Page 1

Instruction Manual

D102087X012

Fisher™ 585C Series Piston Actuators

585C Actuator

March 2021

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 2.................................

Specifications 2...............................

Educational Services 2.........................

Principle of Operation 8.........................

Actuator with Handwheel 8.....................

Actuator with Spring Return 10..................

Installation 10.................................

Bypass Assembly 11...........................

Three‐Way Valve Applications Note 11............

Actuator Mounting 11...........................

Size 25 and 50 Actuator Mounting 11.............

Size 60‐130 Actuator Mounting 13...............

Stem Connector Assembly (Size 60‐130) 13....

585C Handwheels 14...........................

Handwheel Operation (Sizes 25 and 50) 14........

Handwheel Operation (Sizes 60‐130) 14..........

Maintenance (Sizes 25 and 50) 15.................

Replacing Handwheel Housing O‐Ring or

Thrust Bearings (Sizes 25 and 50) 16...........

Replacing Seals, Changing Action, or

Changing Bias Spring(s) (Sizes 25 and 50) 17....

Maintenance (Sizes 60‐130) 20...................

Side‐Mounted Handwheel Maintenance

(Sizes 60‐130) 21...........................

Disassembly of Handwheel Constructions

(Sizes 60 and 68) 21.....................

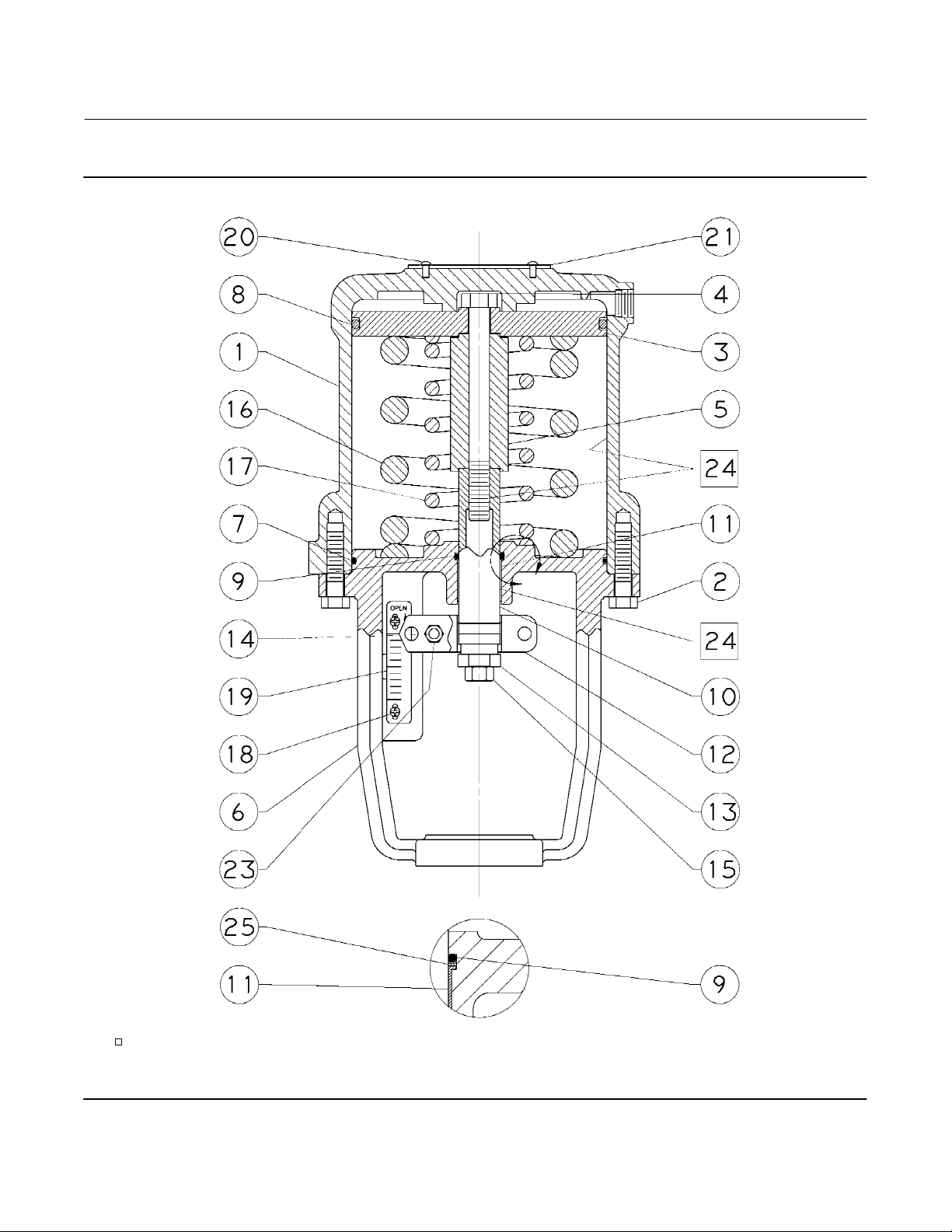

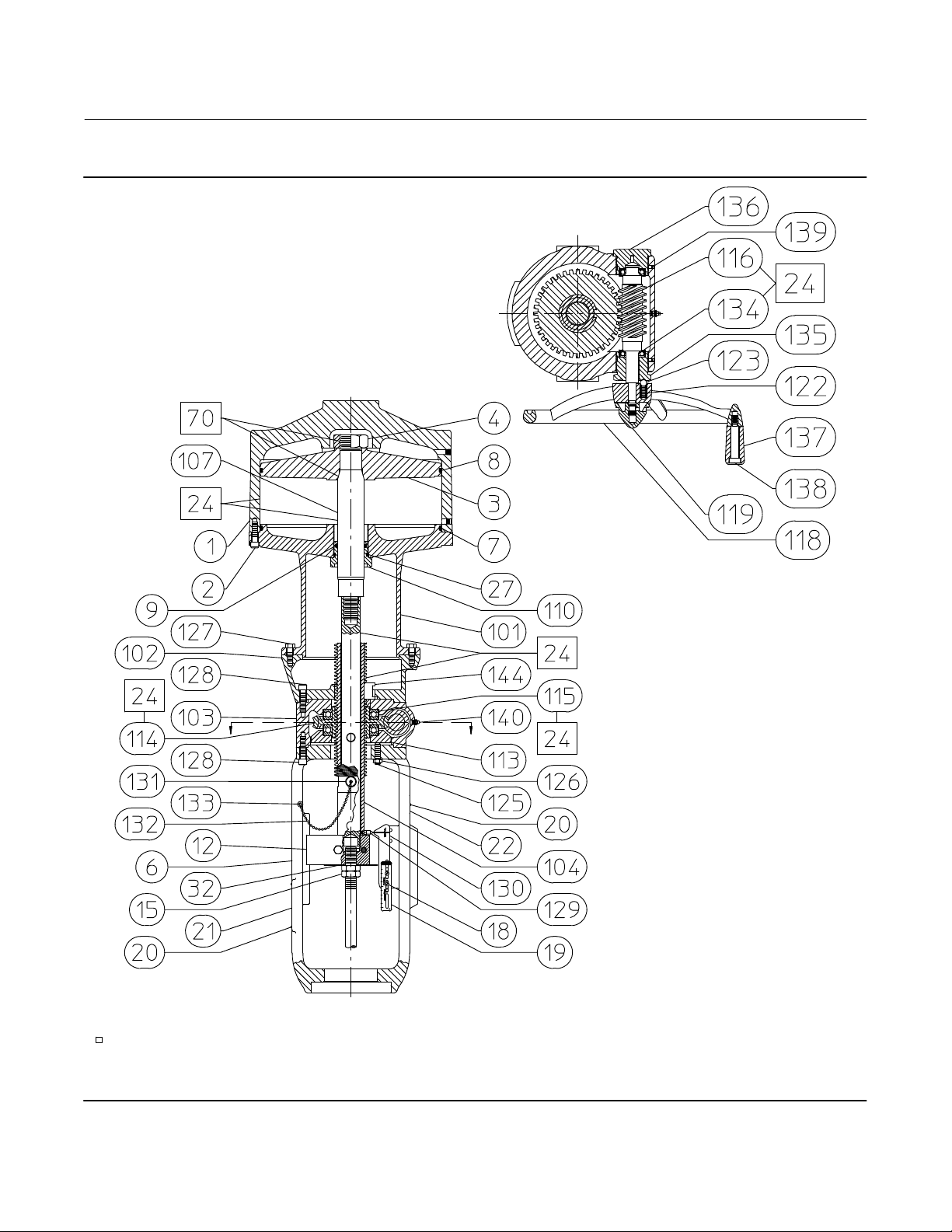

Figure 1. Fisher 585C Series Piston Actuator

X0175-2

Disassembly of Handwheel Constructions

(Sizes 80‐130) 22........................

Reassembly (Sizes 60‐130) 22...............

Parts Ordering 22...............................

Parts Kits 23...................................

Parts List 24...................................

Sizes 25 and 50 24.............................

Sizes 60‐130 30...............................

Introduction

Scope of Manual

This instruction manual provides information on installation, maintenance, and parts ordering for the Fisher 585C

piston actuators. Refer to separate instruction manuals for information about other equipment and accessories used

with these actuators.

Information for the 585CLS long stroke actuator can be found in the Fisher 585CLS Instruction Manual

(D103793X012

www.Fisher.com

).

Do not install, operate, or maintain a 585C Series actuator without being fully trained and qualified in

valve, actuator, and accessory installation, operation, and maintenance. To avoid personal injury or

property damage, it is important to carefully read, understand, and follow all the contents of this

manual, including all safety cautions and warnings. If you have any questions about these instructions,

contact your Emerson sales office

before proceeding.

Page 2

585C Actuator

March 2021

Instruction Manual

D102087X012

Description

585C pneumatic piston actuators (figure 1) provide accurate throttling or on‐off control of sliding‐stem valves. The

585C actuator uses a double‐acting cylinder, which requires air pressure for operation.

Size 25 and 50 actuators are available as a springless construction or with a bias spring. Depending on configuration,

the bias spring will retract or extend the piston rod upon loss of cylinder air pressure. Size 60 through 130 actuators are

available as springless constructions only.

585C actuators are typically supplied with a DVC6200 digital valve controller, or a 3600 P/P or I/P analog positioner.

The 585C actuator is available with a top‐mounted or side‐mounted manual handwheel, depending on actuator size.

Specifications

Specifications for the 585C piston actuators are given in table 1. Some individual actuators come from the factory with

specifications stamped on a nameplate attached to the yoke.

Educational Services

For information on available courses for Fisher 585C Series piston actuators, as well as a variety of other products,

contact:

