Page 1

Form Number D5142

Part Number D301726X012

September 2012

ControlWave Utilities Manual

Remote Automation Solutions

Page 2

IMPORTANT! READ INSTRUCTIONS BEFORE STARTING!

Be sure that these instructions are carefully read and understood before any operation is attempted. Improper

use of this device in some applications may result in damage or injury. The user is urged to keep this book filed

in a convenient location for future reference.

These instructions may not cover all details or variations in equipment or cover every possible situation to be

met in connection with installation, operation or maintenance. Should problems arise that are not covered

sufficiently in the text, the purchaser is advised to contact Emerson Process Management, Remote Automation

Solutions for further information.

EQUIPMENT APPLICATION WARNING

The customer should note that a failure of this instrument or system, for whatever reason, may leave an

operating process without protection. Depending upon the application, this could result in possible damage to

property or injury to persons. It is suggested that the purchaser review the need for additional backup

equipment or provide alternate means of protection such as alarm devices, output limiting, fail-safe valves,

relief valves, emergency shutoffs, emergency switches, etc. If additional information is required, the purchaser

is advised to contact Remote Automation Solutions.

RETURNED EQUIPMENT WARNING

When returning any equipment to Remote Automation Solutions for repairs or evaluation, please note the

following: The party sending such materials is responsible to ensure that the materials retu rned to Remote

Automation Solutions are clean to safe levels, as such levels are defined and/or determined by applicable

federal, state and/or local law regulations or codes. Such party agrees to indemnify Remote Automation

Solutions and save Remote Automation Solutions harmless from any liability or damage which Remote

Automation Solutions may incur or suffer due to such party's failure to so act.

ELECTRICAL GROUNDING

Metal enclosures and exposed metal parts of electrical instruments must be grounded in accordance with

OSHA rules and regulations pertaining to "Design Safety Standards for Electrical Systems," 29 CFR, Part 1910,

Subpart S, dated: April 16, 1981 (OSHA rulings are in agreement with the National Electrical Code).

The grounding requirement is also applicable to mechanical or pneumatic instruments that include electrically

operated devices such as lights, switches, relays, alarms, or chart drives.

EQUIPMENT DAMAGE FROM ELECTROSTATIC DISCHARGE VOLTAGE

This product contains sensitive electronic component s that can b e damaged by exposure to an electrostatic

discharge (ESD) voltage. Depending on the magnitude and duration of the ESD, this can result in erratic

operation or complete failure of the equipment. Read supplemental document S14006 for proper care and

handling of ESD-sensitive components.

Remote Automation Solutions

Page 3

ControlWave Utilities Manual (D5142)

Contents

Chapter 1 – Introduction 1-1

1.1 What are the ControlWave Utilities? ......................................................................................... 1-1

Chapter 2 – Using ControlView 2-1

2.1 Files are downloaded to the ControlWave using ControlWave Downloader ............................ 2-1

2.2 Starting ControlView ................................................................................................................. 2-3

2.3 Establishing a Connection with the ControlWave and Uploading File(s) .................................. 2-4

Chapter 3 – Using DataView 3-1

3.1 Starting DataView ..................................................................................................................... 3-2

3.2 Using the Tool Bar within DataView .......................................................................................... 3-2

3.3 Signing on to a Node ................................................................................................................. 3-3

3.4 Printing the Entries in the Current DataView Window............................................................... 3-3

3.5 Exporting Data Entries to the Windows Clipboard ................................................................. 3-3

3.6 Conducting a Signal Search ...................................................................................................... 3-4

3.6.1 Starting the Signal Search ............................................................................................ 3-4

3.6.2 Saving Search Criteria .................................................................................................. 3-9

3.6.3 Retrieving Search Criteria ............................................................................................. 3-9

3.6.4 Altering Search Criteria ................................................................................................. 3-9

3.7 Viewing Entries in a Signal Window ........................................................................................ 3-10

3.7.1 Changing Signal Values in the Signal Window ........................................................... 3-11

3.7.2 Changing Signal Inhibit/Enable Bits in the Signal Window ......................................... 3-12

3.7.3 Changing the Floating Point Format of Data in the Signal Window ............................ 3-12

3.8 Displaying a Remote Signal List ............................................................................................. 3-13

3.8.1 Selecting a Different Remote Signal List .................................................................... 3-13

3.8.2 Changing Remote List Signal Values, Altering Inhibit/Enable Bits ............................. 3-13

3.9 Creating and Using DataView Lists ........................................................................................ 3-14

3.9.1 Creating a DataView List ............................................................................................. 3-14

3.9.2 Collecting Live Data into the DataView List ................................................................ 3-15

3.9.3 Saving the DataView List ............................................................................................ 3-15

3.9.4 Viewing a Previously Saved DataView List ................................................................. 3-15

3.10 Creating and Using Recipes ................................................................................................... 3-15

3.10.1 Creating a Recipe ....................................................................................................... 3-15

3.10.2 Saving the Recipe ....................................................................................................... 3-16

3.10.3 To View/Modify an Existing Recipe File ...................................................................... 3-17

3.10.4 To Update Signals in the Controller with the Recipe Values ...................................... 3-17

3.10.5 To Read the Current Signal Values From the Controller Into the Recipe Window ..... 3-17

3.10.6 To Cancel Unsaved Modifications to the Recipe Values ............................................ 3-17

3.10.7 Changing the Floating Point Format of Data in the Recipe Window........................... 3-17

3.11 Viewing Data for a Single Signal ............................................................................................. 3-18

3.11.1 Acknowledging an Alarm ............................................................................................. 3-19

3.12 Viewing Data Arrays ................................................................................................................ 3-19

3.12.1 Changing Values in the Data Array ............................................................................. 3-20

3.12.2 Toggling the Time/Value Format ................................................................................. 3-21

3.12.3 Keeping Column 1 Visible While Scrolling Through the Array .................................... 3-21

3.12.4 Calling Up a Different Data Array ................................................................................ 3-21

3.12.5 Changing the Floating Point Format ........................................................................... 3-21

3.13 Viewing Audit Trail Records .................................................................................................... 3-21

3.14 Viewing Archive Data Files ..................................................................................................... 3-24

Issued Sep-2012 Contents iii

Page 4

ControlWave Utilities Manual (D5142)

3.14.1 Keeping Column 1 Visible While Scrolling Through the Archive File ......................... 3-25

3.14.2 Calling Up a Different Archive File .............................................................................. 3-25

3.14.3 Changing the Floating Point Format ........................................................................... 3-25

3.14.4 Restrictions on Archive File Size ................................................................................ 3-25

Chapter 4 – Using the Downloader 4-1

4.1 Downloading to a ControlWave-series Node: ........................................................................... 4-1

4.1.1 Before You Begin .......................................................................................................... 4-1

4.1.2 Starting the ControlWave Downloader.......................................................................... 4-4

4.1.3 Using the ControlWave Downloader ............................................................................. 4-4

Chapter 5 – Using the Flash Configuration utility 5-1

5.1 Starting the Flash Configuration Utility ...................................................................................... 5-1

5.2 Flash Configuration Utility Buttons ............................................................................................ 5-4

5.3 Forcing a Reboot of the ControlWave ....................................................................................... 5-6

5.4 Flash Configuration Utility Tabs ................................................................................................ 5-7

5.5 Soft Switches ............................................................................................................................ 5-8

5.6 Ports .......................................................................................................................................... 5-9

5.6.1 IP Network Security Protocols (CHAP and PAP) Used on PPP Links ....................... 5-14

5.6.2 Challenge Handshaking Authentication Protocol (CHAP) .......................................... 5-15

5.6.3 Password Authentication Protocol (PAP) ................................................................... 5-18

5.7 IP Parameters ......................................................................................................................... 5-25

5.8 Application Parameters ........................................................................................................... 5-30

5.9 Archive .................................................................................................................................... 5-32

5.10 Audit ........................................................................................................................................ 5-37

5.11 IP Routes ................................................................................................................................ 5-40

5.12 Security ................................................................................................................................... 5-42

Chapter 6 – Using the Communication Statistics Tool 6-1

6.1 Accessing the Remote Communication Statistics Tool ............................................................ 6-2

6.2 Signing On to a Node ................................................................................................................ 6-3

6.3 Crash Block Statistics Window ................................................................................................. 6-3

6.4 Port Summary Statistics Window .............................................................................................. 6-5

Port Detail Statistics Window.................................................................................................... 6-6

Master/Expanded Addressing Master Port Statistics ............................................................... 6-6

Slave, Pseudo-Slave, Pseudo-Slave with Alarms, Serial CFE or VSAT Slave Port Statistics 6-7

Custom Port Statistics .............................................................................................................. 6-8

Internet Protocol (IP) Port Statistics ......................................................................................... 6-8

6.5 Version Information Window ..................................................................................................... 6-9

6.6 Node Routing Table Window .................................................................................................. 6-11

6.7 Internet Protocol (IP) Statistics Window .................................................................................. 6-12

IP Statistics Decription ............................................................................................................ 6-13

ICMP Statistics Description .................................................................................................... 6-14

UDP Statistics Description ...................................................................................................... 6-15

IBP Statistics Description ....................................................................................................... 6-16

6.8 Printing the Entries in the Current Window ............................................................................. 6-17

6.9 Exporting Data Entries to the Windows™ Clipboard ................................................................ 6-17

Chapter 7 – Using the System Firmware Downloader 7-1

7.1 What is System Firmware? ....................................................................................................... 7-1

7.2 Requirements for Using the System Firmware Downloader ..................................................... 7-2

7.3 Starting the System Firmware Downloader .............................................................................. 7-3

7.4 Downloading System Firmware to a Single Controller ............................................................. 7-4

7.5 Setting Application Parameters for the System Firmware Downloader .................................... 7-5

iv Contents Issued Sep-2012

Page 5

ControlWave Utilities Manual (D5142)

Security Tab .............................................................................................................................. 7-5

Batch Mode Tab ....................................................................................................................... 7-6

7.6 Using PROM Reporter to see which Firmware is Loaded in an RTU ....................................... 7-6

Issued Sep-2012 Contents v

Page 6

This page is intentionally left blank

Page 7

ControlWave Utilities Manual (D5142)

Chapter 1 – Introduction

This manual provides instructions for using ControlWave utilities

software.

In This Chapter

1.1 What are the ControlWave Utilities? ................................................ 1-1

1.1 What are the ControlWave Utilities?

OpenEnterprise™ Field Tools includes a set of utility programs used

with ControlWave controllers. Most are launched from within

TechView. These utilities include:

ControlView File Viewer – This utility retrieves certain file types

from the ControlWave’s flash memory, and launches associated

applications so you can view them on the PC, such as HTML files.

ControlWave Downloader – This utility takes the ControlWave

project you create with ControlWave Designer and downloads it into

the ControlWave controller.

DataView – This utility collects various kinds of data from the

ControlWave for you to view on screen (variable values, lists,

archives, arrays).

Flash Configuration utility – This utility lets you update

configuration parameters in the ControlWave’s flash memory for

things like communication ports, IP addresses, memory, and so on.

Remote Communication Statistics utility – This utility lets you view

statistics regarding the “health” of ControlWave communications.

System Firmware Downloader – This utility lets you perform an

upgrade to the system firmware in the ControlWave.

Besides these utilities, there are other software programs for

ControlWave devices accessible in Field Tools; for information on

these, consult the sources listed in Table 1-1.

Table 1-1 Finding information about other ControlWave software

included within Field Tools

Software Description See these sources of information

Used to create control

strategy

ControlWave Designer

Debug_Info Tools

Issued Sep-2012 Introduction 1-1

(ControlWave project)

that executes inside

the ControlWave

controller.

Provides certain

debug information;

Getting Started with ControlWave

Designer (D5085)

ControlWave Designer

Programmer’s Handbook (D5125)

Online help in ControlWave Designer

ControlWave Designer

Programmer’s Handbook (D5125) –

Page 8

ControlWave Utilities Manual (D5142)

Software Description See these sources of information

Diagnostics utility

Reset ControlWave utility

TechView

Web_BSI

primarily used by

technical support

personnel.

Runs basic diagnostic

routines on the

ControlWave

hardware.

Allows you to power

cycle the

ControlWave.

Used to launch web

pages, custom

applications, and

configuration tools.

A set of HTML pages

and web controls

specifically geared

towards

communication with

and data collection

from ControlWave

devices.

Appendix B

Diagnostics Manual (D4041A)

ControlWave Designer

Programmer’s Handbook (D5125)

TechView User’s Guide (D5131)

Web_BSI Manual (D5087)

Notes:

Some of these utilities (Remote Communication Statistics,

Debug_Info, Diagnostics, Reset ControlWave) are not accessible

from menus by default because they are typically used by advanced

users.

