Fisher Instruction Manual: Fisher 667NS Diaphragm Actuators Size 40, 45, 70, and 80 Manuals & Guides

Instruction Manual

D102603X012

667NS Actuator

June 2018

Fisher

™

667NS Diaphragm Actuators

Size 40, 45, 70, and 80

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Specifications 3...............................

Educational Services 3.........................

Maximum Pressure Limitations 3..................

Installation 4..................................

Actuator Mounting 5..........................

Direct‐Acting

(Push‐Down‐to‐Close) Valves 5............

Reverse‐Acting

(Push‐Down‐to‐Open) Valves 6............

Loading Connection 8..........................

Adjustments 9.................................

Travel 9......................................

Introduction

Spring 9.....................................

Discussion of Bench Set 9...................

Adjustment Steps 10.......................

Operation 11..................................

Maintenance 11................................

Replacement of the Elastomeric Parts 12..........

Size 40, 45, and 70 Actuators 12.............

Size 80 Actuators 13.......................

Disassembly 14...............................

Size 40, 45, and 70 Actuators 14.............

Size 80 Actuators 14.......................

Assembly 15..................................

Size 40, 45, and 70 Actuators 15.............

Size 80 Actuators 16.......................

Parts Ordering 18...............................

Parts List 18...................................

Scope of Manual

This manual provides installation, maintenance, and parts list information for the Fisher 667NS actuator. Refer to

separate instruction manuals for information regarding the control valve and accessories.

Do not install, operate, or maintain 667NS actuators without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson sales office

proceeding.

or Local Business Partner before

Description

The 667NS actuator is a reverse‐acting, spring‐opposed diaphragm actuator that is used for operation of automatic

control valves. The 667NS actuator yoke construction and special bonnet‐to‐yoke bolting provides a high structural

resonant frequency that exceeds most nuclear service seismic requirements.

