Instruction Manual

D102005X012

846 Transducer

Fisher™ 846 Current-to-Pressure Transducer

May 2022

Contents

Introduction

Scope of Manual 2.............................

Description 2.................................

Specifications 2...............................

Educational Services 5.........................

Installation 6..................................

Hazardous Area Classifications and Special

Instructions for Safe‐Use and Installation

in Hazardous Locations 7.....................

Mounting 8..................................

Pressure Connections 8........................

Supply Pressure 10.........................

Output Pressure 14........................

Electrical Connections 14.......................

Venting Ports 15..............................

Signal Interruption 15..........................

Calibration 16..................................

Standard Performance:

Full Range Input, Direct Action 18.............

Multirange Performance:

Full Range Input, Direct Action 18.............

Standard Performance:

Split Range Input, Direct Action 19.............

4 to 12 mA Input Signal 19..................

12 to 20 mA Input Signal 19.................

Standard Performance:

Full Range Input, Reverse Action 20............

Multirange Performance:

Full Range Input, Reverse Action 20............

Standard Performance:

Split Range Input, Reverse Action 21...........

4 to 12 mA Input Signal 21..................

12 to 20 mA Input Signal 21.................

Transporting the Module Final Assembly 22.......

Principle of Operation 22........................

Electronic Circuit 22...........................

Magnetic Actuator 23..........................

Pilot Stage 23.................................

Booster Stage 24..............................

Troubleshooting 25.............................

Diagnostic Features 25.........................

Stroke Port 25.............................

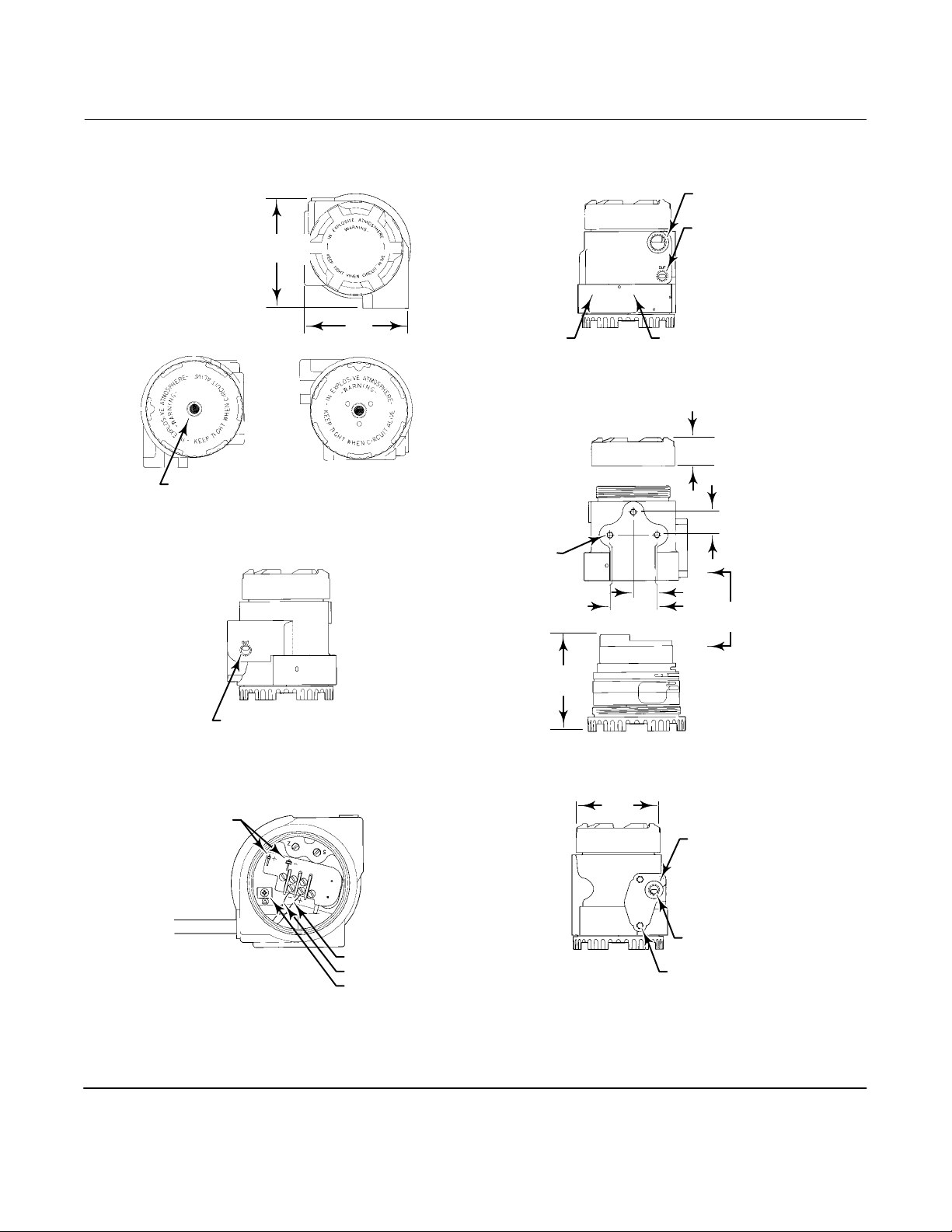

Figure 1. Fisher 846 Current‐to‐Pressure Transducer

X0234

Remote Pressure Reading (RPR) 25...........

Using a Frequency Counter to read the

RPR Signal 25.........................

In‐service Troubleshooting 26...................

Troubleshooting in the Shop 29.................

Maintenance 31................................

Module Final Assembly 32......................

Removing the Module Final Assembly 34......

Replacing the Module Final Assembly 35.......

Electronic Circuit Board 36......................

Remote Pressure Reading (RPR) Jumper 36.....

Range Jumper 37..........................

Action 37.................................

Removing the Electronic Circuit Board 37......

Replacing the Electronic Circuit Board 38......

Pilot/Actuator Assembly 38.....................

Action 38.................................

Removing the Pilot/Actuator Assembly 39.....

Replacing the Pilot/Actuator Assembly 39.....

Module Subassembly 40........................

Terminal Compartment 40.....................

Exhaust and Stroke Port Screens 41..............

Parts 42......................................

www.Fisher.com

846 Transducer

May 2022

Instruction Manual

D102005X012

Introduction

Scope of Manual

This instruction manual provides installation, operating, calibration, maintenance, and parts ordering information for

Fisher 846 current‐to‐pressure transducers. Refer to separate manuals for instructions covering equipment used with

the transducers.

Do not install, operate or maintain an 846 current‐to‐pressure transducer without being fully trained

and qualified in valve, actuator, and accessory installation, operation, and maintenance. To avoid

personal injury or property damage, it is important to carefully read, understand, and follow all of the

contents of this manual, including all safety cautions and warnings. If you have any questions about

these instructions, contact your Emerson sales office

Description

The 846 current‐to‐pressure transducer, shown in figure 1, accepts an electrical input signal and produces a

proportional pneumatic output. Typically, 4 to 20 mA is converted to 0.2 to 1.0 bar (3 to 15 psi). Models are available

in direct or reverse action and field‐selectable for full or split range inputs. Refer to the Calibration section for more

information on input/output combinations.

before proceeding.

