleum based uids. Use with ester based non-ammable hydraulic oils and low pressure steam applications to 300°F (149°C).

4. Except for nitric and sulfuric acid.

Pure Gum

Reinforced

Tear Resistance Excellent Poor-Fair Fair Good Good Fair Poor-Fair Excellent Good Excellent Fair Poor

Aging: Sunlight

Oxidation

Heat

(Maximum

Temperature)

Static (Shelf) Good Good Good Very Good Good Fair Good Good - - - - - - - - Good Good

Flex

Compression Set

Resistance

Oil Resistance:

Oil

Aromatic

Non-Aromatic

Acid Resistance:

Concentrated

Low Temperature

Water Resistance Good Very Good

Alkali Resistance:

Concentrated

Resilience Very Good Fair Fair Very Good Very Good Poor Good Good Good Fair Very Poor Very Good

NATURAL

RUBBER

(93°C)

Excellent Good Good Excellent Excellent Fair Fair Excellent - - - - Excellent Good - - - -

Very Poor

Very Poor

Very Poor

Very Poor

Very Poor

Very Poor

Very Poor

Very Poor

Very Poor

(4)

(-54°C)

BUNA-S

3000

(207)

4500

3000 (207)

(310)

Poor

Good

200°F

Good Good

Very Poor

Very Poor

Good

Very Poor

Very Poor

Very Poor

Very Poor

Very Poor

Very Poor

Very Poor

Good

Fair

-65°F

Good

(-46°C)

Fair

400

(28)

Poor

Fair

200°F

(93°C)

Good

Good

Poor

-50°F

Good

Fair

NITRILE

(NBR)

(41)

4000

(276)

Poor

250°F

(121°C)

Very

Good

Good

Poor

Very Poor

Excellent

Excellent

Very Poor

Good

Excellent

Good

Poor

-40°F

(-40°C)

Very

Good

Good

NEO-

PRENE

600

Excellent

Fair

(93°C)

Excellent Fair Poor Good Poor Poor Good Good Fair

Fair

Very Poor

Fair

Very Poor

Very Poor

(-40°C)

Fair

BUTYL THIOKOL®SILICONE HYPALON

(CR)

3500

(241)

3500

(241)

Good

200°F

Fair

Poor

Fair

Fair

Good

Poor

Good

Fair

Fair

-40°F

Fair Very Good Fair Fair Fair Excellent Fair Fair Very Good

Good

Good

3000

(207)

3000

(207)

Excellent

Good

200°F

(93°C)

Poor

Very Poor

Good

Poor

Very Poor

Very Poor

Poor

Good

Very Poor

Very Poor

Good

Fair

-40°F

(-40°C)

Very Good

Very Good

300

(21)

1500

(103)

Good

Good

140°F

(60°C)

Excellent

Good

Fair

Poor

Excellent

Excellent

Poor

Poor

Excellent

Excellent

Poor

Very Poor

-40°F

(-40°C)

Poor

Poor

200 to 450

(14 to 31)

1100

(76)

Good

Very Good

450°F

(232°C)

Poor

Very Poor

Poor

Very Poor

Poor

Good

Fair

Poor

Poor

Good

Fair

Poor

-100°F

(-73°C)

Fair

Poor

4000

(276)

4400

(303)

Excellent

Very Good

300°F

(149°C)

Fair

Poor

Poor

Very Poor

Fair

Good

Poor

Poor

Poor

Fair

Good

Good

-20°F

(-29°C)

Good

Good

FLUORO-

®

ELASTOMER

(FKM)

- - - - - - - -

2300

(159)

Excellent

Excellent

400°F

(204°C)

Excellent

Very Good

Good

- - - -

Excellent

Excellent

- - - Poor

Good

Very Good

Excellent

Very Good

-30°F

(-34°C)

Excellent

Very Good

(1,2)

POLY-

URETHANE

6500

(448)

Excellent

Excellent

200°F

(93°C)

Very Good

Fair

Poor

- - - -

- - - -

- - - -

- - - Poor

Fair

Good

Fair

Poor

-40°F

(-40°C)

Fair

Poor

POLY-

(2)

(1)

ACRYLIC

100

(7)

1800

(124)

Excellent

Excellent Good

350°F

(177°C)

Good

Poor

Poor

Poor

Excellent

Excellent

Fair

Poor

Fair

Poor

Poor

Poor

-10°F

(-23°C)

Poor

Poor

ETHYLENE-

PROPYLENE

(EPDM)

- - - -

2500

(172)

350°F

(177°C)

Poor

Fair

- - - Poor

Poor

Poor

Poor

Very Good

Fair

Poor

Very Good

Good

-50°F

(-45°C)

Excellent

Good

( 3 )

