Fisher Manuals & Guides: Chemical Sourcebook Chapter 1 and 2: Ethylene Production Polysilicone Production | Fisher Manuals & Guides

Chapter 1

Ethylene Production

NOTE: The following chapter is the

first of many to be released as part

of a Chemical sourcebook. These

chapters will be released to eDocs

as they are completed and when

fully developed, compiled into one

sourcebook.

Ethylene is one of the most important

petrochemical intermediates and is a feedstock for

many various products. End products made with

ethylene include food packaging, film, toys, food

containers, bottles, pipes, antifreeze, carpets,

insulation, housewares, etc. Chemicals that are

made from ethylene in order to produce these end

products are polyethylene, ethylene dichloride,

ethylene oxide, ethylbenzene, and vinyl acetate,

just to name a few.

Global ethylene capacity utilization has remained

above 90% since 2004 until 2008's economic

meltdown. In 2007, 2 million tonnes per year (tpy)

of ethylene capacity was added, according to the

Oil & Gas Journal. As of January 1, 2009, global

capacity was 126.7 million tpy. Capacity has been

added in recent years due to expansions and

debottlenecking at existing plants, as well as

greenfield plants being built in the Middle East and

Asia. Due to the change in market conditions and

the economy, there is an over‐supply of ethylene

capacity. Many plants have been taken offline in

this time period, are operating at reduced rates, or

are undergoing turnarounds. As the ethylene

market rebounds, capacity will increase. In fact,

based on new capacities announced and plants

that are under construction, global ethylene

capacity is expected to be at 162 million tpy by

2012, ahead of the demand growth.

There are five major licensors of ethylene plants:

KBR; Technip; Linde; Shaw, Stone & Webster;

and Lummus. While ethylene production differs

slightly by licensor, the overall process is fairly

similar (see Figure 1‐1). There are also some

differences in the process coming from the type of

feedstock being used. Some of these differences

will be highlighted. This chapter will cover the

general steps in ethylene production and will

discuss the critical valve applications within an

ethylene plant, what valve challenges those

applications present, and the recommended

Emerson solutions.

www.Fisher.com

Figure 1‐1. General ethylene process (naptha fed cracker)

Figure 1‐2. General ethylene furnace schematic

I. Furnace

The two primary feedstocks for ethylene

production are naphtha and natural gas (ethane,

propane, butane, etc.). The first step in the

production of ethylene is to take the feedstock and

crack it into ethylene and other various products in

a furnace. This process is called pyrolysis.

Pyrolysis is the thermal cracking of petroleum

hydrocarbons with steam, also called steam

cracking. The main types of commercial furnaces

are the ABB Lummus Global furnace, Millisecond

furnace (KBR), Shawt furnace (ultraselective

cracking furnace), Technip furnace, and the Linde

PYROCRACKt furnace. See Figure 1‐2 for a

general schematic of an ethylene furnace.

The feed hydrocarbon stream is pre‐heated by a

heat exchanger, mixed with steam, and then

further heated to its incipient cracking temperature

(932_F to 1256_F or 500_C to 680_C depending

upon the feedstock). At this point, it enters a

reactor (typically, a fired tubular reactor) where it is

heated to cracking temperatures (1382_F to

1607_F or 750_C to 875_C). During this reaction,

hydrocarbons in the feed are cracked into smaller

molecules, producing ethylene and co‐products.

products such as ethylene and propylene. Long

residence times will favor the secondary reactions.

Table 1‐1. Furnace Reactions

Primary Reactions

Feedstock/steam

Ethylene C4 products

Propylene C5 products

Acetylene C6 products

Hydrogen Aromatics

Methane C7 products

Etc.

Secondary

Reactions

Heavier

products

Maximum ethylene production requires a highly

saturated feedstock, high coil outlet temperature,

low hydrocarbon partial pressure, short residence

time in the radiant coil, and rapid quenching of the

cracked gas. Valves in the furnace section play a

critical role in maximizing ethylene production and

throughput.

There are three critical control valve applications in

the furnace area: dilution steam ratio control, feed

gas control, and fuel gas control. Each will be

discussed in further detail in the subsequent text.

The cracking reaction is highly endothermic,

therefore, high energy rates are needed. The

cracking coils are designed to optimize the

temperature and pressure profiles in order to

maximize the yield of desired or value products.