The most common application of the transducer is to receive an electrical signal from a controller and produce a

pneumatic output for operating a control valve actuator or positioner. The 846 may also be used to produce a signal

for a pneumatic receiving instrument.

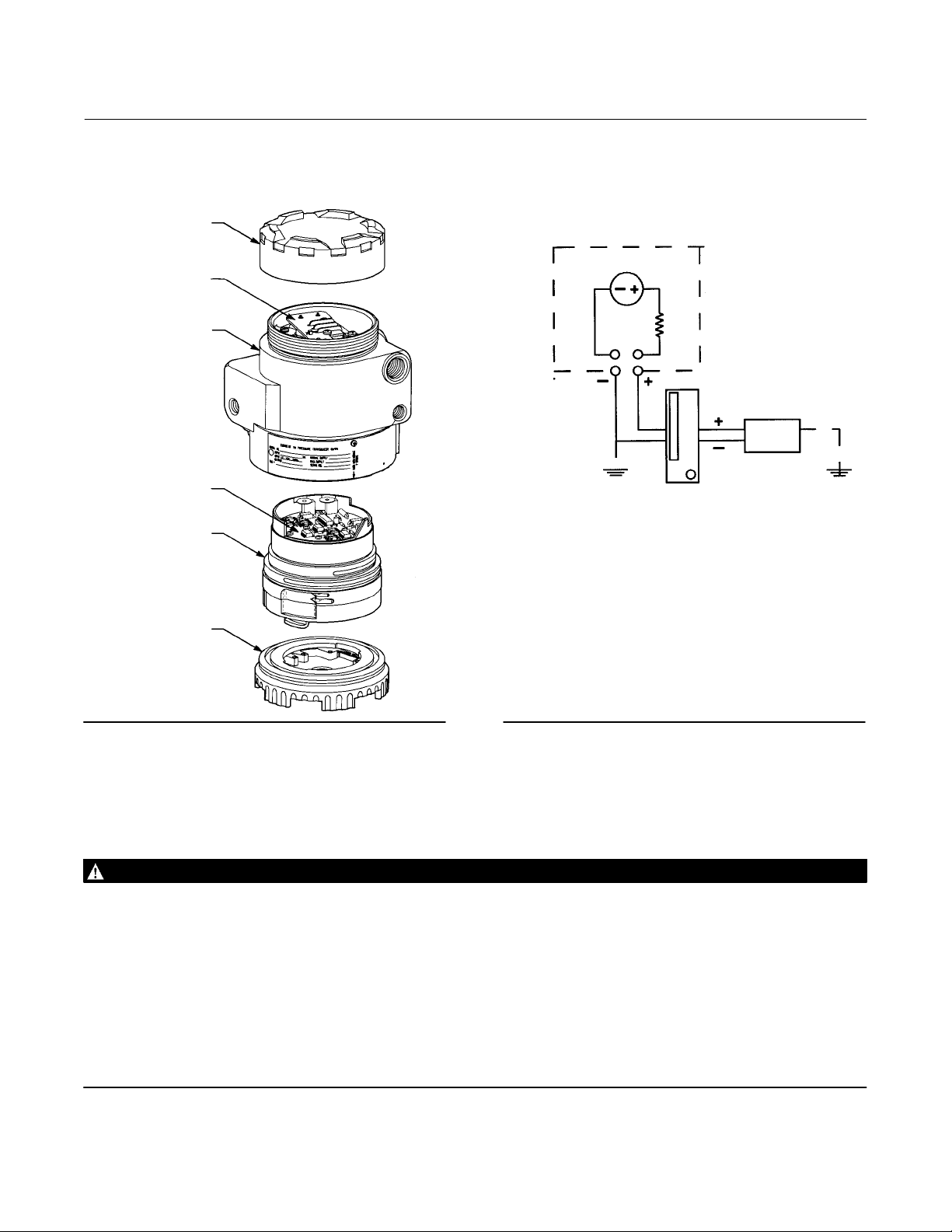

The 846 is an electronic I/P transducer. It has a single electronic circuit board, as shown in figure 2. The circuit contains

a solid‐state pressure sensor that monitors output pressure and is part of an electronic feedback network. The

self‐correcting ability provided by the sensor/circuit combination allows the transducer to produce a very stable and

responsive output signal.

All active mechanical and electrical components of the 846 are incorporated into a single, field‐replaceable module

called the module final assembly, shown in figure 2. The module final assembly contains the electronic circuit board,

pilot/actuator assembly, and booster stage. The module final assembly is easily removed by unscrewing the module

cover. Its design minimizes parts and reduces the time required for repair and troubleshooting.

The terminal compartment and module compartment are separated by a sealed compartment wall. This

multi‐compartment housing also protects the electronics from contaminants and moisture in the supply air.

Specifications

WARNING

This product is intended for a specific range of pressures, temperatures, and other application specifications. Applying

different pressure, temperature and other service conditions could result in a malfunction of the product, property damage

or personal injury.

Specifications for the 846 transducer are listed in table 1.

