Instruction Manual

D103412X012

DVC6200f Digital Valve Controller

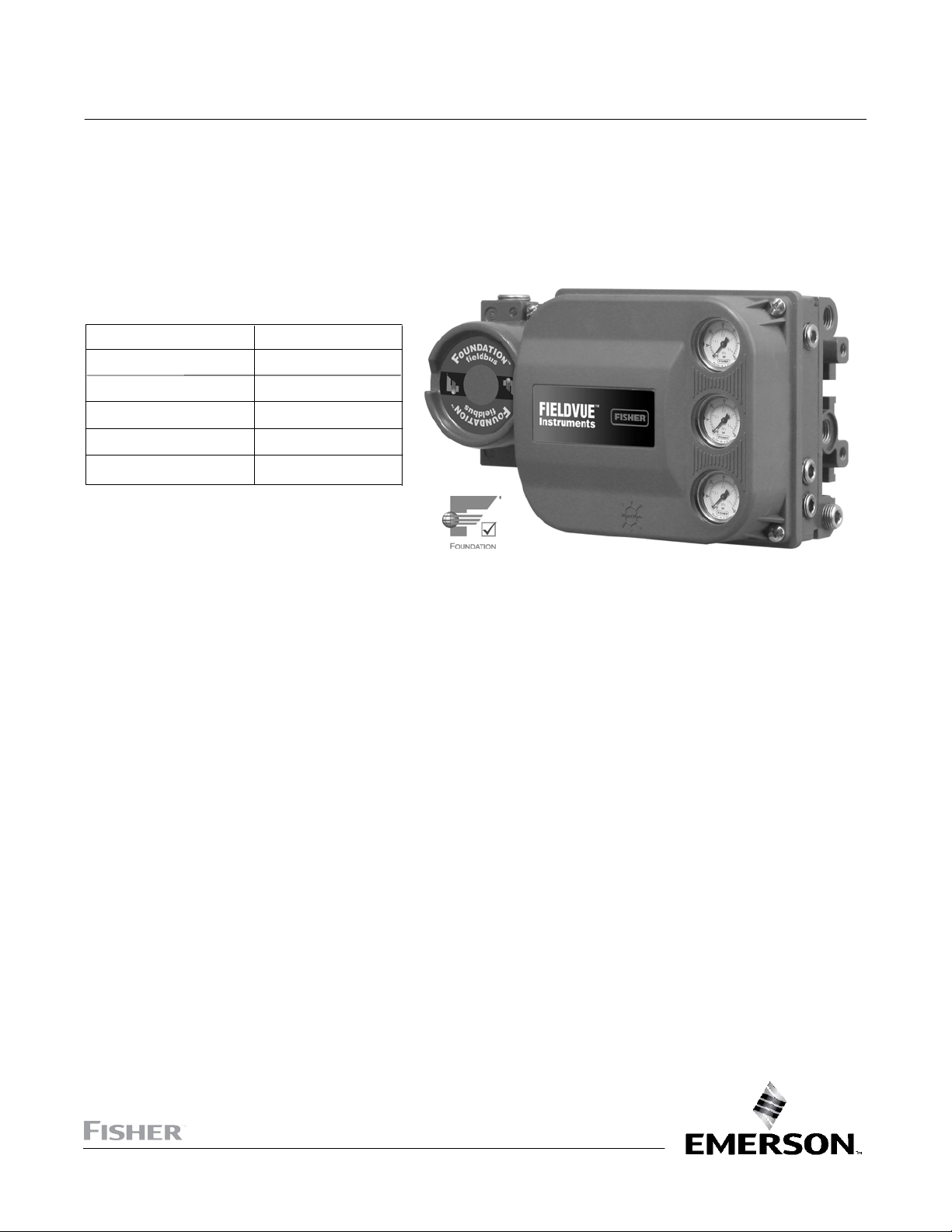

Fisher™ FIELDVUE™ DVC6200f Digital Valve

May 2022

Controller for F

This manual applies to:

Device Type 4602

Device Revision 4

Hardware Revision 8, 9

Firmware Revision 3.1

DD Revision 3

Instrument Level FD, PD, AD, PST

OUNDATION

™

Fieldbus

www.Fisher.com

1

DVC6200f Digital Valve Controller

May 2022

Instruction Manual

D103412X012

2

Instruction Manual

D103412X012

DVC6200f Digital Valve Controller

May 2022

Contents

Section 1 Introduction and

Specifications 5......................

Installation, Pneumatic and Electrical Connections,

and Initial Configuration 5.....................

Scope of Manual 5..............................

Instrument Description 5........................

Using this Manual 4.............................

Specifications 8................................

Related Information 12..........................

Educational Services 12..........................

Section 2 Wiring Practices 13.............

Quick Connect Cable Entry 13....................

Communication Connections 14..................

Simulate Enable Jumper 15.......................

Section 3 Basic Setup 17.................

Basic Setup 17.................................

Transducer Block Mode 17......................

Protection 17.................................

Device Setup 18...............................

Performance Tuner 22.........................

Section 4 Detailed Setup 23..............

Resource Block 23..............................

Configure/Setup 23.............................

Resource Block Mode 23.......................

Write Lock 23.................................

Communication Timeout 24....................

Options 24...................................

Alarm Handling 25............................

Identification 26..............................

Version 27...................................

Alert Handling 27.............................

Parameters Affected by Restart with Defaults 28.....

Resoure Block Parameter List 33..................

View Lists 45...................................

Transducer Block 47............................

Detailed Setup 47..............................

Transducer Block Mode 47......................

Protection 47.................................

Response Control 48...........................

Travel Tuning 48...........................

Pressure Tuning 50........................

Travel Pressure Control 51..................

Characterization 53........................

Custom Characterization Table 53............

Output Block Selection 54...................

Alerts 54......................................

Instrument Alert Conditions 54..................

Field Diagnostic Alerts 54.......................

Field Diagnostic Alert Category 55............

Alerts 55.....................................

Electronic Alerts 55........................

Configuration Alerts 57.....................

Sensor Alerts 58...........................

Environment Alerts 59......................

Travel Alerts 60............................

Proximity Alerts 61.........................

Travel History Alerts 62.....................

Performance Alerts 65......................

FST/PST Alerts 65..........................

Alert Handling 67.............................

Instrument 68................................

Valve and Actuator 69..........................

MAI Channel Map 72...........................

FST/PST 72...................................

Latch 78.....................................

Transducer Block Parameter List 79................

View Lists 114..................................

Section 5 Calibration 119................

Calibration Overview 119........................

Calibration 119.................................

Auto 120.....................................

Manual 120..................................

Relay 121....................................

Supply Pressure Sensor 122.....................

Pressure A or B Sensor 123......................

PST Calibration 124............................

Section 6 Viewing Device

Variables and Diagnostics 125..........

View Lists 125..................................

Resource Block 125.............................

Device Diagnostics 125.........................

Device Variables 129...........................

Transducer Block 131...........................

Device Diagnostics 131.........................

Device Variables 134...........................

Section 7 Maintenance and

Troubleshooting 137..................

Replacing the Magnetic Feedback Assembly 138.....

Module Base Maintenance 138....................

Tools Required 138............................

Component Replacement 139...................

Removing the Module Base 139.................

Replacing the Module Base 140..................

Submodule Maintenance 141.....................

I/P Converter 141..............................

Printed Wiring Board (PWB) Assembly 143.........

Pneumatic Relay 144...........................

Gauges, Pipe Plugs or Tire Valves 145.............

Terminal Box 145...............................

Removing the Terminal Box 145.................

Replacing the Terminal Box 146..................

Stroking the Digital Valve Controller Output 146.....

Instrument Troubleshooting 147..................

Technical Support Checklist 152..................

3

DVC6200f Digital Valve Controller

May 2022

Instruction Manual

D103412X012

Section 8 Parts 153.....................

Parts Ordering 153..............................

Parts Kits 153..................................

Parts List 154..................................

Housing 154..................................

Common Parts 154............................

Module Base 155..............................

I/P Converter Assembly 155.....................

Relay 155....................................

Terminal Box 155..............................

PWB Assembly 156............................

Pressure Gauges, Pipe Plugs, or

Tire Valve Assemblies 156....................

DVC6215 Feedback Unit 156....................

Appendix A Principle of Operation 163.....

Digital Valve Controller Operation 163.............

Appendix B Device Communicator

Menu Tree 165.......................

Appendix C Field Diagnostic Alerts 183.....

Instrument Alert Conditions 183..................

Field Diagnostic Alerts 183......................

Alert Handling 184............................

Alert Reporting 185............................

Field Diagnostic Alerts Set Block Status 185........

Setting Field Diagnostic Alerts 186................

Using Field Diagnostic Alerts 190..................

Appendix D FOUNDATION Fieldbus

Communication 197..................

Function Block Overview 197.....................

Function Blocks 197...........................

Instrument Specific Blocks 198..................

Resource Blocks 198...........................

Transducer Blocks 198.........................

Block Modes 199...............................

Explanation of Modes 200......................

Examples of Modes for Various

Operation Statuses 201......................

Device Descriptions 201.........................

Transducer Block Status and Limit Propagation 201..

Status Propagation 202........................

Limit Propagation 202..........................

Network Communication 203....................

Device Addressing 203.........................

Link Active Scheduler 203.......................

Device Communications 204....................

Scheduled Transfers 204....................

Unscheduled Transfers 205..................

Function Block Scheduling 206..................

Network Management 206.......................

Appendix E Function Blocks 207...........

Analog Output Function Block 209................

Proportional/Integral/Derivative

Function Block 223...........................

Control Selector Function Block 243...............

Input Selector Function Block 255.................

Output Splitter Function Block 271................

Analog Input Function Block 283..................

Mulitple Analog Input Function Block 295..........

Discrete Output Function Block 301...............

Discrete Input Function Block 315.................

Appendix F Device Description

Installation 327......................

Overview 327..................................

Device Descriptions and Methods 328.............

Installing DD on a DeltaV

ProfessionalPLUS Workstation 328................

Installing DDs on Other Fieldbus Host Systems 330...

Displaying the Device Description Revision 331......

Glossary 333...........................

Index 337.............................

4

DVC6200f Digital Valve Controller

Instruction Manual

D103412X012

Introduction and Specifications

Section 1 Introduction and Specifications

Installation, Pneumatic and Electrical Connections,

and Initial Configuration

May 2022

Refer to the DVC6200 Series Quick Start Guide (D103556X012) for DVC6200f

installation, connection, and initial configuration information. If a copy of this quick

start guide is needed contact your Emerson sales office

or visit our website at Fisher.com.

Scan or click

to access

field support

Scope of Manual

This instruction manual is a supplement to the quick start guide that ships with every instrument. This instruction

manual includes product specifications, supplementary installation information, reference materials, custom setup

information, maintenance procedures, and replacement part details for the DVC6200f digital valve controller.

Note

All references to the DVC6200f digital valve controller include the DVC6205f base unit unless otherwise indicated.

This manual describes device setup using an Emerson Device Communicator. For information on using Fisher

ValveLink

™

software with the instrument, refer to the appropriate user guide or help.

Do not install, operate, or maintain a DVC6200f digital valve controller without being fully trained and

qualified in valve, actuator, and accessory installation, operation, and maintenance. To avoid personal

injury or property damage, it is important to carefully read, understand, and follow all of the contents

of this manual, including all safety cautions and warnings. If you have any questions about these

instructions contact your Emerson sales office

before proceeding.

Instrument Description

DVC6200f digital valve controllers for FOUNDATION Fieldbus are communicating, microprocessor‐based instruments. In

addition to the traditional function of converting a digital signal to a pneumatic output pressure, the DVC6200f digital

valve controller, using F

process operation as well as process control. This can be done using a DeltaV console, another F

system console, or with ValveLink software version 13 or later.

Using a compatible fieldbus configuration device, you can obtain information about the health of the instrument, the

actuator, and the valve. You can also obtain asset information about the actuator or valve manufacturer, model, and

serial number. You can set input and output configuration parameters and calibrate the instrument.

Using the F

OUNDATION Fieldbus protocol, information from the instrument can be integrated into control systems.

