Instruction Manual

D103176X012

DVC2000 Digital Valve Controller

Fisher™ FIELDVUE™ DVC2000 Digital Valve

Controller

This manual applies to

Instrument Level HC, AD, PD AC

Device Type 05 F5

Device Revision 1 1

Hardware Revision 1 & 2 1 & 2

Firmware Revision 1, 2, 3, 4 & 5 1, 2, 3, 4 & 5

DD Revision 3 1

July 2020

Contents

Section 1 Introduction and Specifications 3.

Installation, Electrical and Pneumatic Connections,

and Basic Setup and Calibration 3...............

Scope of Manual 3..............................

Instrument Description 3........................

Terminology 4.................................

Specifications 4................................

Related Documents 7...........................

Educational Services 8...........................

Section 2 Detailed Setup and Calibration via

HART Communication 9.................

Detailed Setup 9...............................

Setting Modes 9..............................

Instrument Mode 9........................

Control Mode 9...........................

Restart Control Mode 10....................

Restarting the Instrument 10................

Burst Mode 10............................

Protection 12.................................

General Information 14........................

HART Tag

Message

Descriptor

Date

Valve Serial Number

Instrument Serial Number

Polling Address

LUI Language

W8755

Measured Variable Units and Ranges 15...........

Analog Input Units

Analog Input Range High and Low

Pressure Units

Temperature Units

Actuator and Valve Information 16...............

Maximum Supply Pressure

Actuator Style

Valve Serial Number

Valve Style

Zero Control Signal

Setting Response 16...........................

Tuning Set

Damping Factor

Expert Tuning Gains

Input Characteristic

Custom Characteristic Table

Set Point Filter Time

Limits and Cutoffs

Minimum Opening and Closing Time

Integral Settings

Setting Alerts 19..............................

Travel Alerts 20............................

Cycle Counter Alert 22......................

Other Alerts 23............................

Alert Record 23............................

www.Fisher.com

DVC2000 Digital Valve Controller

July 2020

Instruction Manual

D103176X012

Self-Test Failure for Instrument Shutdown 24......

Transmitter/Switches 25.......................

Tuning 26.....................................

Automatic 26.................................

Manual 26...................................

Calibration 27..................................

Analog Input Calibration 27.....................

Using the Field Communicator 27............

Using Local Operator Interface 28............

Auto Calibrate Travel 28........................

Manual Calibrate Travel 29......................

Analog Calibration Adjust 29................

Digital Calibration Adjust 29.................

Pressure Sensor Calibration 30..................

Output Pressure Sensor 30..................

Position Transmitter 31........................

Section 3 Viewing Device Variables and

Diagnostics 33.........................

Viewing Variables 33............................

Analog Input, Travel, Valve Set Point, Drive Signal

and Output Pressure 33......................

Additional Instrument Variables 33...............

Viewing Device Information 34...................

Viewing Instrument Status 35....................

Section 4 Maintenance and

Troubleshooting 39.....................

Stroking the Digital Valve Controller Output 39......

Replacing the Instrument 40.....................

Replacing the Magnetic Feedback Assembly 41......

Component Replacement 41.....................

Replacing the I/P Converter 41..................

Replacing the Pneumatic Relay 43...............

Troubleshooting 44.............................

Checking Available Voltage 46....................

Technical Support Checklist 47...................

Section 5 Parts 49......................

Parts Ordering 49...............................

Parts Kits 49...................................

Parts List 50...................................

Appendix A Principle of Operation 55......

DVC2000 Operation 55..........................

Appendix B Local Interface Flow Chart and

Field Communicator Menu Trees 57.......

Glossary 65............................

Index 73..............................

2

Instruction Manual

D103176X012

Introduction and Specifications

Section 1 Introduction and Specifications1‐1‐

Installation, Electrical and Pneumatic Connections, and Basic

Setup and Calibration using the Local Operator Interface

July 2020

Refer to the DVC2000 Quick Start Guide (D103203X012) for DVC2000 installation,

connection, and basic setup and calibration using the local operator interface. If a copy

of this quick start guide is needed scan or click the QR code at the right, contact your

Emerson sales office

or visit our website at Fisher.com.

Scan or click

to access

field support

Scope of Manual

This instruction manual is a supplement to the quick start guide that ships with every instrument. This instruction

manual includes specifications, detailed configuration and calibration using an Emerson Field Communicator,

maintenance and troubleshooting information, and replacement part details.

Notes

Fast-key sequences referenced in this manual are only applicable to the 475 Field Communicator. They do not apply to the Trex

Device Communicator.

™

ValveLink

tests. For information on using ValveLink software with the instrument, refer to the appropriate user guide or help.

software can also be used for detailed configuration and calibration, as well as performing diagnostic and performance

Do not install, operate, or maintain a DVC2000 digital valve controller without being fully trained and

qualified in valve, actuator, and accessory installation, operation, and maintenance. To avoid personal

injury or property damage, it is important to carefully read, understand, and follow all of the contents of

this manual, including all safety cautions and warnings. If you have any questions regarding these

instructions, contact your Emerson sales office before proceeding.

Instrument Description

The DVC2000 digital valve controller is a communicating, microprocessor-based current-to-pneumatic valve

positioner. It is designed to replace standard pneumatic and electro-pneumatic valve positioners.

In addition to the traditional function of converting an input current signal (4-20 mA) to a pneumatic output pressure,

the DVC2000 digital valve controller communicates via a local display panel and/or via the HART® protocol. An option

is available which provides isolated circuitry for two (2) integrated limit switches (for open/close valve indication) and a

valve position transmitter (for separate valve position feedback).

3

Introduction and Specifications

July 2020

Instruction Manual

D103176X012

Terminology

Instrument Level— There are four (4) levels of functionality available: AC, HC, AD and PD.

AC—This level provides the capability to setup and calibrate the positioner through the local user interface or the Field

Communicator.

HC—This level provides additional capability for advanced configuration of the positioner (such as travel limits/cutoffs,

custom characterization, and minimum open/closing time). Also, information is available through the HART protocol

for diagnostic alerts such as travel deviation, cycle count, and travel accumulation.

AD—This level provides advanced diagnostic capabilities for performance testing. When used with ValveLink software,

instrument health can be evaluated with tests such as Valve Signature, step response and dynamic error band. The

software program provides detailed analysis with graphics.

PD—This level provides automated, non-intrusive testing of the operating performance of the control valve assembly.

When used with ValveLink

affecting the process.

software, tests to isolate component degradation can be run on the valve assembly without

Local Interface— The DVC2000 comes standard with a Liquid Crystal Display (LCD) and four (4) pushbuttons. The local

interface provides the capability to setup and calibrate the positioner and view basic diagnostic messages.

Magnet Assembly—This is the feedback component that is mounted directly to the valve stem. It supplies a magnetic

field that is sensed by the digital valve controller.

Options Board—The DVC2000 digital valve controller is available with two (2) limit switches and a valve position

transmitter. The options board includes the additional circuitry and terminations that are required to support these

output signals.

Pole Piece—Inserted into the DVC2000 housing and protruding through the back of the instrument is a two-pronged

fork that houses the magnetic sensor for position feedback.

Specifications

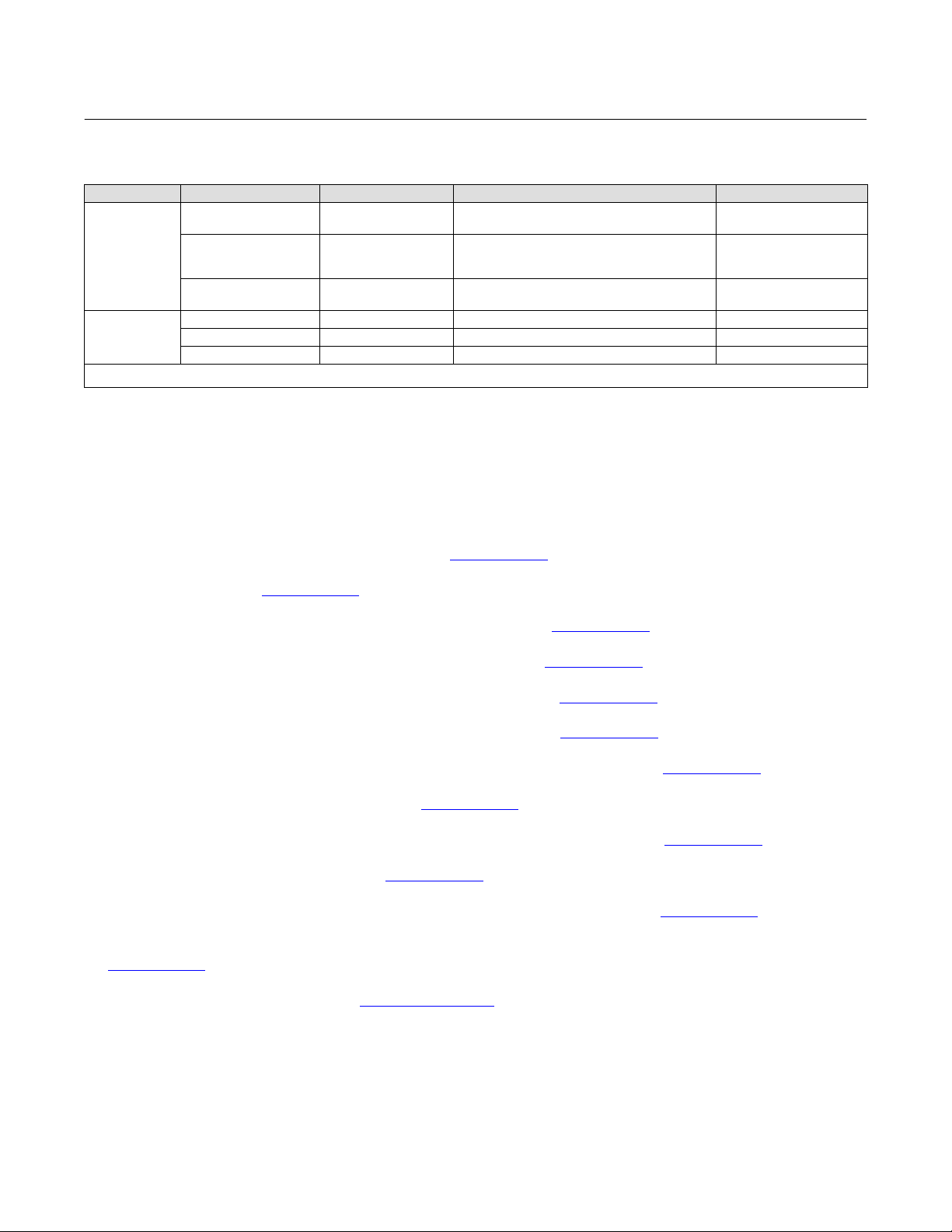

Specifications for the DVC2000 digital valve controller are shown in table 1‐1.

WARNING

This product is intended for a specific range of application specifications. Incorrect configuration of a positioning

instrument could result in the malfunction of the product, property damage, or personal injury.

4

Instruction Manual

D103176X012

Table 1‐1. Specifications

Introduction and Specifications

July 2020

Available Configurations

J Integral mounting to the Fisher GX Control Valve

and Actuator System

J Quarter-turn rotary applications

J Sliding-stem applications

The DVC2000 digital valve controller can also be

mounted on other actuators that comply with IEC

60534-6-1, IEC 60534-6-2, VDI/VDE 3845 and

NAMUR mounting standards.