2

Instruction Manual

D102005X012

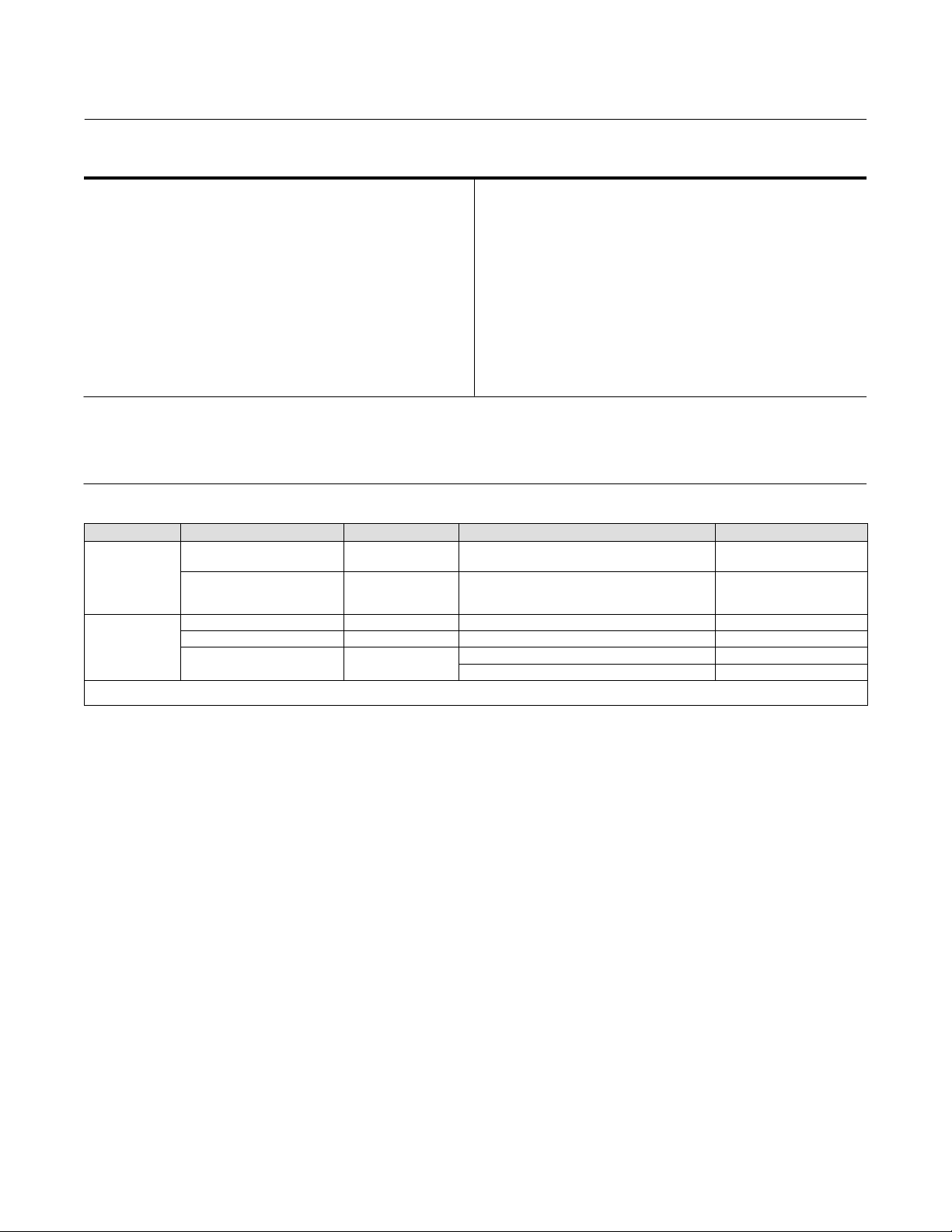

Table 1. Specifications

846 Transducer

May 2022

Input Signal

Standard Performance:

4 to 20 mA DC, 4 to 12 mA DC, or 12 to 20 mA DC.

Field adjustable split ranging.

Multirange Performance:

4 to 20 mA DC. Consult factory for split range input

Equivalent Circuit

See figure 3

Output Signal

(1)

Standard Performance:

(Consult factory for split range output)

Direct Action (Minimum span of 6 psi)

Typical outputs: 0.2 to 1.0 bar (3 to 15 psi).

Rangeability between 0.1 and 1.2 bar (1 and 18 psi)

Reverse Action (Minimum span of 11 psi)

Typical outputs: 1.0 to 0.2 bar (15 to 3 psi)

Rangeability between 1.2 and 0.1 bar (18 and 1 psi)

Multirange Performance:

Direct Action (Minimum span of 6 psi)

Typical outputs: 0.2 to 1.9 bar (3 to 27 psi), 0.4 to

2 bar (6 to 30 psi), and 0.3 to 1.7 bar (5 to 25 psi)

Rangeability between 0.03 and 2.3 bar (0.5 and

33 psi)

Reverse Action (Minimum span of 11 psi)

Typical outputs: 1.9 to 0.2 bar (27 to 3 psi), 2 to

0.4 bar (30 to 6 psi), and 1.7 to 0.3 bar (25 to 5 psi)

Rangeability between 2.3 and 0.03 bar (33 and

0.5 psi)

Supply Pressure

(2)

Standard Performance: 1.2 to 1.6 bar (18 to 24 psi)

Multirange Performance:

(3)

0.2 bar (3 psi)

greater than the maximum

calibrated output pressure

Maximum: 2.4 bar (35 psi)

Per ISO 8573-1

Maximum particle density size: Class 7

Oil content: Class 3

Pressure Dew Point: Class 3 or at least 10°C less than

the lowest ambient temperature expected

Output Air Capacity

(4)

Standard: 6.4 m3/hr (240 scfh) at 1.4 bar

(20 psi) supply pressure

3

Multirange: 9.7 m

/hr (360 scfh) at 2.5 bar

(35 psig) supply pressure

Maximum Steady‐State Air Consumption

(4)

0.3 m3/hr (12 scfh) at 1.4 bar (20 psi) supply pressure

Temperature Limits

(2)

Operating: -40 to 85_C (-40 to 185_F)

Storage :-40 to 93_C (-40 to 200_F)

Humidity Limits

0 to 100% condensing relative humidity

Performance

(5)

Note: The performance of all 846 I/Ps is verified

using computer automated manufacturing systems

to ensure that every unit shipped meets its

performance specifications

Accuracy: $0.30% of output span

Linearity, Hysteresis, and Repeatability: $0.3% of

span.

Temperature Effect (total effect including zero and

span): $0.07%/_C (0.045%/_F) of span

Supply Pressure Medium

Clean, dry air

Per ISA Standard 7.0.01

A maximum 40 micrometer particle size in the air

system is acceptable. Further filtration down to 5

micrometer particle size is recommended. Lubricant

content is not to exceed 1 ppm weight (w/w) or

volume (v/v) basis. Condensation in the air supply

should be minimized

Vibration Effect: $0.3% of span per g during the

following conditions:

5 to 15 Hz at 4 mm constant displacement

15 to 150 Hz at 2 g. 150 to 2000 Hz at 1 g.

per SAMA Standard PMC 31.1, Sec. 5.3, Condition 3,

Steady State

Shock Effect: $0.5% of span, when tested per SAMA

Standard PMC 31.1, Sec. 5.4.

Supply Pressure Effect: Negligible

-Continued-

3

846 Transducer

May 2022

Table 1. Specifications (continued)

Instruction Manual

D102005X012

Performance (continued)

(5)

Electromagnetic Interference (EMI): Tested per IEC

61326‐1:2013. Meets emission levels for Class A

equipment (industrial locations) and Class B

equipment (domestic locations). Meets immunity

requirements for industrial locations (Table A.1 in the

IEC specification document). Immunity performance

is shown in table 2.

Leak Sensitivity

3

4.8 m

/hr (180 scfh) downstream leakage.

(4)

: Less than 1.0% of span for up to

Overpressure Effect: Less than 0.25% of span for

misapplication of up to 7.0 bar (100 psi) supply

pressure for less than 5 minutes to the input port.

Reverse Polarity Protection: No damage occurs from

reversal of normal supply current (4 to 20 mA) or

from misapplication of up to 100 mA.

Connections

Supply Air, Output Signal, and Output Gauge:

1/4‐18 NPT internal connection

Electrical: 1/2‐14 NPT internal conduit connection

Adjustments

Zero and Span: screwdriver adjustments located in

terminal compartment.

Remote Pressure Reading (RPR)

Jumper selectable, ON or OFF, if unit includes

option

Frequency Range: 0 to 10,000 Hz

Amplitude: 0.4 to 1.0 V

p‐p

Required Operating Voltage with Remote pressure

Reading Off

Min. 6.0 V (at 4 mA)

Max. 7.2 V (at 20 mA)

Electrical Classification

Pollution Degree 4

Hazardous area:

CSA C/US—Intrinsically Safe, Explosion-proof,

Non-Incendive

FM—Intrinsically Safe, Explosion-proof, Non-Incendive

ATEX—Intrinsically Safe, Flameproof, Type n

IECEx—Intrinsically Safe, Flameproof

Electrical Housing:

Tropicalization (Fungus test per MIL-STD-810)

CSA C/US—Type 4X

FM—Type 4X

ATEX—IP66

IECEx—IP66

(6)

(6)

Other Classifications/Certifications

CUTR— Customs Union Technical Regulations

(Russian, Kazakhstan, Belarus, and Armenia)

ESMA— Emirates Authority for Standardization and

Metrology - ECAS-Ex (UAE)

INMETRO— National Institute of Metrology, Quality,

and Technology (Brazil)

KTL— Korea Testing Laboratory (South Korea)

CCC— China Compulsory Compliance

NEPSI— National Supervision and Inspection Centre

for Explosion Protection and Safety of

Instrumentation (China)

PESO CCOE— Petroleum and Explosives Safety

Organization - Chief Controller of Explosives (India)

Contact your Emerson sales office

for

classification/certification specific information

Required Operating Voltage with Remote Pressure

Reading On

Min 6.4 V (at 4 mA)

Max. 8.2 V (at 20 mA)

4

Construction Materials

Housing: Low‐copper aluminum with polyurethane

paint, or 316 stainless steel

O‐Rings: Nitrile, except silicone for sensor O‐rings.

