Fisher IM Supplement: HART Field Device Specification - FIELDVUE DVC6000 HW2 Digital Valve Controller Manuals & Guides

Instruction Manual Supplement

D103782X012

DVC6000 HW2 Digital Valve Controller

HART® Field Device Specification

April 2019

Fisher

™

FIELDVUE™ DVC6000 HW2 Digital Valve

Controller

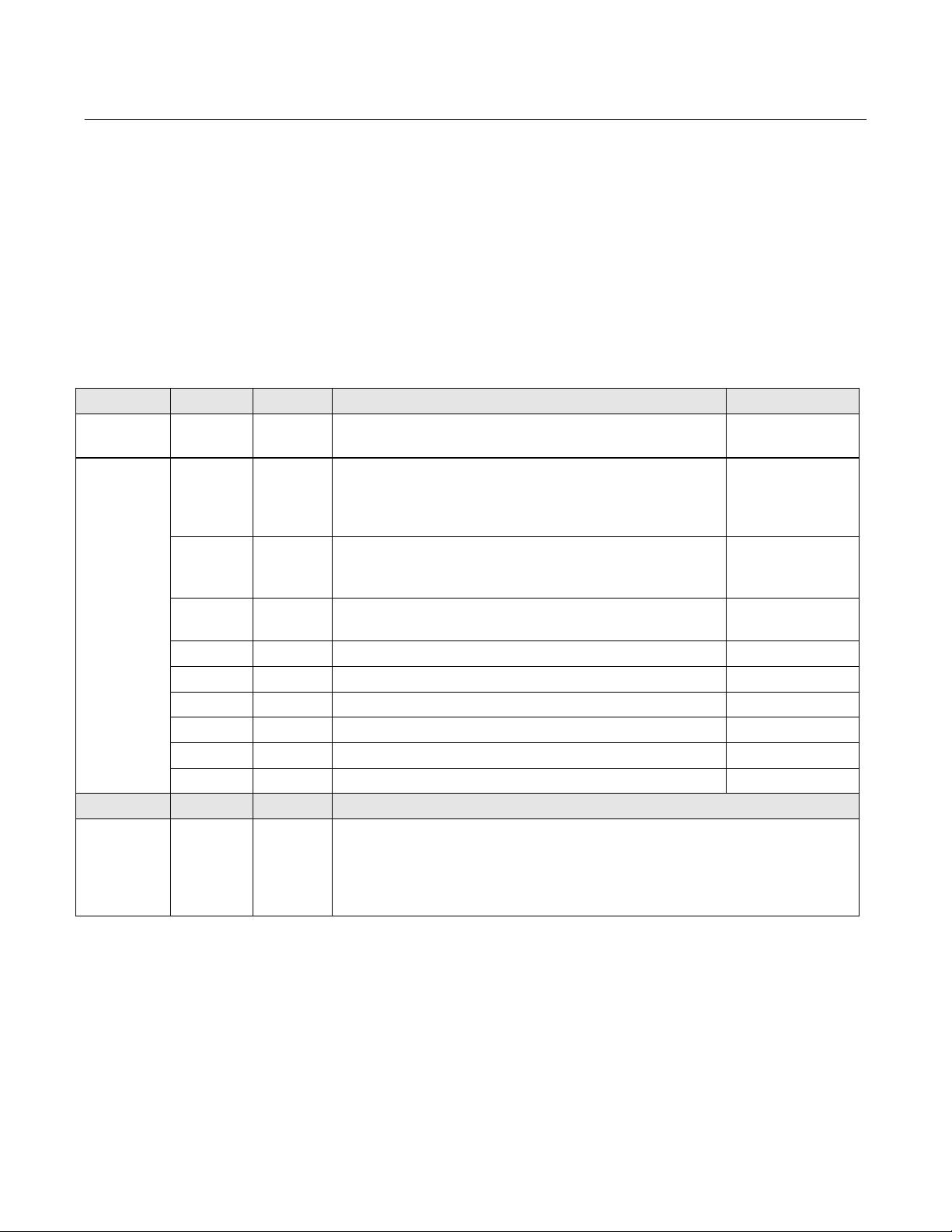

HART Revision Device Type Device Revision Firmware Revision

HART 5

HART 7 130b

Contents

Introduction 2.................................

Product Overview 2............................

Purpose of this document 2.....................

Abbreviations and definitions 2..................

Reference Documentation 3....................

Device Identification 3..........................

Product Interfaces 4............................

Control Valve Interface 4.......................

Host interface 4...............................

Pushbutton Calibration 4.......................

Internal Jumpers and Switches 5.................

Write Protection 5.............................

Dynamic Variables 6............................

Device Variables 6..............................

Unit Codes 7...................................

Status Information 7............................

Device Status 7...............................

