Instruction Manual

D103678X012

Types BLE and BLX

July 2018

Types BLE and BLX Throttle Valves

SUMMARY

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Labelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

WARNING

!

Failure to follow these instructions or to

properly install and maintain this equipment

could result in an explosion and/or re

causing property damage and personal

injury or death.

Fisher™ throttle valve device must

be installed, operated and maintained

in accordance with federal, state and

local codes, rules and regulations and

Emerson Process Management Regulator

Technologies, Inc. (Emerson) instructions.

If the throttle valve vents gas or a leak

develops in the system, service to the unit

may be required. Failure to correct trouble

could result in a hazardous condition.

Call a gas service person to service the

unit. Only a qualied person must install or

service the device.

INTRODUCTION

Scope of the Manual

This manual provides installation, startup, maintenance and

parts ordering information for the Types BLE and BLX

throttle valves.

Figure 1. Type BLE-BLX Throttle Valve

The Type BLX is equipped with an integral slam-shut valve

Type OS2 used to cut off pressure ow in the case of

outlet overpressure.

The Type BLE version consists of:

• A body (Type E body) with removable orice, closed with

a cap also serving as a valve guide.

• A balanced valve plug, opened by uid ow,

linear characteristic.

• A valve plug/orice nitrile disc plug, removable and

tight shutoff.

• A valve plug guide with plastic rings and manual handwheel.

• The button serves as an opening indicator.

The Type BLX version, equipped with slam-shut Type OSE

with release relay Type OS2:

• A body (Type X body) including an inferior opening for

lodging the slam-shut.

The slam-shut includes:

• A valve plug/orice assembly with connecting part.

• A release relay Type OS2 including a mechanism box

(BM and a safety manometric box (BMS).

Product Description

The Type BLE throttle valve functions as a bypass on

transmission pressure reducing stations up to 100 bar.

The Types BLE and BLX are in conformity with the

Pressure Equipment Directive PED 2014/68/UE

and are classied in Category IV.

PS

18.65 100 16 25 40

Security Class

Types BLE and BLX

CHARACTERISTICS

Table 1. Types BLE and BLX Trottle Valve Characteristics

OPERATING PRESSURE

Body PS 100 bar max

Associated BMS* according to size PSD 10 to 100 bar

Maximum inlet pressure Pumax 100 bar

Type DS Differential strength**

OPERATING TEMPERATURE TS -30 / +71 °C

Body Size DN 25, 50, 80, 100

THROTTLE VALVE

Inlet Pressure Pu 100 bar max

Maximum Differential ∆P max 100 bar

FLUID

Groups 1 and 2 according to PED 2014/68/EU, gas 1 sts and 2nd family according to EN437or other gases (compressed air, nitrogen).

The gas must be non corrosive, clean (ltration on inlet size necessary) and dry.

* BMS: Safety Manometric Box

** Differential strength (according to BMS choice)

SLAM SHUT (TYPE BLX ONLY)

European EN Standard EN 14382

Operation Class A or B (see Figure 2)

Response Time ta < 1 s

Diaphragm

Accuracy

Set Pressure Range Wdu - Wdo 0.010 / 100 bar

Rearming Manual after rectication of fault

Travel Indicator On mechanism box

Bellows

Piston 5

AG

Table 2. Flow Coefcients

DN 25 50 80 100

Qf 230 970 2150 3367

Cg 450 1880 4170 6500

C1 35

Materials

Body Steel

Bonnet Steel

Screw holder Bronze

Orice Stainless steel

Valve plug Steel

Disc plug Nitrile

Connections

Inlet / Outlet Class 600B (ANSI 600 RF)

Class 300B (ANSI 300 RF)

Class 150B (ANSI 150 RF)

Other connections available

(contact factory)

