Instruction Manual

D101618X012

DSA Desuperheater

Fisher™ DSA Steam-Atomized Desuperheater

July 2017

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Principle of Operation 2.........................

Installation 2..................................

Operating Instructions 4.........................

Verification of Control Instrumentation 4.........

Maintenance Instructions 6......................

Servicing 7...................................

Troubleshooting 8..............................

Parts Ordering 8................................

Parts List 8....................................

Introduction

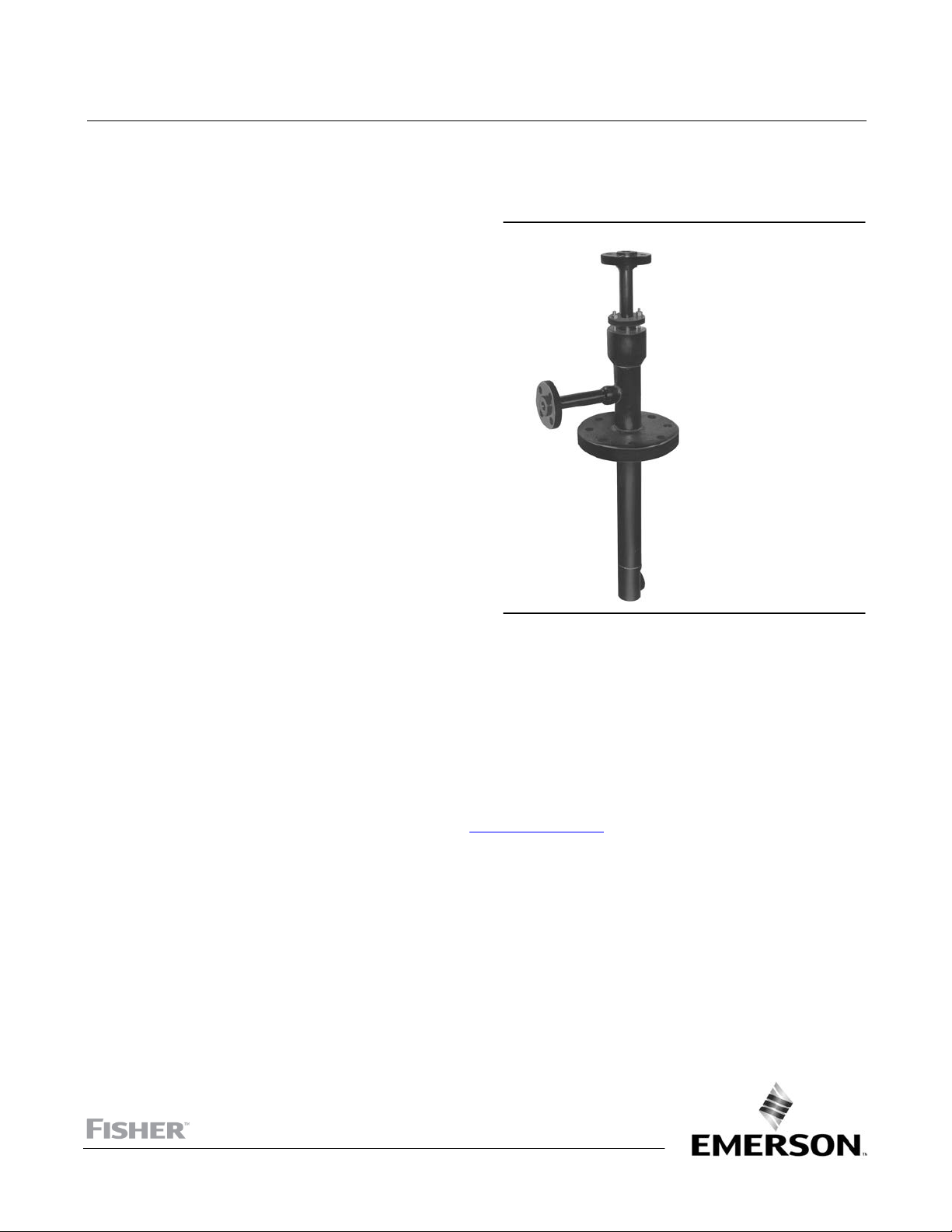

Figure 1. Fisher DSA Steam‐Atomized Desuperheater

W5366‐1

Scope of Manual

This instruction manual includes installation and operation information for the Fisher DSA steam‐atomized

desuperheater.

