Fisher Instruction Manual: Fisher Vee-Ball V200U Rotary Control Valve DN80 through 250 (NPS 3 through 10) Manuals & Guides

Instruction Manual

D104548X012

V200U Valve

Fisher™ Vee‐Ball™ V200U Rotary Control Valve

DN 80 through 250 (NPS 3 through 10)

May 2020

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 2.................................

Specifications 2...............................

Educational Services 2

Installation 3....................................

Maintenance 7..................................

Packing Maintenance 7.........................

Replacing the HD Ball Seal 11....................

Bearing and Ball Maintenance 14.................

Actuator Mounting 19

Determining Mounting Position 20...............

Determining Closed Position 20.................

Parts Ordering 23

Parts Kits 23.....................................

Parts List 24.....................................

................................

..........................

............................

Figure 1. Fisher V200U Flangeless Vee‐Ball with

™

Bettis

RPE Actuator and FIELDVUE™ DVC2000

Digital Valve Controller

X1711

Introduction

Scope of Manual

This instruction manual provides installation, operation, maintenance, and parts information for

the Fisher Vee‐Ball Flangeless V200U rotary control valve sizes DN80 through DN250

(NPS 3 through NPS 10) (see figure 1).

For information on ENVIRO‐SEAL

(D101643X012

www.Fisher.com

). Refer to separate manuals for information concerning the actuator, positioner and accessories.

Do not install, operate, or maintain Vee-Ball valves without being fully trained and qualified in valve,

actuator, and accessory installation, operation, and maintenance. To avoid personal injury or property

damage, it is important to carefully read, understand, and follow all the contents of this manual,

including all safety cautions and warnings. If you have any questions about these instructions, contact

your Emerson sales office

™

packing, see the ENVIRO‐SEAL Packing System for Rotary Valves instruction manual

before proceeding.

V200U Valve

May 2020

Table 1. Specifications

Instruction Manual

D104548X012

Valve Sizes

See table 2

Valve End Connection Styles

Flangeless (all sizes) J mates EN1092-1 PN10-40

Type B raised-face flanges (see table 2) J mates with

ASME B16.5 CL150/CL300 raised-face flanges (see

table 2)

Maximum Inlet Pressure

Consistent with applicable EN 12516-1 or

ASME B16.34 ratings

Standard Flow Direction

Forward (into the convex face of the Vee‐Ball)

Dimensions

See table 4

Actuator Mounting

J Right‐hand, standard or J left‐hand, optional, as

viewed from the valve inlet (see figure 10 and the

Actuator Mounting section)

1. The pressure/temperature limits in this manual, and any applicable code or standard limitation, should not be exceeded.

(1)

Standard: Ball rotates counterclockwise to close

when viewed from actuator side of valve

Optional: Ball rotates clockwise to close

Ball rotation is 90 degrees

Valve/Actuator Action

For right-hand mount actuator, the standard ball

design and actuator action is counter-clockwise to

close (CCW). The ball will rotate to the top of the

valve body when open for a horizontal pipe run with

the valve shaft positioned horizontal. J Left-hand

actuator mounting with CCW action is an option.

Left-hand actuator mounting with a special clockwise

to close (CW) ball design and actuator action is also

available to allow the ball to rotate to the top of the

valve body for a horizontal pipe run with the valve

shaft positioned horizontal.

With diaphragm or piston rotary actuator,

field‐reversible between:J push‐down‐to‐close

(PDTC) (extending actuator rod closes valve) and

J push‐down‐to‐open (PDTO) (extending actuator

rod opens valve.)

Approximate Weight

See table 3

Description

The V200U Vee‐Ball valves (figure 1) with a V‐notch ball are used in throttling or on-off service. The V200U is a

flangeless construction capable of interfacing with EN 1092-1 Type B or ASME B16.5 raised face flanges. The splined or

square drive shaft connects to a variety of rotary‐shaft actuator options.

Specifications

Specifications for these valves are shown in table 1 and in the Fisher V200U Vee-Ball Rotary Control Valves Bulletin

51.3:V200U (D104550X012).

