Fisher IM Supplement: FIELDVUE DVC6200 - Implementation of Lock-in-Last Strategy Manuals & Guides

Instruction Manual Supplement

D103261X012

DVC6200 Digital Valve Controllers

February 2020

Implementation of Lock‐in‐Last Strategy

Supplement to Fisher™ FIELDVUE™ DVC6200 Digital Valve

Controller Instruction Manuals

Many applications require a valve assembly to remain in the position it was prior to a specific control system failure

(lock‐in‐last position). Functionality and safety can be designed into valve assemblies with FIELDVUE digital valve

controllers by utilizing an array of accessories. The following paragraphs describe standard solutions for a number of

generic lock‐in‐last applications with HART

Note

This instruction manual supplement also pertains to FELDVUE DVC6000 digital valve controllers; refer to the appropriate DVC6200

or DVC6000 document below, available from your Emerson sales office or at Fisher.com.

DVC6200 Series Digital Valve Controller Quick Start Guide (D103556X012)

D

D DVC6200 HW2 Digital Valve Controller Instruction Manual (D103605X012)

D

DVC6200 HW1 Digital Valve Controller Instruction Manual (D103409X012)

D DVC6000 Digital Valve Controllers Instruction Manual (D102794X012)

Other related documents include:

D

Fisher 377 Trip Valve Instruction Manaul (D200319X012)

D 167D, 167DA, 167DS and 167DAS Switching Valves Installation Guide (D103234X014)

D 167D, 167DA, 167DS and 167DAS Switching Valves Instruction Manual (D103234X012)

®

Communicating DVC6200 digital valve controllers.

Lock‐in‐Last on Loss of Supply Pressure

Once the supply pressure falls below a minimum value, the digital valve controller can no longer position a valve

assembly; the valve will start to go to the actuator “at rest” position. The locking device senses this change and

activates, preventing the remaining air from venting. The valve is “locked‐in” this new position.

Note

The locked‐in valve position depends on the exhausting speed of the actuator.

Assemblies with Single‐Acting Actuators

A Fisher 167DA three‐way switching valve should be used for locking a single‐acting actuator in place on loss of supply

pressure. Figure 1 is a schematic representing proper assembly layout. In normal operation, the digital valve controller

output passes through the switching valve from port A to port B and on to the actuator.

www.Fisher.com

DVC6200 Digital Valve Controllers

Instruction Manual Supplement

February 2020

Figure 1. Lock‐in‐Last on Loss of Supply Pressure for an Assembly with a Single‐Acting Actuator

FISHER 167DA THREE‐WAY

SWITCHING VALVE

D

D103261X012

DIGITAL

VALVE

CONTROLLER

B

OUTPUT

SUPPLY

A

C

AIR

SUPPLY

FISHER 67CFR

FILTER/REGULATOR

In a fail condition, the pressure at port D is below the switching valve's set point, causing the switching valve to trip.

This closes port B, which locks the pressure in the actuator. Port C is plugged so the digital valve controller output will

not exhaust to the atmosphere.

Assemblies with Double‐Acting Actuators

Similar to the locking strategy used with single‐acting actuators, the locking strategy with double‐acting actuators

also uses a valve for locking supply pressure in the actuator. For assemblies with double‐acting actuators, a Fisher 377L

trip valve is used as the locking device. The 377L trip valve has two output ports for locking pressure on both sides of a

double‐acting actuator. Figure 2 is a schematic representing proper assembly layout.

Figure 2. Lock‐in‐Last on Loss of Supply Pressure for an Assembly with a Double‐Acting Actuator

FISHER 377L TRIP VALVE

INPUT

D

A

E

B

F

C

FISHER 67D

REGULATOR

DIGITAL

VALVE

CONTROLLER

2

OUTPUT

SUPPLY

OUTPUT

AIR

SUPPLY

Instruction Manual Supplement

D103261X012

DVC6200 Digital Valve Controllers

February 2020

Connection of the digital valve controller output to a double‐acting actuator determines the action of the actuator.

