Fisher Instruction Manual: Fisher 1051 and 1052 Size 33 Diaphragm Rotary Actuators Manuals & Guides

Instruction Manual

D101322X012

Fisher™ 1051 and 1052 Size 33

Diaphragm Rotary Actuators

1051 and 1052 Size 33 Actuators

February 2019

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 2.................................

Specifications 3...............................

Installation 3..................................

Actuator Mounting and Changing Actuator

Mounting 5................................

F and G Mounting Adaptations 5.............

H Mounting Adaptation 7...................

J Mounting Adaptation 8....................

1052 Spring Compression Adjustment 10.........

Initial Compression 10......................

Stroking Range 11.........................

Maintenance 11................................

Mounting Adaptations 12......................

Replacing Diaphragm 12.......................

Replacing Diaphragm Plate, Diaphragm Rod,

Spring, and Spring Seat 13....................

Changing Or Replacing Actuator Lever 16.........

Proximity Switches, Lever‐Operated Switches,

and Positioner 18...........................

Installing the Cam 18......................

Installing Proximity Switches 19..............

Switches Indicating Bottom of Stroke 19..

Switches Indicating Top of Stroke 19......

Installing Lever‐Operated Switch 19..........

Installing the Push Rod 20................

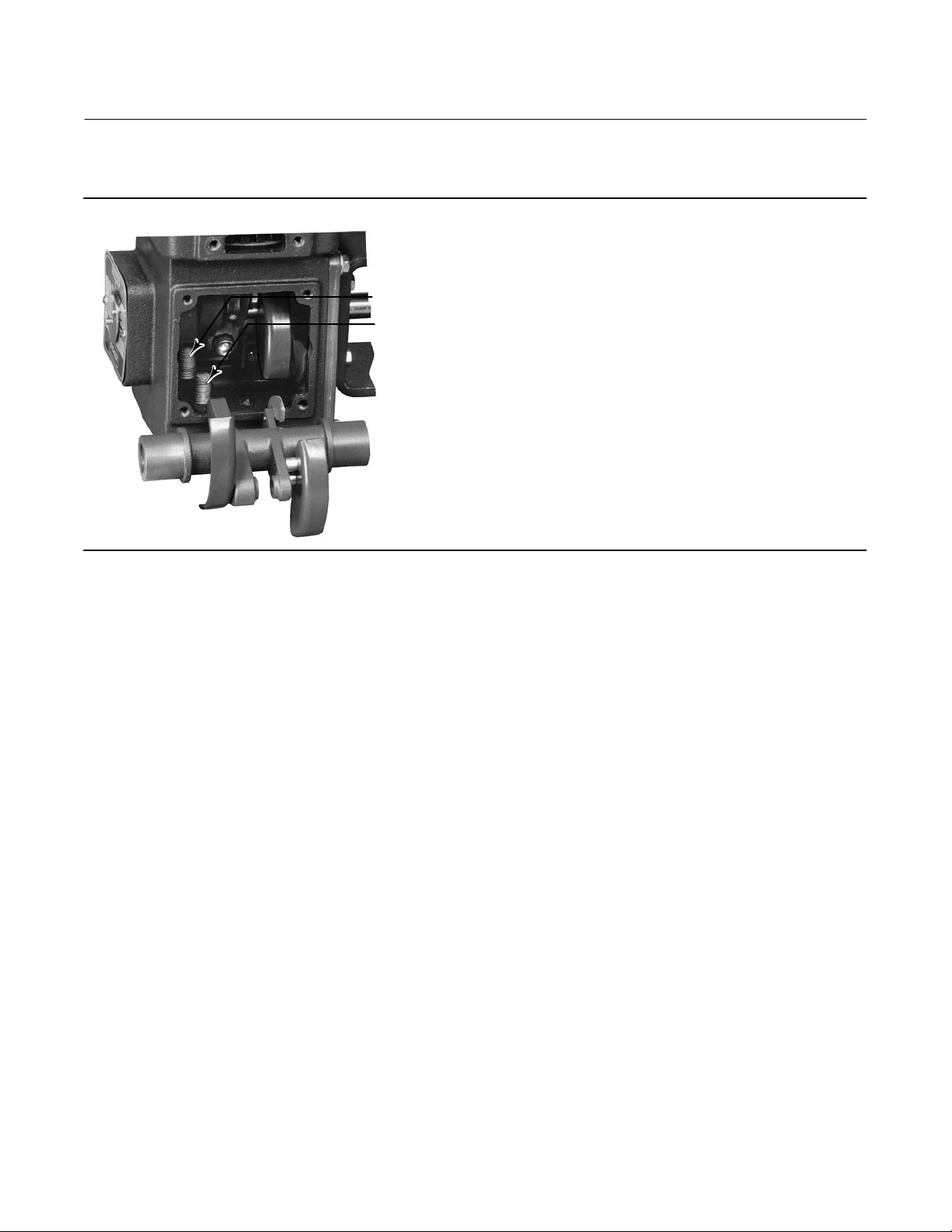

Figure 1. Fisher 1052 Actuator with CV500 Valve and

FIELDVUE™ DVC6200 Digital Valve Controller

W8192‐2

Mounting Lever‐Operated Switch and

Adjustment 20..........................