Input Signal

Analog Input Signal: 4-20 mA DC, nominal; split

ranging available

Minimum Voltage: Voltage available at instrument

terminals must be 8.5 volts for analog control, 9.0

volts for HART communication

Maximum Voltage: 30 volts DC

Minimum Control Current: 4.0 mA (below 3.5 mA

may cause microprocessor restart)

Overcurrent Protection: Input circuitry limits current

to prevent internal damage

Reverse Polarity Protection: No damage occurs from

reversal of loop current

Output Signal

Pneumatic signal as required by the actuator, up to

full supply pressure

Minimum Span: 0.5 bar (7 psig)

Maximum Span: 7 bar (101 psig)

Action: Single Acting, direct

Supply Pressure

(1)

Recommended: 0.5 bar (7 psig) greater than the

maximum actuator requirements

Maximum: 7 bar (101 psig)

Supply pressure medium must be clean, dry air or

noncorrosive gas

Per ISA Standard 7.0.01

A maximum 40 micrometer particle size in the air

system is acceptable. Further filtration down to 5

micrometer particle size is recommended. Lubricant

content is not to exceed 1 ppm weight (w/w) or

volume (v/v) basis. Condensation in the air supply

should be minimized

Per ISO 8573-1

Maximum particle density size: Class 7

Oil content: Class 3

Pressure Dew Point: Class 3 or at least 10_C less than

the lowest ambient temperature expected

-continued-

Temperature Limits

(1)

-40 to 85_C (-40 to 185_F). LCD may not be readable

below -20_C (-4 _F).

Air Consumption

Supply pressure:

At 1.5 bar (22 psig)

At 4 bar (58 psig)

Air Capacity

(2)

(3)

: 0.06 normal m3/h (2.3 scfh)

(4)

: 0.12 normal m3/h (4.4 scfh)

(2)

Supply pressure:

(3)

At 1.5 bar (22 psig)

At 4 bar (58 psig)

: 4.48 normal m3/h (167 scfh)

(4)

: 9.06 normal m3/h (338 scfh)

Independent Linearity

±0.5% of output span

Electromagnetic Compatibility

Meets EN 61326-1:2013

Immunity—Industrial locations per Table 2 of the

EN 61326-1 standard. Performance is shown

in table 1‐2 below

Emissions—Class A

ISM equipment rating: Group 1, Class A

Tested to NAMUR NE21 requirements.

Vibration Testing Method

Tested per ANSI/ISA 75.13.01 Section 5.3.5. A

resonant frequency search is performed on all three

axes. The instrument is subjected to the ISA specified

1/2 hour endurance test at each major resonance,

plus an additional two million cycles.

Input Impedance

The input impedance of the DVC2000 active

electronic circuit is not purely resistive. For

comparison to resistive load specifications, an

equivalent impedance of 450 ohms may be used. This

value corresponds to 9 V @ 20 mA.

Electrical Classification

Hazardous Area:

CSA—Intrinsically Safe and Non-incendive

FM—Intrinsically Safe and Non-incendive

ATEX—Intrinsically Safe

IECEx—Intrinsically Safe

5

Introduction and Specifications

July 2020

Table 1‐1. Specifications (continued)

Instruction Manual

D103176X012

Electrical Housing:

CSA—IP66 and Type 4X

FM, ATEX, IECEx—IP66

Other Classifications/Certifications

CUTR— Customs Union Technical Regulations

(Russia, Kazakhstan, Belarus, and Armenia)

ESMA— Emirates Authority for Standardization and

Metrology - ECAS-Ex (UAE)

INMETRO—National Institute of Metrology, Quality

and Technology (Brazil)

KGS— Korea Gas Safety Corporation (South Korea)

NEPSI—National Supervision and Inspection Centre

for Explosion Protection and Safety of

Instrumentation (China)

PESO CCOE— Petroleum and Explosives Safety

Organisation - Chief Controller of Explosives (India)

SABS— South African Bureau of Standards (South

Africa)

Contact your Emerson sales office

for

classification/certification specific information

Connections

Standard

Supply and Output Pressure: G1/4 internal

Electrical: M20 internal

Optional

Supply and Output Pressure: 1/4 NPT internal

Electrical: 1/2 NPT internal

Shaft Rotation

otary actuators with rated travel between 45

R

degrees and 180 degrees

Mounting

Designed for direct actuator mounting. For

weatherproof housing capability, the vent must be

positioned at the lowest point of the instrument.

Weight

1.5 kg (3.3 lbs)

Options

J Airset: 67CFR with filter

Language Packs:

J Standard: English, German, French, Italian, Spanish,

Japanese, Chinese, Portuguese, Russian, Polish, and

Czech

J Optional: English, German, French, Italian, Spanish,

Japanese, Chinese, and Arabic

J Pipe-away vent

J Limit Switches: Two isolated switches,

configurable throughout calibrated travel range

Supply Voltage: 5-30 VDC

OFF State: 0.5 to 1.0 mA

ON State: 3.5 to 4.5 mA (above 5 V)

Reference Accuracy: 2.5% of travel span

J Transmitter: 4-20 mA output, isolated

(5)

Supply Voltage: 8-30 VDC

Fault Indication: offrange high or low

Reference Accuracy: 1% of travel span

(5)

Materials of Construction

Declaration of SEP

Fisher Controls International LLC declares this

Housing and Cover: A03600 low copper aluminum

alloy

Elastomers: nitrile, fluorosilicone

product to be in compliance with Article 4 paragraph

3 of the PED Directive 2014/68/EU. It was designed

and manufactured in accordance with Sound

Engineering Practice (SEP) and cannot bear the CE

marking related to PED compliance.

Stem Travel

Linear actuators with rated travel between 6.35 mm

(0.25 inch) and 606 mm (23.375 inches)

1. The pressure/temperature limits in this document and any applicable standard or code limitation should not be exceeded. Note: Temperature limits vary based on hazardous area approval.

2. Normal m

3. Low pressure relay: 0 to 3.3 bar (0 to 49 psig).

4. High pressure relay: 3.4 to 7.0 bar (50 to 102 psig).

5. Typical values when calibrated at temperature.

6

3

/hour - Normal cubic meters per hour at 0_C and 1.01325 bar, absolute. Scfh - Standard cubic feet per hour at 60_F and 14.7 psia.

However, the product may bear the CE marking to

indicate compliance with other applicable European

Community Directives.

Instruction Manual

(1)

