Instruction Manual

MCK-1185

March 2010

C831 Series Internal Valves

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion,

re and/or chemical contamination

causing property damage and personal

injury or death.

Fisher equipment must be installed,

operated, and maintained in accordance

with federal, state, and local codes and

Fisher instructions.

Only personnel trained in the proper

procedures, codes, standards, and

regulations of the applicable industrial

service should install and service

this equipment.

C831 Series

The internal valve must be closed except

during product transfer. A line break

downstream of a pump may not actuate

the excess ow valve. If any break

occurs in the system or if the excess

ow valve closes, the system should be

shut down immediately.

Introduction

Scope of Manual

This manual covers instructions for the C831 Series 2

and 3-inch Class 300 Raised Face Flange internal valves.

These valves are serialized for the service specied with

the order. The valves can be used on other compressed

gases, but the user should check with the factory to

make sure the valve materials are suitable for the

intended service.

Description

The valves are typically used on the inlets and outlets of

transport trucks and on large stationary storage tanks.

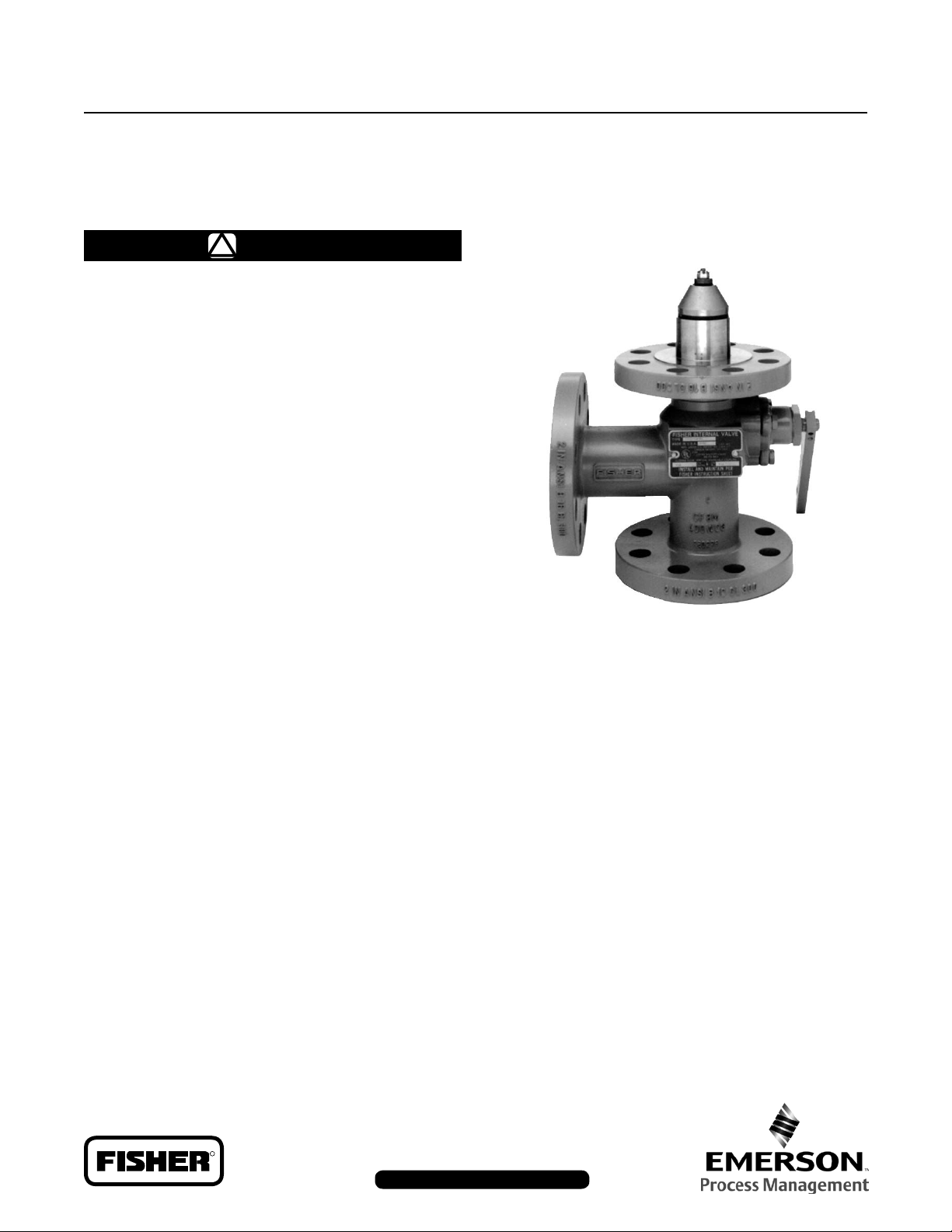

Figure 1. C831 Series

Specications

The Specications table lists specications for C831 Series

internal valves.

DOT Internal Self-Closing Stop Valve Requirement

—U.S. Department of Transportation (DOT) regulations

49CFR§178.337-8(a)(4) require each liquid or vapor

discharge outlet on cargo tanks (except for cargo tanks used

to transport chlorine, carbon dioxide, refrigerated liquid, and

certain cargo tanks certied prior to January 1, 1995) to be

tted with an internal self-closing stop valve. Fisher’s “C”

series internal valves comply with the internal self-closing

stop valve requirement under the DOT regulations.

D450090T012

R

www.FISHERregulators.com/lp

C831 Series

Specications

Body Size and End Connection Style

Inlet: 2 or 3-inch

Class 300 ANSI Raised Face Flanged

Outlet: 2 or 3-inch

Class 300 ANSI Raised Face Flanged

Number of Outlets

C831 Series: 2 (side and straight through)

Maximum Allowable Inlet Pressure

500 psig (34,5 bar) WOG

Excess Flow Springs

2-Inch Size: 85, 110 and 160 GPM

(322, 416, 605 l/min) water

3-Inch Size: 110, 145,175, 270, and 345 GPM

(416, 549, 662, 1022, 1306 l/min) water

Temperature Capabilities

-20° to 150°F (-29° to 66°C)