Educational Services

For information on available courses for Fisher Vee-Ball valves, as well as a variety of other products, contact:

Emerson Automation Solutions

Educational Services - Registration

Phone: 1-641-754-3771 or 1-800-338-8158

E-mail: education@emerson.com

emerson.com/fishervalvetraining

2

Instruction Manual

D104548X012

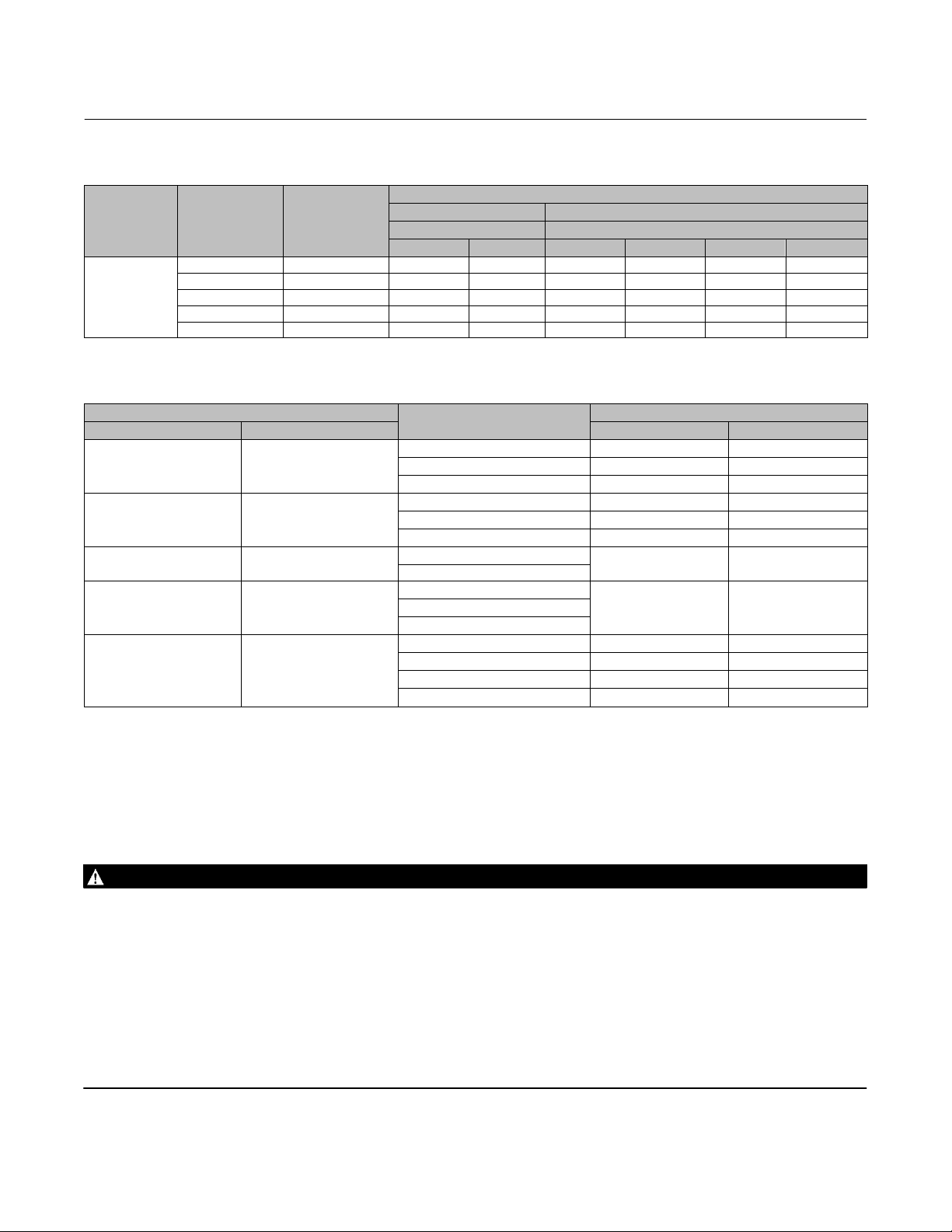

Table 2. Valve Body Materials, End Connections, and Ratings

VALVE BODY

MATERIAL

EN 1.4408/CF8M

VALVE SIZE, DN VALVE SIZE, NPS

80 3 X X X X X X

100 4 X X X X X X

150 6 X X X X X X

200 8 X X X X X X

250 10 X X X X X X

Table 3. V200U Approximate Weights

VALVE SIZE

DN NPS kg lbs

80 3

100 4

150 6

200 8

250 10

ASME B16.5 EN1092-1

Raised Face Flange Type B Raised Face Flange

CL150 CL300 PN10 PN16 PN25 PN40

PN10-40 9 19

CL150 and 300 13 28

PN10/16 12 26

PN25/40 13 28

CL150 and 300

PN10-40

CL150 and 300

PN10/16

PN25/40

PN10/16 64 140

PN25/40 71 156

V200U Valve

FLANGELESS VALVE END CONNECTION COMPATIBILITY

RATING

CL150 8 18

CL300 10 22

27 58

49 109

CL150 64 140

CL300 102 225

WEIGHT

May 2020

Installation

Installation steps are provided in this section for V200U valves. Key numbers in installation procedures are shown in

figure 14 and 15 unless otherwise indicated.

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

Personal injury or equipment damage caused by sudden release of pressure may result if the valve assembly is installed

where service conditions could exceed either the valve body rating or the mating pipe flange joint rating. To avoid such

injury or damage, provide a relief valve for overpressure protection as required by government or accepted industry codes

and good engineering practices.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

3

V200U Valve

May 2020

Instruction Manual

D104548X012

WARNING

When ordered, the valve configuration and construction materials were selected to meet particular pressure, temperature,

pressure drop, and controlled fluid conditions. Responsibility for the safety of process media and compatibility of valve

materials with process media rests solely with the purchaser and end‐user. To avoid possible personal injury and because

some valve/trim material combinations are limited in their pressure drop and temperature ranges, do not apply any other

conditions to the valve without first contacting your Emerson sales office

.

WARNING

The valve drive shaft is not necessarily grounded to the pipeline when installed. Personal injury or property damage could

result from an explosion caused by a discharge of static electricity from valve components if the process fluid or the

atmosphere around the valve is flammable. If the atmosphere around the valve or the process fluid is flammable,

