Fisher IM Supplement: HART Field Device Specification - FIELDVUE DLC3010 Digital Level Controller (Supported Product) Manuals & Guides

Instruction Manual Supplement

D104329X012

HARTr Field Device Specification

DLC3010 Digital Level Controller

May 2022

Fisher

™

FIELDVUE™ DLC3010 Digital Level

Controller (Supported Product)

HART Revision Device Type Device Revision Firmware Revision

HART 5

Contents

Introduction 2.................................

Scope 2......................................

Purpose of this document 2.....................

Abbreviations and definitions 2..................

Reference Documentation 3....................

Device Identification 3..........................

Product Overview 3............................

Product Interfaces 4............................

Process Interface 4............................

Process Temperature Interface 4.................

Electronics Temperature Interface 5..............

Host interface 5...............................

HART Digital Interface 5........................

Local Interfaces, Jumpers and Switches 5..........

Device Variables 6..............................

Dynamic Variables 7............................

Status Information 7............................

Universal Commands 8..........................

Common-Practice Commands 18.................

Device Specific Commands 27....................

Tables 38.....................................

Performance 45................................

Annex A: Compatibility Checklist 48...............

Annex B: Default Configuration 48................

Annex C DLC3010 Parameters as part of a

Rosemount

Gateway 50...............................

™

1410/1420 WirelessHARTr

04 1 8

W7977-2

www.Fisher.com

Product removed from sale April 2022

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

D104329X012

Introduction

Scope

The Fisher DLC3010 digital level controller targeted compliance with HART Protocol Revision 5.2. Additionally, an

effort was made to provide support for the proposed revision 5/6 compatibility rules. This document provides all the

device-specific features and HART communications protocol implementation details. The functionality of this field

device is described sufficiently to allow its proper application in a process and its complete support in HART-capable

host applications.

Purpose of this document

This document provides a description of the field device from a HART Communication perspective. Additional product

information can be found in the DLC3010 product literature, available from your Emerson sales office

Who should use this document

.

The information contained herein is intended for use as a technical reference for HART-capable host application

developers, systems integrators, and knowledgeable end-users. It also provides functional specifications (e.g.,

commands, enumerations, and performance requirements) used during field device development, maintenance, and

testing. Users of this document must be fully trained in HART Protocol requirements and terminology.

Abbreviations and definitions

Additional Device

Status

Byte An 8bit unsigned integer

Common Table <n> A reference to a table in HCF_SPEC-183 (FCG TS20183) Common Tables Specification

Configuration

Variables

Device Variable

DLC DLC3010 digital level controller product

Dynamic Variable

Enumeration A pre-defined set of values or text

Float IEEE 754 floating point format

HART Highway Addressable Remote Transducer

LCD Liquid Crystal Display

Lift-Off Voltage

Status information returned by Command 48

Variables which represent nonvolatile values of manufacturinginitialized data or

userspecified configuration information. These variables cannot be accessed via

Universal or Common Practice Commands.

Uniquely defined data items within a field device, containing process-related

information. They are assigned consecutive code numbers starting with zero.

A Device Variable mapped to a slot in the set of HART commands that support

potential analog channels in the device. Only the first slot is required to have an

associated analog channel.

Minimum supply voltage required at device terminals to guarantee correct behavior,

(including HART communication), during both normal operation and while indicating a

malfunction

2

Instruction Manual Supplement

D104329X012

NVM Non-volatile memory

Packed

RTD Resistance Temperature Detector

STO

Word A 16bit unsigned integer

Uint <n> Unsigned integer with bit length n

Packed ASCII, a special form of characters defined by HART in which four 6bit ASCII

characters are packed into three bytes

Slave Time Out. The time allowed for a slave device to begin its transmission, defined in

HCF_SPEC-081 (FCG TS20081) and tested in HCF_TEST-001 section 7.24 DLL024.

Reference Documentation

DLC3010 Digital Level Controller

May 2022

HART Smart Communications Protocol Specification Revision 5.0; a group of documents specifying the HART

Communication Protocol, physical layers, and Data Link Layers as defined by the FieldComm Group

FIELDVUE DLC3010 Digital Level Controller Instruction Manual, D102748X012

FIELDVUE DLC3010 Digital Level Controller Quick Start Guide, D103214X012

Industrial Platinum Resistance Thermometers and Platinum Temperature Sensors, IEC 60751, International

Electrotechnical Commission

™

.

Device Identification

Manufacturer Name Fisher Controls Model Name(s) DLC3010

Manufacture ID Code 19 (13 Hex) Device Type Code 04 (04 Hex)

HART Protocol Revision 5.2 Device Revision 1

Number of Device Variables 5 (effectively 3, as variables 0, 1 and 2 cannot coexist)

Physical Layers Supported FSK (Bell 202 Current)

Physical Device Category Transmitter (two-wire), Non-DC-isolated Bus Device

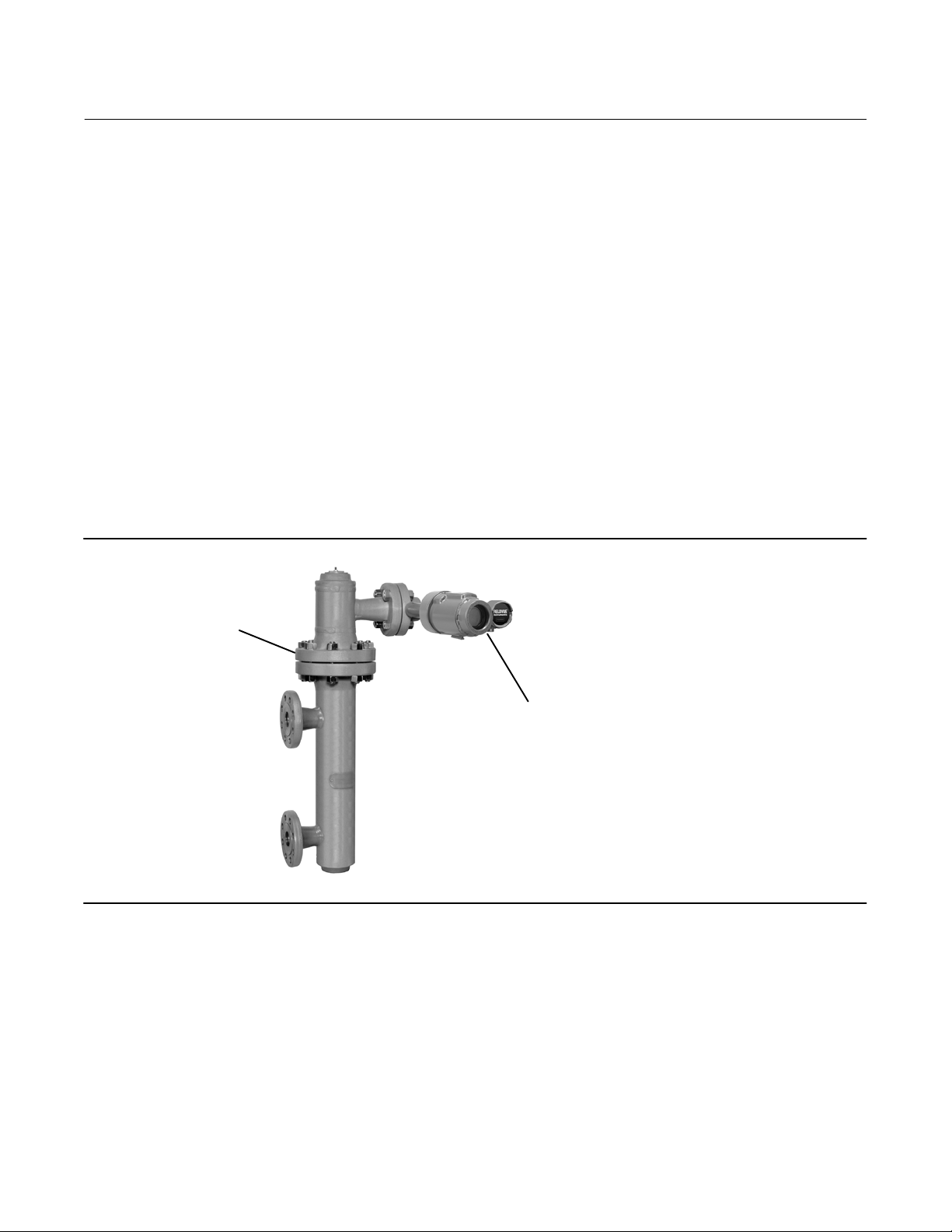

Product Overview

DLC3010 digital level controllers are used with level sensors to measure liquid level, level of the interface between two

liquids, or liquid specific gravity (density). Changes in level or specific gravity exert a buoyant force on a displacer,

which rotates the torque tube shaft. This rotary motion is applied to the digital level controller, transformed to an

electrical signal and digitized. The digital signal is compensated and processed per user configuration requirements,

and converted to a 4-20 mA analog electrical signal. The resulting current output signal is sent to an indicating or final

control element. The name plate is located on the top of the DLC3010 assembly and indicates the model name,

individual product serial number, and any applicable third party approvals.