Figure 2 shows the digital valve controller providing lower cylinder pressure through ports D and E, and upper cylinder

pressure through ports A and B. When the supply pressure falls below the set point of the trip valve, the trip valve

closes ports D and A and connects port B to C and port E to F. Because C and F are plugged, the control valve is locked

in place by locking pressure on both sides of the actuator piston. The assembly returns to normal operation once

supply pressure is restored at the trip valve INPUT port.

Note

Double‐acting actuators with a 377L trip valve require a Fisher 67D or MR95H regulator. Regulators with smaller flow capacities

may cause the trip valve to cycle (lock and unlock repeatedly) due to air flow demand as the assembly attempts to reset. Use a

Fisher 252 or 262C pilot filter to filter supply air.

Both the 167DA switching valve and the 377L trip valve have a deadband that must be overcome. The switching valve must be

calibrated to reset upon restoration of adequate supply pressure to the regulator. The 377L trip valve has only one spring

selection. However, for minimal deadband, the lightest appropriate spring should be selected for the 167DA switching valve.

Lock‐in‐Last Using Solenoid Valves

Solenoid valves are used with valve assemblies in many ways. Their electrical control can be utilized in combination

with switches and controller logic to perform a number of functions.

Note

Solenoid valves placed between the output of a DVC6200 digital valve controller and the input to an actuator require a minimum

C

of 0.49. Greater restrictions can affect the response of the assembly. An example of an appropriate three‐way solenoid valve for

v

use with the digital valve controller is the ASCO

Assemblies with Single‐Acting Actuators

A three‐way universal solenoid valve can be placed between the digital valve controller output and the actuator input.

Switching the valve assembly from an unlocked state to a locked state is controlled by switching power on and off to

the solenoid valve. Figure 3 depicts proper assembly layout.

Under normal operating conditions the solenoid is energized and supply air flows from the digital valve controller

output to the actuator input. In the fail state, power is removed from the solenoid causing the solenoid valve to close,

locking air pressure in the actuator. Port 1 of the solenoid valve is plugged, preventing actuator air pressure from

exhausting to the atmosphere.

™ 8327 Series solenoid valve from ASCO Valve, Inc.

3

DVC6200 Digital Valve Controllers

Instruction Manual Supplement

February 2020

Figure 3. Lock‐in‐Last Strategy for an Assembly with a Single‐Acting Actuator Using a Solenoid Valve

1

SOLENOID VALVE

(ENERGIZED)

DIGITAL

VALVE

CONTROLLER

OUTPUT

SUPPLY

2

3

1

FISHER 67CFR

FILTER/REGULATOR

24 VDC

POWER SUPPLY

AIR

SUPPLY

D103261X012

NOTE:

1A SOLENOID VALVE WITH A MINIMUM C

ASCO 8327 SERIES OR EQUIVALENT, IS REQUIRED FOR THIS ASSEMBLY

OF 0.49, SUCH AS THE

V

Assemblies with Double‐Acting Actuators

Assemblies with double‐acting actuators require a 377L trip valve to lock pressures on both sides of the actuator

piston. Figure 4 is a schematic of a double‐acting actuator with lock‐in‐last capability shown in its normal operating

mode. The solenoid valve is placed in series with the signal port of the trip valve. When tripped, the solenoid valve

exhausts the signal pressure to the trip valve to atmosphere. This simulates a loss in supply pressure, causing the trip

valve to lock pressure in the actuator.