O.D AND THICKNESS TO SUIT CONTAINER

C

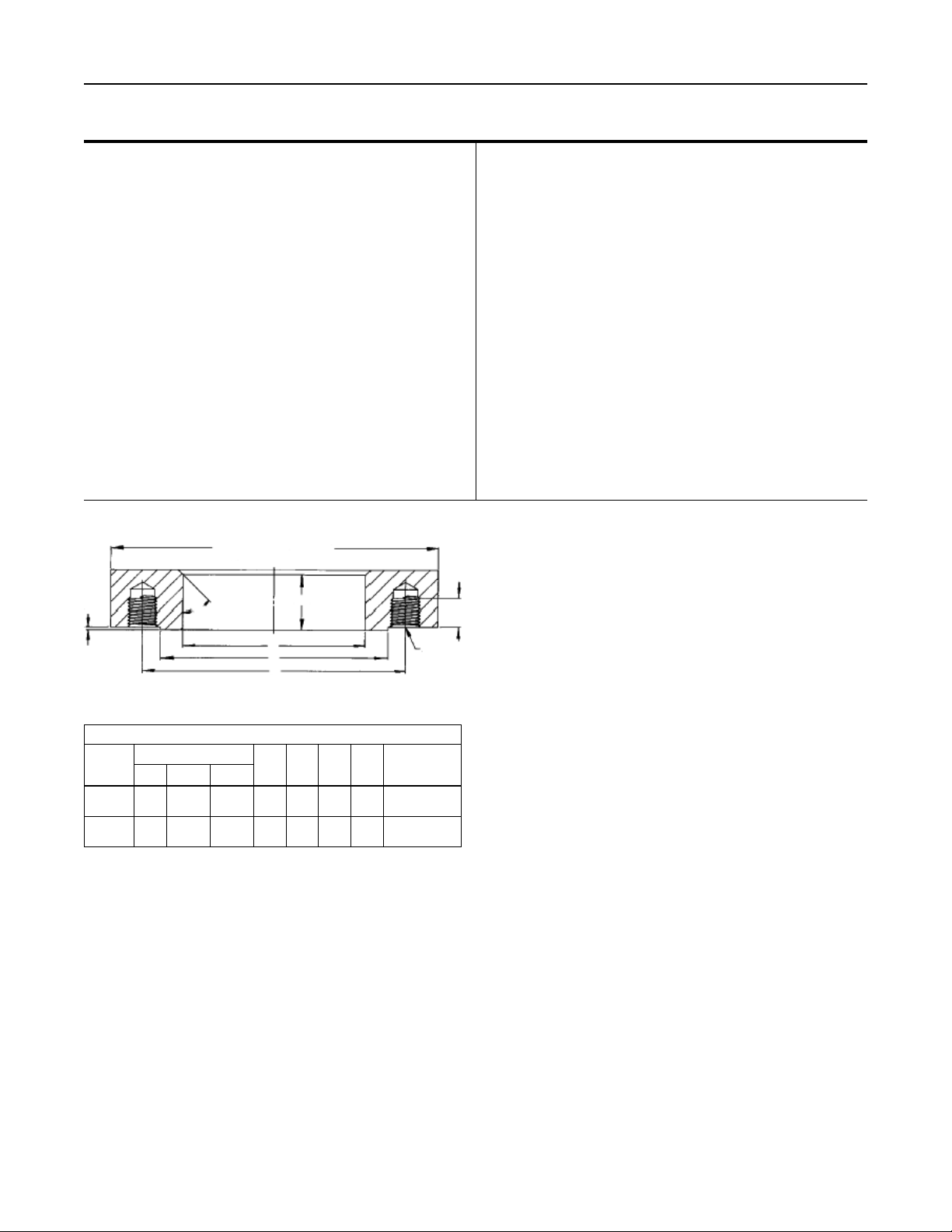

TANK CONNECTION FLANGES - DIMENSIONS ARE IN INCHES (mm)

300 LB

ANSI RF

FLANGE

2-inch

3-inch

A-BOLTING

DBC NO. Size

5.0

8

(127)

6.62

8

(168)

45°

SPECIFICATIONS

E

B

A

Figure 2

B RF C RF D E

5/8

3.62

(15,9)

(92)

3/4

5.75

(19,0)

(146)

D MAX

0.06

(1,5)

0.06

(1,5)

1.45

(36,8)

1.50

(38)

2.46

(62,5)

4.62

(117)

INCH (mm)

MATING

FLANGE O.D.

6.50 (165)

8.25 (210)

1 (25,4)

MINIMUM

3/4-IO UNC

Approximate Weight

2-Inch: 20 pounds (9 kg)

3-Inch: 32 pounds (14 kg)

Construction Materials

Stainless Steel: Lever, Cam, Disc Holder, Springs,

Hexagon Head Cap Screws, Cotter Pin, Stub Shaft,

Stem, Washers, Drive Screw, Plug Holder, Stop

Tube, Body, Gland, Web, Pins, Screws, Bolts, Nut

Washer, Spring Seat, Disc Retainer, Disc Holder,

and Retainer

Plated Steel: Nameplate, Drive Pin

Polyurethane: Rod Wiper

PTFE or Filled PTFE: Gland Packing, Liner Brushing,

Washer, Wear Plug

Nitrile (Standard Construction): Disc and O-Rings

Other Disc and O-Ring Trim Material Available

from Factory: TFE, Neoprene, Ethylene Propylene,

Viton, and Kalrez

Keep piping from the valve outlet to the pump full size and

as short as possible with a minimum number of bends.

Reduction in pipe size to suit smaller pump inlets should

be made as close to the pump as possible using forged

reducers (swage nipples) or venturi tapers rather than

bushings. This assures minimum ow resistance and

efcient pump operation.

The valves have a break off section below the inlet

ange which is intended to permit the lower valve body

to shear off in an accident, leaving the valve seat in the

tank. The break off section is designed for container

installations and will probably not provide shear

protection if the valve is installed in a pipeline.

A hydrostatic relief valve does not need to be installed

adjacent to the valve since the internal valve relieves

excessive line pressure into the tank.

Installation

Note

Installer must furnish 8 stud bolts,

8 ange nuts, and spiral wound gaskets

as these parts are not supplied with the

internal valves.

Coat both sides of the spiral wound gaskets with

Dow Corning #111 silicone grease or equivalent. An

appropriately sized tank ange, see Figure 2, must be

installed in the tank. The internal valve can then be

installed in the tank and outlet piping attached to the

internal valve.