Page 3

Chemical Compatibility of Elastomers and Metals

661

Te c h n i c a l

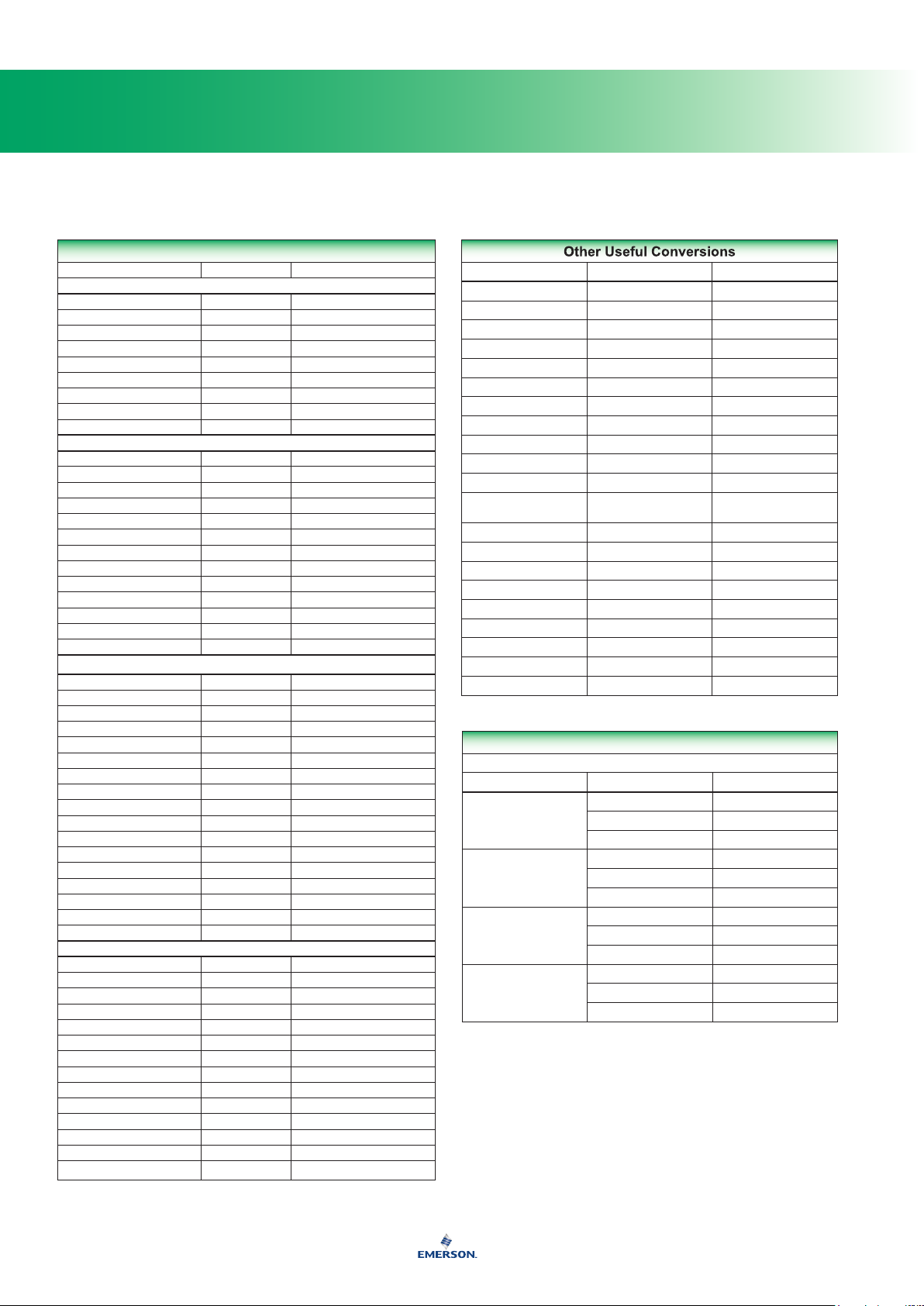

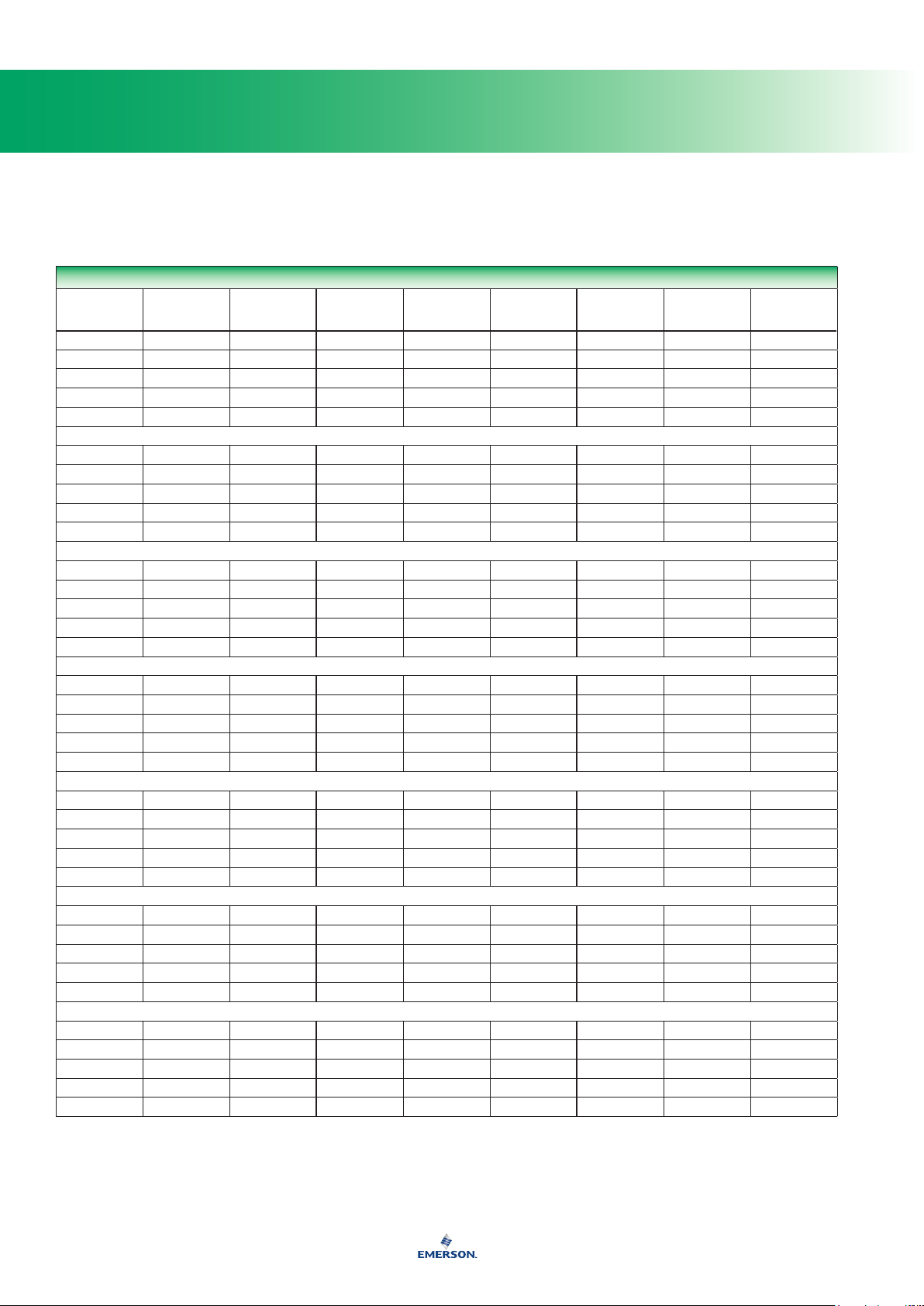

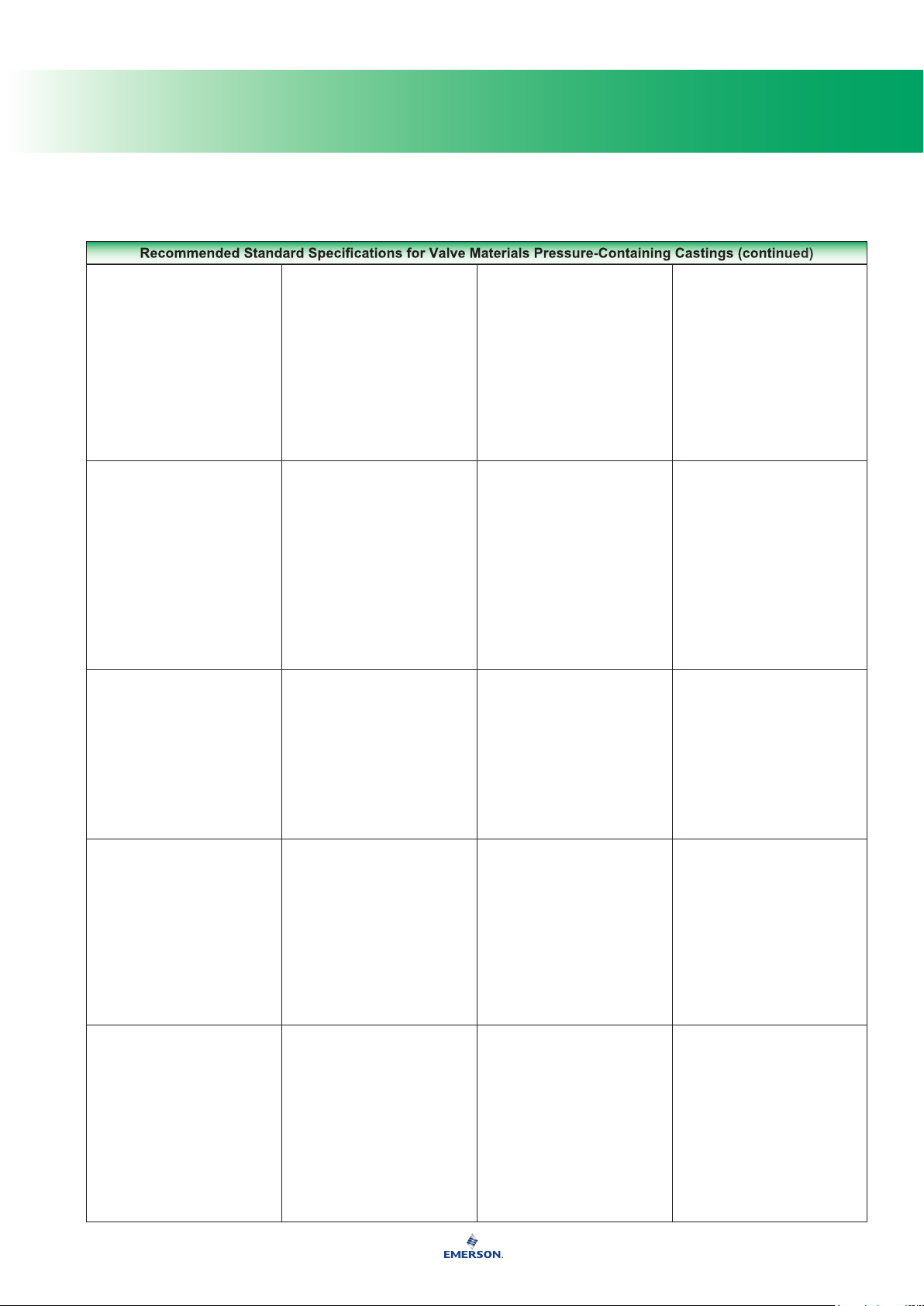

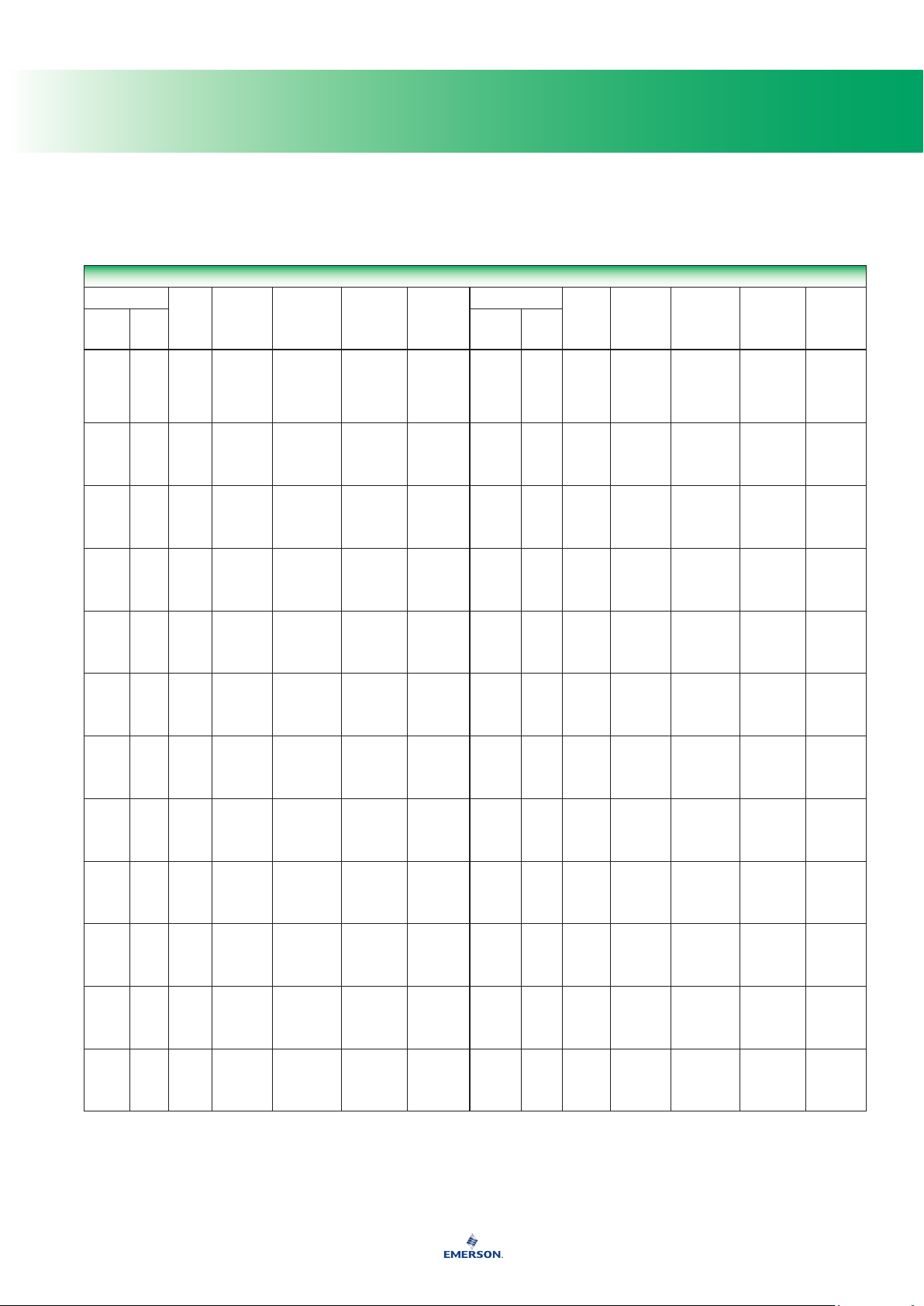

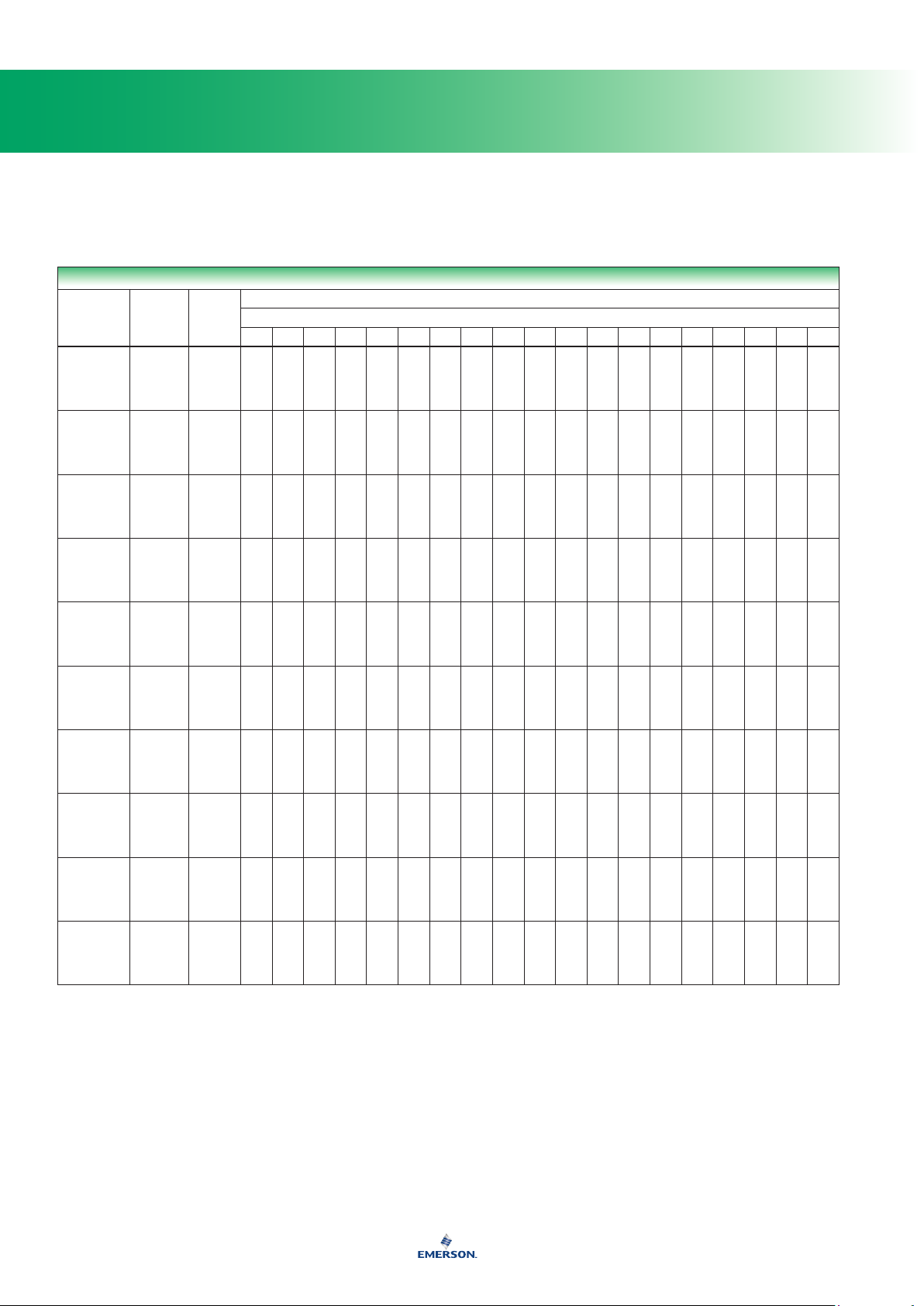

Fluid Compatibility of Elastomers

FLUID

Acetic Acid (30%)

Acetone

Air, Ambient

Air, Hot (200°F (93°C))

Alcohol (Ethyl)

Alcohol (Methyl)

Ammonia (Anhydrous) (Cold)

Ammonia (Gas, Hot)

Beer

Benzene

Brine (Calcium Chloride)

Butadiene Gas

Butane (Gas)

Butane (Liquid)

Carbon Tetrachloride

Chlorine (Dry)

Chlorine (Wet)

Coke Oven Gas

Ethyl Acetate

Ethylene Glycol

Freon 11

Freon 12

Freon 22

Freon 114

Gasoline (Automotive)

Hydrogen Gas

Hydrogen Sulde (Dry)

Hydrogen Sulde (Wet)

Jet Fuel (JP-4)

Methyl Ethyl Ketone (MEK)

MTBE

Natural Gas

Nitric Acid (50 to 100%)

Nitrogen

Oil (Fuel)

Propane

Sulfur Dioxide

Sulfuric Acid (up to 50%)

Sulfuric Acid (50 to 100%)

Water (Ambient)

Water (at 200°F (93°C))

1. Performance worsens with hot temperatures.

A - Recommended

B - Minor to moderate effect. Proceed with caution.

C - Unsatisfactory

N/A - Information not available

Neoprene (CR) Nitrile (NBR) Fluoroelastomer (FKM)

B

C

A

C

A

A

A

B

A

C

A

C

A

C

C

C

C

C

C

A

C

A

A

A

C

A

A

B

B

C

C

A

C

A

C

B

A

B

C

A

C

C

C

A

B

C

A

A

C

A

C

A

C

A

A

C

C

C

C

C

A

B

A

C

A

B

A

(1)

A

C

A

C

C

A

C

A

A

A

C

C

C

A

B

MATERIAL

C

C

A

A

C

C

C

C

A

B

B

B

A

A

A

A

B

A

C

A

A

B

C

B

A

A

C

C

A

C

C

A

B

A

A

A

A

A

A

A

B

Ethylenepropylene

(EPDM)

A

A

A

A

A

A

A

B

A

C

A

C

C

C

C

C

C

C

B

A

C

B

A

A

C

A

A

A

C

A

C

C

C

A

C

C

A

B

B

A

A

Peruoroelastomer

(FFKM)