-continued-

Instruction Manual

D102005X012

Table 1. Specifications (continued)

846 Transducer

May 2022

Options

Declaration of SEP

Fisher 67CFR filter regulator, supply and output

gauges or tire valve remote pressure reading, module

cover with multiple stroke ports, stainless steel

housing, or stainless steel mounting bracket.

Fisher Controls International LLC declares this

product to be in compliance with Article 3 paragraph

4 of the PED Directive 2014/68/EU. It was designed

and manufactured in accordance with Sound

Altitude Rating

Up to 2000 meters (6562 feet)

Weight

Aluminum: 2.9 kg (6.5 lb) excluding options

Stainless Steel: 6.7 kg (14.8 lb) excluding options

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 - Process Instrument Terminology.

1. Metric calibration also available.

2. The pressure/temperature limits in this document, and any applicable standard or code limitation should not be exceeded.

3. 0.14 bar (2 psi) for a 2.3 bar (33 psi) output.

4. Normal m

5. Reference Conditions: 4.0 to 20 mA DC input, 0.2 to 1.0 bar (3 to 15 psi) output, and 1.4 bar (20 psi) supply pressure.

6. ATEX and IECEx Flameproof — IP66 per CSA Letter of Attestation.

3

/hr—Normal cubic meters per hour (0_C and 1.01325 bar, absolute). Scfh—Standard cubic feet per hour (60_F and 14.7 psia).

Engineering Practice (SEP) and cannot bear the CE

marking related to PED compliance.

However, the product may bear the CE marking to

indicate compliance with other applicable European

Community Directives.

Table 2. EMC Immunity Performance Criteria

Port Phenomenon Basic Standard Test Level Performance Criteria

Electrostatic discharge (ESD) IEC 61000‐4‐2

Enclosure

I/O signal/control

Specification limit = ±1% of span

1. A = No degradation during testing. B = Temporary degradation during testing, but is self‐recovering.

Radiated EM field IEC 61000‐4‐3

Burst (fast transients) IEC 61000‐4‐4 1 kV A

Surge IEC 61000‐4‐5 1 kV (line to ground only, each) B

Conducted RF IEC 61000‐4‐6

4 kV contact

8 kV air

80 to 1000 MHz @ 10V/m with 1 kHz AM at 80%

1400 to 2000 MHz @ 3V/m with 1kHz AM at 80%

2000 to 2700 MHz @ 1V/m with 1kHz AM at 80%

150 kHz to 8 MHz at 3 Vrms B

8 MHz to 80 MHz at 3 Vrms A

(1)

A

A

Educational Services

Emerson Automation Solutions

Educational Services - Registration

Phone: +1-800-338-8158

Email: education@emerson.com

emerson.com/mytraining

5

846 Transducer

May 2022

Instruction Manual

D102005X012

Figure 2. Transducer Modular Construction

TERMINAL

COMPARTMENT

COVER

TERMINAL BLOCK

MODULE HOUSING

ELECTRONIC

CIRCUIT BOARD

MODULE FINAL

ASSEMBLY

Figure 3. Equivalent Circuit

846

6 V DC

50

OHMS

POWER

SUPPLY

NOTE:

THE 846 IS NOT A CONSTANT RESISTOR IN SERIES WITH AN INDUCTOR. IT IS BETTER

MODELED IN THE LOOP AS A 50 OHM RESISTOR IN SERIES WITH A 6‐VOLT DC VOLTAGE

DROP WITH NEGLIGIBLE INDUCTANCE.

A6325

MODULE COVER

A6643

Installation

WARNING

To avoid personal injury or property damage from the sudden release of pressure or air:

D Always wear protective clothing, gloves, and eyewear when performing any installation operations.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

6

Instruction Manual

D102005X012

846 Transducer

May 2022

NOTICE

Do not use sealing tape on pneumatic connections. This instrument contains small passages that may become obstructed

by detached sealing tape. Thread sealant paste should be used to seal and lubricate pneumatic threaded connections.