If you want to add one or more of these to the menu, follow the

instructions for adding menu items to initialization files in Appendix

A of the TechView User’s Guide (D5131).

1-2 Introduction Issued Sep-2012

Page 9

ControlWave Utilities Manual (D5142)

Chapter 2 – Using ControlView

The ControlWave-series of process automation controllers can store

user-created files in FLASH memory in a folder called “ControlView.”

These could include HTML files, ZIP files, etc. The underlying file

transfer between the ControlWave and the PC is accomplished using the

industry standard File Transfer Protocol (FTP).

The ControlView utility allows you to retrieve these files from the

ControlWave, copy them to the PC, and launch the associated

application program for those files.

Once you connect to the ControlWave, ControlView displays the

contents of the ControlView folder on the RTU so you can select the

desired file and ControlView automatically uploads the file and

launches the Windows™ application associated with that file type.

For example, if you have created HTML pages for displaying signal

values from the ControlWave (using Web_BSI’s ActiveX controls),

ControlView allows you to connect to the ControlWave, upload the

HTML files from the ControlView folder to your PC (using FTP), and

launch Internet Explorer to allow you to view the HTML pages with

their associated data from the ControlWave.

In This Chapter

2.1 Files are downloaded to the ControlWave using ControlWave

Downloader ...................................................................................... 2-1

2.2 Starting ControlView ........................................................................ 2-3

2.3 Establishing a Connection with the ControlWave and Uploading File(s)

......................................................................................................... 2-4

2.1 Files are downloaded to the ControlWave using ControlWave

Downloader

Files are downloaded to the ControlWave’s FLASH memory using the

ControlWave Downloader included with Field Tools. You must select

the “Download User Files” option in the Downloader, prior to starting

the download.

The Downloader takes all files in the directory defined by the “User

Files Path”, and downloads them to the ControlWave.

Issued Sep-2012 ControlView 2-1

Page 10

ControlWave Utilities Manual (D5142)

Check “Download User Files” when you

download files to the ControlView file area

of the ControlWave’s flash memory.

Figure 2-1. Downloading Files to the ControlWave

The “User Files Path” should follow the format shown below:

\OpenBSI\Downloads\project_name\ControlView

Where:

project_name is the basename of the ControlWave project. The folder

containing the files to be downloaded must be a subdirectory of projectname called ControlView.

So, for example, if the ControlWave project name is STATION3, then

the folder containing the files to be downloaded to FLASH should be

called:

\OpenBSI\Downloads\STATION3\ControlView

IMPORTANT:

If the files you are downloading are to be compressed into a zip file, you

must include a STARTUP.INI file within the zip file, which identifies

which application should be launched when the files are unzipped. This

file takes the format:

[STARTUP]

File = xxxxx.yyy

Program = program_name

Where

xxxxx.yyy is the name of one of the zipped files

2-2 ControlView Issued Sep-2012

Page 11

ControlWave Utilities Manual (D5142)

program_name is the name of the program ControlView should

launch once the zipped file is unzipped. If the

directory containing the program is not part of the

standard Windows™ PATH statement, you must

enter the entire path and filename of the program

executable here.

Example STARTUP.INI File:

[STARTUP]

File=mymenu.htm

Program=iexplore

2.2 Starting ControlView

1. If not already done, use Field Tools to establish a communication

connection (either serial or IP) with the ControlWave controller and

launch TechView. (For information on doing this, see Chapter 3 of

the OpenEnterprise™ Field Tools Quick Setup Guide (D5141) or

consult the online help in Field Tools.

2. Right-click on the icon for the controller and choose ControlView

from the pop-up menu.

Issued Sep-2012 ControlView 2-3

Page 12

ControlWave Utilities Manual (D5142)

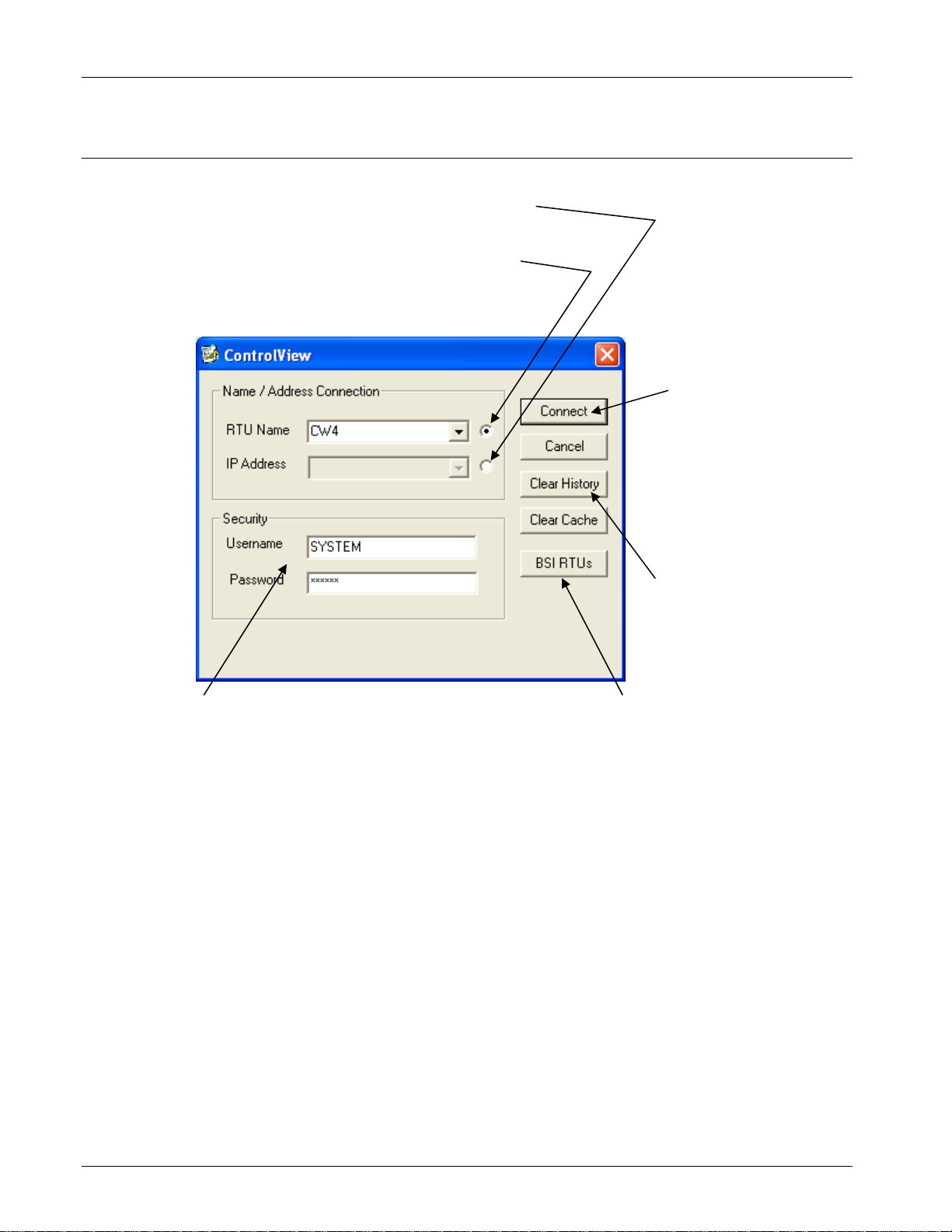

2.3 Establishing a Connection with the ControlWave and Uploading

File(s)

Select this button to enter the IP address

-orSelect this button to use the RTU name

You cannot enter both the IP address and

the RTU name

Click “Connect” to

establish the

connection and display

the files available for

upload.

You must provide a valid

username / password combination

to access the ControlWave.

The list controls allow you

to call up previous

entries. To erase the

previous entries, click

“Clear History.”

Not applicable in Field

1.

Tools.

Figure 2-2. ControlView

1. Field Tools automatically fills in the node name. If you’d rather

specify an IP address select the button to the right of the IP Address

field, then enter the ControlWave’s IP address in the IP Address

field (or use the list control to select it if it appears in the history list

of IP addresses).

2. Enter a valid Username / Password combination for this

ControlWave.

3. Click Connect and ControlView displays a list of files available for

upload from the ControlWave.

2-4 ControlView Issued Sep-2012

Page 13

ControlWave Utilities Manual (D5142)

4. From the list box in the Select File to View dialog box, select the

file you want to view and click OK. ControlView uploads that file

to the PC and launches its application. (Note: If there is only one file

in the ControlView area of FLASH available for uploading, you

don’t have to select it; ControlView uploads it automatically and

launches its associated application.)

Select which file you want

to upload and click OK.

Figure 2-3. Selecting File to Upload

Note: If the file you upload is a zipped (compressed) file, ControlView

automically uncompresses the file; the application it launches

depends on entries in the STARTUP.INI file.

Issued Sep-2012 ControlView 2-5

Page 14

This page is intentionally left blank

Page 15

ControlWave Utilities Manual (D5142)

Chapter 3 – Using DataView

DataView allows you to collect several types of data from a

ControlWave series controller, including signal data, signal lists, archive

data, array values, and audit trail alarm/event information. In addition, it

allows you to search for signals based on various criteria, and also

allows you to send recipes (lists of signal values) to the controller.

In This Chapter

3.1 Starting DataView ............................................................................ 3-2

3.2 Using the Tool Bar within DataView ................................................ 3-2

3.3 Signing on to a Node ....................................................................... 3-3

3.4 Printing the Entries in the Current DataView Window ..................... 3-3

3.5 Exporting Data Entries to the Windows Clipboard ....................... 3-3

3.6 Conducting a Signal Search ............................................................ 3-4

3.6.1 Starting the Signal Search .................................................... 3-4

3.6.2 Saving Search Criteria ......................................................... 3-9

3.6.3 Retrieving Search Criteria .................................................... 3-9

3.6.4 Altering Search Criteria ........................................................ 3-9

3.7 Viewing Entries in a Signal Window .............................................. 3-10

3.7.1 Changing Signal Values in the Signal Window .................. 3-11

3.7.2 Changing Signal Inhibit/Enable Bits in the Signal Window 3-12

3.7.3 Changing Floating Point Format of Data in Signal Window3-12

3.8 Displaying a Remote Signal List .................................................... 3-13

3.8.1 Selecting a Different Remote Signal List ............................ 3-13

3.8.2 Changing Remote List Signal Values ................................. 3-13

3.9 Creating and Using DataView Lists ............................................... 3-14

3.9.1 Creating a DataView List .................................................... 3-14

3.9.2 Collecting Live Data into the DataView List ....................... 3-15

3.9.3 Saving the DataView List ................................................... 3-15

3.9.4 Viewing a Previously Saved DataView List ........................ 3-15

3.10 Creating and Using Recipes .......................................................... 3-15

3.10.1 Creating a Recipe ............................................................... 3-15

3.10.2 Saving the Recipe .............................................................. 3-16

3.10.3 To View/Modify an Existing Recipe File ............................. 3-17

3.10.4 To Update Signals in the Controller with the Recipe Values 3-17

3.10.5 To Read the Current Signal Values From the Controller ... 3-17

3.10.6 To Cancel Unsaved Modifications to the Recipe Values ... 3-17

3.10.7 Changing the Floating Point Format of Data ...................... 3-17

3.11 Viewing Data for a Single Signal ................................................... 3-18

3.11.1 Acknowledging an Alarm .................................................... 3-19

3.12 Viewing Data Arrays ...................................................................... 3-19

3.12.1 Changing Values in the Data Array .................................... 3-20

3.12.2 Toggling the Time/Value Format ........................................ 3-21

3.12.3 Keeping Column 1 Visible While Scrolling Through the Array3-21

3.12.4 Calling Up a Different Data Array ....................................... 3-21

3.12.5 Changing the Floating Point Format .................................. 3-21

3.13 Viewing Audit Trail Records ........................................................... 3-21

3.14 Viewing Archive Data Files ............................................................ 3-24

3.14.1 Keeping Column 1 Visible .................................................. 3-25

3.14.2 Calling Up a Different Archive File ..................................... 3-25

3.14.3 Changing the Floating Point Format .................................. 3-25

3.14.4 Restrictions on Archive File Size ........................................ 3-25

Issued Sep-2012 DataView 3-1

Page 16

ControlWave Utilities Manual (D5142)

