Fisher Instruction Manual: S208 and S209 Pressure Reducing Regulator with Internal Slam-Shut Device | Fisher Manuals & Guides

Instruction Manual

Form 5412

July 2012

Types S208 and S209

Types S208 and S209 Pressure Reducing Regulators

with Internal Slam-Shut Device

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion

and/or re causing property damage

and personal injury or death.

Fisher® regulators must be installed,

operated, and maintained in accordance

with federal, state, and local codes,

rules and regulations, and Emerson

Process Management Regulator

Technologies, Inc. (Regulator

Technologies) instructions.

If the regulator vents gas or a leak

develops in the system, service to

the unit may be required. Failure

to correct trouble could result in a

hazardous condition.

Call a gas service person to service

the unit. Only a qualied person must

install or service the regulator.

Introduction

Scope of the Manual

W7876

Figure 1. Type S208K Pressure Reducing Regulator with

Type VSX-2 Slam-Shut Device

internal relief to allow overpressure caused by thermal

expansion to be released. The Types S208 and S209

include a Type VSX-2 integral slam-shut device. The

Type VSX-2 is a shut-off device that provides over

or over and underpressure protection by completely

shutting off the ow of gas to the downstream system.

The slam-shut device’s actions are independent of

the Types S208 and S209 regulators and of variations

to inlet pressure. The Type VSX-2 has internal

registration, except on the Type S208P or S209P where

a downstream sensing line is required.

This instruction manual provides installation,

adjustment, maintenance, and parts ordering

information for Types S208, S208H, S208P, S208PK,

S209, S209H, S209P, and S209PK gas service

regulators with Type VSX-2 integral slam-shut device.

Description

Types S208 and S209 regulators are typically installed

on industrial and commercial applications. Types S208

and S209 are similar in design to the Types S201 and

S202 regulators. Type S209 units contain a token

www.fisherregulators.com

Specications

The Specications section lists the ratings, pressure

ranges, and other specications for all Types S208 and

S209 regulators. The following information is stamped

on the regulator nameplate at the factory: type

number, manufacture date, spring range, orice size,

Type VSX-2 high and low trip pressures, maximum

inlet pressure, maximum outlet operating pressure,

and outlet pressure that may damage regulator parts.

D102247X012

Types S208 and S209

Specications

Available Congurations

See Table 1

Body Sizes and End Connection Styles

See Table 2

Maximum Inlet Pressure (Body Rating)

(1)

150 psig / 10.3 bar

Maximum Operating Inlet Pressure to Obtain

Optimum Performance by Orice Size

See Table 3

Maximum Outlet Pressure (Casing)

(1)

15 psig / 1.0 bar

Maximum Operating Outlet Pressure To Avoid

Internal Part Damage

(2)

Light Diaphragm Plate: 2 psi / 0.14 bar above

outlet pressure setting

Heavy Diaphragm Plate: 3 psi / 0.21 bar above

outlet pressure setting

Outlet Pressure Ranges

See Table 4

1. The pressure/temperature limits in this Instruction Manual and any applicable standard limitation should not be exceeded.

Type VSX-2 Trip Pressure Ranges

See Table 5

Pressure Setting Adjustment

Adjusting Screw

Pressure Registration

See Table 1

Material Temperature Capabilities

Nitrile (NBR): -20 to 150°F / -29 to 66°C

Fluorocarbon (FKM): 0 to 200°F / -18 to 93°C

(Upper temperature limitation due to

Nylon (PA) appers)

Type VSX-2: -20 to 140°F / -29 to 60°C

Control and Sensing Line Connections

(required on the “P” version only)

Types S208 and S209: 3/4 NPT

Type VSX-2: 1/4 NPT

Approximate Weight

30 pounds / 14 kg

(1)