Emerson Automation Solutions

Educational Services - Registration

Phone: 1-641-754-3771 or 1-800-338-8158

E-mail: education@emerson.com

emerson.com/fishervalvetraining

2

Page 3

Instruction Manual

D102087X012

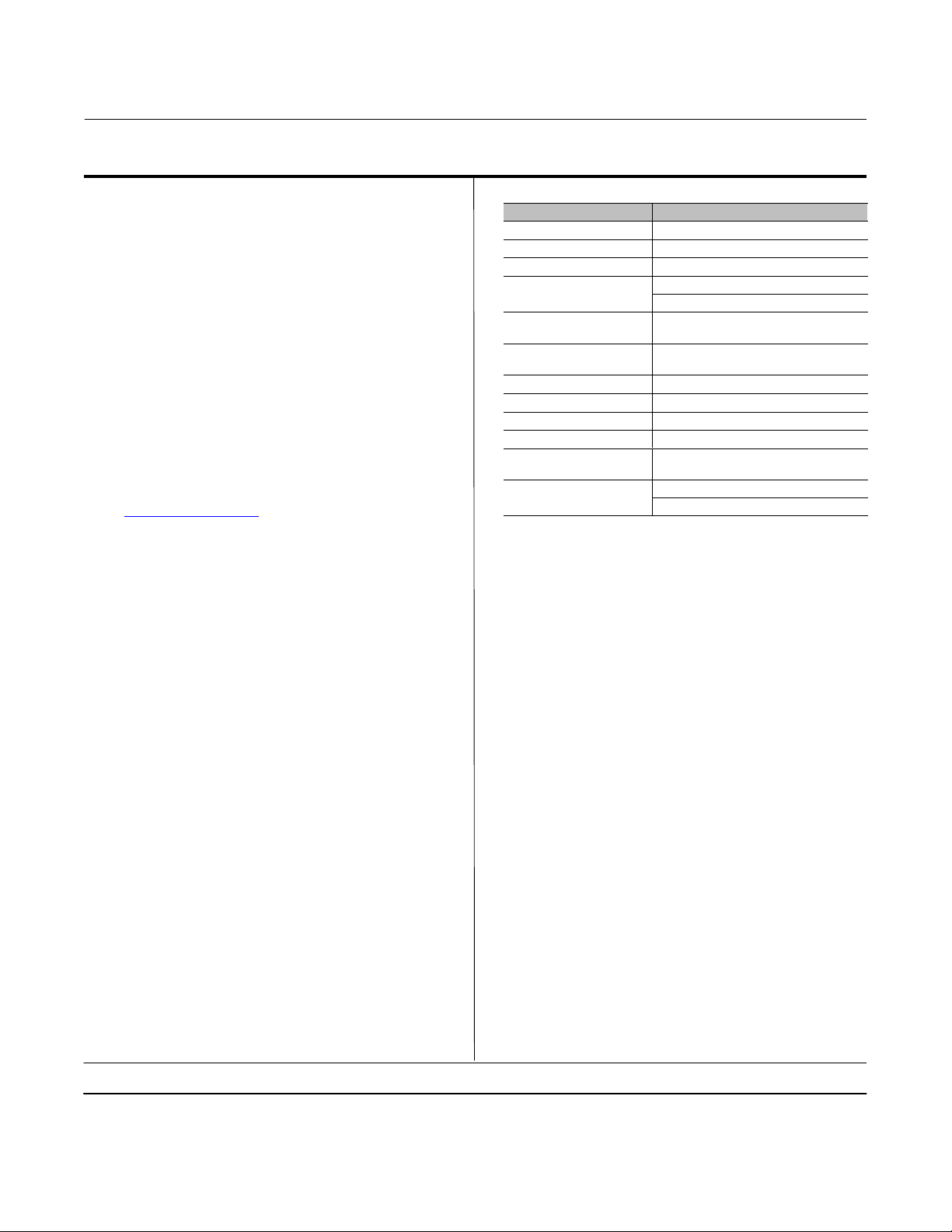

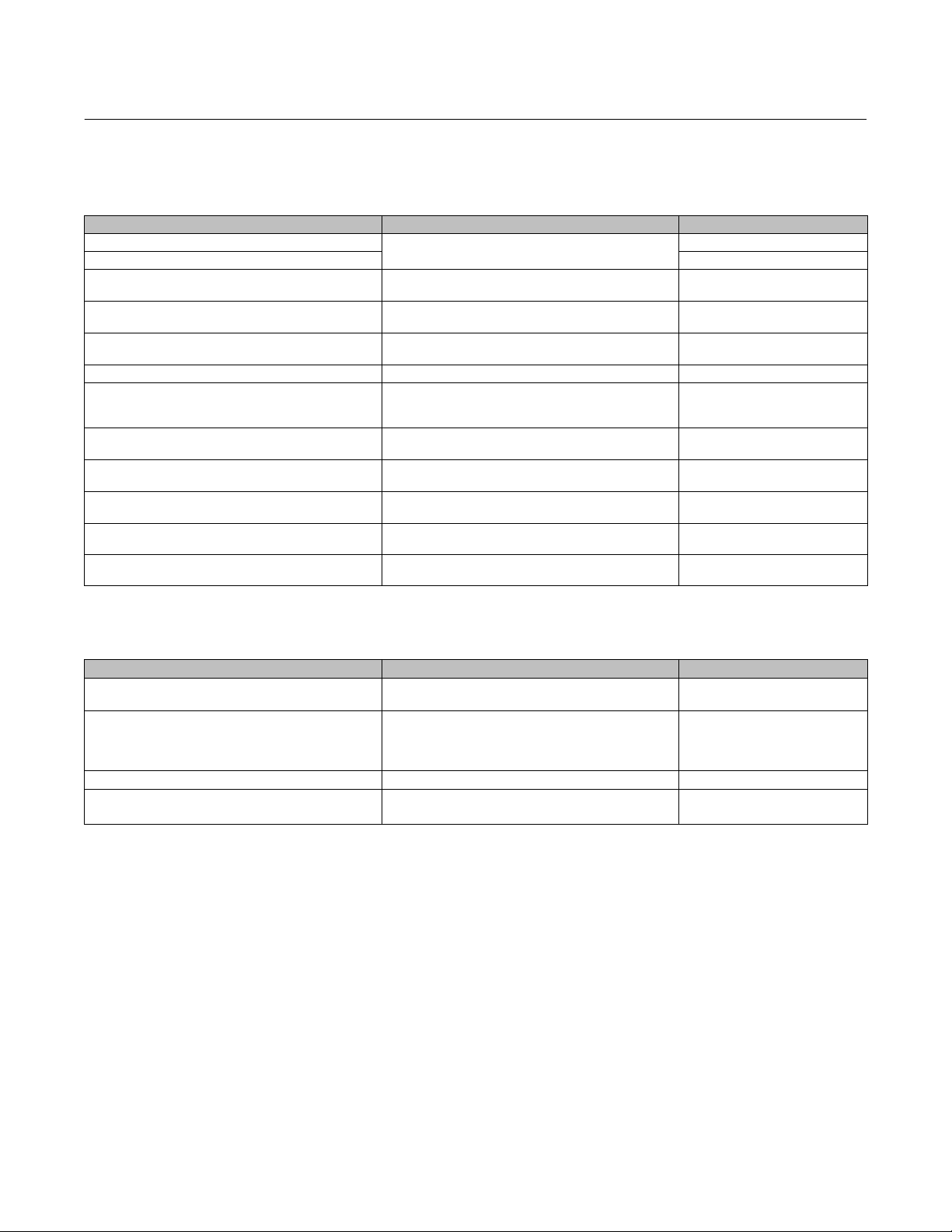

Table 1. 585C Specifications (Sizes 25‐130)

585C Actuator

March 2021

Operating Pressure

(1)

Sizes 25‐50

Maximum Allowable: 10.3 bar (150 psig)

Minimum Recommended: 1.4 bar (20 psig)

Sizes 60‐130

Maximum Allowable: See table 8

Minimum Recommended: 2.4 bar (35 psig)

Travel

See table 2

Thrust Capabilities

See tables 4 through 8

Stroking Speeds

Varies with actuator size, actuator spring, travel, and

supply pressure. If stroking speed is critical, consult

your Emerson sales office

Piston Area

See table 2

Construction Materials

Part Material

Yoke Ductile Iron

Piston Aluminum

Cylinder Aluminum

Bolting and Fasteners

Springs

(sizes 25 and 50 only)

O‐Rings

Actuator Stem Chrome‐plated Steel

Stem Connection Stainless Steel

Travel Indicator Scale Stainless Steel

Paint Polyester Powder

Cylinder Seal Bushings

(sizes 60‐130 only)

Stem Connector

(sizes 60‐130)

Approximate Weights

(less positioner and handwheel)

Size 25

Cylinder Volumetric Displacement

See table 2

2‐1/8 inch yoke boss, 7 kg (16 pounds)

2‐13/16 inch yoke boss, 8 kg (17 pounds)

Size 50

Operative Temperature Limits

(1)

For All Sizes

Standard Construction

(Nitrile O‐Rings): -40 to 80_C (-40 to 175_F)

Optional Construction

(Fluorocarbon O‐Rings): -18 to 149_C (0 to 300_F)

For Sizes 60-130

2‐13/16 inch yoke boss, 20 kg (45 pounds)

3‐9/16 inch yoke boss, 22 kg (48 pounds)

Size 60: 31 kg (68 pounds)

Size 68: 54 kg (120 pounds)

Size 80: 102 kg (225 pounds)

Size 100: 113 kg (250 pounds)

Size 130: 188 kg (415 pounds)

Low Ambient Temperature option:

Fluorosilicone O-Rings: -60 to 80_C (-76 to 175_F)

Options

Sizes 25 and 50

Yoke Boss and Valve Stem Diameters

See table 3

J Top‐mounted handwheel, see figures 5, 7, and 8

and table 9

J Cylinder bypass valve J Limit switches J Fisher

Pressure Connections

Size 25‐60

J 1/4 NPT internal (standard), or J 3/8 NPT internal

(optional)

Sizes 68‐130

J 1/2 NPT internal (standard)

Instrument Mounting

Universal NAMUR mounting

1. The pressure/temperature limits in this manual and any applicable standard or code limitation for valve should not be exceeded.

4200 position transmitter

Sizes 60‐130

J Integral side‐mounted handwheel, (figure 9)

Sizes 25‐130

J FIELDVUEt mounting options

J Fisher 377 trip valve system to fail actuator

J up or J down or J lock in last position

J TopWorxt DXP M21GNEB electrical valve stem

position switch

J Micro‐Switch limit switches

Steel NCF (std)

Stainless Steel (std and low ambient)

Alloy Steel

Nitrile (std), Fluorocarbon,

Fluorosilicone

Brass

Zinc‐plated steel (std)

Stainless Steel (std and low ambient)