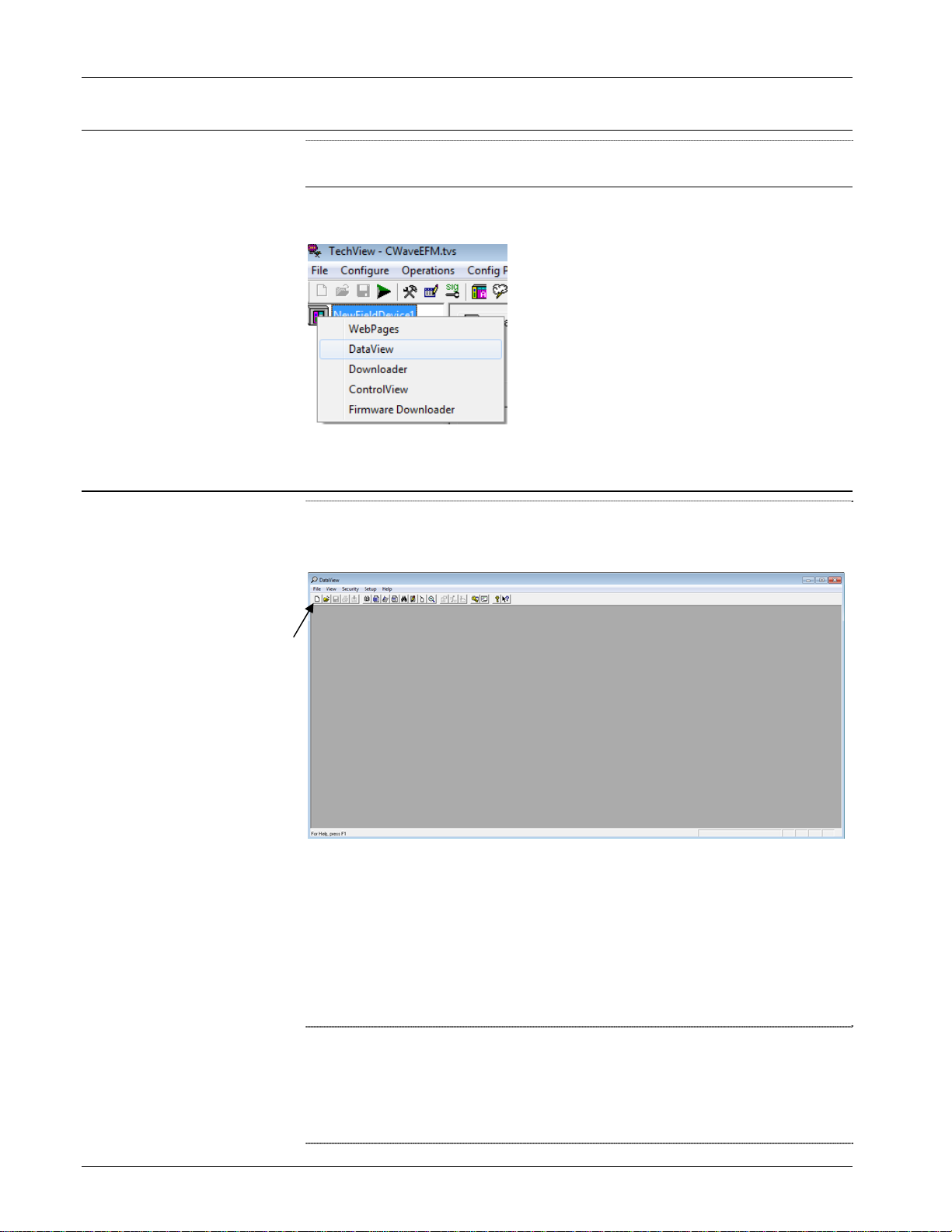

3.1 Starting DataView

Note: Before starting DataView, you must establish communications

with the controller using Field Tools, then launch TechView.

Right click on the RTU name in TechView then choose DataView from

the pop-up menu.

3.2 Using the Tool Bar within DataView

The DataView window includes a tool bar which provides you easy

access to DataView's features and functions, and serves as an alternative

to using the menu bar and pull down menus.

Toolbar

Figure 3-1. DataView

If you position the mouse cursor over any tool bar icon you can see a

label which identifies the icon's function. (Note: The number and

function of active icons in the tool bar varies depending upon which

DataView feature currently runs in the window.) A single click on the

icon activates its feature. See the pages which follow for a description of

the various DataView features.

Notes:

You can run multiple DataView functions simultaneously in

separate windows, if sufficient memory is available.

If sufficient memory is available, you can run multiple copies of

DataView simultaneously.

3-2 DataView Issued Sep-2012

Page 17

ControlWave Utilities Manual (D5142)

3.3 Signing on to a Node

When invoked from within Field Tools, DataView automatically uses

the Field Tools RTU credentials; so you do not need to sign on.

The Automatic Sign-on feature does not apply when launching

DataView through Field Tools.

3.4 Printing the Entries in the Current DataView Window

You can print the textual data displayed in the various types of

DataView Windows on a printer.

Notes:

Before attempting to print, you must configure a printer and connect

it to this workstation, either directly, or through a network. To

access the Windows Print Setup dialog box, click File > Print

Setup.

The types of DataView windows which hold printable data include

Signal windows (which are used to display Signal Searches,

DataView Lists, or Remote Lists) as well as other types of windows

such as Audit Trail windows, Archive windows, and Array

windows. All of these types of windows will be discussed later in

this manual.

To preview the data you want to print, click File>Print Preview from

the menu bar.

To print the entries (data) in the current DataView window, click the

printer icon, shown above, or click File>Print. The Windows Print

dialog box opens. See your Windows™ documentation for further

information.

3.5 Exporting Data Entries to the Windows Clipboard

As an alternative to sending data to the printer, described above, you

can copy DataView window entries as text to the Windows Clipboard.

From the Clipboard, you can export the data to other Windows

applications such as spreadsheets or word processors. DataView formats

its entries specifically for use in Microsoft Excel.

To copy entries in the current DataView window to the Windows

Clipboard, click File>Copy to Clipboard.

See your Windows documentation for more information on using the

Clipboard.

Issued Sep-2012 DataView 3-3

Page 18

ControlWave Utilities Manual (D5142)

3.6 Conducting a Signal Search

A signal search allows you to search for all signals (variables) which

share one or more common characteristics. For example, you can define

the search criteria to be all signals which share the same signal

extension and are control-inhibited. Or you could search for all signals

currently in the high-high alarm state. The following is a list of valid

signal search criteria:

Signal base name, extension, or attribute (ControlWave configured

to use ACCOL names)

Variable/function block instance name

String Search

Current alarm state (logical alarm, high, high-high, low, low-low)

Inhibit/enable bit status (alarm inhibit/enable, control inhibit/enable,

manual inhibit/enable)

Questionable data bit status

3.6.1 Starting the Signal Search

To start a Signal Search, click on the Signal Search tool bar icon (shown

at left), or click File > New, and then click Signal Search in the New

list box. Either method opens the Signal Search Properties dialog box.

Field Tools automatically populates the Node name field. Use the other

fields to specify the parameters of your search.

Notes:

To see all variables in the project (both global and local variables

marked as “PDD”) you can leave all the selection fields blank.

Some of the searches support wildcard characters. Wildcard

characters allow you to search for items for which you don’t know

the exact name, or for which there may be several possible matches.

There are two wildcard characters supported, “*” and “?”

The * indicates that DataView should automatically consider any

characters in the position where the * appears as valid matches for

this search. For example, if you search for “COMP*,” items like

“COMP4,” “COMPRESSOR” and “COMPORT” are all considered

valid matches.

The ? indicates that DataView should accept the substitution of any

one single character for the question mark as a valid match for this

search. For example, if you search for “PUMP?RUN” then

“PUMP1RUN,” “PUMP2RUN” or “PUMPNRUN” are all

considered valid matches.

3-4 DataView Issued Sep-2012

Page 19

ControlWave Utilities Manual (D5142)

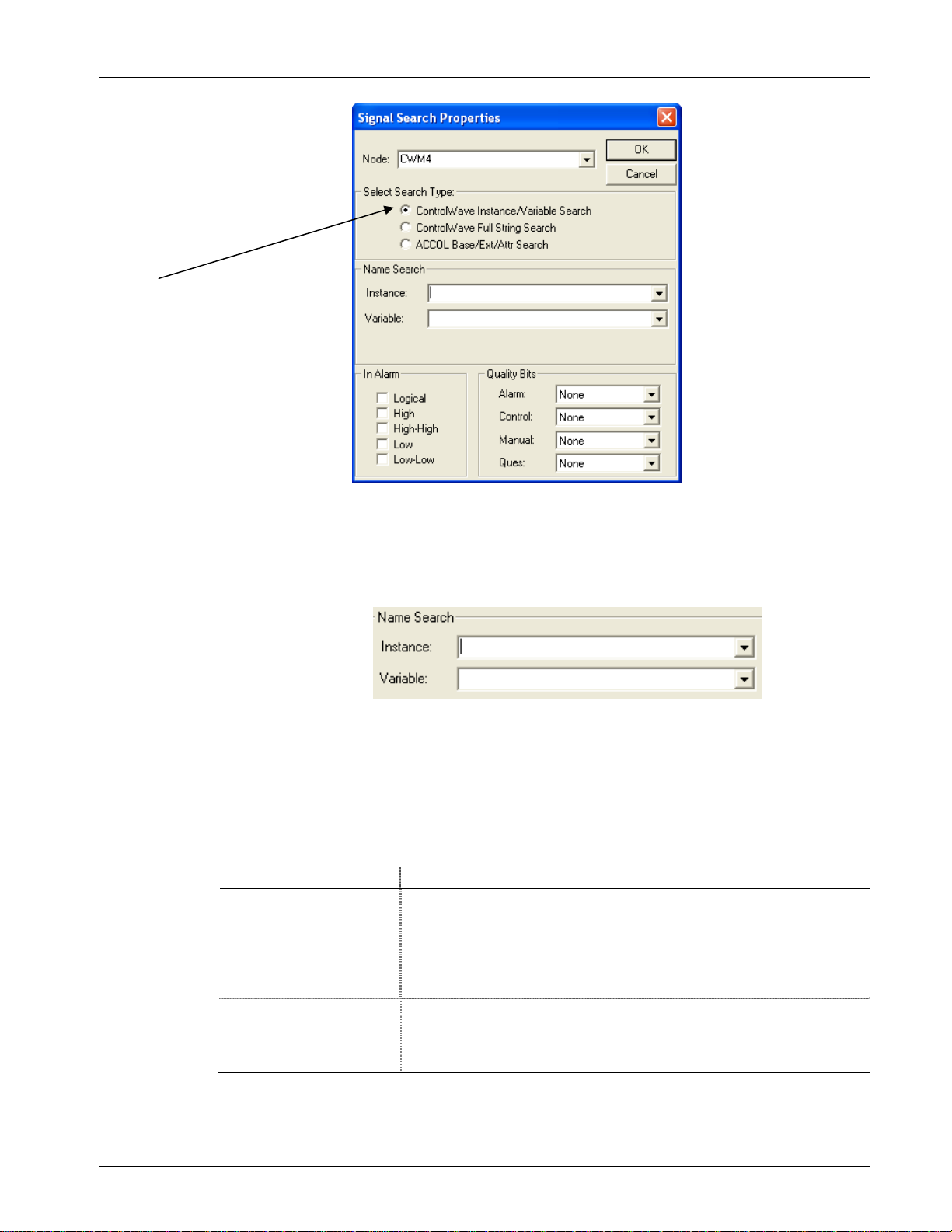

Choose the type of

search you want to

conduct.

Figure 3-2. Signal Search Properties dialog box

Instance/Variable

Search Mode:

For ControlWave controllers you can search based on the POU

Instance name(s), and/or the Variable name. You can use

wildcards in either of these fields.

The same variable can have multiple instance names associated

with it, for example, an instance for the program, followed by the

instance for a function block, etc. A period “.” character follows

each instance therefore an instance name is always to the left of

the last period. DataView considers the portion to the right of the

last period to be the variable name. The signal search can only

find variables which you previously marked as “PDD.”

Field Description

Instance

Variable

You can enter up to 32 characters in the Instance name portion. If

you do NOT use wildcard characters, the instance name must match

exactly to be considered a valid match. For global variables the POU

instance name must be “@GV.” If you leave the Instance field blank,

DataView considers any instance name to be valid, and it only uses

the Variable field in the search.