Short residence times in the furnace are also

important as they increase the yields of primary

1-2

Dilution Steam Ratio Control

The quantity of steam used (steam ratio) varies

with feedstock, cracking severity, and design of

the cracking coil. Steam dilution lowers the

hydrocarbon partial pressure, thereby enhancing

the olefin yield. Because of this, it is important to

obtain the appropriate ratio and maintain proper

control of that ratio. Steam helps to reduce coking

deposits by reacting with coke to form carbon

dioxide (CO

hydrogen (H

), carbon monoxide (CO), and

2

) and also reduces the catalytic effect

2

of the reactor coil's metal walls, which tend to

promote coke formation. An improper ratio

reduces efficiency of the cracker and can result in

the need for more decoking cycles, thus resulting

in less furnace uptime. It is necessary that

decoking be performed on a regular basis. This is

typically done by burning out the coke with a

mixture of steam and air. Time intervals for

decoking will depend upon several factors

including, but not limited to the type of furnace,

how the process is operated, feedstock type, and

the types of coils utilized.

Precise control of the steam dilution valve is

necessary to maintain the proper steam ratio,

which can greatly affect the efficiency of the

furnace. Due to the process conditions seen by the

dilution steam control valve, it requires the use of

graphite packing. Graphite packing often leads to

higher friction than one would see with the use of

PTFE packing. This added friction contributes to

high deadband and high variability, thus the loop

may become unstable. With high deadband and

variability, it's difficult to have precise control within

the valve, which leads to issues controlling the

loop. Due to the location of the valve (near the

furnace), high ambient temperatures are possible,

thus making the location a variable to consider

when selecting the actuator and related

accessories.

The Fisher

R

control valve solution for the dilution

steam ratio control valve is typically a Fisher

easy‐et sliding‐stem valve or a Fisher GX

sliding‐stem valve. Because of the friction

concerns mentioned previously, graphite ULF

packing is recommended. This packing meets the

process temperature requirements and has much

lower friction than standard graphite packing. A

spring‐and‐diaphragm actuator should also be

used as they are proven to provide precise control

in the field as well as in Fisher valve testing

facilities.

The use of a Fisher FIELDVUEt digital valve

controller with Performance Diagnostics (PD) can

be utilized to monitor control valve assembly

performance and allow for predictive maintenance.

When the performance is degrading, the next time

the furnace is brought down for maintenance

(typically decoking), valve maintenance can be

scheduled ahead of time to bring the valve

assembly back to an optimal performance level.

Feed Gas Control

The feed into an ethylene furnace can be ethane,

propane, butane, gas oil, or naphtha. Variation in

the type of feedstock used is related to availability.

Plants in the Middle East tend to use natural gas

feedstock because it is plentiful in the region and

is a low cost feedstock. Asia has a large

availability of naphtha and, therefore, is inclined to

use it more frequently as a feedstock. Plants can

also be designed to handle different types of

feedstocks, allowing them more flexibility to

change based upon availability and cost.

The feed gas control valve controls the flow of

feedstock used in the ethylene plant. Tight control

of the valve is critical in the steam dilution valve so

that the proper reaction ratio can be maintained

within the furnace. Control of the reaction ratio of

feedstock to steam will affect the reaction

efficiency and percentage of conversion to

ethylene. Due to the process conditions, the use of

graphite packing is required. Graphite packing

often leads to higher friction than with the use of

PTFE packing. This added friction contributes to

high deadband and high variability, thus the loop

may become unstable in automatic. With the high

deadband and variability, it's difficult to have

precise control within the valve, which then leads

to issues controlling the loop. Due to the location

of the valve (near the furnace), it can see high

ambient temperatures. This should be a

consideration when selecting the actuator and

related accessories. While most of these issues

mimic those of the steam dilution valve, there is an

additional variable to consider: the use of low

emission packing to reduce the emissions of the

feedstock for environmental and safety concerns.

The Fisher control valve solution for the feed gas

control valve is typically an easy‐e valve or GX

valve. Because of the friction concerns mentioned

and the desire to reduce emissions, use of Fisher

ENVIRO‐SEALt graphite ULF packing is

recommended. A spring‐and‐diaphragm actuator

should also be used as they are proven to provide

precise control in the field and in Fisher valve

testing facilities. A FIELDVUE digital valve

controller with PD can be utilized to monitor control

valve assembly performance and allow for

predictive maintenance. When the performance is

degrading, the next time the furnace is brought

down for maintenance (typically decoking), valve

maintenance can be scheduled ahead of time to

bring the valve assembly back to an optimal

performance level.