PN 16 B, 25 B, 40 B

2.5

B69a

B69b

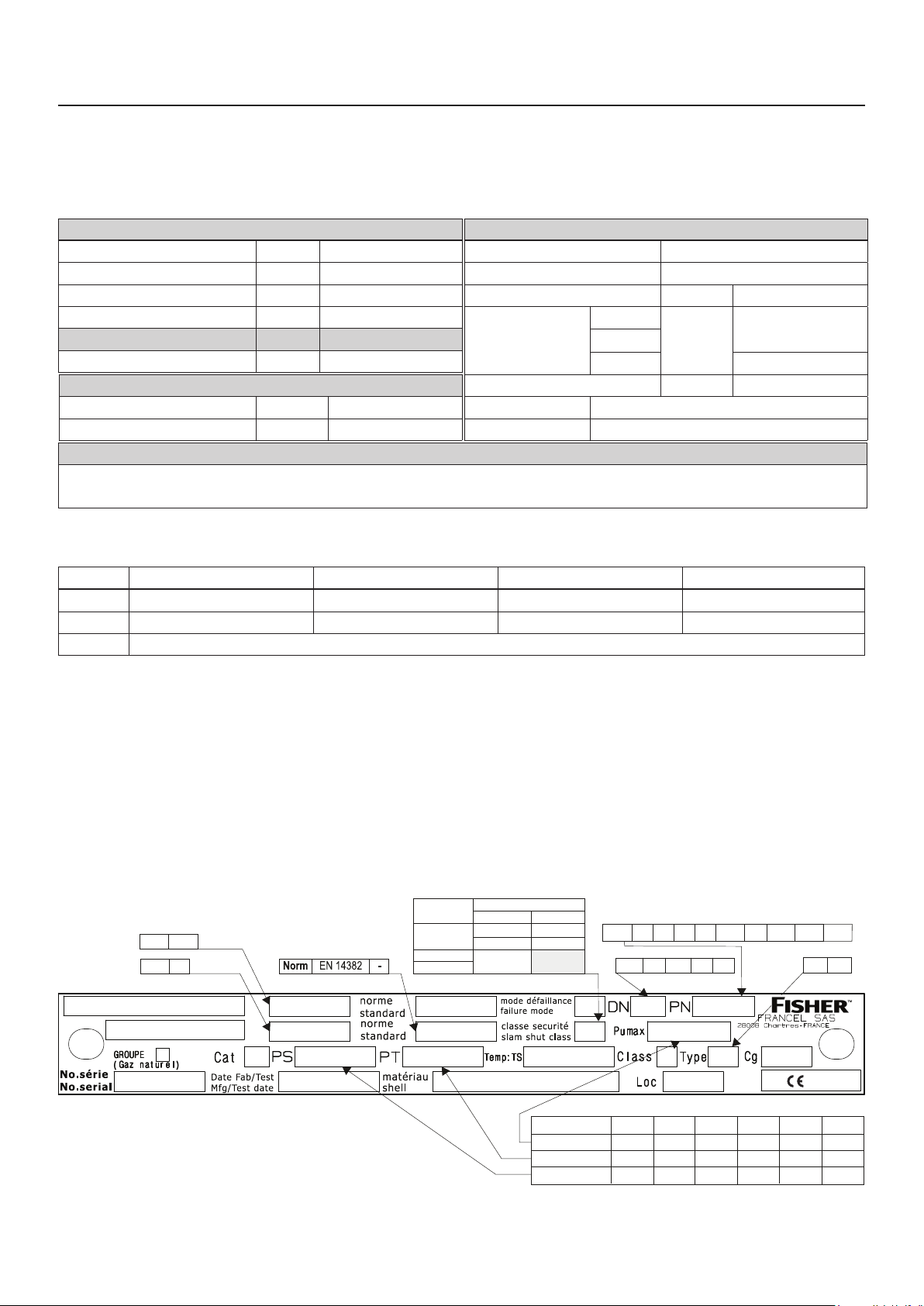

LABELLING

BLE

OS2

VANNE/VALVE

SECURITE/SLAM-SHUT

2

BMS setting

BLX

-

1

IV

DD MM YEAR

bar

Max only

Min only

Max-Min

- -

AB

BMS 027/017 BMS 162

BMS 236/315 BMS 071

All BMS

types

-30/+71 °C

A352LCC+A350LF2

Rating

16B

25B 40B

DN 25 50 80

150 150B 300 300B 600B

100

bar

-

600J

IS

0062

DS

150 300 600 16 25 40Rating

Pumax 18.650 100 16 25 40

PT

32 79 158 26 40 63

Figure 2. Label for Types BLE and BLX Trottle Valve

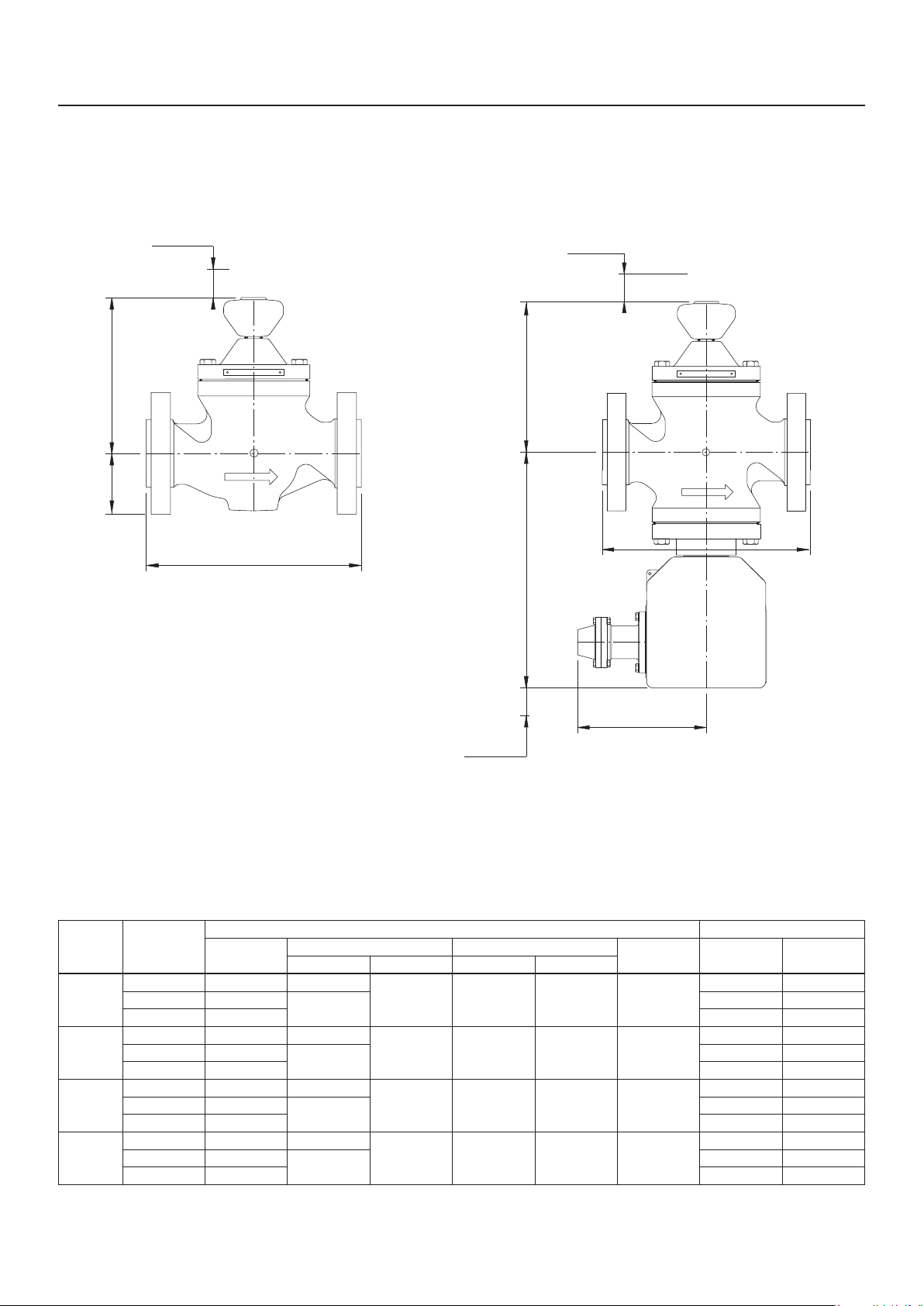

DIMENSIONS AND WEIGHTS

B

A

C

Removal

Types BLE and BLX

B73a

Removal

C

B

A

C

B

Removal

A

DN CLASS

150 185 54

25

50

80

100

300 197

600 210 14 22

150 254 76

300 267

600 287 26.5 40

150 298 95

300 318

600 337 51 65

150 352

300 368

600 394 96 131

220

Removal

Figure 3. Types BLE and BLX Trottle Valve Dimensions

Table 3. Types BLE and BLX Trottle Valve Dimensions and Weights

DIMENSIONS TYPES BLE (WITHOUT SLAM-SHUT) AND BLX (WITH SLAM-SHUT) WEIGHT (kg)

A

(nish B)

BLE BLX BLE BLX

B C

62

83