You can enter up to 32 characters in the Variable name portion. If you

do NOT use wildcard characters, the variable name must match

exactly to be considered a vali d mat ch. If y ou le ave the Variabl e field

blank, DataView only uses the Instance field in the search

Some Examples:

Issued Sep-2012 DataView 3-5

Page 20

ControlWave Utilities Manual (D5142)

e

Let’s say you have a set of variables with the following names (Figure

3-3).

instance

name

multiple

instance

names

@GV.PRESSURE_READING

@GV.MYFB.STATION1_FLOW

@GV.MYFB.STATION2_FLOW

@GV.MYFB.STATION3_FLOW

@GV.MYFB.STATION4_FLOW

@GV.MYFB2.STATION1_FLOW

@GV.MYFB2.STATION2_FLOW

@GV.MYFB2.STATION3_FLOW

@GV.MYFB2.STATION4_FLOW

PROG1.TEMP_HIGH

PROG1.TEMP_LOW

PROG1.TEMP_CURRENT

instance

name

variable name

variable nam

variable name

Figure 3-3. Sample Set of Variables

Table 3-1 lists some resulting matches for searches based on this set of

variables:

Table 3-1. Sample Search Results – Instance / Variable

If you enter

this in the

Instance field

* STATION1* @GV.MYFB.STATION1_FLOW

leave blank

@GV.MYFB* STATION2* @GV.MYFB.STATION2_FLOW

PROG TEMP*

PROG*

And you enter this in

the Variable field

TEMP* PROG1.TEMP_HIGH

leave blank

DataView returns the

following variables from the

set of variables shown in

Figure 3-3.

@GV.MYFB2.STATION1_FLOW

PROG1.TEMP_LOW

PROG1.TEMP_CURRENT

@GV.MYFB2.STATION2_FLOW

No matches; because no wildcard

following ‘PROG’.

PROG1.TEMP_HIGH

PROG1.TEMP_LOW

PROG1.TEMP_CURRENT

@GV.MYFB2

*.* STATION3* @GV.MYFB.STATION3_FLOW

3-6 DataView Issued Sep-2012

leave blank

@GV.MYFB2.STATION1_FLOW

@GV.MYFB2.STATION2_FLOW

@GV.MYFB2.STATION3_FLOW

@GV.MYFB2.STATION4_FLOW

@GV.MYFB2.STATION3_FLOW

Page 21

ControlWave Utilities Manual (D5142)

If you enter

this in the

Instance field

*

*.*

And you enter this in

the Variable field

leave blank

leave blank

DataView returns the

following variables from the

set of variables shown in

Figure 3-3.

@GV.PRESSURE_READING

@GV.MYFB.STATION1_FLOW

@GV.MYFB.STATION2_FLOW

@GV.MYFB.STATION3_FLOW

@GV.MYFB.STATION4_FLOW

@GV.MYFB2.STATION1_FLOW

@GV.MYFB2.STATION2_FLOW

@GV.MYFB2.STATION3_FLOW

@GV.MYFB2.STATION4_FLOW

PROG1.TEMP_HIGH

PROG1.TEMP_LOW

PROG1.TEMP_CURRENT

@GV.MYFB.STATION1_FLOW

@GV.MYFB.STATION2_FLOW

@GV.MYFB.STATION3_FLOW

@GV.MYFB.STATION4_FLOW

@GV.MYFB2.STATION1_FLOW

@GV.MYFB2.STATION2_FLOW

@GV.MYFB2.STATION3_FLOW

@GV.MYFB2.STATION4_FLOW

*.MYFB2

leave blank

or

*

*.MYFB2* STATION2_FL?W @GV.MYFB2.STATION2_FLOW

PROG?

@GV.MYFB?

leave blank

STATION?_FLOW @GV.MYFB.STATION1_FLOW

leave blank

leave blank

@GV.MYFB2.STATION1_FLOW

@GV.MYFB2.STATION2_FLOW

@GV.MYFB2.STATION3_FLOW

@GV.MYFB2.STATION4_FLOW

@GV.MYFB.STATION2_FLOW

@GV.MYFB.STATION3_FLOW

@GV.MYFB.STATION4_FLOW

@GV.MYFB2.STATION1_FLOW

@GV.MYFB2.STATION2_FLOW

@GV.MYFB2.STATION3_FLOW

@GV.MYFB2.STATION4_FLOW

PROG1.TEMP_HIGH

PROG1.TEMP_LOW

PROG1.TEMP_CURRENT

@GV.MYFB.STATION1_FLOW

@GV.MYFB.STATION2_FLOW

@GV.MYFB.STATION3_FLOW

@GV.MYFB.STATION4_FLOW

@GV.MYFB2.STATION1_FLOW

@GV.MYFB2.STATION2_FLOW

@GV.MYFB2.STATION3_FLOW

@GV.MYFB2.STATION4_FLOW

Issued Sep-2012 DataView 3-7

Page 22

ControlWave Utilities Manual (D5142)

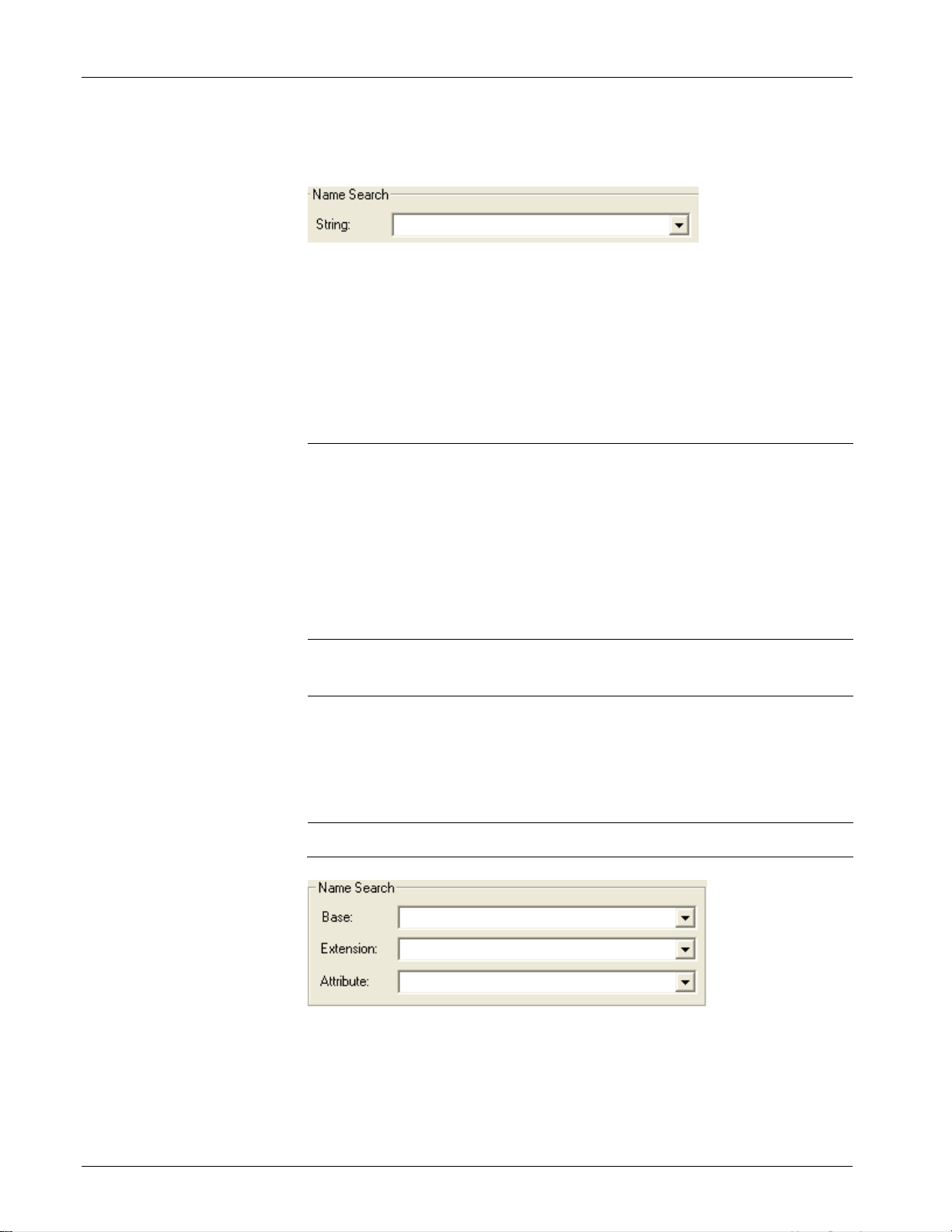

ControlWave Full

String Search

Mode:

For this search, you can enter a string that is in either the instance name

or variable name.

The search string you enter can include wildcards to establish a pattern

for DataView to match.

Table 3-2 shows some examples, using the same set of variables from

Figure 3-3.

Table 3-2. Sample Search Results – String

If you enter

this in the

String field

DataView returns the following variables from the set

of variables shown in Figure 3-3.

*STATION?_F* @GV.MYFB.STATION1_FLOW

@GV.MYFB.STATION2_FLOW

@GV.MYFB.STATION3_FLOW

@GV.MYFB.STATION4_FLOW

@GV.MYFB2.STATION1_FLOW

@GV.MYFB2.STATION2_FLOW

@GV.MYFB2.STATION3_FLOW

@GV.MYFB2.STATION4_FLOW

ACCOL Base,

Extension, and

Attribute Search

Mode

*MYFB?.STA

TION2*

@GV.MYFB.STATION2_FLOW

@GV.MYFB2.STATION2_FLOW

*1* @GV.MYFB.STATION1_FLOW

@GV.MYFB2.STATION1_FLOW

PROG1.TEMP_HIGH

PROG1.TEMP_LOW

PROG1.TEMP_CURRENT

@GV.P* @GV.PRESSURE_READING

If DataView communicates with a ControlWave and you set the

_USE_ACCOL_NAME system variable in your ControlWave project to

TRUE, you can use the Base, Extension and Attribute fields. To work

properly in this case, though, the signal names you search for must fit

the ACCOL II signal naming convention, i.e. no more than eight alphanumeric characters for the base, no more than six for the extension, and

3-8 DataView Issued Sep-2012

Page 23

ControlWave Utilities Manual (D5142)

no more than four for the attribute. In addition, characters such as the at

sign “@” cannot be included. The underscore “_” may work if it’s at the

end of the search parameter, but it will not work at the beginning of the

search parameter.

Notes:

Do not enter wildcard characters in this mode.

You must search using the complete, Base, Extension, or Attribute,

not part of it. For example, to search for an attribute of “FLOW,”

you must enter “FLOW,” not “FLO,” “FL,” or “F.”

In Alarm and

Quality Bits

The In Alarm check boxes let you select signals which share the same

alarm status.

The Quality Bits area list boxes allow you to select signals based on the

inhibit/enable status for each alarm, control, or manual inhibit/enable bit.

You can also select based on the Questionable data status.

Select the desired search criteria, and click OK to execute the search. A

signal window opens to display all signals/variables which share the

selected characteristics. See Viewing Entries in the Signal Window for

information on using the entries in this window to change signal values,

or to alter inhibit / enable bits. See Viewing Data for a Single Signal for

information on viewing more detailed signal information. Note: The

window can only display the first 5000 signals found.