Universal Commands 8..........................

CommonPractice Commands 16.................

Burst Mode 16................................

Condensed Status 16..........................

Device-Specific Commands 22....................

Performance 22................................

Annex A Compatibility Checklist 23................

Annex B DVC6000 HW2 Parameters as part of a

Rosemount

Gateway 24...............................

™

1410/1420 WirelessHART

0b 1

6

2

3 7

®

www.Fisher.com

DVC6000 HW2 Digital Valve Controller

April 2019

Instruction Manual Supplement

D103782X012

Introduction

Product Overview

The FIELDVUE DVC6000 HW2 digital valve controller is designed to control the pneumatic actuator of a process

control valve. It receives a current signal from a host and uses instrument air supply to create a metered pressure

output signal to the pneumatic actuator. Movement of the actuator as it positions the process control valve is

measured by the DVC6000 HW2 travel sensor as its primary feedback. The name plate is located on the bottom side of

the DVC6000 HW2 master module assembly and indicates the model name, individual product serial number, and any

applicable third party approvals.

Purpose of this document

This specification is designed to be a technical reference for HART capable host application developers, system

integrators and knowledgeable end-users. It also provides functional specifications (e.g., commands, enumerations

and performance requirements) used during field device development, maintenance and testing. This document

assumes the reader is familiar with HART Protocol requirements and terminology. Additional product information is

available in DVC6000 HW2 product literature, available from Emerson Automation Solutions.

Abbreviations and definitions

AR Alert Record

Configuration

Variables

Device Variable

Enumeration A pre-defined set of values or text.

MV Measured Variable, a physical input to the instrument.

NV

Point

PS1 The PORT A output pressure which increases with increasing drive signal.

PS2 The PORT B output pressure which decreases with increasing drive signal.

PST Partial Stroke Test, a limited form of ramped valve diagnostic.

Byte An 8bit unsigned integer.

Word A 16bit unsigned integer.

Float Refers to the IEEE 754 floating point format.

Packed ASCII

Standard Span

Format

Variables which represent nonvolatile values of manufacturinginitialized data or

userspecified configuration information. These variables cannot be enumerated via

Command 54 and as such stand on their own with no associated units or range information.

Measured variables that are exposed to HART and can be enumerated using Command 54.

Generally there are variables whose ID is in the range of 0 to 13 and are associated with units

codes, status, and range values.

Named Variable – a logical point inside the device, hardmapped to a given MV as the source

of NV data.

A term that applies to diagnostic data packets. It is defined as a collection of periodically

sampled variables captured at a single instant in time. It does not include the “Monitor” point.

A special form of characters defined by HART in which 6bit ASCII characters are packed into

byte data.

A proprietary 16bit integer format for numerical values used by some of this device’s Device

Specific commands.

2

Instruction Manual Supplement

D103782X012

DVC6000 HW2 Digital Valve Controller

April 2019

Reference Documentation

HART Smart Communications Protocol Specification Revision 7.6; a group of documents specifying the HART

Communication Protocol, physical layers, and Data Link Layers as defined by the HART Communications Foundation.

Bulletin 62.1:DVC6000 HW2 (D103786X012

DVC6005 Remote Mount Digital Valve Controllers Quick Start Guide (D103784X012

DVC6000 HW2 Digital Valve Controller Instruction Manual (D103785X012

)

)

)

Device Identification

Manufacturer Name Fisher Controls Model Name(s) DVC6000 HW2

Manufacture ID Code 19 (13 Hex) Device Type Code 11 (0b Hex)

HART Protocol Revision 7.6 Device Revision 2 & 3

User Selectable HART Revision

between HART 5 and HART 7

Number of Device Variables 13

Physical Layers Supported FSK

Physical Device Category Valve Positioner

Yes

3

DVC6000 HW2 Digital Valve Controller

April 2019

Instruction Manual Supplement

D103782X012

Product Interfaces

Control Valve Interface

The DVC6000 HW2 digital valve controller is mechanically attached to the valve’s actuator by means of a mounting

bracket. The control valve's position is conveyed to the travel sensor of the DVC6000 HW2 digital valve controller by

means of the feedback bracket attached to the actuator’s stem.

DVC6000 HW2

WITH REMOTE TRAVEL SENSOR

MOUNTING

BRACKET

ACTUATOR

MOUNTING

BRACKET

W8373

Pneumatic tubing connected to the DVC6000 HW2 brings instrument supply air to the DVC6000 HW2 and takes

controlled output air from the DVC6000 HW2 to the actuator. Pressure sensors in the DVC6000 HW2 measure these

pressure signals and present them as device variables

Host interface

The input to the DVC6000 HW2 can either be twowire 4to20 mA current loop (in pointtopoint mode) or 24 VDC

(in multidrop mode). This input is connected in the DVC6000 HW2’s terminal box on two terminals marked “LOOP +”

and “LOOP ”. Refer to the DVC6000 HW2 quick start guide for connection details.