OUNDATION Fieldbus communications protocol, gives easy access to information critical to

OUNDATION Fieldbus

5

DVC6200f Digital Valve Controller

Introduction and Specifications

May 2022

Instruction Manual

D103412X012

Figure 1‐1 FIELDVUE DVC6200f Digital Valve

Controller Mounted on a Fisher Sliding‐Stem Valve

Actuator

X1182-1_fieldbus

Figure 1‐2. FIELDVUE DVC6200f Digital Valve

Controller Integrally Mounted to a Fisher GX Control

Valve and Actuator System

W9616_fieldbus

DVC6200f digital valve controllers can be mounted on single or double‐acting sliding‐stem actuators, as shown in

figure 1‐1, or on rotary actuators. It can also be integrally mounted to Fisher 657/667 size 30i to 76i actuators or the

Fisher GX control valve and actuator system, as shown in figure 1‐2. The DVC6200f mounts on most Fisher and other

manufacturers' rotary and sliding‐stem actuators.

DVC6200f digital valve controllers are available with several selections of control and diagnostic capability. Control

selections include:

Standard Control (SC)— Digital valve controllers with Standard Control have the AO, PID, CSEL, ISEL, OS, AI, MAI,

DO, and four DI function blocks in addition to the resource and transducer blocks.

Fieldbus Control (FC)—Digital valve controllers with Fieldbus Control have the AO function block in addition to the

resource and transducer blocks.

Fieldbus Logic (FL)—Digital valve controllers with Fieldbus Logic have the DO, and four DI function blocks, in

addition to the resource and transducer block.

The diagnostic capabilities include:

Partial Stroke Test (PST)

Performance Diagnostics (PD)

Advanced Diagnostics (AD)

Fieldbus Diagnostics (FD)

Partial Stroke Test, Performance, and Advanced Diagnostics are available with ValveLink software. They provide

visibility to instrument alerts. Fieldbus Diagnostics can be viewed with any host system.

6

DVC6200f Digital Valve Controller

Instruction Manual

D103412X012

Introduction and Specifications

May 2022

Instrument Blocks

The digital valve controller is a block‐based device. For detailed information on the blocks within the digital valve

controller, see the Detailed Setup section of this manual.

The DVC6200f digital valve controller includes the resource and transducer block:

Resource Block—The resource block contains the hardware specific characteristics associated with a device; it has

no input or output parameters. The resource block monitors and controls the general operation of other blocks

within the device. For example, when the mode of the resource block is Out of Service, it impacts all function

blocks.

Transducer Block—The transducer block connects the analog output function block to the I/P converter, relay, and

travel sensor hardware within the digital valve controller.

Function Blocks

In addition to the resource and transducer block, the digital valve controller may contain the following function blocks,

Refer to Appendix E, Function Blocks ,for block specific information. For additional information on function blocks,

refer to Appendix D, F

OUNDATION fieldbus Communication.

Analog Output (AO) Function Block—The analog output function block accepts the output from another function

block (such as a PID block) and transfers it as an actuator control signal to the transducer block. If the DO block is

selected, the AO block is not functional.

Proportional‐Integral‐Derivative (PID) Function Block—The PID function block performs

proportional‐plus‐integral‐plus‐derivative control.

Control Select (CSEL) Function Block— The control select function block selects from two or three control signals in

a manner determined by the SEL_TYPE when the block is in Auto mode.

Input Selector (ISEL) Function Block—The input selector function block selects from up to four inputs and may

provide the selected signal as input to the PID block. The input selection can be configured to select the first good

input signal; a maximum, minimum or average value; or a hot spare.

Output Splitter (OS) Function Block—The output splitter function block accepts the output from another function

block (such as a PID block) and creates two outputs that are scaled or split, according to the user configuration. This

block is typically used for split ranging of two control valves.

Analog Input (AI) Function Block—The analog input function block monitors the signal from a DVC6200f sensor or

internal measurement and provides it to another block.

Multiple Analog Input (MAI) Function Block—The Multiple Analog Input (MAI) function block has the ability to

process up to eight DVC6200f measurements and make them available to other function blocks.

Discrete Output (DO) Function Block—The discrete output function block processes a discrete set point and sends it

to a specified output channel, which can be transferred to the transducer block for actuator control. In the digital

valve controller, the discrete output block provides both normal open/closed control and the ability to position the

valve in 5% increments for course throttling applications. If the AO block is selected, the DO block is not functional.

Discrete Input (DI) Function Block—The discrete input function block processes a single discrete input from a

DVC6200f and makes it available to other function blocks. In the digital valve controller, the discrete input function

block can provide limit switch functionality and valve position proximity detection.

7

DVC6200f Digital Valve Controller

Introduction and Specifications

May 2022

Instruction Manual

D103412X012

Using This Manual

Navigation paths and fast‐key sequences are included for procedures and parameters that can be accessed using a

Device Communicator.

For example, to access Resource Block Mode:

Device Communicator RB > Configure/Setup > Setup > Resource Block Mode

An overview of the resource and transducer block menu structures are shown in Appendix B. Menu structures for the

function blocks are included with each function block section in Detailed Setup.

Throughout this document, parameters are typically referred to by their common name or label, followed by the

parameter name and index number; for example, Write Priority (WRITE_PRI [39]). However, not all interface systems

support the use of the parameter label and instead use only the Parameter Name, followed by the index number, when

referring to the block parameters.

Specifications

Specifications for the DVC6200f digital valve controller are shown in table 1‐1.

8

Instruction Manual

D103412X012

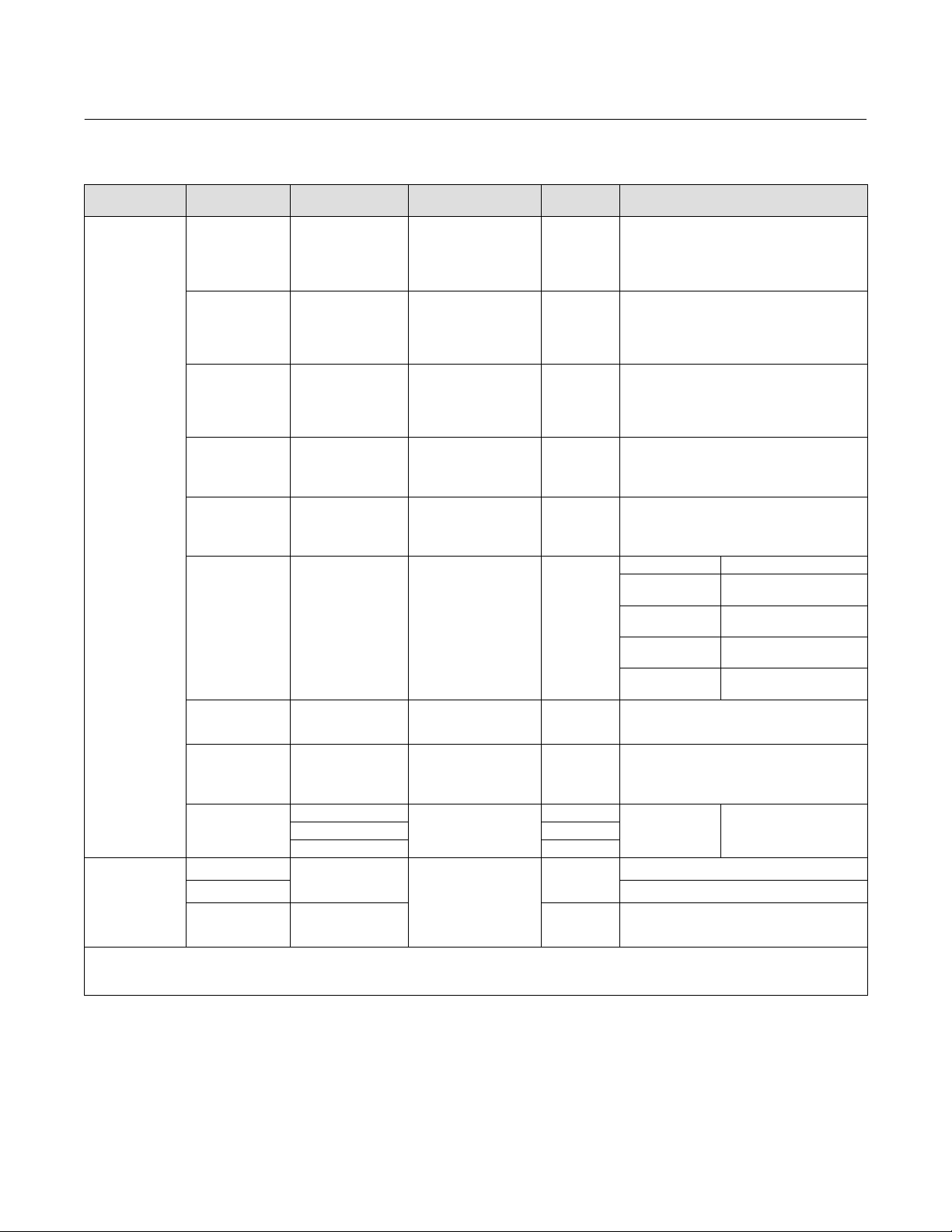

Table 1‐1. Specifications

DVC6200f Digital Valve Controller

Introduction and Specifications

May 2022

Available Mounting

DVC6200f digital valve controller and DVC6215

feedback unit:

GX actuators

actuators,

Quarter‐turn rotary applications

Integral mounting to 657/667 or

Integral mounting to Fisher rotary

Sliding‐stem linear applications

DVC6205f base unit for 2 inch pipestand or wall

mounting (for remote-mount)

The DVC6200f digital valve controller or DVC6215

feedback unit can also be mounted on other

actuators that comply with IEC 60534-6-1, IEC

60534-6-2, VDI/VDE 3845 and NAMUR mounting

standards.

Instrument Blocks

Resource Block

Transducer Block complies with F

OUNDATION Fieldbus

specification FF-906 for valve stroke testing

Function Block Suites

Standard Control (throttling control)

Includes AO, PID, CSEL, ISEL, OS, AI, MAI, DO,

and DI function block

Fieldbus Control (throttling control)

Contains the AO function block

Fieldbus Logic [discrete (on/off) connectivity]

Includes DO, and DI function blocks

Function Block

Instantiation

If a host system supports block instantiation, a

maximum of 20 function blocks can be instantiated in

the device at any given time from the available

function blocks, which may include AO (1), DO (1), AI

(4), DI (6), MAI (1), PID (4), OS (3), ISEL (2), CSEL (2)

Note: Only the function blocks available in the

function block suite can be instantiated by the host

system

Block Execution Times

Electrical Input

Voltage Level: 9 to 32 volts

Maximum Current: 19 mA

Reverse Polarity Protection: Unit is not polarity

sensitive

Termination: Bus must be properly terminated per

ISA SP50 guidelines

Digital Communication Protocol

F

OUNDATION fieldbus registered device

Physical Layer Type(s):

121—Low-power signaling, bus‐powered,

Entity Model I.S.

511—Low-power signaling, bus‐powered, FISCO I.S.

Fieldbus Device Capabilities

Backup Link Master capable

Supply Pressure

(1)

Minimum Recommended: 0.3 bar (5 psig) higher

than maximum actuator requirements

Maximum: 10.0 bar (145 psig) or maximum pressure

rating of the actuator, whichever is lower

Medium: Air or Natural Gas

Supply medium must be clean, dry and noncorrosive

Per ISA Standard 7.0.01

A maximum 40 micrometer particle size in the air

system is acceptable. Further filtration down to

5 micrometer particle size is recommended.

Lubricant content is not to exceed 1 ppm weight

(w/w) or volume (v/v) basis. Condensation in the air

supply should be minimized.