D103176X012

Introduction and Specifications

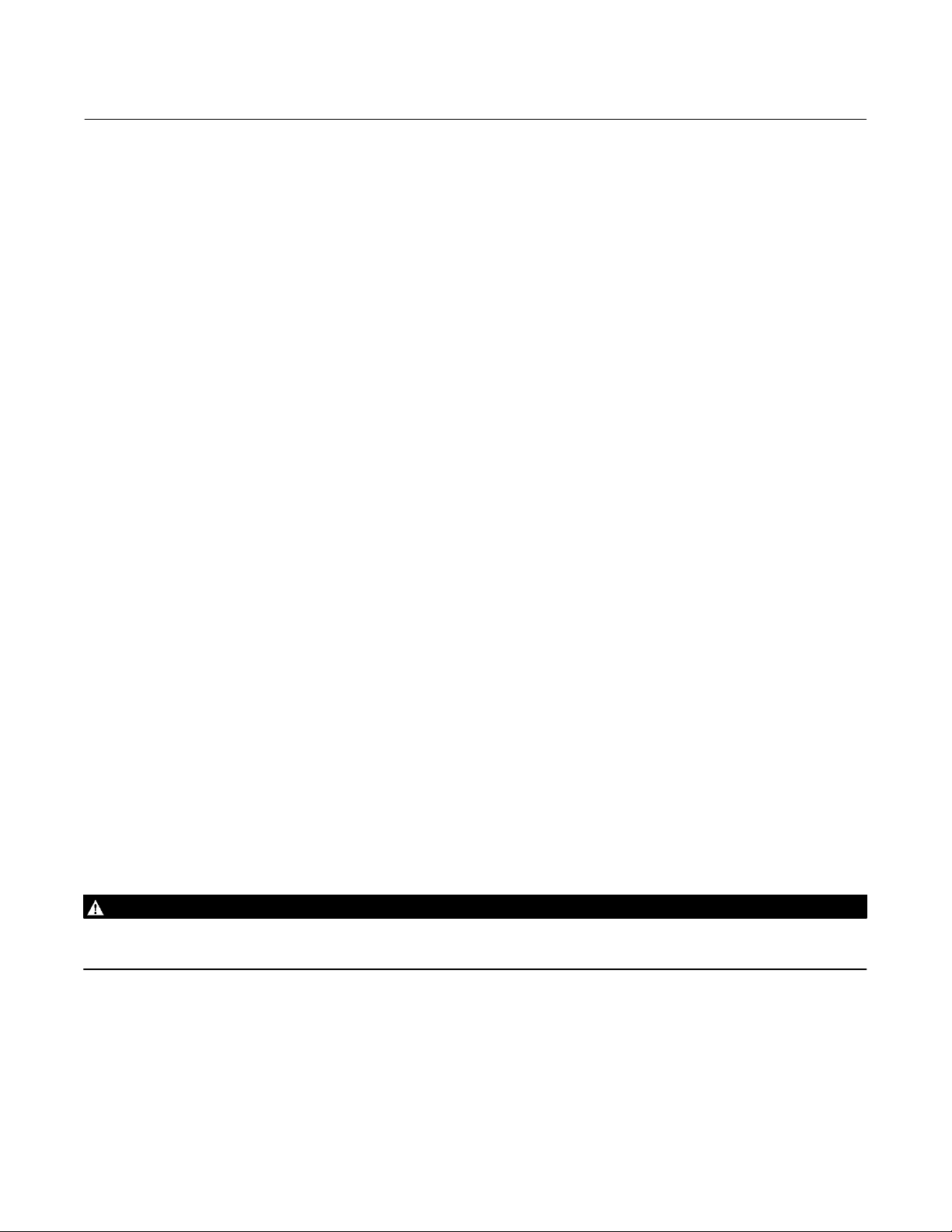

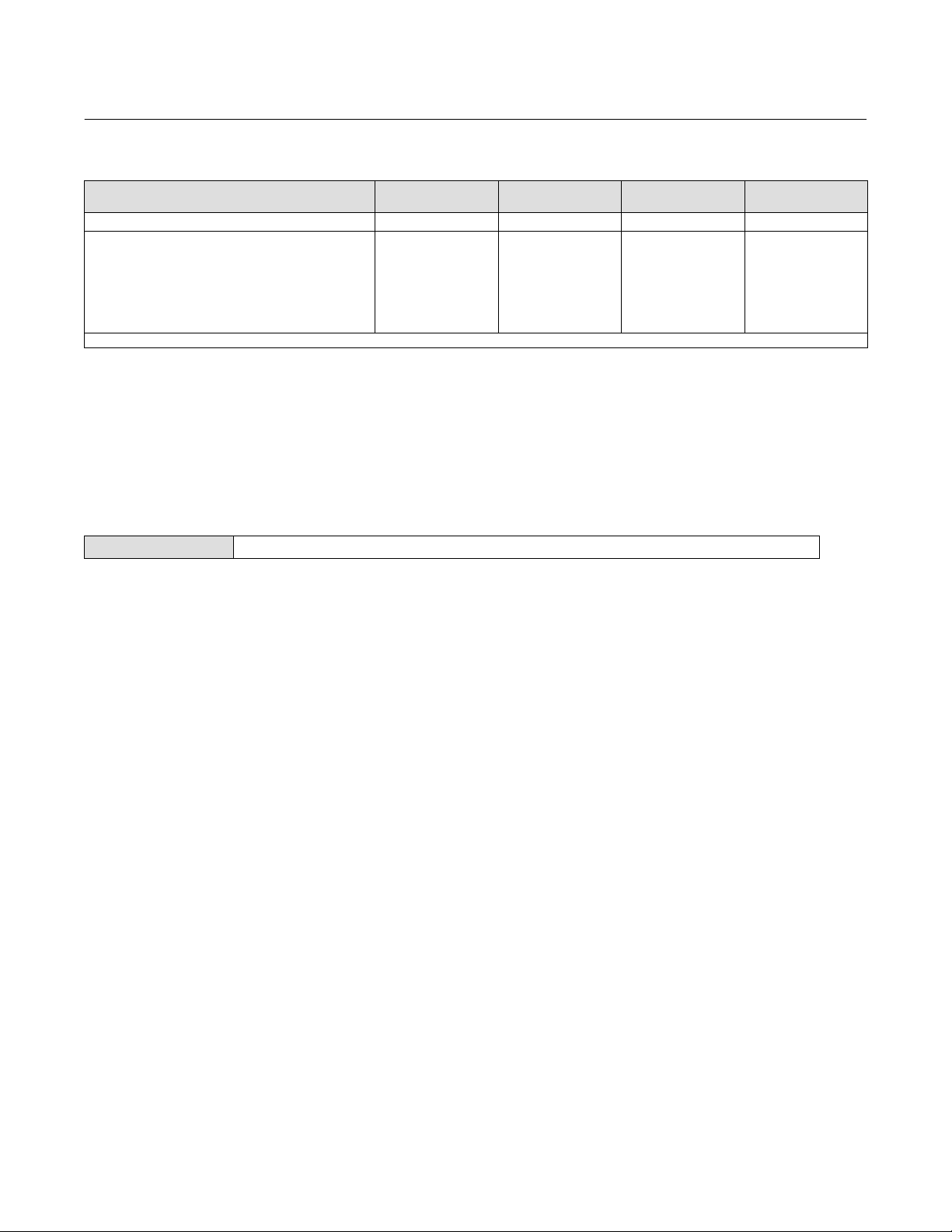

Table 1‐2. EMC Summary Results—Immunity

Port Phenomenon Basic Standard Test Level Performance Criteria

Electrostatic discharge

(ESD)

Enclosure

I/O signal/control

Performance criteria is + / - 1% effect.

1. A = No degradation during testing. B = Temporary degradation during testing, but is self-recovering.

Radiated EM field IEC 61000-4-3

Rated power frequency

magnetic field

Burst (fast transients) IEC 61000-4-4 $1 kV A

Surge IEC 61000-4-5 $1 kV (line to ground only, each) B

Conducted RF IEC 61000-4-6 150 kHz to 80 MHz at 10 Vrms A

IEC 61000-4-2

IEC 61000-4-8 30 A/m at 50 Hz, 60 sec A

6 kV contact

8 kV air

80 to 1000 MHz @ 10V/m with 1 kHz AM at 80%

1400 to 2000 MHz @ 3V/m with 1 kHz AM at 80%

2000 to 2700 MHz @ 1V/m with 1 kHz AM at 80%

Related Documents

Other documents containing information related to the DVC2000 digital valve controller include:

July 2020

B

A

D DVC2000 Digital Valve Controller Quick Start Guide (D103203X012

D Bulletin 62.1:DVC2000 (D103167X012

)

D CSA Hazardous Area Approvals - DVC2000 Digital Valve Controllers (D104224X012

D FM Hazardous Area Approvals - DVC2000 Digital Valve Controllers (D104225X012

D ATEX Hazardous Area Approvals - DVC2000 Digital Valve Controllers (D104226X012

D IECEx Hazardous Area Approvals - DVC2000 Digital Valve Controllers (D104227X012

D INMETRO Hazardous Area Approvals for FIELDVUE DVC2000 Digital Valve Controller (D103780X012

D FIELDVUE Digital Valve Controller Split Ranging (D103262X012

D Using FIELDVUE Instruments with the Smart HART Loop Interface and Monitor (HIM) (D103263X012

D Audio Monitor for HART Communications (D103265X012

)

D HART Field Device Specification - Fisher FIELDVUE DVC2000 Digital Valve Controller (D103783X012

)

)

)

)

)

)

)

)

)

D Using the HART Tri-Loop HART-to-Analog Signal Converter with Fisher FIELDVUE Digital Valve Controllers

(D103267X012

These documents are available from your Emerson sales office

)

or at Fisher.com.

7

Introduction and Specifications

July 2020

Instruction Manual

D103176X012

Educational Services

For information on available courses for the DVC2000 digital valve controller, as well as a variety of other products,

contact:

Emerson Automation Solutions

Educational Services - Registration

Phone: 1-641-754-3771 or 1-800-338-8158

E-mail: education@emerson.com

emerson.com/fishervalvetraining

8

Instruction Manual

D103176X012

Detailed Setup and Calibration

July 2020

Section 2 Detailed Configuration and Calibration via HART

Communication

2‐2‐

Detailed Setup

The DVC2000 digital valve controller has the capability to communicate via the HART protocol. This section describes

the advanced features that can be accessed with the Field Communicator. Table 2‐1 lists the default settings for a

standard factory configuration. Table 2‐2 provides the actuator information required to setup and calibrate the

instrument.

Setting Modes

Field Communicator Setup & Diag > Detailed Setup > Mode (1-2-1)

Instrument Mode

You can change the instrument mode by selecting Instrument Mode from the Mode menu, or press the Hot Key and

select Instrument Mode.

Instrument Mode allows you to either take the instrument Out Of Service or place it In Service. Taking the instrument

Out Of Service allows you to perform instrument calibration and also allows you to change setup variables that affect

control, provided the calibration/configuration protection is properly set. See Setting Protection.

Note

Some changes that require the instrument to be taken Out Of Service will not take effect until the instrument is placed back In

Service or the instrument is restarted.

Control Mode

You can change the control mode by selecting Control Mode from the Mode menu, or press the Hot Key and select

Control Mode.

Control Mode lets you define where the instrument receives its set point. Follow the prompts on the Field

Communicator display to choose one of the following control modes: Analog or Digital.

Choose Analog if the instrument is to receive its set point over the 4-20 mA loop. Normally the instrument control

mode is Analog.

Choose Digital if the instrument is to receive its set point digitally, via the HART communications link.

A third mode, Test, is also displayed. Normally the instrument should not be in the Test mode. The Field

Communicator automatically switches to this mode whenever it needs to stroke the valve, for example during

9

Detailed Setup and Calibration

July 2020

Instruction Manual

D103176X012

calibration or stroke valve. However, if you abort from a procedure where the instrument is in the Test mode, it may

remain in this mode. To take the instrument out of the Test mode, select Control Mode then select either Analog or

Digital.

Restart Control Mode

Restart Control Mode (Restart Cont Mode) lets you choose which operating mode you want the instrument to be in

after a restart. Follow the prompts on the Field Communicator display to define the restart control mode as Resume

Last, Analog, or Digital.

Restarting the Instrument

Restart resets the instrument in the same manner as when power to the instrument is interrupted. When Restart is

issued, all of the newly entered configuration variables become active. Otherwise, they may not take effect until the

instrument is placed In Service.

Burst Mode

Enabling burst mode provides continuous communication from the digital valve controller. Burst mode applies only to

the transmission of burst mode data (analog input, travel target, pressure, and travel) and does not affect the way

other data is accessed.

Access to information in the instrument is normally obtained through the poll/response of HART communication. The

Field Communicator or the control system may request any of the information that is normally available, even while

the instrument is in burst mode. Between each burst mode transmission sent by the instrument, a short pause allows

the Field Communicator or control system to initiate a request. The instrument receives the request, processes the

response message, and then continues “bursting” the burst mode data.

There are four burst mode commands. Command 3 is recommended for use with the Rosemount

Tri-Loop

™

HART-to-analog signal converter. The other three are not used at this time.

™

333 HART

Command 3 provides the following variables:

D Primary variable—analog input in % or mA,

D Secondary variable—travel target (valve set point) in % of ranged travel,

D Tertiary variable—output pressure in psig, bar, or kPa,

D Quaternary variable—travel in % of ranged travel.

To enable burst mode select Mode > Burst > Burst Enable. To send a burst mode command, select Burst Command.

Burst mode must be enabled before you can change the burst mode command.

10

Instruction Manual

(1)

(2)

(2)

D103176X012

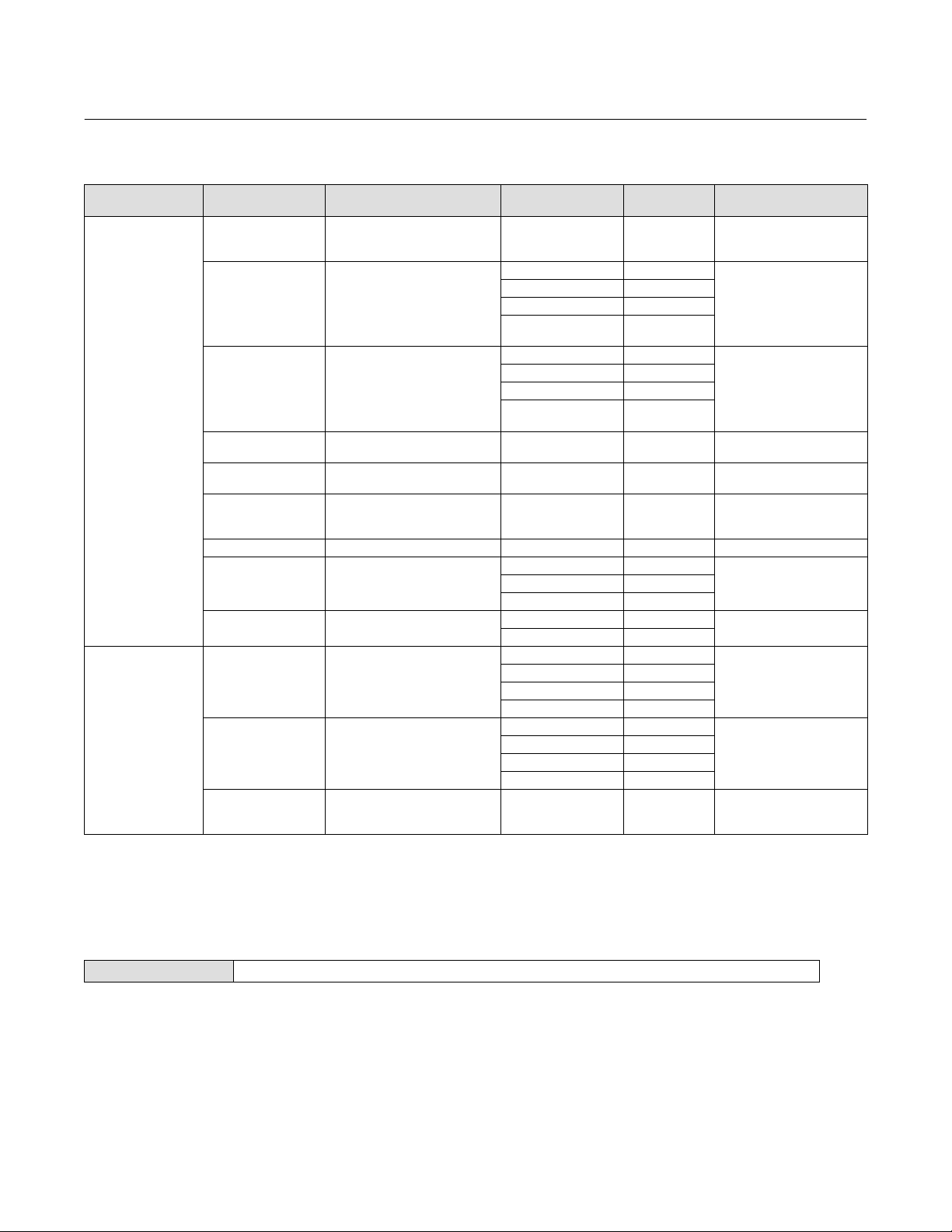

Table 2‐1. Factory Default Detailed Setup Parameters

Setup Parameter Default Setting

Control Mode

Restart Control Mode

Burst Mode Enabled

Burst Mode Command

HART Tag

Message

Description

Date

Valve Serial Number

Polling Address

Max Supply Pressure

Zero Control Signal

Analog Input Units

Analog In Range High

Analog In Range Low

Travel Range High

Travel Range Low

Pressure Units

Temperature Units

Input Characteristic

Setpoint Filter Time

Travel Limit High

Travel Limit Low

Travel Cutoff High

Travel Cutoff Low

Minimum Opening Time

Minimum Closing Time

Integral Gain

Integral Deadband

Travel Hi/Lo Alert Enabled

Travel Hi Hi/Lo Lo Alert Enabled

Travel Alert High Point

Travel Alert Low Point

Travel Alert High-High Point

Travel Alert Low-Low Point

Travel Alert Deadband

Travel Deviation Alert Enable

Travel Deviation Alert Point

Travel Deviation Time

Cycle Counter Alert Enable

Cycle Counter Alert Point

Cycle Counter Deadband

Cycle Counter

Travel Accumulator Alert Enable

Travel Accumulator Alert Point

Travel Accumulator Deadband

Travel Accumulator

Drive Alert Enable

Flash ROM Fail

Ref Voltage Fail

Drive Current Fail

Critical NVM Fail

Temperature Sensor Fail

Pressure Sensor Fail

Travel Sensor Fail

1. The settings listed are for standard factory configuration. DVC2000 instruments can also be ordered with custom configuration

settings. For the default custom settings, refer to the order requisition.