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

Page 4

Chemical Compatibility of Elastomers and Metals

Te c h n i c a l

662

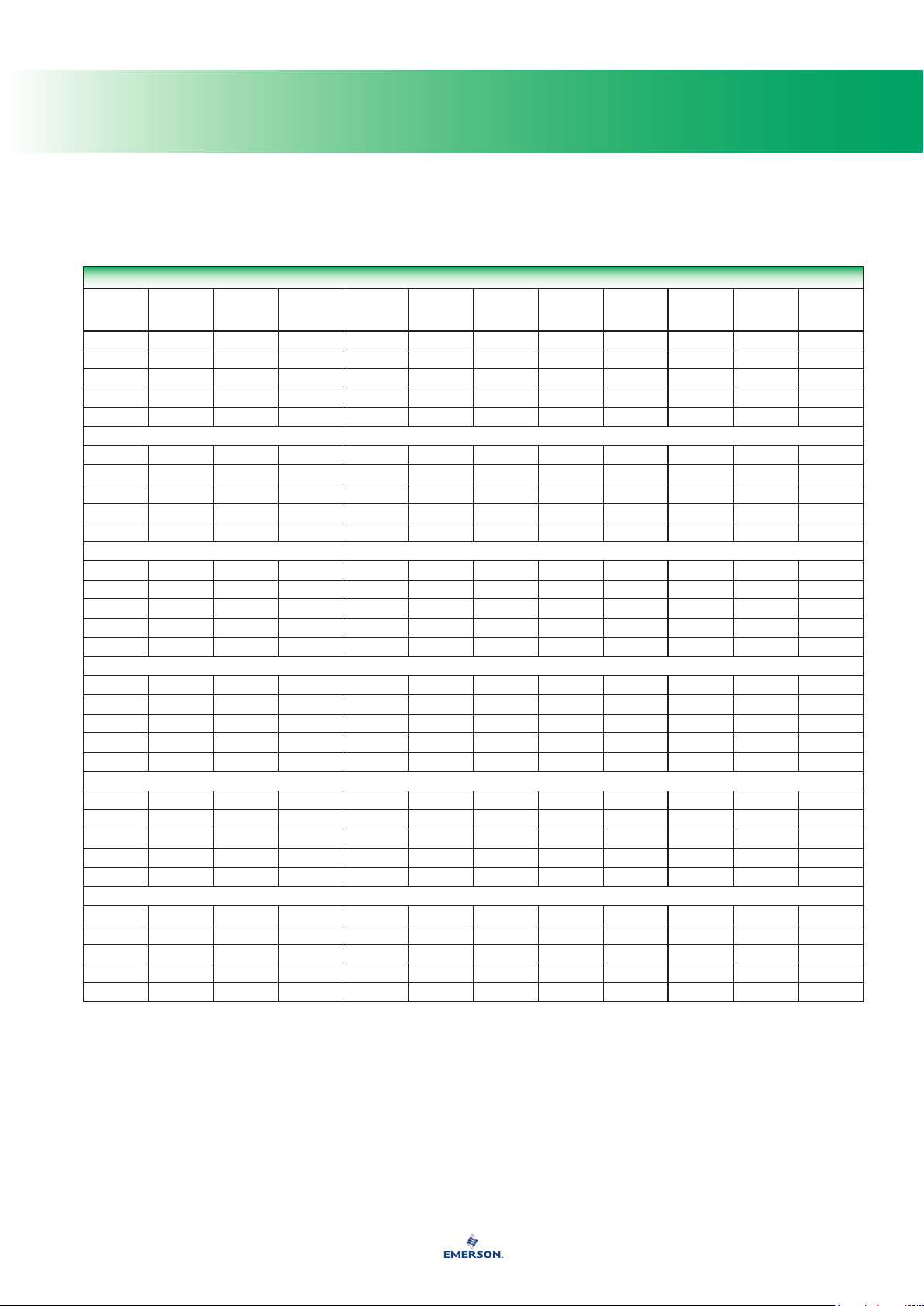

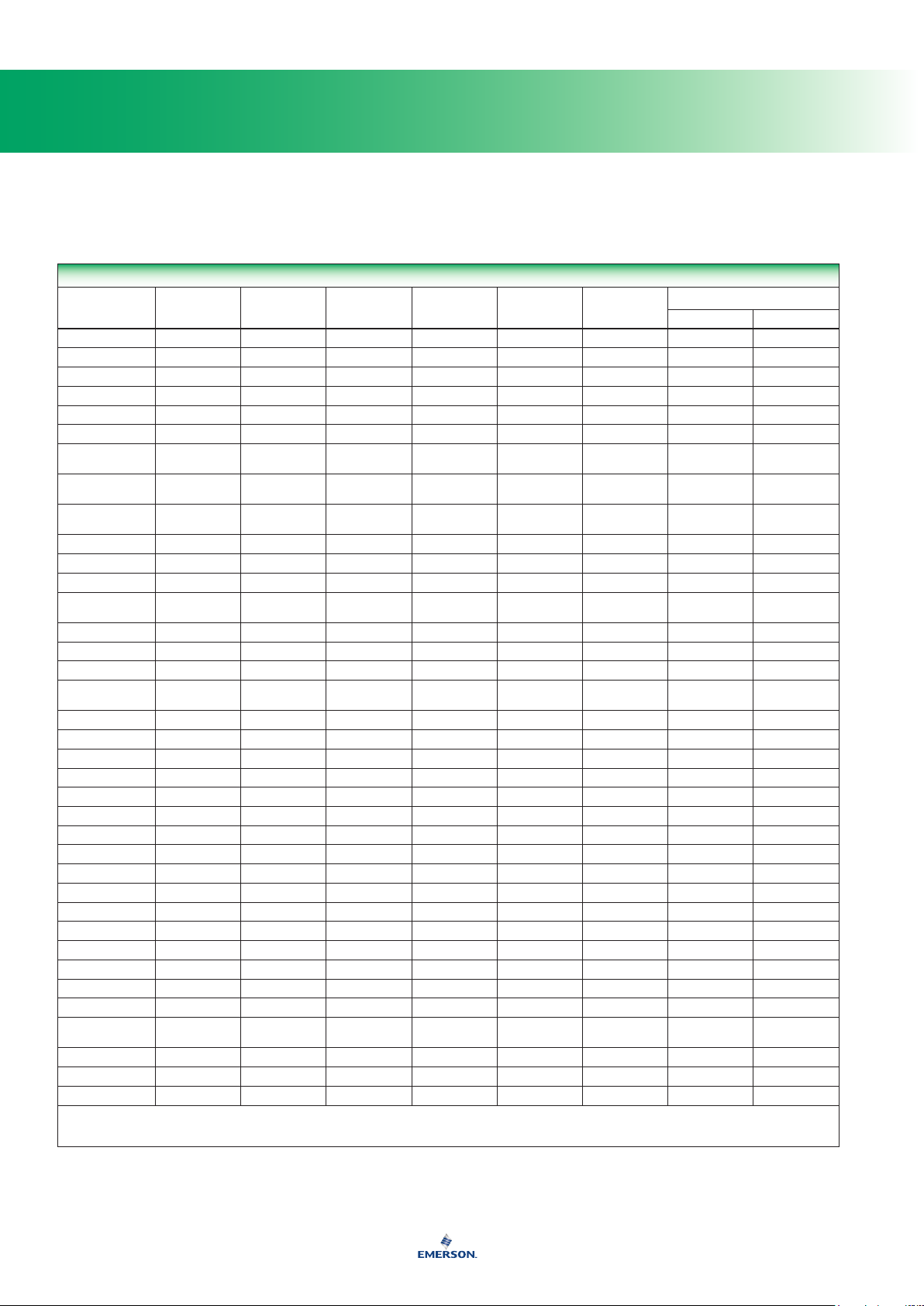

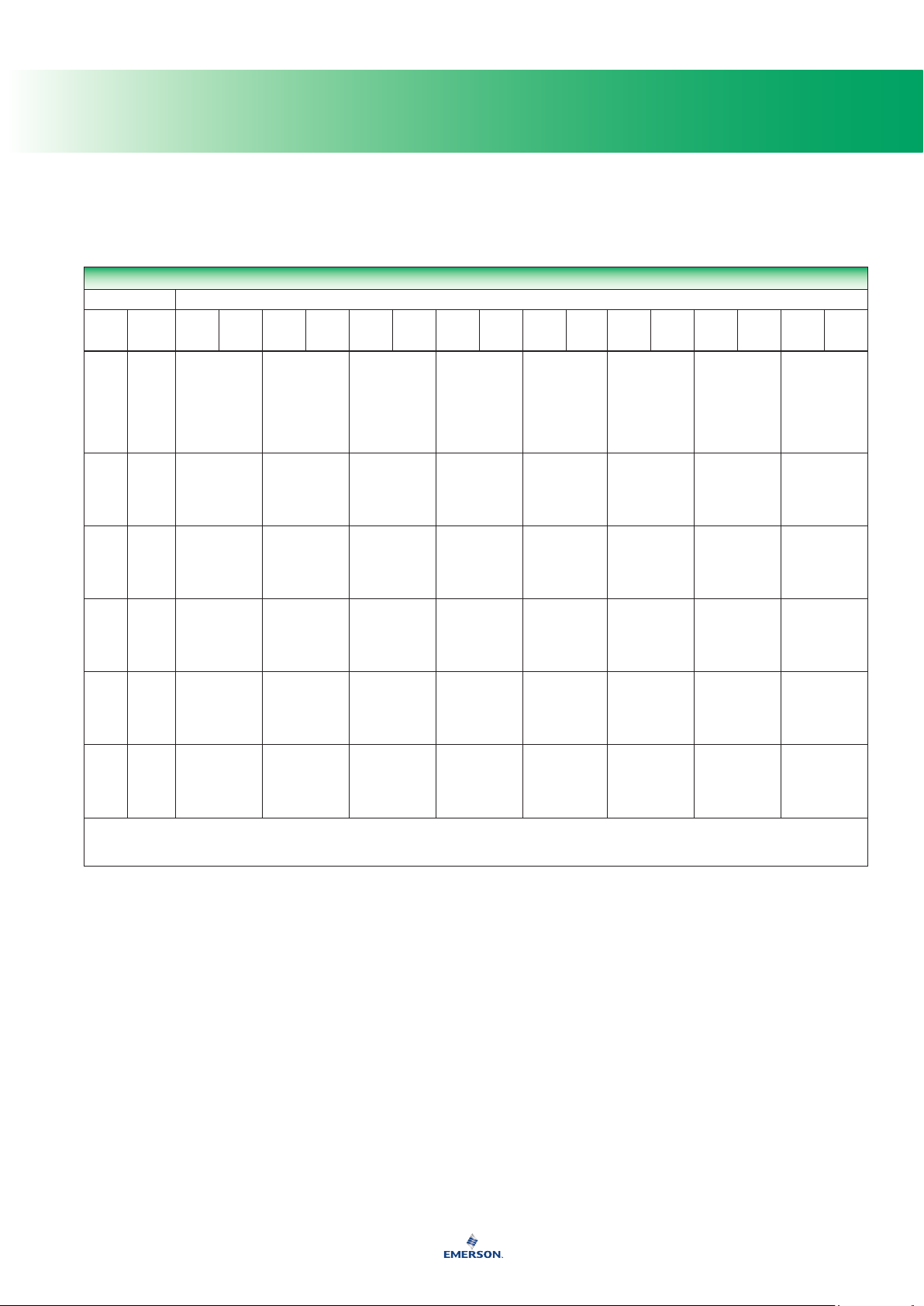

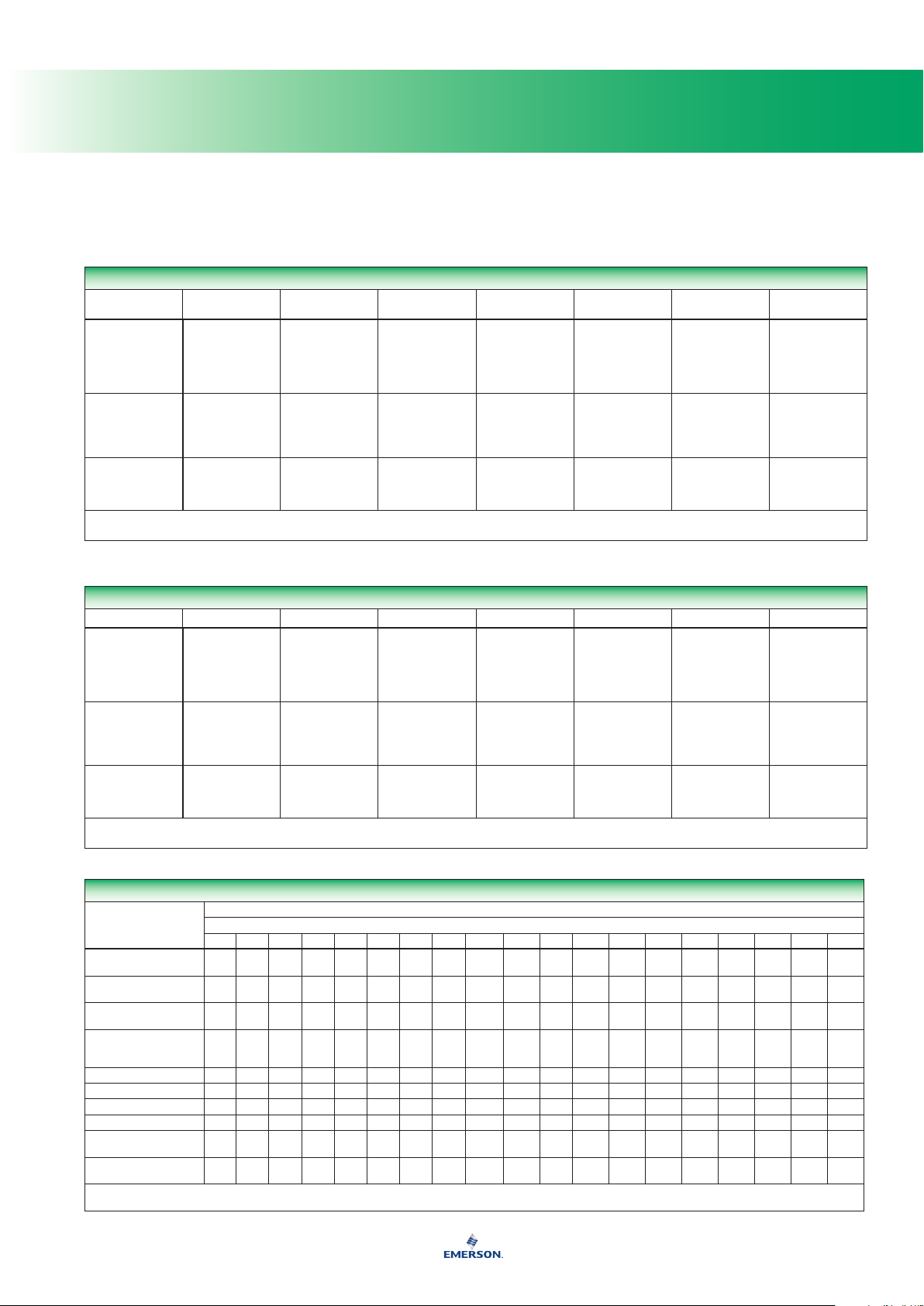

Compatibility of Metals

CORROSION INFORMATION

Material

Fluid

Acetaldehyde

Acetic Acid, Air Free

Acetic Acid, Aerated

Acetic Acid Vapors

Acetone

Acetylene

Alcohols

Aluminum Sulfate

Ammonia

Ammonium Chloride

Ammonium Nitrate

Ammonium Phosphate

(Mono Basic)

Ammonium Sulfate

Ammonium Sulte

Aniline

Asphalt

Beer

Benzene (Benzol)

Benzoic Acid

Boric Acid

Butane

Calcium Chloride

(Alkaline)

Calcium Hypochlorite

Carbolic Acid

Carbon Dioxide, Dry

Carbon Dioxide, Wet

Carbon Disulde

Carbon Tetrachloride

Carbonic Acid

Chlorine Gas, Dry

Chlorine Gas, Wet

Chlorine, Liquid

Chromic Acid

Citric Acid

Coke Oven Gas

Copper Sulfate

Cottonseed Oil

Creosote

Ethane

Ether

Ethyl Chloride

Ethylene

Ethylene Glycol

Ferric Chloride

Formaldehyde

Formic Acid

Freon, Wet

Freon, Dry

Furfural

Gasoline, Rene

A - Recommended

B - Minor to moderate effect. Proceed with caution.

