Fisher IM Supplement: HART Communicating FIELDVUE DVC6200 Digital Valve Controllers-Zero Point Calibration Manuals & Guides

Instruction Manual Supplement

D104328X012

Zero Point Calibration

DVC6200 Digital Valve Controller

June 2018

HART

®

Communicating Fisher™ FIELDVUE

™

DVC6200 Digital Valve Controllers

The Zero Point Calibration procedure allows you replace an existing DVC6200 digital valve controller without

performing a travel calibration. This procedure can be used when a situation occurs that requires the partial or

complete replacement of a digital valve controller when part of a valve assembly that does not have a process bypass

or the process cannot be shut down.

WARNING

Personal injury or property damage, caused by unexpected valve movement and an uncontrolled process, could result if

this procedure is attempted when the valve is not locked at its present position. If you cannot safely lock the valve in

position until this procedure is complete, do not proceed with this procedure.

Notes

This procedure should only used for the partial or complete replacement of a digital valve controller when the valve does not have

a bypass or the process cannot be shut down. Do not proceed with this procedure if the valve has a bypass or the process can be

shut down.

This procedure assumes the array was set up properly on the existing DVC6200 and has not been moved or adjusted since setup.

The valve will need to be locked at its present position. This can be accomplished by using a handwheel or other mechanism. If you

cannot safely lock the valve in position until this procedure is complete, do not proceed with this procedure.

™

This procedure requires the use of a 475 Field Communicator, AMS Trex

This procedure can be used to swap a DVC6200 with another DVC6200. You cannot swap a DVC6000 with a DVC6200 using this

procedure. The DVC6200 used to replace the existing digital valve controller must be a new, factory calibrated instrument. This

procedure will not work if a previously installed and calibrated digital valve controller is used.

Device Communicator, or ValveLink™ software.

Zero Point Configuration Process

HART DD

CAUTION

The touch screen of the 475 Field Communicator or AMS Trex Device Communicator should only be contacted by blunt

items. The use of a sharp instrument can cause damage to the touch screen interface.

www.Fisher.com

DVC6200 Digital Valve Controller

June 2018

Instruction Manual Supplement

475 Field Communicator and AMS Trex Device Communicator

1. If using the 475 Field Communicator, Select the HART Icon from the Main Menu, shown in figure 1.

If using the Trex Communicator, select Field Communicator from the main menu.