electrically bond the drive shaft to the valve.

Note

Standard PTFE packing is composed of a partially conductive carbon‐filled PTFE female adaptor with PTFE V‐ring packing. Standard

graphite packing is composed of all conductive graphite ribbon packing. Alternate shaft‐to‐valve body bonding is available for

hazardous service areas where the standard packing is not sufficient to bond the shaft to the valve (see the following step).

Attach the optional bonding strap assembly (key 131, figure 2) to the valve drive shaft (key 6) with the clamp (key 130,

figure 2) and connect the other end of the bonding strap assembly to the valve body with the cap screw (key 23).

1. If the valve is to be stored before installation, protect the flange mating surfaces and keep the valve body cavity dry

and free of foreign material.

2. Install a three‐valve bypass around the control valve assembly if continuous operation will be necessary during

inspection and maintenance of the valve.

3. The valve is normally shipped as part of a control valve assembly, with an actuator mounted on the valve. If the

valve and actuator have been purchased separately or if the actuator has been removed, mount the actuator

according to the Actuator Mounting section and the appropriate actuator instruction manual.

4. Standard flow direction is forward (fluid flows into the convex face of the V-notch ball).

5. Install the valve in a horizontal or vertical pipeline with the drive shaft in a horizontal position.

CAUTION

Do not allow the valve to be installed in the pipeline with the drive shaft in the vertical position because of excessive wear

to valve component parts.

6. The actuator can be right‐ or left‐hand mounted with the shaft in a horizontal orientation as shown in figure 1. If

necessary, refer to the appropriate actuator instruction manual for actuator installation and adjustment

procedures.

CAUTION

Ensure the valve and adjacent pipelines are free of foreign material that could damage the valve seating surfaces.

4

Instruction Manual

D104548X012

V200U Valve

May 2020

7. Be certain the valve and adjacent pipelines are free of any foreign material that could damage the valve sealing

surfaces.

8. Be sure the pipeline flanges are in line with each other.

Figure 2. Optional Shaft‐to‐Body Bonding Strap Assembly

ACTUATOR

A

A

37A6528‐A

A3143‐2

VALVE

BODY

VIEW A‐A

Installing V200U Valves

1. To avoid potential interference with the valve outlet end pipe flange, the V200U ball should be in the closed

position prior to installation. Install the V200U valve using long studs to connect the two pipeline flanges. Refer to

figure 3 for the length of studs required based on the mating pipeline flange pressure class. Lubricate the studs with

anti‐seize lubricant.