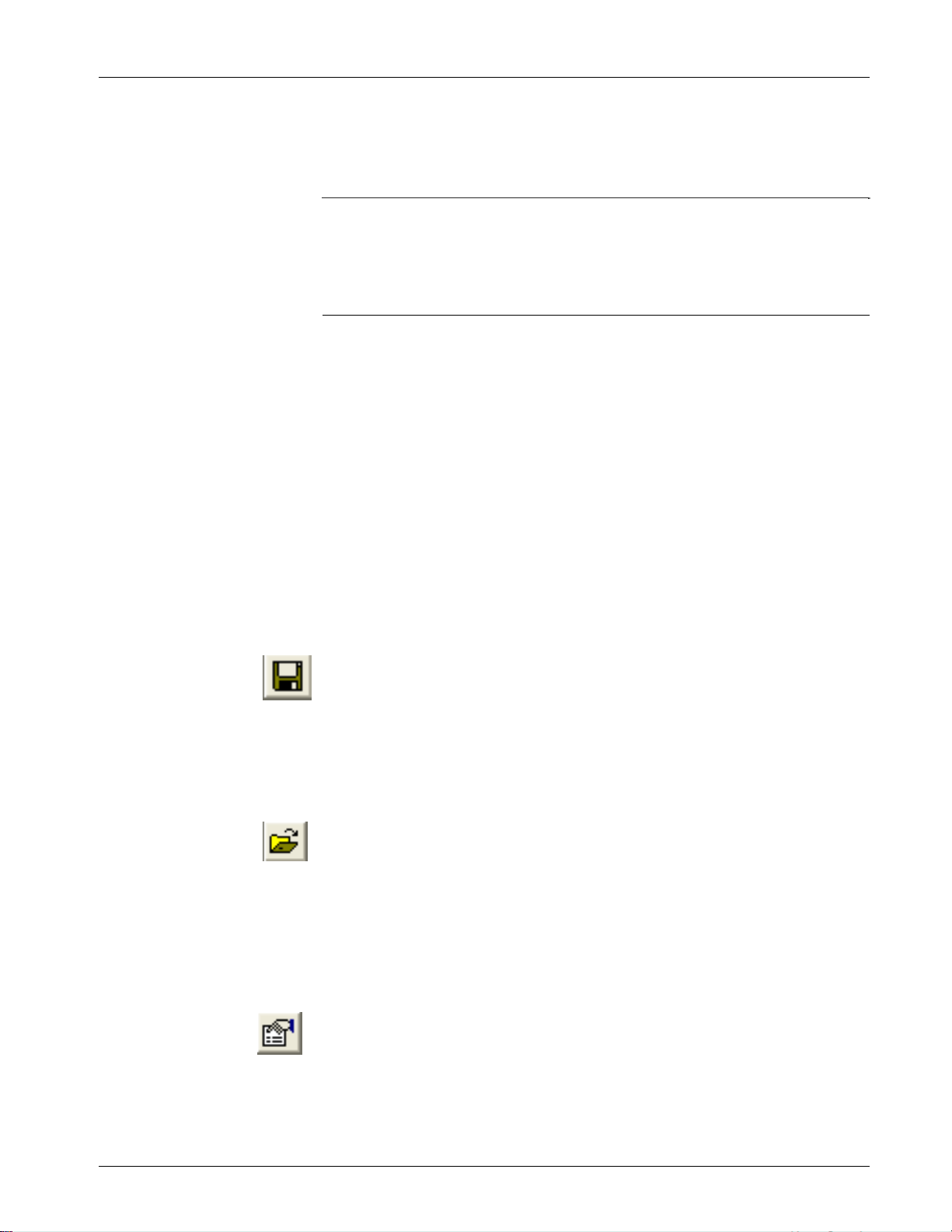

3.6.2 Saving Search Criteria

Once the Signal Window opens you can save its associated signal search

criteria in a file by clicking on the icon, shown at left, or you can click

File>Save As. Enter a name for the search criteria file, with an extension

of .SCH. You can save subsequent modifications to the SCH file if you

click on the same icon, or click File>Save.

3.6.3 Retrieving Search Criteria

DataView lists the names of the last four files viewed (of all file types)

in the File pull down menu. If the search criteria (.SCH) file you want to

view appears in the menu, you can open the file by simply clicking on

the file name. To call up any other search criteria (SCH) file, click the

icon, shown at left, or click File>Open. Select the desired SCH file from

the windows Open File dialog box, and click the Open button.

3.6.4 Altering Search Criteria

Once the Signal Window opens, you can change the search criteria by

Issued Sep-2012 DataView 3-9

clicking on the Properties tool bar icon, shown at left, or by clicking on

Format>Properties. The Signal Search Properties dialog box re-opens

to allow you to define new search criteria.

Page 24

ControlWave Utilities Manual (D5142)

ON/O

t)

tes to controller

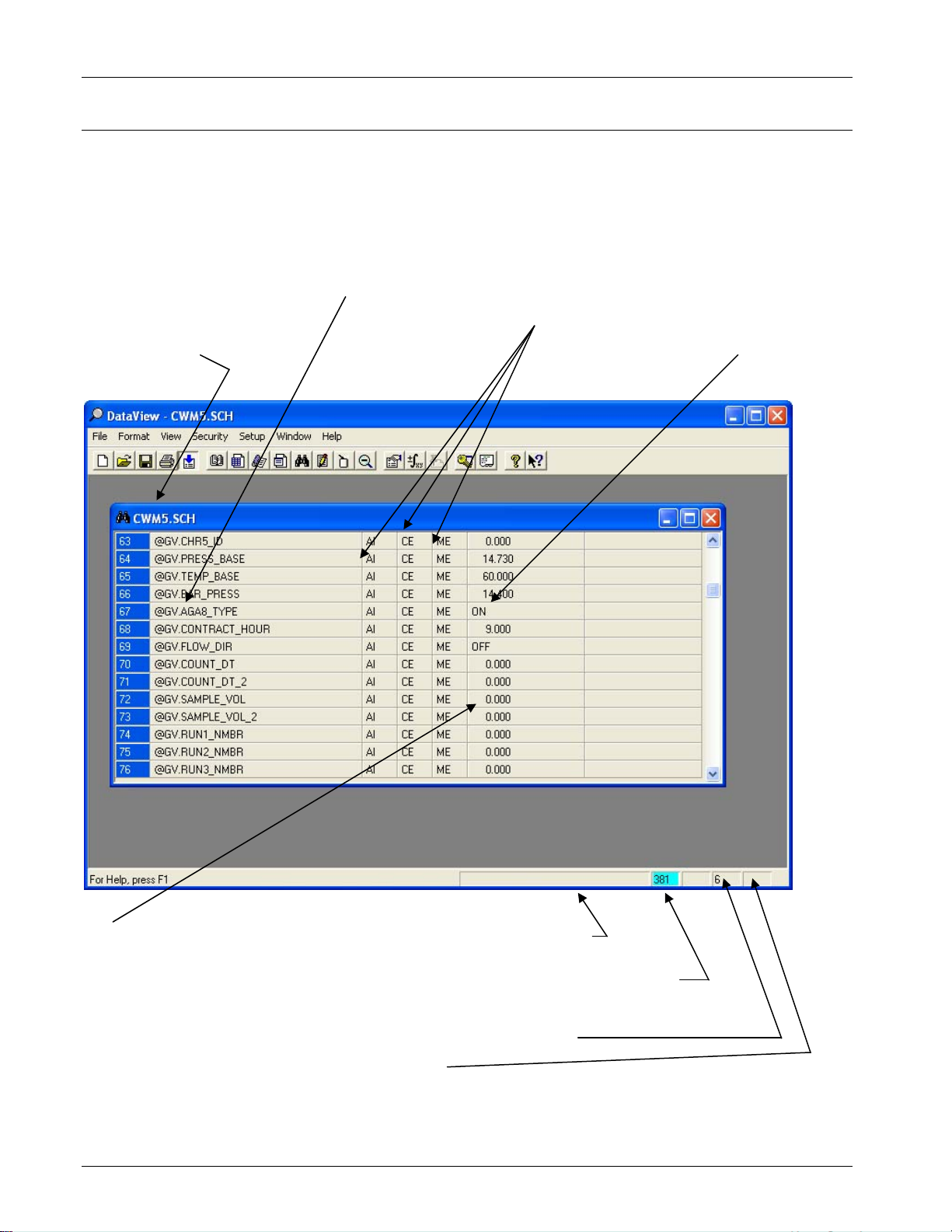

3.7 Viewing Entries in a Signal Window

DataView displays Remote Signal Lists, DataView Lists, and Signal

Searches in a signal window. You can view detailed signal information,

change signal values, or alter the inhibit/enable bits by clicking on those

fields for a particular entry in the signal window. Use the scroll bar to

view any entries not currently visible on the screen. The figure below

summarizes the elements in a signal window.

Signal Name (click

File name for the

signal search

on to get more

detailed info)

Inhibit/Enable status

bits (click on them

to change status)

Units Text (or

FF tex

Signal Value

(click on the

value to

change it)

(If value appears in red, signal

is “in-alarm;” if “!” appears,

alarm has not been

acknowledged by the central

computer (HMI/SCADA

package)

Number of pending

wri

Error/Status

Message area

Number of entries collected

Current

operator

security level

Figure 3- 4. Signal Window

3-10 DataView Issued Sep-2012

Page 25

ControlWave Utilities Manual (D5142)

Notes:

For information on viewing detailed signal information, see Viewing

Data for a Single Signal, later in this section.

For Remote Signal Lists, and Signal Searches, the number of entries

which have been collected are displayed at the bottom of the

window in the status bar. If this value appears with a cyan (light

blue) background, then there are additional entries in the controller

which have not yet been collected

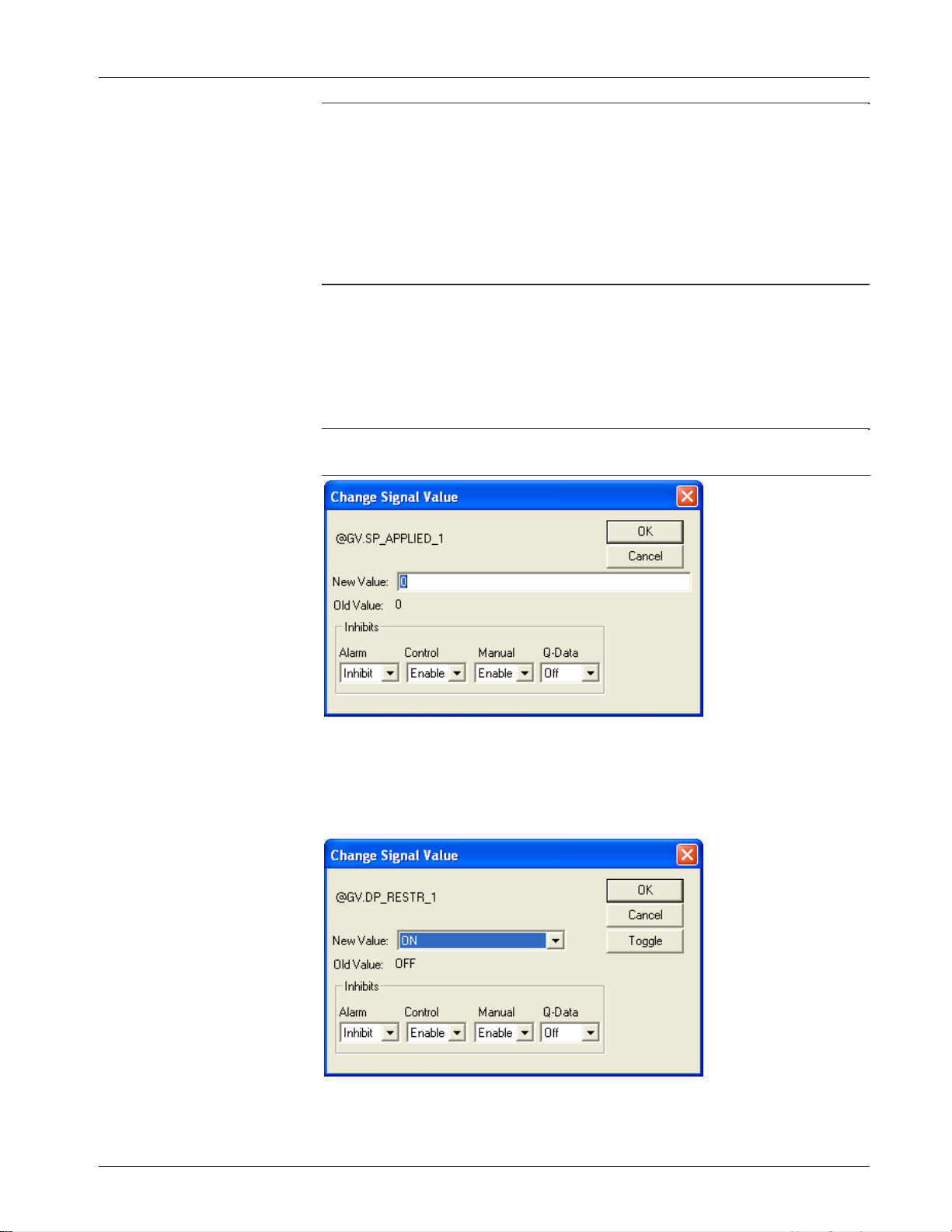

3.7.1 Changing Signal Values in the Signal Window

Click on the signal value you want to change. The Change Signal Value

dialog box opens to allow you to change the signal value, as well as the

manual, control, and alarm inhibit/enable bits, and the questionable data

bit.

Note To change a signal value, you must manually enable the signal (if

it isn’t already).

Figure 3-5. Change Signal Value – Analog

If the signal you want to change is a logical signal, you can either use

the list box to select the new state, or you can simply click on the

Toggle push button.