3

Page 4

585C Actuator

Instruction Manual

March 2021

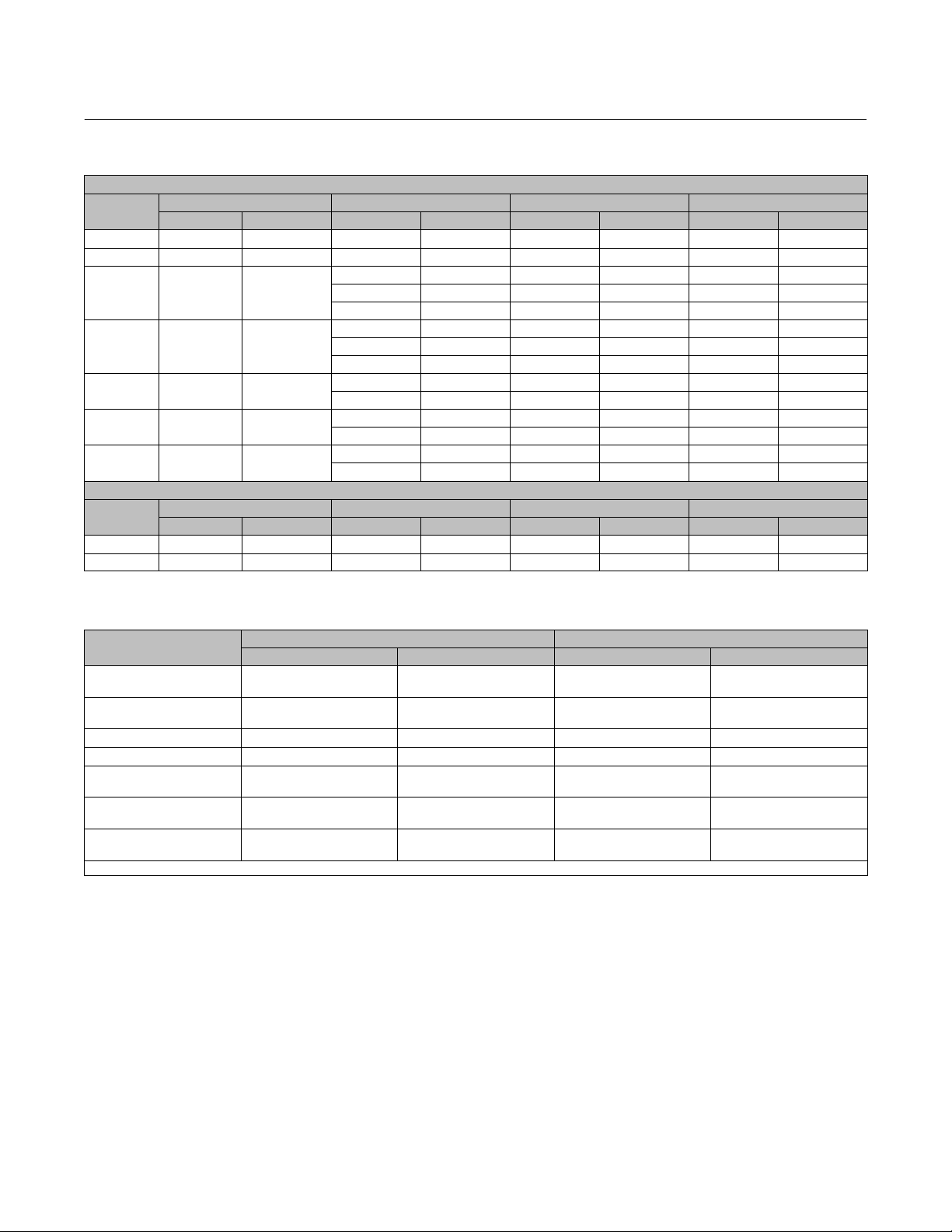

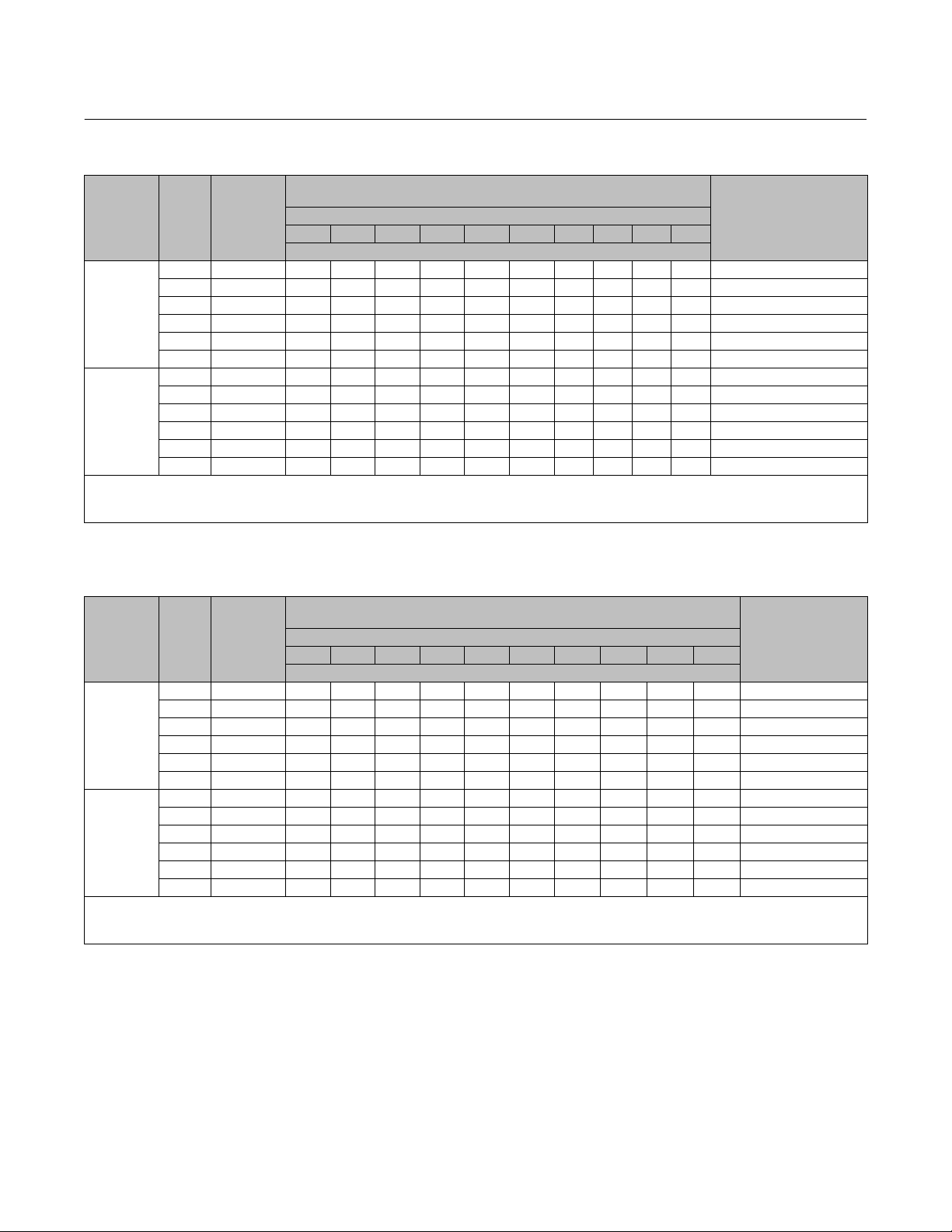

Table 2. Fisher 585C Piston Cylinder Clearance Volumes

PISTON AT TOP OF CYLINDER (SPRINGS BELOW PISTON FOR SIZE 25 AND 50)

Actuator

Size

25 168 26 2.9 1.125 104 6.3 1750 107

50 303 47 5.1 2 330 20 5200 320

60 358 55.5

68 571 88.5

80 571 88.5

100 842 130.5

130 1430 221.5

Actuator

Size

25 168 26 2.9 1.125 77 4.7 1790 109

50 303 47 5.1 2 350 22 5200 320

Piston Area Maximum Actuator Travel Upper Clearance Volume Volume Below Piston

cm

2

Inches

2

cm Inches cm

3

Inches

3

cm

3

5.1 2 310 19 2700 163

10 4 310 19 4400 270

20 8 310 19 8200 500

5.1 2 1230 75 7500 460

10.2 4 1230 75 7500 460

20.3 8 1230 75 13300 810

10.2 4 1230 75 7500 460

20.3 8 1230 75 13300 810

10.2 4 1700 104 10700 650

20.3 8 1700 104 19200 1170

10.2 4 4600 280 18500 1130

20.3 8 4600 280 33000 2000

PISTON AT BOTTOM OF CYLINDER (SPRINGS ABOVE PISTON FOR SIZE 25 AND 50)

Piston Area Maximum Actuator Travel Lower Clearance Volume Volume Above Piston

cm

2

Inches

2

cm Inches cm

3

Inches

3

cm

3

D102087X012

3

Inches

3

Inches

Table 3. Yoke Boss and Valve Stem Diameters

ACTUATOR SIZE

25

50

60 90 3‐9/16 19.1 3/4

68 90 3‐9/16 19.1 3/4

80 127 5, 5H

100 127 5, 5H

130 127 5, 5H

1. Heavy actuator to bonnet bolting.

YOKE BOSS DIAMETER VALVE STEM DIAMETER

mm Inches mm Inches

54

71

71

90

2‐1/8

2‐13/16

2‐13/16

3‐9/16

9.5

12.7

12.7

19.1

25.4

31.8

25.4

31.8

25.4

31.8

3/8

1/2

1/2

3/4

1

1‐1/4

1

1‐1/4

1

1‐1/4

4

Page 5

Instruction Manual

585C Actuator

D102087X012

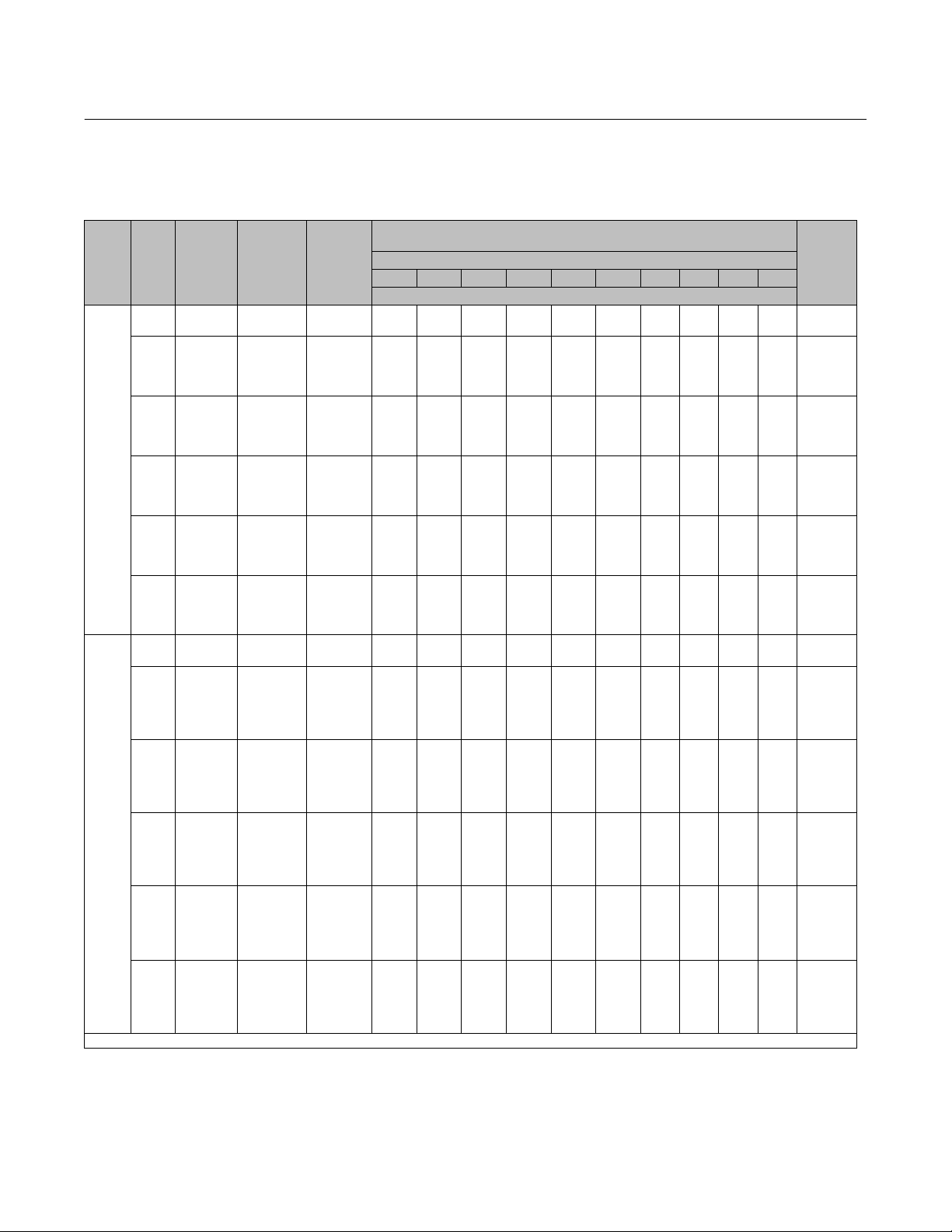

Actuator Thrust Capabilities

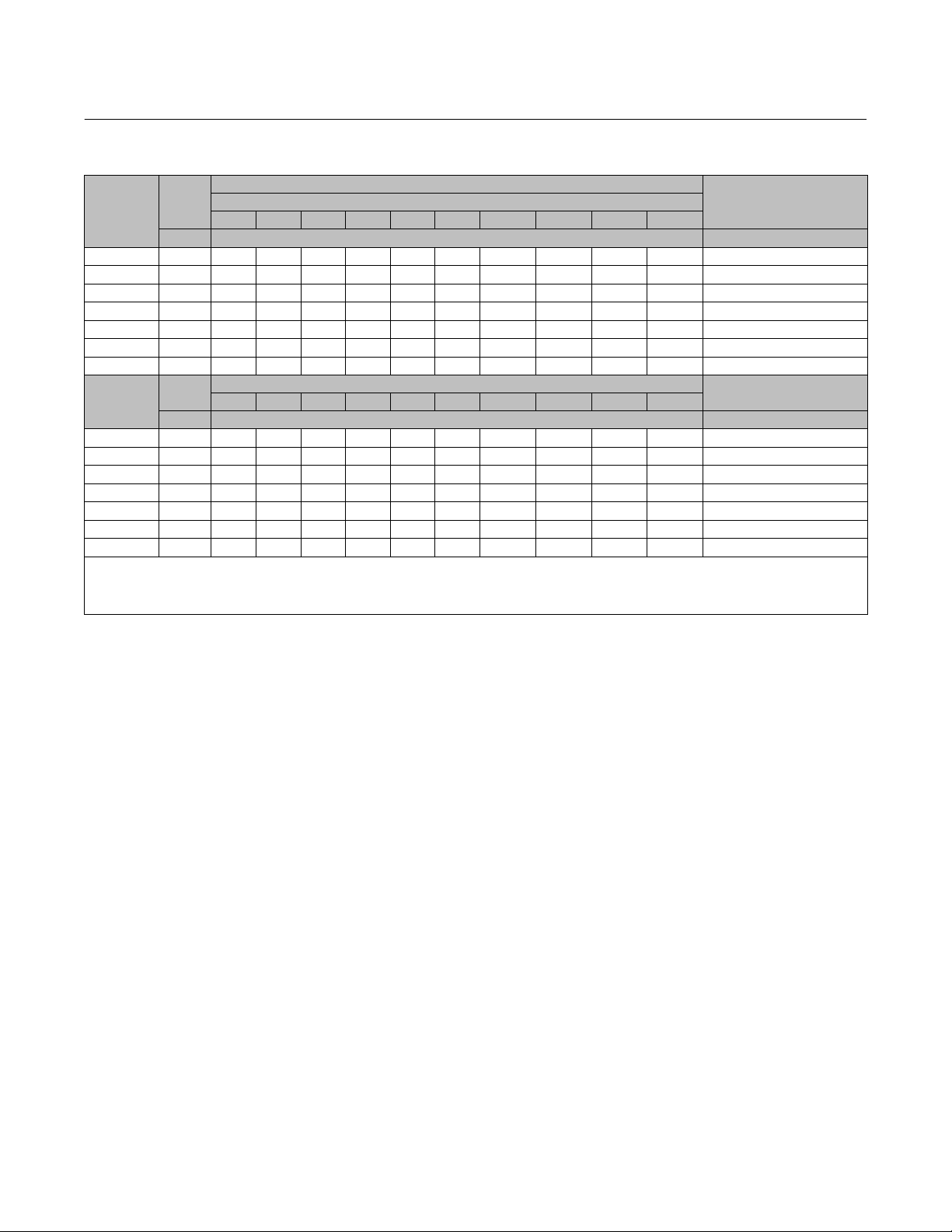

Table 4. Fisher 585C Size 25 and 50 Actuator Thrust Capabilities, U.S. Units (spring retracts actuator stem)

ACTU‐

ATOR

SIZE

25

50

X—Indicates where the listed supply pressure is not sufficient to overcome the opposing bias spring effect.