2. If the instrument is shipped mounted on an actuator, these values depend upon the actuator on which the instrument is mounted.

Analog

Resume Last

No

As specified on order

Factory Calibration Date

3

Blank

Blank

Blank

0

100

(2)

Open

mA

20 mA

4.0 mA

100%

0%

PSI

F

Linear

Filter Off

125%

-25%

99.5%

0.5%

0 secs

0 secs

1 repeat/minute

0.5%

No

No

125%

-25%

125%

-25%

1%

Yes

7%

5 secs

No

2,147,483,646

3%

0

No

2,147,483,646%

3%

0

No

No

No

No

No

No

No

No

Detailed Setup and Calibration

July 2020

11

Detailed Setup and Calibration

July 2020

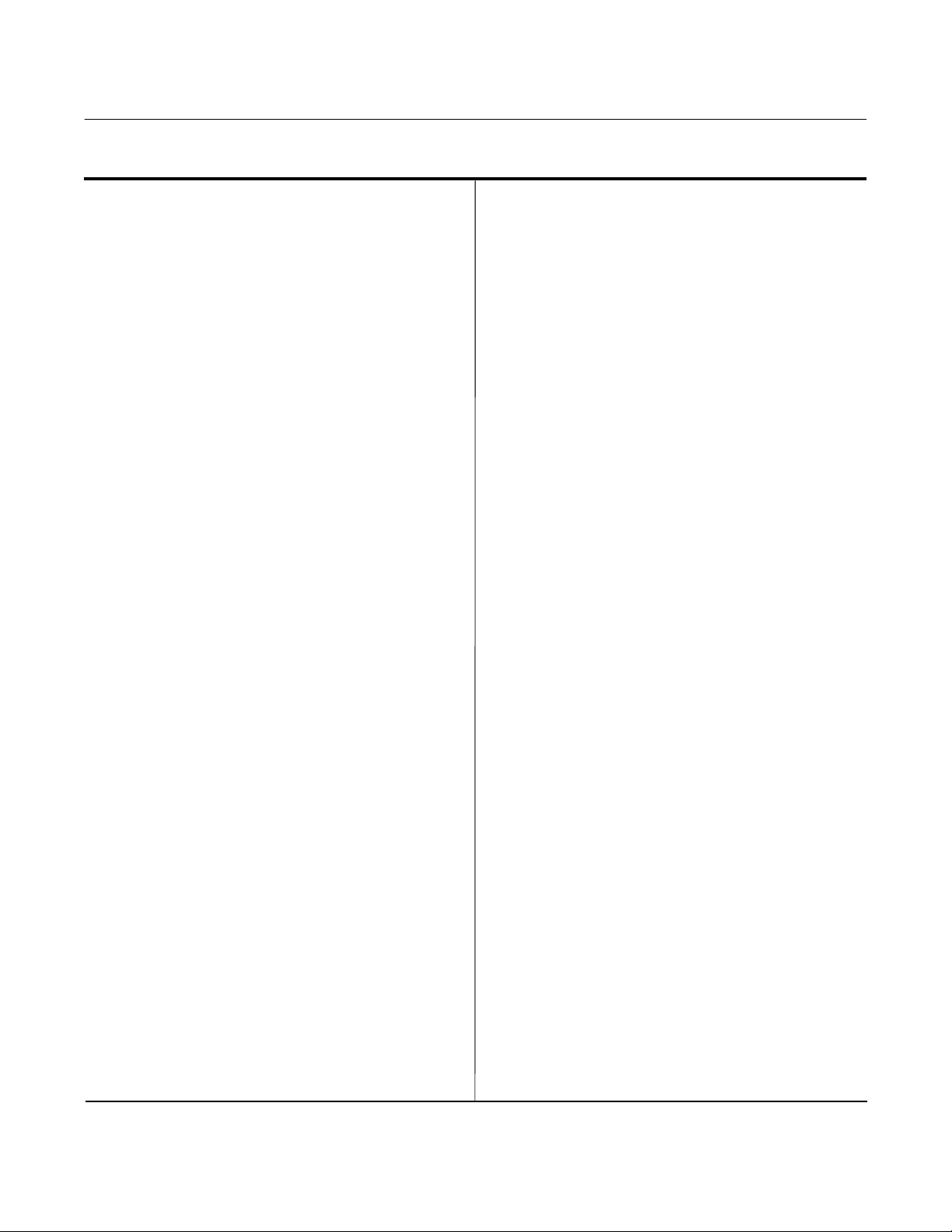

Table 2‐2. Actuator Information for Setup

Actuator

Manufacturer

Fisher

Baumann

Actuator Model Actuator Style Actuator Size

585C & 585CR

657 Spring & Diaphragm

667 Spring & Diaphragm

1051 & 1052 Spring & Diaphragm

1066SR Piston Sgl w/Spring

3024 Spring & Diaphragm

3025 Spring & Diaphragm P460, P462, P900 Undefined Rotary

GX Spring & Diaphragm

GX 3-Way Spring & Diaphragm

Air to Extend Spring & Diaphragm

Air to Retract Spring & Diaphragm

Rotary Spring & Diaphragm

Piston single w/spring. See

actuator instruction manual and

nameplate.

25, 50, 60, 68,

80, 100, 130

30, 30i G

34, 34i, 40, 40i I

45, 45i, 50, 50i J

46, 46i, 60, 60i, 70,

70i & 80-100

30, 30i G

34, 34i, 40, 40i I

45, 45i, 50, 50i J

46, 46i, 60, 60i, 70,

70i, 76, 76i & 80-100

20, 30, 33,

40, 60, 70

20

27, 75

GA 1.21

GA 1.31

GA 1.41

225 G

750 I

1200 K

225 G

750 I

16 C

32 D

54 Undefined

70 H

16 C

32 D

54 Undefined

70 H

10

25

54

Instruction Manual

D103176X012

Starting

Tuning Set

Undefined

Undefined

Undefined

Undefined Rotary

Undefined Rotary

Undefined SStem-Standard

Undefined

Undefined

G

Feedback Connection

SStem-Standard for travels

up to 4 inches. SStem-

Roller for longer travels

SStem-Standard

SStem-Standard

SStem-Standard

SStem-Standard

SStem-Standard

SStem-Standard

Rotary

Setting Protection

Field Communicator Setup & Diag > Detailed Setup > Protection (1-2-2)

Some setup parameters may require changing the protection with the Field Communicator.

Two levels of protection are available:

D None—Neither setup nor calibration is protected. Allows changing calibration and setup parameters.

D Config & Calib—Both setup and calibration are protected. Prohibits changing calibration and protected setup

parameters.

12

Instruction Manual

D103176X012

Detailed Setup and Calibration

July 2020

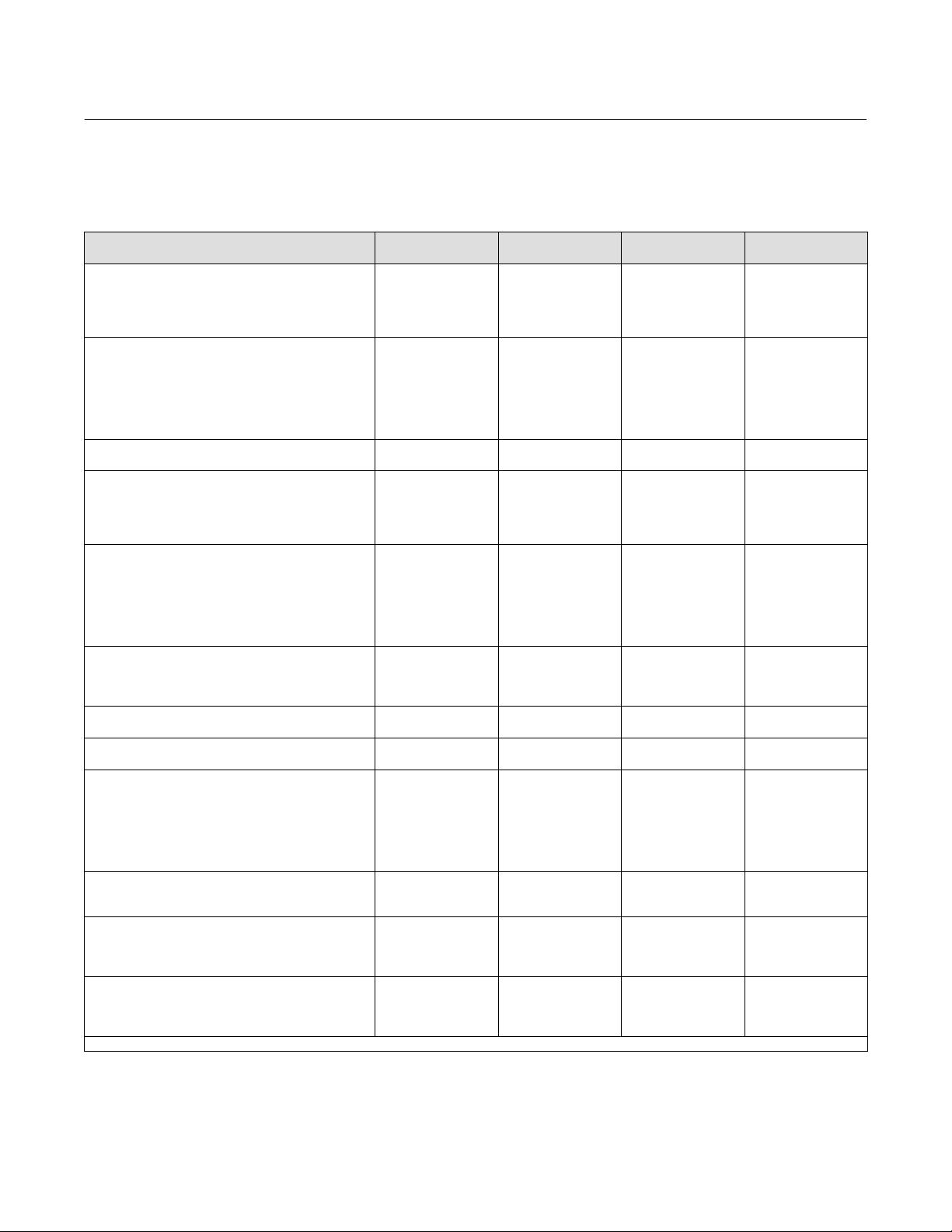

Table 2‐3 lists configurable parameters in the instrument and the requirements for modifying these parameters, in

terms of instrument mode and protection.