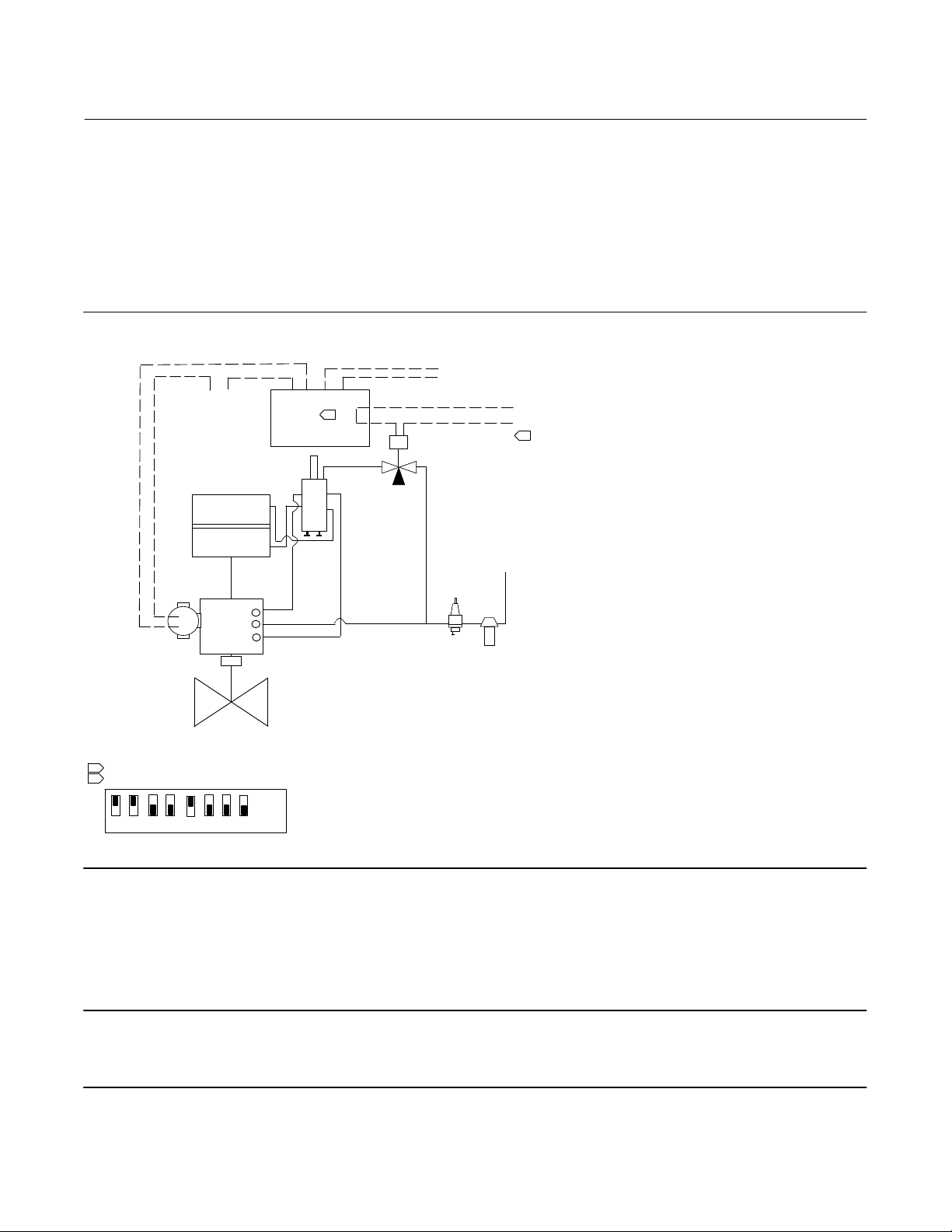

Figure 4. Lock‐in‐Last for an Assembly with a Double‐Acting Actuator Using a Solenoid Valve

2

1

24 VDC

POWER SUPPLY

FISHER 67D

REGULATOR

AIR

SUPPLY

FISHER 252

AIR/GAS FILTER

DIGITAL

VALVE

CONTROLLER

FISHER 377L

TRIP VALVE

OUTPUT

SUPPLY

OUTPUT

SOLENOID VALVE

(ENERGIZED)

1

A

D

E

B

FC

3

NOTE:

1THE ASCO 8320 SERIES SOLENOID VALVE OR EQUIVALENT IS APPROPRIATE FOR THIS ASSEMBLY.

4

Instruction Manual Supplement

D103261X012

The solenoid valve in this solution does not require a Cv greater than 0.49. Flow capacity of this valve can be much

smaller. An example of a proper solenoid valve for this assembly is the 8320 Series three‐way solenoid valve. As with all

solenoid valves, ensure that the solenoid valve operating pressure differential rating is adequate for the supply

pressure.

DVC6200 Digital Valve Controllers

February 2020

Lock‐in‐Last on Loss of Supply Pressure and/or Loss of Loop

Current

Most applications require a valve assembly to be in a lock‐in‐last fail state not only on loss of adequate supply pressure

but also on loss of loop power. Lock‐in‐last on loss of supply pressure is quite straight forward. Lock‐in‐last on loss of

loop power can be more complex.