Positioner Mounting 20........................

Top‐Mounted Handwheel 20....................

Locking Mechanism 21.........................

Parts Ordering 23...............................

Parts Kits 23...................................

Parts List 23...................................

Introduction

Scope of Manual

This instruction manual includes installation, adjustment, operation, maintenance, and parts information for the

Fisher 1051 and 1052 Size 33 diaphragm rotary actuators (figure 1). Mounting adaptations F, G, H, and J are included

in this manual. Instructions for the control valve, positioner, manual actuator, and other accessories are included in

separate manuals.

www.Fisher.com

1051 and 1052 Size 33 Actuators

February 2019

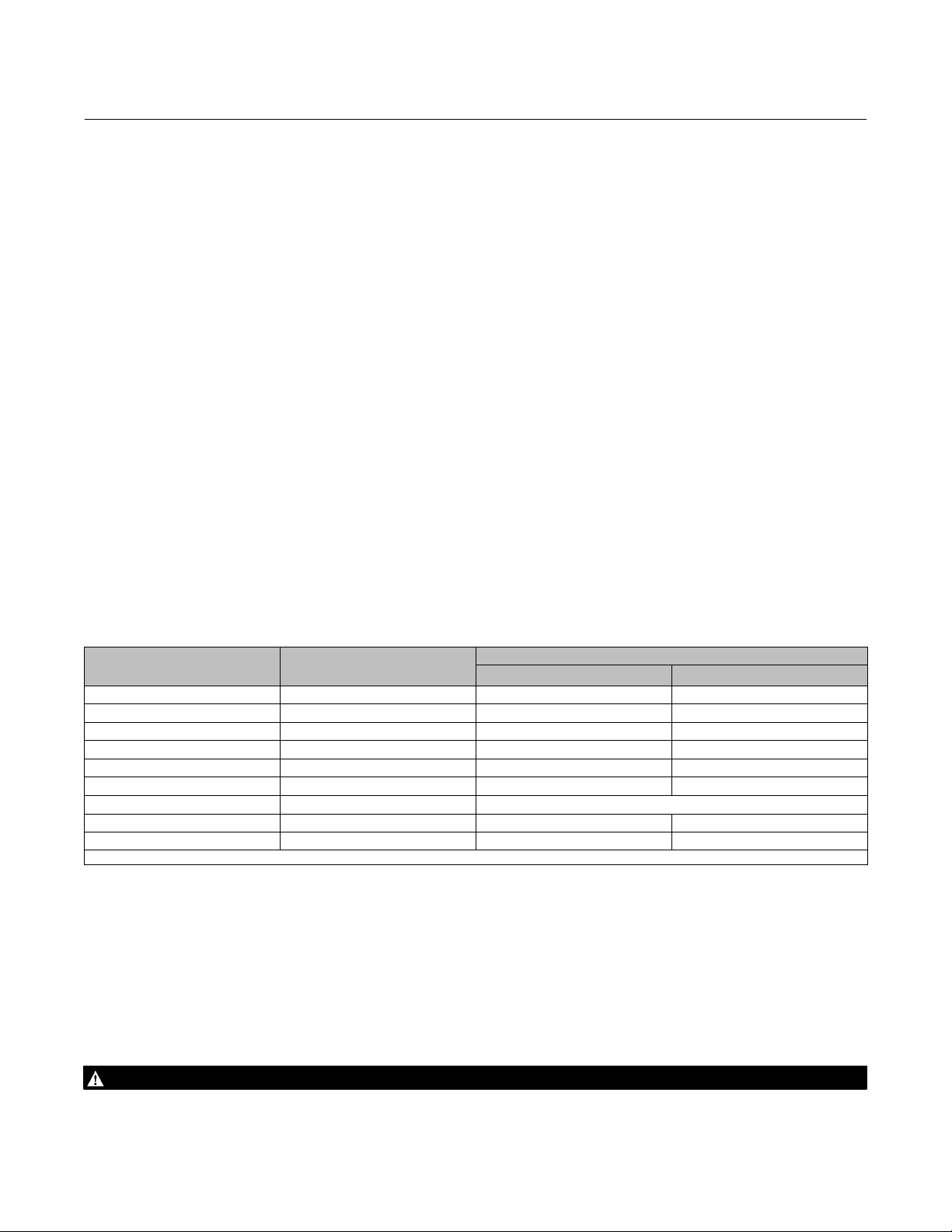

Table 1. Specifications

Instruction Manual

D101322X012

Available Configuration

1051: For on‐off service without a positioner or for

throttling service with a positioner

1052: For on‐off service without a positioner or for

throttling service with or without a positioner

Standard Diaphragm Pressure Ranges

J 0 to 1.2 bar (0 to 18 psig), J 0 to 2.3 bar (0 to 33

psig), J 0 to 2.8 bar (0 to 40 psig), and J 0 to 3.8 bar

(0 to 55 psig)

Maximum Diaphragm Sizing Pressure

(1, 2)

3.8 bar (55 psig)

Maximum Diaphragm Casing Pressure

(1, 7)

4.5 bar (65 psig)

Maximum Valve Shaft Rotation

J 90 degrees (adjustable through 60 degrees with

integral travel stops)

Acceptable Valve Shaft Diameters, mm (Inches)

F and G mounting: J 12.7 (1/2), J 15.9 (5/8), or J

19.1 (3/4)

H mounting: varies—uses 22.2 mm (7/8 inch) output

shaft with two flats

J mounting: J 9.5 (3/8), J 12.7 (1/2), or 15.9 (5/8)

of supply piping. If stroking time is critical, consult

your Emerson Automation Solutions sales office.