3

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

D104329X012

Product Interfaces

Process Interface

Primary Variable Sensor Interface

DLC3010 digital level controllers mount on a wide variety of caged and cageless 249 level sensors. Mounting adaptors

are available to allow using them on other manufacturers' displacer type level sensors. The field device is provided with

a lever that carries a set of magnets across a Hall-Effect sensor to transform angular position into voltage. The lever is

coupled to the buoyancy sensor’s pilot shaft by a clamping bolt and nut. Nominal design rotation of the buoyancy

sensor for a full span change of water level at room temperature is 4.4_. To best utilize the accuracy of the transmitter,

the amount of input rotation used should be close to this range. For applications that would develop a very small

proportional band with standard hardware, (e.g., interface level measurements where the difference between the

densities of the two phases is quite small), custom sensor configurations may be specified to improve the mechanical

gain.

The available lever travel in the digital level controller is approximately ±6_ from the neutral or ‘locked’ position. This

allows right- or left-hand-mounted sensors to be used with out mechanical changes to the transmitter. It also allows

the digital level controller to be used with sensors having mechanical gain slightly higher than nominal by physically

coupling at the center of sensor travel instead of at the lowest process condition.

249 LEVEL SENSOR

DLC3010 DIGITAL

LEVEL CONTROLLER

Process Temperature Interface

An external 100 Ohm Platinum RTD of 2-wire or 3-wire configuration may be installed to provide process temperature

instrumentation. The terminals for the RTD are in the lower bank of the instrument terminal box, and are labeled “Rs”,

“R1”, and “R2”, from left to right. “Rs” and “R1” are used for the two wires from the same node of a 3-wire RTD, and

must be shorted with a jumper when a two-wire RTD is employed. Refer to the Instruction Manual for additional

installation details. When the RTD is installed, configured, and calibrated, and a table of density versus temperature is

entered by the user, this input will be used to drive density compensation for the level calibration. If the RTD is not

installed, the compensation tables can also be driven by a manually-entered value of process temperature. To disable

the density temperature-compensation, the compensation table length is reduced to 1 element.

4

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

The process temperature value derived from the RTD may be checked against user-defined alarm thresholds to

indicate when the sensor is operating outside of recommended temperature limits.

Electronics Temperature Interface

An internal temperature sensor mounted near the Hall Sensor is utilized to drive factory-configured temperature

compensation for magnetic flux and Hall-effect sensitivity variations. It may also be checked against user-defined

alarm thresholds to indicate when the transmitter is operating outside of recommended temperature limits.

Host interface

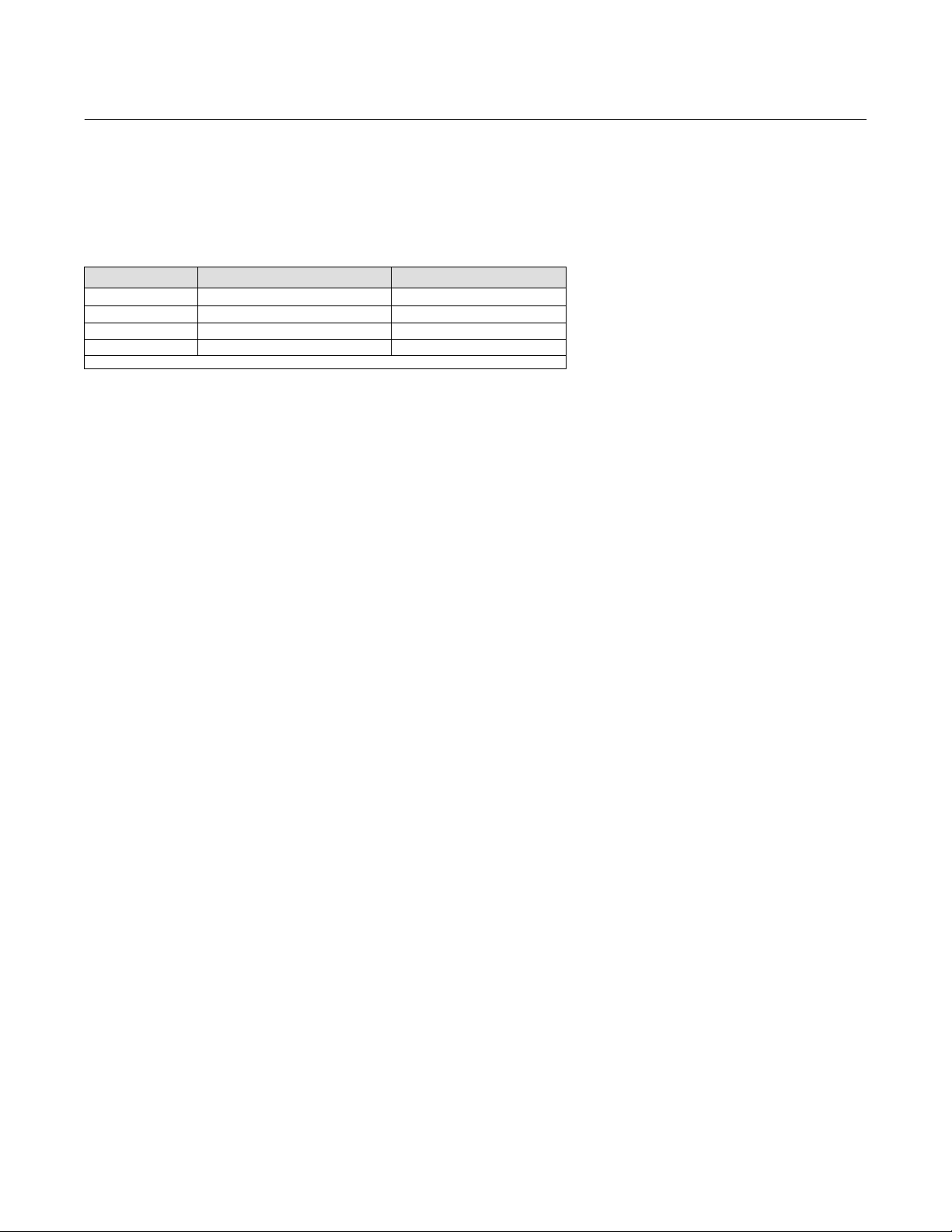

Analog Output: Primary Variable

When available terminal voltage is above the Lift-Off Voltage, the DLC3010 acts as the current source in a twowire

4to20 mA current loop (in pointtopoint mode) or draws 4 mA fixed current (in multidrop mode). This output is

provided in the DLC3010’s terminal box at two terminals marked “+” and “”. Refer to the Quick Start Guide for

connection details. In point-to-point mode, the digital value of the primary variable is mapped to the 4-20 mA signal

by the Range Values.

