Page 1

s

Instruction Manual

Doc Number D5140

Part Number D301719X012

May 2012

ControlWave®

MRMS-IC Configuration Manual

Remote Automa ti on Solution

www.EmersonProcess.com/Remote

Page 2

This page is intentionally left blank

Page 3

ControlWave MRMS-IC Configuration Manual (D5140)

Contents

Chapter 1 – Getting Started 1-1

1.1 What is MRMS-IC? ................................................................................................................... 1-1

1.2 Before You Begin ...................................................................................................................... 1-1

1.3 Installing MRMS-IC Software .................................................................................................... 1-2

1.4 Starting MRMS-IC Software ...................................................................................................... 1-6

1.4.1 MRMS_IC IP Startup ..................................................................................................... 1-6

1.4.2 MRMS_IC Serial Startup ............................................................................................... 1-7

1.4.3 Logging Onto the ControlWave Micro ........................................................................... 1-7

1.5 Accessing Pages of the MRMS_IC Application ........................................................................ 1-8

1.6 Entering Data in Fields of the MRMS_IC Application ............................................................... 1-9

Chapter 2 – Configuring Inputs and Outputs (I/O Tab) 2-1

2.1 I/O Tab ...................................................................................................................................... 2-1

2.2 I/O Usage .................................................................................................................................. 2-2

2.2.1 Discrete Inputs (DI) ....................................................................................................... 2-5

2.2.2 Discrete Outputs (DO) ................................................................................................... 2-5

2.2.3 Analog Inputs (AI) ......................................................................................................... 2-6

2.2.4 Analog Outputs (AO) ..................................................................................................... 2-7

2.2.5 High Speed Counters (HSC) ......................................................................................... 2-8

2.2.6 Ultrasonic Flow Meters (UFM) ...................................................................................... 2-9

2.2.7 Multi-variable Transmitters (Transducers) .................................................................. 2-10

2.3 Local DLM ............................................................................................................................... 2-12

2.4 Customer Modbus Slave ......................................................................................................... 2-14

2.4.1 Signal List Grid ............................................................................................................ 2-17

2.4.2 Floating Point Format .................................................................................................. 2-19

2.5 Generic Modbus Master .......................................................................................................... 2-20

2.6 Load/Save Configuration ......................................................................................................... 2-25

2.6.1 Performing I/O Array Operations. ............................................................................... 2-26

2.6.2 Creating a Recipe ....................................................................................................... 2-27

2.6.3 Saving the Recipe ....................................................................................................... 2-28

2.6.4 Recalling a Saved Recipe, and Sending Its Values to the Controller ......................... 2-29

2.7 Time Set/Daylight Saving Time ............................................................................................... 2-29

Chapter 3 – Configuring Stations and Runs (Measurement Tab) 3-1

3.1 Measurement Tab ..................................................................................................................... 3-2

3.2 Status/Configuration .................................................................................................................. 3-3

3.2.1 Site Configuration Data Tab (Site Configuration) ......................................................... 3-4

3.2.2 MVT Common Settings Tab (Site Configuration).......................................................... 3-7

3.2.3 Station Summaries Tab (Site Configuration) ................................................................ 3-8

3.2.4 Station Configuration Tab (Station Configuration) ...................................................... 3-10

3.2.5 Station Data Tab (Station Configuration) .................................................................... 3-15

3.2.6 Run Configuration Tab ................................................................................................ 3-16