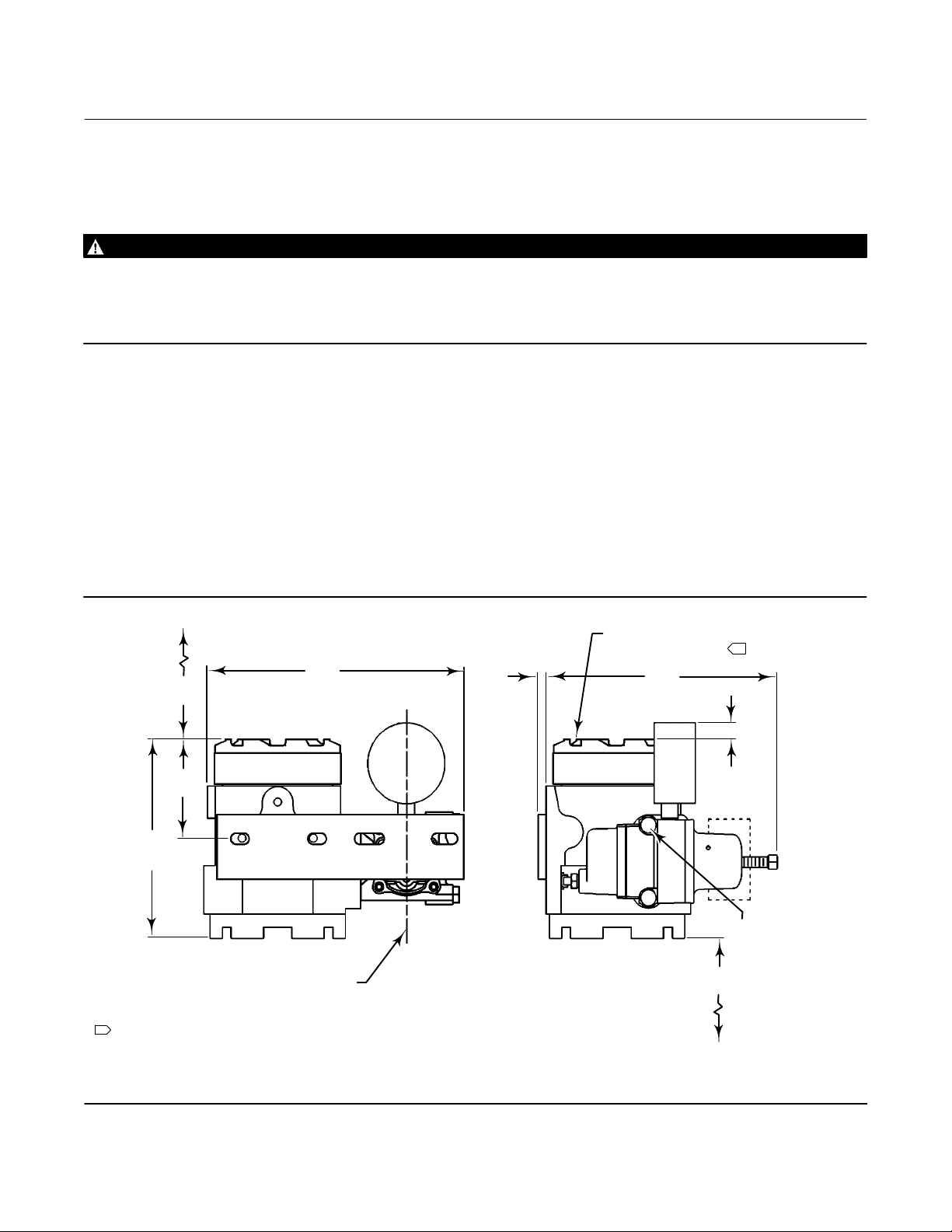

This section presents information on installing the 846 current‐to‐pressure transducer. Figures 4, 5, 6, and 8 can be

used as references for instructions contained in this section.

When a control valve is ordered with an 846 transducer specified to be mounted on the actuator, the factory‐mounted

transducer is connected to the actuator with the necessary tubing and calibrated to the specifications on the order.

If the transducer is purchased separately for mounting on a control valve already in service, all the necessary mounting

parts are furnished, if ordered. This includes the appropriate bracket for attaching the unit to an actuator boss (with

tapped holes) or for attaching it to the diaphragm casing.

If preferred, mounting parts can be supplied for mounting the transducer on a 51 mm (2‐inch) diameter pipestand, a

flat surface, or a bulkhead.

Transducers also can be ordered separately for mounting on a control valve assembly already in service. The

transducer may be ordered with or without mounting parts. Mounting parts include the appropriate bracket and bolts

for attaching the unit to an actuator boss (with tapped holes) or for attaching it to the diaphragm casing.

Hazardous Area Classifications and Special Instructions for “Safe Use” and

Installation in Hazardous Locations

Refer to the following instruction manual supplements for approval information.

D CSA Approval Information for Fisher 846 Current-to-Pressure Transducers (D104218X012

D FM Approval Information for Fisher 846 Current-to-Pressure Transducers (D104219X012

D ATEX Approval Information for 846 Current-to-Pressure Transducers (D104220X012

D IECEx Approval Information for 846 Current-to-Pressure Transducers (D104221X012

D INMETRO Approval Information for Fisher 846 Current-to-Pressure Transducers (D103623X012

D NEPSI Approval Information for Fisher 846 Current-to-Pressure Transducers (D103618X012

All documents are available from your Emerson sales office

other approval/certification information.

or Fisher.com. Contact your Emerson sales office for all

)

)

)

)

)

)

7

846 Transducer

May 2022

Instruction Manual

D102005X012

Mounting

Note

This unit will vent to the atmosphere through the stroke port in the module cover and the exhaust port, located under the

nameplate. Do not remote vent this unit.

The transducer is designed for mounting on a control valve, 51 mm (2‐inch) diameter pipestand, wall, or panel. Figures

5, 6, 7, and 8 show recommended mounting configurations. The mounting positions shown allow any moisture

buildup in the terminal compartment to drain to the signal wire conduit entrance. Any moisture in the pilot stage area

will be expelled through the stroke port without affecting pilot stage operation. In applications with excessive

moisture in the supply air, vertical mounting allows the most effective drainage through the stroke port.

NOTICE

Do not mount the transducer with the terminal compartment cover on the bottom as moisture, or any corrosive elements

in the plant atmosphere, may accumulate in the terminal compartment or pilot stage, resulting in transducer malfunction.

Mounting is accomplished with an optional universal mounting bracket. Before mounting the transducer, note the

following recommendations:

D Ensure that all bolts are fully tightened. The recommended torque is 22 NSm (16 lbfSft).

D Bolts that connect to the transducer and to a valve actuator should have the lock washer placed directly beneath the

bolt head and the flat washer placed between the lock washer and bracket. All other bolts should have the lock

washer next to the nut, and the flat washer placed between the lock washer and bracket.

D Do not mount the transducer in a location where foreign material may cover the stroke port or exhaust port. See the

descriptions of the stroke port and exhaust port later in this section.

Pressure Connections

NOTICE

Do not use sealing tape on pneumatic connections. This instrument contains small passages that may become obstructed

by detached sealing tape. Thread sealant paste should be used to seal and lubricate pneumatic threaded connections.

As shown in figure 4, all pressure connections are 1/4‐18 NPT internal connections. Use 9.5 mm (3/8‐inch) outside

diameter tubing for the supply and output connections.

8

Instruction Manual

D102005X012

Figure 4. Typical Dimensions and Connection Locations (Aluminum Construction Shown)

129

(5.07)

119

STROKE PORT

(4.68)

MODULE COVER WITH

MULTIPLE PORTS

NAMEPLATE

MOUNTING BOLT

HOLES 5/16‐18 (3)

59

(2.31)

846 Transducer

May 2022

CONDUIT CONNECTION

1/2 ‐ 14 NPT

OUTPUT PORT

1/4 ‐ 18 NPT

EXHAUST PORT

UNDERNEATH NAMEPLATE

35

(1.38)

29

(1.13)

29

(1.16)

COVER

REMOVAL

OUTPUT GAUGE PORT 1/4‐18 NPT

TEST PINS

WIRING CONNECTION

NOTE:

REFER TO FIGURE 8 FOR TRANSDUCER DIMENSIONS WITH

ATEX / IECEx FLAMEPROOF CERTIFICATIONS

B2473‐1

POSITIVE

NEGATIVE

INTERNAL GROUND

110

(4.33)

102

(4.00)

O‐RING GROOVE

FOR FILTER REGULATOR

SUPPLY PORT 1/4‐18 NPT

5/16‐18 (2)

mm

(INCHES)

9

846 Transducer

May 2022

Instruction Manual

D102005X012

Supply Pressure

WARNING

Severe personal injury or property damage may occur from process instability if the instrument supply medium is not

clean, dry air. While use and regular maintenance of a filter that removes particles larger than 40 micrometers in diameter

will suffice in most applications, check with an Emerson field office and industry instrument air quality standards if you are

unsure about the proper amount or method of air filtration or filter maintenance.

The supply medium must be clean, dry air that meets the requirements of ISA Standard 7.0.01 or ISO 8573-1. An

output span of 0.2 to 1.0 bar (3 to 15 psi) requires a nominal supply pressure of 1.4 bar (20 psi) and a flow capacity not

less than 6.4 normal m

For multirange performance units with higher output spans, the supply pressure should be at least 0.2 bar (3 psi)

greater than the maximum calibrated output pressure.