Per ISO 8573-1

Maximum particle density size: Class 7

Oil content: Class 3

Pressure Dew Point: Class 3 or at least 10C less than

the lowest ambient temperature expected

AO Block: 20 ms MAI BLock: 35 ms

PID Block: 20 ms DO Block: 20 ms

ISEL Block: 20 ms DI Block: 15 ms

OS Block: 20 ms CSEL Block: 15 ms

AI Block: 20 ms

-continued-

Output Signal

Pneumatic signal, up to full supply pressure

Minimum Span: 0.4 bar (6 psig)

Maximum Span: 9.5 bar (140 psig)

Action:

Double, Single Direct or Reverse

9

DVC6200f Digital Valve Controller

Introduction and Specifications

May 2022

Table 1‐1. Specifications (continued)

Instruction Manual

D103412X012

Steady-State Air Consumption

(2)(3)

Standard Relay

At 1.4 bar (20 psig) supply pressure:

Less than 0.38 normal m

At 5.5 bar (80 psig) supply pressure:

Less than 1.3 normal m

3

/hr (14 scfh)

3

/hr (49 scfh)

Low Bleed Relay

At 1.4 bar (20 psig) supply pressure:

Average value 0.056 normal m

At 5.5 bar (80 psig) supply pressure:

Average value 0.184 normal m

Maximum Output Capacity

At 1.4 bar (20 psig) supply pressure:

10.0 normal m

At 5.5 bar (80 psig) supply pressure:

29.5 normal m

3

/hr (375 scfh)

3

/hr (1100 scfh)

Operating Ambient Temperature Limits

3

/hr (2.1 scfh)

3

/hr (6.9 scfh)

(2)(3)

(1)(4)

-40 to 85C (-40 to 185F)

-52 to 85C (-62 to 185F) for instruments utilizing

the Extreme Temperature option (fluorosilicone

elastomers)

-52 to 125C (-62 to 257F) for remote‐mount

feedback unit

Independent Linearity

(5)

Typical Value: ±0.50% of output span

Electromagnetic Compatibility

Meets EN 61326-1:2013

Immunity—Industrial locations per Table 2 of

the EN 61326-1 standard. Performance is

shown in table 1‐2 below.

Emissions—Class A

ISM equipment rating: Group 1, Class A

Lightning and Surge Protection—The degree of

immunity to lightning is specified as Surge immunity

in table 1‐2. For additional surge protection

commercially available transient protection devices

can be used.

Vibration Testing Method

Tested per ANSI/ISA‐75.13.01 Section 5.3.5. A

resonant frequency search is performed on all three

axes. The instrument is subjected to the ISA specified

1/2 hour endurance test at each major resonance.

Humidity Testing Method

Tested per IEC 61514-2

Electrical Classification

Hazardous Area Approvals

CSA— Intrinsically Safe, FISCO, Explosion‐proof,

Division 2, Dust Ignition‐proof

FM— Intrinsically Safe, FISCO, Explosion‐proof,

Non‐Incendive, Dust Ignition‐proof

ATEX— Intrinsically Safe, FISCO, Flameproof, Type n,

Dust by intrinsic safety

IECEx— Intrinsically Safe, FISCO, Flameproof, Type n,

Dust by intrinsic safety or by enclosure

Electrical Housing

CSA— Type 4X, IP66

FM— Type 4X, IP66

ATEX— IP66

IECEx— IP66

Other Classifications/Certifications

Natural Gas Certified, Single Seal Device— CSA, FM,

ATEX, and IECEx

Lloyds Register— Marine Type Approval

CCC— China Compulsory Certification

CML— Certification Management Limited (Japan)

CUTR— Customs Union Technical Regulations

(Russia, Kazakhstan, Belarus, and Armenia)

DNV— Marine Type Approval

ESMA— Emirates Authority for Standardization and

Metrology - ECAS-Ex (UAE)

INMETRO— National Institute of Metrology, Quality

and Technology (Brazil)

KOSHA— Korean Occupational Safety & Health

Agency (South Korea)

KTL— Korea Testing Laboratory (South Korea)

NEPSI— National Supervision and Inspection Centre

for Explosion Protection and Safety of

Instrumentation (China)

PESO CCOE— Petroleum and Explosives Safety

Organisation - Chief Controller of Explosives (India)

SANS— South Africa National Standards

Contact your Emerson sales office

for

classification/certification specific information

10

-continued-

Instruction Manual

D103412X012

Table 1‐1. Specifications (continued)

DVC6200f Digital Valve Controller

Introduction and Specifications

May 2022

Connections

Supply Pressure: 1/4 NPT internal and integral pad for

mounting 67CFR regulator

Output Pressure: 1/4 NPT internal

Tubing: 3/8‐inch recommended

Optional: Stainless steel

Cover: Thermoplastic polyester

Elastomers

Standard: Nitrile

Extreme Temperature: Fluorosilicone

Vent: 3/8 NPT internal

Electrical: 1/2 NPT internal or M20

Actuator Compatibility

Sliding‐Stem Linear

Linear actuators with rated travel between 6.35 mm

(0.25 inch) and 606 mm (23.375 inches)

Quarter‐Turn Rotary

Rotary actuators with rated travel between

45 degrees and 180 degrees

(6)

Weight

DVC6200f

Aluminum: 3.5 kg (7.7 lbs)

Stainless Steel: 8.6 kg (19 lbs)

DVC6205f: 4.1 kg (9 lbs)

DVC6215: 1.4 kg (3.1 lbs)

Options

Supply and output pressure gauges or Tire

Integral mounted filter regulator

valves

Low‐Bleed Relay

(7)

Extreme Temperature

Natural Gas Certified, Single Seal Device Remote

(8)

Mount

Contact your Emerson sales office

Stainless Steel

or go to Fisher.com

for additional information.

Declaration of SEP

Fisher Controls International LLC declares this

product to be in compliance with Article 4 paragraph

3 of the PED Directive 2014/68/EU. It was designed

and manufactured in accordance with Sound

Engineering Practice (SEP) and cannot bear the CE

marking related to PED compliance.

Construction Materials

Housing, module base and terminal box

Standard: A03600 low copper aluminum alloy

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 - Process Instrument Terminology.

1. The pressure/temperature limits in this document and any other applicable code or standard should not be exceeded.

2. Normal m

3. Values at 1.4 bar (20 psig) based on a single-acting direct relay; values at 5.5 bar (80 psig) based on double-acting relay.

4. Temperature limits vary based on hazardous area approval. Lower temperature limit for CUTR Ex d approval with fluorosilicone elastomers is -53C (-63.4F).

5. Not applicable for travels less than 19 mm (0.75 inch) or for shaft rotation less than 60 degrees. Also not applicable for digital valve controllers in long-stroke applications.

6. Rotary actuators with 180 degree rated travel require a special mounting kit; contact your Emerson sales office for kit availability

7. The Quad O steady-state consumption requirement of 6 scfh can be met by a DVC6200f with low bleed relay A option, when used with up to 4.8 bar (70 psi) supply of

Natural Gas at 16C (60F). The 6 scfh requirement can be met by low bleed relay B and C when used with up to 5.2 bar (75 psi) supply of Natural Gas at 16C (60F).

8. 4‐conductor shielded cable, 18 to 22 AWG minimum wire size, in rigid or flexible metal conduit, is required for connection between base unit and feedback unit. Pneumat

ic tubing between base unit output connection and actuator has been tested to 91 meters (300 feet). At 15 meters (50 feet) there was no performance degradation. At

91 meters there was minimal pneumatic lag.

3

/hour - Normal cubic meters per hour at 0C and 1.01325 bar, absolute. Scfh - Standard cubic feet per hour at 60F and 14.7 psia.

However, the product may bear the CE marking to

indicate compliance with other applicable European

Community Directives.

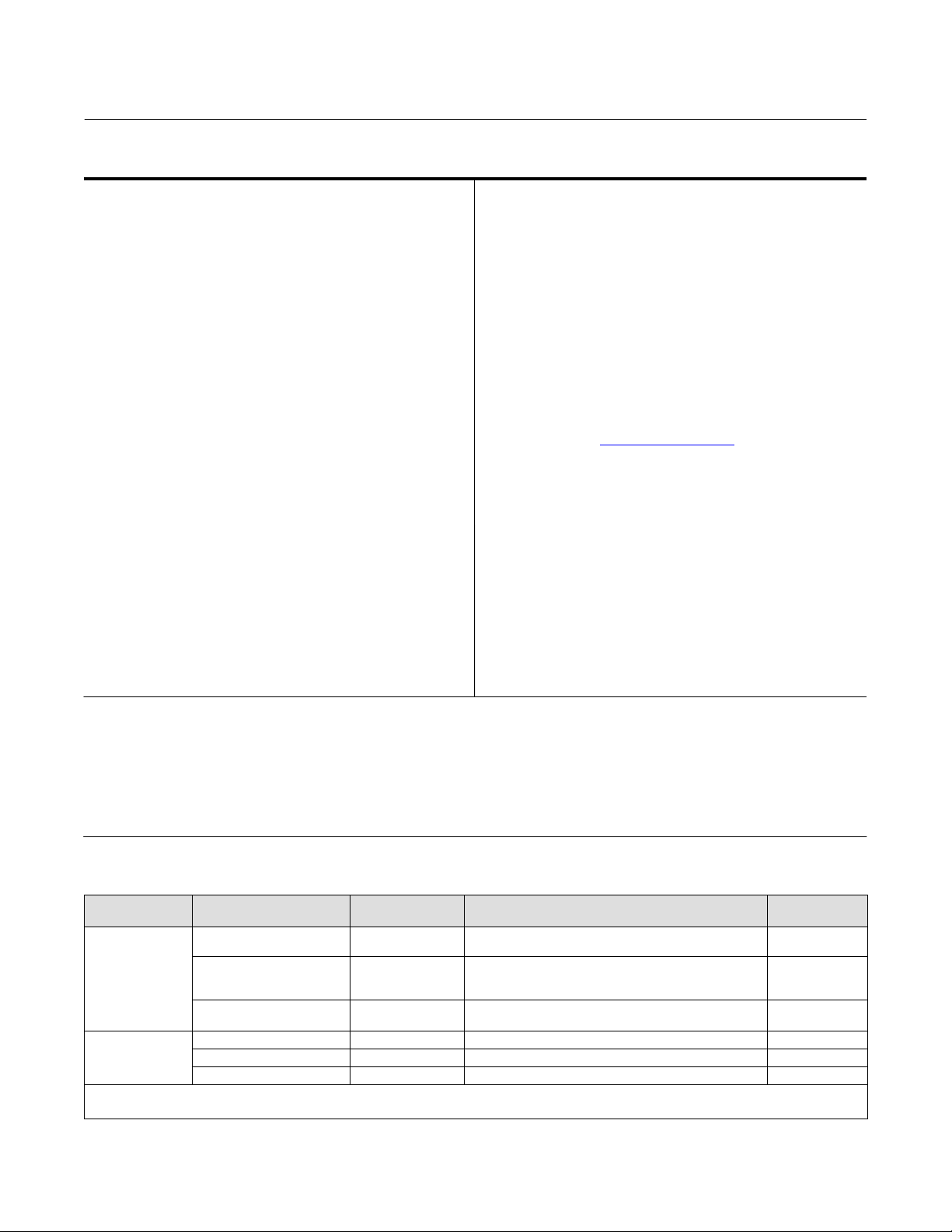

Table 1‐2. EMC Summary Results—Immunity

Port Phenomenon Basic Standard Test Level

Electrostatic discharge (ESD) IEC 61000‐4‐2

Enclosure

I/O signal/control

Performance criteria: +/- 1% effect.

1. A = No degradation during testing. B = Temporary degradation during testing, but is self‐recovering.

2. Excluding Simulate function, which meets Performance Criteria B.

Radiated EM field IEC 61000‐4‐3

Rated power frequency

magnetic field

Burst IEC 61000‐4‐4

Surge IEC 61000‐4‐5

Conducted RF IEC 61000‐4‐6

IEC 61000‐4‐8

4 kV contact

8 kV air

80 to 1000 MHz @ 10V/m with 1 kHz AM at 80%

1400 to 2000 MHz @ 3V/m with 1 kHz AM at 80%

2000 to 2700 MHz @ 1V/m with 1 kHz AM at 80%

30 A/m at 50/60 Hz

1 kV

1 kV

150 kHz to 80 MHz at 3 Vrms

Performance

Criteria

(2)

A

A

A

(2)

A

B

A

(1)

11

DVC6200f Digital Valve Controller

Introduction and Specifications

May 2022

Instruction Manual

D103412X012

Related Information

Fieldbus Installation and Wiring Guidelines

This manual describes how to connect the fieldbus to the digital valve controller. For a technical description, planning,

and installation information for F

Fieldbus Foundation and Fieldbus Installations in a DeltaV System, available from your Emerson sales office

Related Documents

Other documents containing information related to the DVC6200f digital valve controller include:

OUNDATION Fieldbus, refer to the Foundation Technology Overview, available from the

.