ACTUATOR

SPRING

RATE,

lb/in

200

400

500

700

900

330

600

930

1550

1880

STEM

TRAVEL,

INCHES

0 All 0 0 1040 1300 1560 1820 2080 2340 2600 2860 3250 3900

0.5625

0.75

0.875

1.125

0.5625

0.75

0.875

1.125

0.5625

0.75

0.875

1.125

0.5625

0.75

0.875

1.125

0.5625

0.75

0.875

1.125

0 All 0 0 1840 2300 2760 3220 3680 4140 4600 5060 5750 6900

0.75

0.875

1.125

1.5

2

0.75

0.875

1.125

1.5

2

0.75

0.875

1.125

1.5

2

0.75

0.875

1.125

1.5

2

0.75

0.875

1.125

1.5

2

SPRING

THRUST W/

ACTUATOR

STEM

RETRACTED,

POUNDS

200

200

200

200

400

400

400

400

500

500

500

500

700

700

700

700

900

900

900

900

330

330

330

330

330

600

600

600

600

600

930

930

930

930

930

1550

1550

1550

1550

1550

1880

1880

1880

1880

1880

SPRING

THRUST W/

ACTUATOR

STEM

EXTENDED,

POUNDS

313

350

375

425

625

700

750

850

781

875

938

1063

1094

1225

1313

1488

1406

1575

1688

1913

578

619

701

825

990

1050

1125

1275

1500

1800

1628

1744

1976

2325

2790

2710

2906

3294

3875

4650

3290

3525

3995

4700

5640

NET THRUST FOR 585C WITH ACTUATOR STEM FULLY

40 50 60 70 80 90 100 110 125 150

730

990

690

950

660

920

610

870

410

670

340

600

290

550

190

450

520

260

420

160

360

100

240

X

X

200

X

70

X

X

X

X

X

X

X

X

X

X

X

X

1310

1780

1270

1740

1180

1660

1060

1530

900

1370

840

1310

760

1230

610

1080

390

860

90

560

260

730

140

610

X

380

X

30

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

EXTENDED AT FULL TRAVEL

Operating Pressure, psig

Force, Pounds

1250

1510

1210

1470

1180

1440

1130

1390

930

1190

860

1120

810

1070

710

970

780

1040

680

940

620

880

500

760

460

720

330

590

250

510

70

330

150

410

X

240

X

130

X

X

2250

2720

2210

2680

2130

2600

2000

2470

1840

2310

1780

2250

1700

2170

1550

2020

1330

1800

1030

1500

1200

1670

1080

1560

850

1320

500

970

40

510

110

580

X

385

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

1760

1730

1700

1650

1450

1380

1330

1230

1300

1200

1140

1010

980

850

760

590

670

500

390

160

3190

3150

3070

2950

2780

2720

2650

2500

2270

1970

2140

2030

1790

1450

980

1050

855

465

X

X

470

235

X

X

X

2020

1990

1960

1910

1710

1640

1590

1490

1560

1460

1400

1270

1240

1110

1020

850

930

760

650

420

3660

3620

3540

3420

3250

3190

3120

2970

2740

2440

2610

2500

2270

1920

1450

1520

1325

935

355

X

940

705

235

X

X

2280

2250

2220

2170

1970

1900

1850

1750

1820

1720

1660

1530

1500

1370

1280

1110

1190

1020

910

680

4140

4090

4010

3890

3720

3660

3590

3440

3210

2910

3090

2970

2740

2390

1920

1990

1795

1405

825

50

1410

1175

705

X

X

2540

2510

2480

2430

2230

2160

2110

2010

2080

1980

1920

1790

1760

1630

1540

1370

1450

1280

1170

940

4610

4570

4480

4360

4190

4130

4060

3910

3680

3380

3560

3440

3210

2860

2390

2460

2265

1875

1295

520

1880

1645

1175

470

X

2930

2900

2870

2820

2620

2550

2500

2400

2460

2370

2310

2180

2150

2020

1930

1760

1840

1670

1560

1330

5310

5270

5190

5070

4900

4840

4770

4620

4390

4090

4260

4150

3910

3570

3100

3165

2970

2580

2000

1225

2585

2350

1880

1175

235

3580

3550

3520

3470

3270

3200

3150

3050

3110

3020

2960

2830

2800

2670

2580

2410

2490

2320

2210

1980

6490

6450

6370

6250

6080

6020

5950

5800

5570

5270

5440

5330

5090

4750

4280

4345

4150

3760

3180

2405

3765

3530

3060

2355

1415

March 2021

SPRINGS

USED,

BY

COLOR

Springs

Not Used

Gold

Light

Green

White

Gold &

White

Light

Green

& White

Springs

Not Used

Pink

Light

Blue

Pink &

Light

Blue

Green

Pink &

Green

5

Page 6

585C Actuator

March 2021

Instruction Manual

D102087X012

Table 5. Fisher 585C Size 25 and 50 Actuator Thrust Capabilities, Metric Units (spring retracts actuator stem)

ACTU‐

ATOR

SIZE

SPRING

RATE,

N/mm

ATOR

STEM

TRAVEL,

mm

0 All 0 0 4626 5783 6939 8096 9252 10,409 11,565 12,722 14,457 17,348

14.3

19.1

35.0

22.2

28.6

14.3

19.1

70.1

22.2

28.6

ACTU‐

25

122.6

157.7

105.1

50

162.9

271.4

329.2

X—Indicates where the listed supply pressure is not sufficient to overcome the opposing bias spring effect.

14.3

19.1

87.6

22.2

28.6

14.3

19.1

22.2

28.6

14.3

19.1

22.2

28.6

0 All 0 0 8180 10,200 12,300 14,300 16,400 18,400 20,500 22,500 25,600 30,700

19.1

22.2

28.6

57.8

38.1

50.8

19.1

22.2

28.6

38.1

50.8

19.1

22.2

28.6

38.1

50.8

19.1

22.2

28.6

38.1

50.8

19.1

22.2

28.6

38.1

50.8

SPRING

THRUST W/

ACTUATOR

STEM

RETRACTED,

N

890

890

890

890

1780

1780

1780

1780

2225

2225

2225

2225

3115

3115

3115

3115

4005

4005

4005

4005

1468

1468

1468

1468

1468

2669

2669

2669

2669

2669

4137

4137

4137

4137

4137

6894

6894

6894

6894

6894

8362

8362

8362

8362

8362

SPRING

THRUST W/

ACTUATOR

STEM

EXTENDED,

N

1393

1558

1669

1891

2781

3115

3338

3783

3475

3894

4174

4730

4868

5451

5843

6622

6257

7009

7512

8513

2571

2753

3118

3670

4404

4671

5004

5671

6672

8007

7242

7758

8790

10,342

12,410

12054

12925

14652

17236

20683

14634

15679

17770

20906

25087

NET THRUST FOR 585C WITH ACTUATOR STEM FULLY

EXTENDED AT FULL TRAVEL

Operating Pressure, bar

2.8 3.4 4.1 4.8 5.5 6.2 6.9 7.6 8.6 10.3

Force, N

3247

4404

5560

6717

7829

8985

10,142

3069

2936

2713

1824

1512

1290

845

1156

712

445

X

X

X

X

X

X

X

X

X

5827

5649

5249

4715

4003

3736

3381

2713

1735

400

1157

623

X

X

X

X

X

X

X

X

X

X

X

X

X

4226

4092

3870

2980

2669

2447

2002

2313

1868

1601

1068

890

311

X

X

X

X

X

X

7918

7740

7384

6806

6094

5827

5471

4804

3825

2491

3247

2713

1690

133

X

X

X

X

X

X

X

X

X

X

X

5382

5249

5026

4137

3825

3603

3158

3470

3025

2758

2224

2046

1468

1112

311

667

X

X

X

10,008

9831

9475

8896

8185

7918

7562

6895

5916

4582

5338

4804

3781

2224

178

489

X

X

X

X

X

X

X

X

X

6539

6405

6183

5293

4982

4760

4315

4626

4181

3914

3381

3203

2624

2269

1468

1824

1068

578

X

12,099

11,921

11,565

10,987

10,275

10,008

9653

8985

8007

6672

7428

6939

5872

4315

2269

2580

1712

X

X

X

X

X

X

X

X

7695

7562

7340

6450

6139

5916

5471

5783

5338

5071

4493

4359

3781

3381

2624

2980

2224

1735

712

14,190

14,012

13,656

13,122

12,366

12,099

11,788

11,121

10,097

8763

9519

9030

7962

6450

4359

4670

3803

2068

X

X

2091

1045

X

X

X

8852

8718

8496

7606

7295

7073

6628

6939

6494

6227

5649

5516

4938

4537

3781

4137

3381

2891

1868

16,280

16,102

15,747

15,213

14,457

14,190

13,878

13,211

12,188

10,854

11,610

11,121

10,097

8541

6450

6761

5894

4159

1579

X

4181

3136

1045

X

X

10,008

9875

9653

8763

8452

8229

7784

8096

7651

7384

6806

6672

6094

5694

4938

5293

4537

4048

3025

18,416

18,193

17,837

17,303

16,547

16,280

15,969

15,302

14,279

12,944

13,745

13,211

12,188

10,631

8541

8852

7984

6249

3670

222

6272

5226

3136

X

X

11,298

11,165

11,032

10,809

20,506

20,328

19,928

19,394

18,638

18,371

18,060

17,392

16,369

15,035

15,836

15,302

14,279

12,722

10,631

10942

10075

9919

9608

9386

8941

9252

8807

8541

7962

7829

7251

6850

6094

6450

5694

5204

4181

8340

5760

2313

8362

7317

5226

2091

X

13,033

12,900

12,766

12,544

11,654

11,343

11,121

10,676

10,943

10,542

10,275

9697

9564

8985

8585

7829

8185

7428

6939

5916

23,620

23,442

23,086

22,552

21,796

21,529

21,218

20,551

19,528

18,193

18,949

18,460

17,392

15,880

13,789

14078

13211

11476

8896

5449

11498

10453

8362

5226

1045

15,925

15,791

15,658

15,435

14,546

14,234

14,012

13,567

13,834

13,434

13,167

12,588

12,455

11,877

11,476

10,720

11,076

10,320

9831

8807

28,869

28,691

28,335

27,801

27,045

26,778

26,467

25,800

24,777

23,442

24,198

23,709

22,641

21,129

19,038

19,328

18,460

16,725

14,145

10,698

16,748

15,702

13,612

10,476

6294

SPRINGS

USED,

BY

COLOR

Springs

Not

Used

Gold

Light

Green

White

Gold &

White

Light

Green &

White

Springs

Not

Used

Pink

Light

Blue

Pink &

Light

Blue

Green

Pink &

Green

6

Page 7

Instruction Manual

585C Actuator

D102087X012

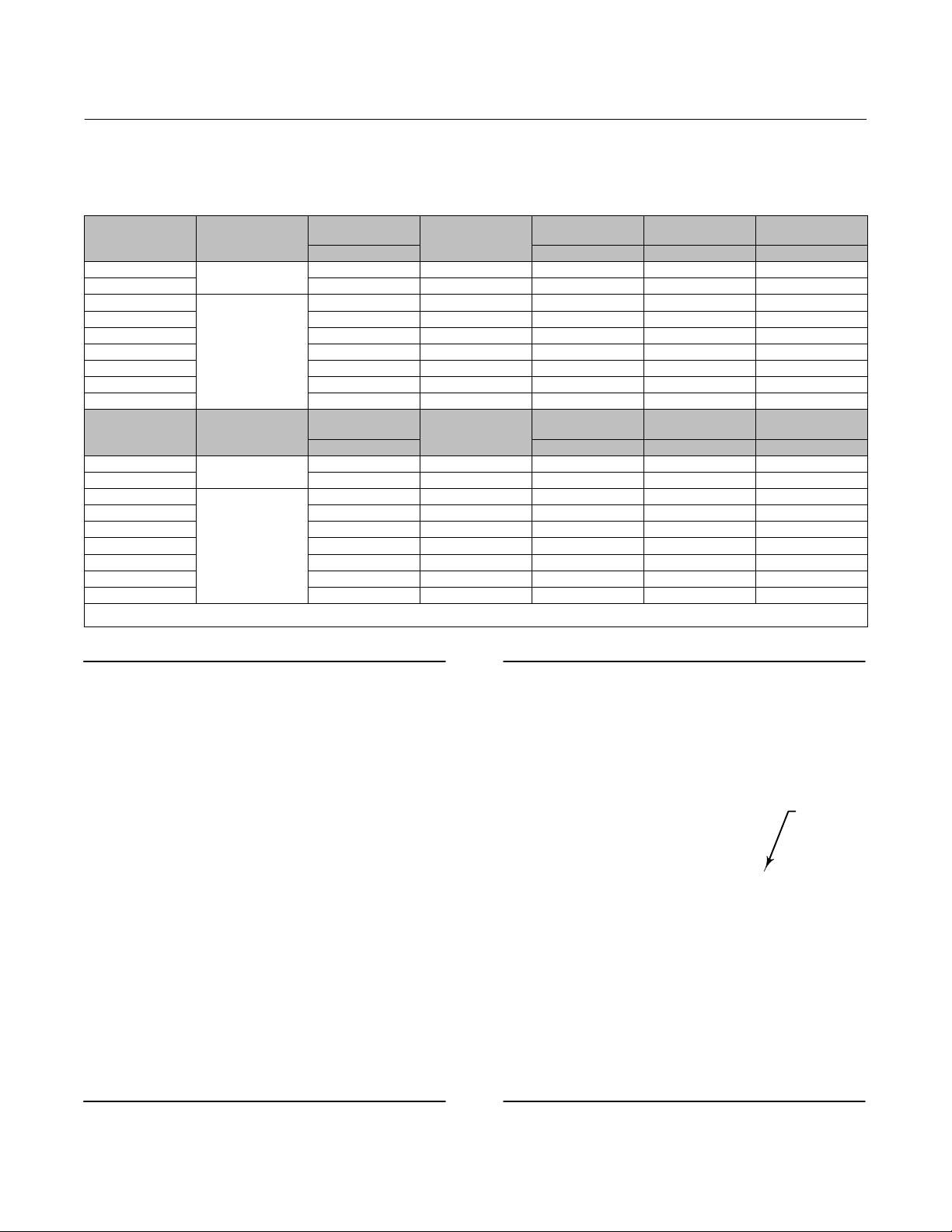

Table 6. Fisher 585CR Size 25 and 50 Actuator Thrust Capabilities, U.S. Units (spring extends actuator stem)

SPRING

lb/in

THRUST W/

ACTUATOR

STEM

EXTENDED,

40 50 60 70 80 90 100 110 125 150

ACTUATOR

SIZE

SPRING

RATE,

POUNDS

0 0 1040 1300 1560 1820 2080 2340 2600 2860 3250 3900 Springs Not Used

200 200 1240 1500 1760 2020 2280 2540 2800 3060 3450 X Gold

25

(2)

400 400 1440 1700 1960 2220 2480 2740 3000 3260 3650 X Light Green

500 500 1540 1800 2060 2320 2580 2840 3100 3360 3750 X White

700 700 1740 2000 2260 2520 2780 3040 3300 3560 X X Gold & White

900 900 1940 2200 2460 2720 2980 3240 3500 3760 X X Light Green & White

0 0 1840 2300 2760 3220 3680 4140 4600 5060 5750 6900 Springs Not Used

330 330 2210 2680 3150 3620 4090 4560 5030 5500 6205 X Pink

50

(3)

600 600 2480 2950 3420 3890 4360 4830 5300 5770 6475 X Light Blue

930 930 2810 3280 3750 4220 4690 5160 5630 6100 6805 X Pink & Light Blue

1550 1550 3430 3900 4370 4840 5310 5780 6250 6720 X X Green

1880 1880 3760 4230 4700 5170 5640 6110 6580 7050 X X Pink & Green

X—Indicates where the listed supply pressure is not sufficient to overcome the opposing bias spring effect.