C - Unsatisfactory

IL - Information lacking

Carbon

Steel

A

C

C

C

A

A

A

C

A

C

A

C

C

C

C

A

B

A

C

C

A

B

C

B

A

C

A

B

C

A

C

C

C

IL

A

C

A

A

A

B

C

A

A

C

B

IL

B

B

A

A

Cast

Iron

A

C

C

C

A

A

A

C

A

C

C

C

C

C

C

A

B

A

C

C

A

B

C

B

A

C

A

B

C

A

C

C

C

C

A

C

A

A

A

B

C

A

A

C

B

C

B

B

A

A

S302

or S304

Stainless

Steel

A

B

A

A

A

A

A

A

A

B

A

A

B

A

A

A

A

A

A

A

A

C

B

A

A

A

A

B

B

B

C

C

C

B

A

B

A

A

A

A

A

A

A

C

A

B

B

A

A

A

S316

Stainless

Steel

A

B

A

A

A

A

A

A

A

B

A

A

A

A

A

A

A

A

A

A

A

B

B

A

A

A

A

B

B

B

C

C

B

A

A

B

A

A

A

A

A

A

A

C

A

B

A

A

A

A

Bronze Monel

A

B

A

B

A

IL

A

B

C

B

C

B

B

C

C

A

B

A

A

A

A

C

B

A

A

B

C

A

B

B

C

B

C

A

B

B

A

C

A

A

A

A

A

C

A

A

A

A

A

A

A

B

A

B

A

A

A

B

A

B

C

B

A

C

B

A

A

A

A

A

A

A

B

A

A

A

B

A

A

A

C

C

A

B

B

C

A

A

A

A

A

A

A

C

A

A

A

A

A

A

®

Hastelloy

B

IL

A

A

IL

A

A

A

A

A

A

A

A

A

IL

A

A

A

A

IL

A

A

A

C

A

A

A

A

B

A

A

C

C

C

A

A

IL

A

A

A

A

A

A

IL

C

A

A

A

A

A

A

®

Hastelloy®

Titanium

Durimet®

C

20

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

B

A

A

A

A

A

A

A

A

A

A

A

IL

B

A

A

A

A

A

A

A

A

A

B

A

A

A

A

A

A

A

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

C

B

C

A

A

A

A

A

A

A

A

A

A

C

A

A

A

A

A

A

Cobalt-

Base

Alloy 6

IL

A

A

A

A

IL

A

A

A

A

A

A

A

A

A

IL

A

A

A

A

IL

A

A

A

A

A

A

A

IL

C

A

C

A

A

A

A

A

IL

A

A

A

A

IL

A

A

C

A

A

A

A

IL

IL

B

IL

IL

IL

IL

IL

B

B

B

B

IL

IL

A

A

A

B

A

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

S416

Stainless

Steel

A

C

C

C

A

A

A

C

A

C

C

B

C

B

C

A

B

A

A

B

A

C

C

IL

A

A

B

C

A

C

C

C

C

B

A

A

A

A

A

A

B

A

A

C

A

C

IL

IL

B

A

440C

Stainless

Steel

A

C

C

C

A

A

A

C

A

C

B

B

C

B

C

A

B

A

A

B

A

C

C

IL

A

A

B

A

A

C

C

C

C

B

A

A

A

A

A

A

B

A

A

C

A

C

IL

IL

B

A

17-4PH

Stainless

Steel

A

B

B

B

A

A

A

IL

IL

IL

IL

IL

IL

IL

IL

A

A

A

A

IL

A

IL

IL

IL

A

A

IL

IL

A

C

C

C

C

B

A

A

A

A

A

A

IL

A

A

IL

A

B

IL

IL

IL

A

- continued -

Page 5

Chemical Compatibility of Elastomers and Metals

663

Te c h n i c a l

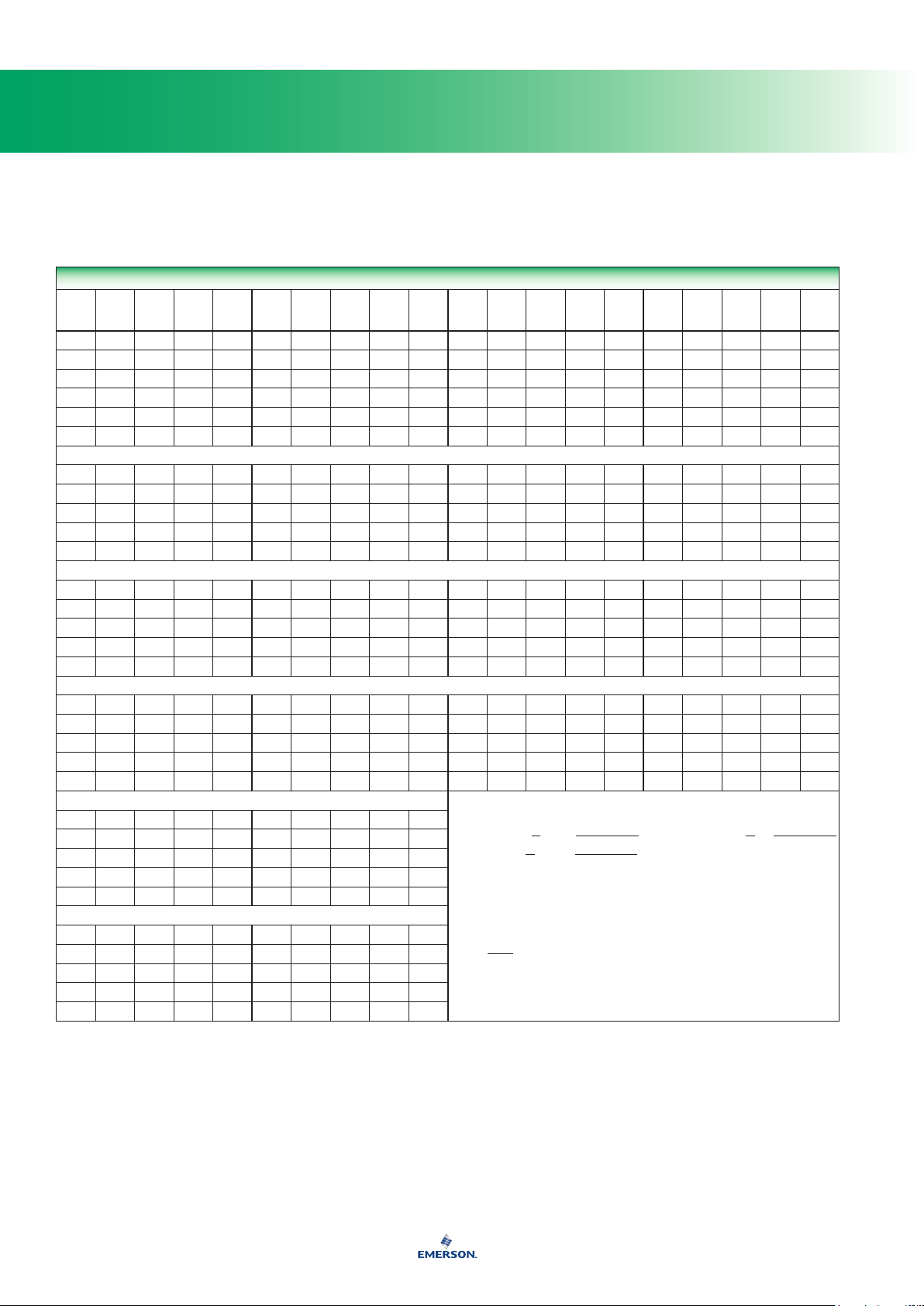

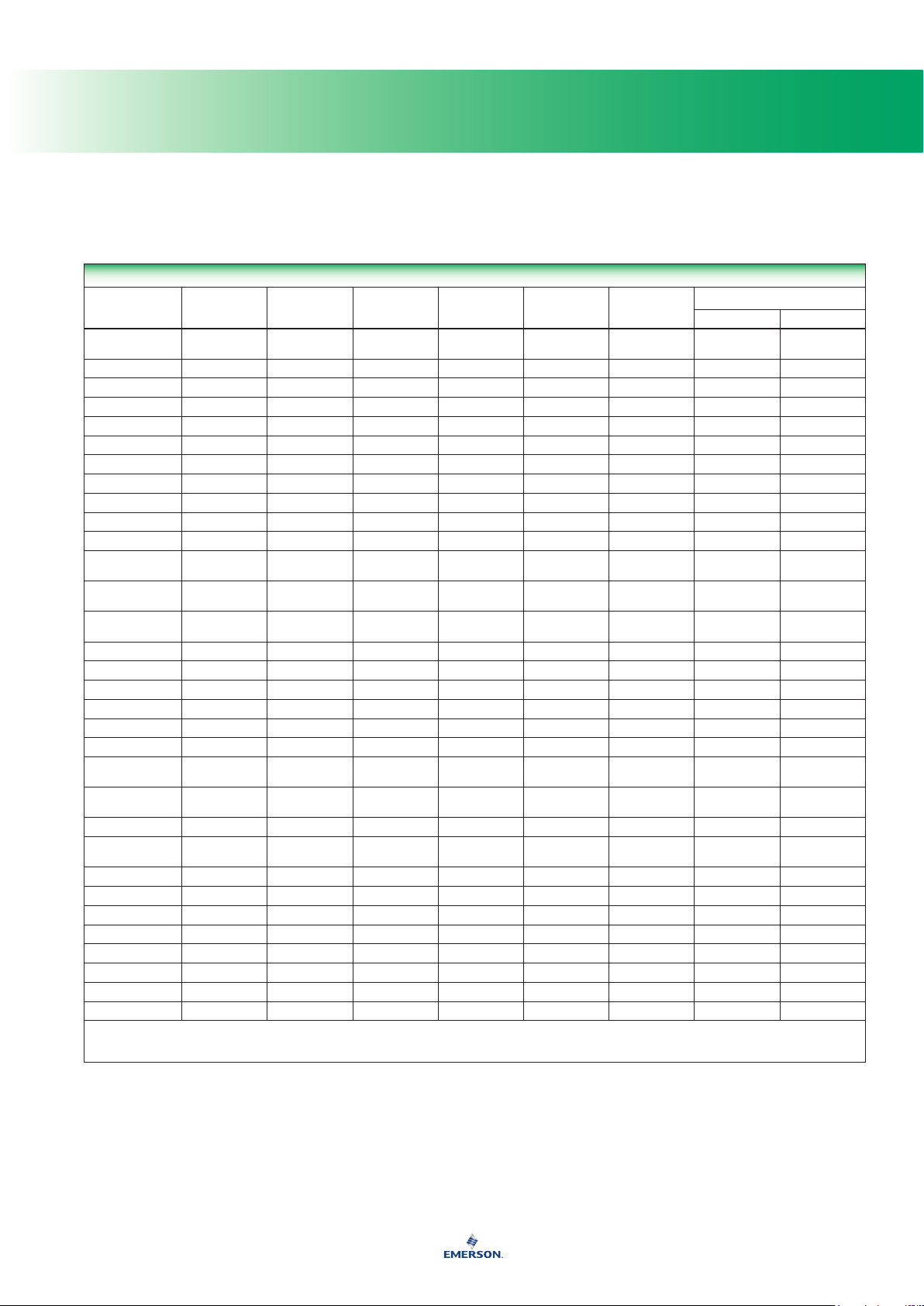

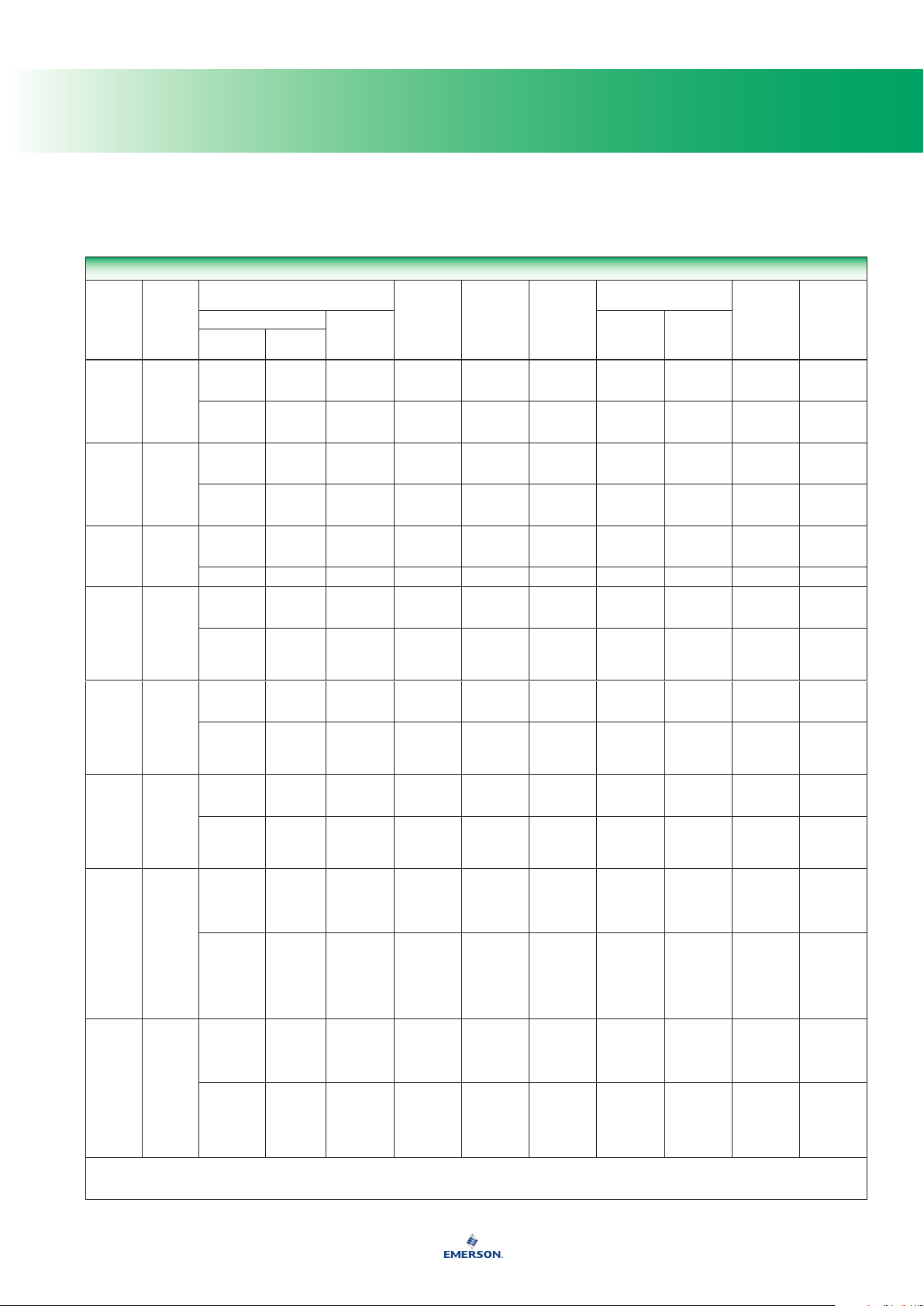

Compatibility of Metals (continued)

CORROSION INFORMATION

Material

Fluid

Carbon

Steel

Cast

Iron

S302

or S304

Stainless

Steel

S316

Stainless

Steel

Bronze Monel

Hastelloy

®

®

Hastelloy® CDurimet®

B

Titanium

20

Cobalt-

Base

Alloy 6

S416

Stainless

Steel

440C

Stainless

Steel

17-4PH

Stainless

Steel

Glucose

Hydrochloric Acid, Aerated

Hydrochloric Acid, Air free

Hydrouoric Acid, Aerated

Hydrouoric Acid, Air free

Hydrogen

Hydrogen Peroxide

Hydrogen Sude, Liquid

Magnesium Hydroxide

Mercury

Methanol

Methyl Ethyl Ketone

Milk

Natural Gas

Nitric Acid

Oleic Acid

Oxalic Acid

Oxygen

Petroleum Oils, Rened

Phosphoric Acid, Aerated

Phosphoric Acid, Air Free

Phosphoric Acid Vapors

Picric Acid

Potassium Chloride

Potassium Hydroxide

Propane

Rosin

Silver Nitrate

Sodium Acetate

Sodium Carbonate

Sodium Chloride

Sodium Chromate

Sodium Hydroxide

Sodium Hypochloride

Sodium Thiosulfate

Stannous Chloride

Stearic Acid

Sulfate Liquor (Black)

Sulfur

Sulfur Dioxide, Dry

Sulfur Trioxide, Dry

Sufuric Acid (Aerated)

Sufuric Acid (Air Free)

Sulfurous Acid

Tar

Trichloroethylene

Turpentine

Vinegar

Water, Boiler Feed

Water, Distilled

Water, Sea

Whiskey and Wines

Zinc Chloride

Zinc Sulfate

A - Recommended

B - Minor to moderate effect. Proceed with caution.

C - Unsatisfactory

IL - Information lacking

A

A

C

C

C

C

B

C

A

C

A

A

IL

A

C

C

A

A

A

A

A

A

A

A

C

C

A

A

C

C

C

C

C

C

A

A

A

A

C

C

C

C

C

C

C

C

B

B

B

B

A

A

B

B

C

C

A

A

A

A

C

C

A

A

A

A

C

C

C

C

B

B

A

C

A

A

A

A

A

A

A

A

C

C

C

C

C

C

A

A

B

B

B

B

C

C

B

C

A

A

B

B

C

C

C

C

C

C

A

C

C

C

C

A

A

A

A

A

A

A

A

A

A

A

B

A

A

A

A

B

A

A

A

A

A

A

B

A

B

A

A

C

A

C

A

A

A

A

A

C

C

B

A

B

A

A

A

A

B

A

C

A

A

C

C

B

B

A

A

A

A

A

A

A

A

A

B

A

B

A

A

A

A

B

A

A

A

A

A

A

A

A

B

A

A

C

A

A

A

A

A

A

A

C

C

B

A

A

A

A

A

A

B

A

C

A

B-C

A

A

B

C

A

A

A

C

B

A

A

C

C

C

C

C

C

C

A

A

A

C

A

C

C

B

A

C

B

A

A

A

A

A

A

A

A

C

C

B

A

B

B

A

A

A

A

C

C

C

B

C

C

C

C

B

B

B

A

A

A

A

A

C

C

A

A

A

A

A

A

A

A

C

A

B-C

C

C

C

B

B

B

C

A

C

A

A

A

A

A

C

C

B

B

B

C

A

A

A

B

A

A

A

A

B

C

A

A

A

A

A

A

A

B

A

A

A

A

A

A

A

C

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

C

A

A

A

A

A

B

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

B

B

A

A

A

B

A

A

A

A

A

A

A

B

A

A

A

A

A

A

IL

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

C

C

C

C

B

C

B

C

A

A

A

A

B

A

A

A

A

A

A

A

A

IL

A

A

A

A

A

A

A

A

A

B

A

A

A

A

A

B

A

B

A

B

A

IL

A

A

A

A

A

A

A

IL

A

A

A

A

A

A

A

A

A

A

A

A

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

B

A

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

IL

A

A

A

A

A

A

A

A

A

A

B

A

A

A

B

C

B

C

B

C

IL

C

A

A

IL

B

A

C

A

A

A

A

A

A

A

A

A

C

A

A

C

C

A

A

B

B

A

A

A

A

A

C

A

C

C

C

IL

B

IL

C

IL

B

A

A

A

A

B

B

A

A

A

B

A

B

A

A

A

B

IL

C

IL

B

IL

C

B

B

A

IL

A

A

A

B

A

B

B

C

B

C

B

C

A

A

B

A

C

B

B

C

C

C

B

A

C

C

C

C

A

B

C

A

A

B

A

C

A

C

A

B

A

A

C

C

C

B

C

B

A

A

B

A

B

B

A

B

C

B

C

B

IL

A

B

B

C

C

C

A

B

A

C

A

B

C

C

C

B

A

C

C

C

IL

A

IL

IL

IL

B

A

A

C

A

B

IL

IL

A

A

IL

IL

IL

IL

IL

IL

A

A

IL

A

A

B

A

A

IL

IL

IL

IL

IL

A

IL

IL

C

C

IL

A

IL

A

A

A

IL

A

IL

IL

IL

Page 6

Regulator Tips

664

Te c h n i c a l

1. All regulators should be installed and used in accordance with

federal, state, and local codes and regulations.

2. Adequate overpressure protection should be installed to protect

the regulator from overpressure. Adequate overpressure

protection should also be installed to protect all downstream

equipment in the event of regulator failure.

3. Downstream pressures signicantly higher than the regulator's

pressure setting may damage soft seats and

other internal parts.

4. If two or more available springs have published pressure

ranges that include the desired pressure setting, use the spring

with the lower range for better accuracy.

5. The recommended selection for orice diameters is the

smallest orice that will handle the ow.

6. Most regulators shown in this application guide are generally

suitable for temperatures to 180°F (82°C). With high

temperature uoroelastomers (if available), the regulators

can be used for temperatures to 300°F (149°C). Check

the temperature capabilities to determine materials and

temperature ranges available. Use stainless steel diaphragms

and seats for higher temperatures, such as steam service.

7. The full advertised range of a spring can be utilized without

sacricing performance or spring life.

8. Regulator body size should not be larger than the pipe size. In

many cases, the regulator body is one size smaller than the

pipe size.

9. Do not oversize regulators. Pick the smallest orice size or

regulator that will work. Keep in mind when sizing a station

that most restricted trims that do not reduce the main port size

do not help with improved low ow control.

10. Speed of regulator response, in order:

• Direct-operated

• Two-path pilot-operated

• Unloading pilot-operated

• Control valve

Note: Although direct-operated regulators give the fastest

response, all types provide quick response.