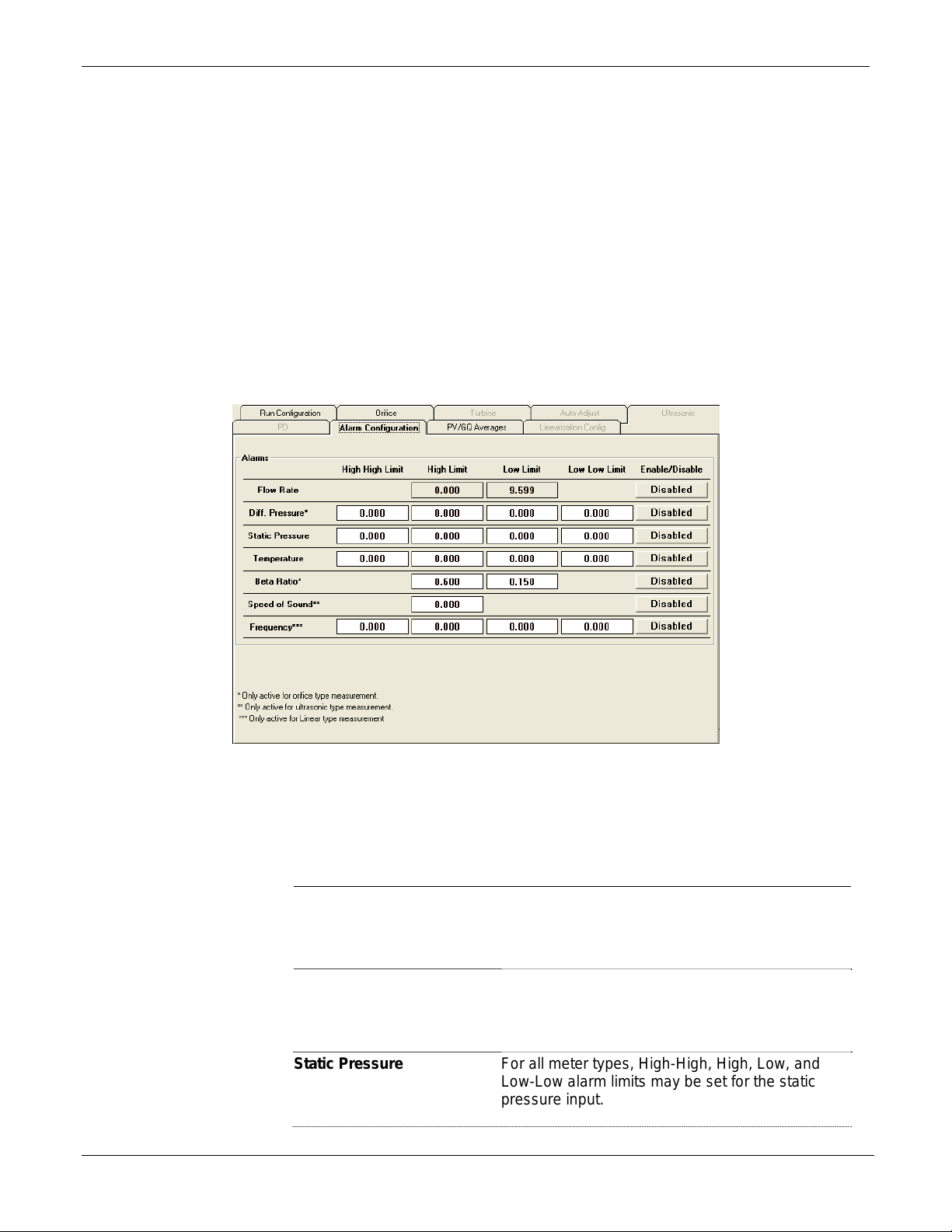

3.2.7 Alarm Configuration Tab (Run Configuration) ............................................................. 3-21

3.2.8 Linearization Config Tab (Run Configuration) ............................................................. 3-23

3.2.9 PV/GQ Averages Tab (Run Configuration) ................................................................. 3-24

3.2.10 Orifice Tab (Run Configuration) .................................................................................. 3-25