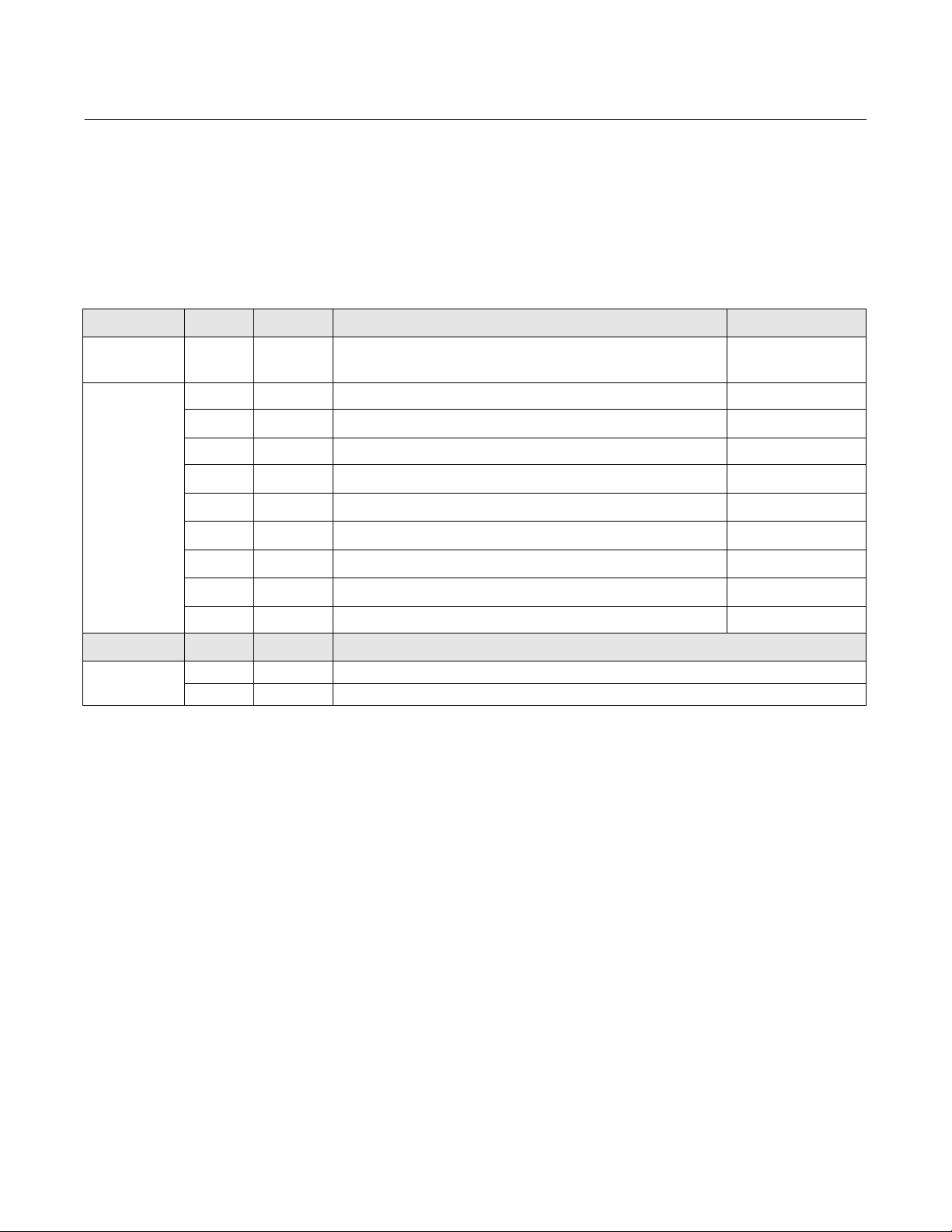

Direction Value (% Range) Value (mA or V)

Saturation Limits

Alarm Indication

Maximum Current 22.5 mA

Multi-Drop Current Draw 4.0 mA

Lift-Off Voltage 12 V.

* User must select one or the other of the alarm indication outputs with a hardware jumper. They are

mutually exclusive.

High PV > +103.13% 20.5 mA

Low PV < -1.25% 3.8 mA

High* 22.5 mA

Low* 3.7 mA

HART Digital Interface

When available terminal voltage is above the Lift-Off Voltage, the DLC3010 can communicate digitally via Bell 202 FSK

HART protocol. This interface is available at test clips in the DLC3010’s terminal box on the two terminals marked “+”

and “”, or across any convenient impedance on the loop that is sufficient to meet the HART signaling requirements.

Refer to the Quick Start Guide for connection details.

Local Interfaces, Jumpers, and Switches

Local Displays

A removable Liquid Crystal Display (LCD) assembly is provided. It displays PV %Range on a circular “bar-graph”, and

different combinations of digital information such as PV %Range, PV in engineering units, Process Temperature, etc.

Display symbols or text are provided for:

D Write-lock (key symbol)

D Display numeric field overflow (OFLOW)

D Hardware failure (Hdwr FL)

5

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

D104329X012

Local Jumpers

A fail-mode jumper is provided on the lower face of the LCD assembly (on the upper right quadrant of the electronics

module when the LCD is not used). This jumper is internal to the electronics compartment and may only be accessed

by removing the main cover. It allows the user to select either the High or Low alarm indication documented in the

table above. Only one alarm indication value can be made available during operation. The fault conditions that trigger

the alarm are documented in table 2a.

Device Variables

These variables represent measurements taken by the device (see table 5), and are all in float format. Their values are

not directly exposed by any standard HART command. However, they are the set of internal variables from which the

Dynamic Variables are selected. Only one of the Liquid Level, Interface Level, or Liquid Density measurements may be

computed in a given configuration, so assigning one of these to PV sets up the structure of the measurement

algorithm. Temperature variable selections are permanently allocated to SV and TV slots, so their indices are used

primarily for units processing. Process temperature is only functional as TV if the RTD is installed, otherwise it is a fixed

parameter entered by the user.

Device Variable 0 - Liquid Level

When Liquid Level is assigned as PV, the process value is derived from the measured rotation of the sensor’s torque

tube by using calibration data to convert the change in rotation to a force measurement, then applying displacer

weight, displacer volume, and fluid density configuration data to convert force to liquid level. This variable is not

computed when it is not assigned as PV.

Device Variable 1 - Interface Level

When the Interface Level is assigned as PV, the process value is derived from the measured rotation of the sensor’s

torque tube by using calibration data to convert the change in rotation to a force measurement, then applying

displacer weight, displacer volume, upper fluid density, and lower fluid density configuration data to convert force to

interface level. This variable is not computed when it is not assigned as PV.

Device Variable 2 – Liquid Density

When the Liquid Density is assigned as PV, the process value is derived from the measured rotation of the sensor’s

torque tube by by using calibration data to convert the change in rotation to a force measurement, then applying

weight and volume configuration data to convert force to fluid density. This variable is not computed when it is not

assigned as PV.

Device Variable 3 – Process Temperature

When an RTD installed in the process fluid is wired to the device and assigned as the Process Temperature Source, the

Process Temperature variable is derived from the measured resistance of the RTD via a table related to IEC 60751. A

60-second lag, factory calibration, and user offset adjustments are applied to the signal before reporting.

When “Manual Entry” is assigned as the Process Temperature Source, this variable simply reports a fixed user-entered

value.

Device Variable 4 – Electronics Temperature

This variable is derived from the voltage drop across a semiconductor junction in a chip mounted in the transducer

housing. A 60-second lag and factory or user offset adjustments are applied to the signal before reporting.

6

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

Dynamic Variables

Three Dynamic Variables are implemented. The PV is user-selectable to one of the first three Device Variables via

Command 51.

Default Meaning Units

PV*

SV Instrument Temperature See table 6

TV Process Temperature See table 6

FV Not Used N/A

* User selectable

Liquid Level See table 6

Status Information

Device Status

The Field Device Status Byte (see table 2a) is the only status byte defined in the HART 5 protocol. The order and

meaning of each of the eight bits within the byte are fixed by the protocol. This byte is one of the status bytes included

with each HART response. It is not part of the Command 48 data.

Extended Device Status

This byte was not defined in the HART 5 specification, so it is not supported.

Additional Status Integrity Bytes

Three Additional Status bytes providing details of internal monitor states are returned in the Command 48 response.

Refer to table 2b for definitions of the bits.

7

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

Universal Commands

The following HART 5.0 Universal Commands are implemented in the DLC3010 firmware:

Command 0: Read Unique HART Identifier

Command 1: Read Primary Variable

Command 2: Read PV Current and Percent Range

Command 3: Read Dynamic Variables and PV Current

Command 6: Write Polling Address

Command 11: Read Unique Identifier with Tag

Command 12: Read Message

Command 13: Read Tag, Descriptor, Date

Command 14: Read PV Sensor Info

Command 15: Read PV Output Info

Command 16: Read Final Assembly Number

Command 17: Write Message

Command 18: WriteTag, Descriptor, Date

D104329X012

Note

At HART 5, Commands 38 and 48 were in the Common Practice group.

Any command can return any of the following response codes:

0 No command specific errors

5 Incorrect Byte Count

8 Warning - value written was truncated (write commands only)

32 Busy

In addition, some commands may return additional error codes. See the “Command Specific Response Codes” part of

the command description for additional codes. One of the error codes associated with writing data to the instrument

is:

7 In Write Protect Mode

A more complete list is available in table 1. All commands will check for the required number of data bytes and return

Incorrect Byte Count if too few bytes are received. If too many bytes are received for the given command, the extra

bytes are ignored. This is the behavior defined by the HART specification, which allows for command expansion with

backward compatibility. If additional bytes are added to any command, an older instrument will still accept the

command with only the original bytes used and will ignore any of the additional bytes.

8

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

Command 0: Read Unique Identifier

Returns identity information about the field device in HART 5 identity format, including: Device Type, revision levels,

and Device ID. This command is implemented by a field device in both Short and Long Frame Formats. Command 0 is

the only command that may respond to a short frame address. The Device Type Code will be returned in the expanded

three-byte format. ("254", Manufacturer Identification Code, Manufacturer's Device Type Code). The combination of

Manufacturer Identification Code, Manufacturer's Device Type Code, and Device Identification Code make up the

Unique Identifier required for the Extended Frame Format of the Data Link Layer.