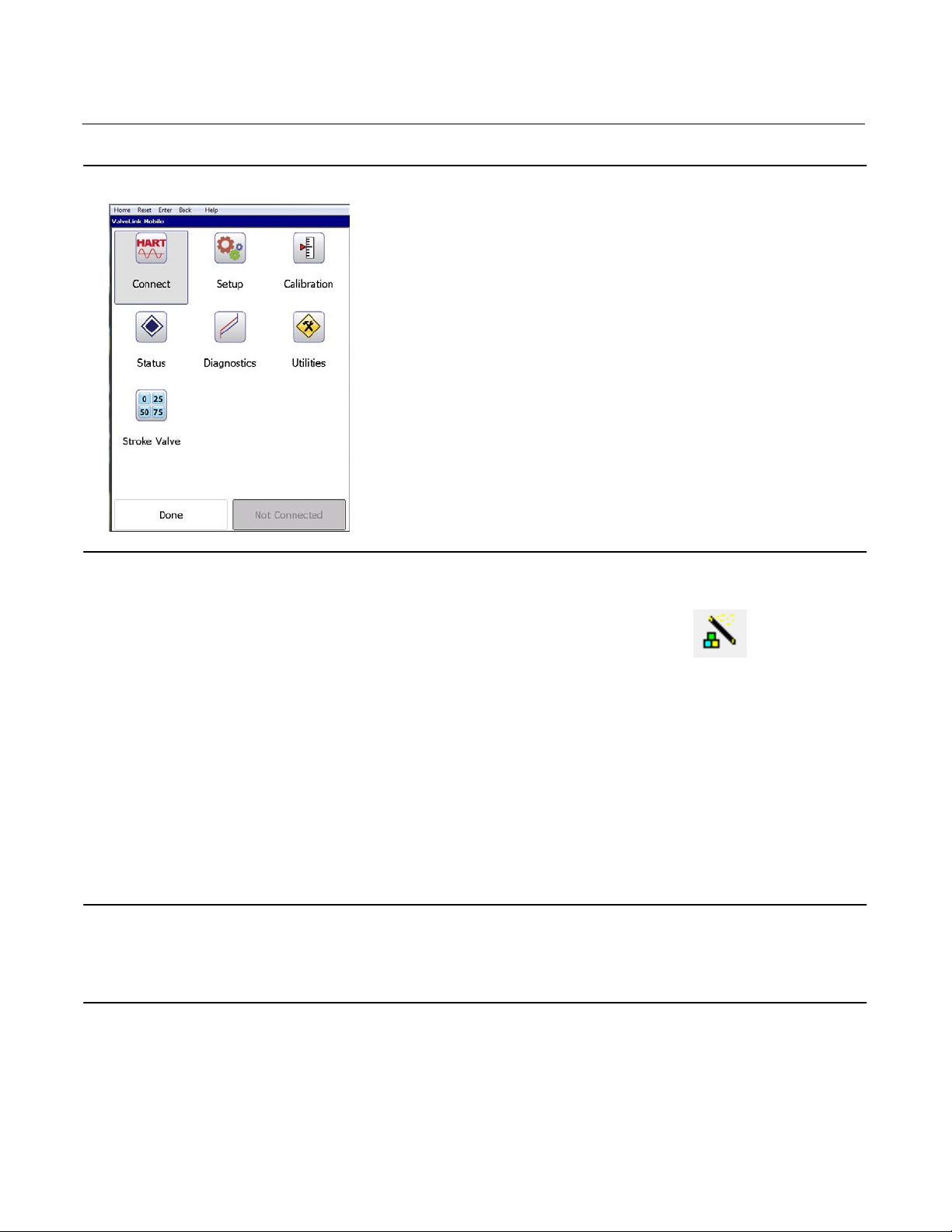

Figure 1. 475 Field Communicator Menu Screen

D104328X012

2. From the Online menu select Configure > Guided Setup > Device Setup.

3. Provide the requested information, including: Pressure Units, Relay Type, Control mode (Travel Control, Pressure

Control, Fallback-Sensor Failure, Fallback-Sensor/Tvl Deviation), max supply pressure, Actuator manufacturer,

Actuator model, Actuator size, Volume Booster/Quick Release.

4. Send the configuration to the instrument.

5. Use factory defaults for setup

6. Select Cancel (475) or Abort (Trex) when prompted to run Auto Tvl Calib.

7. Place the instrument “In Service”.

ValveLink Mobile

AMS Trex Device Communicator or 475 Field Communicator

1. Select ValveLink Mobile from the Field Communicator Main Menu (see figure 1).

2. Select HART device.

3. Select Connect from the ValveLink Mobile main menu (see figure 2) to connect to the instrument.

4. Select Setup > Setup Wizard.

5. Provide the requested information then select Apply.

6. When prompted to run an Auto Travel Calibration select No.

7. Place the instrument “In Service”.

2

Instruction Manual Supplement

D104328X012

Figure 2. ValveLink Mobile Menu Screen

DVC6200 Digital Valve Controller

June 2018

ValveLink software

1. Initiate the Setup Wizard either from the Instrument Setup menu or Setup Wizard Icon .

2. Select the appropriate Travel/Pressure Control Mode and the Relay Type.

3. Set the desired Pressure Units and the Max Supply Pressure for the application.

4. Select the required Actuator Information including: Actuator Make, Actuator Model, Actuator Size, and designate if

a Volume Booster or Quick Exhaust Valve is present.