11. When a regulator appears unable to pass the published

ow rate, be sure to check the inlet pressure measured at

the regulator body inlet connection. Piping up to and away

from regulators can cause signicant owing pressure losses.

12. When adjusting setpoint, the regulator should be owing at

least ve percent of the normal operating ow.

13. Direct-operated regulators generally have faster response to

quick ow changes than pilot-operated regulators.

14. Droop is the reduction of outlet pressure experienced by

pressure-reducing regulators as the ow rate increases. It is

stated as a percent, in inches of water column (mbar) or in

pounds per square inch (bar) and indicates the difference

between the outlet pressure setting made at low ow rates

and the actual outlet pressure at the published maximum

ow rate. Droop is also called offset or proportional band.

15. Downstream pressure always changes to some extent when

inlet pressure changes.

16. Most soft-seated regulators will maintain the pressure within

reasonable limits down to zero ow. Therefore, a regulator

sized for a high ow rate will usually have a turndown ratio

sufcient to handle pilot-light loads during off cycles.

17. Do not undersize the monitor set. It is important to realize

that the monitor regulator, even though it is wide-open,

will require pressure drop for ow. Using two identical

regulators in a monitor set will yield approximately

70 percent of the capacity of a single regulator.

18. Diaphragms leak a small amount due to migration of gas

through the diaphragm material. To allow escape of this gas,

be sure casing vents (where provided) remain open.

19. Use control lines of equal or greater size than the control tap

on the regulator. If a long control line is required, make it

bigger. A rule of thumb is to use the next nominal pipe size

for every 20 feet (6,1 m) of control line. Small control

lines cause a delayed response of the regulator, leading

to increased chance of instability. 3/8-inch (9,5 mm) OD

tubing is the minimum recommended control line size.

20. For every 15 psid (1,0 bar d) pressure differential

across the regulator, expect approximately a one degree

drop in gas temperature due to the natural refrigeration

effect. Freezing is often a problem when the ambient

temperature is between 30° and 45°F (-1° and 7°C).

21. A disk with a cookie cut appearance probably means you had

an overpressure situation. Thus, investigate further.

22. When using relief valves, be sure to remember that the

reseat point is lower than the start-to-bubble point. To

avoid seepage, keep the relief valve setpoint far enough

above the regulator setpoint.

Page 7

Regulator Tips

665

Te c h n i c a l

23. Vents should be pointed down to help avoid the accumulation

of water condensation or other materials in the spring case.

24. Make control line connections in a straight run of pipe about

10 pipe diameters downstream of any area of turbulence,

such as elbows, pipe swages, or block valves.

25. When installing a working monitor station, get as much

volume between the two regulators as possible. This

will give the upstream regulator more room to control

intermediate pressure.

26. Cutting the supply pressure to a pilot-operated regulator

reduces the regulator gain or sensitivity and, thus, may

improve regulator stability. (This can only be used with two

path control.)

27. Regulators with high ows and large pressure drops generate

noise. Noise can wear parts which can cause failure and/or

inaccurate control. Keep regulator noise below 110 dBA.

28. Do not place control lines immediately downstream of rotary

or turbine meters.

29. Keep vents open. Do not use small diameter, long vent lines.

Use the rule of thumb of the next nominal pipe size every

10 feet (3,1 m) of vent line and 3 feet (0,9 m) of vent line

for every elbow in the line.

30. Fixed factor measurement (or PFM) requires the regulator

to maintain outlet pressure within ±1% of absolute pressure.

For example: Setpoint of 2 psig + 14.7 psia = 16.7 psia x

0.01 = ±0.167 psi. (Setpoint of 0,14 bar + 1,01 bar = 1,15 bar x

0,01 = ±0,0115 bar.)

31. Regulating Cg (coefcient of ow) can only be used for

calculating ow capacities on pilot-operated regulators.

Use capacity tables or ow charts for determining a direct-

operated regulator’s capacity.

32. Do not make the setpoints of the regulator/monitor too close

together. The monitor can try to take over if the setpoints are

too close, causing instability and reduction of capacity. Set

them at least one proportional band apart.

33. Consider a butt-weld end regulator where available to lower

costs and minimize ange leakages.

34. Do not use needle valves in control lines; use full-open

valves. Needle valves can cause instability.

35. Burying regulators is not recommended. However, if you

must, the vent should be protected from ground moisture

and plugging.

Page 8

666

Te c h n i c a l

Conversions, Equivalents, and Physical Data

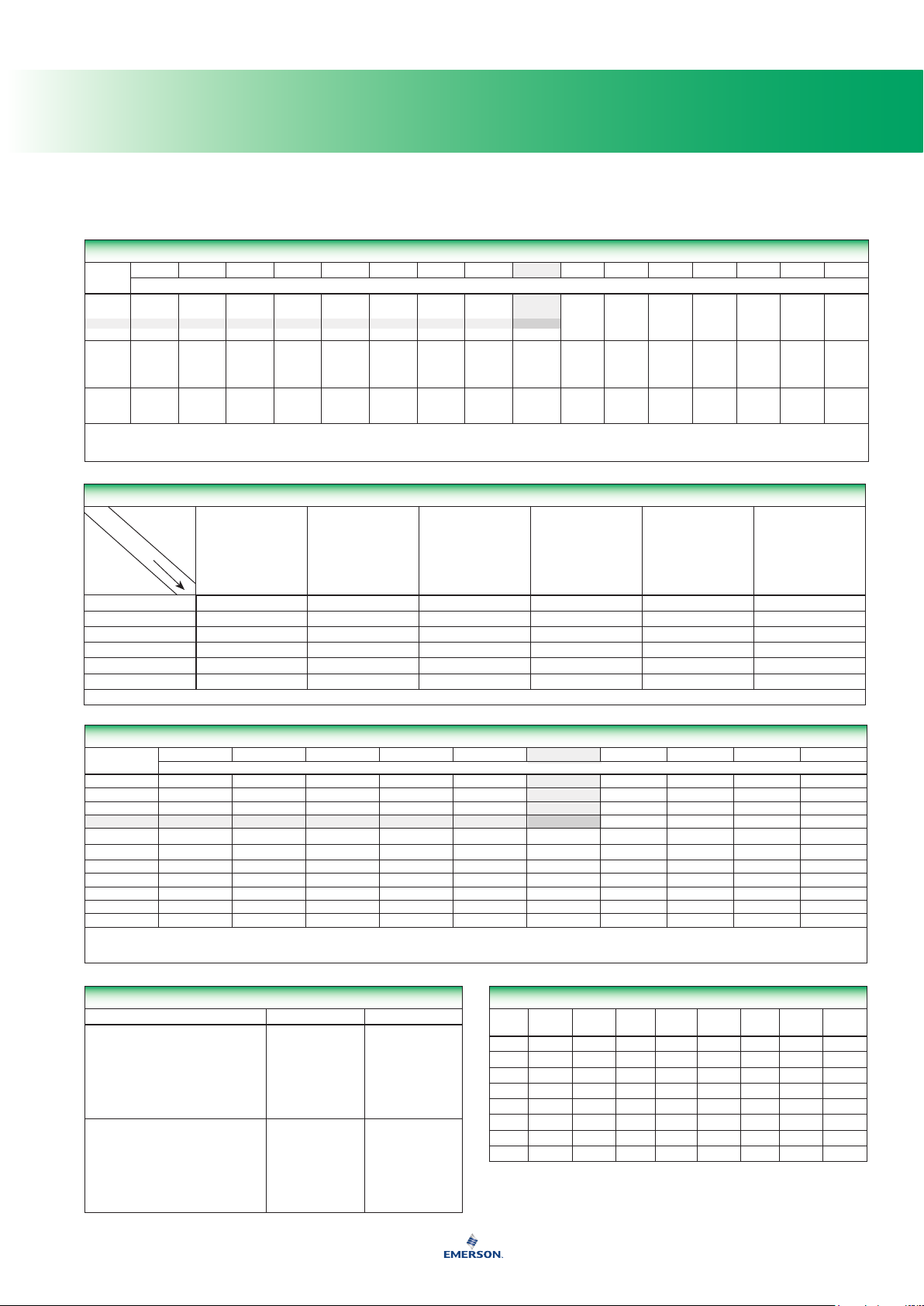

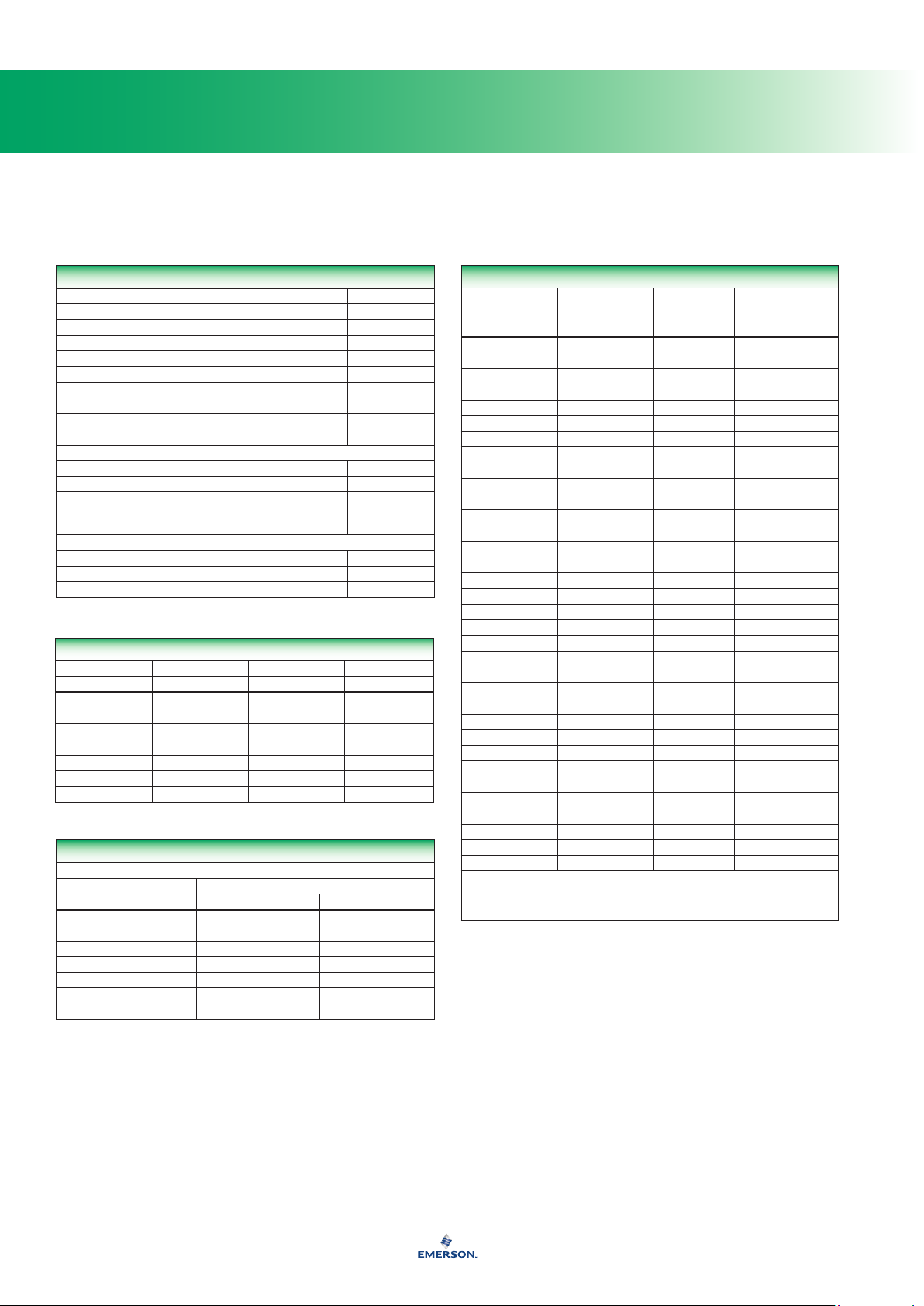

Pressure Equivalents

TO

OBTAIN

BY

MULTIPLY

NUMBER

OF

Kg per square cm 1 14.22 0.9678 0,98067 28.96 98,067 394.05 32.84

Pounds per square inch 0,07031 1 0.06804 0,06895 2.036 6,895 27.7 2.309

Atmosphere 1,0332 14.696 1 1,01325 29.92 101,325 407.14 33.93

Bar 1,01972 14.5038 0.98692 1 29.53 100 402.156 33.513

Inches of Mercury 0,03453 0.4912 0.03342 0,033864 1 3,3864 13.61 1.134

Kilopascals 0,0101972 0.145038 0.0098696 0,01 0.2953 1 4.02156 0.33513

Inches of Water 0,002538 0.0361 0.002456 0,00249 0.07349 0,249 1 0.0833

Feet of Water 0,3045 0.4332 0.02947 0,029839 0.8819 2,9839 12 1

1 ounce per square inch = 0.0625 pounds per square inch

KG PER

SQUARE

CENTIMETER

POUNDS PER

SQUARE INCH

ATMOSPHERE BAR

INCHES OF

MERCURY

KILOPASCALS

INCHES OF

WATER COLUMN

FEET OF

WATER COLUMN

0,414

1,103

1,793

2,482

3,172

3,861

4,551

5,240

5,929

6,619

7,308

(1)

0,482

1,172

1,862

2,551

3,241

3,930

4,619

5,309

5,998

6,688

7,377

0,552

1,241

1,931

2,620

3,309

3,999

4,688

5,378

6,067

6,757

7,446

0,621

1,310

1,999

2,689

3,378

4,068

4,758

5,447

6,136

6,826

7,515

Pressure Conversion - Pounds per Square Inch to Bar

POUNDS PER

SQUARE INCH

0

10

20

30

40

50

60

70

80

90

100

1. To convert to kilopascals, move decimal point two positions to the right; to convert to megapascals, move decimal point one position to the left.

*Note: Round off decimal points to provide no more than the desired degree of accuracy.

To use this table, see the shaded example.

25 psig (20 from the left column plus ve from the top row) = 1,724 bar

0 1 2 3 4 5 6 7 8 9

Bar

0,000

0,689

1,379

2,068

2,758

3,447

4,137

4,826

5,516

6,205

6,895

0,069

0,758

1,448

2,137

2,827

3,516

4,275

4,964

5,585

6,274

6,964

0,138

0,827

1,517

2,206

2,896

3,585

4,275

4,964

5,654

6,343

7,033

0,207

0,896

1,586

2,275

2,965

3,654

4,344

5,033

5,723

6,412

7,102

0,276

0,965

1,655

2,344

3,034

3,723

4,413

5,102

5,792

6,481

7,171

0,345

1,034

1,724*

2,413

3,103

3,792

4,482

5,171

5,861

6,550

7,239

Volume Equivalents

TO

OBTAIN

CUBIC

BY

MULTIPLY

NUMBER

OF

Cubic Decimeters (Liters) 1 61.0234 0.03531 1.05668 0.264178 0,220083 0.00629

Cubic Inches 0,01639 1 5.787 x 10

Cubic Feet 28,317 1728 1 29.9221 7.48055 6,22888 0.1781

U.S. Quart 0,94636 57.75 0.03342 1 0.25 0,2082 0.00595

U.S. Gallon 3,78543 231 0.13368 4 1 0,833 0.02381

Imperial Gallon 4,54374 277.274 0.16054 4.80128 1.20032 1 0.02877

U.S. Barrel (Petroleum) 158,98 9702 5.6146 168 42 34,973 1

1 cubic meter = 1,000,000 cubic centimeters

1 liter = 1000 milliliters = 1000 cubic centimeters

DECIMETERS

(LITERS)

CUBIC INCHES CUBIC FEET U.S. QUART U.S. GALLON IMPERIAL GALLON

-4

1.01732 0.004329 0,003606 0.000103

U.S. BARREL

(PETROLEUM)

Page 9

667

Te c h n i c a l

Conversions, Equivalents, and Physical Data

Volume Rate Equivalents

TO

OBTAIN

BY

MULTIPLY

NUMBER

OF

Liters per Minute 1 0,06 2.1189 60 0.264178 9.057

Cubic Meters per Hour 16,667 1 35.314 1000 4.403 151

Cubic Feet per Hour 0,4719 0,028317 1 28.317 0.1247 4.2746

Liters per Hour 0,016667 0,001 0.035314 1 0.004403 0.151

U.S. Gallons per Minute 3,785 0,2273 8.0208 227.3 1 34.28

U.S. Barrels per Day 0,1104 0,006624 0.23394 6.624 0.02917 1

LITERS

PER MINUTE

CUBIC METERS

PER HOUR

CUBIC FEET

PER HOUR

LITERS

PER HOUR

U.S. GALLONS

PER MINUTE

U.S. BARRELS

PER DAY

Mass Conversion - Pounds to Kilograms

POUNDS

1 pound = 0,4536 kilograms

*NOTE: To use this table, see the shaded example.