1-3

Fuel Gas Control

Fuel gas regulates the temperature of the furnace

by controlling the fuel to the burners. Special

temperature profiles are applied along the cracking

coil to avoid long residence times at low

temperatures. This is because low temperatures

favor the oligomerization reactions involved in the

formation of secondary products. Oligomerization

is a chemical process that converts monomers to a

finite degree of polymerization (i.e. products that

are not desirable in ethylene production). Because

special temperature profiles are applied, the

temperature control of the cracker is critical. The

goal is to maintain the optimum temperature in

order to favor the desired primary reactions and

produce the most ethylene possible.

Due to the nature of the fuel, many plants utilize

emissions control packing to limit the emissions of

the fuel gas. This is for environmental concerns as

well as general safety concerns. As with the other

valves in the furnace area, due to location, the fuel

gas valve may also see high ambient

temperatures. Depending upon on the ambient

temperatures for each particular application,

special care may need to be taken in selecting the

actuator and accessories.

Used with permission of Qenos Pty Ltd

Figure 1‐3. Quench tower

The Fisher control solution for the fuel gas control

valve is typically an easy‐e valve or GX valve. Due

to emissions concern, use of ENVIRO‐SEAL

graphite ULF packing is recommended. A

spring‐and‐diaphragm actuator should also be

used as they are proven to provide precise control

in the field and in Fisher testing facilities. A

FIELDVUE digital valve controller with PD can be

utilized to monitor control valve assembly

performance and allow for predictive maintenance.

When the performance is degrading, the next time

the furnace is brought down for maintenance

(typically decoking), valve maintenance can be

scheduled ahead of time to bring the valve

assembly back to an optimal performance level.

II. Quench Tower

Cracked gases leave the furnace at 1382_F to

1607_F (750_C to 875_C). The gases must be

cooled immediately in order to preserve the

current composition of the gas and prevent

undesirable side reactions from taking place.

These side reactions are generally the secondary

reactions listed in Table 1. The quench tower can

use either quench oil or quench water. Generally,

only quench water is used on natural gas‐based

systems whereas naphtha plants use quench oil

and may use a quench water tower as well.

For situations in which a quench oil tower is being

used for a naphtha fed plant, the quench oil is an

extremely erosive fluid. It is usually dirty with

entrained carbon particles. In order to have a

long‐lasting solution, the erosive nature of the fluid

must be taken into account when selecting an

appropriate valve.

The Fisher V500 eccentric plug rotary control

valve is a well‐suited solution for this application

as it was specifically designed to control erosive,

coking, and other hard to handle fluids. It should

be operated in the reverse flow position for erosive

service as this will help move the downstream

turbulence away from the shutoff surface. For the

quench oil application, a hardened trim should be

applied, either Alloy 6 or ceramic. Ceramic trim is

the typical solution. Sealed metal bearings are

available to help prevent particle buildup and valve

shaft seizure. The seat ring is reversible and will

help improve the lifetime of the construction.