The air supply line can be connected to the 1/4‐18 NPT supply port, or to the supply port of a filter‐regulator mounted

directly to the transducer. Figures 5, 6, 7, and 8 show the installation options.

3

/hr (240 scfh).

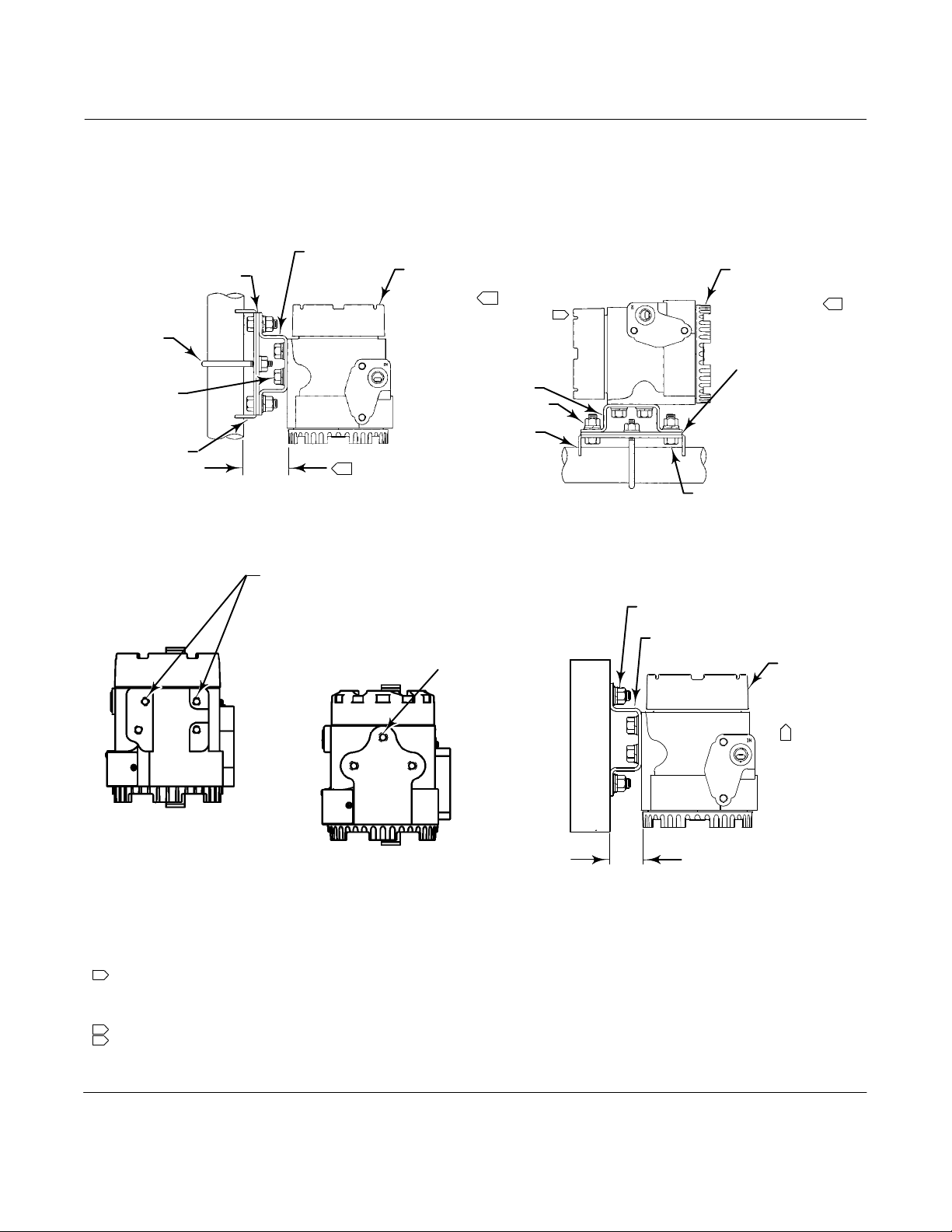

Figure 5. Typical Dimensions with Fisher 67CFR Filter/Regulator and Gauges

215

COVER

REMOVAL

CLEARANCE

NOTE:

1 THE MOUNTING POSITIONS SHOWN ALLOW ANY MOISTURE BUILDUP IN THE TERMINAL COMPARTMENT

TO DRAIN TO THE SIGNAL WIRE CONDUIT ENTRANCE. DO NOT MOUNT THE TRANSDUCER WITH THE TERMINAL

COMPARTMENT COVER ON THE BOTTOM; MOISTURE MAY ACCUMULATE IN THE TERMINAL COMPARTMENT

OR PILOT STAGE, PREVENTING PROPER TRANSDUCER OPERATION. THE VERTICAL MOUNT IS MOST EFFECTIVE

FOR MOISTURE DRAINAGE IN WET APPLICATIONS.

14B7361‐D

A6626-3

67

(2.62)

78

(3.08)

156

(6.15)

(8.48)

CENTERLINE

OF ACTUATOR

YOKE MOUNTED

6

(0.25)

FOR PROPER MOISTURE DRAINAGE

THIS END MUST BE UP

191

(7.51)

MODULE

COVER

REMOVAL

CLEARANCE

1

13

(0.50)

FOR ATEX/IECEx

FLAMEPROOF UNITS:

BOLT ENGAGEMENT

NOT TO EXCEED

137

12.9 mm (0.51 INCHES).

(5.38)

5/16‐18 BOLTS

mm

(INCH)