25 pounds (20 from the left column plus ve from the top row) = 11,34 kilograms

0 1 2 3 4 5 6 7 8 9

Kilograms

0

0,00

0,45

0,91

1,36

1,81

2,27

10

4,54

20

9,07

30

13,61

40

18,14

50

22,68

60

27,22

70

31,75

809036,29

40,82

4,99

9,53

14,06

18,60

23,13

27,67

32,21

36,74

41,28

5,44

9,98

14,52

19,05

23,59

28,12

32,66

37,20

41,73

5,90

10,43

14,97

19,50

24,04

28,58

33,11

37,65

42,18

6,35

10,89

15,42

19,96

24,49

29,03

33,57

38,10

42,64

6,80

11,34*

15,88

20,41

24,95

29,48

34,02

38,56

43,09

2,72

7,26

11,79

16,33

20,87

25,40

29,94

34,47

39,01

43,55

3,18

7,71

12,25

16,78

21,32

25,86

30,39

34,93

39,46

44,00

3,63

8,16

12,70

17,24

21,77

26,31

30,84

35,38

39,92

44,45

4,08

8,62

13,15

17,69

22,23

26,76

31,30

35,83

40,37

44,91

Temperature Conversion Formulas

TO CONVERT FROM TO SUBSTITUTE IN FORMULA

Degrees Celsius Degrees Fahrenheit (°C x 9/5) + 32

Degrees Celsius Kelvin (°C + 273.16)

Degrees Fahrenheit Degrees Celsius (°F - 32) x 5/9

Degrees Fahrenheit Degrees Rankine (°F + 459.69)

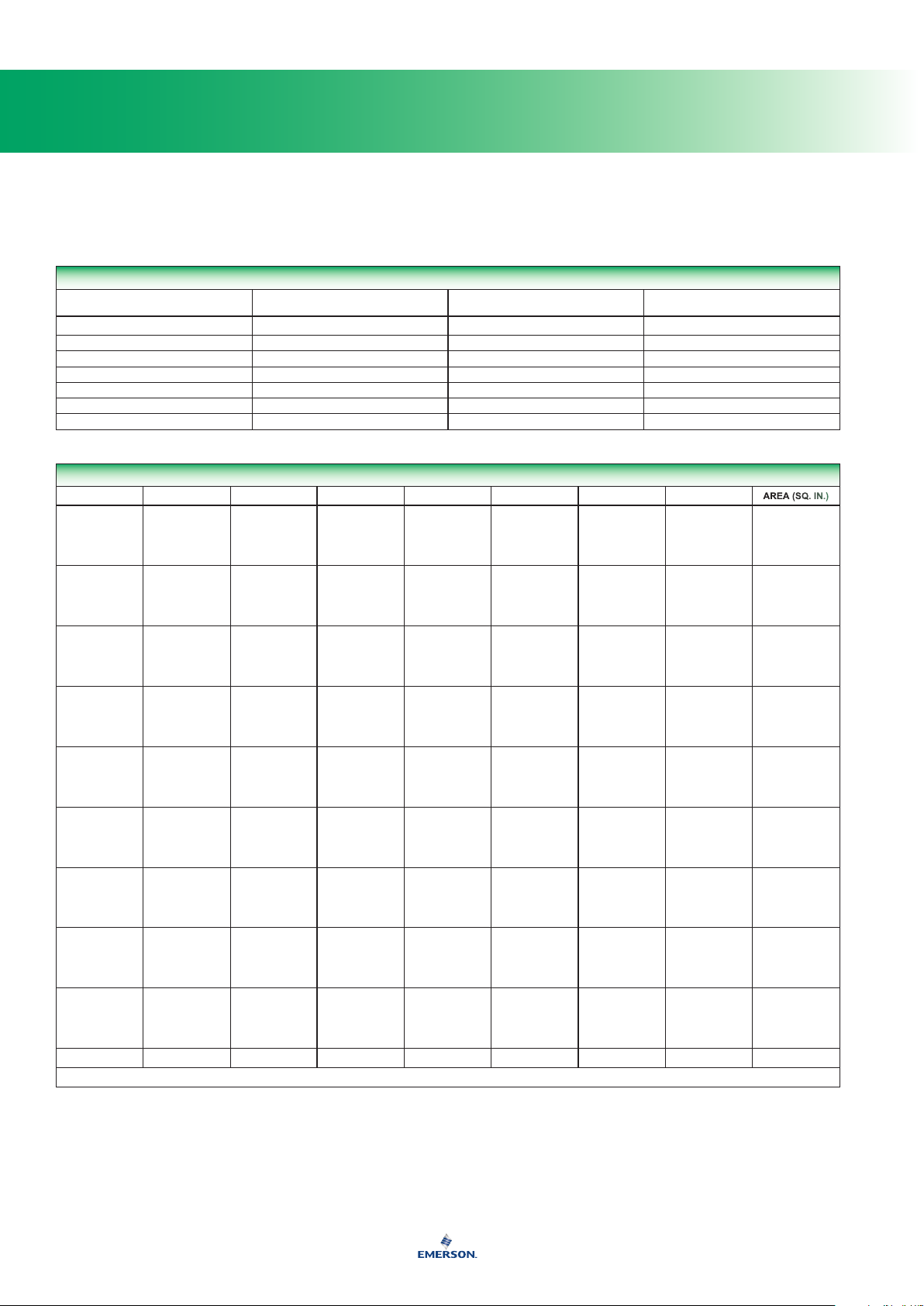

Area Equivalents

TO

OBTAIN

BY

MULTIPLY

NUMBER

OF

Square Meters 1 1549.99 10.7639 3.861 x 10

Square Inches 0,0006452 1 6.944 x 10-32.491 x 10

Square Feet 0,0929 144 1 3.587 x 10-89,29 x 10

Square Miles 2 589 999 - - - - 27,878,400 1 2,59

Square Kilometers 1 000 000 - - - - 10,763,867 0.3861 1

1 square meter = 10 000 square centimeters

1 square millimeter = 0,01 square centimeter = 0.00155 square inches

SQUARE

METERS

SQUARE

INCHES

SQUARE

FEET

SQUARE

MILES

SQUARE

KILOMETERS

-7

-10

6,452 x 10

1 x 10

Kinematic-Viscosity Conversion Formulas

VISCOSITY SCALE RANGE OF t, SEC

Saybolt Universal 32 < t < 100 t > 100

Saybolt Furol 25 < t < 40 t > 40

Redwood No. 1 34 < t < 100 t > 100

Redwood Admiralty - - - - 0.027t - 20/t

Engler - - - - 0.00147t - 3.74/t

KINEMATIC VISCOSITY,

STROKES

0.00226t - 1.95/t

0.00220t - 1.35/t

0.0224t - 1.84/t

0.0216t - 0.60/t

0.00226t - 1.79/t

0.00247t - 0.50/t

-6

-10

-8

Page 10

668

Te c h n i c a l

Conversions, Equivalents, and Physical Data

Conversion Units

MULTIPLY BY TO OBTAIN

Volume

Cubic centimeter 0.06103 Cubic inches

Cubic feet 7.4805 Gallons (US)

Cubic feet 28.316 Liters

Cubic feet 1728 Cubic inches

Gallons (US) 0.1337 Cubic feet

Gallons (US) 3.785 Liters

Gallons (US) 231 Cubic inches

Liters 1.057 Quarts (US)

Liters 2.113 Pints (US)

Miscellaneous

BTU 0.252 Calories

Decitherm 10,000 BTU

Kilogram 2.205 Pounds

Kilowatt Hour 3412 BTU

Ounces 28.35 Grams

Pounds 0.4536 Kilograms

Pounds 453.5924 Grams

Pounds 21,591 LPG BTU

Therm 100,000 BTU

API Bbls 42 Gallons (US)

Gallons of Propane 26.9 KWH

HP 746 KWH

HP (Steam) 42,418 BTU

Pressure

Grams per square centimeter 0.0142 Pounds per square inch

Inches of mercury 0.4912 Pounds per square inch

Inches of mercury 1.133 Feet of water

Inches of water 0.0361 Pounds per square inch

Inches of water 0.0735 Inches of mercury

Inches of water 0.5781 Ounces per square inch

Inches of water 5.204 Pounds per foot

kPa 100 Bar

Kilograms per square centimeter 14.22 Pounds per square inch

Kilograms per square meter 0.2048 Pounds per square foot

Pounds per square inch 0.06804 Atmospheres

Pounds per square inch 0.07031 Kilograms per square centimeter

Pounds per square inch 0.145 KPa

Pounds per square inch 2.036 Inches of mercury

Pounds per square inch 2.307 Feet of water

Pounds per square inch 14.5 Bar

Pounds per square inch 27.67 Inches of water

Length

Centimeters 0.3937 Inches

Feet 0.3048 Meters

Feet 30.48 Centimeters

Feet 304.8 Millimeters

Inches 2.540 Centimeters

Inches 25.40 Millimeters

Kilometer 0.6214 Miles

Meters 1.094 Yards

Meters 3.281 Feet

Meters 39.37 Inches

Miles (nautical) 1853 Meters

Miles (statute) 1609 Meters

Yards 0.9144 Meters

Yards 91.44 Centimeters

Other Useful Conversions

TO CONVERT FROM TO MULTIPLY BY

Cubic feet of methane BTU 1000 (approximate)

Cubic feet of water Pounds of water 62.4

Degrees Radians 0,01745

Gallons Pounds of water 8.336

Grams Ounces 0.0352

Horsepower (mechanical) Foot pounds per minute 33,000

Horsepower (electrical) Watts 746

Kg Pounds 2.205

Kg per cubic meter Pounds per cubic feet 0.06243

Kilowatts Horsepower 1.341

Pounds Kg 0,4536

Pounds of Air

(14.7 psia and 60°F)

Pounds per cubic feet Kg per cubic meter 16,0184

Pounds per hour (gas) SCFH 13.1 ÷ Specic Gravity

Pounds per hour (water) Gallons per minute 0.002

Pounds per second (gas) SCFH 46,160 ÷ Specic Gravity

Radians Degrees 57.3

SCFH Air SCFH Propane 0.81

SCFH Air SCFH Butane 0.71

SCFH Air SCFH 0.6 Natural Gas 1.29

SCFH Cubic meters per hour 0.028317

Cubic feet of air 13.1

Converting Volumes of Gas

CFH TO CFH OR CFM TO CFM

Multiply Flow of By To Obtain Flow of

0.707 Butane

Air

Butane

Natural Gas

Propane

1.290 Natural Gas

0.808 Propane

1.414 Air

1.826 Natural Gas

1.140 Propane

0.775 Air

0.547 Butane

0.625 Propane

1.237 Air

0.874 Butane

1.598 Natural Gas

Page 11

669

Te c h n i c a l

Conversions, Equivalents, and Physical Data

Fractional Inches to Millimeters

INCH

0

1

2

3

4

5

6

7

8

9

10

1-inch = 25,4 millimeters

NOTE: To use this table, see the shaded example.

2-1/2-inches (2 from the left column plus 1/2 from the top row) = 63,5 millimeters

MULTIPLY

NUMBER

OF

1 meter = 100 cm = 1000 mm = 0,001 km = 1,000,000 micrometers

0 1/16 1/8 3/16 1/4 5/16 3/8 7/16 1/2 9/16 5/8 11/16 3/4 13/16 7/8 15/16

0,0

25,4

50,8

76,2

101,6

127,0

152,4

177,8

203,2

228,6

254,0

1,6

27,0

52,4

77,8

103,2

128,6

154,0

179,4

204,8

230,2

255,6

3,2

28,6

54,0

79,4

104,8

130,2

155,6

181,0

206,4

231,8

257,2

4,8

30,2

55,6

81,0

106,4

131,8

157,2

182,6

208,0

233,4

258,8

6,4

31,8

57,2

82,6

108,0

133,4

158,8

184,2

209,6

235,0

260,4

7,9

33,3

58,7

84,1

109,5

134,9

160,3

185,7

211,1

236,5

261,9

9,5

34,9

60,3

85,7

111,1

136,5

161,9

187,3

212,7

238,1

263,5

11,1

36,5

61,9

87,3

112,7

138,1

163,5

188,9

214,3

239,7

265,1

mm

12,7

38,1

63,5

88,9

114,3

139,7

165,1

190,5

215,9

241,3

266,7

14,3

39,7

65,1

90,5

115,9

141,3

166,7

192,1

217,5

242,9

268,3

15,9

41,3

66,7

92,1

117,5

142,9

168,3

193,7

219,1

244,5

269,9

17,5

42,9

68,3

93,7

119,1

144,5

169,9

195,3

220,7

246,1

271,5

19,1

44,5

69,9

95,3

120,7

146,1

171,5

196,9

222,3

247,7

273,1

20,6

46,0

71,4

96,8

122,2

147,6

173,0

198,4

223,8

249,2

274,6

Length Equivalents

TO

OBTAIN

BY

Meters 1 39.37 3.2808 1000 0.0006214 0,001

Inches 0,0254 1 0.0833 25,4 0.00001578 0,0000254

Feet 0,3048 12 1 304,8 0.0001894 0,0003048

Millimeters 0,001 0.03937 0.0032808 1 0.0000006214 0,000001

Miles 1609,35 63,360 5,280 1 609 350 1 1,60935

Kilometers 1000 39,370 3280.83 1 000 000 0.62137 1

METERS INCHES FEET MILLIMETERS MILES KILOMETERS

22,2

47,6

73,0

98,4

123,8

149,2

174,6

200,0

225,4

250,8

276,2

23,8

49,2

74,6

100,0

125,4

150,8

176,2

201,6

227,0

252,4

277,8

Whole Inch-Millimeter Equivalents

INCH

0 0,00 25,4 50,8 76,2 101,6 127,0 152,4 177,8 203,2 228,6

10 254,0 279,4 304,8 330,2 355,6 381,0 406,4 431,8 457,2 482,6

20 508,0 533,4 558,8 584,2 609,6 635,0 660,4 685,8 711,2 736,6

30 762,0 787,4 812,8 838,2 863,6 889,0 914,4 939,8 965,2 990,6

40 1016,0 1041,4 1066,8 1092,2 1117,6 1143,0 1168,4 1193,8 1219,2 1244,6

50 1270,0 1295,4 1320,8 1346,2 1371,6 1397,0 1422,4 1447,8 1473,2 1498,6

60 1524,0 1549,4 1574,8 1600,2 1625,6 1651,0 1676,4 1701,8 1727,2 1752,6

70 1778,0 1803,4 1828,8 1854,2 1879,6 1905,0 1930,4 1955,8 1981,2 2006,6

80 2032,0 2057,4 2082,8 2108,2 2133,6 2159,0 2184,4 2209,8 2235,2 2260,6

90 2286,0 2311,4 2336,8 2362,2 2387,6 2413,0 2438,4 2463,8 2489,2 2514,6

100 2540,0 2565,4 2590,8 2616,2 2641,6 2667,0 2692,4 2717,8 2743,2 2768,6

Note: All values in this table are exact, based on the relation 1-inch = 25,4 mm.

To use this table, see the shaded example.