1-4

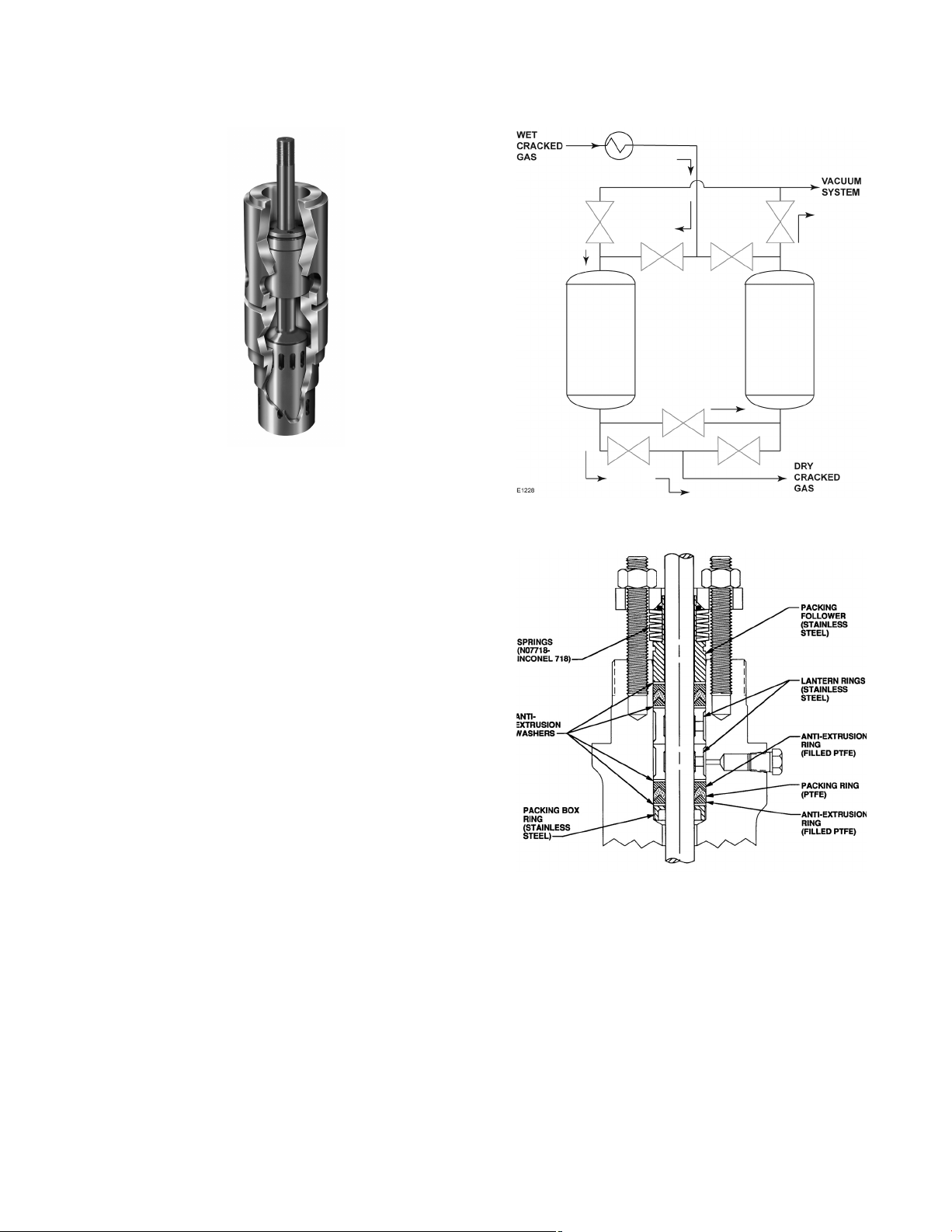

W8359

Figure 1‐4. V500 eccentric plug

rotary control valve

III. Cracked Gas Compressor

After the cracked gas has been cooled in the

quench tower, the next step in the process is

cracked gas compression. A turbine driven

centrifugal compressor is utilized to perform this

compression and there are typically four to five

stages, with intermediate cooling. The number of

stages necessary depends primarily upon the

cracked gas composition and the temperature

level of the cooling medium. All of the throughput

of the ethylene plant will pass through a cracked

gas compressor, so performance and reliability of

this unit are especially important. The compressor

is also an extremely expensive piece of

equipment, resulting in a large percentage of the

overall capital of the plant.

An antisurge control system is designed to protect

this asset. The system is designed to provide a

faster response than adjusting the turbine speed to

control the onset of surge. The controller looks at

multiple variables to prevent the onset of surge. It

requires fast, accurate response in order to

prevent surge conditions. The characteristics of a

surge condition are fast flow reversal (measured in

milliseconds), excessive compressor vibration,

increase in flowing media temperature, noise, and

it may cause the compressor to “trip”.

Consequences of surge situations are substantial

and may include shortened compressor life, loss of

efficiency, reduced compressor output, and

mechanical damage to seals, bearings, impellers,

etc.