Byte Format Description Returned Value

Request Data

bytes

None

0 Enum Expansion code “254” 254

1 Enum Manufacturer Identification code [Common Table 8] 19

2 Enum Manufacturer's Device Type code [Common Table 1] 4

3 Uint8

4 Uint8

5 Uint8

6 Uint8 Software revision level of this device 8

7.7-7.3 Uint5

7.2-7.0 Enum Physical Signaling Code [Common Table 10] 0

8 Bits Flags [Common Table 11] 0

9-11 Uint24 (Unique) Device Identification Number

Code Class Description

Number of preambles required for master to slave

request, including those required for message detection

Revision level of the universal command document

implemented by this device. Levels 254 and 255 are

reserved.

Revision level of the device - specific document

implemented. Levels 254 and 255 are reserved

Hardware revision level. Does not necessarily trace

component changes

5

5

1

1

Response

Codes

6

Error Device-Specific Command Error

9

DLC3010 Digital Level Controller

May 2022

Command 1: Read Primary Variable

The Primary Variable is returned along with its Units Code.

Byte Format Description

Instruction Manual Supplement

D104329X012

Request Data

Bytes

Response

Data Bytes

Response

Codes

None

0 Enum Primary Variable Units (table 6, DLC3010 Unit Codes)

1-4 Float Primary Variable

Code Class Description

6

8

16

Error Device-Specific Command Error

Warning Update Failure

Error Access Restricted

Command 2: Read Loop Current and Percent of Range

The Loop Current should match the current that would be measured by a milliammeter in series with the field device.

The actual implementation reports the commanded value driving the output Digital to Analog converter.

The Percent of Range signal follows the PV as mapped by URV and LRV in normal operation. However, the value

reported by Command 2 in the DLC3010 at firmware 8 is derived from the current command, thus reflecting

saturation limits and alarm values, instead of following PV out to Sensor Limits.

Byte Format Description Returned Value

Request Data

Bytes

Response

Data Bytes

None

0-3 Float Primary Variable Loop Current (milliamperes)

4-7 Float Primary Variable Percent of Range (%)

Response

Codes

10

Code Class Description

6

8

Error

Warning

Device-Specific Command Error

Update Failure

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

Command 3: Read Dynamic Variables and Loop Current

The Loop Current should match the current that would be measured by a milliammeter in series with the field device.

The actual implementation reports the commanded value driving the output Digital to Analog converter.

The remaining Response Data include the PV with its Units Code, Process Temperature and Electronics Temperature

with Temperature Units Codes.

Byte Format Description Returned Value

Request Data

Bytes

Response

Data Bytes

Response

Codes

None

0-3 Float Primary Variable Loop Current (mA)

4 Enum Primary Variable Units Code (table 6)

5-8 Float Primary Variable

9 Enum Secondary Variable Units Code (table 6)

10-13 Float Secondary Variable (Electronics Temperature)

14 Enum Tertiary Variable Units Code (table 6)

15-18 Float Tertiary Variable (Process Temperature)

19 Enum Not Used

20-23 Float Not Computed NaN

Code Class Description

6

8

Error Device-Specific Command Error

Warning Update Failure

250

11

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

D104329X012

Command 6: Write Polling Address

This is a Data Link Layer Management Command.

This command writes the Polling Address to the field device. The address is used to control the Primary Variable

Analog Output and provide a means of device identification in Multidrop installations.

The Primary Variable Analog Output responds to the applied process only when the Polling Address of the device is set

to 0. When the address assigned to a device is in the range from 1 through 15, the Analog Output is Not Active and

does not respond to the applied process. While the Analog Output is Not Active, the Analog Output is set to its

minimum; the Transmitter Status Bit #3, Primary Variable Analog Output Fixed, is set; and the Upscale/Downscale

Alarm is disabled. If the Polling Address is changed back to 0, the Primary Variable Analog Output will become Active

and respond to the applied process.

In the HART 5 specification, no Read Command was provided for Polling Address. A Device-Specific Command is used

to acquire its value for display in the interface.

Byte Format Description

0 Uint8 Polling Address

Request Data

bytes

Response

Data Bytes

Response

Codes

0 Analog Output Active

1 – 15 Analog Output Not Active

16 - 255 Invalid

0 Uint8 Polling Address

0 Analog Output Active

1 – 15 Analog Output Not Active

16 - 255 Invalid

Code Class Description

2 Error Invalid Selection

5

6

7

Error Too Few Data Bytes Received

Error Device-Specific Command Error

Error In Write-Protect Mode

12

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

Command 11: Read Unique Identifier Associated with Tag

This command returns the Expanded Device Type code, revision levels, and Device Identification Number from a

device containing the requested Tag. This command is unique in that no response will be made unless the Tag

matches that of the device.

The Device Type Code will always be returned in expanded 3-byte format: "254", Manufacturer Identification Code,

Manufacturer's Device Type code.

Byte Format Description Returned Value

Request Data

bytes

Response Data

Bytes

Response

Codes

0-5

0 Enum Device Type Code for Expansion 254

1 Enum Manufacturer Identification Code 19

2 Enum Device Type Code 4

3 Uint8

4 Uint8

5 Uint8

6 Uint8 Software revision level of this device 8

7.7-7.3 Uint5

7.2-7.0 Enum3 Physical Signaling Code [Common Table 10] 0

8 Bits Flags [Common Table 11] 0

9-11 Uint24 Device Identification Number

Code Class Description

6 Error Device-Specific Command Error

Packed Tag

Number of Preambles required for request from Master to

Slave, including those required for message detect

Revision Level of the Universal Command Specification

implemented by this device

Revision level of the device - specific document

implemented.

Hardware revision level. Does not necessarily trace

component changes

5

5

1

1

13

DLC3010 Digital Level Controller

May 2022

Command 12: Read Message

This command reads a user-defined message contained within the device.

Byte Format Description

Instruction Manual Supplement

D104329X012

Request

Data bytes

Response

Data Bytes

Response

Codes

None

023 Packed Message String

Code Class Description

6 Error Device-Specific Command Error

Command 13: Read Tag, Descriptor, Date

This command reads the tag, descriptor, and date contained within the device.

Byte Format Description

Request

Data bytes

Response

Data Bytes

Response

Codes

None

05 Packed Tag

617 Packed Descriptor

1820 Uint8[3] Date; Respectively: day, month, year – base year (1900)

Code Class Description

6 Error Device-Specific Command Error

14

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

Command 14: Read Primary Variable Sensor Information

Reads the Primary Variable Sensor Serial Number, Primary Variable Sensor Limits/Minimum Span Units Code, Primary

Variable Upper Sensor Limit, Primary Variable Lower Sensor Limit, and Primary Variable Minimum Span for the sensor.

The Primary Variable Sensor Limits and Minimum Span Units will be the same as the Primary Variable Units.

Note

The sensor serial number is not applicable to the DLC3010 and is set to “0”.

3 bytes (2^24 = 16,777,216 ) were insufficient to code Fisher serial numbers, which have passed the 17,000,000 mark, and may

also contain non-numeric elements. We have created a device-specific variable to hold the displacer serial number

Byte Format Description Returned Value

Request Data

bytes

Response

Data Bytes

Response

Codes

None

02 Uint24 Not used in DLC3010 - Sensor Serial Number 000000

3 Enum Sensor Limits and Minimum Span Units Code From Cmd 44

Level Offset plus 120% of

47 Float Upper Sensor Limit

displacer length, or a density of

1.5 SGU

Level Offset minus 20% of

811 Float Lower Sensor Limit

displacer length, or a density of

0.1 SGU

Closest usable spacing

between upper/lower range

1215 Float Minimum Span

values before accuracy issues

need to be considered, 25% of

displacer length or a density

difference of 0.25 SGU.

Code Class Description

6 Error Device-Specific Command Error

15

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

D104329X012

Command 15: Read Primary Variable Output Information

This command reads the Instrument alarm selection code (condition of the hardware jumper), units code for the PV

range variables, upper and lower range values, PV damping value, and private label distributor code. This command

has the HART 5 structure, 1 byte shorter than the HART 7 version.

Byte Format Description

Request Data

None

bytes

0 Enum Hardware Alarm Selection Code (Ignore)

1 Enum

2 Enum

PV Transfer Function Code

PV Upper and Lower Range Value Units Code, refer to table 6.

(2)

(1)

36 Float PV Upper Range Value

Response

Data Bytes

710 Float PV Lower Range Value

1114 Float PV Damping Value (units of seconds)

15 Enum Write Protect Code (0=Not Protected, 1=Protected)

16 Enum Private Label Distributor Code, refer to table 3

Code Class Description

Response

Codes

1. The enumeration assignments for Alarm Selection Code in the DLC3010 do not comply with the definition in HCF_SPEC-183 Common Tables

Specification, Table 6. Therefore, it is not referenced in DD menus, and the associated data item is handled by a device-specific command and variable.

2. The value of Transfer Function Code in the DLC3010 was inadvertently hard-coded to ‘1’ during development. The DD uses a post-read action to reset it

to the correct value of ‘0’, but it must be ignored when accessed outside of the DD.