10

Instruction Manual

D102005X012

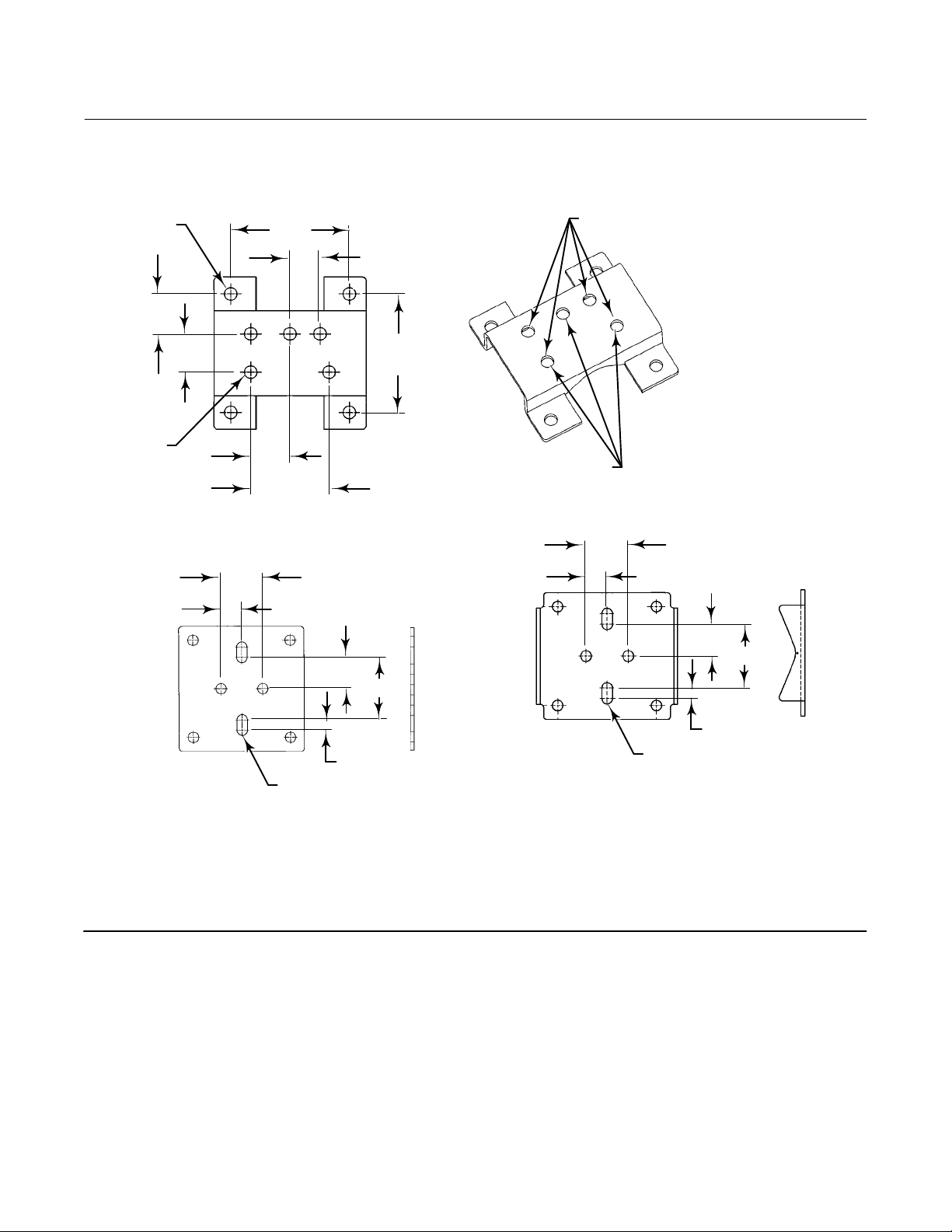

Figure 6. Typical Transducer Mounting with Universal Mounting Bracket

846 Transducer

May 2022

ADDITIONAL ADAPTER PLATE

PART NUMBER 03311‐0318‐0001

REQUIRED FOR I/P WITH

STAINLESS STEEL HOUSING

U BOLT

5/16‐18 x 5/8

BOLTS

ADAPTER PLATE

(SEE DETAIL “B”)

(1.61)

VERTICAL MOUNT

MOUNTING BRACKET

(SEE DETAIL “A”)

FOR PROPER MOISTURE

DRAINAGE, THIS END

MUST BE UP

5/16‐18 HEX NUT (4 PLACES)

41

3

2‐INCH PIPESTAND MOUNTING

FOR ATEX/IECEx FLAMEPROOF

UNITS: BOLT ENGAGEMENT NOT TO

EXCEED 8.8 mm (0.35 INCHES).

5/16‐18 BOLT HOLES

1

MOUNTING BRACKET

(SEE DETAIL “A”)

ADAPTER PLATE

(SEE DETAIL “B”)

FOR ATEX/IECEx

FLAMEPROOF UNITS:

BOLT ENGAGEMENT

NOT TO EXCEED

8.1 mm (0.32 INCHES).

5/16‐18 BOLT HOLES

2

HORIZONTAL MOUNT

FOR PROPER MOISTURE

DRAINAGE, THE I/P

MUST BE MOUNTED ON

TOP OF THE PIPE

ADDITIONAL ADAPTER

PLATE PART NUMBER

03311‐0318‐0001

REQUIRED FOR I/P

WITH STAINLESS STEEL

HOUSING

5/16‐18 x 3/4 BOLTS (4 PLACES)

5/16‐18 x 3/4 BOLTS

(4 PLACES)

MOUNTING BRACKET (SEE DETAIL “A”)

FOR PROPER

MOISTURE

DRAINAGE,

THIS END

MUST BE UP

1

1

GE06214 SHT 3

BOLT HOLES FOR STAINLESS

STEEL CONSTRUCTION

(COVERLOCK SHOWN)

GE06214 SHT 2

BOLT HOLES FOR ALUMINUM

CONSTRUCTION (COVERLOCK SHOWN)

NOTES:

1 THE MOUNTING POSITIONS SHOWN ALLOW ANY MOISTURE BUILDUP IN THE TERMINAL COMPARTMENT

TO DRAIN TO THE SIGNAL WIRE CONDUIT ENTRANCE. DO NOT MOUNT THE TRANSDUCER WITH THE TERMINAL

COMPARTMENT COVER ON THE BOTTOM; MOISTURE MAY ACCUMULATE IN THE TERMINAL COMPARTMENT

OR PILOT STAGE, PREVENTING PROPER TRANSDUCER OPERATION. THE VERTICAL MOUNT IS MOST EFFECTIVE

FOR MOISTURE DRAINAGE IN WET APPLICATIONS.

2 IF MOUNTED ON HORIZONTAL PIPE, THE I/P MUST BE ON TOP OF THE PIPE FOR PROPER MOISTURE DRAINAGE.

3 THIS DIMENSION IS 44 (1.74) FOR STAINLESS STEEL HOUSING.

14B7332

19B9484‐B

E0786

32

(1.25)

WALL/PANEL MOUNTING

(ALUMINUM HOUSING)

mm

(INCH)

11

846 Transducer

May 2022

Figure 6. Typical Transducer Mounting with Universal Mounting Bracket (continued)

Instruction Manual

D102005X012

4 X 10 (0.375)

(1.18)

5 X 10 (0.375)

U‐BOLT SLOTS

19 (0.75)

30

29

(1.13)

38

(1.50)

(3.50)

29

(1.16)

(2.312)

59

89

(.89)

23

89

(3.50)

FOR ALUMINUM HOUSING,

ALIGN 3 HOLES WITH I/P HOUSING

DETAIL “A” MOUNTING BRACKET

29

(1.125

57

(2.25)

U‐BOLT SLOTS

19 (0.75)

FOR STAINLESS STEEL HOUSING,

ALIGN 4 HOLES WITH I/P HOUSING

38

(1.50)

29

(1.125

57

(2.25)

2 X 10 (0.375)

03311-0318

4 X 5 (0.188)

2 X 10 (0.375)

DETAIL “B” ADAPTER PLATE

4 X 5 (0.188)

mm

(INCH)

ADDITIONAL ADAPTOR PLATE (PART NUMBER 03311‐0318‐0001)

REQUIRED FOR I/P WITH STAINLESS STEEL HOUSING

NOTES:

1. ATTACH THE BRACKET SHOWN IN DETAIL “A” TO THE TRANSDUCER

2. ATTACH THE ADAPTER PLATE SHOWN IN DETAIL “B” TO THE VALVE OR PIPE.

3. CONNECT THE TWO PIECES.

34B4990‐C

34B5000‐B

E0787

The mounting boss for the air supply connection contains two 5/16‐18 UNC tapped holes that are 2‐1/4 inches apart.