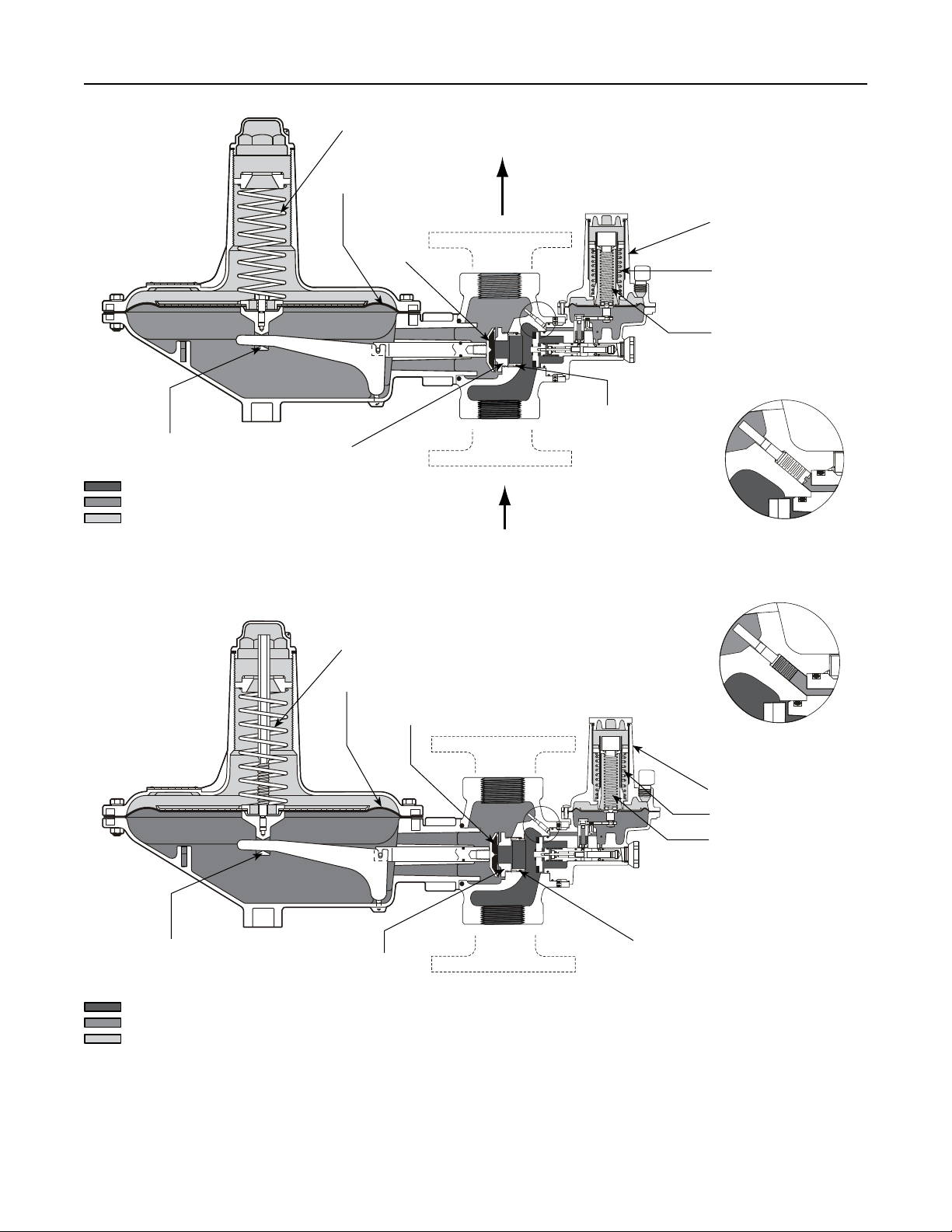

Principle of Operation (Figure 2)

Types S208 and S209

When the downstream demand decreases, the

pressure under the diaphragm increases. This

pressure overcomes the regulator setting (which is

set by a spring). Through the action of the pusher

post assembly, the valve disk moves closer to the

orice and reduces gas ow. If demand downstream

increases, pressure under the diaphragm decreases.

Spring force pushes the pusher post assembly

downward, the valve disk moves away from the orice,

and the gas ow increases.

The Type S209 regulators include a limited capacity

internal relief valve for relief of thermal expansion. If the

downstream pressure exceeds the regulator setting by

8 inches w.c. to 2 psig / 20 mbar to 0.14 bar, depending

on the main spring used, the relief valve opens and

excess gas is vented through the stabilizer vent in the

upper spring case.

Type VSX-2 Slam-Shut Device

The Type VSX-2 slam-shut device on the Types S208

and S209 regulators is a fast acting shut-off valve which

provides over or over and underpressure protection by

completely shutting off the ow of gas to the downstream

system. The shutoff module’s actions are independent

of the Types S208 and S209 regulators and variations

to the inlet pressure. The Type VSX-2 has internal or

external registration. External registration requires a

downstream sensing line.

The shutoff disk is held in the open position (reset

position) by a small ball holding the disk stem. If

the pressure below the diaphragm increases (or

decreases) reaching the Type VSX-2 setpoint,

the diaphragm will travel upwards (or downwards)

operating a level which in turn releases the ball.