6 Error Device-Specific Command Error

Command 16: Read Final Assembly Number

This command reads a 24-bit user-defined identification number from the device.

Request Data

bytes

Response

Data Bytes

Response

Codes

16

Byte Format Description

None

02 Uint24 Final Assembly Number

Code Class Description

6 Error Device-Specific Command Error

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

Command 17: Write Message

This command allows you to write a 24-character informational message into the device.

Byte Format Description

May 2022

Request

Data bytes

Response

Data Bytes

Response

Codes

023 Packed

023 Packed Message String

Code Class Description

5 Error Too few data bytes

6 Error Device Specific command error

7 Error In write protect mode

Message string

Command 18: Write Tag, Descriptor, Date

This command writes the tag, descriptor, and date into the device.

Byte Format Description

05 Packed Tag

Request

Data bytes

Response

Data Bytes

Response

Codes

617 Packed Descriptor

1820 Uint8[3] Date; Respectively: day, month, year – base year (1900)

05 Packed Tag

617 Packed Descriptor

1820 Uint8[3] Date; Respectively: day, month, year – base year (1900)

Code Class Description

5 Error Too few data bytes

6 Error Device Specific command error

7 Error In write protect mode

Command 19: Write Final Assembly Number

This command writes the user-defined final assembly number into the device.

Byte Format Description

Request Data

bytes

Response

Data Bytes

Response

Codes

02 Uint24 Final Assembly Number

02 Uint24 Final Assembly Number

Code Class Description

5 Error Too few data bytes

6 Error Device Specific command error

7 Error In write protect mode

17

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

CommonPractice Commands

The DLC3010 field device supports the following common practice commands:

Command 34: Write Primary Variable Damping Value

Command 35: Write Primary Variable Range Values

Command 36: Set Primary Variable Upper Range Value

Command 37: Set Primary Variable Lower Range Value

Command 38: Reset Configuration Change Flag

Command 40: Enter/Exit Fixed Current Mode

Command 41: Perform Transmitter Self Test

Command 42: Perform Master Reset

Command 44: Write PV Units Code

Command 45: Trim PV Current DAC Zero

Command 46: Trim PV Current DAC Gain

Command 48: Read Additional Transmitter Status

Command 50: Read Dynamic Variable Assignments

Command 51: Write Dynamic Variable Assignments

Command 53: Set Device Variable Units

Command 59: Write Number of Response Preambles

D104329X012

Burst Mode

This field device supports Burst Mode and the following commands:

Command 108: Write Burst Mode Command Number

Command 109: Burst Mode Control

Catch Device Variable

This field device does not support Catch Device Variable.

18

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

Command 34: Write Primary Variable Damping Value

Writes the damping value applied to the PV filter, in seconds. This term sets the time constant of the digital filter.

Byte Format Description Allowable choices

Request Data

Bytes

Response

Data Bytes

Response

Codes

0-3 Float Damping Value for Primary Variable 0 to 16 seconds

0-3 Float Damping Value for Primary Variable

Code Class Description

3 Error Passed parameter too large

4 Error Passed parameter too small

5 Error Too few data bytes received

7 Error In Write Protect mode

8 Warning Set to nearest possible value

Command 35: Write Primary Variable Range Values

This command writes the primary variable ranging values with the associated units code. The Upper Range Value may

be set lower than the Lower Range Value to implement reverse action for the analog output. Changing action via

Command 35 is more robust than attempting to use Commands 36 and 37 iteratively for that purpose.

The unit code supplied in this command is not stored in the instrument. The supplied ranges will be converted to

current PV units before being applied. Range values must be validated in the DD to assure that they are within the

allowable limits and are separated by a minimum span. The unit code is checked in the instrument and Invalid

Selection will be returned for a code that is not supported by the device in the current operating mode.

Byte Format Description

0 Uint8 Upper and Lower Range Values Unit Code

Request Data

Bytes

Response

Data Bytes

Response

Codes

1 4 Float Primary Variable Upper Range Value

5 8 Float Primary Variable Lower Range Value

0 Uint8 Upper and Lower Range Values Unit Code

1 4 Float Primary Variable Upper Range Value

5 8 Float Primary Variable Lower Range Value

Code Class Description

2 Error Invalid selection

9 Error Lower Range too high

10 Error Lower Range too low

11 Error Upper Range too high

12 Error Upper Range too low

14 Warning Span is too small (Data is accepted)

19

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

D104329X012

Command 36: Set Primary Variable Upper Range Value

The value of the process applied to the process variable becomes the primary variable upper range value. The lower

range value remains the same.

Byte Format Description

Request Data

Bytes

Response

Data Bytes

Response

Codes

None

None

Code Class Description

7 Error In Write Protect mode

9 Error Applied process too high

10 Error Applied process too low

14 Warning Span is too small (Data is accepted)

Command 37: Set Primary Variable Lower Range Value

The value of the process applied to the process variable becomes the primary variable lower range value. To maintain

the same span, the device will attempt to shift the upper range value by the same amount that the lower range value

changes.

Byte Format Description

Request Data

Bytes

Response

Data Bytes

Response

Codes

Note: Response Codes 9 and 10 will take precedence if the new span between LRV and URV is less than the minimum span given by command 15.

None

None

Code Class Description

7 Error In Write Protect mode

9 Error Applied process too high

10 Error Applied process too low

14 Warning New Lower Range Value pushed Upper Range Value over limit. Data is

accepted in instrument. The Upper Range Value will be clamped at the sensor

limit.

20

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

Command 38: Reset Configuration Change Flag

Resets the configuration changed flag associated with the requesting master1 in the device status byte. Masters

should issue this command after the configuration change has been detected and all needed configuration data has

been read from the device.

Byte Format Description

Request Data

Bytes

Response

Data Bytes

Response

Codes

1 The standard now requires that 2 copies of this flag be maintained, one for each type of master. Both copies must be set for any change that affect

configuration, and each type of master may only reset its own copy. It must be the responsibility of the host to decide when the flag copy can be cleared,

and to make sure it does get cleared.

None

None

Code Class Description

None

Note: The HART specification provides response code 7 (In Write protect

mode), but blocking the reset action just because the device is

write-protected would defeat the general principle behind the mechanism

implemented by this command

Command 40: Enter/Exit Fixed PV Current Mode

The device is placed in the Fixed Primary Variable Current Mode with the PV current set to the value received. A

commanded level of ‘0’ forces exit from the Fixed PV Current Mode. This mode is also cleared when power is removed

from the device. Value sent is in mA. Range checking is performed in the instrument (3.7 mA to 22.5 mA). The current

command will be clamped to these limits if the request violates them.

Byte Format Description

Request

Data bytes

Response

Data Bytes

Response

Codes

0-3 Float Current Value (in mA) requested for Fixed Current Mode

0-3 Float Applied PV Current command (in mA)

Code Class Description

14 Error In Multi-Drop Mode

Command 41: Perform Transmitter Self Test

This command is reserved for factory testing only.

21

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

D104329X012

Command 42: Perform Master Reset

Respond immediately and then reset the microprocessor. This is equivalent to a power cycle in the DLC3010.

Byte Format Description

Request

Data bytes

Response

Data Bytes

Response

Codes

None

None

Code Class Description

None

Command 44: Write Primary Variable Units

This command is used to change the units of the Primary Variable. Range checking is performed in the instrument.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response

Codes

0 Uint8 Primary Variable Units Code

0 Uint8

Code Class Description

2 Error Invalid selection

5 Error Too few data bytes received

7 Error In Write Protect mode

Primary Variable Units Code

Command 45: Trim Primary Variable Current DAC Zero

Trim the zero of the analog output so that the commanded signal current is accurately produced. This trim is typically

performed using the Fixed Current Mode by adjusting the associated DAC output to 4.0 mA as observed on a precision

meter. Reasonableness range checking must be done in the DD.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response

Codes

0-3 Float Externally measured current level (mA)

0-3 Float

Code Class Description

3 Error Passed parameter too large

4 Error Passed parameter too small

5 Error Too few data bytes received

7 Error In Write Protect mode

9 Error Not in proper current mode

11 Error In Multidrop mode

Instrument current level (mA)

22

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

Command 46: Trim Primary Variable Current DAC Gain

Trim the gain of the analog output so that the commanded signal current is accurately produced. This trim is typically

performed using the Fixed Current Mode by adjusting the associated DAC output to 20.0 mA as observed on a

precision meter. Reasonableness range checking must be done in the DD.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response

Codes

0-3 Float Externally measured current level (mA)

0-3 Float

Code Class Description

3 Error Passed parameter too large

4 Error Passed parameter too small

5 Error Too few data bytes received

7 Error In Write Protect mode

9 Error Not in proper current mode

11 Error In Multidrop mode

Instrument current level (mA)

Command 48: Read Additional Status

Returns status information which is not included in the response code bytes. The free time alarm bit will be cleared by

this read action. Command 48 returns 3 bytes of data (see table 2b).