CAUTION

For DN 100, 200, and 250 (NPS 4, 8, and 10), damage to the ball (key 2) could occur if the downstream piping interferes

with the ball rotation. Prior to installing the valve body between adjacent flanges, reference dimension P in table 4 and

measure carefully to ensure the ball will rotate without interference.

2. Install two studs in the flanges before you place the valve in the line. Place the two studs so they will contact the

line‐centering features at the bottom of the valve body.

3. Insert appropriate flange gaskets that are compatible with the process fluid.

4. Place the valve on the two studs. Install all remaining studs. Measure carefully to be sure the valve is centered on the

pipeline flanges, and tighten the flange stud nuts. Tighten the nuts in a criss‐cross sequence to be sure the flange

gaskets are properly torqued.

5. Connect pressure lines to the actuator as indicated in the actuator instruction manual. When an auxiliary manual

actuator is used with a power actuator, install a bypass valve on the power actuator (if one is not supplied) for use

during manual operation.

WARNING

Personal injury could result from packing leakage. Valve packing was tightened before shipment; however the packing

might require some readjustment to meet specific service conditions. Check with your process or safety engineer for any

additional measures that must be taken to protect against process media.

5

V200U Valve

(1)P(2)

(3)

(3)

May 2020

Instruction Manual

D104548X012

If the valve has ENVIRO‐SEAL live‐loaded packing installed, this initial re‐adjustment will probably not be required. See

ENVIRO‐SEAL Packing System for Rotary Valves instruction manual (D101643X012

) for packing instructions.