Figure 3-6. Change Signal Value – Logical

Issued Sep-2012 DataView 3-11

Page 26

ControlWave Utilities Manual (D5142)

Note: The questionable data bit for logical signals can only be changed

through this dialog box; there is no automatic questionable

checking from the discrete I/O boards.

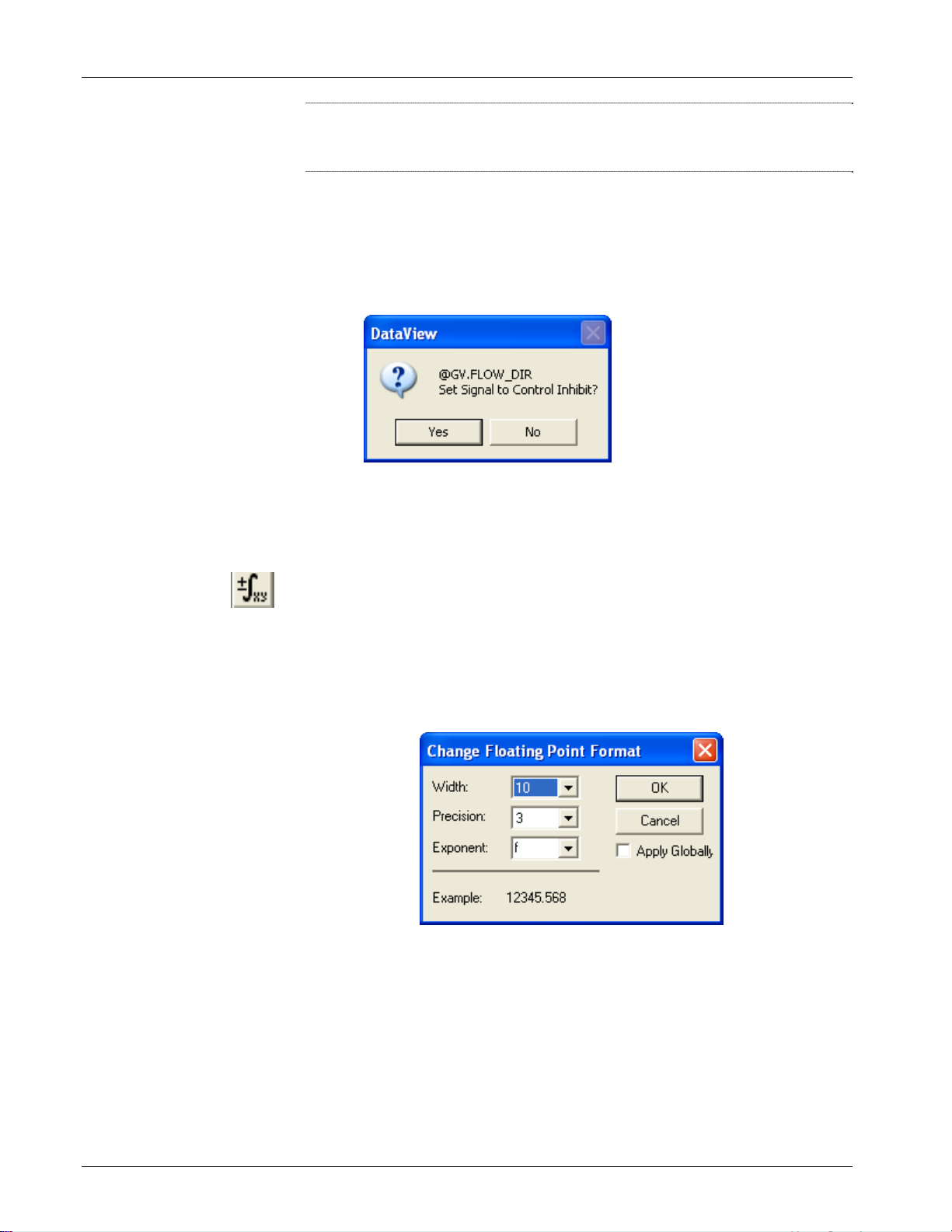

3.7.2 Changing Signal Inhibit/Enable Bits in the Signal Window

Click the inhibit/enable bit you would like to change. DataView

prompts you to confirm that you want to change the inhibit/enable

status. You can also change the inhibit/enable status using the Change

Signal Value dialog box, above.

Figure 3-7. Change Inhibit/Enable Status

3.7.3 Changing the Floating Point Format of Data in the Signal

Window

The Signal Window (and certain other types of windows) displays

analog values according to a default floating point format. To alter this

default format, click on the Change Floating Point Format tool bar icon

(shown at left) or click Format > Floating Point. The Change Floating

Point Format dialog box opens. Use the Width list box to specify the

total number of characters in the field (including the decimal point) used

to display a floating point number.

Figure 3-8. Change Floating Point Format dialog box

Use the Precision list box to choose the number of places to the right of

the decimal point which the window should display.

Use the Exponent list box to choose floating point format f, exponential

notation e or choose g to have DataView choose the “best fit” format.

If you want the floating point format defined here to apply throughout

the DataView windows, check the Apply Globally check box.

3-12 DataView Issued Sep-2012

Page 27

ControlWave Utilities Manual (D5142)

3.8 Displaying a Remote Signal List

The Signal Window (and certain other types of windows) displays

analog values according to a default floating point format. To alter this

default format, click on the Change Floating Point Format tool bar icon

(shown at left) or click Format Floating Point. The Change Floating

Point Format dialog box opens. Use the Width list box to specify the

total number of characters in the field (including the decimal point) used

to display a floating point number.

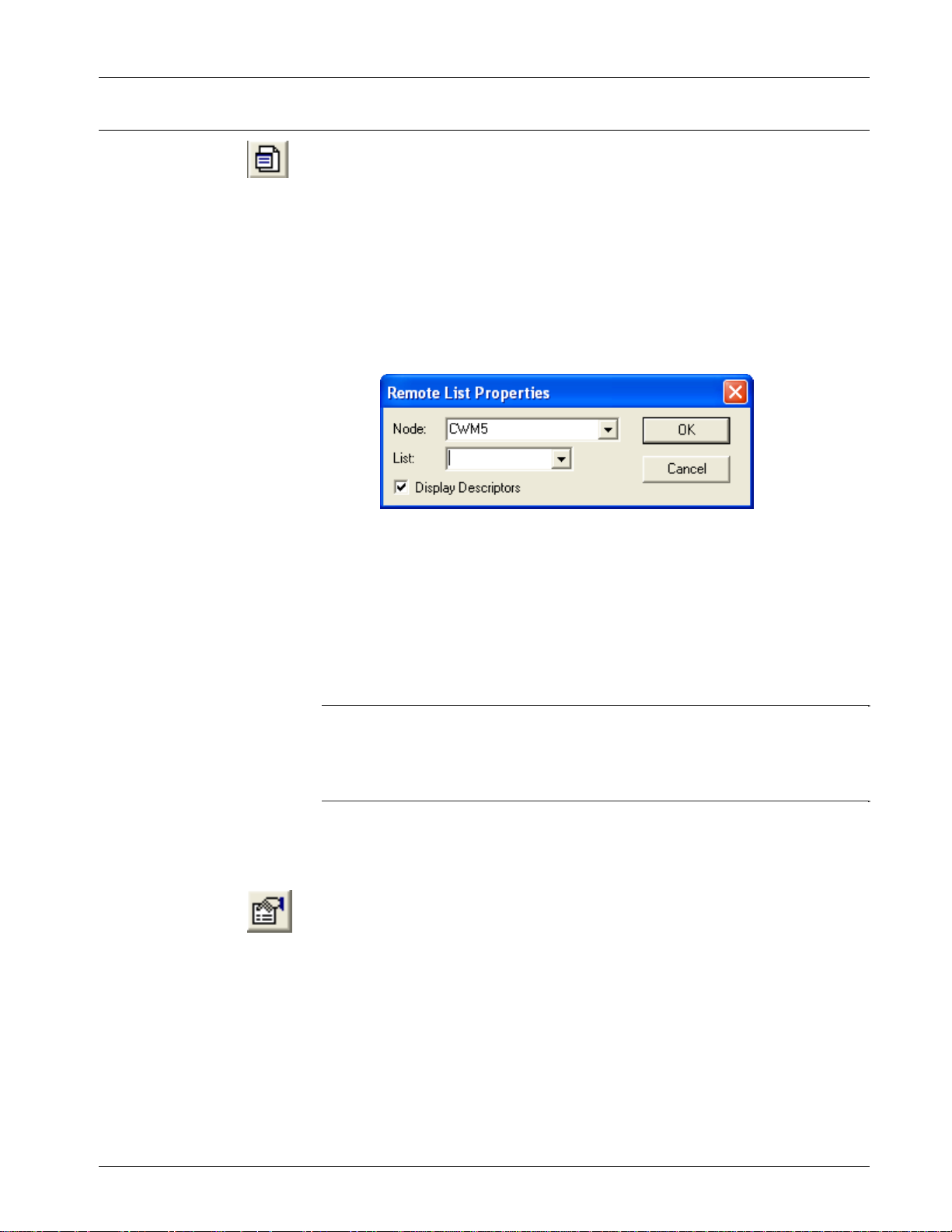

To view a signal list in the remote process controller, click the Remote

List tool bar icon, shown at left or click File>New. Choose Remote

List from the New list box.

Figure 3-9. Remote List Properties dialog box

You can use the List list box to see which signal lists exist in the

controller, and then select a list from it, or you can just type the list

number in the box; then click OK. A signal window opens containing

the signal list entries.

If you check Display Descriptors, signal descriptive text, if it exists,

appears in the signal window instead of the signal name.

Notes:

DataView cannot display more than 10,000 signals from a particular

list.

DataView cannot display lists numbered higher than 255.

3.8.1 Selecting a Different Remote Signal List

Once the Signal Window opens, you can recall the Remote List

Properties dialog box to call up a different list by clicking the Properties

icon, shown at left, or by clicking Format>Properties.

3.8.2 Changing Remote List Signal Values, Altering Inhibit/Enable

Bits

See Section 3.7 for information on using the entries in this window to

change signal values, or to alter inhibit/enable bits. See Viewing Data

for a Single Signal (later in this manual) for information on viewing

more detailed signal information.

Issued Sep-2012 DataView 3-13

Page 28

ControlWave Utilities Manual (D5142)

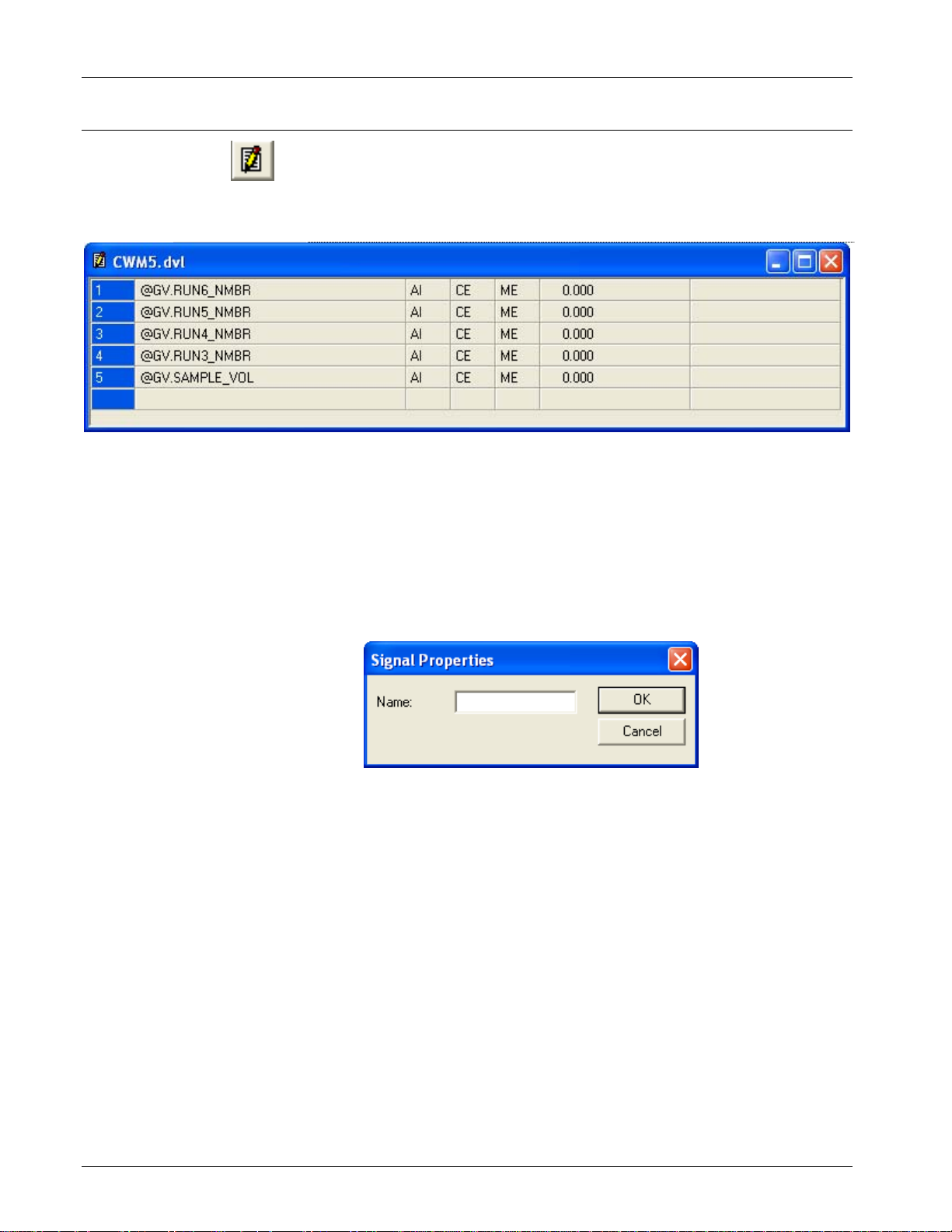

3.9 Creating and Using DataView Lists

A DataView List is a file, stored on the PC, that contains the names of

signals, from a single controller, from which you would like to collect

data. You can open the DataView list file in DataView to collect and

display data for the designated signals.

