Instruction Manual

MCK-1155

April 1981

Type N550

Type N550 Packing Removal/Replacement

WARNING

!

Only qualified servicemen should

attempt to repair these valves. The skill

required is similar to the complexity

involved in pump repair.

Before starting any type of repair, close

off the upstream valves and remove all

gas pressure from both the outlet and

inlet sides of the Type N550 emergency

shutoff valve (ESV).

Before Removing Packing

If the Type N550’s operating handle closes slowly or

binds in a “no flow” condition, it could be from binding in

the packing gland area or from external binding, such

as a bent operating handle catching on the latch block,

etc. Check for some type of external binding first.

If the binding appears to be internal, it could be from

uneven or over-tightened gland bolts (key 33), refer to

Figures 1 and 24. Try loosening these two bolts onehalf turn each, and tap the shaft (key 15) lightly side

to side to align the gland and follower bearing. Snug

the bolts down evenly, only tight enough to prevent

leakage. If this does not free the handle, the packing

must be removed and be either cleaned or replaced.

Removal of Packing

Refer to Figure 24.

Note

If there is leakage around the shaft

(key 15), the packing should be replaced.

Order parts kit T13090 which includes a

Figure 1. Uneven gland bolts could cause binding

graphite packing adaptor (black), a TFE

packing ring (white), a TFE male adaptor

(white), a gasket, and two washers

(key nos. 26, 29, & 30). With no leakage,

only binding, the packing probably can

be reused, and the only replacement

parts required are the gasket (key 26)

and washer (key 29). In either case, use

Magnalube G grease (part no. T13049,

1/2 oz. tube which will lubricate many

valves) of the regulator.

CAUTION

Throughout the entire removal and

replacement procedure, be sure that

the shaft (key 15) is not pulled out of

the internal lever holding the poppet

assembly. If the shaft is pulled out, the

D450042T012

R

www.FISHERregulators.com/lp

Type N550

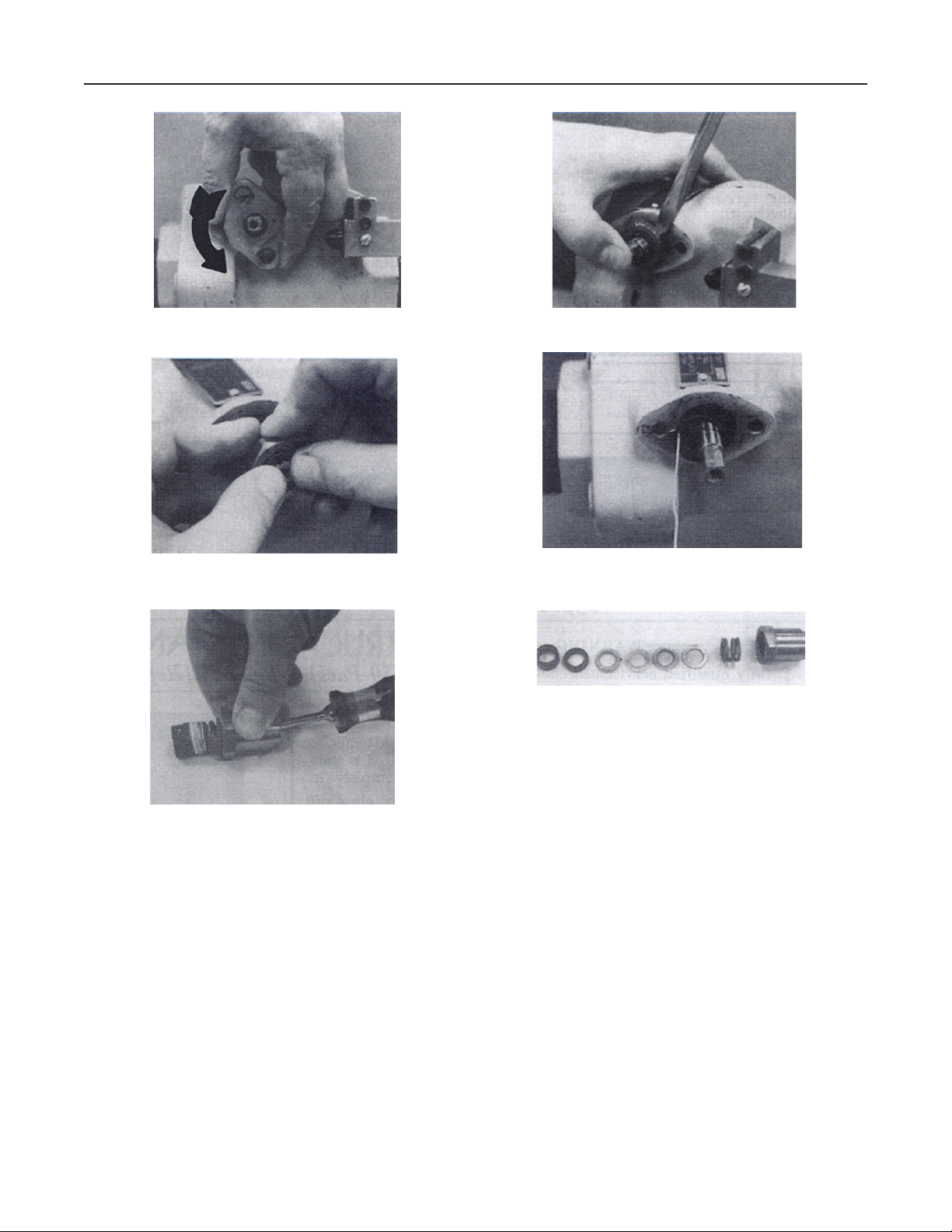

Figure 2. Turn gland retainer (step 3)