Table 2‐3. Conditions for Modifying FIELDVUE DVC2000 Digital Valve Controller Parameters

Parameters

Control Mode

Restart Ctrl Mode

Burst Mode Enable

Burst Mode Command

Protection

HART Tag

Message

Description

Date

Valve Serial Num

Inst Serial Num

Polling Address

Max Supply Pressure

Zero Ctrl Signal

Analog In Units

Input Range High

Input Range Low

Pressure Units

Temp Units

Tuning Set

Prop Gain

Velocity Gain

MLFB Gain

Input Char

Define Custom Char

Set Pt Filter Time

Tvl Limit High

Tvl Limit Low

Tvl Cutoff High

Tvl Cutoff Low

Min Opening Time

Min Closing Time

Integral Gain

Integral Deadband

Tvl Hi/Lo Enab

Tvl HH/LL Enab

Tvl Alert Hi Pt

Tvl Alert Lo Pt

Tvl Alert HiHi Pt

Tvl Alert LoLo Pt

Tvl Alrt DB

Tvl Dev Alrt Enab

Tvl Dev Alrt Pt

Tvl Dev Time

Cycl Cnt Alrt Enab

Cycl Count Alrt Pt

Cycl Count DB

Cycl Count

Tvl Acum Alrt Enab

Tvl Acum Alrt Pt

Tvl Acum DB

Tvl Acum

n—indicates parameter may be modified for instrument mode and protection shown.

In Service/

Config Protected

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

-Continued-

In Service/

Config Unprotected

- - -

- - -

n

- - -

n

n

n

n

n

n

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

n

n

n

n

n

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

Out of Service/

Config Protected

n

- - -

n

- - -

n

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

n

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

Out of Service/

Config Unprotected

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

13

Detailed Setup and Calibration

July 2020

Instruction Manual

D103176X012

Table 2‐3. Conditions for Modifying FIELDVUE DVC2000 Digital Valve Controller Parameters

Parameters

Drive Alert Enable n n n n

Flash ROM Fail

Ref Voltage Fail

Drive Current Fail

Critical NVM Fail

Temp Sensor Fail

Press Sensor Fail

Tvl Sensor Fail

n—indicates parameter may be modified for instrument mode and protection shown.

In Service/

Config Protected

- - -

- - -

- - -

- - -

- - -

- - -

- - -

In Service/

Config Unprotected

- - -

- - -

- - -

- - -

- - -

- - -

- - -

Out of Service/

Config Protected

- - -

- - -

- - -

- - -

- - -

- - -

- - -

Out of Service/

Config Unprotected

n

n

n

n

n

n

n

To change an instrument's protection, press the Hot key on the Field Communicator display window and select

Protection or select Protection from the Detailed Setup menu. Select the desired level of protection. Follow the prompts

on the Field Communicator display to set the protection level.

General Information

Field Communicator Setup & Diag > Detailed Setup > General (1-2-3)

Follow the prompts on the Field Communicator to enter or view information in the following fields:

D HART Tag—Enter an up to 8 character HART tag for the instrument. The HART tag is the easiest way to distinguish

between instruments in a multi-instrument environment. Use the HART tag to label instruments electronically

according to the requirements of your application. The tag you assign is automatically displayed when the Field

Communicator establishes contact with the digital valve controller at power-up.

D Message—Enter any message with up to 32 characters. Message provides the most specific user-defined means for

identifying individual instruments in multi-instrument environments.

D Descriptor—Enter a descriptor for the application with up to 16 characters. The descriptor provides a longer

user-defined electronic label to assist with more specific instrument identification than is available with the HART

tag.

D Date—Enter a date with the format MM/DD/YY. Date is a user-defined variable that provides a place to save the date

of the last revision of configuration or calibration information.

D Valve Serial Num—Enter the serial number for the valve in the application with up to 12 characters.

D Inst Serial Num—Enter the serial number on the instrument nameplate, up to 12 characters.

D Polling Address—If the digital valve controller is used in point-to-point operation, the Polling Address is 0. When

several devices are connected in the same loop, such as for split ranging, each device must be assigned a unique

polling address. The Polling Address is set to a value between 0 and 15. To change the polling address the

instrument must be Out Of Service.

For the Field Communicator to be able to communicate with a device whose polling address is not 0, it must be

configured to automatically search for all or specific connected devices.

D LUI Language—Select the language to be displayed on the local user interface; English, French, German, Italian,

Spanish, Chinese and Japanese.

14

Instruction Manual

D103176X012

Detailed Setup and Calibration

July 2020

Measured Variable Units and Ranges

Field Communicator Setup & Diag > Detailed Setup > Measured Var (1-2-4)

Follow the prompts on the Field Communicator to define the following measured variables units and ranges:

D Analog In Units—Permits defining the Analog Input Units in mA or percent of 4-20 mA range.

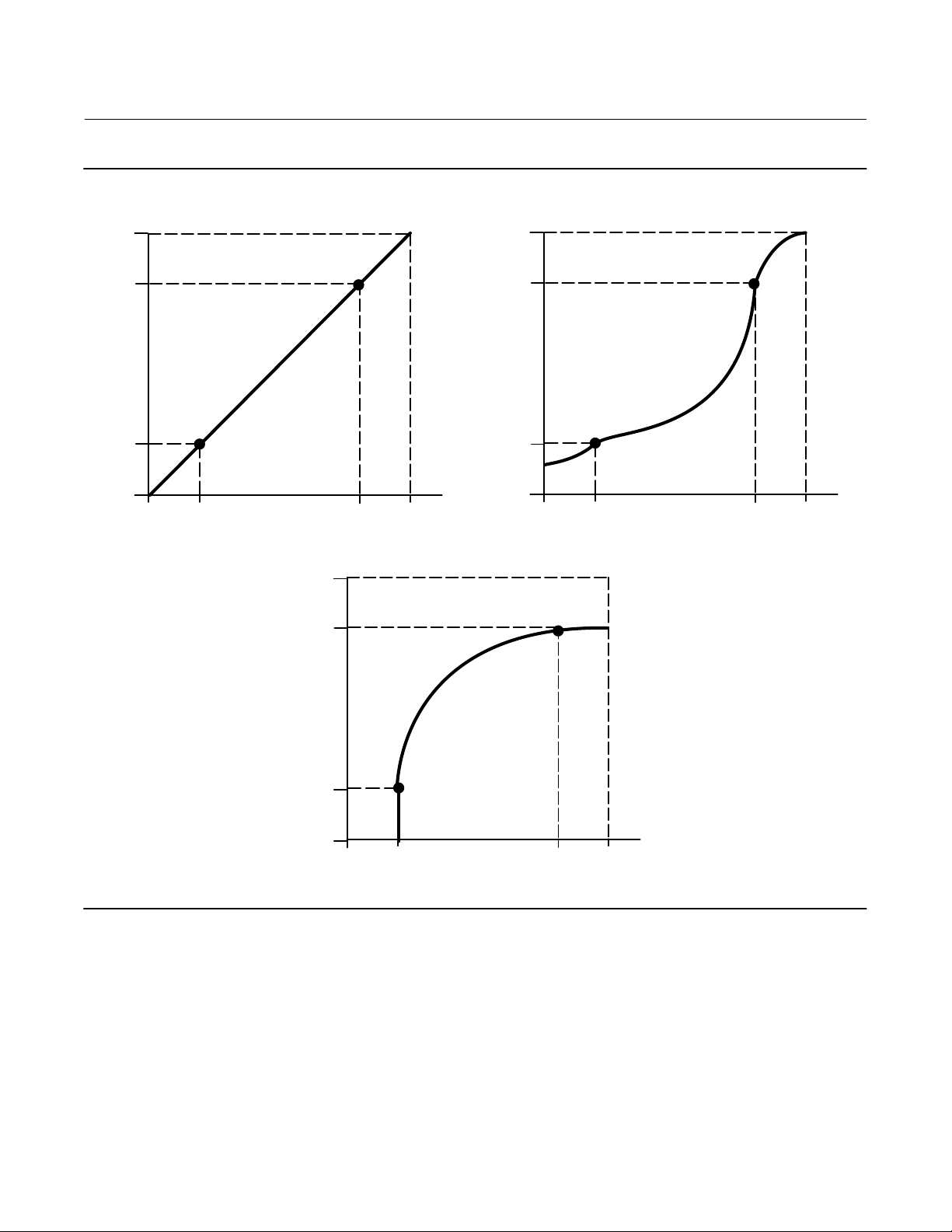

D Input Range Hi—Permits setting the Input Range High value. Input Range High should correspond to Travel Range

High, if the Zero Control Signal is configured as closed. If the Zero Control Signal is configured as open, Input Range

High corresponds to Travel Range Low. See figure 2‐1.

D Input Range Lo—Permits setting the Input Range Low value. Input Range Low should correspond to Travel Range

Low, if the Zero Control Signal is configured as closed. If the Zero Control Signal is configured as open, Input Range

Low corresponds to Travel Range High. See figure 2‐1.

D Pressure Units—Defines the output and supply pressure units in either psi, bar, or kPa.

D LUI Pressure Units—Enter the pressure units displayed on the local user interface; psi, bar, or kPa.

D Temp Units—Degrees Fahrenheit or Celsius. The temperature measured is from a sensor mounted on the digital

valve controller's printed wiring board.