25-inches (20 from the left column plus ve from the top row) = 635 millimeters

MULTIPLICATION FACTOR PREFIX SYMBOL

1 000 000 000 000 000 000 = 10

1 000 000 000 000 000 = 10

0.000 000 000 000 001 = 10

0.000 000 000 000 000 001 = 10

0 1 2 3 4 5 6 7 8 9

Metric Prexes and Symbols

1 000 000 000 000 = 10

1 000 000 000 = 10

1 000 000 = 10

1 000 = 10

100 = 10

10 = 10

0.1 = 10

0.01 = 10

0.001 = 10

0.000 01 = 10

0.000 000 001 = 10

0.000 000 000 001 = 10

18

15

12

9

6

3

2

1

-1

-2

-3

-6

-9

-12

-15

-18

exa

peta

tera

giga

mega

kilo

hecto

deka

deci

centi

milli

micro

nano

pico

femto

atto

E

P

T

G

M

k

h

da

d

c

m

m

n

p

f

a

mm

Greek Alphabet

LOWER

CASE

GREEK

NAME

CAPS

Α α Alpha Ι ι Iota Ρ ρ Rho

Β β Beta Κ κ Kappa Σ σ Sigma

Γ γ Gamma Λ λ Lambda Τ τ Tau

Δ δ Delta Μ μ Mu Υ υ Upsilon

Ε ε Epsilon Ν ν Nu Φ φ Phi

Ζ ζ Zeta Ξ ξ Xi Χ χ Chi

Η η Eta Ο ο Omicron Ψ ψ Psi

Θ θ Theta Π π Pi Ω ω Omega

CAPS

LOWER

CASE

GREEK

NAME

CAPS

LOWER

CASE

GREEK

NAME

Page 12

670

Te c h n i c a l

Conversions, Equivalents, and Physical Data

Length Equivalents - Fractional and Decimal Inches to Millimeters

INCHES

Fractions Decimals Fractions Decimals Fractions Decimals Fractions Decimals

0.00394 0.1 0.23 5.842 1/2 0.50 12.7 0.77 19.558

0.00787 0.2 15/64 0.234375 5.9531 0.51 12.954 0.78 19.812

0.01 0.254 0.23622 6.0 0.51181 13.0 25/32 0.78125 19.8438

0.01181 0.3 0.24 6.096 33/64 0.515625 13.0969 0.78740 20.0

1/64 0.015625 0.3969 1/4 0.25 6.35 0.52 13.208 0.79 20.066

0.01575 0.4 0.26 6.604 0.53 13.462 51/64 0.796875 20.2406

0.01969 0.5 17/64 0.265625 6.7469 17/32 0.53125 13.4938 0.80 20.320

0.02 0.508 0.27 6.858 0.54 13.716 0.81 20.574

0.02362 0.6 0.27559 7.0 35/64 0.546875 13.8906 13/64 0.8125 20.6375

0.02756 0.7 0.28 7.112 0.55 13.970 0.82 20.828

0.03 0.762 9/32 0.28125 7.1438 0.55118 14.0 0.82677 21.0

1/32 0.03125 0.7938 0.29 7.366 0.56 14.224 53/64 0.828125 21.0344

0.0315 0.8 19/64 0.296875 7.5406 9/16 0.5625 14.2875 0.83 21.082

0.13543 0.9 0.30 7.62 0.57 14.478 0.84 21.336

0.03937 1.0 0.31 7.874 37/64 0.578125 14.6844 27/32 0.84375 21.4312

0.04 1.016 5/16 0.3125 7.9375 0.58 14.732 0.85 21.590

3/64 0.046875 1.1906 0.31496 8.0 0.59 14.986 55/64 0.859375 21.8281

0.05 1.27 0.32 8.128 0.5905 15.0 0.86 21.844

0.06 1.524 21/64 0.328125 8.3344 19/32 0.59375 15.0812 0.86614 22.0

1/16 0.0625 1.5875 0.33 8.382 0.60 15.24 0.87 22.098

0.07 1.778 0.34 8.636 39/64 0.609375 15.4781 7/8 0.875 22.225

5/64 0.078125 1.9844 11/32 0.34375 8.7312 0.61 15.494 0.88 22.352

0.07874 2.0 0.35 8.89 0.62 15.748 0.89 22.606

0.08 2.032 0.35433 9.0 5/8 0.625 15.875 57/64 0.890625 22.6219

0.09 2.286 23/64 0.359375 9.1281 0.62992 16.0 0.90 22.860

3/32 0.09375 2.3812 0.36 9.144 0.63 16.002 0.90551 23.0

0.1 2.54 0.37 9.398 0.64 16.256 29/32 0.90625 23.0188

7/64 0.109375 2.7781 3/8 0.375 9.525 41/64 0.640625 16.2719 0.91 23.114

0.11 2.794 0.38 9.652 0.65 16.510 0.92 23.368

0.11811 3.0 0.39 9.906 21/32 0.65625 16.6688 59/64 0.921875 23.1456

0.12 3.048 25/64 0.390625 9.9219 0.66 16.764 0.93 23.622

1/8 0.125 3.175 0.39370 10.0 0.66929 17.0 15/16 0.9375 23.8125

0.13 3.302 0.40 10.16 0.67 17.018 0.94 23.876

0.14 3.556 13/32 0.40625 10.3188 43/64 0.671875 17.0656 0.94488 24.0

9/64 0.140625 3.5719 0.41 10.414 0.68 17.272 0.95 24.130

0.15 3.810 0.42 10.668 11/16 0.6875 17.4625 61/64 0.953125 24.2094

5/32 0.15625 3.9688 27/64 0.421875 10.7156 0.69 17.526 0.96 24.384

0.15748 4.0 0.43 10.922 0.70 17.78 31/32 0.96875 24.6062

0.16 4.064 0.43307 11.0 45/64 0.703125 17.8594 0.97 24.638

0.17 4.318 7/16 0.4375 11.1125 0.70866 18.0 0.98 24.892

11/64 0.171875 4.3656 0.44 11.176 0.71 18.034 0.98425 25.0

0.18 4.572 0.45 11.430 23/32 0.71875 18.2562 63/64 0.984375 25.0031

3/16 0.1875 4.7625 29/64 0.453125 11.5094 0.72 18.288 0.99 25.146

0.19 4.826 0.46 11.684 0.73 18.542 1 1.00000 25.4000

0.19685 5.0 15/32 0.46875 11.9062 47/64 0.734375 18.6531

0.2 5.08 0.47 11.938 0.74 18.796

13/64 0.203125 5.1594 0.47244 12.0 0.74803 19.0

0.21 5.334 0.48 12.192 3/4 0.75 19.050

7/32 0.21875 5.5562 31/64 0.484375 12.3031 0.76 19.304

0.22 5.588 0.49 12.446 49/64 0.765625 19.4469

Note: Round off decimal points to provide no more than the desired degree of accuracy.

mm

INCHES

mm

INCHES

mm

INCHES

mm

Page 13

671

Te c h n i c a l

Conversions, Equivalents, and Physical Data

Temperature Conversions

TEMP. IN °C

°C

OR °F TO BE

CONVERTED

-273,16 -460 -796 -90,00 -130 -202.0 -17,8 0 32.0 21,1 70 158.0

-267,78 -450 -778 -84,44 -120 -184.0 -16,7 2 35.6 22,2 72 161.6

-262,22 -440 -760 -78,89 -110 -166.0 -15,6 4 39.2 23,3 74 165.2

-256,67 -430 -742 -73,33 -100 -148.0 -14,4 6 42.8 24,4 76 168.8

-251,11 -420 -724 -70,56 -95 -139.0 -13,3 8 46.4 25,6 78 172.4

-245,56 -410 -706 -67,78 -90 -130.0 -12,2 10 50.0 26,7 80 176.0

-240,00 -400 -688 -65,00 -85 -121.0 -11,1 12 53.6 27,8 82 179.6

-234,44 -390 -670 -62,22 -80 -112.0 -10,0 14 57.2 28,9 84 183.2

-228,89 -380 -652 -59,45 -75 -103.0 -8,89 16 60.8 30,0 86 186.8

-223,33 -370 -634 -56,67 -70 -94.0 -7,78 18 64.4 31,1 88 190.4

-217,78 -360 -616 -53,89 -65 -85 -6,67 20 68.0 32,2 90 194.0

-212,22 -350 -598 -51,11 -60 -76.0 -5,56 22 71.6 33,3 92 197.6

-206,67 -340 -580 -48,34 -55 -67.0 -4,44 24 75.2 34,4 94 201.2

-201,11 -330 -562 -45,56 -50 -58.0 -3,33 26 78.8 35,6 96 204.8

-195,56 -320 -544 -42,78 -45 -49.0 -2,22 28 82.4 36,7 98 208.4

°F °C

TEMP. IN °C

OR °F TO BE

CONVERTED

°F °C

TEMP. IN °C

OR °F TO BE

CONVERTED

°F °C

TEMP. IN °C

OR °F TO BE

CONVERTED

°F

-190,00 -310 -526 -40,00 -40 -40.0 -1,11 30 86.0 37,8 100 212.0

-184,44 -300 -508 -38,89 -38 -36.4 0 32 89.6 43,3 110 230.0

-178,89 -290 -490 -37,78 -36 -32.8 1,11 34 93.2 48,9 120 248.0

-173,33 -280 -472 -36,67 -34 -29.2 2,22 36 96.8 54,4 130 266.0

-169,53 -273 -459.4 -35,56 -32 -25.6 3,33 38 100.4 60,0 140 284.0

-168,89 -272 -457.6 -34,44 -30 -22.0 4,44 40 104.0 65,6 150 302.0

-167,78 -270 -454.0 -33,33 -28 -18.4 5,56 42 107.6 71,1 160 320.0

-162,22 -260 -436.0 -32,22 -26 -14.8 6,67 44 111.2 76,7 170 338.0

-156,67 -250 -418.0 -31,11 -24 -11.2 7,78 46 114.8 82,2 180 356.0

-151,11 -240 -400.0 -30,00 -22 -7.6 8,89 48 118.4 87,8 190 374.0

-145,56 -230 -382.0 -28,89 -20 -4.0 10,0 50 122.0 93,3 200 392.0

-140,00 -220 -364.0 -27,78 -18 -0.4 11,1 52 125.6 98,9 210 410.0

-134,44 -210 -356.0 -26,67 -16 3.2 12,2 54 129.2 104,4 220 428.0

-128,89 -200 -328.0 -25,56 -14 6.8 13,3 56 132.8 110,0 230 446.0

-123,33 -190 -310.0 -24,44 -12 10.4 14,4 58 136.4 115,6 240 464.0

-117,78 -180 -292.0 -23,33 -10 14.0 15,6 60 140.0 121,1 250 482.0

-112,22 -170 -274.0 -22,22 -8 17.6 16,7 62 143.6 126,7 260 500.0

-106,67 -160 -256.0 -21,11 -6 21.2 17,8 64 147.2 132,2 270 518.0

-101,11 -150 -238.0 -20,00 -4 24.8 18,9 66 150.8 137,8 280 536.0

-95,56 -140 -220.0 -18,89 -2 28.4 20,0 68 154.4 143,3 290 665.0

-continued-

Page 14

672

Te c h n i c a l

Conversions, Equivalents, and Physical Data

Temperature Conversions (continued)

°C

21,1 70 158.0 204,4 400 752.0 454,0 850 1562.0

22,2 72 161.6 210,0 410 770.0 460,0 860 1580.0

23,3 74 165.2 215,6 420 788.0 465,6 870 1598.0

24,4 76 168.8 221,1 430 806.0 471,1 880 1616.0

25,6 78 172.4 226,7 440 824.0 476,7 890 1634.0

26,7 80 176.0 232,2 450 842.0 482,2 900 1652.0

27,8 82 179.6 237,8 460 860.0 487,8 910 1670.0

28,9 84 183.2 243,3 470 878.0 493,3 920 1688.0

30,0 86 186.8 248,9 480 896.0 498,9 930 1706.0

31,1 88 190.4 254,4 490 914.0 504,4 940 1724.0

32,2 90 194.0 260,0 500 932.0 510,0 950 1742.0

33,3 92 197.6 265,6 510 950.0 515,6 960 1760.0

34,4 94 201.2 271,1 520 968.0 521,1 970 1778.0

35,6 96 204.8 276,7 530 986.0 526,7 980 1796.0

36,7 98 208.4 282,2 540 1004.0 532,2 990 1814.0

TEMP. IN °C

OR °F TO BE

CONVERTED

°F °C

TEMP. IN °C

OR °F TO BE

CONVERTED

°F °C

TEMP. IN °C

OR °F TO BE

CONVERTED

°F

37,8 100 212.0 287,8 550 1022.0 537,8 1000 1832.0

43,3 110 230.0 293,3 560 1040.0 543,3 1010 1850.0

48,9 120 248.0 298,9 570 1058.0 548,9 1020 1868.0

54,4 130 266.0 304,4 580 1076.0 554,4 1030 1886.0

60,0 140 284.0 310,0 590 1094.0 560,0 1040 1904.0

65,6 150 302.0 315,6 600 1112.0 565,6 1050 1922.0

71,1 160 320.0 321,1 610 1130.0 571,1 1060 1940.0

76,7 170 338.0 326,7 620 1148.0 576,7 1070 1958.0

82,2 180 356.0 332,2 630 1166.0 582,2 1080 1976.0

87,8 190 374.0 337,8 640 1184.0 587,8 1090 1994.0

93,3 200 392.0 343,3 650 1202.0 593,3 1100 2012.0

98,9 210 410.0 348,9 660 1220.0 598,9 1110 2030.0

104,4 220 428.0 354,4 670 1238.0 604,4 1120 2048.0

110,0 230 446.0 360,0 680 1256.0 610,0 1130 2066.0

115,6 240 464.0 365,6 690 1274.0 615,6 1140 2084.0

121,1 250 482.0 371,1 700 1292.0 621,1 1150 2102.0

126,7 260 500.0 376,7 710 1310.0 626,7 1160 2120.0

132,2 270 518.0 382,2 720 1328.0 632,2 1170 2138.0

137,8 280 536.0 287,8 730 1346.0 637,8 1180 2156.0

143,3 290 665.0 393,3 740 1364.0 643,3 1190 2174.0

-continued-

Page 15

673

Te c h n i c a l

Conversions, Equivalents, and Physical Data

Temperature Conversions (continued)