2

Selectively Filling Manifolded Tanks

Fisher internal valves provide positive shutoff only in one

direction, from out of the tank to downstream of the valve.

The internal valves are designed to allow gas to ow into

a tank when the downstream line pressure exceeds tank

pressure. If you want to selectively ll one or more of the

other tanks in a tank manifold system, you must place a

positive shutoff valve downstream of the internal valve,

otherwise, all tanks will be lled at the same time and at

about the same rate.

C831 Series

Actuators

The remote operating control system for the valve is

extremely important, and it must be installed to conform

with the applicable codes. DOT MC331, for example,

most generally applies for trucks.

Fisher offers both cable controls and air cylinder

systems to operate the C831 Series internal valves. It

may also be possible to use cable controls from other

manufacturers or to fabricate a linkage mechanism.

Any control system requires thermal protection (fuse

links) at the valve, at the remote control point and, if

necessary, near the hose connections. The instruction

manuals for Fisher Controls actuator systems show how

to install the fuse links.

Installation instructions on Fisher Types P650, P163A,

and P164A cable controls, are in Form MCK-1083. Air

cylinder actuator installation is covered in Form

MCK-1137. Type P340 latch/remote release instructions

are on Form MCK-2048.

The operating linkage must allow the operating lever to

move from the fully closed position to within 2° of the fully

open position. The linkage should not apply strong force

to the lever past the fully open position or the valve could

be damaged.

CAUTION

The internal valve’s closing spring is

not designed to overcome drag in the

control linkage in order to close the valve.

Depending upon the control system

used, an external spring (such as Fisher

drawing number 1K4434) or positive

closing linkage may be needed. Be sure

the control system is installed to prevent

binding that could cause the valve to stick

in the open position.

Excess Flow Operation

Likewise, if the internal valve is installed on a stationary

tank or in the related downstream piping system, the

integral excess ow valve can provide protection against

an unintentional release of hazardous materials in the

event that a pump or piping attached directly to the

internal valve is sheared off before the rst valve, pump,

or tting downstream of the internal valve, provided that

the ow of product through the internal valve reaches the

rated ow specied by Fisher.

!

EXPLOSION HAZARD

Restrictions incorporated in the discharge

system of a bobtail truck or transport or of

a stationary tank (due to pumps, pipe and

hose length and dimensions, branching,

elbows, reductions in pipe diameter, or a

number of other in-line valves or ttings),

low operating pressure as a result of

ambient temperature, or a partially closed

valve downstream from the integral excess

ow valve, can restrict the rate of ow

through the internal valve below the level

necessary to actuate the integral excess

ow valve. Therefore, DO NOT USE the

excess ow function of the internal valve

for the purpose of providing protection

against the discharge of hazardous

materials in the event of a rupture of hose

or piping at a point in the discharge system

downstream from the rst valve, pump, or

tting downstream of the internal valve.

The internal valve is designed with an

internal bleed feature for equalization of

pressure. After the integral excess ow

valve closes, the leakage through the

bleed must be controlled or a hazard can

be created. For this reason the operator

must be familiar with the closure controls

for the internal valve and must close

the internal valve immediately after the

integral excess ow valve closes.

The internal valve contains an excess ow function, or

“integral excess ow valve”, that will close when the ow

exceeds the ow rating established by Fisher. Fisher’s

integral excess ow valve installed on a bobtail truck or

transport can provide protection against the discharge

of hazardous materials during an unloading operation of

a bobtail truck or transport in the event that a pump or

piping attached directly to the internal valve is sheared

off before the rst valve, pump, or tting downstream of

the internal valve, provided that the cargo tank pressure

produces a ow rate greater than the valve’s excess

ow rating.

Failure to follow this warning could result in

serious personal injury or property damage

from a re or explosion.

DOT Passive Shutdown Equipment Requirement

—DOT regulations 49CFR§173.315(n)(2) require certain

cargo tanks transporting propane, anhydrous ammonia

and other liqueed compressed gases to be equipped

with passive emergency discharge control equipment

that will automatically shut off the ow of product without

human intervention within 20 seconds of an unintentional

release caused by complete separation of a delivery

hose. The design for each passive shutdown system

3

Loading...

Loading...