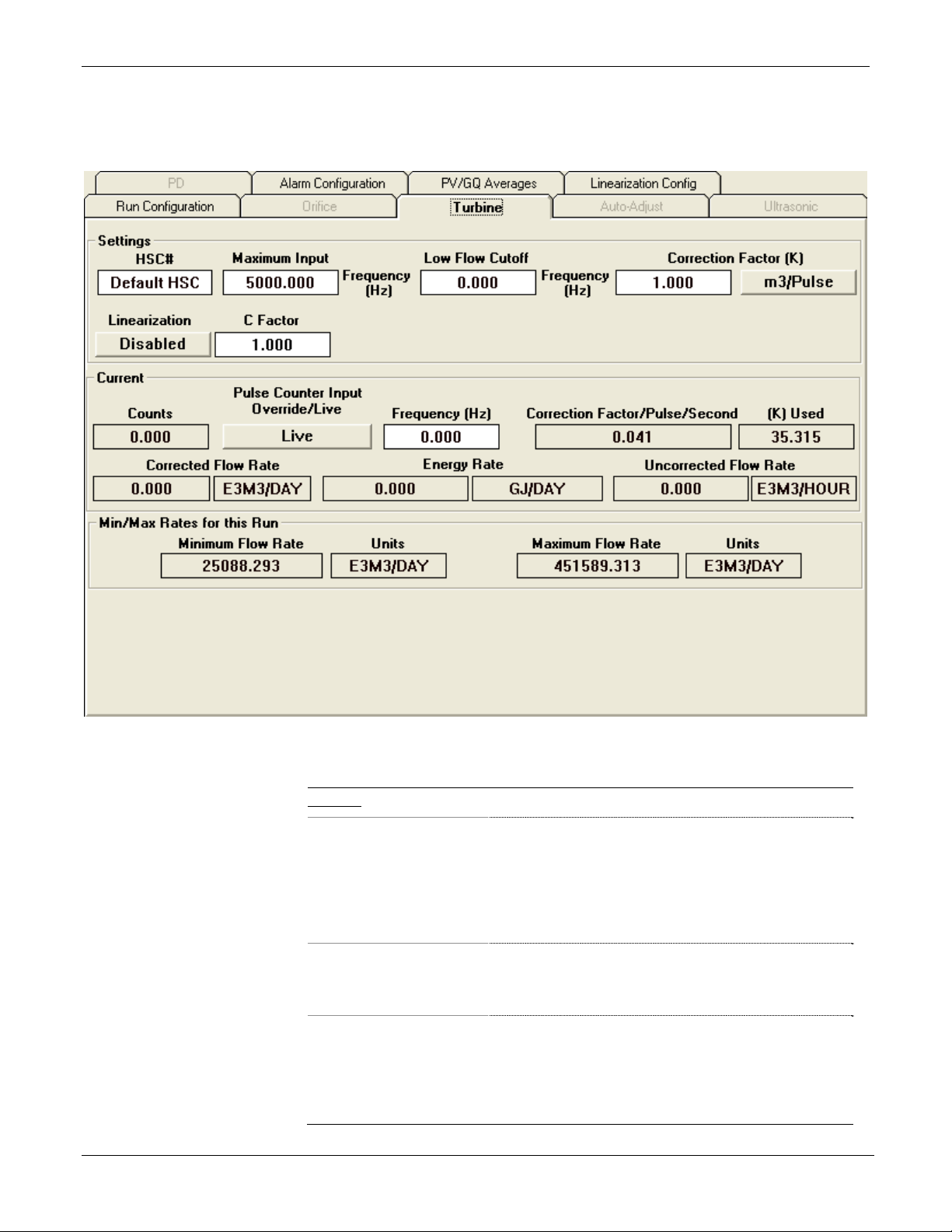

3.2.11 Turbine Tab (Run Configuration) ................................................................................ 3-29

3.2.12 Auto-Adjust Tab (Run Configuration) .......................................................................... 3-32

3.2.13 Ultrasonic Tab (Run Configuration) ............................................................................ 3-34

3.2.14 PD Tab (Run Configuration) ........................................................................................ 3-37

Issued: May-2012 Contents iii

Page 4

ControlWave MRMS-IC Configuration Manual (D5140)

3.3 View Local Archives ................................................................................................................ 3-39

3.3.1 Selecting Logs to View ................................................................................................ 3-39

3.4 Collect Local Logs ................................................................................................................... 3-40

3.4.1 Selecting Archives for Collection ................................................................................ 3-40

3.4.2 Collecting a Single Archive ......................................................................................... 3-40

3.4.3 Collecting Multiple Archives ........................................................................................ 3-40

3.4.4 Log Collection Parameters .......................................................................................... 3-40

3.5 View Audit Log ........................................................................................................................ 3-43

3.5.1 Data Storage Parameters dialog box .......................................................................... 3-44

3.5.2 Search Data Collection Criteria dialog box ................................................................. 3-45

3.6 Maintenance Mode .................................................................................................................. 3-46

3.6.1 Site Tab ....................................................................................................................... 3-46

3.6.2 Station Tab .................................................................................................................. 3-49

3.6.3 Run Tab ...................................................................................................................... 3-51

3.6.4 PVs Tab ...................................................................................................................... 3-53