www.Fisher.com

667NS Actuator

June 2018

Instruction Manual

D102603X012

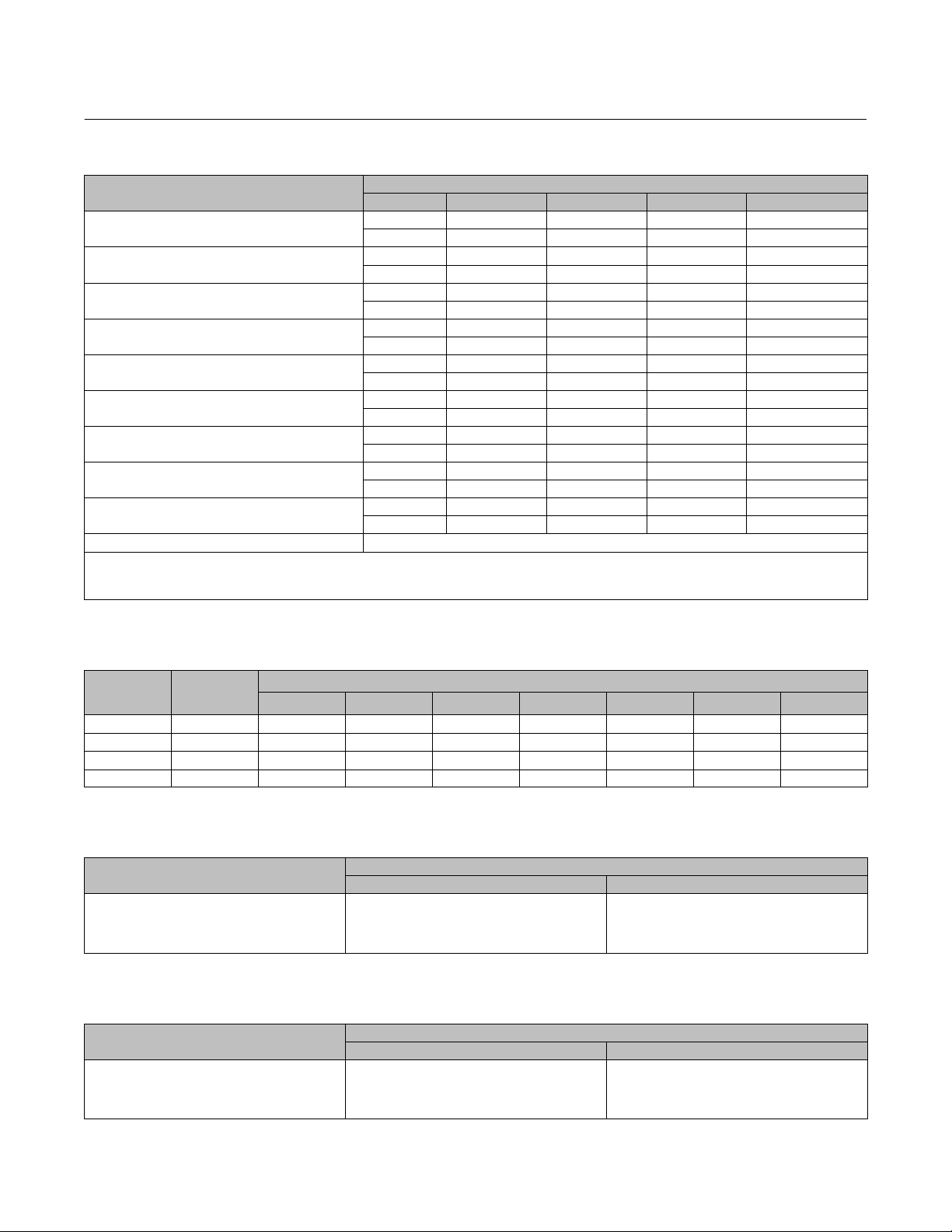

Table 1. Fisher 667NS Specifications

SPECIFICATION

2

Nominal Effective Diaphragm Area

Yoke Boss Diameters

Acceptable Valve Stem Diameters

Maximum Allowable Output Thrust

(1)

Maximum Travel

Maximum Diaphragm Pressure to Stroke

Maximum Excess Diaphragm Pressure

Maximum Casing Pressure for Actuator Sizing

Maximum Diaphragm Casing Pressure

Material Temperature Capabilities

1. See also the Specifications portion of the Introduction section. Do not exceed maximum allowable valve stem load when applying maximum allowable thrust.

2. Maximum diaphragm casing pressure must not be exceeded and must not produce a force on the actuator stem greater than the maximum allowable actuator output thrust or the maxi

mum allowable stem load.

3. The pressure and temperature limitations in this manual, and any applicable code limitation, should not be exceeded.

Actuator

(2,3)

(2,3)

(3)

(2,3)

(3)

cm

2

Inch

mm 71 71 90 5H

Inch 2‐13/16 2‐13/16 3‐9/16 5H

mm 12.7 12.7 19.1 25.4 & 31.8

Inch 1/2 1/2 3/4 1 & 1‐1/4

N 12,015 30,371 42,720 88,110

Lb 2700 6825 9600 19,800

mm 38 51 76 76

Inch 1.5 2 3 3

Bar 4.5 4.5 3.5 4.8

Psig 65 65 50 70

Bar 1.4 0.7 0.7 1.4

Psig 20 10 10 20

Bar 4.8 4.5 3.4 4.9

Psig 70 65 50 70

Bar 6.2 5.2 4.1 5.5

Psig 90 75 60 80

40 45 70 80

445 677 1419 see table 5

69 105 220 see table 5

-40 to 82_C (-40 to 180_F) with nitrile diaphragm

ACTUATOR SIZE

Table 2. Diaphragm Casing Volumes, cm3 (Inch3)

ACTUATOR

SIZE

CLEARANCE

VOLUME, cm

(INCH3)

3

11 (0.4375) 16 (0.625) 19 (0.75) 29 (1.125) 38 (1.5) 51 (2) 76 (3)

40 934 (57) 1475 (90) 1704 (104) 1852 (113) 2327 (142) 2786 (170) ‐ ‐ ‐ ‐ ‐ ‐

45 1556 (95) ‐ ‐ ‐ 2786 (170) 2999 (183) 3720 (227) 4424 (270) 5408 (330) ‐ ‐ ‐

70 3490 (213) 5244 (320) 5948 (363) 6424 (392) 7833 (478) 9242 (564) 11,110 (678) 14,879 (908)

80 4818 (294) ‐ ‐ ‐ ‐ ‐ ‐ ‐ ‐ ‐ 10,488 (640) 12,454 (760) 14,863 (907) 19,337 (1180)