Figure 3-10. DataView List

3.9.1 Creating a DataView List

Click the DView List icon, shown above, or click File>New and then

click DView List in the New list box; in either case, an empty

DataView List signal window opens.

From the menu bar, click Edit>Insert, and the Signal Properties dialog

box opens.

Figure 3-11. Remote List Properties dialog box

Enter a signal name in the Name field, and click OK; the dialog box

inserts the signal on the currently highlighted line, and pushes down any

entries that begin on that line. Repeat this step for each additional signal

you want to include in the DataView List. Note: Be sure you include the

proper punctuation for the signal/variable.

If you make a mistake on a particular line, click on the line you want to

change, then click Edit>Modify; the Signal Properties dialog box reopens, allowing you to edit the signal name.

If you want to delete a particular line, click the line you want to delete,

and then click Edit>Delete. The system prompts you to confirm that

you want to delete the line from the DataView List; click Yes and the

system removes that signal from the DataView List.

3-14 DataView Issued Sep-2012

Page 29

ControlWave Utilities Manual (D5142)

3.9.2 Collecting Live Data into the DataView List

The system suspends collection of DataView List data while you create

or modify the DataView List, or if certain error conditions exist. When

you finish creating/editing the list, you can activate collection if you

click View>Refresh.

3.9.3 Saving the DataView List

If this is a new DataView List, you must save it by clicking on the icon,

shown at left, or by clicking File>Save As. Assign a name to the

DataView List file using the Windows Save As dialog box. All

DataView Lists have a file extension of (.DVL).

To save modifications to a previously saved DataView List, click on

Save toolbar icon, shown above, or click File>Save.

3.9.4 Viewing a Previously Saved DataView List

The File pull down menu shows the names of the last four files viewed

(of all file types). If the DataView List (.DVL) file you want to view

appears in the menu, you can open the file simply by clicking on the file

name. To view any other DataView List (.DVL file), click the Open File

tool bar icon, shown above, or click File>Open. The Windows Open

File dialog box opens. Select the DataView List file, and click the Open

button. The selected DataView List displays on the screen. Assuming

TechView is already running, you can also open a DataView list by

double-clicking on the DVL filename in Windows.

Note: DataView cannot display more than 100 signals from a

DataView list.

See Section 3.7 for information on using the entries in this window to

change signal values, or to alter inhibit/enable bits. See Viewing Data

for a Single Signal (later in this manual) for information on viewing

more detailed signal information.

3.10 Creating and Using Recipes

A recipe is a list of signals, together with signal values, which DataView

stores in a file, on the PC. You call up the recipe file, within DataView,

and you can send the signal values to the remote process controller, to

update the current values of those signals in the controller. This provides

a quick way to change the values of several signals in a running load at

the same time.

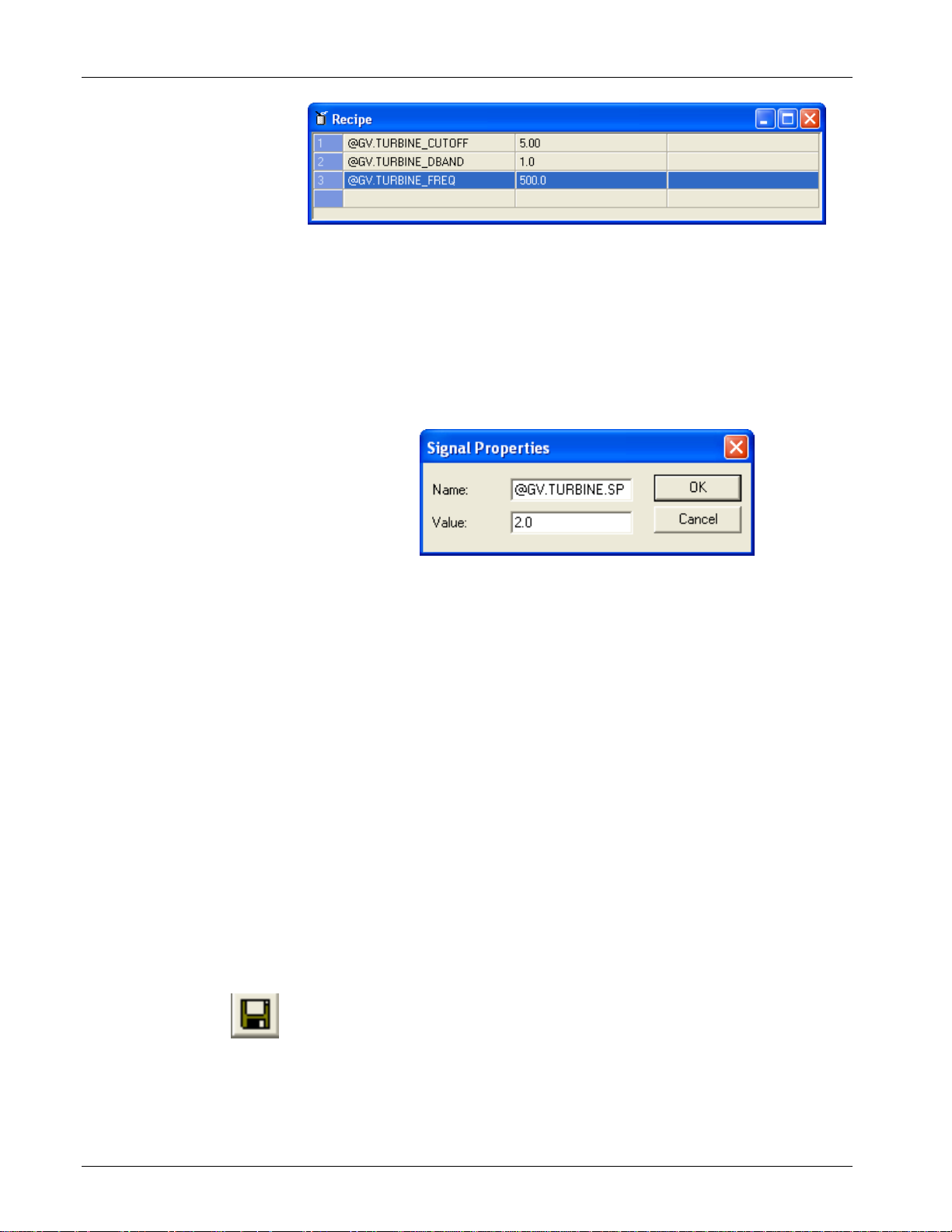

3.10.1 Creating a Recipe

Click the Recipe icon, shown above, or click File>New, and select

Recipe from the New list box. An empty recipe window opens.

Issued Sep-2012 DataView 3-15

Page 30

ControlWave Utilities Manual (D5142)

Figure 3-12. Recipe Window

Click Edit>Insert and the Signal Properties dialog box opens. Enter a

signal name in the Name field, and a value for the signal in the Value

field, then click OK. DataView inserts the signal on the currently

highlighted line, and pushes down any entries that begin on that line.

Repeat this step for each additional signal you want to include in the

Recipe.

Figure 3-13. Adding Signals to the Recipe

\\

Although DataView performs no verification with the remote load when

you create the recipe, you should remember that if you enter a logical

signal in the recipe, only two values are valid: 1.0 for ON, and 0.0 for

OFF.

If you make a mistake on a particular line, click on the line you want to

change, then click Edit>Modify; the Signal Properties dialog box

opens, allowing you to edit the signal name and/or value.

If you want to delete a particular line, click on the line you want to

delete, then click Edit>Delete. DataView prompts you to confirm that

you want to delete the line from the Recipe; click Yes and DataView

removes that signal from the Recipe.

Recipes can include up to 10,000 lines.

3.10.2 Saving the Recipe

When the Recipe is complete, you must save it by clicking on the icon,

shown at left, or click File>Save As. Assign a name to the Recipe file

using the Windows Save As dialog box. All Recipes have a file

extension of (.RCP).

To save modifications to a previously saved Recipe, click the Save

toolbar icon, shown above, or click File>Save.

3-16 DataView Issued Sep-2012

Page 31

ControlWave Utilities Manual (D5142)

3.10.3 To View/Modify an Existing Recipe File

The File pull down menu displays the names of the last four files viewed

(of all file types). If the Recipe (.RCP) file you want to view appears in

the menu, you can open the file by simply clicking on the file name. To

view any other Recipe (.RCP) file, click the Open File tool bar icon,

shown above, or click File>Open. Select the recipe file from the Open

File dialog box, and the recipe displays on the screen in a recipe

window. Assuming OpenBSI is already running, you can also open a

Recipe if you double-click on the RCP filename in Windows.

You can make modifications to signal names in the recipe by clicking

on the line you want to change, and choose Edit>Modify. You can then

change the signal name and/or value using the Signal Properties dialog

box. You can also change recipe values by overwriting the values with

the current values in the controller (see To Read the Current Signal

Values from the Controller into the Recipe Window).

3.10.4 To Update Signals in the Controller with the Recipe Values

Bring up the recipe to view (described above under To View/Modify an

Existing Recipe File) and click Recipe>Write to RTU. The Select New

Node dialog box opens. Select the node which you want to receive the

new values and sign-on to that node; DataView writes the values to the

corresponding signals in the node. Note: In order to update the signals,

you must manually enable them.

3.10.5 To Read the Current Signal Values From the Controller Into

the Recipe Window

Bring up the recipe to view (described above under To View/Modify an

Existing Recipe File). Next, click on Recipe>Read from RTU. The

Select New Node dialog box opens. Select the node which will provide

the new values and sign-on to that node. DataView copies the values in

the node, for the signals in the recipe, into the window.

3.10.6 To Cancel Unsaved Modifications to the Recipe Values

If you made changes to recipe values in the recipe window, but have not

saved them, and you want to cancel the changes, and return to the

previously saved recipe values, click Recipe>Reload. DataView

restores the previously saved recipe values into the recipe window.

3.10.7 Changing the Floating Point Format of Data in the Recipe

Window

You can change the floating point format in which DataView presents

signal values. See the sub-section on floating point formats in the

Viewing Entries in the Signal Window section.

Issued Sep-2012 DataView 3-17

Page 32

ControlWave Utilities Manual (D5142)

eadbands

y

3.11 Viewing Data for a Single Signal

You can view detailed signal information by clicking on a signal name

in any Signal Window you open using DataView's Signal Search,

DataView List, or Remote List features. Alternatively you may also

view detailed information on a single signal by clicking on the Signal

Detail toolbar icon (shown above) or you can click File>New, and then

select Signal Detail from the list box. The Signal Detail Properties

dialog box opens.

Field Tools automatically completes the Node list box for you. Enter the

complete signal name i.e. base.extension.attribute and click OK.