TEMP. IN °C

°C

OR °F TO BE

CONVERTED

148,9 300 572.0 315,6 600 1112.0 482,2 900 1652.0 648,9 1200 2192.0

154,4 310 590.0 321,1 610 1130.0 487,8 910 1670.0 654,4 1210 2210.0

160,0 320 608.0 326,7 620 1148.0 493,3 920 1688.0 660,0 1220 2228.0

165,6 330 626.0 332,2 630 1166.0 498,9 930 1706.0 665,6 1230 2246.0

171,1 340 644.0 337,8 640 1184.0 504,4 940 1724.0 671,1 1240 2264.0

176,7 350 662.0 343,3 650 1202.0 510,0 950 1742.0 676,7 1250 2282.0

182,2 360 680.0 348,9 660 1220.0 515,6 960 1760.0 682,2 1260 2300.0

187,8 370 698.0 354,4 670 1238.0 521,1 970 1778.0 687,8 1270 2318.0

189,9 380 716.0 360,0 680 1256.0 526,7 980 1796.0 693,3 1280 2336.0

193,3 390 734.0 365,6 690 1274.0 532,2 990 1814.0 698,9 1290 2354.0

204,4 400 752.0 371,1 700 1292.0 537,8 1000 1832.0 704,4 1300 2372.0

210,0 410 770.0 376,7 710 1310.0 543,3 1010 1850.0 710,0 1310 2390.0

215,6 420 788.0 382,2 720 1328.0 548,9 1020 1868.0 715,6 1320 2408.0

221,1 430 806.0 287,8 730 1346.0 554,4 1030 1886.0 721,1 1330 2426.0

226,7 440 824.0 393,3 740 1364.0 560,0 1040 1904.0 726,7 1340 2444.0

°F °C

TEMP. IN °C

OR °F TO BE

CONVERTED

°F °C

TEMP. IN °C

OR °F TO BE

CONVERTED

°F °C

TEMP. IN °C

OR °F TO BE

CONVERTED

°F

232,2 450 842.0 398,9 750 1382.0 565,6 1050 1922.0 732,2 1350 2462.0

237,8 460 860.0 404,4 760 1400.0 571,1 1060 1940.0 737,8 1360 2480.0

243,3 470 878.0 410,0 770 1418.0 576,7 1070 1958.0 743,3 1370 2498.0

248,9 480 896.0 415,6 780 1436.0 582,2 1080 1976.0 748,9 1380 2516.0

254,4 490 914.0 421,1 790 1454.0 587,8 1090 1994.0 754,4 1390 2534.0

260,0 500 932.0 426,7 800 1472.0 593,3 1100 2012.0 760,0 1400 2552.0

265,6 510 950.0 432,2 810 1490.0 598,9 1110 2030.0 765,6 1410 2570.0

271,1 520 968.0 437,8 820 1508.0 604,4 1120 2048.0 771,1 1420 2588.0

276,7 530 986.0 443,3 830 1526.0 610,0 1130 2066.0 776,7 1430 2606.0

282,2 540 1004.0 448,9 840 1544.0 615,6 1140 2084.0 782,2 1440 2624.0

287,8 550 1022.0 454,4 850 1562.0 621,1 1150 2102.0 787,0 1450 2642.0

293,3 560 1040.0 460,0 860 1580.0 626,7 1160 2120.0 793,3 1460 2660.0

298,9 570 1058.0 465,6 870 1598.0 632,2 1170 2138.0 798,9 1470 2678.0

304,4 580 1076.0 471,1 880 1616.0 637,8 1180 2156.0 804,4 1480 2696.0

310,0 590 1094.0 476,7 890 1634.0 643,3 1190 2174.0 810,0 1490 2714.0

Page 16

674

Te c h n i c a l

Conversions, Equivalents, and Physical Data

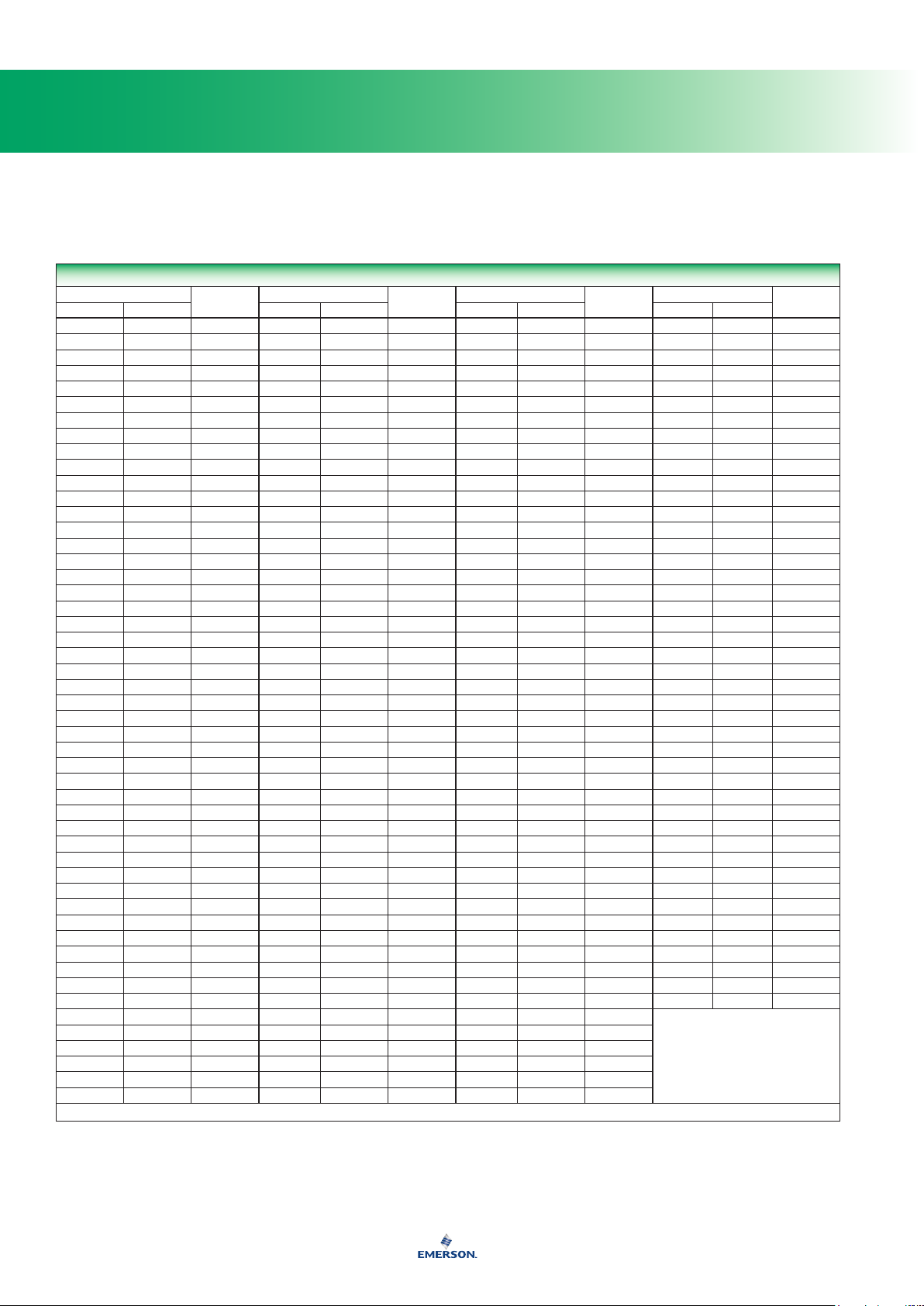

A.P.I. and Baumé Gravity Tables and Weight Factors

A.P.I.

Baumé

Specic

Gravity

Gravity

0 10.247 1.0760 8.962 0.1116 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

1 9.223 1.0679 8.895 0.1124 31 30.78 0.9808 7.251 0.1379 61 60.46 0.7351 6.119 0.1634 81 80.25 0.6659 5.542 0.1804

2 8.198 1.0599 8.828 0.1133 32 31.77 0.8654 7.206 0.1388 62 61.45 0.7313 6.087 0.1643 82 81.24 0.6628 5.516 0.1813

3 7.173 1.0520 8.762 0.1141 33 32.76 0.8602 7.163 0.1396 63 62.44 0.7275 6.056 0.1651 83 82.23 0.6597 5.491 0.1821

4 6.148 1.0443 8.698 0.1150 34 33.75 0.8550 7.119 0.1405 64 63.43 0.7238 6.025 0.1660 84 83.22 0.6566 5.465 0.1830

5 5.124 1.0366 8.634 0.1158 35 34.73 0.8498 7.075 0.1413 65 64.42 0.7201 6.994 0.1668 85 84.20 0.6536 5.440 0.1838

6 4.099 1.0291 8.571 0.1167 36 35.72 0.8448 7.034 0.1422 66 65.41 0.7165 5.964 0.1677 86 85.19 0.6506 5.415 0.1847

7 3.074 1.0217 8.509 0.1175 37 36.71 0.8398 6.993 0.1430 67 66.40 0.7128 5.934 0.1685 87 86.18 0.6476 5.390 0.1855

8 2.049 1.0143 8.448 0.1184 38 37.70 0.8348 6.951 0.1439 68 67.39 0.7093 5.904 0.1694 88 87.17 0.6446 5.365 0.1864

9 1.025 1.0071 8.388 0.1192 39 38.69 0.8299 6.910 0.1447 69 68.37 0.7057 5.874 0.1702 89 88.16 0.6417 5.341 0.1872

10 10.00 1.0000 8.328 0.1201 40 39.68 0.8251 6.870 0.1456 70 69.36 0.7022 5.845 0.1711 90 89.15 0.6388 5.316 0.1881

Gravity

Lbs/U.S.

Gallons

U.S.

Gallons-

/Lb

A.P.I.

Gravity

Baumé

Gravity

Specic

Gravity

Lbs/U.S.

Gallons

U.S.

Gallons-

/Lb

A.P.I.

Gravity

Baumé

Gravity

Specic

Gravity

Lbs/U.S.

Gallons

U.S.

Gallons-

/Lb

A.P.I.

Gravity

Baumé

Gravity

Specic

Gravity

Lbs/U.S.

Gallons

U.S.

Gallons-

/Lb

11 10.99 0.9930 8.270 0.1209 41 40.67 0.8203 6.830 0.1464 71 70.35 0.6988 5.817 0.1719 91 90.14 0.6360 5.293 0.1889

12 11.98 0.9861 8.212 0.1218 42 41.66 0.8155 6.790 0.1473 72 71.34 0.6953 5.788 0.1728 92 91.13 0.6331 5.269 0.1898

13 12.97 0.9792 8.155 0.1226 43 42.65 0.8109 6.752 0.1481 73 72.33 0.6919 5.759 0.1736 93 92.12 0.6303 5.246 0.1906

14 13.96 0.9725 8.099 0.1235 44 43.64 0.8063 6.713 0.1490 74 73.32 0.6886 5.731 0.1745 94 93.11 0.6275 5.222 0.1915

15 14.95 0.9659 8.044 0.1243 45 44.63 0.8017 6.675 0.1498 75 74.31 0.6852 5.703 0.1753 95 94.10 0.6247 5.199 0.1924

16 15.94 0.9593 7.989 0.1252 46 45.62 0.7972 6.637 0.1507 76 75.30 0.6819 5.676 0.1762 96 95.09 0.6220 5.176 0.1932

17 16.93 0.9529 7.935 0.1260 47 50.61 0.7927 6.600 0.1515 77 76.29 0.6787 5.649 0.1770 97 96.08 0.6193 5.154 0.1940

18 17.92 0.9465 7.882 0.1269 48 50.60 0.7883 6.563 0.1524 78 77.28 0.6754 5.622 0.1779 98 97.07 0.6166 5.131 0.1949

19 18.90 0.9402 7.930 0.1277 49 50.59 0.7839 6.526 0.1532 79 78.27 0.6722 5.595 0.1787 99 98.06 0.6139 5.109 0.1957

20 19.89 0.9340 7.778 0.1286 50 50.58 0.7796 6.490 0.1541 80 79.26 0.6690 5.568 0.1796 100 99.05 0.6112 5.086 0.1966

The relation of degrees Baume or A.P.I. to Specic Gravity is expressed by these formulas:

21 20.88 0.9279 7.727 0.1294 51 50.57 0.7753 6.455 0.1549

22 21.87 0.9218 7.676 0.1303 52 51.55 0.7711 6.420 0.1558

23 22.86 0.9159 7.627 0.1311 53 52.54 0.7669 6.385 0.1566

24 23.85 0.9100 7.578 0.1320 54 53.53 0.7628 6.350 0.1575

25 24.84 0.9042 7.529 0.1328 55 54.52 0.7587 6.136 0.1583

26 25.83 0.8984 7.481 0.1337 56 55.51 0.7547 6.283 0.1592

27 26.82 0.8927 7.434 0.1345 57 56.50 0.7507 6.249 0.1600

28 27.81 0.8871 7.387 0.1354 58 57.49 0.7467 6.216 0.1609

29 28.80 0.8816 7.341 0.1362 59 58.48 0.7428 6.184 0.1617

30 29.79 0.8762 7.296 0.1371 60 59.47 0.7389 6.151 0.1626

For liquids lighter than water: For liquids heavier than water:

Degrees Baume = Degrees Baume =

Degrees A.P.I. =

G = Specic Gravity = ratio of weight of a given volume of oil at 60°F to the weight of the same

volume of water at 60°F.

The above tables are based on the weight of 1 gallon (U.S.) of oil with a volume of 231 cubic

inches at 60°F in air at 760 mm pressure and 50% relative humidity. Assumed weight of 1 gallon

of water at 60°F in air is 8.32828 pounds.

To determine the resulting gravity by mixing oils of different gravities:

D =

D = Density or Specic Gravity of mixture

m = Proportion of oil of d1 density

n = Proportion of oil of d2 density

d1 = Specic gravity of m oil

d2 = Specic gravity of n oil

140 140

- 130 G =

G 130 + Degrees Baume

141 141.5

- 131.5 G =

5 131.5 + Degrees A.P.I.

md1+md

2

m + n

145 145

145 - G =

5 145 – Degrees Baume

Page 17

675

Te c h n i c a l

Conversions, Equivalents, and Physical Data

Characteristics of the Elements

ELEMENT SYMBOL

Actinium

Aluminum

Americum

Antimony

(Stibium)

Argon

Arsenic

Astatine

Barium

Berkelium

Beryllium

Bismuth

Boron

Bromine

Cadmium

Calcium

Californium

Carbon

Cerium

Cesium

Chlorine

Chromium

Cobalt

Copper

Curium

Dysprosium

Einsteinium

Erbium

Europium

Fermium

Fluourine

Francium

Gadolinium

Gallium

Germanium

Gold

Hafnium

Helium

Holmium

Hydrogen

Indium

Iodine

Iridium

Iron

Krypton

Lanthanum

Lawrencium

Lead

Lithium

Lutetium

Magnesium

Manganese

Mendelevium

Mercury

Molybdenum

Neodymium

1. Mass number shown is that of stable isotope most common in nature. Mass numbers shown in parentheses designate the isotope with the longest half-life (slowest rate of

radioactive decay) for those elements having an unstable isotope.

2. Calculated

> Greater than

Ac

Am

Sb

Ar

As

Ba

Bk

Be

Br

Cd

Ca

Cf

Ce

Cs

Cr

Co

Cu

Cm

Dy

Es

Er

Eu

Fm

Gd

Ga

Ge

Au

Hf

He

Ho

Fe

Kr

La

Lw

Pb

Lu

Mg

Mn

Mv

Hg

Mo

Nd

Al

At

Bi

B

C

Cl

F

Fr

H

In

I

Ir

Li

ATOMIC

NUMBER

89

13

95

51

18

33

85

56

97

4

83

5

35

48

20

98

6

58

55

17

24

27

29

96

66

99

68

63

100

9

87

64

31

32

79

72

2

67

1

49

53

77

26

36

57

103

82

3

71

12

25

101

80

42

60

MASS

NUMBER

(227)

27

(243)

121

40

75

(210)

138

(247)

9

209

11

79

114

40

(249)

12

140

133

35

52

59

63

(248)

164

(254)

166

153

(252)

19

(223)

158

69

74

197

180

4

165

1

115

127

193

56

84

139

(257)

208

7

175

24

55

(256)

202

98

142

MELTING

(1)

POINT (°C)

sublimes at 615

1278±5

1150±50

-259.14

2620±10

BOILING

POINT (°C)

1600†

659.7

630.5

-189.2

sublimes at 615

850

271.3

2300

-7.2

320.9

842±8

>3550

804

28.5

-103±5

1890

1495

1083

-223 -188

29.78

958.5

1063

1700

-272

156.4

113.7

2454

1535

-156.6

826

327.43

186

651

1260

-38.87

840

1560±5

(2)

2000±10

184.35

1336±5

356.58

2057

1380

-185.7

1140

2970

2550

58.78

767±2

1240

4200

1400

670

-34.6

2480

2900

2336

1983

2700

2600

>3200

-268.9

-252.8

>4800

3000

-152.9

1620

1107

1900

4800

ELEMENT SYMBOL

Neon

Neptunium

Nickel

Niobium

Nitrogen

Nobelium

Osmium

Oxygen

Palladium

Phosphorus

Platinum

Plutonium

Polonium

Potassium

Praseodymium

Promethium

Protactinium

Radium

Radon

Rhenium

Rhodium

Rubidium

Ruthenium

Samarium

Scandium

Selenium

Silicon

Silver

Sodium

Strontium

Sulfur

Tantalum

Technetium

Tellurium

Terbium

Thallium

Thorium

Thulium

Tin

Titanium

Tungsten

(Wolfram)

Uranium

Vanadium

Xenon

Ytterbium

Yttrium

Zinc

Zirconium

Ne

Np

Nb

No

Os

Pd

Pu

Po

Pm

Pa

Ra

Rn

Re

Rh

Rb

Ru

Sm

Sc

Se