Most control loops operate on a 4‐20 mA control signal. A solenoid valve, adequately sized for the application, requires

more than 4 mA to energize. Therefore, the control loop cannot be used to energize the solenoid. Instead the solenoid

must be powered by a separate 24 volt power source. Thus an additional device is required to monitor the current to

the digital valve controller and control the power to the solenoid.

A current threshold switch can be used to monitor the 4‐20 mA signal to the digital valve controller. Upon loss of this

signal, or when the signal falls below the threshold, the threshold switch will open an internal relay. This relay, if placed

between a solenoid valve and its power supply, will essentially open and close the solenoid valve. The solenoid valve

can be placed in line with the tubing to the actuator to provide the lock‐in‐last function.

To ensure adequate response time of a locking system to a loss of loop current, a threshold switch with a maximum

deadtime of 0.025 seconds should be used. The locking system will be faster than the response of the positioning

system to the failure.

One switch that meets the maximum deadtime requirements is the Phoenix Contact Dual Setpoint Module, Mini

MCR-SL-UI-REL.

Note

The Mini MCR-SL-UI-REL switch is not provided by Emerson. Order this switch from Phoenix Contact.

Assemblies with Single‐Acting Actuators

Assemblies with a single‐acting actuator use a 167DA three‐way switching valve in conjunction with a solenoid valve.

Figure 5 is a schematic of a single‐acting actuator assembly with lock‐in‐last capability on loss of supply pressure or

loop current. Under normal operating conditions power is supplied to the solenoid valve and adequate supply pressure

is available to the switching valve. Upon loss of supply pressure, the set point of the switching valve is exceeded and

the switching valve trips.

Note

After the threshold switch is connected, as shown in figure 5, use a single set point source to apply 4 mA to power both the switch

and the digital valve controller.

The threshold switch low trip point is established using the potentiometer, which is located under the switch cover along with a

Yellow LED indicator. If the LED is on, adjust the potentiometer just to the point that the light goes off. Then adjust the

potentiometer back until the light just comes back on. If the light was off when power was first applied adjust the potentiometer

as described previously until the light just comes on. This sets the the low trip point for the switch.

5

DVC6200 Digital Valve Controllers

February 2020

Instruction Manual Supplement

D103261X012

If the switch is connected and calibrated correctly, the LED indicator should stay lit as long as the digital valve controller and switch

are sufficiently powered from the control system AO and have a control signal of 4 mA or higher. If the LED is not on it indicates

that a fault state exists and the threshold switch relay will open to disconnect power to the solenoid and the valve should be in the

lock-in-last state.

Figure 5. Lock‐in‐Last on Loss of Loop Current and/or Supply Pressure for an Assembly with a Single‐Acting Actuator

FISHER 167DA

THREE‐WAY

SWITCHING VALVE

B

DIGITAL

+

VALVE

-

CONTROLLER

4‐20

-

NOTE:

1THE ASCO 8320 SERIES SOLENOID VALVE OR EQUIVALENT IS APPROPRIATE FOR THIS ASSEMBLY.

2MINI MCR-SL-UI-REL DIP SWITCH SETTINGS:

1 2 3 4 5 67 8

mA

ON

OFF

1

+

OUTPUT

SUPPLY

SOLENOID VALVE

(ENERGIZED)

PHOENIX

2

SWITCH

MCR-SL-UI-REL

65

D

A

C

FISHER 67CFR

FILTER/REGULATOR

AIR

SUPPLY

1

3

2

3

2

87

+

-

24 VDC

POWER SUPPLY

+

Upon loss of loop current, the threshold switch relay opens, and trips the solenoid valve by cutting the power to the

solenoid. When the solenoid valve trips, the supply pressure that was holding the switching valve open is exhausted to

atmosphere. This simulates a loss of supply pressure, causing the switching valve to trip.

Note

Use a single 24 V power source for both the analog output (AO) card providing loop current to the digital valve controller and the

solenoid valve. This ensures power is maintained to the solenoid valve as long as the AO card is sufficiently powered.