Antisurge control valves present many various

challenges. The key challenge is ensuring valve

reliability. There is an extended period between

W8950‐1

Figure 1‐5. Antisurge control system

maintenance cycles and it is important to ensure a

reliable control valve assembly solution. The

antisurge valve is the main piece of equipment that

protects the compressor from damage caused by

a surge. When these valves are called upon to

move, they are required to stroke very quickly,

typically in the open direction only. For example,

valves with travels up to 20 inches (50.8 cm) have

been required to stroke in as little as 0.75

seconds. This can necessitate oversized actuator

connections and the use of volume booster(s) and

quick exhaust valve(s). The improper selection of

these accessories will result in poor valve

performance and tuning difficulties. During a surge

event, the pressure drop and flow rate

experienced by the valve can be high, causing

excessive levels of noise. This must be considered

in valve selection, although noise control

throughout the entire range of valve travel may not

be required. This valve may also be required to

throttle intermittently from 0 to 100% open. These

cases require the valve to have fast, accurate

control for incremental step sizes. Any delays can

cause a surge to occur. The antisurge valve must

be able to pass the highest possible output

capacity of the compressor. Application of a

1-5

W6980

Figure 1‐6. WhisperFlo Trim cage

multiplying factor to the compressor capacity figure

is common and may lead to selection of an

oversized valve. Valves with too much capacity

often have controllability issues and can cause

unstable operation.

Emerson has developed an optimized antisurge

package to meet the challenging demands of this

application. Some highlights of this package will be

discussed, but for more information, please see

the brochure titled “Fisher Optimized Antisurge

Control Valves”. These valves use a spoked plug

versus the traditional balanced plug. With the

traditional plug, when the valve is asked to move

very quickly, there is not enough area in the

balance holes to keep the plug in a balanced state;

therefore, creating a differential pressure situation

between the top and the bottom of the plug. This

differential pressure case can lead to plug

instability. The spoked plug has large balance

areas so that this does not occur. For surge events

where noise is a concern, a Fisher valve with a

Whisper Trimt III or WhisperFlot trim is

recommended.

Emerson has the engineering capability to

characterize these trims in order to meet the

specific application needs and tailor a solution

towards them. For situations when the valve

assembly is called upon to move quickly,

mechanical air cushions have been added to the

actuator cylinder to provide controlled deceleration

to help protect actuator and valve components.

The Fisher optimized antisurge package also

includes a FIELDVUE digital valve controller with

the Optimized Digital Valve (ODV) tier. There are

features within this tier and ValveLinkt software

to meet the needs of the application. For example,

factory expertise is not required to tune the Fisher

optimized antisurge valve. A technician can simply

use ValveLink software's performance tuner or the

stabilize/optimize feature with real time graphics.

Configuration and tuning can also be performed

Figure 1‐7. Rich amine letdown system

remotely by operators as process requirements

change. This feature gives plant operators and

technicians the capability to tune this assembly in

the field. The lead‐lag filter in the ODV tier can be

used to improve the response to small amplitude

steps by overdriving the set point. Asymmetric

adjustments allow the response to be set

independently in the open and closing directions.

Integrated, real time graphics allow adjustments to

be done remotely as well. Also, diagnostics can be

collected, viewed, and analyzed using ValveLink

software to look at items such as packing friction,

air path leakage, actuator spring rate, and bench

set. Partial stroke tests can also be performed to

check the health of the valve and ensure the

antisurge valve is going to move when it is

requested to.

IV. Acid Gas Removal

The acid gas removal system is typically located

between the 3rd and 4th or between the 4th and

5th stages of the compressor. In all process

configurations, acid gas removal must be located

upstream of the drying unit in order to avoid

formation of ice and hydrates in the following

fractionation steps. Acid gases are typically

scrubbed on a once‐through basis or in

combination with a regenerative chemical.

Regenerative pre‐scrubbing, before a final sodium

hydroxide treatment, is applied for high sulfur

feedstocks. This will reduce the sodium hydroxide

consumption. Regenerative scrubbing can employ

alkanolamines. The use of alkanolamines should

then require the use of a rich amine letdown valve

as seen in Figure 1‐7.

After any free liquids are removed from the gas at

an inlet scrubber, the gas passes to the absorber

1-6

section. Here, it rises counter‐currently in close

contact with the descending amine solution.

Purified gas leaves from the top of the absorber.

Lean amine enters the tower at the top where it

flows across trays and downward against the flow

of the gas. At the bottom of the absorption tower,

the acid gas rich amine leaves through the rich

amine letdown valve that is actuated by a

liquid‐level controller. The rich amine then goes to

a flash tank, operating at a reduced pressure,

where large portions of the physically absorbed

gases are offgassed. From there, the rich amine

goes through various processes to be regenerated

and the cycle starts over again.