1. The maximum design pressure for size 25 and 50 actuator is 150 psig.

2. Maximum thrust is 3900 lbs.

3. Maximum thrust is 6900 lbs.

TOTAL THRUST FOR 585CR WITH ACTUATOR STEM FULLY

EXTENDED

Operating Pressure, psig

(1)

Force, Pounds

SPRINGS USED, BY COLOR

March 2021

Table 7. Fisher 585CR Size 25 and 50 Actuator Thrust Capabilities, Metric Units (spring extends actuator stem)

SPRING

ACTUATOR

SIZE

SPRING

RATE,

N/mm

THRUST W/

ACTUATOR

STEM

EXTENDED,

2.8 3.4 4.1 4.8 5.5 6.2 6.9 7.6 8.6 10.3

N

0 0 4626 5782 6939 8095 9251 10408 11565 12721 14456 17347 Springs Not Used

35.0 890 5516 6672 7828 8985 10141 11298 12454 13610 15346 X Gold

25

(2)

70.0 1780 6405 7562 8718 9874 11031 12188 13344 14500 16235 X Light Green

87.6 2225 6850 8006 9163 10319 11476 12632 13789 14945 16680 X White

122.6 3115 7740 8896 10052 11209 12365 13655 14678 15835 X X Gold & White

157.6 4005 8629 9786 10942 12099 13255 14412 15568 16724 X X Light Green & White

0 0 8180 10200 12300 14300 16400 18400 20500 22500 25600 30700 Springs Not Used

57.8 1468 9830 11921 14011 16102 18192 20282 22373 24464 27600 X Pink

50

(3)

105.1 2670 11031 13122 15212 17303 19393 21484 23574 25665 28800 X Light Blue

162.8 4135 12499 14589 16680 18770 20861 22952 25042 27133 30269 X Pink & Light Blue

271.4 6894 15256 17347 19438 21528 23619 25709 27800 29891 X X Green

329.2 8362 16724 18815 20906 22996 25087 27177 29268 31358 X X Pink & Green

X—Indicates where the listed supply pressure is not sufficient to overcome the opposing bias spring effect.

1. The maximum design pressure for size 25 and 50 actuator is 10.3 bar.

2. Maximum thrust is 17347 N.

3. Maximum thrust is 31358 N.

TOTAL THRUST FOR 585CR WITH ACTUATOR STEM FULLY

EXTENDED

Operating Pressure, bar

(1)

Force, N

SPRINGS USED, BY

COLOR

7

Page 8

585C Actuator

March 2021

Instruction Manual

D102087X012

Table 8. Fisher 585C Thrust (springless construction)

ACTUATOR

SIZE

25 168 4630 5780 6940 8100 9260 10400 11600 12700 14500 17300 17300

50 303 8180 10200 12300 14300 16400 18400 20500 22500 25600 30700 31400

60 358 9880 12300 14800 17300 19800 22200 24700 27200 30900 36900 36900

68 571 15700 19700 23600 27600 31500 35400 39400 43300 49200 55600 55600

80 571 15700 19700 23600 27600 31500 35400 39400 43300 49200 58700 58700

100 842 23200 29000 34800 40600 46400 52200 58000 63900 72600 86700 86700

130 1430 39400 49300 59100 69000 78700 88500 98800 108100 X X 111200

ACTUATOR

SIZE

25 26 1040 1300 1560 1820 2080 2340 2600 2860 3250 3900 3900

50 47 1840 2300 2760 3220 3680 4140 4600 5060 5750 6900 7050

60 55.5 2220 2780 3330 3890 4440 5000 5550 6110 6940 8300 8300

68 88.5 3540 4430 5310 6200 7080 7970 8850 9740 11100 12500 12500

80 88.5 3540 4430 5310 6200 7080 7970 8850 9740 11100 13200 13200

100 130.5 5220 6530 7830 9140 10440 11700 13100 14400 16300 19500 19500

130 221.5 8860 11100 13300 15500 17700 19900 22200 24300 X X 25000

X—Indicates where the listed supply pressure will exceed the maximum thrust allowable.

1. The maximum design pressure for size 25 through 100 actuators is 10.3 bar (150 psig). The size 68 and 130 actuators are limited to 9.7 and 7.8 bar (140 and 113 psig) respectively.

2. The size 25 and 50 data is for the construction without a bias spring.

3. Minimum operating pressure for sizes 60‐130 actuators is 2.4 bar (35 psig).

4. The size 68 actuator with a handwheel is limited to 40000 Newtons (9000 lb) thrust.

PISTON

AREA

2

cm

PISTON

AREA

Inches

2.8 3.4 4.1 4.8 5.5 6.2 6.9 7.6 8.6 10.3

40 50 60 70 80 90 100 110 125 150

2

TOTAL THRUST FOR 585C

Operating Pressure, bar

Force, Newtons

Operating Pressure, psig

Force, Pounds

(1)

(3)

(2)

(3)

(2)

MAXIMUM ALLOWABLE

THRUST

Newtons

MAXIMUM ALLOWABLE

THRUST

Pounds

(4)

(4)

Principle of Operation

The 585C piston actuator (figures 2 and 3) uses a piston that moves inside the actuator cylinder. An O‐ring (see figure

3) provides a seal between the piston and the cylinder.

From an equilibrium state, the actuator reacts to a force unbalance that is created by increasing supply pressure on

one side of the piston, and decreasing it on the other. This moves the piston up or down, and results in a repositioning

of the valve plug.

Actuator with Handwheel (figures 2 and 5)

The handwheel version can be used to open or close the valve manually (either during normal operation or in an

emergency), to position the valve at any point in the stroke, or to act as a travel stop.

Size 25 and 50 actuators use an integral top‐mounted handwheel. See figure 5.

Size 60 to 130 actuators use a side‐mounted handwheel, and come with a spring‐loaded ball detent which prevents

vibration from changing the handwheel setting. Handwheels for most types are either 203 mm (8 inches) in diameter

with beveled gears or 432 mm (17 inches) in diameter with worm gears.