Assemblies with Double‐Acting Actuators

The same principle used for assemblies with single‐acting actuators is used for assemblies with double‐acting

actuators. Figure 6 is a schematic of the double‐acting assembly with lock‐in‐last capability shown under normal

operating conditions.

Note

After the threshold switch is connected, as shown in figure 6, use a single set point source to apply 4 mA to power both the switch

and the digital valve controller.

6

Instruction Manual Supplement

D103261X012

DVC6200 Digital Valve Controllers

February 2020

The threshold switch low trip point is established using the potentiometer, which is located under the switch cover along with a

Yellow LED indicator. If the LED is on, adjust the potentiometer just to the point that the light goes off. Then adjust the

potentiometer back until the light just comes back on. If the light was off when power was first applied adjust the potentiometer

as described previously until the light just comes on. This sets the the low tirp point for the switch.

If the switch is connected and calibrated correctly, the LED indicator should stay lit as long as the digital valve controller and switch

are sufficiently powered from the control system AO and have a control signal of 4 mA or higher. If the LED is not on it indicates

that a fault state exists and the threshold switch relay will open to disconnect power to the solenoid and the valve should be in the

lock-in-last state.

Figure 6. Lock‐in‐Last on Loss of Loop Current and/or Supply ressure for an Assembly with a Double‐Acting Actuator

+

24VDC POWER SUPPLY

-

7

-

+

4‐20 mA

56

PHOENIX

SWITCH

MCR-SL-UI-REL

FISHER 377L

TRIP VALVE

8

2

2

3

A

D

E

B

C

F

1

3

SOLENOID VALVE

(ENERGIZED)

2

+

-

1

AIR SUPPLY

FISHER 67D

REGULATOR

DIGITAL

+

VALVE

CONTROLLER

NOTE:

1THE ASCO 8320 SERIES SOLENOID VALVE OR EQUIVALENT IS APPROPRIATE FOR THIS ASSEMBLY.

2MINI MCR-SL-UI-REL DIP SWITCH SETTINGS:

1 2 3 4 5 67 8

OUTPUT

SUPPLY

OUTPUT

FISHER 252

AIR/GAS FILTER

ON

OFF

Note

DVC6200 digital valve controllers require approximately 0.5 seconds to initialize upon power up. During this time, the digital valve

controller cannot provide control. In the case where control of a previously locked valve is restored to a digital valve controller prior

to the completion of initialization, the valve will travel toward its fail‐safe position. A relay with an engagement deadtime, such as

the MCR-SL-UI-REL from Phoenix Contact, can be used to delay the release of the locking system until the digital valve controller

has completely initialized. An engagement delay of 1.0 seconds will adequately minimize the dip in travel.

Note

While the valve is in a locked state, the set point from the digital valve controller may change in response to changes in process

conditions. This change in set point may result in a process bump when control is restored to the digital valve controller.

7

DVC6200 Digital Valve Controllers

(1)

February 2020

Phoenix Threshold Switch Specifications

Instruction Manual Supplement

D103261X012

Switch Model Number

Mini MCR-SL-UI-REL

Connect switch in series between the solenoid valve

and 24 VDC power supply

Power Supply + to switch terminal 2

Size

Solenoid wire to switch terminal 3

6.2 x 93.1 x 101.2 mm (0.24 x 3.67 x 3.98 inches)

Configuration

Mounting

Mounts in control room (DIN rail mount)

Wiring

Connect switch in series between control loop and

field device

Control Loop + to switch terminal 5

Digital Valve Controller + to switch terminal 6

24 VDC Power Supply to switch connections

Power Supply + to switch terminal 7

Power Supply - to switch terminal 8

1. The Phoenix threshold switch is not supplied by Emerson. Order the switch from the manufacturer, Phoenix Contact (www.phoenixcontact.com). For complete installation details, see the

instruction manual provided by the switch manufacturer.

Engagement Deadtime: 1 second

Switch Settings

Switch Setting Description

1

2

3

4

5

6

7

8

On

On

Off

Off

On

Off

Off

Off

In

In

Hysteresis

Hysteresis

Delay

Delay

Delay

Operating Current

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and FIELDVUE are marks owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

8

E 2006, 2020 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...