Page 1

Bulletin LP-7:R222

Type R222 Second-Stage Regulator

Introduction

The T ype R222 is an Underwriters Laboratories (UL®)

listed regulator designed for T wo-Stage LP-Gas systems.

The unit is designed to reduce the outlet pressure from

a rst-stage regulator (usually 10 psig / 0.69 bar) to an

outlet pressure of 11-inches w.c. / 27 mbar. The unit’s

capacity, up to 650,000 BTU/hour, is sized for small

domestic loads. The units compact size makes it ideal for

tight t applications. A screened drip-lip vent is oriented

over the inlet in the standard conguration.

Features

• 20 Year Recommended Replacement Life—The

Type R222 is designed using rugged time proven

design concepts and constructed of corrosion

resistant materials, both internally and externally.

With proper installation and periodic inspection and

maintenance, the Type R222 regulator will meet a

20 Year Recommended Replacement Life.

• Dual Gauge Taps—Built-in 1/8-inch threaded NPT

gauge taps, oriced to a number 54 drill size on the

inlet and outlet side of the regulator allow for easy

gas system checks.

• Durability—The design utilizes the same

durable valve stem linkage design used in

R600 Series regulators for reliable lockup and

regulation performance.

Figure 1. Type R222 Second-Stage Regulator

• Superior Overpressure Protection—The

combination of a high capacity relief valve and

large vent provide overpressure protection which

exceeds UL standards and is capable of limiting the

downstream pressure to 2 psig / 0.14 bar even in a

double failure situation when used with a Fisher

Type R122H or R622H rst-stage regulator.

• Corrosion-Resistant—Added corrosion resistance

from an internal and external coating process for

all castings prior to painting, stainless steel relief

valve spring and retainer and a corrosion resistant

relief valve seat.

December 2012

• Improved Regulation—A large fabric-reinforced

diaphragm delivers accurate and stable regulation.

• Easy Installation—The units compact size and

easily accessible inlet and outlet wrench ats

make installation easy even in the tightest locations.

Optional vent orientation with the vent oriented over

outlet is available.

www.sherregulators.com

• Positive Draining Spring Case—When installed

properly with the spring case vents pointed down,

the design allows moisture formed in the spring

case to drain out limiting the problems with

corrosion and freezing water in the spring case.

D450154T012

Page 2

Bulletin LP-7:R222

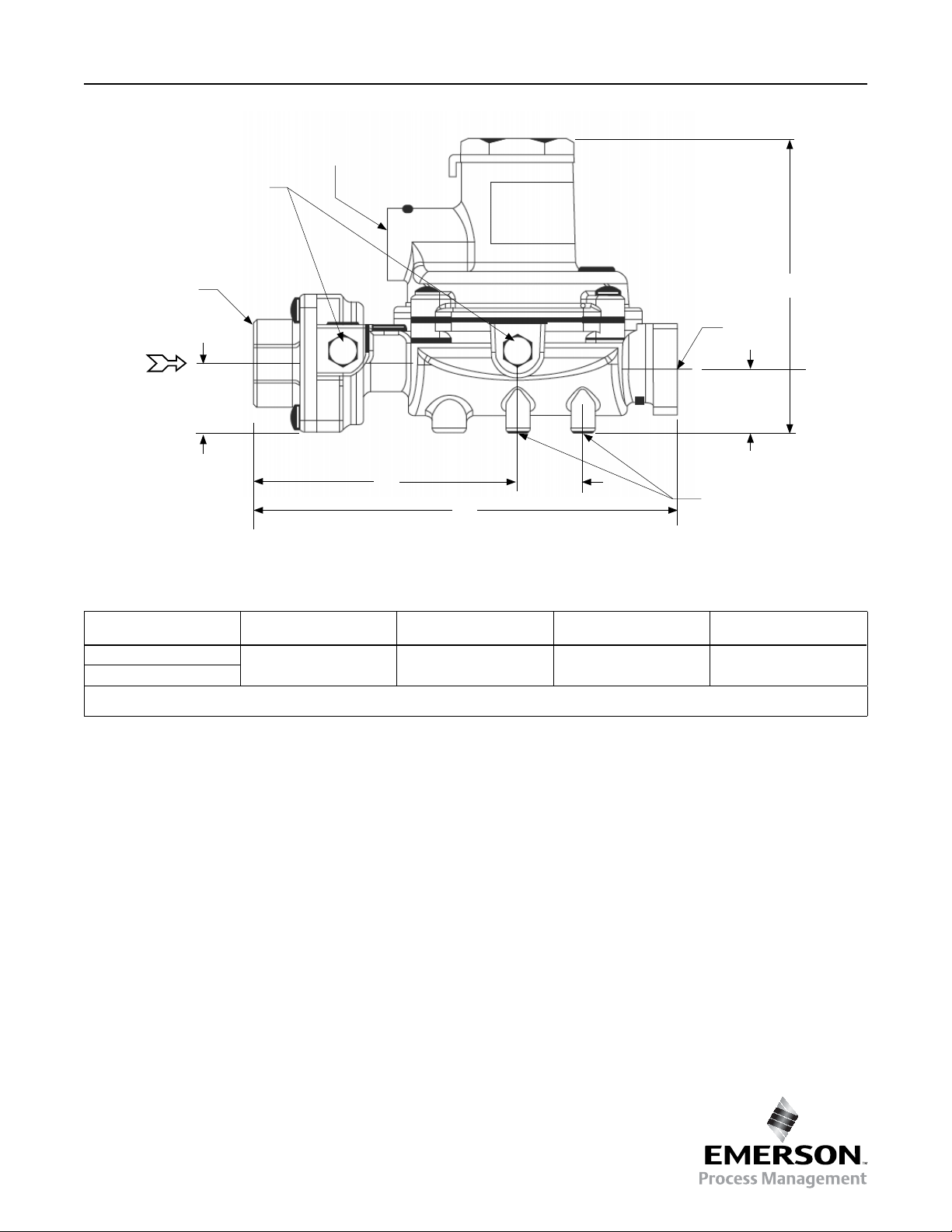

3/8-18 NPT

SCREENED VENT

1/8-27 NPT

INLET/OUTLET

GAUGE TAPS

NO. 54 RESTRICTED

1/2-14 NPT

INLET FITTING

1.1 /

27.9

4 /

102

6.5 /

165

Figure 2. Type R222 Dimensions

Table 1. Ordering Information

TYPE NUMBER

R222-BAF

R222-BAFXA

1. Capacity is based on 10 PSIG / 0.69 bar inlet pressure and 2-inches w.c. / 5 mbar droop.

2. Spring case vent over outlet.

(2)

CAPACITY, BTU/HOUR

PROPANE

(1)

650,000 1/2 x 1/2-inch NPT

CONNECTIONS

INLET X OUTLET

1.0 /

25.4

OUTLET PRESSURE

11-inches w.c. /

SETTING

27 mbar

4.5 /

114

1/2-14 NPT

0.9 /

22.9

MOUNTING SCREW HOLES

INCHES /

mm

OUTLET PRESSURE

RANGE

9.5 to 13-inches w.c. /

24 to 32 mbar

LP-Gas Equipment

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872, USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

For further information visit www.fisherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls International LLC,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

©Emerson Process Management Regulator Technologies, Inc., 2003, 2012; All Rights Reserved

Loading...

Loading...