Bulletin 62.1:DVC6200f - DVC6200f Digital Valve Controller (D103399X012

Bulletin 62.1:DVC6200f FD - DVC6200f Digital Valve Controller (D103422X012

Bulletin 62.1:DVC6200f PST - DVC6200f Digital Valve Controller - PST Instrument Level (D104160X012

Bulletin 62.1:DVC6200(S1) - DVC6200 Digital Valve Controller Dimensions (D103543X012

Bulletin 62.1:Digital Valve Controller - Fisher FIELDVUE Digital Valve Controller Product Selection (D104363X012

FIELDVUE DVC6200 Series Quick Start Guide (D103556X012

CSA Hazardous Area Approvals - DVC6200 Series Digital Valve Controllers (D104203X012

FM Hazardous Area Approvals - DVC6200 Series Digital Valve Controllers (D104204X012

ATEX Hazardous Area Approvals - DVC6200 Series Digital Valve Controllers (D104205X012

IECEx Hazardous Area Approvals - DVC6200 Series Digital Valve Controllers (D104206X012

DVC6200f Digital Valve Controller PST Calibration and Testing using ValveLink Software (D104217X012

™

AMS Trex

ValveLink Software Help or Documentation

Device Communicator User Guide

)

)

)

)

)

)

)

)

)

)

)

All documents are available from your Emerson sales office or at Fisher.com.

Educational Services

For information on available courses for the DVC6200f digital valve controller, as well as a variety of other products,

contact:

Emerson Automation Solutions

Educational Services - Registration

Phone: +1-641-754-3771 or +1-800-338-8158

e‐mail: education@emerson.com

emerson.com/fishervalvetraining

12

DVC6200f Digital Valve Controller

Instruction Manual

D103412X012

Installation Information

May 2022

Section 2 Wiring Practices 2-2-

Quick Connect Cable Entry

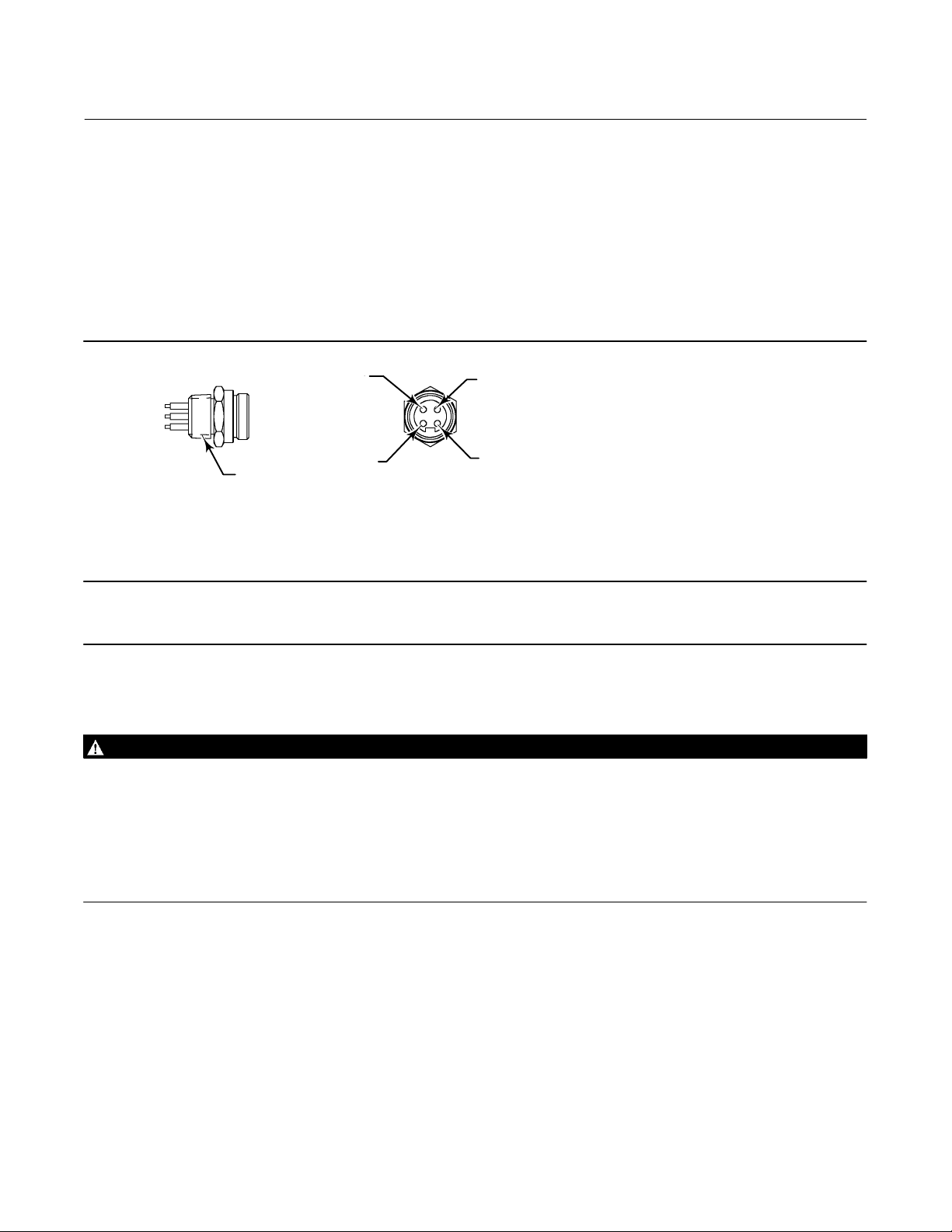

The DVC6200f is offered with a quick connect cable entry option, shown in figure 2‐1, for the FOUNDATION Fieldbus

signal. The quick connect cable entry provides an easier and more reliable interface to fieldbus devices and support

modules by providing a standard connection.

Figure 2‐1. Quick Connect Connector

1 (BLUE)

3 (NC)

2 (BROWN)

1/2‐14 NPT

NOTES:

1. COLORS ARE WIRE COLORS.

2. NC=NO CONNECTION.

18B9424‐A

Note

The quick connect cable entry option is only available for intrinsically safe and non‐incendive installations.

4 (GREEN/YELLOW)

Refer to figure 8‐2 for identification of parts.

WARNING

Personal injury or property damage, caused by fire or explosion, can result from the discharge of static electricity. Connect

a 14 AWG (2.08 mm

gases are present. Refer to national and local codes and standards for grounding requirements.

To avoid static discharge from the plastic cover, do not rub or clean the cover with solvents. Clean with a mild detergent

and water only.

To avoid personal injury or property damage, do not use the Quick Connect option on instruments in explosion‐proof or

flameproof installations.

2

) ground strap between the digital valve controller and earth ground when flammable or hazardous

1. The quick connect cable entry should be installed on the digital valve controller at the factory. If it is, proceed to

step 3. If not continue with step 2.

2. To install the Quick Connect:

a. Remove the terminal box cap (key 4) from the terminal box (key 3).

b. Apply sealant to the threads of the quick connector.

c. Insert the wire pigtail into the desired conduit opening on the terminal box. Tighten the quick connector in the

conduit opening.

13

DVC6200f Digital Valve Controller

Installation Information

May 2022

Instruction Manual

D103412X012

d. The instrument is not polarity sensitive. Refer to figure 2‐2. Connect the blue wire to the negative (-) LOOP

terminals in the terminal box. Connect the brown wire to the positive (+) LOOP terminal. Isolate the green/yellow

wire inside of the DVC6200f and ensure that the shield is totally isolated at the instrument end.

Note

The green/yellow wire is isolated inside the DVC6200f to help prevent ground loop issues.

e. Replace the terminal box cap on the terminal box and tighten until no gap remains. Secure the terminal box cap

by engaging the lock screw.

3. Connect the field wiring connector to the installed quick connector.

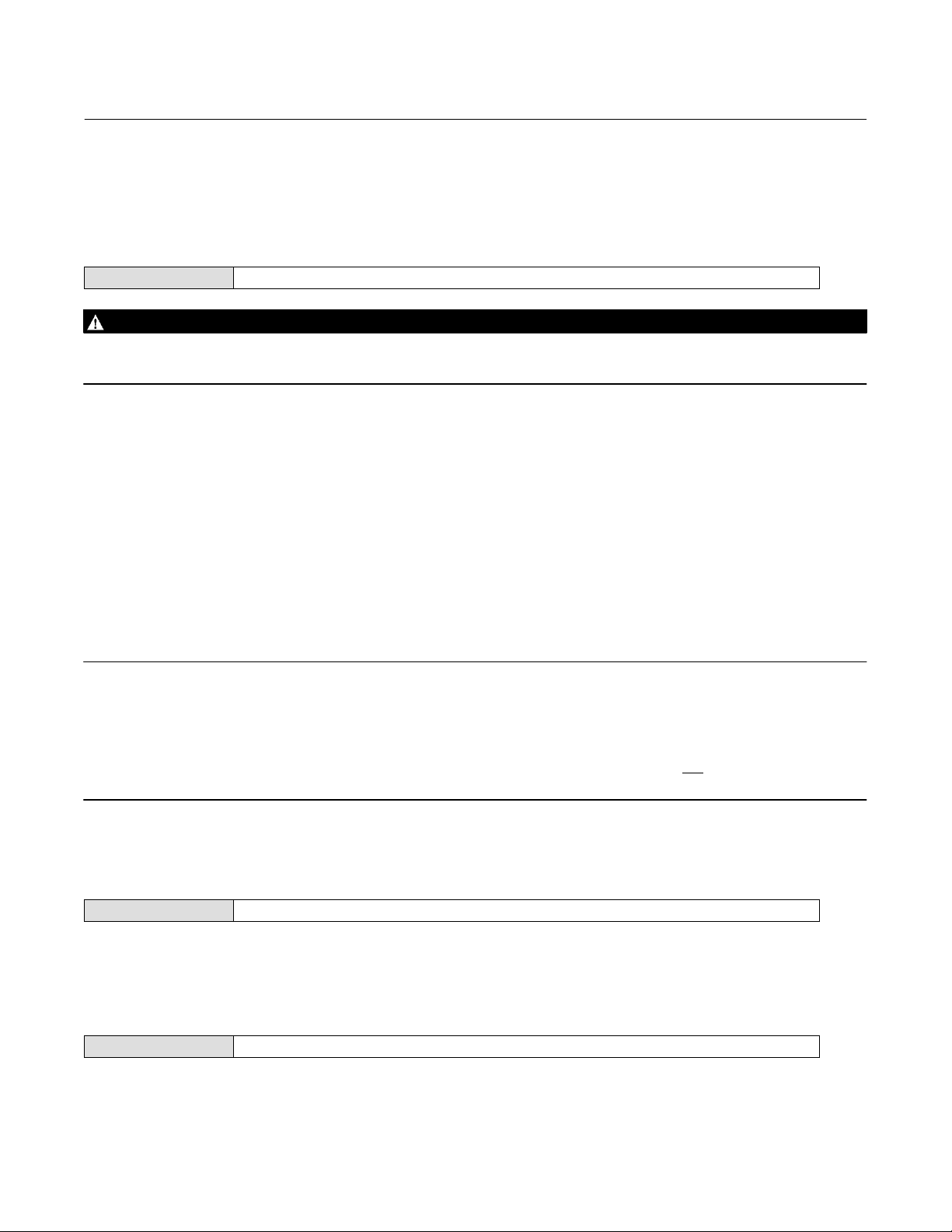

Figure 2‐2. Loop Connections Terminal Box

SAFETY

GROUND

GE41456-A

TALK

TALK

EARTH

GROUND

LOOP

LOOP

Communication Connections

WARNING

Personal injury or property damage caused by fire or explosion may occur if this connection is attempted in a potentially

explosive atmosphere or in an area that has been classified as hazardous. Confirm that area classification and atmosphere

conditions permit the safe removal of the terminal box cap before proceeding.