Byte Format Description

Request

Data bytes

Response

Data Bytes

Response

Codes

None

0 Uint8 Command 48 Response Byte 0

1 Uint8 Command 48 Response Byte 1

2 Uint8 Command 48 Response Byte 2

Code Class Description

None

23

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

D104329X012

Command 50: Read Dynamic Variable Assignments

This command command reads the variable assigned to the primary variable, namely: Level, Interface, or Density, plus

the fixed assignments. Number of variables matches the HART spec, even though only three variables are read from

the instrument.

Byte Format Description

Request Data

Bytes

Response

Data Bytes

Response

Codes

None

0 Enum ID of variable returned as the first variable (PV) in Command 3, see table 5

1 Enum

2 Enum

3 Enum Code for Unused (250 decimal)

Code Class Description

None

ID of variable returned as the second variable (SV) in Command 3, see table 5

Fixed at Electronics Temperature

ID of variable returned as the third variable (TV) in Command 3, see table 5

Fixed at Process Temperature

Command 51: Write Dynamic Variable Assignments

This command assigns the variable to be used as the primary variable: Level, Interface, or Density. It writes only a

single variable, not the 4 variables defined in the HART specification. The instrument performs validity checking.

Parameters 2, 3, and 4 are not writable and will return what the instrument is using. Note: The instrument may need to

be reconfigured to get valid PV units and upper and lower range values after changing the primary variable. Therefore,

this command should only be issued from a method that takes care of such clean up.

Byte Format Description

0 Enum Device variable ID assigned to PV, see table 5

Request Data

Bytes

Response Data

Bytes

Response

Codes

1 Enum Unused and Ignored by instrument

2 Enum Unused and Ignored by instrument

3 Enum Unused and Ignored by instrument

0 Enum Device variable ID assigned to PV

1 Enum

2 Enum

3 Enum Code for Unused (250 decimal)

Code Class Description

2 Error Invalid selection

7 Error In Write Protect Mode

Device variable ID assigned to SV

Electronics Temperature code from table 5.

Device variable ID assigned to TV

Process Temperature code from table 5.

24

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

Command 53: Set Device Variable Units

This command writes the units associated with the specified parameter. Range checking is performed in the

instrument. Note: Process temperature and electronics temperature share the same unit code so writing new units to

one will change the units for the other.

Byte Format Description Allowable choices

Request Data

Bytes

Response Data

Bytes

Response

Codes

0 Enum Device Variable ID See table 5

1 Enum Units Code See table 6

0 Enum Device Variable ID

1 Enum Units Code

Code Class Description

5 Error Too few data bytes received

7 Error In Write Protect mode

11 Error Invalid Variable ID

12 Error Invalid units code

Command 59: Write Number of Response Preambles

This This is a Data Link Layer Management Command. This command selects the number of preambles to be sent by a

device before the start of a response packet. The instrument range checks this value from 5-20. It stores and reads this

value from NVM, but will use a RAM copy with a minimum value of 5 no matter what it reads from NVM.

Byte Format Description Allowable choices

Request Data

Bytes

Response Data

Bytes

Response

Codes

0 Uint8

0 Uint8

Code Class Description

3 Error Passed parameter is too large

4 Error Passed parameter is too small

5 Error Too few data bytes received

7 Error In Write Protect mode

Number of preambles to be sent prior

to the response message from the

DLC3010 slave to the Master

Number of preambles to be sent prior

to the response message from the

DLC3010 slave to the Master

5-20

25

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

D104329X012

Command 108: Write Burst Command Number

This command is used to select the response command the device transmits while in Burst Mode. HART 5 did not

provide a Read Command for Burst Command Number, so a Device-Specific Command is used to access the value for

display.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

0 Enum Burst Command Number (1, 2, or 3)

0 Enum Burst Command Number (1, 2, or 3)

Code Class Description

Response Codes

2 Error Invalid Selection

Command 109: Write Burst Mode Control

This command is used to enter and exit Burst Mode. HART 5 did not provide a Read Command for Burst Mode, so a

Device-Specific Command is used to access the value for display.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response Codes

0 Enum Burst Mode (0 = Off, 1= On)

0 Enum Burst Mode

Code Class Description

2 Error Invalid Selection

26

Instruction Manual Supplement

D104329X012

Device-Specific Commands

The DLC3010 field device supports the following DeviceSpecific HART Commands.

Command 128: Read Float Variables with Selectable Units

Command 129: Write Float Variables with Selectable Units

Command 130: Read Float Variables with Fixed Units

Command 131: Write Float Variables with Fixed Units

Command 132: Read Byte Variables

Command 133: Write Byte Variables

Command 134: Read NVM (private)

Command 135: Write NVM (private)

Command 137: Read Word Variables

Command 138: Write Word Variables

Command 139: Read Displacer Serial Number

Command 140: Write Displacer Serial Number

Command 142: Read Table Entry

Command 143: Write Table Entry

Command 144: Read Trend Buffer

Command 145: Read Device Variable Alert Params

Command 146: Write Hi Alert

Command 147: Write Hi Hi Alert

Command 148: Write Lo Alert

Command 149: Write Lo Lo Alert

Command 150: Read NVM Count Remaining

Command 151: Capture Zero Reference Angle

Command 152: Set Write Lock

DLC3010 Digital Level Controller

May 2022

27

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

Command 128: Read Float Variables with Selectable Units

This command is used to read a floating-point variable and its associated units code.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

0 Enum Variable Index Number from table 7

0 Enum Variable Index Number from table 7

1 Enum Units Code. See table 6

2-5 Float Value of Selected Variable in Associated Units

Code Class Description

D104329X012

Response Codes

2 Error Invalid Selection

5 Error Too few data bytes received

Command 129: Write Float Variables with Selectable Units

This command is used to write the value of a floating-point variable in its associated units code. The instrument will

convert the value from the presented units to standard internal units before storing it in NVM. The unit code is not

stored. Range checking must be performed in the DD.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response Codes

0 Enum Variable Index Number from table 7

1 Enum Units Code, see table 6

2-5 Float Value of Selected Variable in Associated Units

0 Enum Variable Index Number

1 Enum Units Code

2-5 Float Value of Selected Variable in Associated Units

Code Class Description

2 Error Invalid Selection (Units Code)

3 Error Passed parameter is too large

4 Error Passed parameter is too small

5 Error Too few data bytes received

7 Error In Write Protect mode

28

15 Error Invalid Index (Variable)

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

Command 130: Read Float Variables with Fixed Units

This command is used to read a floating-point variable without any associated units code. The DD must check for

invalid selections.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

0 Enum Variable Index Number from table 8

0 Enum Variable Index Number from table 8

1-4 Float Value of Selected Variable.

Code Class Description

Response Codes

2 Error Invalid Selection

5 Error Too few data bytes received

Command 131: Write Float Variables with Fixed Units

This command is used to write the value of a floating-point variable without any associated units code. Range checking

must be performed in the DD.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response Codes

0 Enum Variable Index Number from table 8

1-4 Float Value of Selected Variable

0 Enum Variable Index Number from table 8

1-4 Float Value of Selected Variable

Code Class Description

2 Error Invalid Selection

3 Error Passed parameter is too large

4 Error Passed parameter is too small

5 Error Too few data bytes received

7 Error In Write Protect mode

Command 132: Read Byte Variables

This command is used to read a byte variable.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response Codes

0 Enum Variable Index Number from table 9

0 Enum Variable Index Number from table 9

1 Enum Value of Selected Byte Variable

Code Class Description

2 Error Invalid Selection

5 Error Too few data bytes received

29

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

D104329X012

Command 133: Write Byte Variables

This command is used to write the value of a byte variable. The instrument only provides range checking for the Hall

drive-current setting and the Number of Meter Decimal Places. All other range checking must be performed in the DD.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response Codes

0 Enum Variable Index Number from table 9

1 Enum Value of Selected Variable

0 Enum Variable Index Number from table 9

1 Enum Value of Selected Variable

Code Class Description

2 Error Invalid Selection

5 Error Too few data bytes received

7 Error In Write Protect mode

15

Error Invalid Index

Command 134: Read NVM

Command 134 description is included in the proprietary version of this document.

Contact your Emerson sales office

if additional information is required.

Command 135: Write NVM

Command 135 description is included in the proprietary version of this document.

Contact your Emerson sales office

if additional information is required.

Command 137: Read Word Variables

This command is used to read Word-size parameters. Range checking must be done outside the instrument. For

invalid index numbers, the instrument will return 0 for data. (This command was not utilized in the user interface.)