TRAVEL, mm (INCH)

Table 3. Actuator Stem Assembly Bolt Torque Values

ACTUATOR SIZE

40

45

70

80

NSm LbfSFt

68

183

183

542

TORQUE

50

135

135

400

Table 4. Bonnet‐to‐Actuator Bolt Torque Values

ACTUATOR SIZE

40

45

70

80

BONNET‐ACTUATOR STUD BOLT TORQUE

NSm LbfSFt

102

102

176

292

75

75

130

215

2

Instruction Manual

D102603X012

667NS Actuator

June 2018

Table 5. Size 80 Diaphragm Area

TRAVEL AREA

mm Inch cm

0

19

29

38

51

64

76

0

0.75

1.125

1.5

2

2.5

3

2039

1903

1865

1845

1832

1800

1761

2

Inch

316

295

289

286

284

279

273

2

Specifications

Tables 1 and 2 provide specifications for the various sizes of 667NS actuators discussed in this instruction manual.

WARNING

To avoid personal injury or property damage, do not exceed pressure and temperature limits specified in table 1.

Educational Services

For information on available courses for the Fisher 667NS diaphragm actuator, as well as a variety of other products,

contact:

Emerson Automation Solutions

Educational Services - Registration

Phone: 1-641-754-3771 or 1-800-338-8158

E-mail: education@emerson.com

emerson.com/fishervalvetraining

Maximum Pressure Limitations

The casing and diaphragm of 667 actuators are pressure operated. This air pressure provides energy to compress the

spring, to stroke the actuator, and lift the diaphragm away from the valve. The following explanations describe the

maximum pressure limits for an actuator. Refer to table 1 for maximum values.

WARNING

To avoid personal injury or property damage, do not exceed pressure and temperature limits specified in table 1.

D Maximum Diaphragm Pressure to Stroke the Actuator: This is the maximum pressure that can be applied at less

than full travel of the actuator. If this stroking pressure is exceeded before the upper diaphragm plate contacts the

travel stop, damage to the stem or other parts might result.

3

667NS Actuator

June 2018

Instruction Manual

D102603X012

D Maximum Excess Diaphragm Pressure: Additional pressure may be added when the actuator is at full travel. If the

Maximum Excess Diaphragm Pressure is exceeded, damage to the diaphragm or diaphragm casing might result.

Because the actuator has traveled its specified travel, and the diaphragm head is physically stopped from movement,

the energy from any additional air pressure is transmitted to the diaphragm and diaphragm casings. The amount of air

pressure that can be added once the actuator has traveled to the stops is limited by the resultant adverse effects that

may occur. Exceeding this limiting factor could result in leakage or casing fatigue due to the deformation of the upper

diaphragm casing.

D Maximum Diaphragm Casing Pressure: If the Maximum Diaphragm Casing Pressure is exceeded, damage to the

diaphragm, diaphragm casing, or actuator might result. For some actuator sizes, the maximum casing pressure is

the sum of the maximum stroking pressure added to the maximum excess pressure. For other actuator sizes, the

value is lower than the sum of the two pressures.

Installation

The diaphragm actuator is normally shipped mounted on a valve body. Follow the valve body instructions when

installing the control valve in the pipeline.

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

If the cover (key 84, figure 4) is not in place on the actuator, install it as shown in figure 4.

WARNING

If the control valve and actuator are installed with the actuator in any position other than vertical, the actuator may not

conform with safety‐related qualifications. Nonvertical orientation should be part of existing qualification analysis on file

at the plant site to ensure conformance with safety‐related qualifications.

The control valve assembly may be installed with any orientation; however, the actuator should not be installed in

ways that allow water to collect in the yoke and actuator spring areas.

Note

The 667NS actuator will not mount on a standard valve bonnet; it requires a style NS bonnet having eight bonnet‐to‐yoke stud

bolts.

4

Instruction Manual

D102603X012

667NS Actuator

June 2018

If the actuator and control valve body are separate, mount the 667NS actuator on the valve body by following the

procedures in the Actuator Mounting section of this manual.

Actuator Mounting

Direct‐Acting (Push‐Down‐to‐Close) Valves

Refer to figure 1.