A FOUNDATION Fieldbus communicating device, such as an Emerson Device Communicator or a personal computer

running ValveLink software, interfaces with the DVC6200f digital valve controller from any wiring termination point in

the segment. If you choose to connect the fieldbus communicating device directly to the instrument, attach the

device to the LOCAL connections inside the terminal box to provide local communications with the instrument.

14

DVC6200f Digital Valve Controller

Instruction Manual

D103412X012

Installation Information

May 2022

Simulate Enable Jumper

WARNING

Personal injury or property damage caused by fire or explosion may occur if this connection is attempted in a potentially

explosive atmosphere or in an area that has been classified as hazardous. Confirm that area classification and atmosphere

conditions permit the safe removal of the terminal box cap before proceeding.

Install a jumper across the SIMULATE ENABLE terminals to enable the instrument to accept a simulate command.

(These terminals are marked AUX on the terminal board, see figure 2‐2). With the jumper in place and the simulate

parameter in the AO or DO block set to enabled, the transducer block ignores the output of the AO or DO block. The

simulate value and status become the readback value and status to the AO or DO block and the transducer block is

ignored. For more information on running simulations, see the Detailed Setup section of this manual, the

Fieldbus specifications, and the host documentation.

WARNING

Removing the jumper will disable the simulate, which may cause the valve to move. To avoid personal injury and property

damage caused by the release of pressure or process fluid, provide some temporary means of control for the process.

FOUNDATION

15

DVC6200f Digital Valve Controller

Installation Information

May 2022

Instruction Manual

D103412X012

16

DVC6200f Digital Valve Controller

Instruction Manual

D103412X012

Basic Setup

May 2022

Section 3 Basic Setup3-3-

Basic Setup

Device Communicator TB > Configure/Setup > Basic Setup

WARNING

Changes to the instrument setup may cause changes in the output pressure or valve travel. Depending on the application,

these changes may upset process control, which may result in personal injury or property damage.

When the DVC6200f digital valve controller is ordered as part of a control valve assembly, the factory mounts the

digital valve controller and sets up the instrument as specified on the order. When mounting to a valve in the field, the

instrument needs to be setup to match the instrument to the valve and actuator.

Before beginning basic setup, be sure the instrument is correctly mounted as described in the Installation section.

Basic Setup includes the following procedures:

Device Setup

Performance Tuner (Optional)

Note

The DVC6200f may keep the Transducer Block Mode Out‐of‐Service if the instrument is not properly mounted.

To setup and calibrate the instrument, the Transducer Block Mode must be Manual, and the Protection must be None.

When using DD methods the method will request that you change the mode, but make changes in Protection automatically. If you

have a host system that overrides transducer block parameters ensure that the Protection setting is not

result in transducer block parameters being overwritten.

left as None. Doing so will

Transducer Block Mode

Device Communicator TB > Device Variables > TB Block Mode

To setup and calibrate the instrument, the transducer block mode must be in Manual. For more information about

transducer block mode, refer to page 47.

Protection

Device Communicator TB > Configure/Setup > Detailed Setup > Protection

To setup and calibrate the instrument, the protection must be set to None with the Device Communicator. For more

information about configuration protection refer to page 47.

17

DVC6200f Digital Valve Controller

Basic Setup

May 2022

Instruction Manual

D103412X012

Device Setup

Device Communicator TB > Configure/Setup > Basic Setup > Device Setup

Follow the prompts on the Device Communicator display to automatically setup the instrument using specified

actuator information. Table 3‐2 provides the actuator information required to setup and calibrate the instrument.

Note

If reverse‐acting relay B is used, you must manually set the Relay Type (BASIC_SETUP.RELAY_TYPE [42.5]) to B. This will not be set

during Device Setup.

1. Select whether Travel, Travel with Pressure fallback (auto recovery or manual recovery) or Pressure Control is

desired. Refer to page 51 for additional information.

2. Enter the pressure units: kPa, bar, psi, inHg, inH

3. Enter the maximum instrument supply pressure and output pressure range (if required).

4. Enter the manufacturer of the actuator on which the instrument is mounted. If the actuator manufacturer is not

listed, select Other.

5. Enter the actuator model or type. If the actuator model is not listed, select Other.

6. Enter the actuator size.

7. Indicate whether a Volume Booster is being used.

8. Specify if factory defaults should be used for basic setup. If you select YES for factory default, the Device

Communicator sets the setup parameters to the values listed in table 3‐1. If you select NO for the factory defaults,

the setup parameters listed in the table remain at their previous settings.

O, or kg/cm2.

2

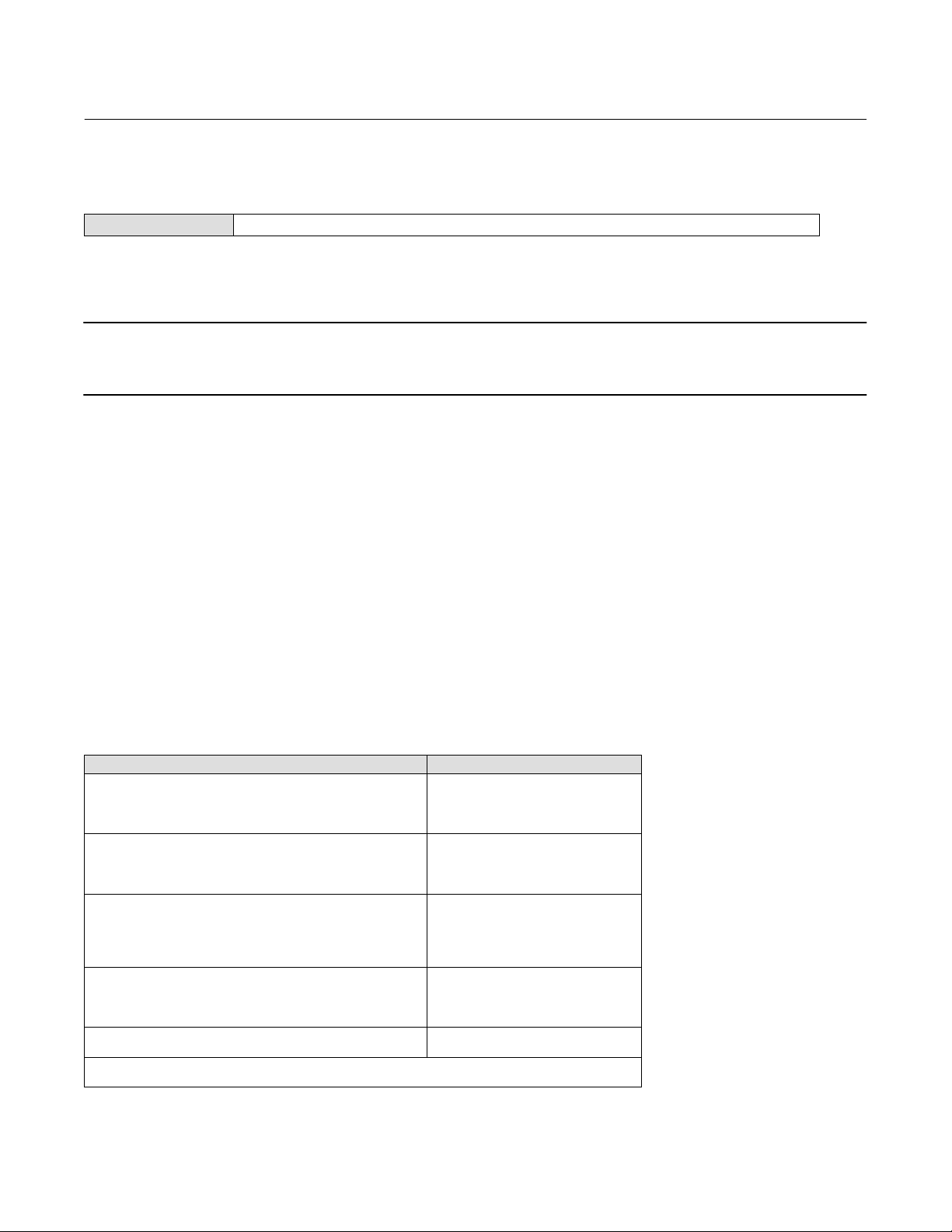

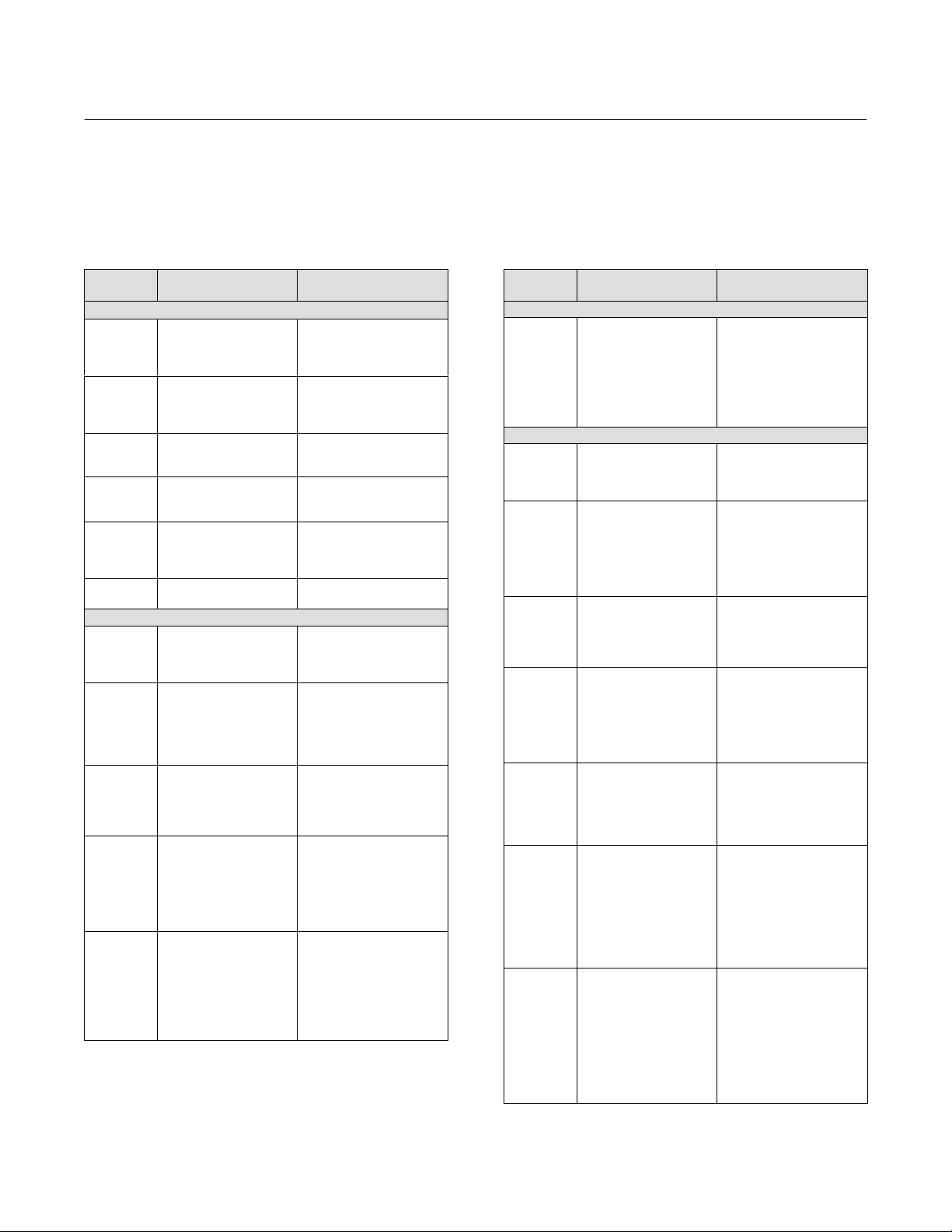

Table 3‐1. Factory Default Settings

Setup Parameter

Travel Cutoff Hi

Travel Cutoff Lo

Travel Integral Gain

Travel Calibration Trigger

Travel Integral Enable

Travel Integral Limit Hi

Travel Integral Limit Lo

Travel Integral Deadzone

Pressure Cutoff Hi

Pressure Cutoff Lo

Pressure Integral Deadzone

Pressure Integral Hi Limit

Pressure Integral Lo Limit

Input Characterization

Shutdown Trigger

Shutdown Recovery

Output Block Timeout

STOP Hi Pos

STOP Lo Pos

1. For PST instruments, the PST prohibited configuration will be erased if the instrument is set to factory default

settings. These parameters will need to be re-configured if the PST prohibited configuration is desired.