105

137

315 183 196 55

330 196 213 75

361 223 241 95

410 267 289 120

Removal BLE BLX

12 20

13 21

22.5 36

24.5 38

43 57

49 63

80 115

92 127

B73b

B74

3

Types BLE and BLX

OPERATION

Type BLE or BLX

The Type BLE throttle valve is a balanced plug type, opened

by pressure ow.

The opening control is manually performed by a torque

handwheel (approx. 4 N

(see Table 4).

Tight shutoff is achieved by a nitrile disc plug situated on the

valve plug. The disc plug and orice are easily replaced.

The opening control is progressive to start and then linear.

In closed position, an O-ring situated below the handwheel

protects the control screw for exterior corrosion.

A rotation of 1/8 turn after contact with the valve plug / orice

is sufcient to assure tight shutoff.

Slam-Shut (Type BLX)

The pressure of the zone to be protected (in general the

pipeline, outlet side of the regulator and after the slam-shut)

reacts on the safety manometric box (BMS).

•m). 1 handwheel turn = 2 mm travel

If the pressure rises above the set range, the release relay

releases the valve plug.

Due to the action of the closing spring and the uid (trying to

close), the valve plug closes on the orice.

The gas ow is obstructed until the fault has been corrected

and the mechanism box manually rearmed.

Equal pressure balance on inlet and outlet sides are

necessary to reopen the valve plug.

The mechanism box is rearmed after opening the

internal bypass.

Rearming and balancing are achieved at the same time.

Table 4. Opening Control Measurements

DN NO. OF TURNS TRAVEL

25 4 8

50 7.5 15

80 11.5 23

100 15 30

INSTALLATION

WARNING

!

Personal injury or equipment damage, due

to bursting of pressure-containing parts

may result if this device is overpressured or

is installed where service conditions could

exceed the limits given in the Specication

section and on the appropriate nameplate

or where conditions exceed any rating of

the adjacent piping or piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices to prevent service conditions

from exceeding those limits. Also, be sure

the installation is in compliance with all

applicable codes and regulations.