Once the ball is released, the spring force on the stem

will push the stem and disk to the closed position

against the seat shutting off all gas ow. The manual

reset has an internal bypass to equalize the reset

pressure on either side on the shut-off disk.

2

Type S208

July 2008

Type S208

Type VSX-2 with

External Registration

Type VSX-2 with

Internal Registration

Type S208

Type S209

Type S208

Type VSX-2 with

PUSHER POST ASSEMBLY

E0234

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

CONTROL SPRING

DIAPHRAGM

VALVE DISK

ORIFICE

TYPE S208

Types S208 and S209

TYPE VSX-2 MODULE

HIGH CONTROL SPRING

LOW CONTROL SPRING

ORIFICE INSERT

AND O-RING

TYPE VSX-2 WITH EXTERNAL

REGISTRATION

PUSHER POST ASSEMBLY

B2507

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

CONTROL SPRING

DIAPHRAGM

VALVE DISK

ORIFICE

TYPE S209

TYPE VSX-2 WITH INTERNAL

REGISTRATION

TYPE VSX-2 MODULE

HIGH CONTROL SPRING

LOW CONTROL SPRING

ORIFICE INSERT AND O-RING

Figure 2. Operational Schematics

3

Types S208 and S209

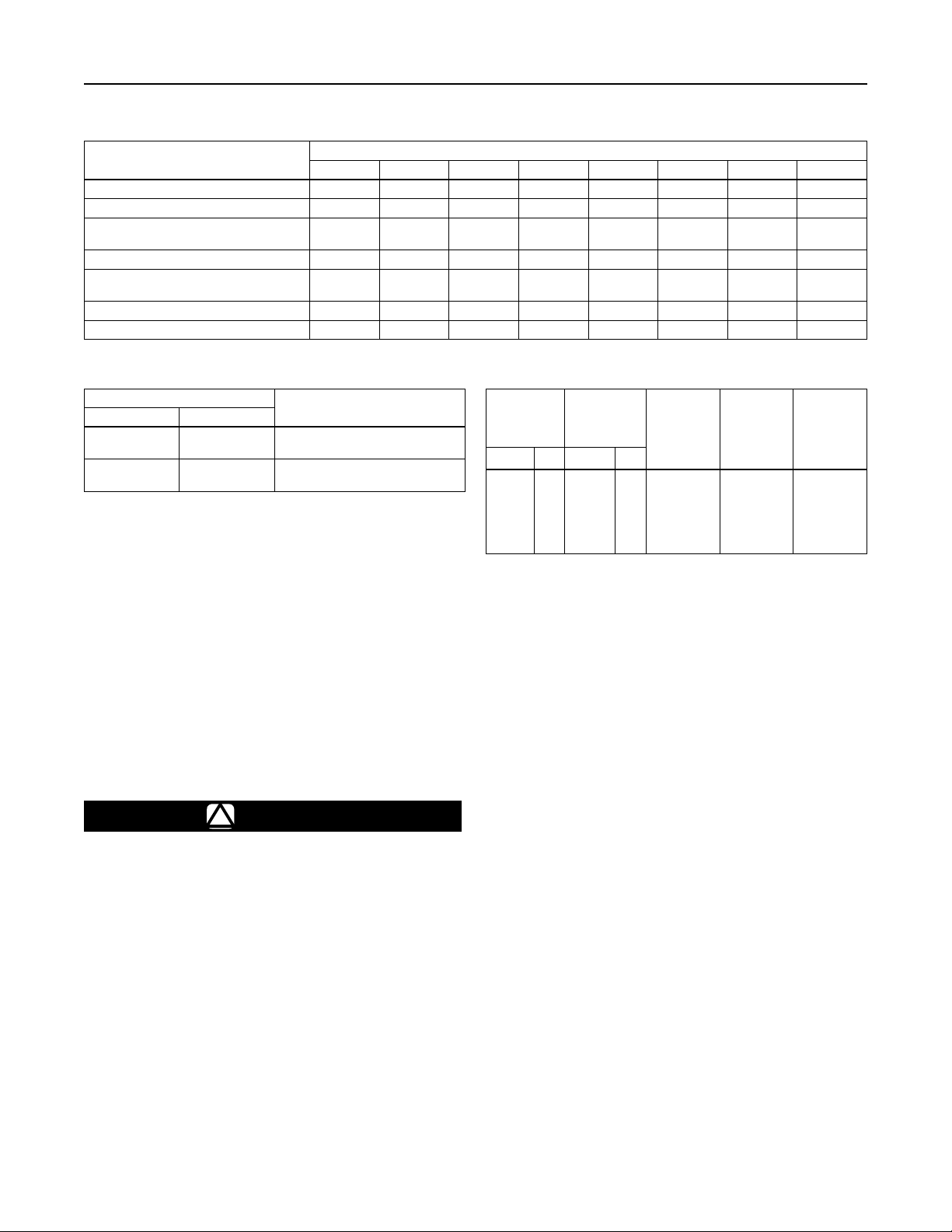

Table 1. Available Congurations

CONSTRUCTION FEATURES

Light diaphragm plate X X

Heavy diaphragm plate X X X X

Either light or heavy diaphragm plate

depending on outlet pressure range

Internal registration X X X X X

External registration - O-ring stem seal and

downstream control line connection

Internal relief - Token X X X

Type VSX-2 X X X X X X X X

S208 S208H S208K S208P S208PK S209 S209H S209P

Table 2. Body Sizes and End Connection Styles

BODY SIZE

NPS DN

1-1/4, 1-1/2, or

1-1/2 x 2

2 50

32, 40, or 40 x 50 NPT

END CONNECTION STYLE

NPT, CL125 FF anged, CL250 RF

anged, or PN 10/16 RF anged

In order for the Underpressure Shutoff (UPSO) of

any slam shut to be triggered, the downstream pipe

pressure must drop below the UPSO setpoint. In the

case of a downstream line break, numerous factors

can prevent the downstream pipe pressure from

decreasing below the slam-shut UPSO setpoint. These

factors include the distance of pipe to the break, the

diameter of the pipe, size of the break, and the number

of restrictions, such as valves, elbows and bends,