Byte Format Description

Request Data

Bytes

Response Data

Bytes

0 Enum Variable Index Number from table 10

0 Enum Variable Index Number from table 10

1 Uint8 LS Byte of Word

2 Uint8 MS Byte of Word

Code Class Description

Response Codes

30

2 Error Invalid Selection

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

Command 138: Write Word Variables

This command is used to write Word-size parameters. Range checking must be done by the DD. For valid writes, the

configuration changed bit will be set. For invalid writes, the bit will not be set. (This command was not utilized in the

user interface.)

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response Codes

0 Enum Variable Index Number from table 10

1 Uint8 LS Byte of Word

2 Uint8 MS Byte of Word

0 Enum Variable Index Number from table 10

1 Uint8 LS Byte of Word

2 Uint8 MS Byte of Word

Code Class Description

2 Error Invalid Selection

9 Error Passed value too high

10 Error Passed value too low

Command 139: Read Serial Number

This command is used to read the instrument or displacer serial number. If the passed index is invalid, the device sets it

to 1.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response Codes

0 Enum Serial Number Index: (0 = Displacer, 1 = Instrument)

0 Enum Serial Number Index

1-16 ASCII Serial Number string

Code Class Description

None

Command 140: Write Serial Number

This command is used to write the instrument or displacer serial number.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

0 Enum Serial Number Index: (0 = Displacer, 1 = Instrument)

1-16 ASCII Serial Number string

0 Enum Serial Number Index

1-16 ASCII Serial Number string

Code Class Description

Response Codes

5 Error Too few data bytes received

15 Error Invalid index

31

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

D104329X012

Command 142: Read Table Entry

This command is used to read an entry from one of the tables in the instrument. The arguments allow selection of the

table, and the row of the table to be read. The instrument returns the pair of data associated with the table entry.

Range checking for proper table index and row number must be done in the DD.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

0 Enum Table Index from table 12

1 Uint8 Row Number (0-9)

0 Enum Table Index

1 Uint8 Row Number

2-5 Float Temperature Value

6-9 Float Coefficient Value

Code Class Description

Response Codes

2 Error Invalid selection

5 Error Too few data bytes received

Command 143: Write Table Entry

This command is used to write an entry into a compensation table in the instrument. Arguments allow selection of the

table, and the row of the table. If the tables are not full, a column 2 (coefficient value) entry of 0.0 will signal the end of

valid data for the table. The DD interface must write the last entry of 0.0 for column 2 to signal the device that the

table is complete and can be used for computations, unless the table has valid data in all 10 rows.

Byte Format Description

0 Enum Table Index from table 12

Request Data

Bytes

Response Data

Bytes

1 Uint8 Row Number (0-9)

2-5 Float Temperature Value (Column 1 entry)

6-9 Float Coefficient Value (Column 2 entry)

0 Enum Table Index

1 Uint8 Row Number

2-5 Float Temperature Value

6-9 Float Coefficient Value

Code Class Description

2 Error Invalid selection

Response Codes

32

3 Error Passed parameter too large

4 Error Passed parameter too small

5 Error Too few data bytes received

15 Error Invalid row number

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

Command 144: Read Trend Buffer

This command is used to read trend data from the instrument. See table 6 for trend variable definitions. The trend

buffer is zeroed after each read. This results in ‘zero’ values being displayed for slots that have not had time to be filled

with samples since the last read of the buffer. The trend buffer is continuously updated at the trend interval whether it

is read or not. (This feature has been removed from the DD in recent revisions, since the available range for trend

interval is quite small.)

Byte Format Description

Request Data

Bytes

Response Data

Bytes

None

Gap Flag: 00 = No gap in data since last read

0 Enum

1-4 Float First Trend Sample

5-8 Float Second Trend Sample

9-12 Float Third Trend Sample

13-16 Float Fourth Trend Sample

17-20 Float Fifth Trend Sample

Code Class Description

10 = Illegal trend variable specified

11 = Gap in data since last read

Response Codes

None

Command 145: Read Device Alert Parameters

This command is used to read the user-configurable alarm thresholds stored in the instrument. It returns all 4 alarm

thresholds for the primary variable, and only the Hi and Lo thresholds for temperature alarms. The Hi-Hi and Lo-Lo

thresholds for temperature will return Not-a-Number. Only a single set of alarm threshold variables exist in firmware

for the Primary Variable, (i.e., there are not separate values maintained for Interface and Density when Level is the

active mode). The values must be edited when the Primary Variable code is changed between (Liquid Level or Interface

Level) and Liquid Density, as the measurement has different dimensions.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response Codes

0 Enum Device Variable Code, see table 5

0 Enum Device Variable Code

1 Enum Units Code

2-5 Float Hi Alarm Threshold

6-9 Float Hi-Hi Alarm Threshold

10-13 Float Lo Alarm Threshold

14-17 Float Lo-Lo Alarm Threshold

Code Class Description

2 Error Invalid selection

5

Error Too few databytes received

33

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

D104329X012

Command 146: Write Hi Alert

This command is used to write the Hi alert threshold for the specified Device Variable. Range checking must be done in

the DD for both range and valid Device Variable code. The Device Variable should be either one of the two

temperatures or the current PV variable code.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response Codes

0 Enum Device Variable Code, see table 5

1 Enum Units Code

2-5 Float Hi Alert Threshold

0 Enum Device Variable Code

1 Enum Units Code

2-5 Float Hi Alert Threshold

Code Class Description

2 Error Invalid selection

3 Error Passed parameter too large

4 Error Passed parameter too small

5 Error Too few data bytes received

7 Error In Write Protect mode

15 Error Invalid index

Command 147: Write Hi Hi Alert

This command is used to write the Hi Hi alert threshold for the Primary Variable. Range checking must be done in the

DD for both valid PV code and range. Using a variable code that is not the current PV variable code will result in

corrupting the alarm threshold values. The Device Variable index used in the request should be the current PV variable

code.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response Codes

0 Enum Device Variable Code, see table 5

1 Enum Units Code

2-5 Float Hi Hi Alert Threshold

0 Enum Device Variable Code

1 Enum Units Code

2-5 Float Hi Hi Alert Threshold

Code Class Description

2 Error Invalid selection

3 Error Passed parameter too large

4 Error Passed parameter too small

5 Error Too few data bytes received

7 Error In Write Protect mode

15 Error Invalid index

34

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

Command 148: Write Lo Alert

This command is used to write the Lo alert threshold for the specified Device Variable. Range checking must be done

in the DD for both range and valid Device Variable code. The Device Variable should be either one of the two

temperatures or the current PV variable code.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response Codes

0 Enum Device Variable Code, see table 5

1 Enum Units Code

2-5 Float Lo Alert Threshold

0 Enum Device Variable Code

1 Enum Units Code

2-5 Float Lo Alert Threshold

Code Class Description

2 Error Invalid selection

3 Error Passed parameter too large

4 Error Passed parameter too small

5 Error Too few data bytes received

7 Error In Write Protect mode

15 Error Invalid index

Command 149: Write Lo Lo Alert

This command is used to write the Lo Lo alert threshold for the Primary Variable. Range checking must be done in the

DD for both valid PV code and range. Using a variable code that is not the current PV variable code will result in

corrupting the alarm threshold values. The Device Variable index used in the request should be the current PV variable

code.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response Codes

0 Enum Device Variable Code, see table 5

1 Enum Units Code

2-5 Float Lo Lo Alert Threshold

0 Enum Device Variable Code

1 Enum Units Code

2-5 Float Lo Lo Alert Threshold

Code Class Description

2 Error Invalid selection

3 Error Passed parameter too large

4 Error Passed parameter too small

5 Error Too few data bytes received

7 Error In Write Protect mode

15 Error Invalid index

35

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

D104329X012

Command 150: Read NVM Remaining

This command returns the number of NVM write counts remaining in each of the three NVM sections. Their type is

“unsigned integer”.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

None

0-1 Uint16 NVM Writes Remaining in Microprocessor EEPROM

2-3 Uint16 NVM Writes Remaining in On-Board NVM

4-5 Uint16 NVM Writes Remaining in Transducer Board

Code Class Description

Response Codes

None

Command 151: Capture Zero Reference Angle

This command is used to mark the current pilot shaft position as the zero (differential) buoyancy reference. The

instrument will read the internal variable representing shaft rotation, and store it for use in all measurement

calculations.

In Level measurement mode, where the SG value represents the differential density between the upper and lower

phase, this command should be issued after the lever assembly has been unlocked, and the displacer is at the lowest

buoyancy process condition.

In Interface or Density measurement mode, the variable being marked must represent true zero buoyancy. Because of

this, it is not possible to use this command effectively with an over-weight displacer in those modes. In this condition,

the sensor linkage is on a travel stop at zero buoyancy and does not reflect the full theoretical deflection. The required

zero-reference value must be back-computed from two calibration data points, and written explicitly with the Write

NVM command.

This command does not check write lock status, although it affects the instrument calibration. It therefore should be

used only inside a method in the instrument DD, where write protect status can be enforced explicitly.