The rich amine letdown valve is a demanding

application because the process has entrained gas

in solution. As the fluid passes through the letdown

valve, it takes a pressure drop due to the pressure

differential between the tower and the flash tank.

As this pressure drop takes place in the valve, a

large amount of outgassing occurs. Outgassing is

when the entrained gas comes out of solution. As

a result of outgassing, the valve has a two phase

flow. One phase is the liquid amine and the other

and/or hydrogen sulfide (H2S) that comes

is CO

2

out of solution. This two‐phase flow may produce

excessive vibration and may be very erosive due

to high velocity impingement of the liquid phase on

the valve trim.

W0961

Figure 1‐8. Whisper Trim I cage

Outgassing is very similar in effect to flashing and

requires special consideration in the proper choice

of valve, trim style, and materials. Generally, the

overall approach is dependent on the severity of

the pressure drop experienced. Although some

sizing methods predict cavitation, small orifice

anti‐cavitation trim should not be used on this

service for two reasons: first, the vapor cushions

any cavitation bubble implosions and then

cavitation damage should not be experienced and

second, the accelerated gas breakout that, in turn,

accelerates the liquid, would rapidly erode the

multiple passage trim structure because of

incompressible fluid impingement.

For pressure drops of 300 to 600 psi (20.7 to 41.4

bar), use of slotted (Whisper Trim I) or drilled hole

(Whisper Trim III) trim styles installed in the flow

up direction are recommended. The slotted or

drilled hole cages “break up” the flow, minimizing

the potential energy available to be dissipated

during the outgassing process. Many relatively

small sources of energy do not possess the

damage capabilities of fewer large sources. By

flowing the process fluid up, these small sources

of energy are kept away from other critical trim

parts. Standard hardened cage, plug, and seat

W6787

Figure 1‐9. DST

parts are recommended. For pressure drops over

600 psi (41.4 bar), use of a slotted Whisper Trim I

cage made of solid Alloy 6 is recommended. A

hardened valve plug and seat ring should also be

used.

Other options for this condition include the use of a

Fisher NotchFlot Dirty Service Trim (DST) valve

or DST‐G trim designed for outgassing. For all rich

amine letdown applications, NACE materials are

likely specified.

V. Drying

The cracked gas is saturated with water before

compression and after each intercooler stage.

Moisture must be removed before fractionation to

prevent the formation of hydrates and ice.

Temperatures of -148_F (-100_C) would form ice

1-7

W9603

Figure 1‐10. DST‐G

compounds that could block pipes and/or damage

equipment. Typically this is accomplished by

chilling and by adsorption on molecular sieves.

The drying process is similar to that of a two bed

pressure swing adsorption (PSA) skid. Older

plants also use absorption by a glycol scrubbing

system or adsorption on alumina. Drying is

arranged before the first fractionation step,

typically after the last compression stage. Multiple

adsorption beds make continuous water removal

possible. One or more adsorption beds are in

operation while at least one unit is being

regenerated. The inability to dry because of

molecular sieve issues will shut down the plant.

Generally, line‐sized butterfly valves or

quarter‐turn ball valves are used in molecular

sieve switching valve applications. Over‐sizing can

occur and high cycle demands will cause wear on

the valves. As a result, galled bearings and seal

wear will also occur. In the case of high output

torque, bed lifting of the adsorption beads can

occur if the valve is controlling poorly or opens too

quickly and “jumps” out of the seat. This can

damage the adsorption beads and cause them to

rub or abrade together and create dust. This

reduces the drying effectiveness of the adsorption

beads. The dust or fines from bead wear can get

stuck in the bearing area and cause damage. At

the very worst, it can cause seizing of the valve.

The adsorption bead dust or fines can also cause

seal wear.

Emerson has experience and success in

molecular sieve applications for the ethanol

industry. Fisher A81 valves with a 316 SST

chrome plated disc and UHMWPE seal technology

Figure 1‐11. Molecular sieve drying system

A6163‐1

Figure 1‐12. ENVIRO‐SEAL PTFE packing system

have been used with good results. The UHMWPE

seal allows for tight shutoff. Tight shutoff allows for

improved bed drying. PTFE lined PEEK bearings

should also be used as these have been shown in

molecular sieve applications to last longer than

wire mesh bearings. ENVIRO‐SEAL packing may

also be considered to avoid leakage of the cracked

gas.