downstream of the regulator and/or slam-shut device.

Due to these factors additional protections should be

installed to stop ow in the event of a line break.

WARNING

!

Personal injury or system damage

may result if this regulator is installed,

without appropriate overpressure

protection, where service conditions

could exceed the limits given on

the regulator nameplate. Regulator

installations should be adequately

protected from physical damage.

All vents should be kept open to permit

free ow of gas to the atmosphere. Protect

openings against entrance of rain, snow,

insects, or any other debris that may

plug the vent or vent line. On outdoor

installations, point the spring case vent

TYPE NUMBER

X X

X X X

Table 3. Orice Sizes and Maximum Operating Inlet Pressures

MAXIMUM

6.4

9.5

13

19

25

30

OPERATING

INLET

PRESSURE

125

8.6

125

8.6

100

6.9

60

4.1

25

1.7

13

0.90

C

53

110

190

415

700

910

g

C

1.51

3.14

5.43

11.9

20

26

v

C

1

35

ORIFICE SIZE

Inches mm psig bar

1/4

3/8

1/2

3/4

1

1-3/16

downward to allow condensate to drain.

This minimizes the possibility of freezing

of water or other foreign material from

entering the vent and interfering with

proper operation.

Under enclosed conditions or indoors,

escaping gas may accumulate and be

an explosion hazard. In these cases,

the vent should be piped away from the

regulator to the outdoors.

If the regulator or slam-shut device is

exposed to an overpressure condition,

it should be inspected for any damages

that may have occured. Operation

below these limits does not preclude

the possibility of damage from external

sources or from debris in the pipeline.

In the case of a downstream line break,

numerous factors affect the capability to

evacuate gas from the pipeline. These

factors include the distance of pipe to the

break, the diameter of the pipe, size of

the break, and the number of restrictions,

such as valves, elbows and bends,

downstream of the regulator and/or

slam-shut device. Due to these factors

additional protections should be installed

to stop ow in the event of a line break.