5. Select Yes when prompted to Use Factory Default Settings.

6. When prompted to run an Auto Travel Calibration select No.

7. Place the instrument “In Service”.

Alignment Verification

Note

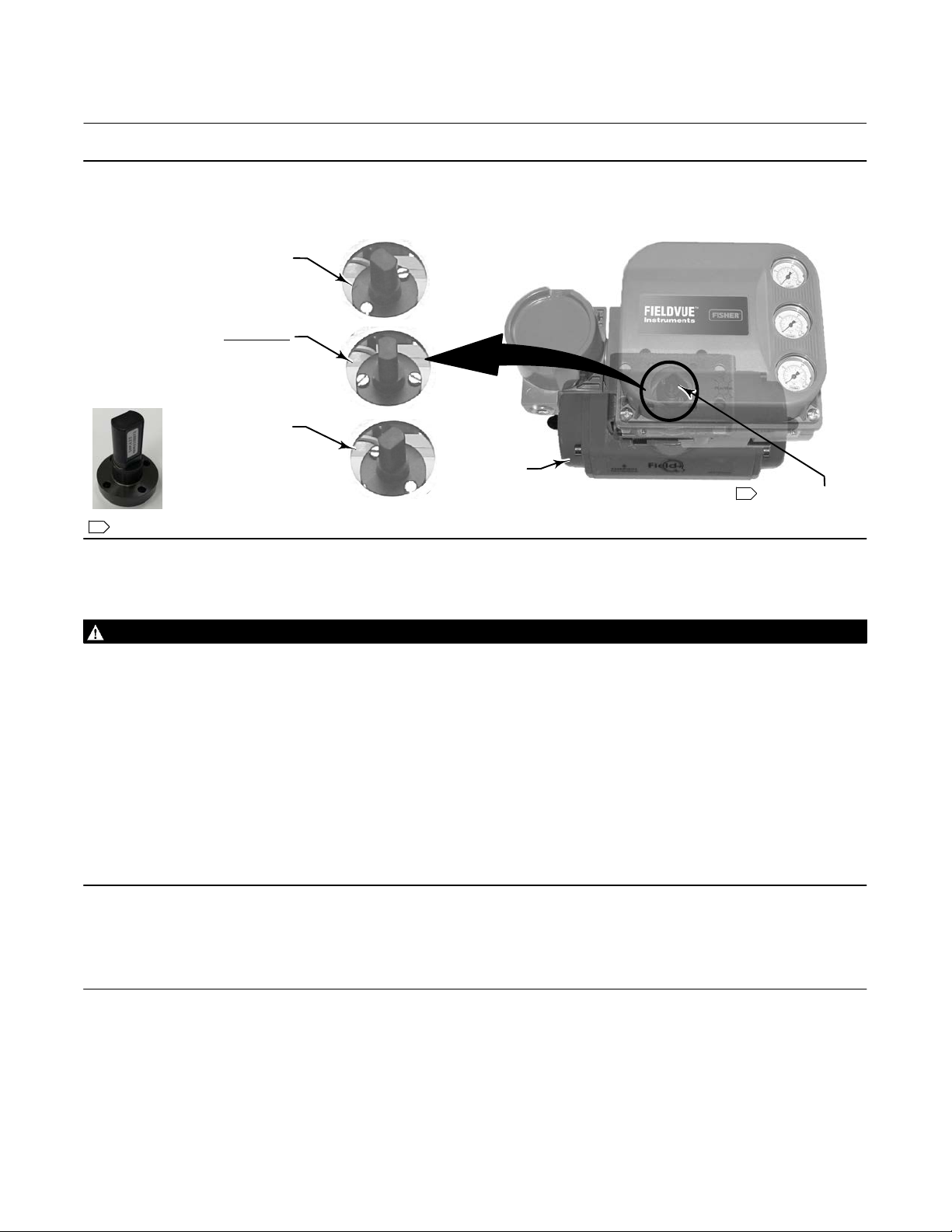

The rotary end mount array is the only array that must be verified. If the array is not at mid-travel, remove and reposition prior to

mounting the DVC6200.