18

(1)

99.5%

0.5%

9.4 repeats/min

No

On

30%

-30%

0.25%

99.5%

-0.5%

0.25%

50.0%

-50.0%

Linear

All Off

All Auto Recovery

600 sec

98%

2%

Default Setting

Instruction Manual

D103412X012

DVC6200f Digital Valve Controller

Basic Setup

May 2022

Table 3‐2. Actuator Information for Initial Setup

Actuator

Manufacturer

Fisher

Baumann

NOTE: Refer to table 4‐9 for feedback connection (magnet assembly) information.

1. X = Expert Tuning. Proportional Gain = 4.2; Velocity Gain = 3.0; Minor Loop Feedback Gain = 18.0

2. Travel Sensor Motion in this instance refers to the motion of the magnet assembly.

3. Values shown are for Relay A and C. Reverse for Relay B.

Actuator Model Actuator Size Actuator Style

25

585C & 585CR

657

667

1051 & 1052

1061

1066SR

2052

3024

GX

Air to Extend

Air to Retract Towards the top of the instrument

Rotary

50

60

68, 80

100, 130

30, 30i

34, 34i, 40, 40i

45, 45i, 50, 50i

46, 46i, 60, 60i, 70,

70i & 80‐100

30, 30i

34, 34i, 40, 40i

45, 45i, 50, 50i

46, 46i, 60, 60i, 70,

70i, 76, 76i & 80‐100

20, 30

33

40

60, 70

30

40

60

68, 80, 100, 130

20

27, 75

1

2

3

30, 30E

34, 34E, 40, 40E

45, 45E

225

750 K

1200 M

16

32

54

10

25

54

Piston Dbl w/ or w/o

Spring. See actuator

instruction manual and

nameplate.

Spring & Diaphragm

Spring & Diaphragm

Spring & Diaphragm

(Window-mount)

Piston Dbl w/o Spring

Piston Sgl w/Spring

Spring & Diaphragm

(Window-mount)

Spring & Diaphragm

Spring & Diaphragm

Spring & Diaphragm

Starting

Tuning Set

E

I

J

L

M

H

K

L

M

H

K

L

M

H

I

K

M

J

K

L

M

G

L

H

K

M

E

H

K

(1)

X

C

E

H

E

H

J

Travel Sensor Motion

Relay A or C

User Specified

Away from the top of the instrument

Towards the top of the instrument

Away from the top of the instrument

Depends upon pneumatic connections. See

description for Travel Sensor Motion

Mounting Style Travel Sensor Motion

A

B

C

D

Away from the top of the instrument

For Po operating mode (air opens):

Towards the top of the instrument

For P

operating mode (air closes):

s

Away from the top of the instrument

Air to Open

Towards the top

of the instrument

Away from the top of the instrument

Away from the top of the

Towards the top of the

Towards the top of the

Away from the top of the

Away from the top of the

Specify

(2)

(3)

instrument

instrument

instrument

instrument

Air to Close

instrument

19

DVC6200f Digital Valve Controller

Basic Setup

May 2022

Instruction Manual

D103412X012

Typically Device Setup determines the required setup information based upon the actuator manufacturer and model

specified. However, if you enter OTHER for the actuator manufacturer or the actuator model, then you will be

prompted for setup parameters such as:

Actuator Style—Select spring & diaphragm, piston double‐acting without spring, piston single‐acting with spring,

piston double‐acting with spring.

Valve Style—Select the valve style, rotary or sliding‐stem.

Zero Power Condition—this identifies whether the valve is fully open or fully closed when the input is 0%. If you are

unsure how to set this parameter, disconnect the instrument from the segment. (With double‐acting and

single‐acting direct digital valve controllers, disconnecting the instrument from the segment is the same as setting

the output A pressure to zero. For single‐acting reverse digital valve controllers, disconnecting the instrument from

the segment is the same as setting the output B pressure to supply.)

WARNING

If you answer YES to the prompt for permission to move the valve when setting the Travel Sensor Motion, the instrument

will move the valve through its full travel range. To avoid personal injury and property damage caused by the release of

pressure or process fluid, isolate the valve from the process and equalize pressure on both sides of the valve or bleed off the

process fluid.

Travel Sensor Motion—Device Setup asks if it can move the valve to determine travel sensor motion. If you answer

Yes, the instrument will stroke the valve the full travel span to determine travel sensor motion. If you answer No,

then you must specify the direction of travel movement. For quarter‐turn actuators determine rotation by viewing

the rotation of the magnet assembly from the back of the instrument.

Note

Travel Sensor Motion in this instance refers to the motion of the magnet assembly. Note that the magnet assembly may be

referred to as a magnetic array in user interface tools.

For instruments with relay A or C If increasing air pressure at output A causes the magnet assembly to move up, or

the actuator shaft to rotate counterclockwise, enter “Towards Top of Instrument/CCW.” If it causes the magnet

assembly to move down, or the actuator shaft to rotate clockwise, enter “Away From Top of Instrument/CW.” For

instruments with relay B.

For instruments with relay B If decreasing air pressure at output B causes the magnet assembly to move up, or the

actuator shaft to rotate counterclockwise, enter “Towards Top of Instrument/CCW.” If it causes the magnet

assembly to move down, or the actuator shaft to rotate clockwise, enter “Away From Top of Instrument/CW.”

Note

Relay A adjustment may be required before Device Setup can determine travel sensor motion. Follow the prompts on the Device

Communicator display if relay adjustment is necessary.

Table 3‐2 lists the required Travel Sensor Motion selections for Fisher and Baumann actuators.

20

DVC6200f Digital Valve Controller

Instruction Manual

D103412X012

Basic Setup

May 2022

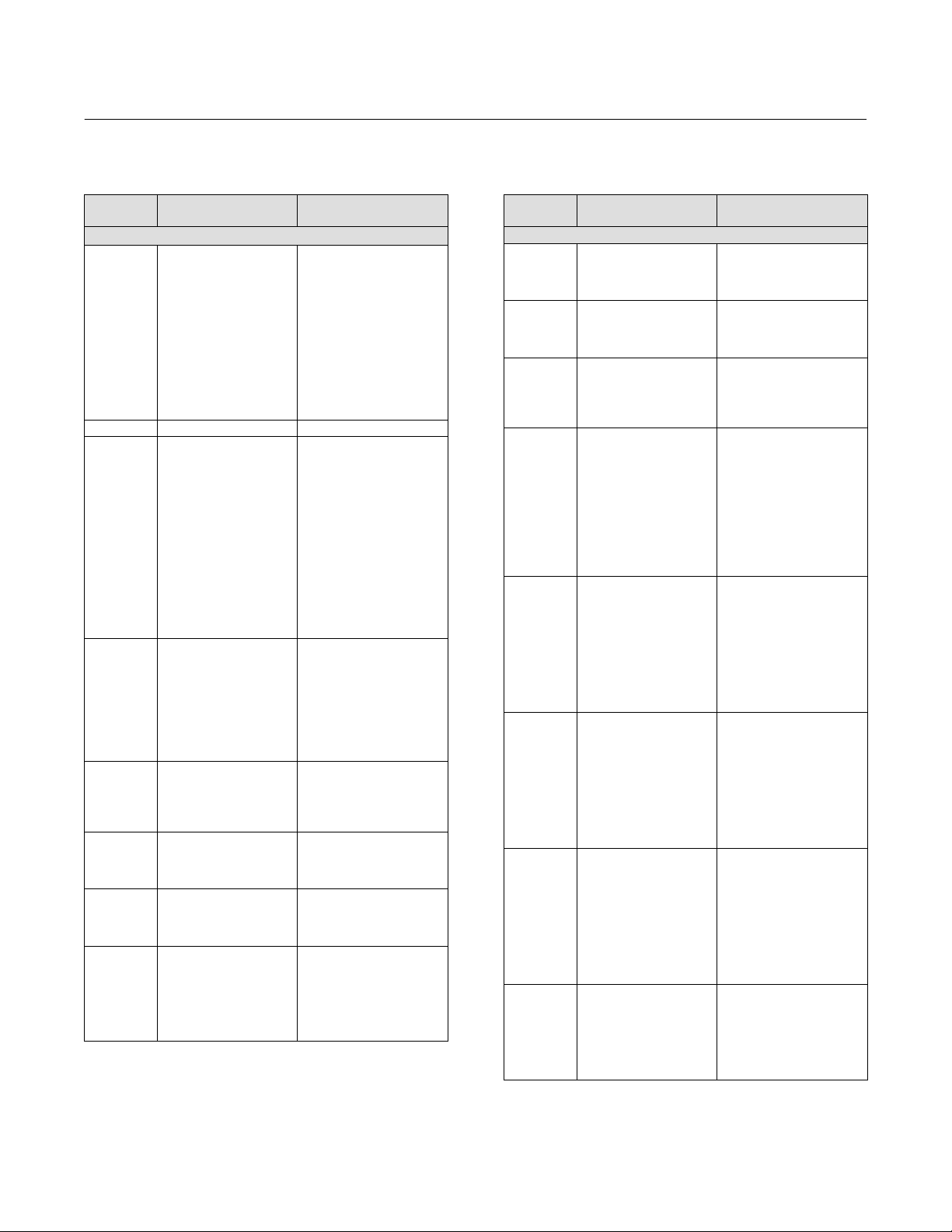

Tuning Set—There are twelve tuning sets to choose from. Each tuning set provides a preselected value for the digital

valve controller gain settings. Tuning set C provides the slowest response and M provides the fastest response. For

smaller actuators use tuning set C or D. For larger actuators using tuning set F or G. Table 3‐3 lists the values for

preselected tuning sets.

Note

Tuning set B is only available in Pressure Control Mode.

Table 3‐3. Gain Values for Preselected Tuning Sets

Travel Pressure

Tuning Set

B

C

D

E

F

G

H

I

J

K

L

M

X (Expert) User Adjusted User Adjusted User Adjusted User Adjusted User Adjusted User Adjusted

Proportional Gain Velocity Gain

‐ ‐ ‐

4.4

4.8

5.5

6.2

7.2

8.4

9.7

11.3

13.1

15.5

18.0

‐ ‐ ‐

3.0

3.0

3.0

3.1

3.6

4.2

4.8

5.6

6.0

6.0

6.0

Minor Loop

Feedback Gain

‐ ‐ ‐

35

35

35

35

34

31

27

23

18

12

12

Proportional Gain Integrator Gain

0.5

2.2

2.4

2.8

3.1

3.6

4.2

4.8

5.6

6.6

7.8

9.0

0.3

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

Minor Loop

Feedback Gain

35

35

35

35

35

34

31

27

23

18

12

12

WARNING

Changes to the tuning set may cause the valve/actuator assembly to stroke. To avoid personal injury or property damage

caused by moving parts, keep hands, tools, and other objects away from the valve/actuator assembly.

In addition, you can select Expert, which allows you to individually set the proportional gain, velocity gain, and minor

loop feedback gain for travel tuning and pressure proportional gain, pressure integrator gain, and pressure minor loop

feedback gain for pressure tuning. Refer to page 48 for additional information on travel tuning and page 50 for

pressure tuning.

Note

Use Expert tuning only if standard tuning has not achieved the desired results.

Stabilize/Optimize or Performance Tuner may be used to achieve the desired results more rapidly than expert tuning.

Table 3‐2 provides tuning set selection guidelines for Fisher and Baumann actuators. These tuning sets are only

recommended starting points. After you finish setting up and calibrating the instrument, use Stabilize/Optimize to

adjust the tuning set to get the desired response.

21

DVC6200f Digital Valve Controller

Basic Setup

May 2022

Instruction Manual

D103412X012

When Device Setup is complete you are asked if you wish to run Auto Calibration now. Select yes to automatically

calibrate instrument travel at this time. Follow the prompts on the Device Communicator display. The calibration

procedure uses the valve and actuator stops as the 0% and 100% calibration points. For additional information, refer to

Auto Calibration in the Calibration section.