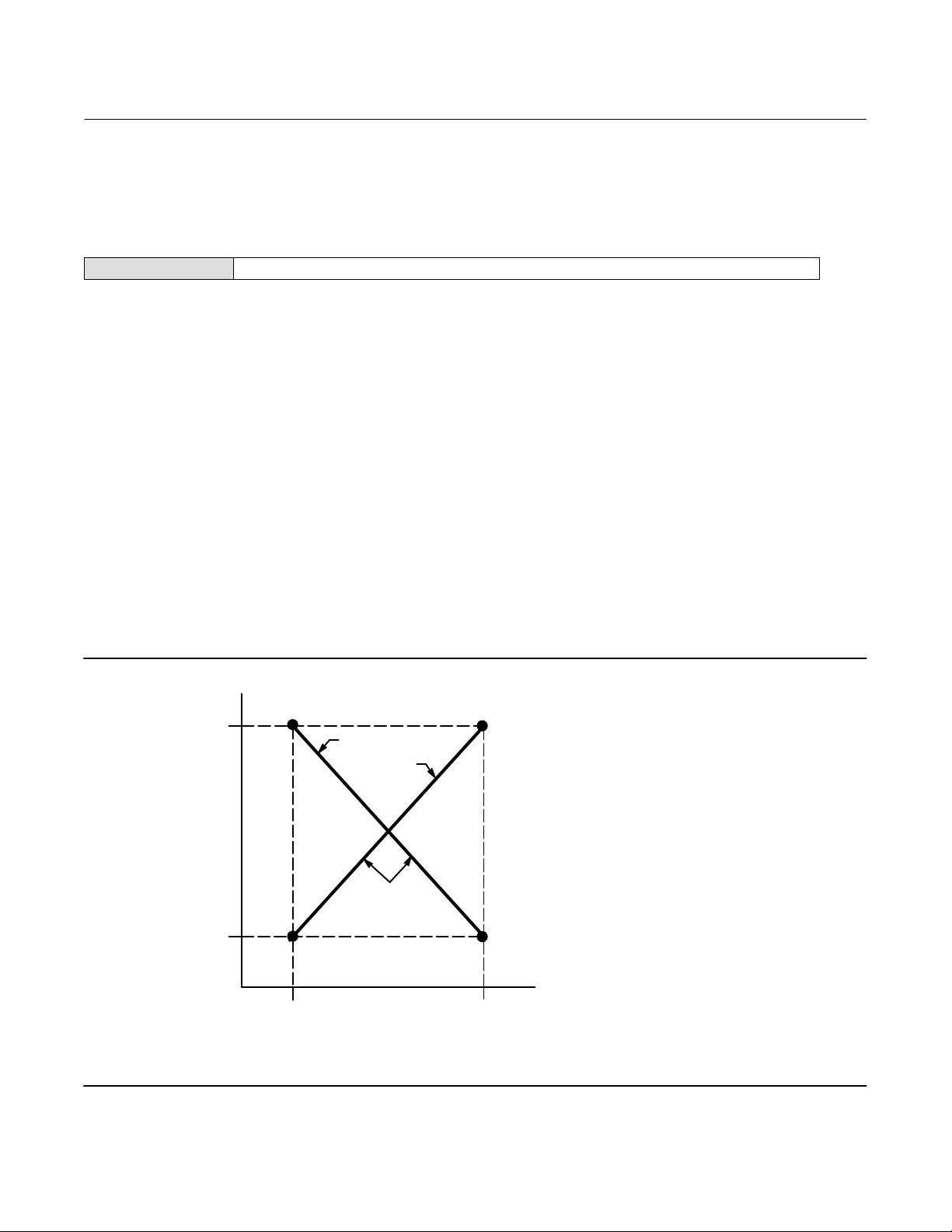

Figure 2‐1. Calibrated Travel to Analog Input Relationship

TRAVEL

A6531-1

RANGE

HIGH

CALIBRATED TRAVEL, %

TRAVEL

RANGE

LOW

INPUT RANGE

LOW

NOTE:

ZCS = ZERO CONTROL SIGNAL

ZCS = OPEN

ZCS = CLOSED

THE SHAPE OF

THESE LINES DEPENDS ON

THE INPUT CHARACTERISTICS

LINEAR CHARACTERISTIC SHOWN

ANALOG INPUT

MA OR % OF 4-20 MA

INPUT RANGE

HIGH

15

Detailed Setup and Calibration

July 2020

Instruction Manual

D103176X012

Actuator and Valve Information

Field Communicator Setup & Diag > Detailed Setup > Actuator & Valve (1-2-5)

Follow the prompts on the Field Communicator to edit or view information in the following fields:

D Max Supply Press—Enter the maximum supply pressure in psi, bar, or kPa, depending on what was selected for

pressure units.

Note

If the actual measured pressure exceeds this setting by 25%, the Output A pressure measurement will not be displayed.

D Actuator Style—Enter the actuator style, spring and diaphragm, piston double-acting without spring, piston

single-acting with spring, or piston double-acting with spring.

D Valve Style—Enter the valve style, rotary or sliding-stem

D Zero Control Signal—Identifies whether the valve is fully open or fully closed when the input is 0%. If you are unsure

how to set this parameter, disconnect the current source to the instrument. The resulting valve travel is the Zero

Control Signal. (With direct-acting digital valve controllers, disconnecting the current source is the same as setting

the output pressure to zero.)

Setting Response

Field Communicator Setup & Diag > Detailed Setup > Response Control (1-2-6)

Follow the prompts on the Field Communicator to configure the following response control parameters:

WARNING

Changes to the tuning set may cause the valve/actuator assembly to stroke. To avoid personal injury and property damage

caused by moving parts, keep hands, tools, and other objects away from the valve/actuator assembly.

D Tuning Set—There are eleven tuning sets to choose from. Each tuning set provides a preselected value for the digital

valve controller gain settings. Tuning set C provides the slowest response and M provides the fastest response.

Table 2‐4 lists the proportional gain, velocity gain, and minor loop feedback gain values for preselected tuning sets.

16

Instruction Manual

D103176X012

Detailed Setup and Calibration

July 2020

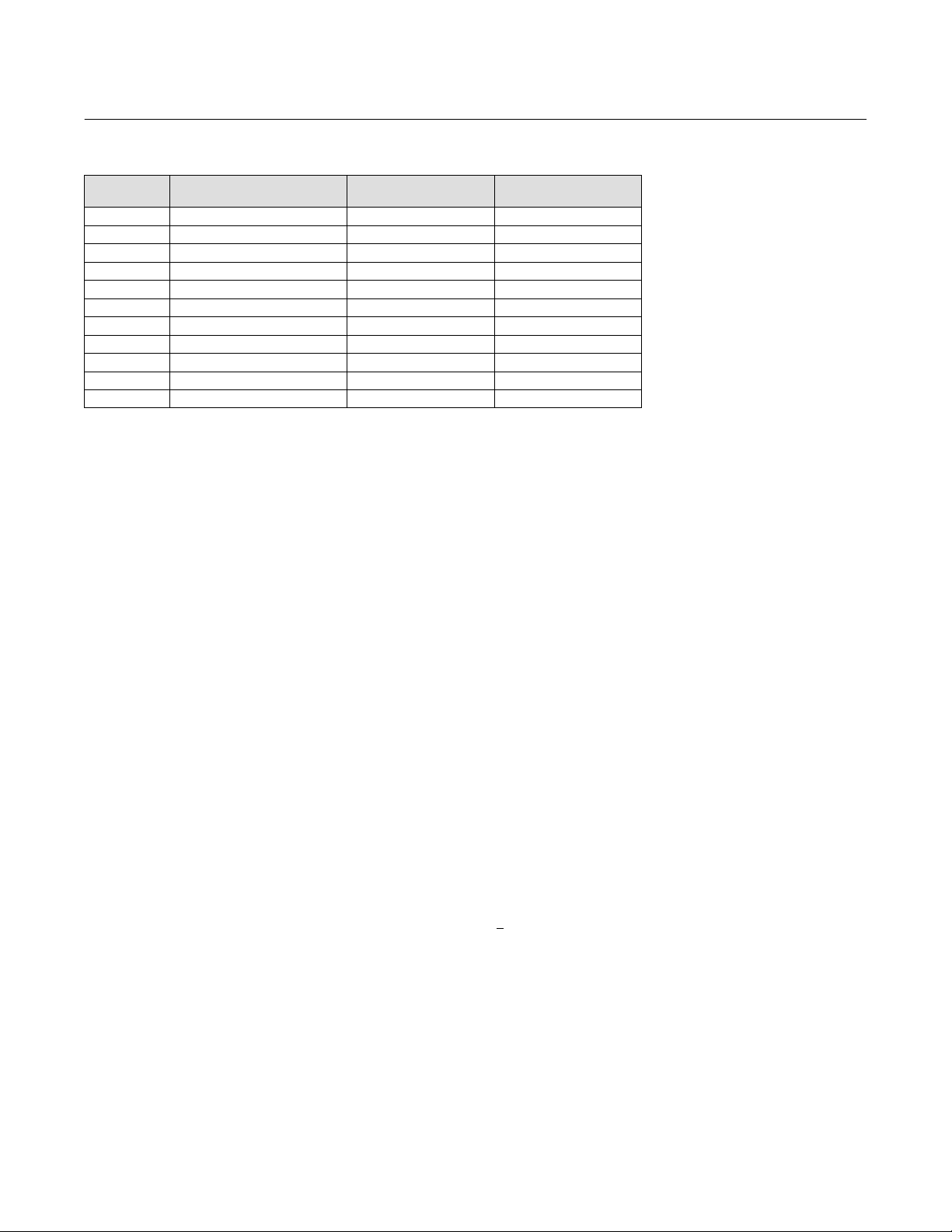

Table 2‐4. Gain Values for Preselected Turning Sets

Tuning Set Proportional Gain Velocity Gain

C 5 2 55

D 6 2 55

E 7 2 55

F 8 2 52

G 9 2 49

H 10 2 46

I 11 2 44

J 12 1 41

K 14 1 38

L 16 1 35

M 18 1 35

Minor Loop Feedback

Gain

D Damping Factor—If after selecting a tuning set the valve travel overshoot is excessive or unsatisfactory, the damping

factor allows you to either decrease damping to allow more overshoot, or increase damping to decrease the

overshoot.

D Expert Tuning Gains—With Expert Tuning, you can specify the proportional gain, velocity gain, and minor loop

feedback gain.

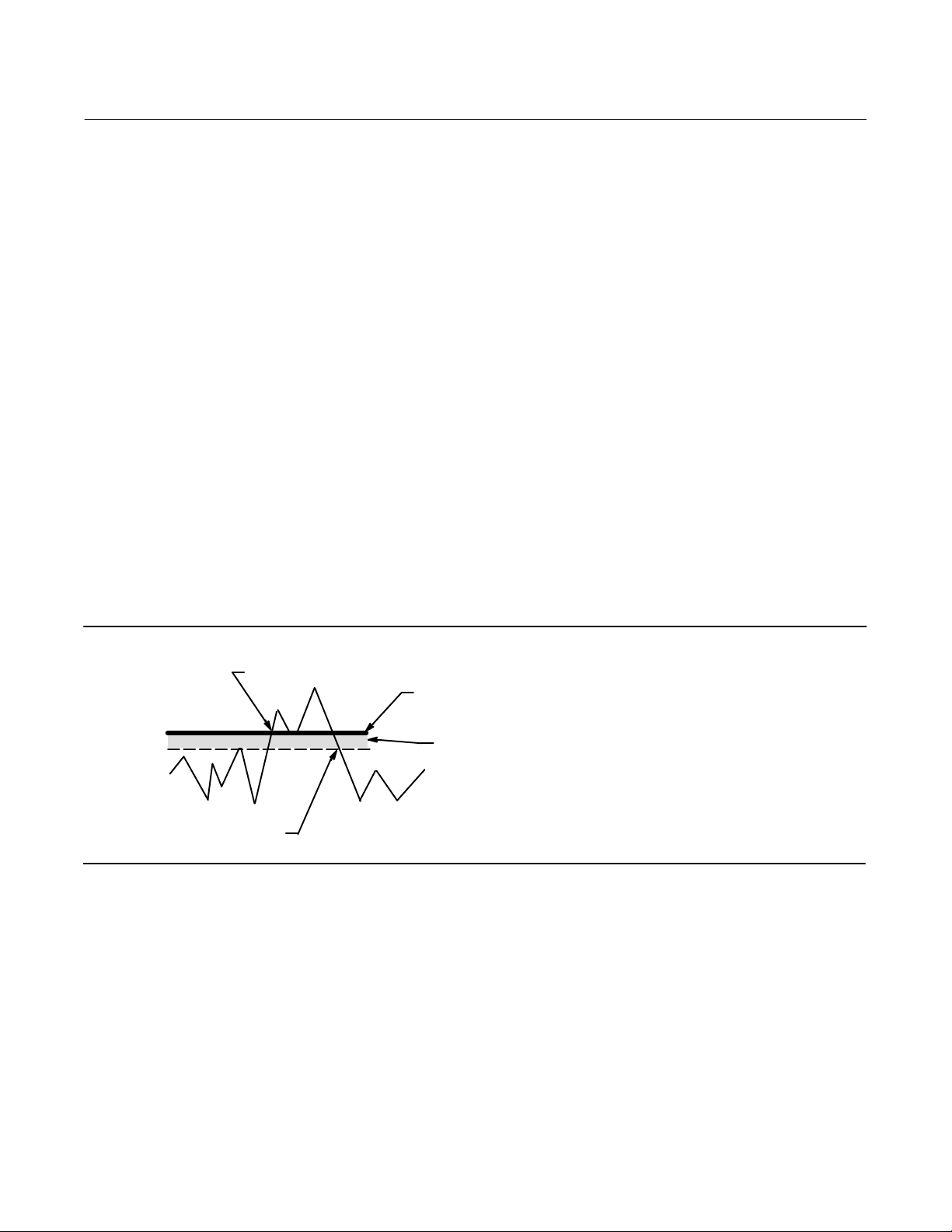

D Input Char—Defines the relationship between the travel target and ranged set point. Ranged set point is the input to

the characterization function. If the zero control signal equals closed, then a set point of 0% corresponds to a ranged

input of 0%. If the zero control signal equals open, a set point of 0% corresponds to a ranged input of 100%. Travel

target is the output from the characterization function.