1. Screw the stem locknuts all the way onto the valve stem. Put the travel indicator disk, not used with the size 80

actuator, on the locknuts. The concave side of the disk should face the valve.

2. Place the actuator on the valve bonnet.

3. Insert the cap screws and tighten the hex nuts (not shown), securing the actuator to the bonnet. Tighten the cap

screws to the torque shown in table 4.

4. Apply loading pressure to the actuator to retract the actuator stem fully (against the travel stop).

5. With the travel indicator scale attached to the actuator yoke, make a temporary mark on the actuator stem in line

with the top mark on the scale (the mark on the end of the scale that is marked “OPEN”). (The distance from the top

mark on the scale to the bottom mark is equal to the travel of the valve.)

Note

Before turning the spring adjuster on size 70 or 80 actuators, assemble the stem connector around the actuator stem and the

anti‐rotating lug on the yoke. Mark the actuator stem as a visual reference to verify that stem rotation does not occur. Remove the

stem connector before rechecking the bench set.

6. Refer to the actuator nameplate to determine the bench set pressure range of the actuator. Reduce actuator

loading pressure to the lower end of the bench set range. (For size 80, remove the cap screw (key 91, figure 4) and

remove the adjusting screw cover (key 84, figure 4). Rotate the spring adjustor (key 74, figure 2 for sizes 40 and 45;

key 74, figure 3 for size 70; and key 74, figure 4 for size 80) until the mark you made on the actuator stem is in line

with the bottom mark on the travel indicator scale. (Replace the size 80 adjusting screw cover and cap screw when

you have completed the adjustments.)

7. Increase actuator loading pressure to the upper end of the bench range and check to be sure that the mark on the

actuator stem is in line with the top mark on the travel indicator scale.

If the marks are in line, the actuator is properly bench set.

If the marks are not in line, the spring is not correct for the specified bench set. It is necessary to use a different spring

or a different bench set.

8. Reduce actuator loading pressure until the mark on the actuator stem is in line with the bottom mark on the travel

indicator scale.

CAUTION

Do not clamp just the tip of either the valve stem or the actuator stem in the stem connector. Incomplete engagement of

the valve stem and/or actuator stem in the stem connector might result in stripped threads or improper operation. Be sure

that the length of each stem clamped in the stem connector is equal to or greater than the diameter of that stem.

5

667NS Actuator

June 2018

Instruction Manual

D102603X012

9. Push the valve stem firmly against its seat, and be sure that it remains firmly against the seat. Clamp the actuator

stem and valve stem between the two stem connector halves.

If necessary, increase actuator loading pressure slightly to allow the valve stem, actuator stem, and stem connector

threads to match.

Insert and tighten the stem connector cap screws.

WARNING

To avoid personal injury due to the sudden, uncontrolled movement of parts, do not loosen the cap screws when the stem

connector has spring or loading pressure force applied to it.

10. Raise the travel indicator disk (sizes 40 through 70 only) to the stem connector. For all sizes, thread the stem

locknuts against the stem connector.

11. Remove all actuator loading pressure. Move the travel indicator scale so that the indicator disk (or pointer) is in

line with the bottom mark of the travel indicator scale.

12. Check the valve travel to be sure that the valve travels fully with no overtravel.

Reverse‐Acting (Push‐Down‐to‐Open) Valves

Refer to figure 1.

1. Screw the stem locknuts all the way onto the valve stem. Put the travel indicator disk, not used with the size 80

actuator, on the locknuts. The concave side of the disk should face the valve.

2. Place the actuator on the valve bonnet.

3. Insert the cap screws and tighten the hex nuts (not shown), securing the actuator to the bonnet. Tighten the cap

screws to the torque in table 4.

Note

Before turning the spring adjuster on size 70 or 80 actuators, assemble the stem connector around the actuator stem and the

anti‐rotating lug on the yoke. Mark the actuator stem as a visual reference to verify that stem rotation does not occur. Remove the

stem connector before rechecking the bench set.

4. (For size 80, remove the cap screw (key 91, figure 4) and remove the adjusting screw cover (key 84, figure 4).

Rotate the spring adjustor (key 74, figure 2 for sizes 40 and 45; key 74, figure 4 for size 70; and key 74, figure 4 for

size 80) to position the actuator stem at its fully extended position.