4

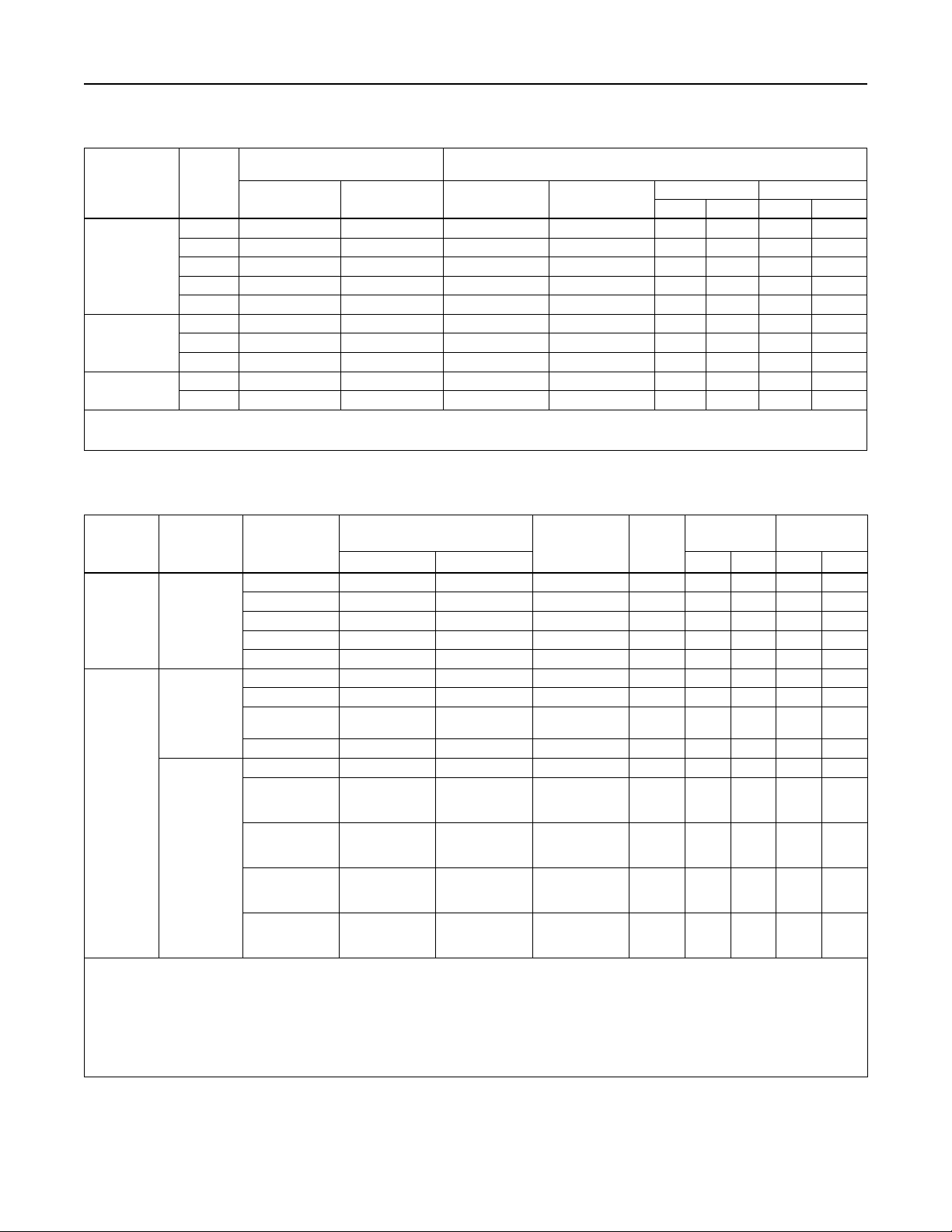

Table 4. Outlet Pressure Ranges

Types S208 and S209

TYPES

S208, S209,

S208P, and

S209P

OUTLET (CONTROL)

SPRING

NUMBER

- - - - 2 to 4.5

PRESSURE RANGE

Inch w.c. mbar Part Number Color Code

(1)

5 to 11

(1)

1D892527022 Brown Stripe 6.12 15.5 0.109 2.77

1 3.5 to 6.5 9 to 16 1D892627022 Red 7.5 19.1 0.120 3.05

2 5 to 9 12 to 22 1D892727012 Black 7.88 20.0 0.130 3.30

3 8.5 to 18 21 to 45 1D893227032 Gray 7.5 19.1 0.156 3.96

PILOT CONTROL SPRING

Free Length Wire Diameter

Inches cm Inches mm

4 14 to 30 35 to 75 1D893327032 Dark Green 7.25 18.4 0.182 4.62

5 1 to 2 psig 0.07 to 0.14 bar 1H975827032 Dark Blue 7.38 18.7 0.225 5.72

(2)

S208H, S208P

S209H, and

S209P

S208K and S208PK

1. With regulator installed so control spring is on top of diaphragm. If installed so control spring is on bottom, lower end of outlet pressure range can be reduced by 1-inch w.c. / 2 mbar

for regulator with light diaphragm plate or 2-inches w.c. / 5 mbar for regulator with heavy diaphragm plate.