You can select from the three fixed input characteristics shown in figure 2‐2 or you can select a custom

characteristic. Figure 2‐2 shows the relationship between the travel target and ranged set point for the fixed input

characteristics, assuming the Zero Control Signal is configured as closed.

You can specify 21 points on a custom characteristic curve. Each point defines a travel target, in % of ranged travel,

for a corresponding set point, in % of ranged set point. Set point values range from -6.25% to 106.25%. Before

modification, the custom characteristic is linear.

With input characterization you can modify the overall characteristic of the valve and instrument combination.

Selecting an equal percentage, quick opening, or custom (other than the default of linear) input characteristic

modifies the overall valve and instrument characteristic. However, if you select the linear input characteristic, the

overall valve and instrument characteristic is the characteristic of the valve, which is determined by the valve trim

(i.e., the plug or cage).

D Custom Char Table—To define a custom input characteristic, s

elect Custom Char Table. Select the point you wish to

define (1 to 21), then enter the desired set point value. Press Enter then enter the desired travel target for the

corresponding set point. When finished, select point 0 to return to the Response Control menu.

17

Detailed Setup and Calibration

July 2020

Instruction Manual

D103176X012

Figure 2‐2. Travel Target Versus Ranged Set Point, for Various Input Characteristics (Zero Control Signal = Closed)

125

100

Travel Target, %

0

-25

−25

Ranged Set Point, %

0 125

100

Input Characteristic = Linear

125

100

125

100

Travel Target, %

0

-25

−25

Ranged Set Point, %

0 125

100

Input Characteristic = Equal Percentage

Travel Target, %

0

A6535-1

-25

−25

Input Characteristic = Quick Opening

Ranged Set Point, %

0 125

100

D Setpt Filter Time—Time constant for the set point filter, in seconds. The set point filter slows the response of the

digital valve controller and is typically used with noisy or fast processes. The filter provides improved closed loop

process control. To disable the filter, set the time constant to 0 seconds.

D Limits and Cutoff

Travel Limit Hi—Defines the high limit for the travel in percent (%) of ranged travel. It is the maximum allowable

travel (in percent of ranged travel) for the valve. During operation, the travel target will not exceed this limit. When

a Travel Limit High is set, the Travel Cutoff High is deactivated, since only one of these parameters can be active.

Travel Limit High is deactivated by setting it to 125.0%.

18

Instruction Manual

D103176X012

Detailed Setup and Calibration

July 2020

Travel Limit Lo—Defines the low limit for the travel in percent (%) of ranged travel. It is the minimum allowable travel

(in percent of ranged travel) for the valve. During operation, the travel target will not exceed this limit. When a

Travel Limit Low is set, the Travel Cutoff Low is deactivated, since only one of these parameters can be active. Travel

Limit Low is deactivated by setting it to -25.0%.

Travel Cutoff Hi—Defines the high cutoff point for the travel in percent (%) of ranged travel. Above this cutoff, the

travel target is set to 123.0% of the ranged travel. When a Travel Cutoff High is set, the Travel Limit High is

deactivated, since only one of these parameters can be active. Travel Cutoff High is deactivated by setting it to

125.0%.

Travel Cutoff Lo—Defines the low cutoff point for the travel. Travel Cutoff Low can be used to ensure proper seat load

is applied to the valve. When below the travel cutoff low, the output is set to zero or to full supply pressure,

depending upon the zero control signal. A Travel Cutoff Low of 0.5% is recommended to help ensure maximum

shutoff seat loading.

When a Travel Cutoff Low is set, the Travel Limit Low is deactivated, since only one of these parameters can be

active. Travel Cutoff Low is deactivated by setting it to -25.0%.

D Min Open/Close

Min Opening Time—Minimum Opening Time is configured in seconds and defines the minimum time for the travel to

increase the entire ranged travel. This rate is applied to any travel increases. A value of 0.0 seconds deactivates this

feature and allows the valve to stroke open as fast as possible. This parameter should be set to 0 in firmware 1, 2, 3,

and 4.

Min Closing Time—Minimum Closing Time is configured in seconds and defines the minimum time for the travel to

decrease the entire ranged travel. This rate is applied to any travel decreases. A value of 0.0 seconds deactivates this

feature and allows the valve to stroke closed as fast as possible. This parameter should be set to 0 in firmware 1, 2,

3, and 4.

D Integral Settings

Enab Int Control—Select Yes or No

Integral Gain—By setting this value to 0.0 the positioner integrator is disabled. Any other value will provide reset

action to improve static performance.

Integral Dead Zone—When the travel target and actual target deviate by less than this amount, the integrator is

automatically disabled. This prevents the positioner integrator from fighting with the process controller integrator

which may result in valve oscillation.

Setting Alerts

Field Communicator Setup & Diag > Detailed Setup > Alerts (1-2-7)

The following menus are available for configuring Alerts. Items on the menus may be changed with the instrument In

Service. Protection does not need to be removed (no need to set to None). Alerts are not processed when a Diagnostic

is in progress. Follow the prompts on the Field Communicator display to configure alerts.

Note

Alerts are not available with instrument level AC.

19

Detailed Setup and Calibration

July 2020

Instruction Manual

D103176X012

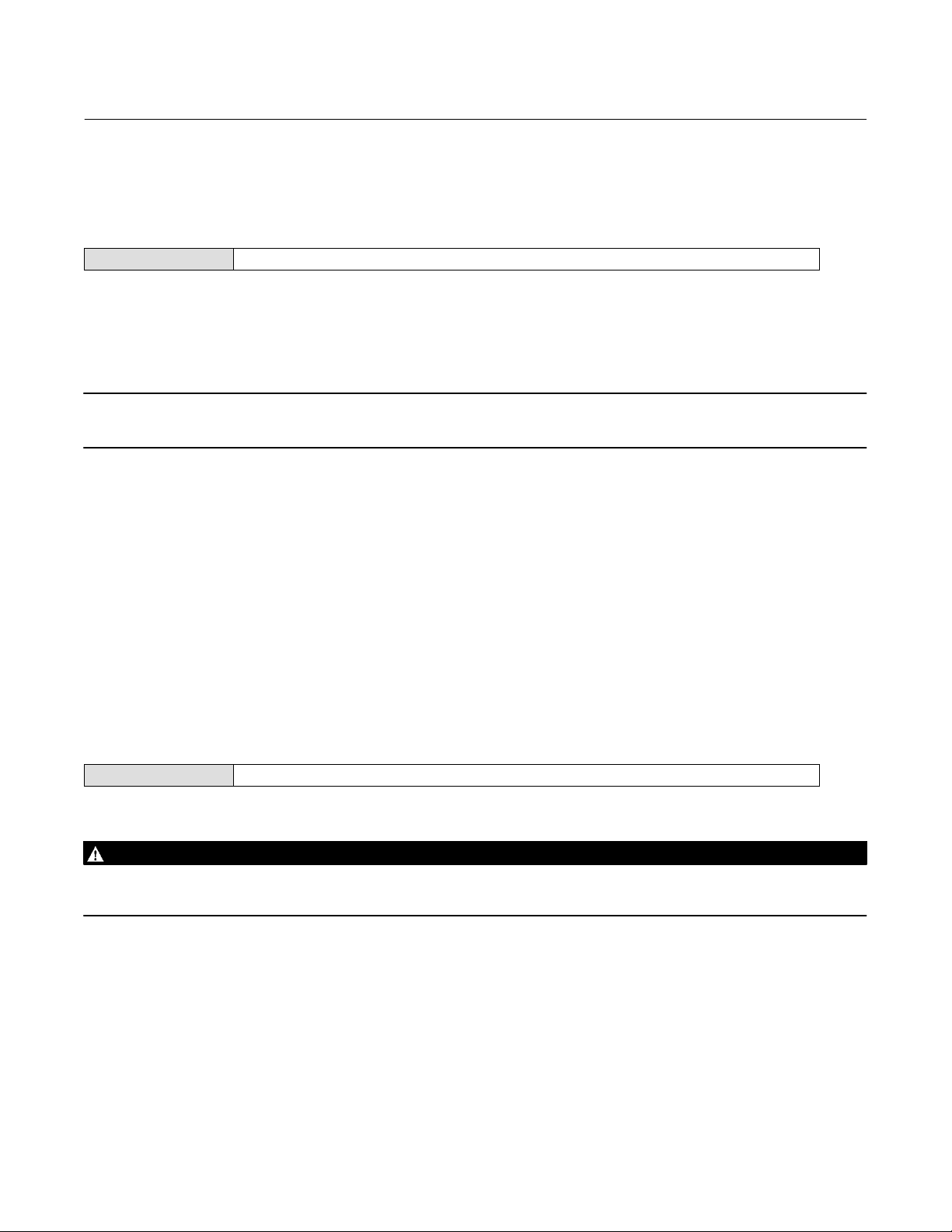

Setting Travel Alerts

Setting High, High-High, Low and Low-Low Alerts

Follow the prompts on the Field Communicator to set the following travel alerts:

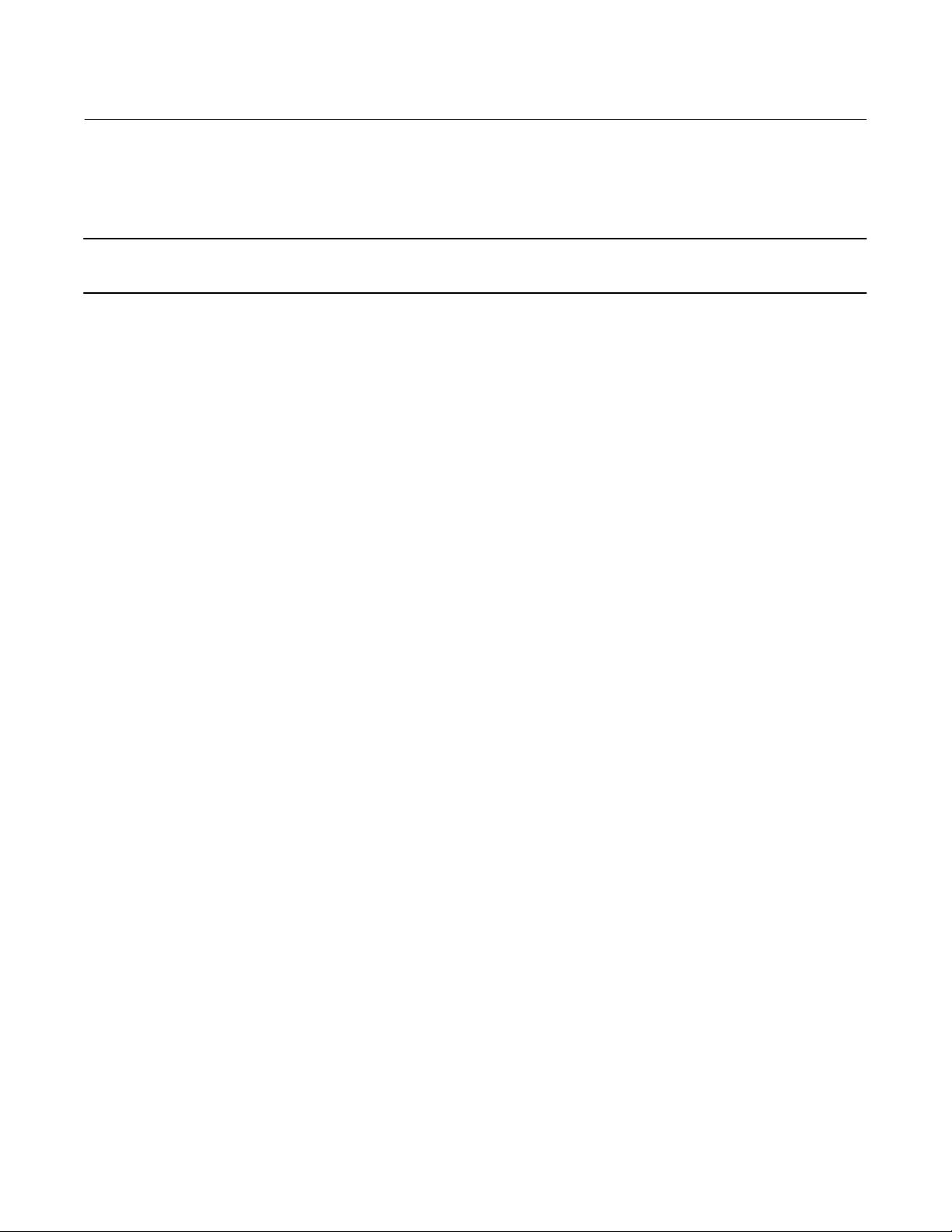

D Tvl Hi/Lo Enab—Yes or No. Travel Hi/Lo Enable activates checking of the ranged travel against the Travel Alert High