Note

Single‐acting relay B and C are not user‐adjustable. However, it is recommended that you check the relay adjustment for

double‐acting relay A in new installations before proceeding with travel calibration.

Refer to page 121 for relay adjustment instructions.

If after completing setup and calibration the valve cycles or overshoots (unstable), or is unresponsive (sluggish), you

can improve operation by running Performance Tuner or Stabilize/Optimize.

Performance Tuner

Device Communicator TB > Configure/Setup > Detailed Setup > Response Control > Travel Tuning > Performance Tuner

WARNING

During performance tuning the valve may move, causing process fluid or pressure to be released. To avoid personal injury

and property damage caused by the release of process fluid or pressure, isolate the valve from the process and equalize

pressure on both sides of the valve or bleed off the process fluid.

The Performance Tuner is used to determine digital valve controller tuning. It will move the valve slightly and monitor

the effects of small tuning changes until an optimum control response is achieved. Because the Performance Tuner

can detect internal instabilities before they become apparent in the travel response, it can generally optimize tuning

more effectively than manual tuning. Typically, the Performance Tuner takes 3 to 5 minutes to tune an instrument,

although tuning instruments mounted on larger actuators may take longer.

22

DVC6200f Digital Valve Controller

Instruction Manual

D103412X012

Detailed Setup - Resource Block

May 2022

Section 4 Detailed Setup 4-4-

Resource Block

The resource block contains the hardware specific characteristics associated with a device; it has no input or output

parameters. The resource block monitors and controls the general operation of other blocks within the device. Most of

the resource block parameters are operational parameters that provide information about the instrument such as

identification, hardware information, available options, etc. and are read only. Configuration of the resource block

involves selecting features from those that are available, setting the mode, setting write lock, and setting up alert

reporting details.

The following procedures address only the key resource block parameters; however, all resource block parameters are

listed in table 4‐2.

Configure/Setup

Device Communicator RB > Configure/Setup

Resource Block Mode

Modes

The resource block can be in one of two modes (MODE_BLK [5]):

Automatic (Auto) is the operational mode for this block. When the resource block is in the Auto mode, all other

function blocks are allowed to function normally.

Out of Service (OOS)—Placing the resource block in Out of Service mode stops all function block execution, by

setting their modes to Out of Service as well. The actual mode of the function blocks is changed to Out of Service, but

the function block target modes are retained. Placing the resource block in the Out of Service mode does not affect

the mode of the transducer block.

Write Lock

Write Lock (WRITE_LOCK [34]) determines if writes are permissible to other device parameters. The write lock feature

must be selected to be able to use Write Lock (see Features Available). When Write Lock is set to Locked, no writes are

permitted to any parameters within the device except to set Write Lock to Not Locked. When locked, the device

functions normally, updating inputs and outputs and executing algorithms. When Write Lock is set to Not Locked, the

Write Alarm (WRITE_ALM [40]) alert is active.

Write Priority (WRITE_PRI [39]) sets the priority for Write Alarm. The lowest priority is 0. The highest is 15.

23

DVC6200f Digital Valve Controller

Detailed Setup - Resource Block

May 2022

Instruction Manual

D103412X012

Communication Timeout

Shed Remote Cascade

Note

Typically this parameter does not need to be changed. The unit will be operational using the default values assigned by the factory.

Perform this procedure only if a remote computer is sending setpoints from your “advanced” control.

Default value for RCas Timeout is 20 seconds.

Shed Remote Cascade (SHED_RCAS [26]) determines how long function blocks in the DVC6200f should wait before

giving up on remote computer writes to RCas parameters. When the timeout is exceeded, the block sheds to the next

mode as defined by the block shed options. If Shed Remote Cascade is set to 0, the block will not shed from RCas.

Enter a positive value in the Shed Remote Cascade field. Time duration is in 1/32 milliseconds (640000

Shed Remote Out

= 20 secs).

Note

Typically this parameter does not need to be changed. The unit will be operational using the default values assigned by the factory.

Perform this procedure only if a remote computer is sending setpoints from your “advanced” control.

Default value for Shed Remote Out is 20 seconds.

Shed Remote Out (SHED_ROUT [27]) determine how long function blocks in the DVC6200f should wait before giving

up on computer writes to ROut parameters. When the timeout is exceeded, the block sheds to the next mode as

defined by the block shed options. If Shed Remote Out is set to 0, the block will not shed from ROut. Enter a positive

value in the Shed Remote Out field. Time duration is in 1/32 milliseconds (640000

= 20 secs).

Options

Diagnostic Tier (DIAG_OPTIONS [103]) show which diagnostic options are available in the instrument.

Function Block Options (FB_OPTIONS [102]) show which function blocks are available in the instrument.

Miscellaneous Options (MISC_OPTIONS [104]) indicate which miscellaneous licensing options are enabled.

Features Available (FEATURES [17]) indicates which feature options are available in the resource block.

Reports enables alert and event reporting. Reporting of specific alerts may be suppressed. See Alerts on page 54.

Fault State enables the ability of the output block to react to various abnormal conditions by shedding mode. See

parameter descriptions for Set Fault State (SET_FSTATE [29]) and Clear Fault State (CLR_FSTATE [30]) in table 4‐2

and “Action on Fault Detection”.

Write Lock permits using Write Lock (WRITE_LOCK [34]) to prevent any external change to parameter values. Block

connections and calculation results will proceed normally, but the configuration is locked. Also see Write Lock, on

page 23.

24

DVC6200f Digital Valve Controller

Instruction Manual

D103412X012

Detailed Setup - Resource Block

May 2022

Multi‐bit Alarm (Bit‐Alarm) Support permits the instrument to treat each Field Diagnostic alert separately when

broadcast to the Host. Without Multi‐Bit Alarm Support, an individual Field Diagnostic alert must be acknowledged

before another Field Diagnostic alert can be broadcast to the Host.

Features Selected

Note

Typically this parameter does not need to be changed. The unit will be operational using the default values assigned by the factory.

Fault State, Software Write Lock, and Output Readback are set by default.

Features Selected (FEATURE_SEL [18]) indicates which Resource Block Options features have been selected and is used

to select the desired features.

Reports—Selecting reports enables alert and event reporting. Reporting of specific alerts may be suppressed. See

Alerts on page 54.

Fault State—Selecting fault state enables the ability of the output block to react to various abnormal conditions by

shedding mode. See parameter descriptions for Set Fault State (SET_FSTATE [29]) and Clear Fault State

(CLR_FSTATE [30]) in table 4‐2 and “Action on Fault Detection”.

Soft Write Lock—When selected, permits using Write Lock (WRITE_LOCK [34]) to prevent any external change to

parameter values. Block connections and calculation results will proceed normally, but the configuration is locked.

Also see Write Lock, on page 23.

Multi‐bit Alarm (Bit‐Alarm) Support— When selected, the instrument will allow the instrument to treat each Field

Diagnostic alert separately when broadcast to the Host.

Alarm Handling

Alert Key (ALERT_KEY [4]) is a number that permits grouping alerts. This number may be used to indicate to the

operator the source of the alert, such as the instrument, plant unit, etc. Enter a value between 1 and 255.

Confirm Time (CONFIRM_TIME [33]) determines the time, in 1/32 of a millisecond, the instrument waits for

confirmation of receipt of a report before trying again. If Confirm Time is 0, the instrument does not retry to send the

report. Enter 0 or a value between 320000 (10 secs) and 640000 (20 secs).

Limit Notify (LIM_NOTIFY [32]) is the number of alert reports that the device can send without getting a confirmation

up to the maximum permitted in Maximum Notify (MAX_NOTIFY [31]). If Limit Notify is set to zero, no alerts are

reported. Enter a value between 0 and 4.

To have the instrument report alerts without having the host poll the alerts parameters, select the Reports feature (see

Feature Select).

Maximum Notify (MAX_NOTIFY [31]) indicates the maximum number of alert reports that the device can send without

getting a confirmation. This limit is determined by the amount of memory available for alert messages. The number

can be set lower, to control alert flooding, by adjusting Maximum Alerts Allowed (LIM_NOTIFY [32]).

Block Alarm Disabled The Block Alarm (BLOCK_ALM [36]) is used for all configuration, hardware, connection failure or

system problems in the block. Alarm Summary (ALARM_SUM [37]) determines if the Write Alarm (WRITE_ALM [40])

and Block Alarm [BLOCK_ALM [36]) are disabled.

25

DVC6200f Digital Valve Controller

Detailed Setup - Resource Block

May 2022

Block Alarm Auto Acknowledge (ACK_OPTION [38]) determines if the block alarm will be automatically

acknowledged.

Discrete Alarm Disabled The Write Alarm (WRITE_ALM [40]) is used to alert when parameters are writable to the

device. Alarm Summary (ALARM_SUM [37]) determines if the Discrete Alarm is disabled.

Discrete Alarm Auto Acknowledge (ACK_OPTION [38]) determines if the Write Alarm associated with the block will be

automatically acknowledged.

Instruction Manual

D103412X012

Identification

Device ID (DEVICE_ID [110]) is the 32 character Device ID.

Electronics Serial Number (ELECTRONICS_SN [106]) is set at the factory.

Factory Serial Number (FACTORY_SN [107]) is the instrument serial number set at the factory.

Field Serial Number (FIELD_SN [108]) is the serial number of instrument assigned in field.

Tag Description (TAG_DESC [2]) is used to assign a unique 32 character description to each block within the digital

valve controller to describe the intended application for the block.

Strategy (STRATEGY [3]) permits strategic grouping of blocks so the operator can identify where the block is located.

The blocks may be grouped by plant area, plant equipment, etc. Enter a value between 0 and 65535 in the Strategy

field.

Manufacturer (MANUFAC_ID [10]) identifies the manufacturer of the instrument. It is used by the host system to

locate the DD file for the device. For Fisher the Manufacturer ID is 0x5100.

Device Type (DEV_TYPE [11]) identifies the type of device. It is used by the host system to locate the DD file for the

device. For a DVC6200f digital valve controller the device type is 0x4602.

Diagnostic Options (DIAG_OPTIONS [45]) shows the diagnostic options available in the instrument.

26

DVC6200f Digital Valve Controller

Instruction Manual

D103412X012

Detailed Setup - Resource Block

May 2022

Version

Device Revision (DEV_REV [12]) is the manufacturer's revision number associated with the resource, used by an

interface device to locate the DD file for the resource.

Firmware Revision (FIRMWARE_REVISION [105]) identifies the revision of the firmware that is currently in use.

Standby Firmware Revision (STBY_FIRMWARE_REVISION [111]) identifies the revision of the alternative firmware.

Hardware Revision (HARDWARE_REVISION [83]) identifies the revision of the electronic hardware.

ITK Version (ITK_VER [41]) identifies the major version of the Interoperability Tester used by the Fieldbus Foundation

in certifying the device as interoperable. This device revision meets the requirements of version 6.

Alert Handling

Simulate Enabled/Disabled (FD_SIMULATE [73]), when enabled, allows the user to write to the following Field

Diagnostic and Instrument alert parameters; Failed Active, Maintenance Active, Offspec Active, and Check Active. This

provides a way to simulate these alerts for testing. In order to enable Field Diagnostic Alerts Simulate, the Aux

Terminal must be jumpered.

Simulate Active Alerts is cleared on a power cycle. It can also be cleared manually, or by removing the Aux terminal

jumper.

Refer to Alerts on page 54 for additional information setting Field Diagnostic and Instrument alerts.