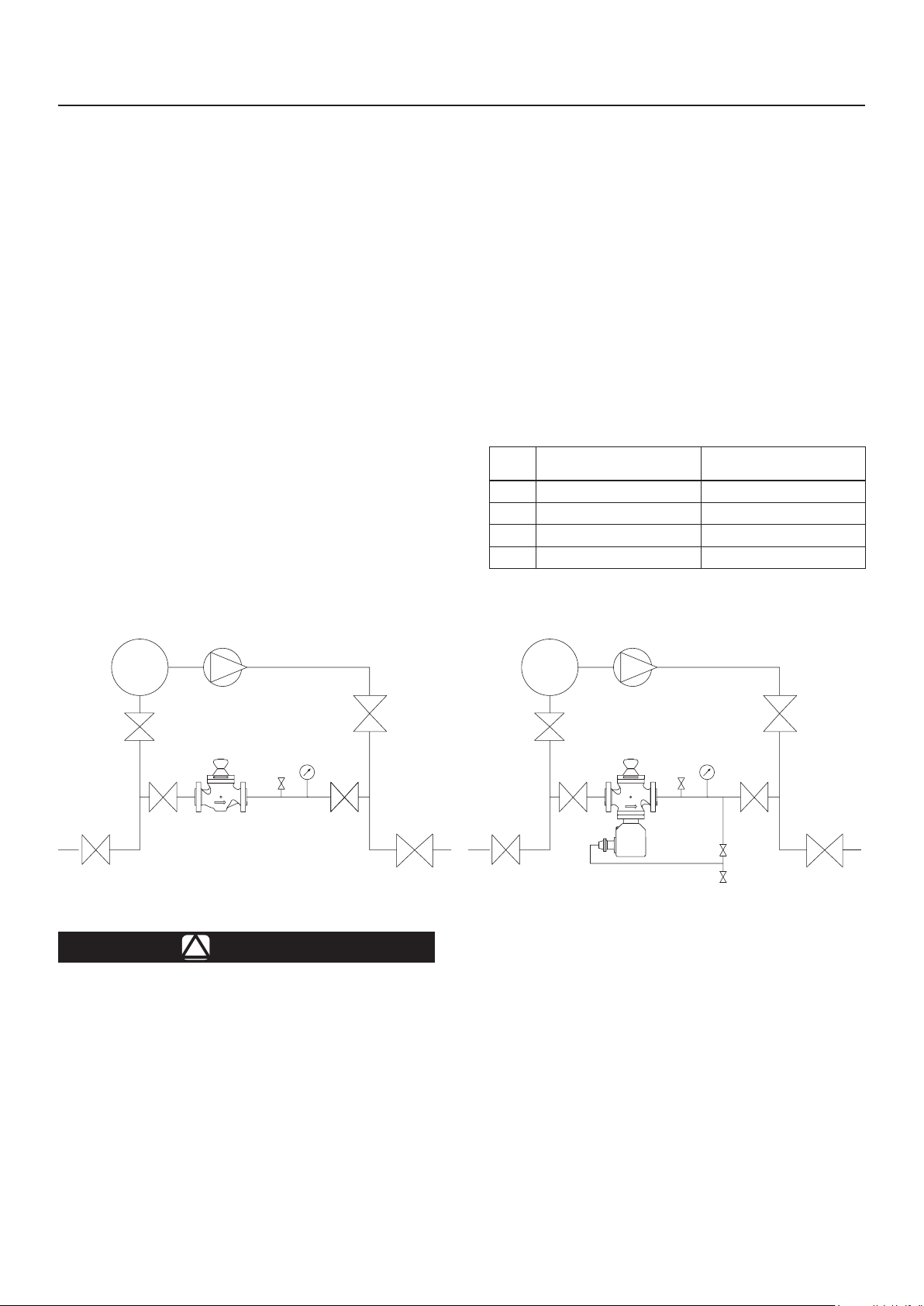

Figure 4. Types BLE and BLX Installation

Additionally, physical damage to the device

can cause personal injury and property

damage due to bursting of pressurecontaining parts. To avoid such injury and

damage, a possible approach could be e.g.

install the device in a safe location.

Respect the direction of the uid ow and the

position of the valve (uid opening the throttle

valve plug).

All interventions on the equipment should

only be performed by qualied and

trained personnel.

Type BLE version, the valve is to be installed on

horizontal or vertical pipeline with the control

handwheel in a top, bottom or lateral position.

B75

4

Loading...

Loading...