8

Page 9

Instruction Manual

D102087X012

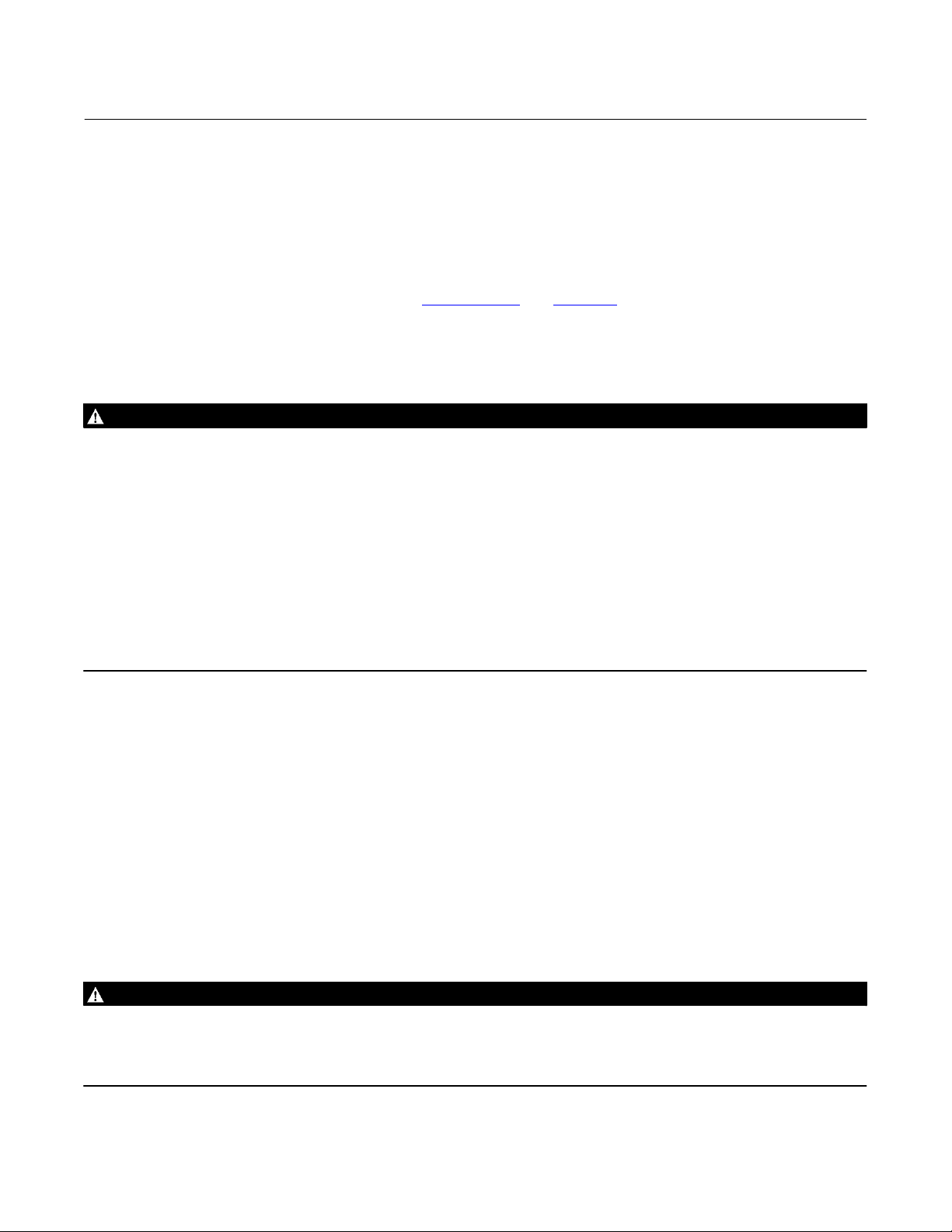

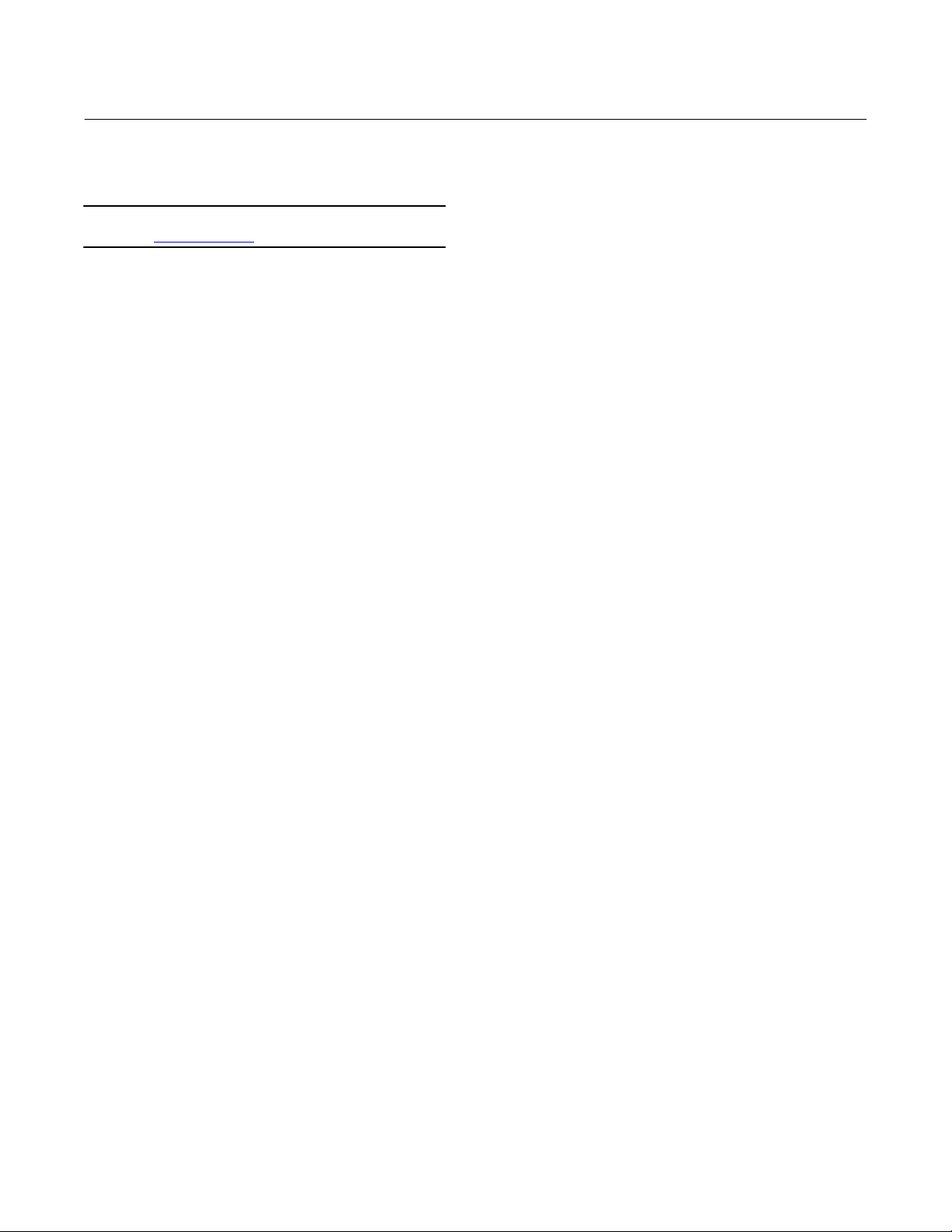

Handwheel Specifications

Table 9. Fisher 585C Handwheel Specifications

ACTUATOR SIZE

25

50 482 0.5 445 23,790 20

(1)

60

(2)

60

(1)

68

(2)

68

80 432 0.4 423 50000 35

100 432 0.4 623 75600 94

130 432 0.4 623 75600 123

ACTUATOR SIZE

25

50 19 12 100 5350 45

(1)

60

(2)

60

(1)

68

(2)

68

80 17 10 95 11250 77

100 17 10 140 17000 208

130 17 10 140 17000 272

1. 2 and 4 inch maximum travel constructions.

2. 8 inch maximum travel construction.

HANDWHEEL

MOUNTING

Top‐Mounted

Integral

Side‐Mounted

HANDWHEEL

MOUNTING

Top‐Mounted

Integral

Side‐Mounted

HANDWHEEL

DIAMETER

mm Newtons Newtons kg

356 0.5 325 12,810 17

203 0.6 276 40000 28

356 0.6 160 40000 30

203 0.6 276 40000 30

356 0.6 160 40000 33

HANDWHEEL

DIAMETER

Inches Pounds Pounds Pounds

14 12 73 2880 37

8 16 62 9000 61

14 16 36 9000 66

8 16 62 9000 66

14 16 36 9000 71

TURNS PER mm

TRAVEL

TURNS PER INCH

TRAVEL

MAXIMUM RIM

FORCE REQUIRED

MAXIMUM RIM

FORCE REQUIRED

HANDWHEEL

OUTPUT FORCE

HANDWHEEL

OUTPUT FORCE

585C Actuator

March 2021

HANDWHEEL

WEIGHT

HANDWHEEL

WEIGHT

Figure 2. Fisher 585C Piston Actuator

with Handwheel

E0410

Figure 3. Fisher 585C Piston Actuator

with Spring Return

PISTON

O‐RING

W7447‐1

9

Page 10

585C Actuator

March 2021

Instruction Manual

D102087X012

Actuator with Spring Return (figure 3)

585C size 25 and 50 actuators are available with bias springs in two configurations. The 585C actuator, with the bias

spring under the piston, fully retracts the actuator stem upon loss of cylinder pressure. The 585C actuator, with the

bias spring on top of the piston, fully extends the actuator stem upon loss of cylinder pressure. No additional parts are

required to convert from one actuator type to the other.

For more detailed information on the 3610 positioner and DVC6200 digital valve controllers, refer to the Principle of

Operation section in the 3610J Instruction Manual (D200149X012

)and DVC6200 instruction manuals.

Installation

WARNING

To avoid personal injury or property damage caused by cylinder fracture as a result of piston impact, install the stem

connector securely before supplying pressure to the positioner. Use only a regulator-controlled air supply to move the

actuator piston so that you can install the stem connector. Do not use the positioner to move the actuator piston before

installing the stem connector.

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

To avoid personal injury or property damage caused by bursting of pressure‐retaining parts, be certain the cylinder

pressure or other pressure ratings do not exceed the limits listed in table 1. Use pressure‐limiting or pressure‐relieving

devices to prevent cylinder pressure or other pressure ratings from exceeding these limits.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance sections in this

instruction manual.

When an actuator and valve are shipped together as a control valve assembly, the actuator is normally mounted on the

valve. Follow the valve instructions when installing the control valve in the pipeline. If the actuator is shipped

separately or if it is necessary to mount the actuator on the valve, perform the Actuator Mounting procedures in this

instruction manual corresponding to your actuator size. For information on mounting valve positioners, refer to the

3610J Instruction Manual (D200149X012) or DVC6200 instruction manuals for details.

If a 585C actuator is being installed without a positioner, the cylinder loading pressures should be supplied through a

4‐way solenoid valve or a switching valve. The bottom side of the piston is pressured through the bottom side of the

mounting flange on the actuator yoke (key 6, figures 4 and 6) for sizes 25 and 50 or the connection at the lower side of

the cylinder (key 1, figure 9 to 13) for sizes 60 to 130. The top side of the piston is pressured through the connection in

the cylinder cover (key 1 for figures 4, 6; and 9 to 13).

The supply pressure medium should be clean, dry filtered air. If the supply source is capable of exceeding the

maximum actuator operating pressure or positioner supply pressure, appropriate steps must be taken during

installation to protect the positioner and all connected equipment against overpressure.

WARNING

Dropping the actuator and any attached accessories and/or valve may cause personal injury and/or equipment damage. For

all mounting procedures use an adequately sized chain, sling, hoist, or crane to handle the actuator and any attached

accessories and/or valve. Use caution during lifting and handling to prevent slippage, swinging, faulty equipment

connections, or sudden shock loads.

10

Page 11

Instruction Manual

D102087X012

585C Actuator

March 2021

CAUTION

To avoid damage to actuator parts and difficult operation of actuator handwheels, open the bypass valve before using a

handwheel.

If manual operation is required, the actuator should be equipped with a manual handwheel. To manually move the

piston rod with the handwheel, first open the bypass needle valve (key 66 for sizes 25 and 50, figure 8; key 92 for sizes

60 to 130, figure 14), place the handwheel pointer in the neutral position, and insert the locking pin in the sleeve

assembly (for size 60‐130). Then turn the handwheel in the selected direction as indicated on the wheel.

The control valve should be located where it will be accessible for servicing. Room should be left above and below the

control valve to permit removal of the actuator and valve plug.

Bypass Assembly

The bypass is furnished as shown in figures 5, 7, 8, and 14 only when a handwheel actuator is specified. The bypass

allows the pressure to equalize on either side of the piston, so that the manual actuator can be used to position the

valve.

Flow through the bypass tubing is controlled by an angle needle valve (key 66 for figures 5, 7, and 8; and key 92 for

figure 14), which is operated manually. This valve should be closed when air pressure is being used to operate the

valve.

Three‐Way Valve Applications Note

WARNING

To avoid loss of control of process fluid and subsequent personal injury or property damage caused by bursting of

pressure‐retaining parts, be sure the cylinder pressure does not exceed 80 psig in high cycle‐rate, fast stroking speed,

three‐way valve applications.

In three‐way valve applications where the actuator fully strokes at a frequency of once per minute or faster, and the

stroking speed is rapid (less than 0.5 seconds per stroke), there is a possibility that the stem can fracture at the plug if

the actuator cylinder pressure is greater than 80 psig. This can cause loss of control of process fluid and further

damage to the actuator. Consideration should be given to the use of high‐strength, fatigue‐resistant stem materials in

these applications.

Actuator Mounting

Size 25 and 50 Actuator Mounting

The following procedure describes how to mount a 585C actuator size 25 and 50 on a push‐down‐to‐close valve so

that the piston stem to valve plug stem connection allows full travel and proper shutoff. Key numbers referenced in

the following steps are shown in figures 4 through 8.

11

Page 12

585C Actuator

March 2021

Instruction Manual

D102087X012

1. If not already removed, remove the stem connector (key 12) by loosening the cap screws (key 14).

2. Thread the stem connector nuts (keys 13 and 15) onto the valve stem, and run the nuts to the bottom of the valve

stem threads.

3. Push the valve plug stem until the valve plug is closed for push‐down‐to‐close valve plug action.

4. Place the actuator on the bonnet of the valve and secure the actuator tightly to the bonnet with the yoke locknut.

CAUTION

In the following procedure, do not rotate the valve plug while it is seated since this may cause damage to the seating

surface and thereby allow excessive leakage. Also, during adjustment, use tools carefully to avoid damaging the valve plug

stem. A damaged valve plug stem could cut the packing and allow leakage.

Note

When using an actuator with handwheel in the following step to stroke the valve plug, be sure the bypass valve (key 66, figure 5, 7,

or 8) is open. Rotating the handwheel (key 47, figure 5, 7, or 8) clockwise extends the actuator stem (key 10); rotating the

handwheel counterclockwise retracts the actuator stem.

5. Perform one of the following procedures (a or b as appropriate):

a. For a 585C actuator with spring retraction upon loss of cylinder pressure (figures 4 and 5) on a

push‐down‐to‐close valve, manually move the valve plug to the seated position. Rotate the handwheel or apply

pressure to the pressure connection in the cylinder (key 1) until the piston (key 3) and actuator stem (key 10)

move down the specified travel. Run the stem connector nut (key 13) up on the valve stem until it contacts the

actuator stem. Be sure the flats on the actuator stem are perpendicular to the scale indicator web on the yoke

(key 6). Adjust the stem connector nut as necessary, so that the flats on the nut and the actuator stem are

parallel. Clamp the actuator stem and stem connector nut together with the stem connector (key 12) and the

two cap screws and hex nuts (keys 14 and 23). Run the hex nut (key 15) up the valve stem and tighten against the

stem connector nut (key 13).

b. For a 585C actuator with spring extension upon loss of cylinder pressure (figures 6 and 7) with

push‐down‐to‐close valve, manually move the valve plug to the seated position. Run the stem connector nut

(key 13) up the valve stem until it contacts the actuator stem (key 10). Rotate the handwheel or apply pressure

to the pressure connection in the yoke (key 6) to move the actuator stem (key 10) approximately 1/4 inch away

from the stem connector nut. Rotate the stem connector nut so that it moves up the valve stem two full turns.

Manually move the valve plug so that the stem connector nut again contacts the actuator stem. Be sure the flats

on the actuator stem are perpendicular to the scale indicator web on the yoke (key 6). Adjust the stem connector

nut, as necessary, so that the flats on the nut and the actuator stem are parallel. Clamp the actuator stem and

stem connector nut together with the stem connector (key 12) and the two cap screws and hex nuts (keys 14

and 23). Run the hex nut (key 15) up the valve stem and tighten it against the stem connector nut (key 13).

6. Cycle the actuator several times to check for proper operation.

Note

In the following step, make sure the correct travel indicator scale (key 19) is used per the Parts List for the desired travel.

7. If necessary, remove the travel indicator scale screws (key 18) and reposition the travel indicator scale (key 19) so

that the scale arrow points in the same direction as the valve plug moves when opening. Close the valve. Adjust the

scale up or down so that the stem connector (key 12) indicator lines up with the closed mark on the scale. Secure

the scale with the scale screws.

12

Page 13

Instruction Manual

D102087X012

585C Actuator

March 2021

Size 60‐130 Actuator Mounting

The following procedure describes how to mount a 585C size 60 to 130 actuator on a push‐down‐to‐close valve so

that the piston stem to valve plug stem connection allows full travel and proper shutoff. Key numbers referenced in

the following steps are shown in figures 9 through 13.

If an actuator is purchased separately for field installation on a control valve, mount it on the valve and secure it in

place with the yoke locknut for size 60 and 68 or with eight bolts on actuator sizes 80, 100, and 130 which use a 127

mm (5‐inch) yoke boss.

The stem connector should then be set up to clamp the actuator stem and valve plug stem together to provide the

proper valve travel. This procedure is outlined in the Stem Connector Assembly procedures of this instruction manual.

Stem Connector Assembly (Size 60‐130)

CAUTION

To avoid damaging the seating surfaces, do not rotate the valve plug while it is seated. Also avoid damage to the valve plug

stem by careful use of tools during travel adjustment.