Diaphragm Casing Displacement

Clearance Volume

Casing Volume

(3)

: 623 cm3 (38 cubic inches)

(4)

90 Degree Rotation: 2390 cm3 (146 cubic inches)

60 Degree Rotation: 1890 cm

Material Temperature Capabilities

NBR (nitrile) Diaphragm or O‐rings

3

(115 cubic inches)

(1)

(5)

:

-40 to 82_C (-40 to 180_F)

VMQ (silicone) Diaphragm:

-40 to 149_C (-40 to 300_F)

POM (polyoxymethylene) Push Rods and Guides

(used with lever‐operated switches):

-40 to 82_C

(6)

(-40 to 180_F)

Travel Indication

Graduated disk and pointer

Pressure Connections

Standard: 1/4 NPT internal

Optional: J 1/2 or J 3/4 NPT internal

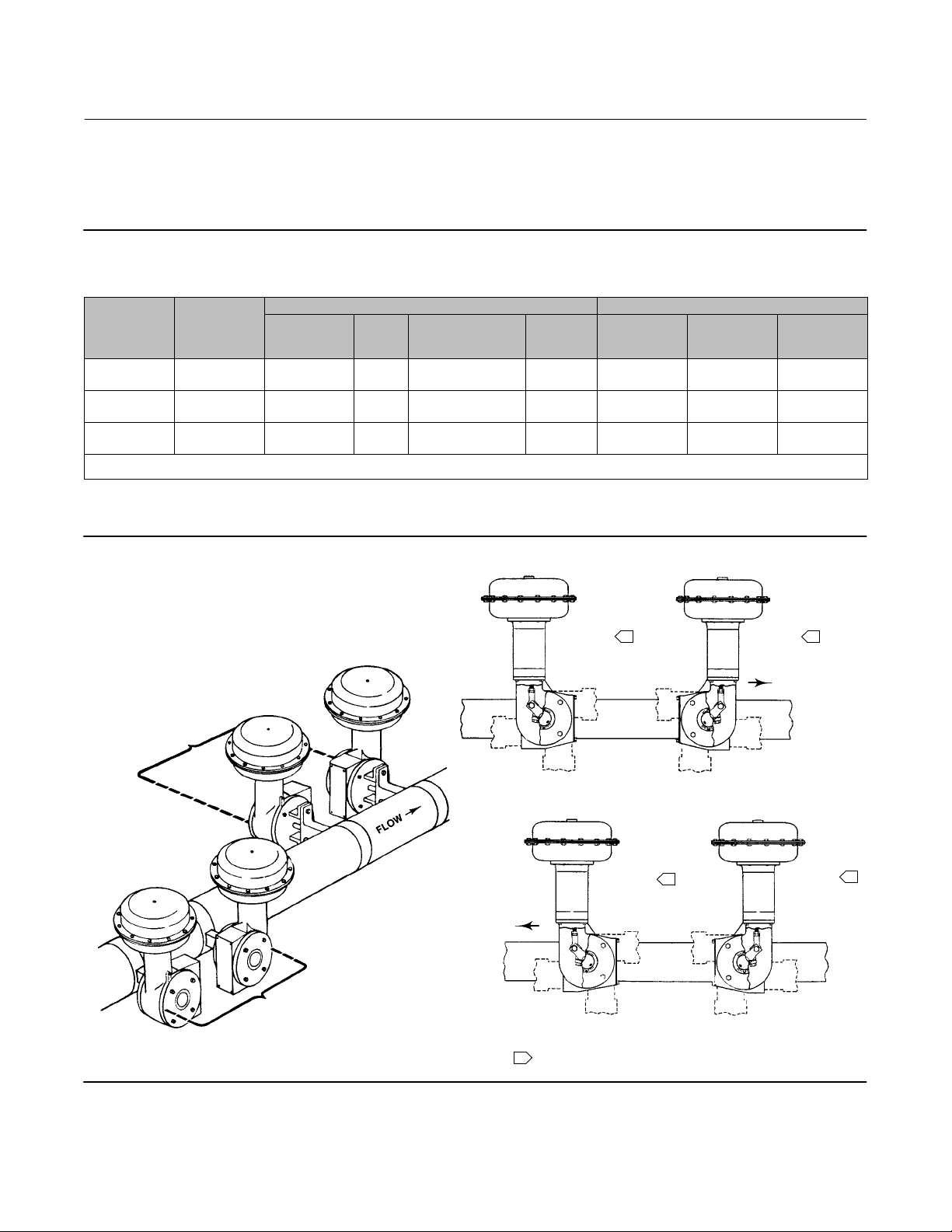

Mounting Positions

See figure 2

Stroking Time

Dependent of actuator size, rotation, spring rate,

initial spring compression, supply pressure, and size

1. The pressure/temperature limits in this manual and any applicable standard or code limitation for valve should not be exceeded.