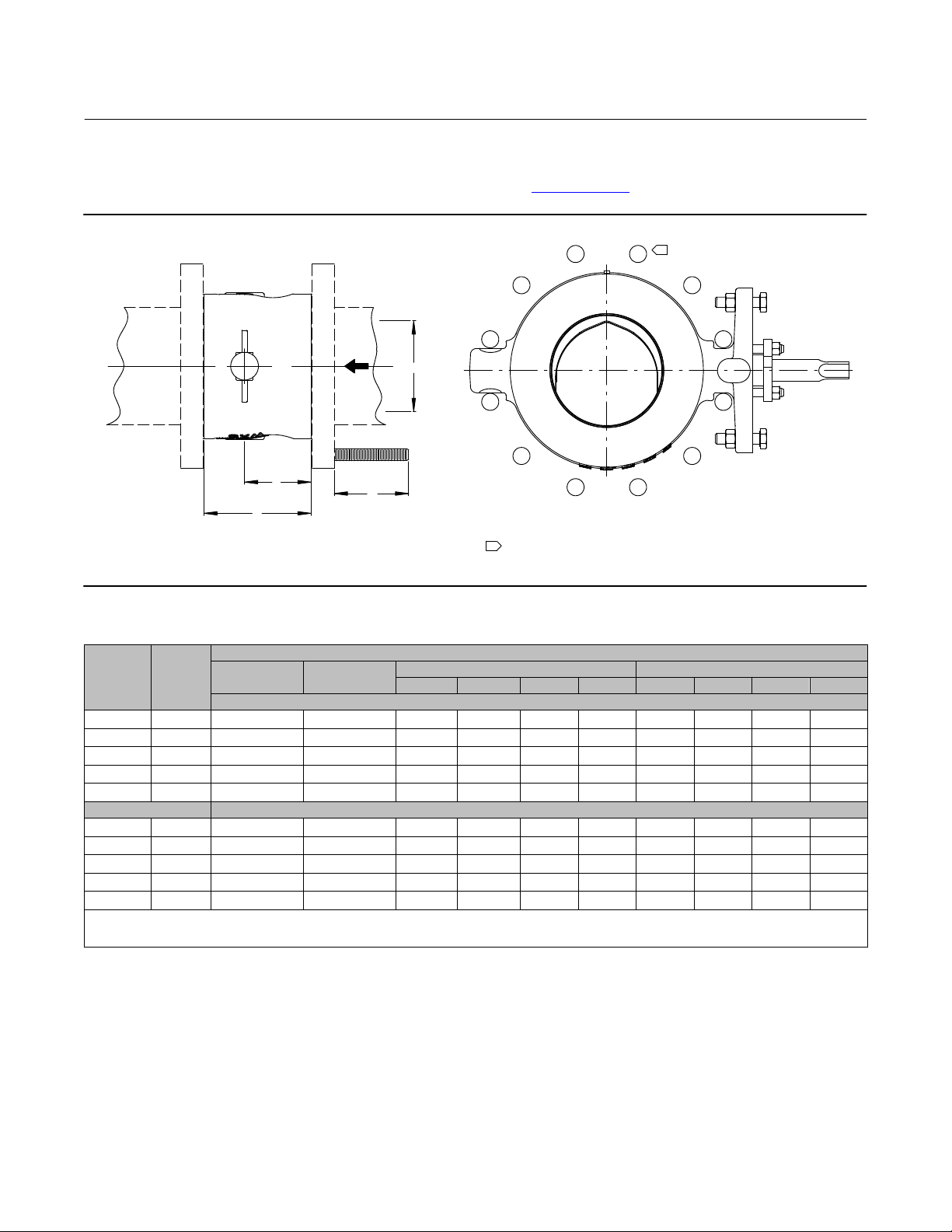

Figure 3. Fisher V200U Dimensions and Required Clearances for Installation

1

P

GG69033-A

B

A

M

GG69042

NOTE:

1

STUD QUANTITY AND PLACEMENT SHOWN FOR EXAMPLE DN200 PN40 FLANGE.

Table 4. Fisher V200U Dimensions and Required Clearances for Installation

VALVE

SIZE,

DN

VALVE

SIZE,

NPS

A B

PN 10/16 PN 25/40 CL150 CL300 PN 10/16 PN 25/40 CL150 CL300

80 3 100 59 225 240 204 216 - - - - - - - - - - - -

100 4 116 68 250 270 223 242 103 104 99 99

150 6 160 89 310 340 274 299 - - - - - - - - - - - -

200 8 200 124 355 405 324 356 188 190 188 188

250 10 240 147 410 470 375 413

80 3 3.94 2.34 8.86 9.45 8.00 8.50 - - - - - - - - - - - -

100 4 4.58 2.67 9.85 10.63 8.75 9.50 4.06 4.09 3.90 3.90

150 6 6.30 3.52 12.21 13.39 10.75 11.75 - - - - - - - - - - - -

200 8 7.87 4.89 13.98 15.95 12.75 14.00 7.40 7.48 7.40 7.40

250 10 9.45 5.78 16.15 18.51 14.75 16.25

1. Clearance necessary to remove the bolt.

2. Minimum internal diameter of the mating pipe or flange required for Vee-Ball clearance.

3. The NPS 10 CL300 construction requires 4 bolts per side (8 total) to be installed in blind, tapped holes on the valve body. The M value for these 1 – 8 UNC fasteners is 140 mm (5.5 inch).

DIMENSION

M

mm

253 253 242 237

Inches

9.96 9.96 9.53 9.33

6

Instruction Manual

D104548X012

V200U Valve

May 2020

Maintenance

Valve parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of inspection

and replacement depends upon the severity of service conditions.

Key numbers in this procedure are shown in figures 14 and 15 unless otherwise noted.

WARNING

The Vee‐Ball closes with a shearing, cutting motion, which could result in personal injury. To avoid injury, keep hands,

tools, and other objects away from the Vee‐Ball while stroking the valve.

Avoid personal injury from sudden release of process pressure. Before performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations.

D The valve packing area may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Packing Maintenance

Key numbers in this procedure are shown in figures 14 and 15 unless otherwise noted. A detailed view of the packing is

also shown in figure 4.

If the valve is equipped with the ENVIRO‐SEAL Packing System, refer to:

D The separate ENVIRO‐SEAL Packing System for Rotary Valves instruction manual (D101643X012

instructions, and

D The Parts List section of this manual for retrofit kits, parts kits, and individual parts.

If the packing is relatively new and tight on the drive shaft (key 6), and if tightening the packing follower nuts does not

stop leakage, it is possible that the drive shaft is worn or nicked so that a seal cannot be made. If the leakage comes

from the outside diameter of the packing, it is possible that the leakage is caused by nicks or scratches on the packing

box wall. Inspect the drive shaft and packing box wall for nicks or scratches while performing the following procedure.

Replacing Packing

When using this procedure, it is recommended that the actuator not be removed from the valve while the valve is still

in the pipeline or between flanges. Valve/actuator adjustments must be made with the valve out of the pipeline. Refer

to the Determining Closed Position portion of the Actuator Mounting section.