WARNING

D To avoid personal injury or property damage caused by cylinder fracture as a result of piston impact, install the stem

connector securely before supplying pressure to the positioner. Incomplete engagement of valve stem and/or actuator

stem in the stem connector can result in stripped threads or improper operation. Be sure that the length of each stem

clamped in the stem connector is equal to or greater than the diameter of that stem. Do not loosen the cap screws

when the stem connector has spring or loading pressure force applied to it.

D Install the stem connector securely before a positioner is mounted to the actuator and pressurized, using only a

regulator- controlled air supply, not the positioner, to move the actuator piston to position the actuator stem.

D To avoid personal injury or property damage, keep hands and tools out of the actuator stem travel path while

pressuring the actuator to move the actuator stem in the following steps.

585C Size 60‐130 Direct‐Acting (Push‐Down‐to‐Close) Valves

1. With the valve assembled and the actuator mounted, make sure the valve plug is in the closed position, and the

actuator is at the top of its stroke. Then screw the two stem locknuts (key 15) all the way onto the stem thread and

place the travel indicator disk (key 32) (if any) on the stem locknuts.

2. Keeping your hands away from any moving parts, use a regulator-controlled air supply to move the actuator stem

(key 10) down from the top of its stroke to the specified valve travel.

3. Using one half of the stem connector (key 12), align the actuator stem and the valve stem with threads from both

stems mated root-to-crest with the stem connector. Install the other half of the stem connector and tighten the cap

screws. With the stem locknuts (key 15), raise the travel indicator disk (key 32) to the stem connector (key 12).

4. Cycle the actuator to check availability of desired total travel and that the valve plug seats before the actuator

contacts the lower travel stop. Minor travel adjustments can be made by loosening the stem connector (key 12)

slightly, tightening the locknuts (key 15) together, and screwing the valve stem either into or out of the stem

connector (key 12) with a wrench on the locknuts (key 15). If the valve stem cannot be turned, as with a bellows seal

bonnet, remake the stem connection to achieve the desired travel.

5. Once the total travel is adequate, tighten the stem connector (key 12) securely, lock the stem locknuts (key 15)

against the connector, and adjust the indicator scale (key 19) on the yoke to show correct valve plug position.

13

Page 14

585C Actuator

March 2021

6. Provide a gauge to measure the pressure to the actuator. Make a final adjustment of the actuator or its positioner to

set the starting point of valve travel and to obtain full travel for the given instrument range.

Instruction Manual

D102087X012

585C Size 60‐130 Reverse‐Acting (Push‐Down‐to‐Open) Valves

1. Keeping your hands away from moving parts, pressure the actuator, using a regulator-controlled air supply, to

move the actuator stem (key 10) to the extreme upward position then reverse loading pressure to lower the

actuator stem (key 10) approximately 3 mm (1/8 inch).

2. Pull the valve stem up to seat the valve plug.

3. Using one half of the stem connector (key 12), align the actuator stem and the valve stem with threads from both

stems mated root-to-crest with the stem connector. Install the other half of the stem connector and tighten the cap

screws.

4. If there is a travel indicator disk (key 32), raise it to the stem connector (key 12) and tighten in position with the

stem locknuts (key 15). The indicator disk (key 32) should show the valve to be open with the piston (key 3) at the

bottom of its stroke. If it does not, loosen two screws (key 18) and shift the travel indicator scale (key 19) to indicate

OPEN.

5. Cycle the actuator to check availability of desired total travel and that the valve plug seats before the actuator

contacts the upper travel stop. Minor travel adjustments can be made by loosening the stem connector (key 12)

slightly, tightening the locknuts (key 15) together, and screwing the valve stem either into or out of the stem

connector (key 12) with a wrench on the locknuts. If the valve stem cannot be turned, as with a bellows seal bonnet,

remake the stem connection to achieve the desired travel.

6. Once the total travel is adequate, tighten the stem connector (key 12) securely, lock the stem locknuts (key 15)

against the connector, and adjust the indicator scale (key 19) on the yoke to show correct valve plug position.

7. Provide a gauge to measure the pressure to the actuator. Make a final adjustment of the actuator or its positioner to

set the starting point of valve travel and to obtain full travel for the given instrument range.

585C Handwheels

Handwheel Operation (Sizes 25 and 50)

Key numbers referenced in the following steps are shown in figures 5, 7, and 8 for the 585C actuator.

The handwheel assembly on a 585C actuator may be used as an adjustable travel stop to limit full upward or

downward travel of the actuator stem (key 10), or as a manual actuator to fully stroke the valve. When the neutral

indicator (key 42) is in the neutral position, travel is not restricted. With clockwise handwheel (key 47) rotation, the

operating nut (key 46) is screwed downward, forcing the actuator stem (key 10) down. With counterclockwise

rotation, the operating nut is screwed upward against the handwheel stem washer (key 45), pulling the actuator stem

up.

Note

When using an actuator with handwheel to stroke the valve plug or position the travel stop, be sure the bypass valve (key 66) is

open.

Handwheel Operation (Sizes 60‐130)

The 585C handwheel assembly for sizes 60 through 130 actuators (figures 9 and 10) has three main functions:

14

Page 15

Instruction Manual

D102087X012

585C Actuator

March 2021

a. To open or close the valve manually or to position the valve at any point in the stroke, regardless of the cylinder

pressure. The tapered pin is inserted during manual throttling operation.

b. To act as a travel stop to limit full opening or closing of the valve but not both at the same time. The tapered pin

is left out when the assembly is used as a travel stop.

c. To open or close the valve manually in an emergency without the necessity of inserting the tapered pin.

Bevel gears are used in sizes 60 and 68 and worm gears in sizes 80 through 130. A spring‐loaded ball detent is provided

in the handwheel to prevent a change in setting due to vibration. The following table 10 lists pertinent information on

these handwheel units.

Table 10. Handwheel Information

Actuator Size 60‐68 80‐130

Handwheel Diameter, Inches 8 17

Turns Required for One Inch of Travel 16 10

Maintenance (Sizes 25 and 50)

Actuator parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of

inspection and replacement depends on the severity of service conditions. This section provides two separate

procedures, one on Replacing Handwheel Housing O‐Ring or Thrust Bearings, and the other on Replacing Seals,

Changing Action, or Changing Bias Spring(s).

Refer to figures 5 and 7.

For an actuator with handwheel, a grease fitting (key 50) is provided on the bearing cover (key 38) for periodic bearing

lubrication with lithium grease (key 24).

WARNING

Avoid personal injury from sudden release of process pressure. Before performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and release all bias spring compression force by slowly unscrewing the

cylinder cover bolting in a crisscross pattern.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

15

Page 16

585C Actuator

March 2021

Instruction Manual

D102087X012

Replacing Handwheel Housing O‐Ring or Thrust Bearings

(Sizes 25 and 50)

Perform this procedure if inspecting or replacing the handwheel housing O‐ring, handwheel thrust bearings, or any

other handwheel parts located above the cylinder (key 1). Inspection or replacement of the cylinder O‐ring, handwheel

stem, or handwheel stem jam nut (key 57, 56, or 52) are covered in the Replacing Seals, Changing Action, or Changing

Bias Spring(s) procedure. Key numbers are referenced in figure 5 for a 585C actuator (spring retracts actuator rod) and

in figure 7 for a 585C actuator (spring extends actuator rod).

Note

This procedure may be performed without removing the cylinder, or yoke (key 1 or 6) from the bonnet of the valve.

Disassembly

Isolate the control valve from the line pressure, release pressure from both sides of the valve body, and drain the

process media from both sides of the valve. Shut‐off all pressure lines and power to the actuator, and release all

pressure from the actuator. Use lock‐out procedures to be sure that the above measures stay in effect while you work

on the equipment.

WARNING

Refer to the WARNING at the beginning of the Maintenance section in this instruction manual.

1. Shut off the bypass valve (key 66). Remove the cylinder pressure piping and bypass tubing from the bypass tees

(key 68) on the cylinder (key 1).

2. Turn the handwheel (key 47) in the appropriate direction so the neutral indicator (key 42) is behind the NEUTRAL

position of the neutral indicator plate (key 37).

3. Unscrew and remove the neutral indicator cover (key 35).

4. Remove the handwheel retaining ring, handwheel, and locking key (keys 48, 47, and 65).

5. Loosen the bearing cover set screws (key 51), and unscrew and carefully remove the bearing cover (key 38).

6. Remove the handwheel housing O‐ring (key 58) and the top set of thrust bearings (key 39).

7. Since both the handwheel housing (key 36) and the operating nut (key 46) have left‐hand threads, unscrew the

handwheel housing by turning it clockwise off the operating nut. Carefully remove the detent ball and detent spring

(keys 64 and 63), and remove the bottom set of thrust bearings (key 39).

8. Unscrew the handwheel stem cap screw (key 60) while using a 7/8 inch wrench to hold the handwheel stem

(key 56). Remove the handwheel stem washer (key 45), and the operating nut (key 46) with attached neutral

indicator (key 42).

9. Unscrew the neutral indicator (key 42) counterclockwise if necessary to separate it from the operating nut (key 46).

Reassembly

1. If the neutral indicator (key 42) was removed, coat its threads with thread locking adhesive (medium strength)

(key 70) and screw it into the operating nut (key 46). Position the 90‐degree elbow of the neutral indicator so that it

will not interfere with the neutral indicator cover (key 35) when assembled.

2. If necessary, replace the anti‐rotation key (key 40), by pushing the key outward from the cylinder (key 1) then install

the replacement key (key 40) into the anti‐rotation hole of the cylinder.

16

Page 17

Instruction Manual

D102087X012

3. Lubricate the inside surface of the operating nut (key 46) with lithium grease (key 24). Install the operating nut with

the attached neutral indicator, and the handwheel stem washer (key 45), onto the handwheel stem (key 56) and

secure with the handwheel stem cap screw (key 60). Tighten the cap screw to 169 NSm (125 lbfSft).

4. Place the bottom set of thrust bearings (key 39) on top of the cylinder (key 1). Insert the detent spring and ball

(keys 63 and 64) into the cylinder.

5. Install the handwheel housing O‐ring (key 58) on the handwheel housing (key 36). Since both the handwheel

housing and the operating nut (key 46) have left‐hand threads, thread the handwheel housing onto the operating

nut by turning it counterclockwise over the operating nut until the handwheel housing is snug against the bottom

set of thrust bearings (key 39).

6. Install the top set of thrust bearings (key 39) over the handwheel housing (key 36).

7. Carefully slide the bearing cover (key 38) over the handwheel housing (key 36) and thread the bearing cover hand

tight onto the cylinder (key 1). Secure by tightening the set screws (key 51) to 18 NSm (13 lbfSft).

8. Install the locking key, handwheel, and handwheel retaining ring (keys 65, 47, and 48).

9. Screw the neutral indicator cover (key 35) hand tight only onto the handwheel housing (key 36).

10. Install the bypass tubing with attached bypass valve (key 66) into the bypass tees (key 68) in the cylinder (key 1).

585C Actuator

March 2021

Replacing Seals, Changing Action, or Changing Bias Spring(s)

(Sizes 25 and 50)

Key numbers are referenced in figures 4 and 5 for a 585C actuator (spring retracts actuator rod) and in figures 6 and 7

for a 585C actuator (spring extends actuator rod).

Disassembly

Isolate the control valve from the line pressure, release pressure from both sides of the valve body, and drain the

process media from both sides of the valve. Shut‐off all pressure lines and power to the actuator, release all pressure

from the actuator, and release all bias spring compression force by slowly unscrewing the cylinder cover bolting in a

crisscross pattern. Use lock‐out procedures to be sure that the above measures stay in effect while you work on the

equipment.

WARNING

Refer to the WARNING at the beginning of the Maintenance section in this instruction manual.

For 585C actuators with push‐only handwheel, figure 8, be sure the handjack stem is backed out of the cylinder as far

as it will go to relieve any extra spring compression.

1. Remove the cylinder pressure piping. With a handwheel construction, perform steps 1. through 2. of the

Replacing Handwheel Housing O‐Ring or Thrust Bearings procedure.

Note

In the following step, loosen each cylinder‐to‐yoke cap screw a slight amount in turn in a crisscross pattern to keep the cylinder

square with the yoke while relieving spring precompression.

2. While carefully allowing bias spring precompression to be slowly released, remove the cylinder‐to‐yoke cap screws

and cylinder cover (keys 2 and 1).

17

Page 18

585C Actuator

March 2021

Instruction Manual

D102087X012

CAUTION

When performing the following step, set the cylinder on a protective surface to prevent damage to the cylinder surfaces.

3. Remove the cylinder (key 1). Set the cylinder on a protective surface to prevent damage to the cylinder surfaces.

With a handwheel construction, inspect the cylinder O‐ring (key 57) and replace it if necessary, applying lithium

grease (key 24) to the replacement O‐ring.

4. Inspect the piston O‐ring (key 8) and replace, if necessary. If the only further maintenance to be performed is

replacement of the piston O‐ring, skip to step 3 of this procedure.

Note

585C actuators may be used with or without the bias springs. In the following procedures, references are made to the bias springs.

If the bias springs are not used, disregard references to them when performing the maintenance procedures.