2. Use this value to determine the maximum torque output allowed.

3. Volume when the diaphragm is in the up position.

4. Includes clearance volume.

5. NBR (nitrile) O‐rings are used in the optional top‐mounted handwheel and in the optional up travel stop assembly.

6. For higher temperature ratings, contact your Emerson sales office.

7. This maximum casing pressure is not to be used for normal operating pressure. Its purpose is to allow for typical regulator supply settings and/or relief valve tolerances.

Approximate Weights

1051: 20 kg (45 pounds)

1052: 21 kg (46 pounds)

Do not install, operate, or maintain a 1051 or 1052 actuator without being fully trained and qualified in valve, actuator,

and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important

to carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If

you have any questions about these instructions, contact your Emerson sales office

before proceeding.

Description

1051 and 1052 Size 33 spring‐and‐diaphragm actuators are used on rotary‐shaft valve bodies for throttling or on‐off

applications. The 1051 may be used for on‐off service without a positioner or for throttling service with a positioner.

The 1052 uses an adjustable spring seat to control spring compression. It may be used for on‐off service without a

positioner, or it may be used for throttling service with or without a positioner, depending on service conditions.

2

Instruction Manual

D101322X012

1051 and 1052 Size 33 Actuators

February 2019

A top‐mounted handwheel may be mounted for infrequent service as a manual override. A manual actuator is

recommended for routine and repeated manual operation. Externally adjustable travel stops are used to limit the

degree of rotation at both ends of the actuator stroke. Provisions are included for integral mounting of optional

magnetic proximity switches. Lever‐operated, mechanical switches are also available.

The lever for the 1051 and 1052 size 33 actuator is supported by bushings. The lever may be changed to

accommodate valve bodies with different size valve shafts and different mounting adaptations. Levers and accessories

are available for mounting valve bodies and equipment with the following mounting adaptations:

F and G mounting adaptations (figures 9 and 10) are for use with Fisher splined‐shaft rotary valve bodies with 12.7,

15.9, and 19.1 mm (1/2, 5/8, and 3/4 inch) valve shaft diameters. A stub shaft is available for installation on the end of

the lever opposite the valve body for use as a wrench‐operated extension (for emergency override) or as a means of

connecting a manual actuator (see figure 14).

H mounting (figure 11) is for use with non‐Fisher products and user‐provided mounting brackets and shaft couplings.

It includes a mounting surface with threaded holes for attaching the user‐provided mounting bracket. A 22.2 mm (7/8

inch) stub shaft with flats is pinned to the lever and is used to couple the actuator to the operated equipment. A

second stub shaft may be installed on the opposite end of the lever for use as a wrench‐operated extension (for

emergency override) or as a means for connecting a manual actuator (see figure 14). Stub shafts are available in

standard and reverse constructions (see figure 12) to provide proper operation with the mounting position and

actuator action desired (see figure 2).

J mounting (figure 13) permits use of the actuator with Fisher keyed‐shaft valve bodies and other keyed‐shaft

equipment with 9.5, 12.7, and 15.9 mm (3/8, 1/2, and 5/8 inch) shaft diameters. A stub shaft is pinned to the lever and

a valve shaft coupling is pinned to the stub shaft. The coupling has multiple keyways (see figure 4) to accommodate

mounting in the desired position. A second stub shaft may be installed on the opposite end of the lever for use as a

wrench‐operated extension (for emergency override) or as a means for connecting a manual actuator (see figure 14).

Table 2. Bolting Torque Requirements

DESCRIPTION KEY NUMBER BOLT SIZE

Diaphragm Casing 5 3/8‐24 27 20

Travel Stop 8 7/16‐14 27 20

Diaphragm to rod 9 3/8‐24 54 40

Rod end to lever 18 3/8‐16 54 40

Housing to yoke 23 5/16‐18 41 30

Housing to cover 34 5/16‐18 41 30

Yoke to valve 71 3/8‐16 (See appropriate valve instruction manual)

Clamped lever 28 3/8‐16 54 40

Switch Nut 78 3/8‐16 27 20

1. Exceeding any torque requirements could damage the actuator and impair safe operation.

(1)

TORQUE

NSm LbfSft

Specifications

Specifications are shown in table 1 for 1051 and 1052 size 33 actuators. Some specifications for a given actuator as it

originally comes from the factory are stamped on a metal nameplate attached to the actuator.

Installation

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations.

3

1051 and 1052 Size 33 Actuators

February 2019

Instruction Manual

D101322X012

Check with your process or safety engineer for any other hazards that may be present from exposure to process media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

VALVE SERIES OR DESIGN VALVE SERIES OR DESIGN

MOUNTING ACTION

Right‐Hand

Left‐Hand

Left‐Hand

(Optional)

1. PDTC—Push‐down‐to‐close, and PDTO—Push‐down‐to‐open.

2. A left hand ball will be required for the NPS 3 through 12 Series B and the NPS 14 to 20, with or without attenuator.

(2)

(1)

PDTC

PDTO

PDTC

PDTO

PDTC

PDTO

BALL/PLUG

ROTATION TO

CLOSE

CCW

CCW

CCW

CCW

CW

CW

V250 V150, V200 & V300

A

B

NA

NA

NA

NA

A

B

D

C

C

D

CV500

V500

A

B

D

C

NA

NA

DISK/BALL

ROTATION TO

CLOSE

CW

CW

CW

CW

NA

NA

V250

NA

NA

C

D

NA

NA

8510B, 8532,

8560

& 9500

B

A

C

D

NA

NA

Figure 2. Mounting Styles and Positions for Fisher 1051 and 1052 Actuators

STYLE A

POSITION 1

STYLE D

STYLE C

43A6505‐A

A1584‐3

LEFT‐HAND

MOUNTING

STYLE B

STYLE A

RIGHT‐HAND

MOUNTING

4

3

STYLE D

FLOW

4

NOTES:

1

(SHOWN IN DOTTED LINES) ARE ALTERNATIVES.