All other arrays can be mounting in any direction, as they are not affected by north south polarity.

Alignment of the rotary array can impact the ability of the DVC6200 digital valve controller to properly follow the

setpoint. To ensure proper operation, the array must be mounted to the actuator with the label facing the gauge side

of the positioner when the valve is at 50% (mid) travel, see figure 3 below. If the array position is different, the array

should be removed and reoriented prior to mounting the DVC6200.

3

DVC6200 Digital Valve Controller

June 2018

Figure 3. Rotary Array Orientation

ORIENTATION

AT ONE TRAVEL

EXTREME

ORIENTATION

AT MID‐TRAVEL

(FLATS PARALLEL

TO DVC6200

CHANNEL)

ORIENTATION

AT THE OTHER

TRAVEL EXTREME

1 ROTARY ARRAY WITH STICKER SHOWN

ACTUATOR

Instruction Manual Supplement

D104328X012

DVC6200

W9700

STICKER WILL BE

1

ON GAUGE SIDE

To change a DVC6200 on the valve

WARNING

Avoid personal injury or property damage from sudden release of process pressure or bursting of parts. Before proceeding

with any Installation procedures:

D Always wear protective clothing, gloves, and eyewear to prevent personal injury or property damage.

D Do not remove or uncouple the actuator from the valve while the valve is still pressurized.

D The valve will need to be locked at its present position. If you cannot safely lock the valve in position until this procedure

is complete, do not proceed with this procedure.

D After the valve has been safely locked in position, disconnect any operating lines providing air pressure, electric power,

or a control signal to the actuator. Be sure the actuator cannot suddenly open or close the valve.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Note

The lack of a travel calibration can impact the accuracy of the position feedback. While this does not impact the positioner’s ability

to control the process, it can influence the results of specific diagnostic tests. These tests include: Valve Signature, Dynamic Error

Band, and Step Response.

Block the valve into position either with a handwheel, with a pneumatic bypass arrangement that includes a regulator

and pressure gauge, or by mechanicallylocking the valve. Remove the existing digital valve controller by disconnecting

mounting hardware, being careful NOT to loosen or move the magnetic array that is connected to the valve stem

block. The magnetic array will remain on the valve and its position must remain the same. Install the new DVC6200

over the existing array assembly.

4

Instruction Manual Supplement

D104328X012

DVC6200 Digital Valve Controller

June 2018

WARNING

Personal injury or property damage, caused by unexpected valve movement, could result if the digital valve controller is

put in service with the connector arm or array moved from its original position.

If the connector arm or array is moved, the digital valve controller must be calibrated before putting it in service. Refer to

the appropriate instruction manual or quick start guide for calibration information.

Ensure that air and signal is supplied to the digital valve controller and remove mechanism for locking the valve in

place. Allow for a slow transition from manual to auto loop control.

Note

For a DVC6200 on a DeltaV system go to Detailed Setup to ensure the input units are set to 0 - 100%.

Note

To ensure greater accuracy, perform an auto travel calibration on the digital valve controller when conditions allow.

Related Documents

D Fisher FIELDVUE DVC6200 Series Digital Valve Controller Quick Start Guide (D103566X012)

D Fisher FIELDVUE DVC6200 HW2 Digital Valve Controller Instruction Manual (D103605X012

D Fisher FIELDVUE DVC6200 HW1 Digital Valve Controller Instruction Manual (Supported) (D103409X012

These documents are available from your Emerson sales office

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher, FIELDVUE, ValveLink, and Trex are marks owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co.

Emerson Automation Solutions, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property

of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

or Local Business Partner, or at www.Fisher.com.

)

)

E 2017, 2018 Fisher Controls International LLC. All rights reserved.

5

Loading...

Loading...