2. Types S208P and S209P require heavy diaphragm plate for outlet pressures over 1 psig / 0.07 bar.

,

(2)

6 1.5 to 3.25 psig 0.10 to 0.22 bar 1H975927032 Orange 7.38 18.7 0.250 6.35

7 2 to 5 psig 0.14 to 0.34 bar 1P615427142 Yellow 6.5 16.5 0.283 7.19

8 2 to 5.5 psig 0.14 to 0.38 bar 0Y066427022 Green Stripe 6.00 15.2 0.363 9.22

9 4 to 10 psig 0.28 to 0.69 bar 1H802427032 Unpainted 6.00 15.2 0.406 10.31

Table 5. Type VSX-2 High and Low Trip Pressure Ranges

SETPOINT

RANGES

SLAM-SHUT

REGISTRATION

WITH MAIN

VALVE SPRING

NUMBER

(1,2)

1, 2 12 to 25 30 to 62 T14162T0012 Black 3.15 80.0 0.067 1.70

1, 2, 3, 4 20 to 52 50 to 129 T14163T0012 Brown 3.15 80.0 0.080 2.03

FOR USE

Overpressure

Shutoff

Internal or

External

3, 4, 5, 6 1.4 to 3.9 psig 0.10 to 0.27 bar T14164T0012 Red 3.15 80.0 0.091 2.31

5, 6, 7, 8, 9 3.8 to 8.7 psig 0.26 to 0.60 bar T14165T0012 Orange 3.15 80.0 0.120 3.05

9 5.8 to 16 psig 0.40 to 1.1 bar T14166T0012 Pink 3.15 80.0 0.138 3.51

2, 3 2 to 12 5 to 30 T14168T0012 White 3.15 80.0 0.043 1.09

3, 4, 5, 6 4 to 30 10 to 75 T14169T0012 Blue 3.15 80.0 0.055 1.40

External

5, 6, 7, 8

7, 8, 9 1.5 to 10.8 psig 0.10 to 0.75 bar T14171T0012 Olive 3.15 80.0 0.125 3.18

(3)

2, 3, 4

(4)

Underpressure

5, 6

Shutoff

(4)

5, 6, 7, 8

Internal

(4)

7, 8

(4)

9

1. See Table 4 for main valve spring number.

2. Other spring combinations are available, please contact your local Sales Ofce for additional information. Trip pressure that are 2 or 3 psig / 0.14 to 0.21 bar

over set pressure may result in internal parts damage.

3. Regulator main valve spring numbers 2, 3, and 4 cannot be used with an internally registered Type VSX-2 to provide underpressure shutoff under owing conditions. If protection

against loss of inlet pressure is the only required function for the Type VSX-2 then an internally registered Type VSX-2 may be used with the same minimum trip pressures as an

externally registered Type VSX-2.

4. 50% of regulator setpoint is the minimum allowable underpressure shutoff setting for an internally registered Type VSX-2 used with main valve spring numbers 5, 6, 7, and 8.

70% of regulator setpoint is the minimum allowable underpressure shutoff setting for an internally registered Type VSX-2 used with main valve spring number 9. If protection against

loss of inlet pressure is the only required function for the Type VSX-2 then an internally registered Type VSX-2 may be used with the same minimum trip pressures as an externally

registered Type VSX-2.

MINIMUM TO MAXIMUM

TRIP PRESSURE

Inch w.c. mbar Inches mm Inches mm

10 inches w.c.

to 2.3 psig

25 mbar to

0.16 bar

TYPE VSX-2

SPRING PART

NUMBER

SPRING

COLOR

T14170T0012 Silver 3.15 80.0 0.067 1.70

SPRING FREE

LENGTH

SPRING WIRE

DIAMETER

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

50% of regulator

setpoint to

30

50% of regulator

setpoint to

2.3 psig

50% of regulator

setpoint to

10.8 psig

70% of regulator

setpoint to

10.8 psig

50% of regulator

setpoint to

75

50% of regulator

setpoint to

0.16 bar

50% of regulator

setpoint to

0.75 bar

70% of regulator

setpoint to

0.75 bar

T14169T0012 Blue 3.15 80.0 0.055 1.40

T14170T0012 Silver 3.15 80.0 0.067 1.70

T14171T0012 Olive 3.15 80.0 0.125 3.18

T14171T0012 Olive 3.15 80.0 0.125 3.18

5

Loading...

Loading...