Pushbutton Calibration

A pushbutton near the wiring terminals in the terminal box provides a quick means to autocalibrate the travel of the

instrument. The button must be pressed for 3 to 10 seconds. Autocalibration will move the valve through the full

range of travel whether the Instrument Mode is In Service or Out of Service. However, if the Write Protection is

Protected, this button will not be active. To abort, press the button again for 1 second. The calibration button is

disabled by default.

4

Instruction Manual Supplement

D103782X012

DVC6000 HW2 Digital Valve Controller

April 2019

Internal Jumpers And Switches (Optional)

The input to the DVC6000 HW2 is determined by the PtPt/MultiDrop switch on the printed wiring board.

The DVC6000 HW2 also has a pair of optional “Output” terminals that can either function as a position transmitter or a

discrete switch. Electrical configuration of the output circuit requires the proper setting of a DIP switch on the

DVC6000 HW2’s printed wiring board. Additionally, the functional operation of the output circuit must be configured

with the user interface.

Refer to the DVC6000 HW2 instruction manual for additional details on the settings of the selection switches.

WITH OPTIONAL I/O PACKAGE

DIP SWITCH FOR

TRANSMITTER/SWITCH

SELECTION

PT-PT/

MULTI-DROP

SELECTION

PT-PT/

MULTI-DROP

SELECTION

X0432

X0427

X0430

WITHOUT I/O PACKAGE

X0431

OUTPUT+

OUTPUT-

Write Protection

There are two Write Protection states for the DVC6000 HW2: Not Protected or Protected. Protected prevents

configuration and calibration changes to the instrument. The default setting is Not Protected. Protection is controlled

under software control. Write Protection can be enabled remotely. However, to disable Write Protection to Not

Protected, you must have physical access to the instrument. The procedure will require you to press a button inside

the terminal box when directed by the software as a security measure.

5

DVC6000 HW2 Digital Valve Controller

April 2019

Instruction Manual Supplement

D103782X012

Dynamic Variables

Four Dynamic Variables are implemented.

Default Meaning Units

PV Analog Input mA, %

SV* Travel Setpoint %

TV* Pressure PSI, BAR, KPA, Kg/cm

FV* Travel %

* User selectable

The SV, TV, and FV variables are user selectable via Command 51 to any of the following variables. Variable selections

are listed below:

Variable Units

Travel %

Travel Setpoint %

Pressure Port A PSI, BAR, KPA, Kg/cm

Pressure Port B PSI, BAR, KPA, Kg/cm

Pressure A – B PSI, BAR, KPA, Kg/cm

Supply Pressure PSI, BAR, KPA, Kg/cm

2

2

2

2

Drive Signal %

Analog Input mA, %

2

Device Variables

These variables represent measurements taken by the device, are read only values, and are all in float format. These

can be read with Commands 9, 33, and 54.

Variable ID Meaning Units

0 Analog Input mA, %

1 Internal Temperature _C, _F

2 Pressure Port A PSI, BAR, KPA, Kg/cm

3 Travel %

4 Drive Signal %

5 Pressure Port B PSI, BAR, KPA, Kg/cm

6 Travel Setpoint %

7 Differential Pressure (Port A – Port B) PSI, BAR, KPA, Kg/cm

8 Supply Pressure PSI, BAR, KPA, Kg/cm

9 Implied Valve Position %

10 Primary Feedback (user selected, either Travel or Pressure) %

11 Friction* As defined in ValveLink software

12 Deadband* As defined in ValveLink software

* Only available with PD diagnostic level

2

2

2

2

6

Instruction Manual Supplement

D103782X012

Unit Codes

Variable Units Code Units

0 No Units

6 Pounds per square inch, psi

7 Bar

10 ($0A) Kilograms per square centimeter, kg/cm

12 ($0C) Kilopascals, kPa

32 ($20) Celsius, _C

33 ($21) Fahrenheit, _F

39 ($27) Milliamps, mA

57 ($39) Percent, %

DVC6000 HW2 Digital Valve Controller

April 2019

2

Status Information

Device Status

The Field Device Status Byte is the only status byte defined in the HART protocol. The order and meaning of each of the

eight bits within the byte are fixed by the protocol. This byte is one of the status bytes included with each HART

response. It is not part of the Command 48 data.

Bit Name of Status Bit Meaning

7 Field Device Malfunction

6 Configuration Changed

5 Cold Start

4 More Status Active when any bit in command 48 is active.

3 Analog Input Fixed

2 Analog Input Saturated The loop current reading is beyond sensor limits.

1 Internal Sensor Out of Limits

0 Variable Out of Range Set when any variable 0, 1, 2, 3, 5, 8 or 10, is saturated.

Set / cleared by the firmware based on self test results. This bit is set if the

pressure, position or temperature sensors provide invalid readings.