Enable/Disable FD Simulation

All Diag Tiers FD Alerts

PST Diag Tier FD Alerts

27

DVC6200f Digital Valve Controller

Detailed Setup - Resource Block

May 2022

Parameters Affected by Restart with Defaults

Instruction Manual

D103412X012

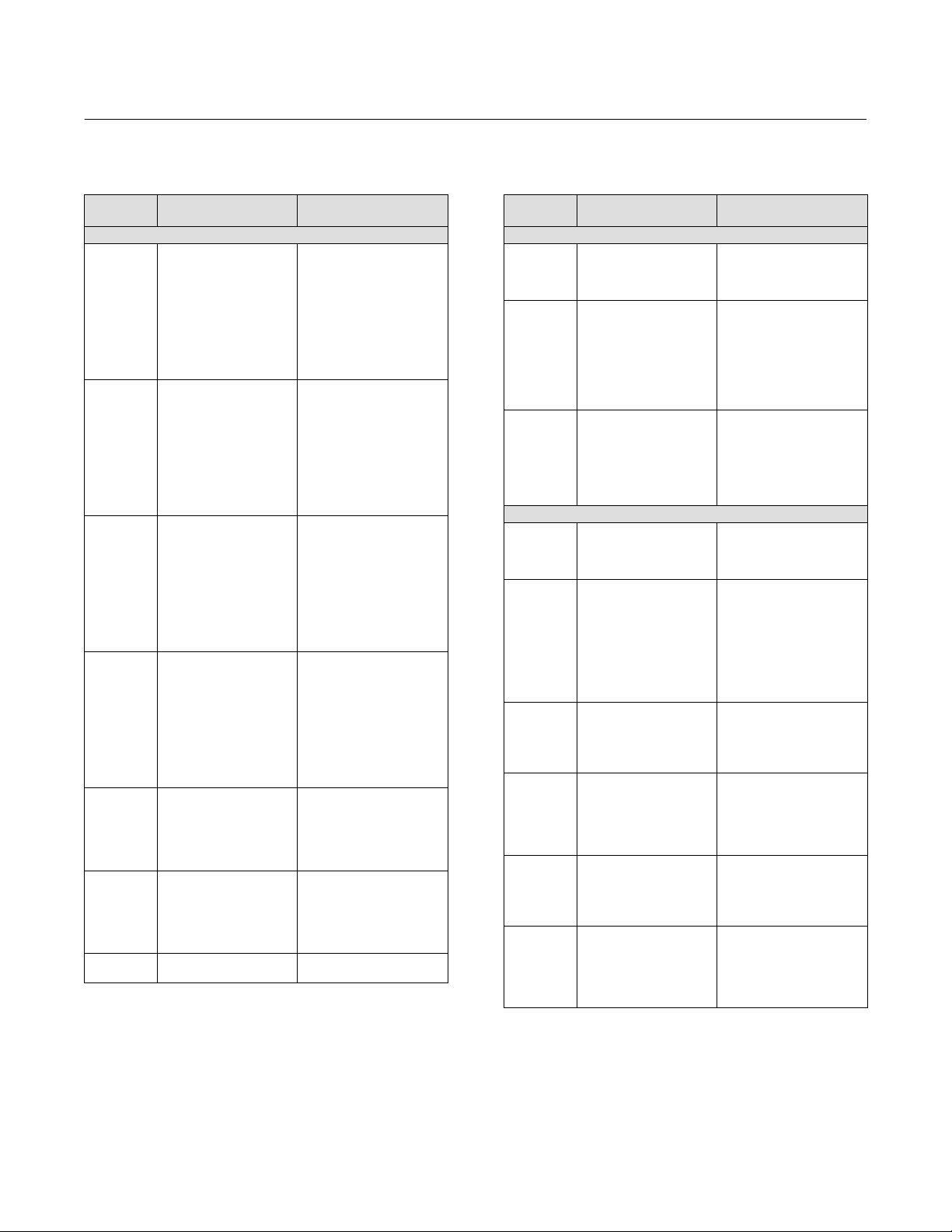

Table 4‐1. Parameters Affected by Restart with

Defaults

Index

Number

1

2

3

4

5 MODE_BLK

14

18

20

26

27

28

32

33

34

37

38

39

1

2

3

4

5

8

9

11 PV_SCALE

12

14

15

17

18

19

20

21

22

Parameter Name Initial Value

Resource Block

ST_REV

TAG_DESC

STRATEGY

ALERT_KEY

TARGET

PERMITTED

NORMAL

GRANT_DENY

FEATURE_SEL

CYCLE_SEL

SHED_RCAS

SHED_ROUT

FAULT_STATE

LIM_NOTIFY

CONFIRM_TIME

WRITE_LOCK

ALARM_SUM_DISABLED

ACK_OPTION

WRITE_PRI

AO Block

ST_REV

TAG_DESC

STRATEGY

ALERT_KEY

MODE_BLK

TARGET

PERMITTED

NORMAL

SP

OUT

EU 100%

EU 0%

Engineering Units

Decimal Places

XD_SCALE

EU 100%

EU 0%

Engineering Units

Decimal Places

IO_OPTS

STATUS_OPTS

CAS_IN

SP_RATE_DN

SP_RATE_UP

SP_HI_LIM

SP_LO_LIM

CHANNEL

-Continued-

0

spaces

0

0

OOS

AUTO or OOS

AUTO

All bits: 0

Set by mfgr.

0:0

640000

640000

1: Clear

MAX_NOTIFY

640000

1: Unlocked

All bits: 0

Disabled

0

0

spaces

0

0

OOS

OOS+MAN+AUTO+CAS+RCAS

CAS+Auto

Dynamic

Dynamic

100

0

%

0

100

0

%

0

All off

All off

BAD

Not Connected

Not Limited

+INF

+INF

100

0

Setpoint

Table 4‐1. Parameters Affected by Restart with

Defaults

Index

Number

23

24

26

27

1

2

3

4

5

8

9

10 PV_SCALE

11

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

Parameter Name Initial Value

AO Block (continued)

FSTATE_TIME

FSTATE_VAL

RCAS_IN

Status

Value

SHED_OPT

PID Block Parameters

ST_REV

TAG_DESC

STRATEGY

ALERT_KEY

MODE_BLK

TARGET

PERMITTED

NORMAL

SP

OUT

EU 100%

EU 0%

Engineering Units

Decimal Places

OUT_SCALE

EU 100%

EU 0%

Engineering Units

Decimal Places

CONTROL_OPTS

STATUS_OPTS

IN

Status

Value

PV_FTIME

BYPASS

CAS_IN

Status

Value

SP_RATE_DN

SP_RATE_UP

SP_HI_LIM

SP_LO_LIM

GAIN

RESET

BAL_TIME

RATE

BKCAL_IN

Status

Value

-Continued-

0

0

BAD

Not Connected

Not Limited

0 Trk

Uninitialized

0

spaces

0

0

OOS

OOS+MAN+AUTO+CAS+

RCAS+ROUT

AUTO

Dynamic

Dynamic

100

0

%

0

100

0

%

0

0: Bypass enable

All off

BAD

Not Connected

Not Limited

0

0

Uninitialized

BAD

Not Connected

Not Limited

0

+INF

+INF

100

0

1

+INF

0

0

BAD

Not Connected

Not Limited

0

28

Instruction Manual

D103412X012

DVC6200f Digital Valve Controller

Detailed Setup - Resource Block

May 2022

Table 4‐1. Parameters Affected by Restart with

Defaults

Index

Number

28

29

30

32

33

34 SHED_OPTS Uninitialized

38

39

40

41

42

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

66

69

70

71

72

73

74

Parameter Name Initial Value

PID Block (continued)

OUT_HI_LIM

OUT_LO_LIM

BKCAL_HYS

RCAS_IN

Status

Value

ROUT_IN

Status

Value

TRK_IN_D

Status

Value

TRK_VAL

Status

Value

FF_VAL

Status

Value

FF_SCALE

EU 100%

EU 0%

Engineering Units

Decimal Places

FF_GAIN

ALARM_SUM

DISABLED

ACK_OPTION

ALARM_HYS

HI_HI_PRI

HI_HI_LIM

HI_PRI

HI_LIM

LO_PRI

LO_LIM

LO_LO_PRI

LO_LO_LIM

DV_HI_PRI

DV_HI_LIM

DV_LO_PRI

DV_LO_LIM

BIAS

SP_FTIME

MATHFORM

STRUCTURECONFIG

GAMMA

BETA

IDEABAND

-Continued-

100

0

0.5%

BAD

Not Connected

Not Limited

0 Trk

BAD

Not Connected

Not Limited

0 Trk

BAD

Not Connected

Not Limited

0

BAD

Not Connected

Not Limited

0

BAD

Not Connected

Not Limited

0

100

0

%

0

0

All Off

All Off

0.5%

0

Infinity

0

Infinity

0

- Infinity

0

- Infinity

0

+INF

0

-INF

0

Standard

Err on PI_D

1

0

Table 4‐1. Parameters Affected by Restart with

Defaults

Index

Number

1

2

3

4

5 MODE_BLK

8 OUT_RANGE

10

11

12

13

14

15

16

17

18

19

20

22

Parameter Name Initial Value

ISEL Block

ST_REV

TAG_DESC

STRATEGY

ALERT_KEY

TARGET

PERMITTED

NORMAL

EU_100

EU_0

UNITS_INDEX

DECIMAL

STATUS_OPTS

IN_1

Status

Value

IN_2

Status

Value

IN_3

Status

Value

IN_4

Status

Value

DISABLE_1

Status

Value

DISABLE_2

Status

Value

DISABLE_3

Status

Value

DISABLE_4

Status

Value

SELECT_TYPE

MIN_GOOD

OP_SELECT

Status

Value

-Continued-

0

spaces

0

0

OOS

OOS+MAN+AUTO

AUTO

BAD

100

0

%

0

All off

BAD

Not Connected

Constant

0

BAD

Not Connected

Constant

0

BAD

Not Connected

Constant

0

BAD

Not Connected

Constant

0

BAD

Not Connected

Constant

Use

BAD

Not Connected

Constant

Use

BAD

Not Connected

Constant

Use

BAD

Not Connected

Constant

Use

All off

0

BAD

Not Connected

Constant

0

29

DVC6200f Digital Valve Controller

Detailed Setup - Resource Block

May 2022

Instruction Manual

D103412X012

Table 4‐1. Parameters Affected by Restart with

Defaults

Index

Number

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

50

Parameter Name Initial Value

ISEL Block (continued)

IN_5

Status

Value

IN_6

Status

Value

IN_7

Status

Value

IN_8

Status

Value

DISABLE_5

Status

Value

DISABLE_6

Status

Value

DISABLE_7

Status

Value

DISABLE_8

Status

Value

AVG_USE

ALARM_SUM

DISABLED

ACK_OPTION

ALARM_HYS

HI_HI_PRI

HI_HI_LIM

HI_PRI

HI_LIM

LO_PRI

LO_LIM

LO_LO_PRI

LO_LO_LIM

ALM_SEL

-Continued-

BAD

Not Connected

Constant

0

BAD

Not Connected

Constant

0

BAD

Not Connected

Constant

0

BAD

Not Connected

Constant

0

BAD

Not Connected

Constant

Use

BAD

Not Connected

Constant

Use

BAD

Not Connected

Constant

Use

BAD

Not Connected

Constant

Use

8

All off

All off

0.5%

0

Infinity

0

Infinity

0

-Infinity

0

-Infinity

All off

Table 4‐1. Parameters Affected by Restart with

Defaults

Index

Number

1

2

3

4

5

10

11

13

14

15

16

20

21

22

23

1

2

3

4

5

10

11 OUT_2_RANGE

13

14

19 BKCAL_1_IN

20

21

Parameter Name Initial Value

DI Block

ST_REV

TAG_DESC

STRATEGY

ALERT_KEY

MODE_BLK

TARGET

PERMITTED

NORMAL

XD_STATE

OUT_STATE

IO_OPTS

STATUS_OPTS

CHANNEL

PV_FTIME

ALARM_SUM

DISABLED

ACK_OPTION

DISC_PRI

DISC_LIM

OS Block

ST_REV

TAG_DESC

STRATEGY

ALERT_KEY

MODE_BLK

TARGET

PERMITTED

NORMAL

OUT_1_RANGE

EU_100

EU_0

UNITS_INDEX

DECIMAL

EU_100

EU_0

UNITS_INDEX

DECIMAL

STATUS_OPTS

CAS_IN

Status

Value

Status

Value

BKCAL_2_IN

Status

Value

BAL_TIME

-Continued-

0

spaces

0

0

OOS

OOS+MAN+AUTO

AUTO

0

0

All off

All off

0

0

All off

All off

0

0

0

spaces

0

0

OOS

OOS+AUTO+CAS

AUTO+CAS

100

0

%

0

100

0

%

0

All Off

Bad

Not Connected

Not Limited

0

Bad

Not Connected

Not Limited

0

Bad

Not Connected

Not Limited

0

0 seconds

30

Loading...

Loading...