(RED indicates

currently in

alarm state)

Signal Value

Read Priority

Inhibit/Enable Bits

Alarm Limits

Alarm

D

Figure 3-14. Signal Detail Properties dialog box

Signal / Variable Name

Node Name

Units Text

Descriptive Text

MSD Address

(Emerson use only)

Write Priorit

Alarm Acknowledge

Alarm Priority:

Critical

Non-Critical

Operator Guide

Event

Show / Hide

alarm limits

and deadbands

Current Alarm State: On = In Alarm

Off = Not in Alarm

Alarm Report State:

Blank = no report

Mo = momentary alarm

Mult = multiple alarms

Single = one alarm

Ack Status:

Acked = Acknowledged

NotAck= Not acknowledged

Figure 3-15. Signal Detail Window

3-18 DataView Issued Sep-2012

Page 33

ControlWave Utilities Manual (D5142)

A Signal Detail window contains the signal name, base name

descriptive text, inhibit/enable bit values, signal value, units text or

ON/OFF text, read priority, write priority, and other data. The figure

above shows the window for an analog alarm signal. If you want, you

can change the signal's value, or alter the inhibit/enable bits by clicking

on those fields, and entering the new data via a dialog box.

3.11.1 Acknowledging an Alarm

If the signal you view is an alarm signal in an alarm state, and this alarm

has not been acknowledged (as indicated by an exclamation point “!”

next to the signal's value) you can acknowledge the alarm if you click

on the Ack Alarm button. A message box opens indicating the status of

the acknowledgment operation.

3.12 Viewing Data Arrays

To view a Data Array in the controller, click on the Array tool bar icon

(shown above) or click File>New, then select Array.

The Array Properties dialog box opens. Choose the node which contains

the array using the Node list box. Specify the Array Type as either

analog or logical.

Figure 3-16. Array Properties dialog box

Use the Array Num list box to determine which arrays exist in the

controller. Select the array from the list box, or enter the array number

in the box. If the array is large, and you want to begin viewing from

some row other than 1, enter that row in the Starting Row field.

Click OK; and DataView displays the array.

Note: If you cannot see a list of arrays using the Array Num list box, it

means DataView does not have access to your control strategy

file.

Issued Sep-2012 DataView 3-19

Page 34

ControlWave Utilities Manual (D5142)

If this is a large array, a scroll bar appears to let you view portions

which do not currently fit in the window.

The lower right corner of the window displays the total number of array

rows, total number of array columns, and the current operator security

level.

Number of rows

Error / status messages

Current operator security level

Number of columns

Figure 3-17. Array Window

3.12.1 Changing Values in the Data Array

If this is a read-write array, you can alter data array values if you click

on the array cell you want to change, and enter a new value using the

Change Value dialog box.

3-20 DataView Issued Sep-2012

Page 35

ControlWave Utilities Manual (D5142)

Figure 3-18. Change Value dialog box

3.12.2 Toggling the Time/Value Format

Depending upon how you configure the data array, it may include Julian

date/time stamps in the first column. To convert these time/date stamps

to the numerical total used by the system to store the date and time, and

vice versa, click Format> View First Column as Date/Time.

3.12.3 Keeping Column 1 Visible While Scrolling Through the Array

As you scroll through columns of the data array, the first column (which

may contain date/time stamps) may disappear from the window as

higher numbered columns come into the window. To prevent this, click

the icon, shown above, or click Format>Freeze First Column.

3.12.4 Calling Up a Different Data Array

Once a data array opens in the window, you can replace it with a

different data array by clicking on the Properties tool bar icon, or by

clicking Format>Properties. Either of these actions will re-open the

Array Properties dialog box, from which you can select a different array.

3.12.5 Changing the Floating Point Format

Like analog data presented in a signal window, you can alter the floating

point format for data in array windows. (See Changing the Floating

Point Format of Data in the Signal Window in the Viewing Entries in a

Signal Window section.)

3.13 Viewing Audit Trail Records

To view Audit Trail buffer entries from the Audit function block, click

the Audit tool bar icon, shown at left, or click File>New, then select

Audit from the New list box.

The Audit Collection dialog box opens.

Issued Sep-2012 DataView 3-21

Page 36

ControlWave Utilities Manual (D5142)

Figure 3-19. Audit Collection dialog box

Choose the controller

containing the audit

records you want to

view.

Choose the type of

audit information you

want to collect.

Choose how much audit

information you want to

collect.

Choose the order in

which audit records are

displayed.

First, choose the controller (RTU) from which you want to collect audit

records using the Node list box.

Then choose whether you want to retrieve alarms, events, or both.

If you choose Collect All Available Records, DataView collects all

audit records in the RTU.

Use the Start Date to specify the first date from which data will be

displayed. Depending on the Direction you choose, all following lines

of data will either be from before that date, or since that date.

If you choose Specified Period you can request audit records only from

a set period of time. Choices are records from Today, This Week or This

Month.

The Direction specifies the order in which the window displays the audit

records. From Oldest to Newest displays the earliest records first. From

Newest to Oldest displays the most recent audit records first.

Click OK to begin the collection. DataView displays the Audit Trail

buffer entries in a window on the screen. Use the scroll bar to view any

portions not currently visible.

Notes:

The total number of entries which have been collected appears in the

status bar at the bottom of the window. If this number appears with a

cyan (light blue) background, then additional entries have not yet

been collected from the controller.

DataView cannot show more than 1,000 Audit Trail buffer entries.

Any audit entries already collected using the OpenBSI Harvester, or

the Historical Log Storage control, are inaccessible to DataView.

3-22 DataView Issued Sep-2012

Page 37

ControlWave Utilities Manual (D5142)

Timestamp Text describing alarm / event

Local

Sequence

Number

Global Sequence Number

Figure 3-20. Viewing Audit Records

To re-open the Select New Node dialog box to choose a different node,

click the Properties tool bar icon, shown above, or click

Format>Properties.

Number of Entries

Current Operator Security Level

Issued Sep-2012 DataView 3-23

Page 38

ControlWave Utilities Manual (D5142)

3.14 Viewing Archive Data Files

If your controller has archive data, you can view it, in DataView, if you

click on the Archive tool bar icon, shown at left. Alternatively, you can

click File>New, and then select Archive from the list box. Either of

these methods opens up the Archive Properties dialog box.

Figure 3-21. Archive Properties dialog box

Select the RTU name from the Node list box, and enter the number of

the archive file you would like to view in the File Number field. If you

would like the oldest archive file entries to appear first, check the Start

from oldest record box.

After you choose the Node and File Number, click OK to display the

selected archive file.

The archive file opens in a window. Use the scroll bar to view portions

of the file not currently visible.

Figure 3-22. Archive File

3-24 DataView Issued Sep-2012

Page 39

ControlWave Utilities Manual (D5142)

Notes:

DataView cannot display more than 1000 archive records from a

particular archive file.

The total number of entries which have been collected appears in

the status bar at the bottom of the window. If this number appears

with a cyan (light blue) background, then additional entries have not

yet been collected from the controller.

DataView can display string-based archives.

3.14.1 Keeping Column 1 Visible While Scrolling Through the

Archive File

As you scroll through the archive file window, the first column (which

may contain date/time stamps) may disappear from the window as you

bring higher numbered columns into the window. To prevent this, click

the icon, shown at left, or click Format>Freeze First Column.

3.14.2 Calling Up a Different Archive File

Once you open an archive file in the window, you can replace it with a

different archive file if you click the Properties tool bar icon, or click

Format>Properties. Either of these actions re-opens the Archive

Properties dialog box, from which you can select a different archive file.

3.14.3 Changing the Floating Point Format

Like analog data presented in a signal window, you can alter the floating

point format for data in the archive window. (See Changing the

Floating Point Format of Data in the Signal Window in the Viewing

Entries in a Signal Window section.)

3.14.4 Restrictions on Archive File Size

When you use DataView to collect Archive files over a serial

connection, you can only display archive records that are 220 bytes or

less. The system uses a total of four bytes of the 220 to display the

timestamp, plus two bytes to store the local sequence number, and two

bytes to store the global sequence number. This leaves 212 bytes for

other columns of data. This could include up to 53 columns of floating

point data.

Table 3-3. Archive File Sizing

Type of Data Number of Bytes Required

Timestamp 4

Local Sequence Number 2

Global Sequence Number 2

Issued Sep-2012 DataView 3-25

Page 40

ControlWave Utilities Manual (D5142)

Analog Floating Point value 4

Logical / BOOL value 1

Type of Data Number of Bytes Required

3-26 DataView Issued Sep-2012

Page 41

ControlWave Utilities Manual (D5142)

Chapter 4 – Using the Downloader

When you finish creating your control strategy file using ControlWave

Designer you have to transfer it to the actual controller; this process is

called downloading.

In This Chapter

4.1 Downloading to a ControlWave-series Node: .................................. 4-1

4.1.1 Before You Begin ................................................................. 4-1

4.1.2 Starting the ControlWave Downloader ................................. 4-4

4.1.3 Using the ControlWave Downloader .................................... 4-4

The ControlWave Downloader transfers an IEC 61131 ControlWave

project from the Field Tools laptop to a running ControlWave series

RTU.

Never attempt to download an untested program into an RTU currently

Warning

running an industrial process or plant. Prior to downloading, isolate the

RTU from the process and disconnect I/O. Failure to take such

precautions could result in injury to persons or damage to property.

4.1 Downloading to a ControlWave-series Node:

Note: You can also download a project to a ControlWave directly from

within ControlWave Designer. See the ControlWave Designer

documentation for details.

4.1.1 Before You Begin

There are certain things you must do before you can download to a

ControlWave-series controller.

You must save your project as a ControlWave project *.MWT file.

You must generate a boot project file during compilation in

ControlWave Designer. To do this, you must check the Generate

bootproject during compile box for your resource.

Issued Sep-2012 Downloader 4-1

Page 42

ControlWave Utilities Manual (D5142)

Make sure this box is checked in

ControlWave Designer when you

compile/build your project.

Figure 4-1. Generating a Bootproject During Compilation

You must generate a zipped project file (*.ZWT) in ControlWave

Designer. One way you can do this is to manually save your

ControlWave project as a zip file:

First click the “Save Project As/Zip

Project As” option in ControlWave

Designer.

Next, make sure you choose “Zipped

Project Files (*.zwt) in the Save as

type list box, or else the project won’t

be zipped.

Finally, click the “Zip” button.

Figure 4-2. Zipping Your ControlWave Project

4-2 Downloader Issued Sep-2012

Page 43

ControlWave Utilities Manual (D5142)

Use the “…” button to specify the directory which will hold

your download files. When you initiate a transfer, the utility

creates a sub-directory of the download directory to hold

the boot and zip files for this particular project.

If you didn’t

generate a ZWT file

yet, check this box

and the utility does

it for you.

Click here to start the transfer.

Figure 4-3. Transferring the Project File to the Download Directory

You must transfer the bootfile and zip file for this project to a sub-

directory of whichever directory you want to use for downloads.

You can accomplish this if you click Build > Transfer Download

Files in ControlWave Designer. In this utility, you must specify the

download directory in the Download dir field. (See Figure 4-3.)

If you check Zip Project and Transfer Zip File (default), the

system zips the current project automatically, in preparation for the

transfer. If you select the Compress user libraries into download

project option, the system zips the user libraries and includes them

in the zip project.

Note: Zip Project and Transfer Zip overwrites any pre-existing zip

file for this project. To prevent this, you can disable the option,

however, if you do, you must have a previously created zip

available for transfer.

When you finish making selections, click Transfer and the file

transfer begins.

If your ControlWave-series node includes a key operated RUN /

REMOTE/ LOCAL switch, you must turn the switch to either the

REMOTE or LOCAL position, depending upon how the PC

connects to the ControlWave. Downloading CANNOT occur with

the switch in the RUN position.

Issued Sep-2012 Downloader 4-3

Page 44

ControlWave Utilities Manual (D5142)

4.1.2 Starting the ControlWave Downloader

Note: Before starting the Downloader, you must establish

communications with the controller using Field Tools, then

launch TechView.

Right-click on the icon for the controller name in TechView, and choose

Downloader from the pop-up menu.

4.1.3 Using the ControlWave Downloader

When the ControlWave Downloader dialog box opens, complete the

fields as described, below:

Field Tools uses the RTU

credentials setting to supply the

proper username and password

for this controller.

Click here to start the download.

RTU node name

(populated

automatically by

Field Tools)

Check this to allow

the ZWT file to

download.

Shows the

progress of the

download.

When downloading a project, click “Warm Boot” to perform a

warm download (project is started from the beginning using

values saved as RETAIN – if project hasn’t changed to a degree

that those values don’t apply). If you de-select “Warm Boot” a

cold download occurs (project is started from the beginning

using initial values.

Use this browse

button to choose

the sub-directory

containing your

bootfile.pro and

.zwt file.

Use this browse button to

choose the sub-directory

containing user files. You