Two such bits exist internally, one for each HART master. Both copies are set

when any variable, HART message, tag, descriptor or date are changed from

HART. Cleared by command 38, separately for each master. This bit survives

loss of power.

Set by the firmware whenever a RESET sequence is executed or at initial

device power up. Cleared by the first HART command. Two such bits exist

internally, one for each HART master.

Active if the Instrument Mode of the DVC6000 HW2 is in the “Out Of

Service” condition or if the Control Mode of the DVC6000 HW2 is in one of

the digital set point modes.

(This bit is named “NonPrimary Variable Out Of Limits” in the HART

documentation for transmitters. It has been renamed to reflect the fact that

these variables are INTERNAL INPUTS to FIELDVUE products). The firmware

sets this bit when any sensor (pressure, position, temperature) exceeds its

operating limits.

7

DVC6000 HW2 Digital Valve Controller

April 2019

Instruction Manual Supplement

D103782X012

Universal Commands

The DVC6000 HW2 field device implements all Universal Commands. Commands 14, 15, 17, 48 are listed below to

indicate their unique responses.

Command 0: Read Unique Identifier

Command 1: Read Primary Variable

Command 2: Read Primary Variable (current) and Percent of Range

Command 3: Read Dynamic Variables and Primary Variable (current)

Command 6: Write Polling Address

*Command 7: Read Loop Configuration

*Command 8: Read Dynamic Variable Classifications

*Command 9: Read Device Variable with Status

Command 11: Read Unique Identifier Associated with Tag

Command 12: Read Message

Command 13: Read Tag, Descriptor, Date

Command 14: Read Primary Variable Transducer Information

Command 15: Read Primary Variable Output Information

Command 16: Read Final Assembly Number

Command 17: Write Message

Command 18: Write Tag, Descriptor, Date

Command 19: Write Final Assembly Number

*Command 20: Read Long Tag

*Command 21: Read Unique Identifier Associated with Long Tag

*Command 22: Write Long Tag

Command 38: Reset Configuration Changed Flag

Command 48: Read Additional Status

*Commands 7, 8, 9, 20, 21, and 22 are HART 7 only.

8

Instruction Manual Supplement

D103782X012

DVC6000 HW2 Digital Valve Controller

April 2019

Command 14: Read Primary Variable Transducer Information

The transducer limits reported in this command are either 420 milliamps, or 0100%, and reflect the units code most

recently supplied in command 44.

Note

The Transducer Serial Number is not applicable to the DVC6000 HW2 and is set to “0”.

Byte Format Description Returned Value

Request

Data

bytes

Response

Data

Bytes

Response

Codes

None

02 UINT24 Transducer Serial Number 000000

3 Enum Transducer Limits and Minimum Span Units Code From Cmd 44

47 Float Upper Transducer Limit 20mA

811 Float Lower Transducer Limit 4.0mA

1215 Float Minimum Span 1.0mA

Code Class Description

None

9

DVC6000 HW2 Digital Valve Controller

April 2019

Instruction Manual Supplement

D103782X012

Command 15: Read Primary Variable Output Information

This command returns the upper/lower range values for the primary variable which is defined to be the loop current

signal. These are the loop current values for the ends of physical travel, and are used to derive set point from the loop

current. It reports the range supplied in Command 35.

For example, the lower range, for an increase to open valve, will be the current which will produce a 0% set point.

However, for an increase to close valve, the lower range will be the loop current for a 100% set point.

The range values can be changed via Command 35.

The DVC6000 HW2 assumes 0% = 4mA and 100% = 20mA.

Byte Format Description Returned Value

Request

Data bytes

Response

Data Bytes

Additional

Device

Related

Response

Codes

None

PV Alarm Selection Code. The Alarm Selection Code

0 Enum

1 Enum

2 Enum

36 Float AI Upper Range Value From Cmd 35

710 Float AI Lower Range Value From Cmd 35

1114 Float PV Damping Value (units of seconds) 0.0

15 Enum Write Protect Code (0=Disabled, 1=Enabled) 0 or 1

16 Enum Reserved. Must be set to “250”, Not Used. 250

17 Uint8 PV Analog Channel Flags 01

Code Class Description

None

indicates the action taken by the device under error

conditions. For Actuators, the action taken by the

positioner is indicated.

PV Transfer Function Code. The Transfer Function Code

must return “0”, Linear, if transfer functions are not

supported by the device.

AI Upper and Lower Range Values Units Code, as

supplied in command 35.

250 (Not Used)

250 (Not Used)

From CMD 35

10

Loading...

Loading...