5. Perform one of the following disassembly procedures (a, b, c, d, or e, as appropriate):

a. For 585C actuators without handwheel (If the bias spring is present, it extends the piston rod.) (figure 6), remove

the piston cap screw (key 4), piston (key 3), bias spring(s) (key 16 and/or key 17), and travel stop spacer (key 5).

b. For 585C actuators with handwheel (If the bias spring is present, it extends the piston rod.) (figure 7), remove the

handwheel stem (key 56) with attached piston stud (key 69), piston (key 3), bias spring(s) (key 16 and/or key 17),

and travel stop spacer (key 5).

c. For 585C actuators without handwheel (If the bias spring is present, it retracts the piston rod.) (figure 4), remove

the bias spring(s) (key 16 and/or key 17), piston cap screw (key 4), travel stop spacer (key 5) and piston (key 3).

d. For 585C actuators with handwheel (If the bias spring is present, it retracts the piston rod.) (figure 5), remove the

bias spring(s) (key 16 and/or key 17), the handwheel stem (key 56) with attached piston stud (key 69), travel

stop spacer (key 5), and piston (key 3).

e. For 585C actuators with push‐only handwheel (figure 8), remove the cotter pin and slotted nut (keys 73 and 72)

and lift off the handwheel. Remove the jam nut (key 52). Remove the cap screws (key 60) and lift off the

handwheel housing (key 36). Back the handwheel stem (key 56) out of the housing. Inspect the O‐rings (keys 57

and 58). Replace these parts as necessary.

6. If inspection or replacement of the actuator stem O‐ring or bearing (key 9 or 11) is necessary, perform steps 1.

through 7. Otherwise, skip to step 2, being sure to comply with the note preceding step 2.

7. Loosen the two cap screws in the stem connector (key 14) and remove it. If the actuator is mounted on a valve,

separate the actuator stem (key 10) from the valve plug stem. Remove the actuator from the valve.

8. To inspect the actuator stem bearing (key 11), actuator stem O‐ring (key 9), or backup ring (key 25, size 50 only)

remove the actuator stem (key 10) from the yoke (key 6). Replace these parts if necessary. Apply lithium grease

(key 24) to the replacement O‐ring or bearing and install it into the yoke.

Assembly

1. Install the actuator stem through the yoke.

Note

Make certain the travel indicator scale (key 19) correctly matches the travel per the Parts List.

18

Page 19

Instruction Manual

D102087X012

585C Actuator

March 2021

2. To achieve the desired construction (either a direct‐acting or a reverse‐acting 585C actuator), perform one of the

following assembly procedures (a, b, or c, as appropriate):

a. For 585C actuators (bias spring retracts the piston rod) (figures 4 and 5), center the inner bias spring, if used,

(key 17 per table 6 or 7) around the center boss in the yoke (key 6). If used per table 6 or 7, center the outer bias

spring (key 16) around the inner bias spring. The outer bias spring should be within the outer boss in the yoke.

Put the travel stop spacer and the piston (keys 5 and 3) on the actuator stem. Apply lithium grease (key 24) to

the threads of the piston cap screw or piston stud (key 4 or 69). Insert the piston cap screw, or stud plus attached

handwheel stem (key 56), through both the piston and travel stop spacer and into the actuator stem. Use a

wrench on the flats of the actuator stem to prevent it from turning. Tighten the piston cap screw, or stud plus

attached handwheel stem, to 102 NSm (75 lbfSft) for size 25 actuators or 136 NSm (100 lbfSft) for size 50

actuators.

b. For 585C actuators with push‐only handwheel (figure 8), lubricate the O‐rings and handjack stem threads with

lithium grease. Install the O‐ring (key 57) and handjack stem (key 56), turning the screw into the housing as far as

possible. Place the O‐ring (key 58) over the housing and insert into the cylinder (key 1). Replace the cap screws

(key 60) and tighten to 41 NSm (30 lbfSft) on size 25 actuators or 81 NSm (60 lbfSft) on size 50 actuators. Replace

the jam nut (key 52), handwheel (key 47), and slotted nut and cotter pin (keys 72 and 73).

c. For 585C actuators (bias spring extends the piston rod) (figures 6 and 7), put the piston (key 3) on the actuator

stem and the travel stop spacer (key 5) on the piston. Apply lithium grease (key 24) to the threads of the piston

cap screw or piston stud (key 4 or 69). Insert the piston cap screw, or stud plus attached handwheel stem (key

56), through both the travel stop spacer and piston and into the actuator stem. Use a wrench on the flats of the

actuator stem to prevent it from turning. Tighten the piston cap screw, or stud plus attached handwheel stem,

to 102 NSm (75 lbfSft) for size 25 actuators or 136 NSm (100 lbfSft) for size 50 actuators. Center the inner bias

spring, if used, (key 17 per table 4 or 5) around the travel stop spacer. If used per table 4 or 5, center the outer

bias spring (key 16) around the inner bias spring. The outer bias spring should be within the outer boss on the

piston.

3. Install the piston O‐ring (key 8) if it was removed from the piston, and the yoke O‐ring (key 7, figure 4 or 6) if it was

removed from the yoke (key 6). Apply lithium grease (key 24) to the wall of the cylinder (key 1) and carefully slide

the cylinder over the piston O‐ring. Be sure the cylinder pressure connection is aligned with the yoke pressure

connection. Square the cylinder in place over the yoke O‐ring.

4. Line up the cylinder holes with the yoke holes making sure for a handwheel construction that the anti‐rotation

groove in the handwheel stem (key 56) is aligned with the hole in the cylinder for the anti‐rotation key (key 40).

Note

When placing the cylinder on the yoke and tightening the cylinder‐to‐yoke bolts, be sure to keep the cylinder square and aligned

with the top of the yoke.

5. Lubricate the cylinder‐to‐yoke bolts (key 2) with lithium grease (key 24). In a criss cross pattern, alternately tighten

each cylinder‐to‐yoke bolt a slight amount so that the cylinder stays square with the yoke. When all cylinder

surfaces are in contact with the yoke, tighten each cylinder‐to‐yoke bolt to 70 NSm (55 lbfSft) for a size 25 or 95

NSm (70 lbfSft) for a size 50.

6. With a handwheel construction, perform steps 2 through 10 of the Replacing Handwheel Housing O‐ring or Thrust

Bearings procedure.

7. If the actuator will be mounted on a valve, perform the appropriate actuator mounting procedure. Otherwise, place

the stem connector nut (key 13), stem connector (key 12), two cap screws (key 14), two hex nuts (key 23) and hex

nut (key 15) in a parts bag and attach the bag to the actuator yoke.

19

Page 20

585C Actuator

March 2021

Instruction Manual

D102087X012

Maintenance (Sizes 60‐130)

WARNING

To avoid personal injury or property damage caused by cylinder fracture as a result of piston impact, install the stem

connector securely before supplying pressure to the positioner. Use only a regulator-controlled air supply to move the

actuator piston so that you can install the stem connector. Do not use the positioner to move the actuator piston before

installing the stem connector.

WARNING

Avoid personal injury from sudden release of process pressure or uncontrolled process fluid. Before starting disassembly:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure to the actuator. Be sure the actuator cannot suddenly open or

close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Key numbers indicated refer to figures 9 through 13.

Isolate the control valve from the line pressure, release pressure from both sides of the valve body, and drain the

process media from both sides of the valve. Shut‐off all pressure lines and power to the actuator, and release all

pressure from the actuator. Use lock‐out procedures to be sure that the above measures stay in effect while you work

on the equipment.

1. If positioner is not used, go to step 5. If positioner is used, shut off all pressure lines to the positioner then remove

all tubing lines (cylinder, instrument and supply) from the positioner.

CAUTION

Do not use wrenches or other tools directly on the valve stem. Damage to the stem surface could result in subsequent

damage to the valve packing.

2. Remove the stem connector (key 12) and the piston rod boot (key 29) used to protect the lower end of the actuator

stem.

3. Remove the socket head cap screws that hold the cylinder (key 1) to the yoke (key 6).

CAUTION

Exercise care in the following step to prevent damage to the cylinder wall during removal of the cylinder from the yoke.

20

Page 21

Instruction Manual

D102087X012

4. Insert a screwdriver in the two slots on the lower edge of the cylinder casting and pry the cylinder loose from the

yoke. Remove the cylinder, being careful not to mar the cylinder wall.

5. The piston (key 3) and actuator stem (key 10) will come out with the cylinder. The piston can then be removed by

forcing it out the open end of the cylinder.

6. Unscrew the seal bushing (key 110 or 26), in the upper end of the yoke (key 6).

7. With the unit disassembled, inspect all parts for excessive wear. Replace all worn O‐rings. Lubricate with lithium

grease for standard service and Krytox

assembly drawings. Apply sealant (key 70) as indicated on the assembly drawings.

8. When reassembling the actuator after the piston nut (key 4) has been removed from the actuator stem (key 10),

clean the threads of the piston nut thoroughly and apply thread sealant to the threads. Tighten the piston nut

securely to a torque of 237 NSm (175 lbfSft) for size 60 actuators, 1290 NSm (950 lbfSft) for size 68, 80, and 100

actuators, or 2070 NSm (1530 lbfSft) for size 130 actuators.

®

GPL 202 for low ambient temperature service (key 24) as indicated on the

585C Actuator

March 2021

Side‐Mounted Handwheel Maintenance (Sizes 60‐130)

Refer to figure 9 and 10.

1. The handwheel gears should be lubricated periodically. A grease fitting (key 140) is provided on sizes 80, 100, and

130. On sizes 60 and 68, remove the handwheel (key 118) and the bevel pinion (key 116) and pack the gear case

with lithium grease. Loosen the set screw (key 139) before attempting to remove the pinion and extension.

2. If it is necessary to change the valve plug action from push‐down‐to‐close to push‐down‐to‐open or vice versa,

change the handwheel arrangement so that the arrow indicates the correct rotation required to open the valve.

a. For sizes 60 and 68, remove the handwheel, invert and replace it. On sizes 60 and 68 (figure 9), remove and

replace the spring‐loaded ball assembly (key 123) in the opposite side.

b. For sizes 80‐100, remove the handwheel assembly and install in the opposite end of the gear case by unscrewing

the back and front worm retainers (keys 135 and 136, not shown) and turn the handwheel to disengage the

bevel pinion (key 116).

Disassembly of Handwheel Constructions (Sizes 60 and 68)

WARNING

Refer to the WARNING at the beginning of the Maintenance section (Sizes 60‐130) in this instruction manual.

To disassemble 585C piston actuators sizes 60 and 68 (with handwheel) for maintenance, perform the following

procedures (figure 9 and 10):

1. Be sure that all pressure is out of the cylinder and valve body.

2. Remove all tubing lines to the positioner.

3. Remove the cap screws (key 2) on the underside of either the cylinder flange (key 100) for size 60 or the adapter

flange (key 76) for size 68. Remove the cylinder (key 1).

4. Remove the piston nut (key 4), then use a mallet to tap the piston (key 3) off the piston connector (key 107).

5. Remove the handwheel extension (key 117) by loosening the set screw (key 139) and unscrewing the extension.

6. Remove the cap screws (key 2) holding the cylinder flange (key 100) to the yoke (key 6).

7. Lift the cylinder flange (key 100) off the yoke (key 6).

8. Inspect the handwheel gears and bearings as needed.

21

Page 22

585C Actuator

March 2021

9. To remove the actuator stem (not shown), loosen the stem connection (key 12) and pull the actuator stem out the

top of the sleeve assembly (key 104).

10. Remove the sleeve by screwing it out of the sleeve assembly (key 104).

11. Unscrew the seal bushing (key 110) to inspect the O‐rings (keys 9 and 27).

Instruction Manual

D102087X012

Disassembly of Handwheel Constructions (Sizes 80‐130)

WARNING

Refer to the WARNING at the beginning of the Maintenance section (Sizes 60‐130) in this instruction manual.

To disassemble 585C piston actuators sizes 80‐130 (with handwheel) for maintenance, perform the following

procedures (figure 10):

1. Be sure that all pressure is out of the cylinder and valve body.

2. Remove all tubing lines to the positioner.

3. Remove the cap screws (key 2) on the underside of the cylinder adapter (key 101) and remove the cylinder (key 1).

4. Remove the piston nut (key 4), then use a mallet to remove the piston (key 3) from the piston connector (key 107).

5. Remove the cap screws (key 127) and cylinder adaptor (key 101).

6. Remove the cap screws (key 128) and remove the spacer (key 102), being careful not to lose the key (key 144).

7. Remove the locking pin (key 131), disconnect the stem connector (key 12) and pull out the actuator stem.

8. Remove the pointer (key 129) and turn the sleeve out of the sleeve assembly (key 104).

9. Remove the cap screws (key 128) holding the gear case (key 103) to the yoke (key 6).

10. Lift the gear case (key 103) to expose the handwheel assembly.

Reassembly (Sizes 60‐130)

When reassembling the 585C piston actuator with side‐mounted handwheel, adjust the setscrew (key 125) to

eliminate play in gear bearings. When properly set, lock with key 126.

When reassembling the actuator after the piston nut (key 4) has been removed from the piston connector (key 107),

clean the threads of the piston nut thoroughly and apply thread sealant to the threads. Tighten the piston nut securely