) for maintenance

7

V200U Valve

May 2020

Instruction Manual

D104548X012

Disassembly

WARNING

Observe the steps in the WARNING at the beginning of the Maintenance section.

1. Isolate the control valve from the line pressure, release pressure from both sides of the valve body, and drain the

process media from both sides of the valve. If using a power actuator, shut off all pressure lines to the power

actuator, release pressure from the actuator, and disconnect the pressure lines from the actuator. Use lock‐out

procedures to be sure that the above measures stay in effect while you are working on the equipment.

2. To avoid potential interference with the valve outlet end pipe flange, the V200U ball should be in the closed

position prior to removal.

3. Remove line bolting, remove the control valve from the pipeline, and place the valve/actuator assembly on a flat

surface with the seal protector ring facing up.

4. Remove the actuator cover. Take note of the orientation of the actuator with respect to the valve body and the

lever orientation with respect to the valve drive shaft (see figure 12) for Fisher actuation.

WARNING

When the actuator is removed from the valve, the ball/shaft assembly may suddenly rotate, with a shearing, cutting

motion, which could result in personal injury. To avoid injury, carefully rotate the ball to a stable position at the bottom of

the valve body cavity. Make sure the ball will not rotate.

CAUTION

When removing the actuator from the valve, do not use a hammer or similar tool to drive the lever or actuator off the valve

shaft. Driving the lever or actuator off the valve shaft could damage the ball, seal, and valve.

If necessary, use a puller to remove the lever or actuator from the valve shaft. It is okay to tap the puller screw lightly to

loosen lever or actuator, but hitting the screw with excessive force could damage the ball, seal, and valve.

5. Remove the clamped lever (do not loosen the actuator turnbuckle adjustment), remove the actuator mounting

screws and nuts (keys 23 and 24), and remove the actuator. (If necessary, refer to the actuator instruction manual

for assistance.)

6. If applicable, remove the bonding strap assembly before attempting to remove the packing (see figure 2).

7. Remove the packing follower nuts and packing follower (keys 17 and 20). For alloy packing constructions, the

packing follower (key 17) and a separate packing flange (key 40) must be removed if present.

If the valve is equipped with the ENVIRO‐SEAL packing system, refer to the ENVIRO‐SEAL Packing System for Rotary

Valves instruction manual (D101643X012

) for disassembly.

WARNING

Personal injury could result from packing leakage. Do not scratch the drive shaft or packing box wall while removing

packing parts in the following procedure.

8

Instruction Manual

D104548X012

V200U Valve

May 2020

8. Remove the packing parts (see figure 4, keys 16, 17, 35, and 39 depending on construction) using a formed wire

hook with a sharp end. Pierce the rings with the sharp end of the hook in order to remove them. Do not scratch the

drive shaft or packing box wall; scratching these surfaces could cause leakage. Clean all accessible metal parts and

surfaces to remove particles that would prevent the packing from sealing.

Assembly

If the valve is equipped with the ENVIRO‐SEAL packing system, refer to the ENVIRO‐SEAL Packing System for Rotary

Valves instruction manual (D101643X012

1. To help ensure correct centering of the Vee‐Ball (key 2) on the seal (key 11), make sure the ball is closed while you

install or tighten new packing. Insert a screwdriver, pry bar, or similar tool between the lower ear of the ball and the

valve body. Use the pry to move the ball tightly against the bearing on the actuator side of the valve (see figure 5).

Keep the ball in that position until you have completed packing installation and adjustment.

2. Install the new packing parts using the parts sequence shown in figure 4. Install the packing follower (key 17).

3. Secure the packing follower with the packing follower nuts (key 20). Tighten the nuts far enough to stop leakage

under operating conditions.

Note

If the valve is equipped with a bonding strap assembly (figure 2), re‐install the assembly.

) for assembly.

4. Reconnect the actuator and lever in accordance with the orientations that were noted in step 3 of the disassembly

procedures. If necessary, use figure 10 to identify the correct index marks.

5. Refer to the appropriate actuator instruction manual to complete actuator assembly and adjustment.

6. When the control valve is in operation, check the packing follower for leakage and re-tighten the packing follower

nuts (key 20) as necessary.

9

Loading...

Loading...