and Low Points. Travel Alert Hi is set if the ranged travel rises above the alert high point. Once the alert is set, the

ranged travel must fall below the alert high point by the Travel Alert Deadband before the alert is cleared. See figure

2‐3.

Travel Alert Lo is set if the ranged travel falls below the alert low point. Once the alert is set, the ranged travel must

rise above the alert low point by the Travel Alert Deadband before the alert is cleared. See figure 2‐3.

D Tvl HH/LL Enab—Yes or No. Travel HH/LL Enable activates checking of the ranged travel against the Travel Alert

High-High and Low-Low Points. Travel Alert Hi Hi is set if the ranged travel rises above the alert high-high point.

Once the alert is set, the ranged travel must fall below the alert high-high point by the Travel Alert Deadband before

the alert is cleared. See figure 2‐3.

Travel Alert Lo Lo is set if the ranged travel falls below the alert low-low point. Once the alert is set, the ranged travel

must rise above the alert low-low point by the Travel Alert Deadband before the alert is cleared. See figure 2‐3.

Figure 2‐3. Travel Alert Deadband

ALERT IS SET

TRAVEL ALERT

HIGH POINT

TRAVEL ALERT

DEADBAND

A6532

ALERT IS CLEARED

D Tvl Alert Hi Pt—Travel Alert High Point is the value of the travel, in percent (%) of ranged travel, which, when

exceeded, sets the Travel Alert High alert.

D Tvl Alert Lo Pt—Travel Alert Low Point is the value of the travel, in percent (%) of ranged travel, which, when

exceeded, sets the Travel Alert Low alert.

D Tvl Alert Hi Hi Pt—Travel Alert High-High Point is the value of the travel, in percent (%) of ranged travel, which, when

exceeded, sets the Travel Alert Hi Hi alert.

D Tvl Alert Lo Lo Pt—Travel Alert Low-Low Point is the value of the travel, in percent (%) of ranged travel, which, when

exceeded, sets the Travel Alert Lo Lo alert.

20

Instruction Manual

D103176X012

Detailed Setup and Calibration

July 2020

D Tvl Alrt DB—Travel Alert Deadband is the travel, in percent (%) of ranged travel, required to clear a travel alert, once it

has been set. The deadband applies to both Travel Alert Hi/Lo and Travel Alert Hi Hi/Lo Lo. See figure 2‐3.

Note

The Travel Alert Deadband applies to the Travel Deviation as well as Travel Alert Hi/Lo and Travel Alert Hi Hi/Lo Lo.

Setting Travel Deviation Alert

Follow the prompts on the Field Communicator to set the following travel deviation alerts:

D Tvl Dev Alrt Enab—Yes or No. When enabled, checks the difference between the travel target and the actual travel. If

the difference exceeds the Travel Deviation Alert Point for more than the Travel Deviation Time, the Travel

Deviation Alert is set. It remains set until the difference between the travel target and the actual travel is less than

the Travel Deviation Alert Point minus the Travel Alert Deadband.

D Tvl Dev Alrt Pt—Travel Deviation Alert Point is the alert point for the difference, expressed in percent (%), between

the travel target and the actual travel. When the difference exceeds the alert point for more than the Travel

Deviation Time, the Travel Deviation Alert is set.

D Tvl Dev Time—Travel Deviation Time is the time, in seconds, that the travel deviation must exceed the Travel

Deviation Alert Point before the alert is set.

Setting Travel Accumulation Alert

Follow the prompts on the Field Communicator to set the following travel accumulation alerts:

D Tvl Acum Alrt Enab—Yes or No. Travel Accumulator Alert Enable activates checking of the difference between the

Travel Accumulator value and the Travel Accumulator Alert Point. The Travel Accumulator Alert is set when the

Travel Accumulator value exceeds the Travel Accumulator Alert Point. It is cleared after you reset the Travel

Accumulator to a value less than the alert point.

D Tvl Accum Alrt Pt—Travel Accumulator Alert Point is the value of the Travel Accumulator, in percent (%) of ranged

travel, which, when exceeded, sets the Travel Accumulator Alert.

D Tvl Accum DB—Travel Accumulator Deadband is the area around the travel reference point, in percent (%) of ranged

travel, that was established at the last increment of the accumulator. This area must be exceeded before a change

in travel can be accumulated. See figure 2‐4.

D Tvl Accum—Travel Accumulator records the total change in travel, in percent (%) of ranged travel, since the

accumulator was last cleared. The value of the Travel Accumulator increments when the magnitude of the change

exceeds the Travel Accumulator Dead- band. See figure 2‐4. You can reset the Travel Accumulator by configuring it

to zero.

21

Detailed Setup and Calibration

July 2020

Figure 2‐4. Travel Accumulator Deadband (set at 10%)

DEADBAND EXCEEDED,

NEW REFERENCE POINT

ESTABLISHED

Instruction Manual

D103176X012

DEADBAND REFERENCE POINT

DEADBAND (+/- 5%)

A6534

THIS AMOUNT OF CHANGE IS

ADDED TO THE TRAVEL

ACCUMULATOR.

Cycle Counter Alert

Follow the prompts on the Field Communicator to set the following cycle counter alerts:

D Cycl Cnt Alrt Enab—Yes or No. Cycle Counter Alert Enable activates checking of the difference between the Cycle

Counter and the Cycle Counter Alert point. The Cycle Counter Alert is set when the value exceeds the Cycle Counter

Alert point. It is cleared after you reset the Cycle Counter to a value less than the alert point.

D Cycl Cnt Alrt Pt—Cycle Counter Alert Point is the value of the Cycle Counter, in cycles, which, when exceeded, sets the

Cycle Counter Alert.

D Cycle Count DB—Cycle Counter Deadband is the area around the travel reference point, in percent (%) of ranged

travel, that was established at the last increment of the Cycle Counter. This area must be exceeded before a change

in travel direction can be counted as a cycle. See figure 2‐5.

Figure 2‐5. Cycle Counter Deadband (set at 10%)

DEADBAND EXCEEDED, AND DIRECTION

CHANGED, NEW REFERENCE POINT

ESTABLISHED

22

A6533-1

POINT AT WHICH

CYCLE IS COUNTED.

DEADBAND REFERENCE POINT

DEADBAND (+/- 5%)

Instruction Manual

D103176X012

D Cycle Count—Cycle Counter records the number of times the travel changes direction. The change in direction must

occur after the deadband has been exceeded before it can be counted as a cycle. See figure 2‐5. You can reset the

Cycle Counter by configuring it as zero.

Detailed Setup and Calibration

July 2020

Other Alerts

Follow the prompts on the Field Communicator to configure Drive Alert Enable:

D Drive Alert Enab—Yes or No. Drive Alert Enable activates checking of the relationship between the Drive Signal and

the calibrated travel. If one of the following conditions exists for more than 20 seconds, the Drive Alert is set.

For the case where Zero Control Signal is defined as closed:

Drive Signal < 10% and Calibrated Travel > 3%

Drive Signal > 90% and Calibrated Travel < 97%

For the case where Zero Control Signal is defined as open:

Drive Signal < 10% and Calibrated Travel < 97%

Drive Signal > 90% and Calibrated Travel > 3%

Alert Record

The alert record can store up to 20 alerts from any of the enabled alert groups: Valve Alerts, Failure Alerts, or

Miscellaneous Alerts. Starting from a cleared database, the first 20 alerts that become active will be stored in memory.

Follow the prompts on the Field Communicator to set or display the following:

D Display Record—Displays all recorded alerts and the date and time the alerts were recorded.

D Clear Record—Clears the alert record. To clear the alert record, all alerts in enabled groups must be inactive.

D Inst Date & Time—Permits setting the instrument clock. When alerts are stored in the alert record, the date and time

(obtained from the instrument clock) that they were stored is also stored in the record. The instrument clock uses a

24-hour format. Enter the date and time in the form: MM/DD/YYYY HH:MM:SS, where MM is two digits for the

month (1 through 12), DD is two digits for the day (1 through 31), and YYYY is four digits for the year (1980 through

2040), HH is two digits for the hour (00 to 23), MM is two digits for the minutes (00 to 59), and SS is two digits for

the seconds (00 through 59).

D Record Group Enab—Permits enabling one or more alert groups. Table 3‐2 lists the alerts included in each of the

groups. When any alert from an enabled group becomes active, active alerts in all enabled groups are stored.

23

Detailed Setup and Calibration

July 2020

Instruction Manual

D103176X012

Self Test Failures for Instrument Shutdown

Field Communicator Setup & Diag > Detailed Setup > Self Test Shutdown (1-2-8)

Upon shutdown, the instrument attempts to drive its output pressure to the zero current condition and no longer

executes its control function. In addition, the appropriate failure statuses are set. Once the problem that caused the

shutdown has been fixed, the instrument can be restarted by cycling the power or selecting Restart from the Mode

menu of the Field Communicator. Also see the Viewing Instrument Status section on page 35 for further details about

failures.

Follow the prompts on the Field Communicator display to determine the self test shutdown criteria from the

following:

D Done—Select this if you are done modifying the self test shutdown criteria.

D Flash ROM Fail—When enabled, the instrument shuts down whenever there is a failure associated with flash ROM

(read only memory).

D Temp Comp Fail—When enabled, the instrument shuts down whenever this is a failure associated with Temperature

Compensation.

D Ref Voltage Fail—When enabled, the instrument shuts down whenever there is a failure associated with the internal

voltage reference.

D Drive Current Fail—When enabled, the instrument shuts down whenever the drive current does not read as expected.

D NVM Fail—When enabled, the instrument shuts down whenever there is a failure associated with NVM (non-volatile

memory).

D Temp Sensor Fail—When enabled, the instrument shuts down whenever there is a failure associated with the internal

temperature sensor.

D Press Sensor Fail—When enabled, the instrument shuts down whenever there is a failure associated with the pressure

sensor.

D Travel Sensor Fail—When enabled, the instrument shuts down whenever there is a failure associated with the travel

sensor.

24

Loading...

Loading...