STYLE B

1

2

4

POSITION 1

2

3

RIGHT‐HAND MOUNTING

STYLE C

POSITION 1

3

1

2

4

3

LEFT‐HAND MOUNTING

POSITION 1 IS STANDARD; POSITIONS 2 THROUGH 4

1

FLOW

POSITION 1

2

1

4

Instruction Manual

D101322X012

1051 and 1052 Size 33 Actuators

February 2019

CAUTION

To avoid parts damage, do not use an operating pressure that exceeds the Maximum Diaphragm Casing Pressure (table 1)

or produces a torque greater than the Maximum Allowable Valve Shaft Torque (see Catalog 14). Use pressure‐limiting or

pressure‐relieving devices to prevent the diaphragm casing pressure from exceeding its limit.

The actuator, as it comes from the factory, is normally mounted on a valve body. Follow the procedures given in the

valve instruction manual when installing the control valve in the pipeline.

If a positioner is ordered with the actuator, the pressure connection to the actuator is normally made at the factory. If

it is necessary to make this connection, run either 1/4 inch pipe or 3/8 inch tubing (for standard diaphragm case

fittings) between the pressure connection and the instrument. Keep the length of tubing or pipe as short as possible to

avoid transmission lag in the control signal.

When the control valve is completely installed and connected to the controlling instrument, check to make sure that

the action is correct (air‐to‐open or air‐to‐close) and that the controlling instrument is properly configured for the

desired action. For successful operation, the diaphragm rod, lever, and valve shaft must move freely in response to

changes in the loading pressure on the diaphragm.

Actuator Mounting and Changing Actuator Mounting

Use the following steps to mount the actuator or to change actuator mounting style or position.

F and G Mounting Adaptations

Unless otherwise specified, key numbers referenced in the following procedures are shown in figure 9 for the 1051

actuator and in figure 10 for the 1052 actuator.

1. Proceed as appropriate:

If the Actuator is mounted on a valve body and it is necessary to change mounting style or position, the actuator must

first be separated from the valve body. Proceed to the Disassembly portion of the Changing or Replacing Actuator

Lever procedure, observe all warnings, perform steps 1 through 6, and return to step 2 which follows.

If the Actuator is not mounted on a valve body, proceed to the Disassembly portion of the Changing or Replacing

Actuator Lever procedure, perform steps 2 through 5, and return to step 2 which follows.

2. Refer to figure 2 for available mounting styles and positions. When mounting on a Vee‐Ball™ V150, V200 or V300

valve, check the valve manual to determine if it is Series B. The actuator is normally positioned vertically with the

valve in a horizontal pipeline.

3. Determine whether the actuator mounting yoke (key 22) will be mounted on the housing cover assembly (key 33)

side or on the actuator housing boss side of the actuator. If the desired mounting position and style require moving

the mounting yoke and travel indicator (key 35) to opposite sides of the actuator, remove the machine screws (key

38), the travel indicator pointer (key 37), the machine screws, and the travel indicator scale (key 35). Remove the

cap screws (key 23) and the mounting yoke. Install the mounting yoke in the desired position (on the housing cover

assembly or on the actuator housing boss). See table 2 for recommended torque for the mounting cap screws.

Install the travel indicator components on the opposite side of the actuator. See figure 14 for travel indicator

components used with wrench‐operated extensions and manual actuators.

4. Before sliding the valve shaft into the lever, position the valve ball or disk as follows:

For push‐down‐to‐close action, the valve ball or disk should be in the fully open position.

5

1051 and 1052 Size 33 Actuators

February 2019

Instruction Manual

D101322X012

For push‐down‐to‐open action, the valve ball or disk should be in the fully closed position (see the valve body

instruction manual).

5. Make sure that the index markings on the valve shaft are properly aligned with the markings on the lever and slide

the valve shaft into the lever. Install the valve mounting cap screws, washers, and nuts and tighten to the torque

value given in the appropriate valve body instruction manual.

6. Ensure all end play in the valve shaft is removed by pulling the valve shaft toward the actuator as much as possible.

Make sure the actuator rod is perpendicular to the valve shaft. Refer to the valve instruction manual for specific end

play considerations.