3.6.5 AI Maintenance Tab .................................................................................................... 3-54

3.7 Gas Chromatograph Configuration ......................................................................................... 3-56

3.7.1 General ....................................................................................................................... 3-56

3.7.2 Current Tab (Gas Chromatograph Configuration) ...................................................... 3-61

3.7.3 Component Tab (Gas Chromatograph Configuration) ................................................ 3-65

3.7.4 Delta Limit Tab (Gas Chromatograph Configuration) ................................................. 3-67

3.7.5 Normalization Tab (Gas Chromatograph Configuration) ............................................ 3-68

3.7.6 Custom Tab (Gas Chromatograph Configuration) ...................................................... 3-69

3.8 Summary Pages ...................................................................................................................... 3-70

3.8.1 Measurement Tab ....................................................................................................... 3-70

3.8.2 Alarm Tab .................................................................................................................... 3-71

3.9 Limits Page (Gas Composition Allowable Ranges) ................................................................ 3-72

3.10 Daily Run Corrected and Uncorrected Volume ....................................................................... 3-73

Chapter 4 – Sampler (Control Tab) 4-1

4.1 Sampler ..................................................................................................................................... 4-1

4.1.1 List 29 ............................................................................................................................ 4-4

Appendix E - Troubleshooting E-1

Index IND-1

iv Contents Issued: May-2012

Page 5

ControlWave MRMS-IC Configuration Manual (D5140)

Chapter 1 – Getting Started

This chapter discusses how to install the MRMS-IC application and

provides some general information about how to use it.

In This Chapter

1.1 What is MRMS-IC? .......................................................................... 1-1

1.2 Before You Begin ............................................................................. 1-1

1.3 Installing MRMS-IC Software .......................................................... 1-2

1.4 Starting MRMS-IC Software ............................................................ 1-6

1.4.1 MRMS_IC IP Startup ............................................................ 1-6

1.4.2 MRMS_IC Serial Startup ...................................................... 1-7

1.4.3 Logging Onto the ControlWave Micro .................................. 1-7

1.5 Accessing Pages of the MRMS_IC Application ............................... 1-8

1.6 Entering Data in Fields of the MRMS_IC Application ...................... 1-9

1.1 What is MRMS-IC?

1.2 Before You Begin

Multi-Run Multi-Station (MRMS) software with Industry Canada (IC) /

Measurement Canada approvals is a software application that allows the

ControlWave Micro controller to manage up to six (6) natural gas

measurement stations.

The MRMS-IC application consists of:

A ControlWave project file (*.PRO) pre-programmed for multi-run

multi-station natural gas measurement.

A customized flash configuration profile (*.FCP) file that configures

the ports, audit, and archive parameters of the ControlWave Micro

for the MRMS_IC.

A TechView session. This includes the TechView session file

(*.TVS), associated *.INI files, and a set of HTM menus customized

for the MRMS-IC application. You use these menus to configure the

application.

You must install the ControlWave Micro controller on site and

connect field devices to its I/O modules. For information on

ControlWave Micro hardware, see document CI-ControlWave

Micro.

You must install OpenBSI 5.7 software including TechView on your

PC workstation. You must also install the latest service pack and

patches (Service Pack 2, Patch D). See the OpenBSI Utilities

Manual (D5081), the BSI_Config User’s Manual (D5128), and the

TechView User Manual (D5131) for details on installation

requirements.

Issued: May-2012 Getting Started 1-1

Page 6

ControlWave MRMS-IC Configuration Manual (D5140)

You must connect the PC workstation to the ControlWave Micro

controller. You can communicate using a serial cable or an Ethernet

cable. Cable diagrams are included in CI-ControlWave Micro.

The ControlWave Micro must be running a flash configuration

profile file (*.FCP) compatible with MRMS-IC software. For

information on updating FCP files, see Chapter 5 of the OpenBSI

Utilities Manual (D5081).

The ControlWave Micro must be running the ControlWave project

(*.PRO) file configured for the MRMS-IC. See Chapter 7 of the

OpenBSI Utilities Manual (D5081) for information on downloading

a ControlWave project (*.PRO) file.

Note: If you ordered your ControlWave Micro with MRMS-IC

software pre-installed, the FCP and PRO files are already loaded

when the unit ships from the factory.