Use of a FIELDVUE digital valve controller can

increase the response to set point at the beginning

of the adsorption and regeneration cycle without

1-8

overshoot. It precisely controls the rate of opening

to eliminate adsorption bead bed disturbance.

VI. Distillation Columns

The fractionation section receives the compressed

cracked gas at a pressure of 464 to 551 psi (32‐38

bar) for further fractionation into different products

and fractions at specified qualities. This is done

through a series of distillation columns and

hydrogenation reactors. Cryogenic separation is

the predominant method for cracked gas

separation. Although gas separation processes via

adsorption, absorption, or membrane technology

have made progress in the recent past, they have

not found major applications within the ethylene

industry. Today, three processing routes have

gained commercial importance, with the main

characteristics being the first separation step and

the position of the acetylene hydrogenation. These

routes are demethanizer first with tail‐end

hydrogenation, deethanizer first with front‐end

hydrogenation, and depropanizer first with

front‐end hydrogenation. The following is a listing

of the various distillation columns and their

functions:

D Demethanizer: Demethanization of the

cracked gas separates methane as an overhead

component from C

components. Concurrently, hydrogen is removed

from the cracked gas stream and may be obtained

as a product by purification before or after

demethanization. Methane is typically used as a

plant fuel or sold. C

sent to the recovery system.

D Deethanizer: Deethanization of cracked gas

separates acetylene, ethylene, and ethane as

overhead components from C

components.

D Depropanizer: Depropanization separates

propane and lighter fractions as overhead

components from C

components.

splitter or ethylene fractionation: Ethylene

D C

2

fractionation separates ethylene as a high‐purity

overhead product from ethane, which is combined

with propane and recycled for cracking.

splitter or propylene fractionation:

D C

3

Propylene fractionation separates propylene as a

chemical grade overhead product or more

and heavier bottom

2

and heavier components are

2

+ bottom

3

+ fractions as bottom

4

frequently as polymer grade propylene from

propane. Propane is recycled for cracking.

D Primary fractionator: With liquid pyrolysis

feedstocks (naphtha fed plants), the primary

fractionation column is the first step in the cracked

gas processing route. Cracked gas enters the

column and it is contacted with circulating oil and,

at the top of the column, with a heavy pyrolysis

gasoline fraction obtained from the subsequent

water quench tower. Cracked gas leaves the top of

the primary fractionator free of oil but still

containing all the dilution steam. Hot oil, which

functions as a heat carrier, is collected at the

bottom of the column. After cooling, it is

recirculated as reflux to the middle section of the

primary fractionator and to the quench nozzles

downstream of the transfer line heat exchangers.

Distillation columns occur in all types of chemical

plants. The objective is to separate a feed stream

into light‐component and heavy‐component

product streams. It relies on the relative volatility

between the components that make up the feed

stream. The high volatility (lighter) components

boil at a lower temperature than the low volatility

(heavier) components. Therefore, when heat is

added to the column through a bottom reboiler, the

lighter materials are vaporized and rise to the top

of the column. The overhead vapors are cooled

until they condense and become a liquid again.

The efficiency of distillation depends on the

amount of contact between the vapor rising and

the liquid falling down the column. Therefore,

some of the overhead liquid product is sent back

(refluxed) to the top of the column. Increasing the

reflux will improve the purity of the overhead

product. However, it also requires more heat from

the reboiler to re‐vaporize the lighter components

in the reflux stream. Some distillation columns can

operate with a side reboiler as well, such as the

demethanizer. The operation of a distillation

column is a balancing act between product purity

and energy usage. If the amount of vapor and

liquid traveling through the column becomes too

great, the column can “flood.” Too much reflux, too

much reboil heat resulting in too much vapor, or

both can causing flooding. When flooding occurs,

the efficiency of the distillation column is

dramatically reduced with corresponding drops in

product purities.

Figure 1‐13 shows the general schematic of a

distillation column. The valves associated with this

are the feed, reflux, bottom product, overhead

product, pressure control, and reboil valves.

Feed valves are usually used as flow or level

control loops. An upstream unit or process often

1-9

Loading...

Loading...