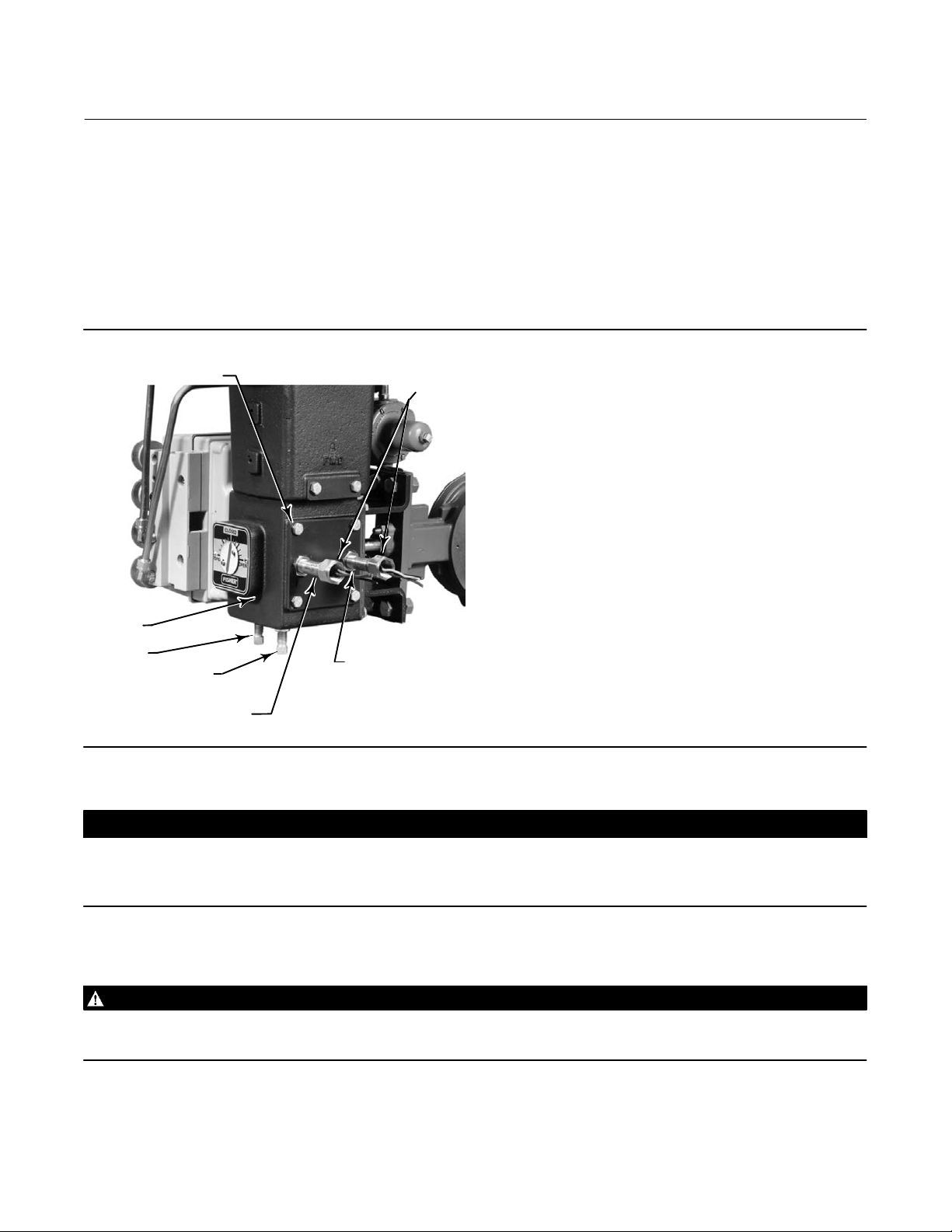

Figure 3.Travel Stops and Switch Positions on the Fisher 1051 and 1052 Size 33 Actuator

HOUSING COVER

ASSEMBLY (KEY 33)

PROXIMITY

SWITCHES

YOKE

MOUNTING

BOSS

UP TRAVEL

STOP

DOWN TRAVEL STOP

MOUNTING POSITION FOR SWITCH

INDICATING BOTTOM OF STROKE

(ACTIVATED BY INNER CAM)

W4738

MOUNTING POSITION FOR

SWITCH INDICATING

TOP OF STROKE

(ACTIVATED BY

OUTER CAM)

7. Tighten the socket head cap screw which compresses the splined lever connection to the valve shaft (see table 2).

CAUTION

When adjusting the travel stop for the closed position of the valve ball or disk, refer to the appropriate valve instruction

manual for detailed procedures. Undertravel or overtravel at the closed position may result in poor valve performance

and/or damage to the equipment.

8. Adjust the up travel stop (see figure 3) so that the valve ball or disk is in the desired position.

WARNING

To avoid personal injury and equipment damage from moving parts, keep fingers and tools clear while stroking the

actuator with the cover removed.

9. Stroke the actuator and adjust the down travel stop so that the valve ball or disk is in the desired position.

6

Instruction Manual

D101322X012

1051 and 1052 Size 33 Actuators

February 2019

10. Make sure that the travel indicator pointer matches the ball or disk position. Remove and install in the proper

position if necessary.

11. Install the cover plate or switch mounting plate (key 59) with cap screws (key 60).

12. Refer to the table of contents for accessory installation procedures.

H Mounting Adaptation

Unless otherwise specified, key numbers referenced in the following procedures are shown in figure 9 for the 1051

actuator and in figure 10 for the 1052 actuator. Unique parts used for the H mounting adaptation are shown in figure

11 for single stub shaft construction and in figure 14 for dual stub shaft construction.