Do not install, operate, or maintain a DSA desupheater without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson sales office

proceeding.

or Local Business Partner before

Description

The DSA steam‐atomized desuperheater (figure 1) serves a wide range of desuperheating applications. It is best suited

for those installations requiring high rangeability in low steam velocity pipelines. With adequate controls, this unit

provides an efficient means of atomizing spraywater over wide fluctuations in flow rate while maintaining downstream

steam temperature to within 6 to 8_C (10 to 15_F) of saturation. The DSA desuperheater is easily installed directly into

the steam line. The standard mounting is with the desuperheater perpendicular to the steam line. However, the DSA

desuperheater can be made to fit angle or elbow installations.

www.Fisher.com

DSA Desuperheater

July 2017

Table 1. Specifications

Instruction Manual

D101618X012

Steam Line Sizes

J NPS 6 to 60

Steam Line Connection Sizes

NPS J 3, J 4, and J 6 J CL150, J CL300,

J CL600, J CL900, J CL1500, and J CL2500

raised‐face flange

Spraywater and Atomizing Steam Connection Sizes

NPS J 1, J 1-1/2, and J 2 J CL150, J CL300,

J CL600, J CL900, J CL1500, and J CL2500

Inherent Rangeability

Up to 50:1

Spraywater Pressure Required

3.5 to 35 bar (50 to 500 psi) greater than steam line

pressure

Minimum Steam Velocity

1.5 m/s (5 feet per second) depending on actual

operating conditions

raised‐face flange

Atomizing Steam

Maximum Inlet Pressures

Consistent with applicable CL150, 300, 600, 900,

1500, or 2500 pressure‐temperature ratings per

ASME B16.34

1. Do not exceed the pressure or temperature limits in this instruction manual, nor any applicable code or standard limitations.

2. Ratio of maximum to minimum controllable Cv.

(1)

Atomizing steam should be at least 2.0 times the

pressure of the steam to be desuperheated. Total

atomizing steam flow (lb/hr) will be 10 to 15 percent

of the maximum spraywater flow (lb/hr).

Principle of Operation

(2)

The DSA desuperheater utilizes the energy of atomizing steam to produce a fine spray of cooling water for injection

into the steam line. An external spraywater control valve controls the quantity of cooling water. The water flows into

the desuperheater and fills the main body of the unit just ahead of the atomizing head. Here the water is directed into

a number of flow channels where it is mixed and atomized by the high velocity atomizing steam (see figure 3).

The atomizing steam is controlled via an automatic or manual shutoff valve. The steam flows down the center of the

desuperheater body toward the atomizing head. Here too, the steam is directed into a number of flow channels. These

channels are sized to produce a critical pressure drop. This assures very high steam velocities and maximum kinetic

energy for spraywater atomization.

The atomizing steam mixes with the cooling water and produces a spraywater cloud with almost infinite surface area.

This spray cloud is almost instantaneously vaporized when injected into the main steam line, resulting in steam at a

reduced temperature.

The atomizing steam tube inside the desuperheater is only secured at the atomizing head. The packing box on top

allows for the free movement of the unit due to thermal expansion from steam/water temperature differentials.

Installation

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

2

Instruction Manual

D101618X012

Personal injury or equipment damage caused by sudden release of pressure may result if the desuperheater is installed

where service conditions could exceed the limits given in table 1 or on the nameplate. To avoid such injury or damage,

provide a relief valve for over‐pressure protection as required by government or accepted industry codes and good

engineering practices.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

DSA Desuperheater

July 2017

CAUTION

When ordered, the desuperheater configuration and construction materials were selected to meet particular pressure,

temperature, pressure drop, and fluid conditions. Do not apply any other conditions to the desuperheater without first

contacting your Emerson Automation Solutions sales office.

1. Insert the DSA desuperheater into the flanged pipe stud on the steam line (see figure 2 for the proper “T” length

dimension). Bolt the unit to the pipe in accordance with standard piping practice.

2. Clean and flush out the cooling water line before connecting to the desuperheater. Use only clean sources of

cooling water. Use of clean water decreases wear to the valve trim and prevents clogging of the desuperheater by

solid particles.

WARNING

Personal injury or property damage could result from clogging of the desuperheater. Emerson Automation Solutions

recommends installation of a strainer and isolating valve on the water line leading to the desuperheater. Failure to do so

may result in clogging of the desuperheater by solid particles, thus hampering temperature control of the steam.

3. A straight run of pipe is required downstream of the desuperheater to assure complete vaporization of cooling

water. Consult the desuperheater certified drawing for the required distance of straight pipe.

4. The temperature sensor should be mounted according to manufacturer's instructions. Minimum distance to the

sensor is approximately 9.1 m (30 feet) downstream of the desuperheater. This distance changes with higher

velocity steam flow and percentage of spraywater required. Consult the desuperheater certified drawing for the

exact distance.

5. Allow no branching out from the steam line, to divide the steam flow, between the temperature sensor and the

desuperheater.

A typical control loop is illustrated in figure 4. A temperature sensor generates a pneumatic instrument air signal

through a transmitter. This signal is transmitted to a remote mounted temperature indicating control station. The

output signal from the control station is sent to the positioner on the spraywater control valve. The positioner output

signal is piped to the actuator, which strokes the valve and controls the flow of cooling water to the desuperheater.

The atomizing steam valve is normally controlled so that it fully opens as soon as the spraywater control valve starts to

open.

WARNING

Personal injury could result from packing leakage. Valve packing was tightened prior to shipment; however some

readjustment will be required to meet specific service conditions.

3

Loading...

Loading...