Figure 4. Remove gland (step 6)

Figure 3. Pry out gland (step 5)

Figure 5. Remove gasket (step 7)

Figure 7. Remove packing carefully (step 8)

Figure 6. Remove packing carefully (step 8)

N550 will have to be removed from the

line in order to properly reassemble it.

Holding the shaft in place permits the

valve to be left in-line if all line pressure

is removed.

1. Remove the operating handle (key 18), fuse

link assembly (key 22), and retainer (key 24) by

unscrewing the bolt (key 23).

2. Take out the two gland bolts (key 33).

3. Turn the gland retainer (key 32) one-half turn

counterclockwise, refer to Figure 2.

2

4. Remove the gland retainer from the gland (key 27).

5. Holding the valve’s shaft firmly in place, pry out

the gland with a screwdriver, Figure 3.

6. Still holding the shaft in place, work the gland

over the end of shaft to remove the gland, Figure 4.

7. The gasket (key 26) may be on the end of the

gland, but most likely it is still in the body. Use a stiff

wire (such as a paper clip), Figure 5 to remove the

gasket. The gasket should be discarded and a new

one used when reassembling.

8. Carefully remove the packing stack (key 30) from

the rear of the gland. Use a screwdriver, Figure 6, to

push between the coils of the spring (key 28) to avoid

cutting the packing or scratching the gland.

9. The part shown in Figure 7 will be removed from

the gland: follower bearing (key 31), packing stack

Type N550

(key 30), includes graphite female adaptor, two TFE

packing rings, and a TFE male adaptor), a washer

(key 29), and the packing spring (key 28).

10. Clean the packing (if it is to be reused), the

gland, and the shaft of dirt, grease, and paint.

CAUTION

Paint on the shaft may damage

the packing.

Reassembly of Packing

Figure 8. Replacement parts for gland

Refer to Figure 25.

Note

4. Lubricate the shaft, gland, packing, and follower

bearing with a liberal amount of Magnalube G grease,

Figure 12.

5. Replace the male TFE packing adaptor with the

flat side in

into the gland. Be careful not to damage this adaptor.

Apply a liberal amount of Magnalube G grease on the

face of this adaptor, Figure 14, so that it will be trapped

under the next ring.

6. Install one TFE packing ring with the

in, Figure 15, using the same procedure as in step 5.

Again apply a liberal layer of Magnalube G grease.

7. Install the graphite adaptor flat side out, Figure 16.

8. Install the follower bearing and press it in place with

the gland retainer, Figure 17. The bearing will extend

about 1/8-inch (3,2 mm) from the gland, Figure 18.

9. Install the gland retainer over the gland. Turn the

retainer about one-quarter turn clockwise Figure 19,

then let the spring turn the gland back until it stops.

10. Remove the retainer and fit it back on the

gland so that the bolt holes line up as closely as

possible with bolt holes in the body, Figure 20.

11. Wind the gland retainer

and install the bolts (key 33), Figure 21.

, Figure 13, working it over the shaft and

female side

one-half turn clockwise

The parts shown in Figure 8 are to be

replaced in the gland: packing spring

(key 28), two washers (key 29), packing

stack (key 30) includes graphite female

adaptor one TFE packing ring, and a

TFE male adaptor), and the follower

bearing (key 31).

1. Install a new gasket (key 26) on the step at the

back of the gland (key 27). Note the small hole on the

back of the gland, Figure 9. This hole must engage

the end of the closing spring (key 25) when the gland

is installed in the body. Look in the body and note the

position of the end of the closing spring, Figure 10.

2. Insert the gland into the body, and slowly turn the

gland while pushing it into place. When the closing

spring snaps in the gland’s hole, the gland fits in the

body as deeply as it had originally.

3. Install the packing spring and the two washers into

the gland, Figure 11.

Note

Winding the retainer tightens the closing

spring. If the spring is wound more than

one-half turn, It may bind and pull the

end out of the gland when the valve is

opened. If not wound enough, the valve

may be sluggish on closing.

12. Install the handle assembly (key nos. 18,

22, 23, and 24), Figure 22, and carefully open the

valve. If there is binding before the handle goes fully

open, the closing spring has been wound too tightly.

Repeat steps 9-11 to get the proper spring winding

before proceeding.

13. If the handle moves freely to the open position,

tap the shaft lightly side to side, Figure 23, to align the

follower bearing. The valve should now the be ready

for service.

14. Carefully repressure the line and check for leaks.

3

Loading...

Loading...