1. To change mounting style or position, the actuator must be separated from the valve body (or other operated

equipment). Remove the cap screws used to attach the actuator to the valve body (or other operated equipment)

and remove the actuator.

2. Determine the desired mounting position. Note that stub shafts are available in standard and reverse constructions

so that proper alignment with the operated equipment can be achieved (see figure 12). Refer to figure 2 for

available mounting styles and positions.

3. If it is necessary to install or change stub shaft(s), the actuator lever (key 27) must be removed. Perform all

applicable operations in the Disassembly portion of the Changing or Replacing Actuator Lever procedure. Install the

stub shafts for the construction desired (refer to figures 11 and 14) and reassemble the actuator.

4. Determine whether the operated equipment will be mounted on the housing cover assembly (key 33) side or on

the actuator housing boss side of the actuator. Depending on the desired mounting style and position, it may be

necessary to move the operated equipment and travel indicator components to opposite sides of the actuator. If

so, remove the travel indicator components, the operated equipment, and the mounting bracket if used. Install the

operated equipment or mounting bracket in the desired position (on the housing cover assembly or on the actuator

housing boss). See table 2 for recommended torque for the mounting cap screws. Install the travel indicator

components on the side of the actuator opposite the operated equipment. Refer to figure 14 for travel indicator

components used with wrench‐operated extensions and manual actuators.

5. Before coupling the operated equipment to the actuator stub shaft, position the equipment as follows:

For push‐down‐to‐activate (open) action, the equipment should be in the fully deactivated (closed) position.

For push‐down‐to‐deactivate (close) action, the equipment should be in the fully activated (open) position.

6. Install the required shaft coupling and the operated equipment.

CAUTION

When adjusting the travel stops to limit rotation, be certain that the rotation produced does not exceed the safe limit of the

operated equipment. Undertravel or overtravel may result in poor performance and/or damage to the equipment.

7. Adjust the up travel stop (see figure 3) so that the operated equipment is in the desired position.

WARNING

To avoid personal injury and equipment damage from moving parts, keep fingers and tools clear while stroking the

actuator with the cover removed.

8. Stroke the actuator and adjust the down travel stop so that the operated equipment is in the desired position.

7

1051 and 1052 Size 33 Actuators

February 2019

Instruction Manual

D101322X012

9. Make sure that the travel indicator pointer matches the ball or disk position. Remove and install in the proper

position if necessary.

10. Refer to the table of contents for accessory installation procedures.

J Mounting Adaptation

Unless otherwise specified, key numbers referenced in the following procedures are shown in figure 9 for the 1051

actuator and in figure 10 for the 1052 actuator. Unique parts used for the J mounting adaptation are shown in figure

13 for single stub shaft construction and in figure 14 for dual stub shaft construction.

1. If the actuator is mounted on a valve body and it is necessary to change mounting style or position, the actuator

must be separated from the valve body. Proceed to the disassembly portion of the Changing or Replacing Actuator

Lever procedure, observe all warnings, perform steps 1 through 6, and return to step 2 which follows.

2. Refer to figure 2 for available mounting styles and positions. The actuator is normally mounted vertically on a valve

body that is installed in a horizontal pipeline.

3. If it is necessary to install or change stub shaft(s), the actuator lever (key 27) must be removed. Perform all

applicable operations in the Disassembly portion of the Changing or Replacing Actuator Lever procedure. Install the

stub shafts for the construction desired as shown in figure 13 and reassemble the actuator.

4. Determine whether the actuator mounting yoke (key 22) will be mounted on the housing cover assembly (key 33)

or on the actuator housing boss. If the desired mounting position and style requires moving the mounting yoke and

travel indicator components to opposite sides of the actuator, remove the travel indicator components, the valve

shaft coupling (key 80 for 1051, or key 90 for 1052), cap screws (key 23), and the mounting yoke. Install the

mounting yoke in the desired position (on the housing cover assembly or on the actuator housing boss). See table 2

for recommended torque for the mounting cap screws. Install the valve shaft coupling on the actuator stub shaft.

Install the travel indicator components on the opposite side of the actuator. See figure 14 for travel indicator

components used with wrench‐operated extensions and manual actuators.

5. Before coupling the valve to the actuator, position the valve ball or disk as follows:

For push‐down‐to‐close action, the valve ball or disk should be in the fully open position.

For push‐down‐to‐open action, the valve ball or disk should be in the fully closed position (see the valve body

instruction manual).

6. The valve shaft coupling (see figure 4) has two keyways lettered A and B (the letters C and D on the coupling are not

used and may be disregarded). Align the appropriate keyway with the keyway in shaft of the operated equipment.

When used with a Fisher butterfly valve body, refer to the table and illustration in figure 4 for proper orientation of

the coupling and valve shaft. Install the woodruff key (key 81 for 1051, key 91 for 1052) in the valve shaft keyseat,

lubricate the inside of the coupling, and slide the valve shaft into the coupling.

7. Install the valve mounting cap screws, washers, and nuts and tighten to the torque value given in the appropriate

valve body instruction manual.