Byte Format Description

Request Data

Bytes

Response Data

Bytes

None

None

Code Class Description

Response Codes

36

None

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

May 2022

Command 152: Set Write Lock

This command is used to either set or clear the write lock. This command is also sensitive to Primary/Secondary Master

status in the message. If a primary master sets write lock, then only a primary master can clear write lock, not a

secondary, and vice versa. However, this variable is stored in RAM and will be reset to the OFF condition (writes

enabled) after power-up, providing a work-around if the correct master priority is unavailable.

Write lock status is checked by the following:

Universal commands: 6, 17, 18, 19.

Common Practice commands: 34, 35, 36, 37, 40, 44, 45, 46, 51, 53, 59, 108, 109.

Device-Specific commands: 129, 131, 133, 138, 140, 143, 146, 147, 148, 149, (and 152 with respect to a different

master hierarchy).

Byte Format Description

Request Data

Bytes

Response Data

Bytes

Response Codes

0 Enum Write Lock request: (0 = OFF, 1 = ON)

0 Enum Write Lock state

Code Class Description

2 Error Invalid selection

16 Error Access Restricted (Another host has possession of the lock)

37

DLC3010 Digital Level Controller

May 2022

Instruction Manual Supplement

D104329X012

Tables

Table 1: DLC3010 HART Response Codes

The following codes represent a sub-set of the HART Response Codes which can be returned by the DLC3010

instrument.

Code Meaning

0 No command specific errors

2 Invalid Selection

3 Parameter Too Large

4 Parameter Too Small

5 Incorrect Byte Count

7 In Write Protect Mode

8 Data Truncated (warning)

Lower Range Too High

9

10

11

12

13

14

15 Invalid Index

16 Access Restricted

32 Busy

64 Command Not Implemented

Not in Proper Mode

Process Too High

Zero Range Too High

Lower Range Too Low

Process Too Low

Zero Range Too Low

In MultiDrop Mode

Invalid Variable Code

Span Range Too High

Starting Address Too Low

Upper Range Too High

Starting Address Too High

Upper Range Too Low

Span Lower Out of Limits

Upper/Lower Out of Limits

New LRV Pushed URV Over Limit (Warning)

Span Too Small (Warning)

38

Instruction Manual Supplement

D104329X012

Table 2a: Device Status

Bit Name of Status Bit Meaning

- This bit should be set whenever the firmware detects a serious error or failure

7 Field Device Malfunction

6 Configuration Changed

that compromises device operation. In DLC3010 firmware 8, the only event that

sets it is a time-out during writes to Description or Message, caused by a

firmware bug involving an improperly initialized timer. Its functional severity

is thus downgraded to advisory.

Two such bits exist internally, one for each HART master. Both copies are set

when any variable, HART message, tag, descriptor or date are changed from

HART. Cleared by command 38, separately for each master. This bit survives

loss of power. A firmware 8 bug prevents it from being returned to the

secondary master.

DLC3010 Digital Level Controller

May 2022

5 Cold Start

device power up. Cleared by the first HART command. Two such bits exist

internally, one for each HART master.

4 More Status Active when any bit in command 48 is active.

Set by the firmware whenever a RESET sequence is executed or at initial

Primary Variable Analog

3

Output Fixed

Primary Variable Analog

2

Output Saturated

The analog output for the Primary Variable is being held at a fixed value and is

not responding to process variations.

The analog output for the Primary Variable has reached its upper (or lower)

endpoint limit and cannot increase (or decrease) any further.

A Device Variable not mapped to the Primary Variable is beyond the operating

Non-Primary Variable Out of

1

Limits

limits of the device. The “Read Additional Transmitter Status” Command,

#48, may be required to identify the variable. This bit is the logical OR of the

Middle Status Byte, Bits 3 through 0, (Process Temperature and Electronics

Temperature Alarms).

0 Primary Variable Out of Limits Primary Variable is beyond the operating limits of the device.

39

DLC3010 Digital Level Controller

May 2022

Table 2b: Additional Status Bytes

Byte Bit Name of Status Bit Meaning

7 Reserved

6 Reserved

5 Sensor Signal Failed

4 Sensor Drive Failed

0

3 Reference Voltage Failed

2 NVM Write Limit Exceeded

1 Free Time Limit Exceeded

Process Temperature Sensor

0

Failed

The torque tube position reading has exceeded the hard-coded

limits, either above or below.

The Hall sensor drive current read-back has exceeded the

hard-coded limit.

The reference voltage for the A/D has exceeded the hard-coded

limits, either above or below.

The total number of writes to NVM has exceeded the hard-coded

limit. This bit is an OR of all the NVM write limit flags.

There is insufficient free time remaining in the execution period to

complete the scheduled tasks.

The apparent resistance measured at the RTD terminals is less than

10 ohms or greater than 320 ohms.

7 PV Hi Limit Exceeded Active when user-configured threshold is violated.

6 PV HiHi Limit Exceeded Active when user-configured threshold is violated.

5 PV Lo Limit Exceeded Active when user-configured threshold is violated.

4 PV LoLo Limit Exceeded Active when user-configured threshold is violated.

Process Temperature Hi Limit

3

1

Exceeded

Process Temperature Lo Limit

2

Exceeded

Electronics Temperature Hi

1

Limit Exceeded

Electronics Temperature Lo

0

Limit Exceeded

Active when user-configured threshold is violated.

Active when user-configured threshold is violated.

Active when user-configured threshold is violated.

Active when user-configured threshold is violated.

2 All Reserved

"Reserved" bits are always set to 0

Instruction Manual Supplement

D104329X012

Table 3: Manufacturer Identification Code

Code

Meaning

19 Fisher Controls

Table 4: Physical Signaling Codes

Code

Meaning

0 Bell 202 Current Mode

1 Bell 202 Voltage Mode

40

Instruction Manual Supplement

D104329X012

DLC3010 Digital Level Controller

Table 5: DLC3010 Device Variable Codes

(Index for commands 50, 51, 145, 146, 147, 148, 149)

Code Variable Class Unit Codes

0 Liquid Level None Length (table 6)

1 Interface Level None Length (table 6)

2 Liquid Density None Density (table 6)

3 Process Temperature None Temperature (table 6)

4 Electronics Temperature None Temperature (table 6)

Table 6: DLC3010 Enumeration Codes

Length Units

Code

44 feet

45 meters

47 inches

48 centimeters

49 millimeters

Density Units

Code

90 SGU (specific gravity units)

91 grams/cubic centimeter

92 kilograms/cubic meter

93 pounds/gallon

94 pounds/cubic feet

95 grams/milliliter

96 kilograms/liter

97 grams/liter

98 pounds/cubic inch

Temperature Units

Code

32 Centigrade

33 Fahrenheit

Weight Units

Code

60 gram

61 kilogram

63 pound

125 ounce

Units

Units

Units

Units

Volume Units

Code

Units

41 liter

113 cubic inches

240 cubic millimeters

241

milliliters (cubic

centimeters)

Torque Rate Units

Code

Units

247 inch pound/degree

248 Newton meter/degree

249 dyne centimeter/degree

Sensor Mounting

Code

Meaning

0 Left of displacer

1 Right of displacer

LCD Meter Installation

Code

Meaning

0 Not installed

1 Installed

LCD Meter Display Mode

Code

Meaning

0 All cells off

1 All cells on

2 PV only

Alternate:

3

PV, Proc Temp,

Degrees Rotation

4 Percent only

5

Alternate:

PV, Percent

May 2022

41

DLC3010 Digital Level Controller

(1)

May 2022

Table 6: DLC3010 Enumeration Codes (continued)

LCD Meter Decimal Point

Code

Meaning

0 Autoranging

1 1 digit after decimal point

2 2 digits after decimal point

3 3 digits after decimal point

4 4 digits after decimal point

Trend Variable

Code

Meaning

0 Trending disabled

1 Primary Variable

2 Process temperature

3 Electronics Temperature

RTD Type

Code

Meaning

0 No RTD installed (manual)

1 2-wire RTD

2 3-wire RTD

Hall Sensor Drive Level

Code

Meaning

0 Low level (≅500 μA)

1 High level (≅725 μA)

Instruction Manual Supplement

PV Alert Enable Bits

(1=enabled, 0 = disabled)

Bit Mask

0x80 Reserved

0x40 Reserved

0x20 Reserved

0x10 Reserved

0x08 PV Hi

0x04 PV HiHi

0x02 PV Lo

0x01 PV LoLo

Temperature Alert Enable Bits

(1=enabled, 0 = disabled)

Bit Mask

0x80 Reserved

0x40 Reserved

0x20 Reserved

0x10 Reserved

0x08 Process Temperature Hi

0x04 Process Temperature Lo

0x02 Electronics Temperature Hi

0x01 Electronics Temperature Lo

Monitor