The tapped holes allow direct connection (integral mount) of a 67CFR filter‐regulator, if desired. When the

filter‐regulator is factory mounted, the mounting hardware consists of two 5/16‐18 x 3‐1/2 inch stainless steel bolts

and one O‐ring. When the filter‐regulator is field mounted, the mounting hardware consists of two 5/16‐18 x 3‐1/2

inch stainless steel bolts, two spacers (which may or may not be required) and two O‐rings (of which only one will fit

correctly into the housing O‐ring groove and the other may be discarded). This is due to the fact that the current

housing has been slightly modified from its original design, hence, the additional hardware (if needed) when field

mounting the 67CFR filter‐regulator.

12

Instruction Manual

D102005X012

Figure 7. Typical Transducer Dimensions with Gauges

846 Transducer

May 2022

81

(3.2)

9

(0.36)

14B7332‐D

E0776

49

(1.92)

(2.83)

OUTPUT GAGE

72

SUPPLY

GAGE

FILTER‐

REGULATOR

67CFR

14‐18 NPT

SUPPLY CONN

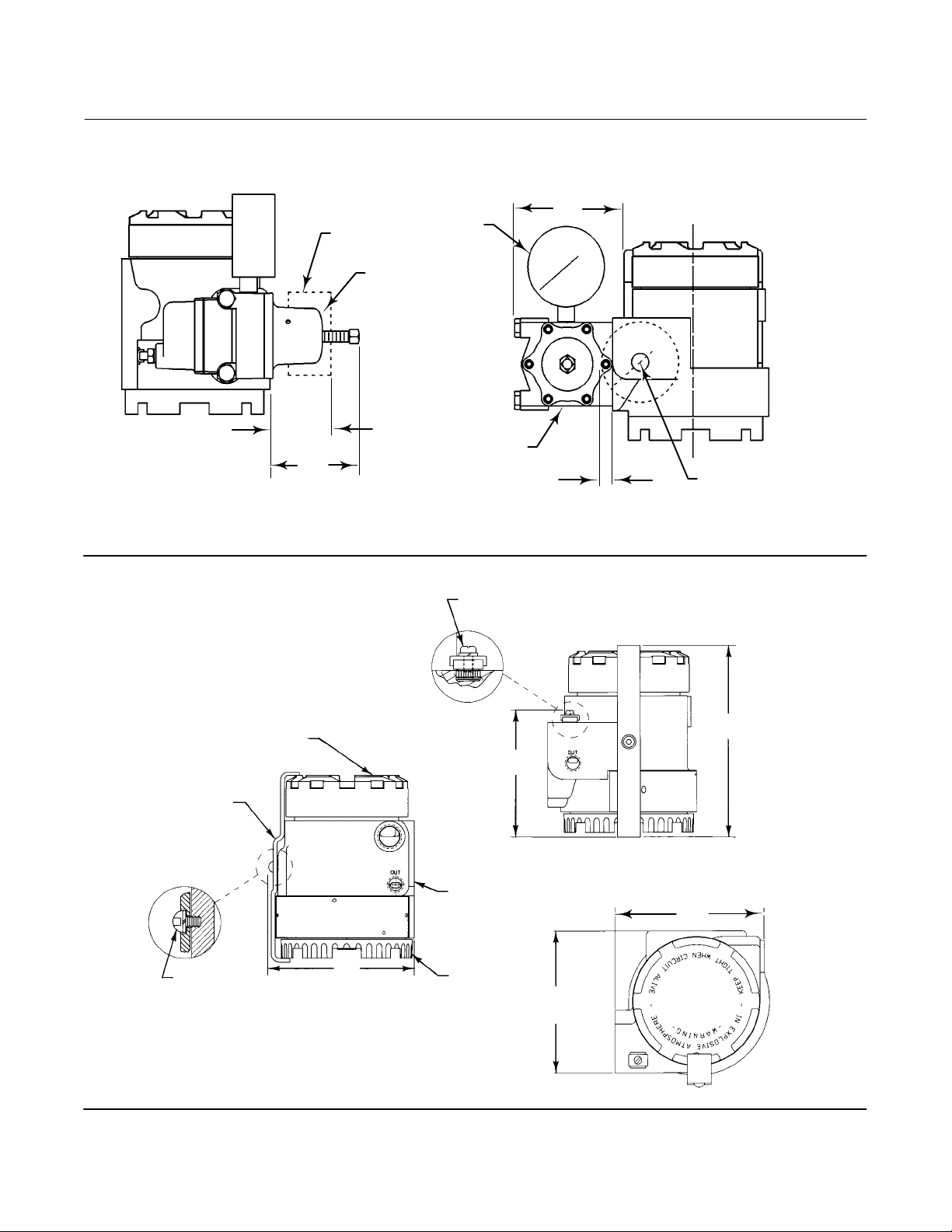

Figure 8. Transducer Dimensions with ATEX / IECEx Flameproof Certifications

EXTERNAL EARTHING CONNECTION, SST TERMINAL

CLAMP AND SLOTTED M5 SCREW AND SPLIT RING WASHER

1/4‐18 NPT

OUTLET CONN

PLUGGED WHEN

GAUGE NOT

FURNISHED

mm

(INCH)

B2465

COVER LOCK

INTERNAL

HEX DRIVE

ROUND HEAD

SCREW (3 mm)

TERMINAL

COMPARTMENT

COVER

4.75

(121)

162

(6.38)

3.62

(92)

HOUSING

129

(5.07)

MODULE COVER

121

(4.75)

mm

(INCH)

13

846 Transducer

May 2022

Instruction Manual

D102005X012

Output Pressure

Connect the output signal line to the transducer at the output port. The output port is 1/4‐18 NPT, as shown in figure

4. The output gauge port can be used as an alternate signal port. If the gauge port is used as a signal port, a threaded

plug must be installed in the output port.

The output gauge port allows connection of an output gauge to provide local output signal indication. The output

gauge port is 1/4‐18 NPT. If an output gauge is not specified, a threaded plug is shipped with the transducer. The plug

must be installed in the output gauge port when the port is not used.

Electrical Connections

WARNING

Personal injury or property damage could result from fire or explosion. In explosive atmospheres, remove power and shut

off the air supply to the I/P unit before attempting to remove the terminal compartment cover or module cover. Failure to

do so could result in an electrical spark or explosion.

Personal injury or property damage could result from an uncontrolled process. Perform the steps in the WARNING at the

beginning of the Installation section before removing the module cover to ensure the process is properly controlled.

Unscrewing the module cover removes power from the electronics and opens the supply and output air passages to

atmosphere resulting in an output signal of 0.0 psi.

NOTICE

Excessive current can damage the transducer. Do not connect an input current of more than 100 mA to the transducer.

Note

For North American explosion‐proof applications, 846 transducers have been designed so that a conduit seal is not required. For all

other applications install the product per local, regional, or national code, rules, and regulations.

WARNING

Select wiring and/or cable glands that are rated for the environment of use (such as hazardous location, ingress protection,

and temperature). Failure to use properly rated wiring and/or cable glands can result in personal injury or property damage

from fire or explosion.

Signal wiring is brought to the terminal compartment through a 1/2‐14 NPT housing conduit connection, shown in

figure 4. Where condensate is common, use a conduit drip leg to help reduce liquid buildup in the terminal

compartment and avoid shorting of the input signal. Electrical connections are made at the terminal block. Internal

and external grounding lugs are provided to facilitate a separate ground when required. The internal ground is shown

in figure 4, and the external grounding lug is shown in figure 8.

14

Loading...

Loading...