CAUTION

When adjusting the travel stop for the closed position of the valve ball or disk, refer to the appropriate valve body

instruction manual for detailed procedures. Undertravel or overtravel at the closed position may result in poor valve

performance and/or damage to the equipment.

8. Adjust the up travel stop so that the valve ball or disk is in the desired position.

8

Instruction Manual

D101322X012

1051 and 1052 Size 33 Actuators

February 2019

DESIRED

ACTUATOR

ACTION

DESIRED

SHAFT

ROTATION,

DEGREES

ACTUATOR

MOUNTING

POSITION

COUPLING

KEYWAY

(3)

TO USE

VALVE SHAFT KEYWAY TO USE FOR FISHTAIL™

DISK VALVE BODIES

Clockwise to

Close Valve Action

Flow Left

(2)

to Right

(2)

Flow Right

to Left

(1)

(SEE FIGURE 2)

Counterclockwise to

Close Valve Action

(2)

Flow Left

to Right

(2)

(2)

Flow Right

to Left

1 B Nose Tail Tail Nose

Push Down to Open

(PDTO)

60 or 90

2 A Tail Nose Nose Tail

3 B Tail Nose Nose Tail

4 A Nose Tail Tail Nose

1 A Tail Nose Tail Nose

Push Down to Close

(PDTC)

60

(3)

or 90

2 B Tail Nose Tail Nose

3 A Nose Tail Nose Tail

4 B Nose Tail Nose Tail

1. For conventional disk valve bodies, use either valve shaft keyway.

2. When viewed from actuator side of valve body.

3. For 60‐degree rotation with PDTC action, the coupling and actuator output shaft assembly will offset 30 degrees clockwise (for actuator housing construction style B), or counterclock

wise (for actuator housing construction Style A) in the lever when viewed from the splined end of the actuator shaft. 30 degrees is one spline tooth for 9.5, 12.7, and 15.9 mm (3/8, 1/2,

and 5/8 inch) valve shafts and two spline teeth for 19.1 mm (3/4 inch) valve shafts.

Figure 4. Valve Shaft Coupling for the J Mounting Adaptation

1

COUPLING

FULL KEYWAY

LOCATED ON

NOSE AND TAIL

SIDE OF VALVE SHAFT

VALVE SHAFT

(2)

USE APPROPRIATE LETTERED

KEYWAY AS INDICATED IN

PARTIAL KEYWAY

FOR DETERMINING

DISK POSITION

TABLE 5

USE APPROPRIATE

VALVE SHAFT

KEYWAY AS

KEYWAY A

KEYWAY B

ABOVE

KEYWAY A

INDICATED

IN TABLE 5

EXPLODED VIEW OF VALVE SHAFT

AND COUPLING

19A1465‐B

NOTES:

1

A3253*

FOR USE WITH J MOUNTING ADAPTATION.

REFERENCE COUPLING ORIENTATION

FOR TABLE 5

WARNING

To avoid personal injury and equipment damage from moving parts, keep fingers and tools clear while stroking the

actuator with the cover removed.

9. Stroke the actuator and adjust the down travel stop so that the valve ball or disk is in the desired position.

10. Make sure that the travel indicator pointer matches the ball or disk position. Remove and install in the proper

position if necessary.

9

1051 and 1052 Size 33 Actuators

February 2019

11. Refer to the table of contents for accessory installation procedures.

Figure 5. Spring Adjustment

TRAVEL

STOPS

W4767

Instruction Manual

D101322X012

1052 Spring Compression Adjustment

Initial Compression

Key numbers referred to in this procedure are shown in figure 10 unless otherwise specified.

The 1052 nameplate specifies an initial set adjusted into the actuator spring. Initial set is the casing pressure at which

the diaphragm (key 3) and diaphragm rod (key 10) begin to move away from the stop in the upper diaphragm case

(key 1) when the actuator is disengaged from the control valve body or other operated equipment. The initial set was

determined from the service conditions specified when the actuator was ordered, so that when the actuator and valve

are in service, the valve ball or disk seats properly and full travel is obtained with the supply pressure specified on the

order and shown on the nameplate.

Before adjusting spring tension to change initial set, the valve body or other operated equipment must be removed or

otherwise disengaged from the actuator. Refer to the applicable steps given under the appropriate mounting

adaptation in the Actuator Mounting and Changing Actuator Mounting procedure.

To gain access to the spring adjusting screw, either the spring adjuster cover (key 117) or the switch mounting plate

(key 59) must be removed. If externally mounted switches are used, remove them as an assembly by removing the cap

screws (key 75, figure 16) and the switch mounting plate (key 1, figure 16). In order to gain access to the cap screws, it

may be necessary to loosen the hex nuts (key 77, figure 16) and slide the switches away from the actuator housing.

Note that the lower part of the spring adjusting screw (key 74) is notched so that it can be rotated with a screwdriver

or other flat‐bladed tool. To decrease spring compression, rotate the spring adjusting screw to the right (see figure 5).

To increase spring compression, rotate the spring adjusting screw to the left (clockwise when viewed from above).

Adjust the spring so that the diaphragm rod just starts to travel at the initial set pressure specified on the nameplate.

When the desired initial set has been achieved, install the spring adjuster cover or switch mounting plate.

10

Loading...

Loading...