5. With the travel indicator scale attached to the actuator yoke, make a temporary mark on the actuator stem in line

with the bottom mark on the scale (the mark on the end of the scale that is marked “OPEN”). (The distance from the

bottom mark on the scale to the top mark is equal to the travel of the valve.)

6. Refer to the actuator nameplate to determine the bench set pressure range of the actuator. Apply an actuator

loading pressure to the actuator equal to the lower end of the bench set range and rotate the spring adjustor until

the mark you made on the actuator stem is in line with the bottom mark on the travel indicator scale. (Replace the

size 80 adjusting screw cover and cap screw when you have completed the adjustments.)

6

Instruction Manual

D102603X012

Figure 1. Schematic and Stem Connection Details for Fisher 667NS

AIR

LIFTS

A3833‐A

SPRING

PUSHES

DOWN

SCHEMATIC

YOKE

TRAVEL

INDICATOR

STEM

LOCKNUTS

55A9191‐H

SIZES 40 AND 45

667NS Actuator

June 2018

SPRING

ADJUSTOR

STEM

CONNECTOR

TRAVEL

INDICATOR

DISK

VALVE

STEM

VENT

DIAPHRAGM

CASING

YOKE

ACTUATOR

VALVE

STUDS

AND NUTS

FISHER

DBQ-NS

VALVE

A5958/MM1

C0762‐1

YOKE

TRAVEL

INDICATOR

STEM

LOCKNUTS

55A9193‐F

TRAVEL

INDICATOR

YOKE

STEM

LOCKNUTS

56A1032‐D

SPRING

ADJUSTOR

TRAVEL

INDICATOR

DISK

VALVE

STEM

SIZE 70

TRAVEL

INDICATOR

POINTER

STEM

CONNECTOR

VALVE

STEM

SIZE 80

STEM CONNECTION

DETAILS

7

667NS Actuator

June 2018

7. Increase actuator loading pressure to the upper end of the bench range and check to be sure that the mark on the

actuator stem is in line with the top mark on the travel indicator scale.

If the marks are in line, the actuator is properly bench set.

If the marks are not in line, the spring is not correct for the specified bench set. It is necessary to use a different spring

or a different bench set.

Instruction Manual

D102603X012

CAUTION

Do not clamp just the tip of either the valve stem or the actuator stem in the stem connector. Incomplete engagement of

the valve stem and/or actuator stem in the stem connector might result in stripped threads or improper operation. Be sure

that the length of each stem clamped in the stem connector is equal to or greater than the diameter of that stem.

8. Pull the valve stem firmly against its seat, and be sure that it remains firmly against the seat. Clamp the actuator

stem and valve stem between the two stem connector halves.

If necessary, decrease actuator loading pressure slightly to allow the valve stem, actuator stem, and stem connector

threads to match.

Insert and tighten the stem connector cap screws.

WARNING

To avoid personal injury due to the sudden uncontrolled movement of parts, do not loosen the cap screws when the stem

connector has spring or loading pressure force applied to it.

9. Raise the travel indicator disk to the stem connector (sizes 40 through 70 only). For all sizes, thread the stem

locknuts against the stem connector.

10. Remove all actuator loading pressure. Move the travel indicator scale so that the indicator disk (or pointer) is in line

with the bottom mark of the travel indicator scale.

11. Check the valve travel to be sure that the valve travels fully with no overtravel.

Loading Connection

1. Connect the loading pressure piping to the NPT internal connection in the top of the actuator yoke.

2. For size 70 actuators, remove the 1/4‐inch bushing in the 1/2 NPT internal connection to increase connection size, if

necessary. Use either piping or tubing.

3. Keep the length of tubing or piping as short as possible to avoid transmission lag in the control signal. If an

accessory (such as a volume booster or valve positioner) is used, be sure that the accessory is properly connected to

the actuator. Refer to the positioner instruction manual if necessary.

4. Cycle the actuator several times to check that the valve stem travel is correct and that the travel occurs when the

correct pressure range is applied to the diaphragm.

5. If valve stem travel is incorrect, refer to the Travel procedure in the Adjustments section.

6. If the pressure range is incorrect, refer to the Spring procedure in the Adjustments section.

8

Loading...

Loading...