1.3 Installing MRMS-IC Software

Note: MRMS_IC runs on the following Windows operating systems:

Windows XP

1. Double-click on the MRMS-IC application icon.

2. Click Next on the welcome screen of the installer.

Click “Next”

Figure 1-1. MRMS_IC Installer – Welcome Screen

1-2 Getting Started Issued: May-2012

Page 7

ControlWave MRMS-IC Configuration Manual (D5140)

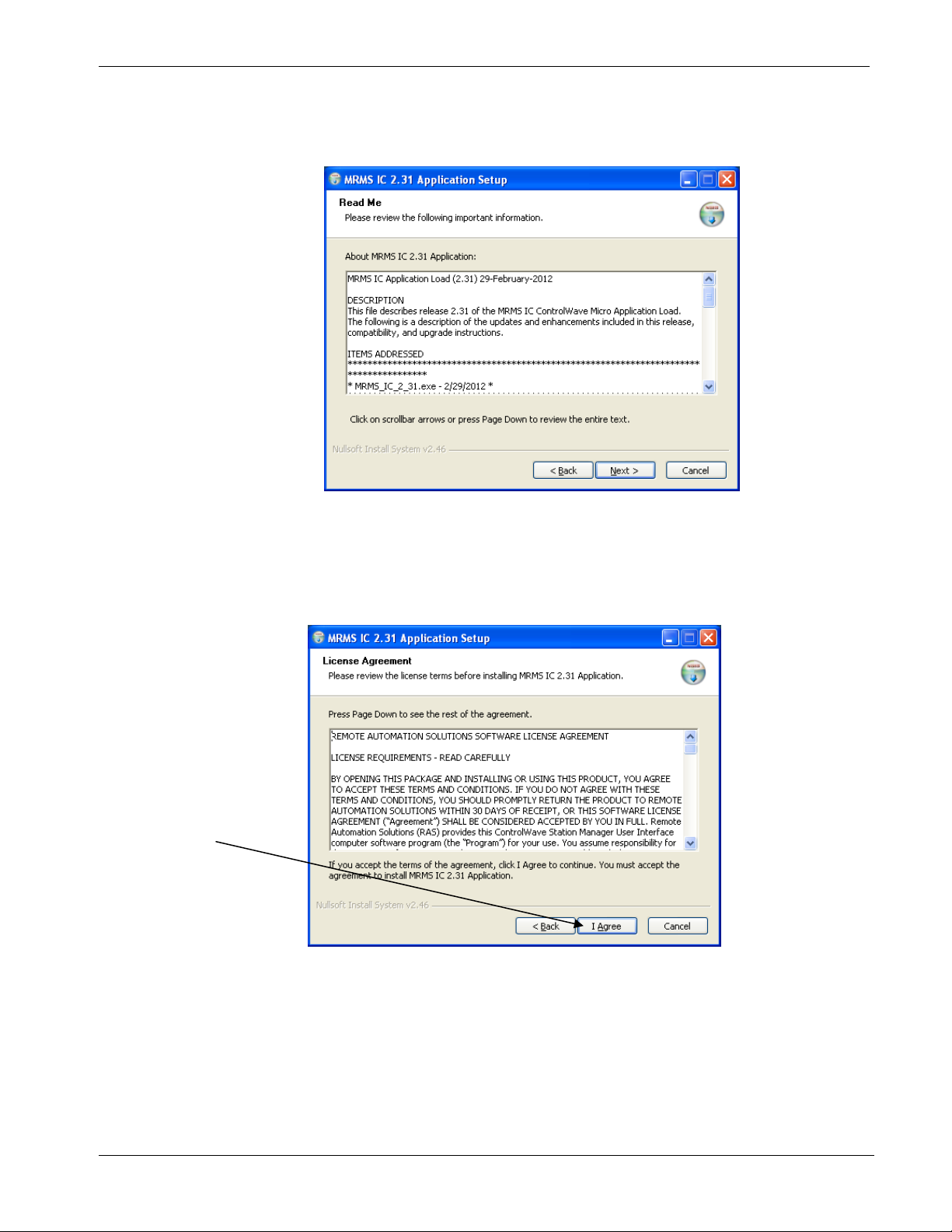

3. The next screen includes a “Read Me” file which describes the

changes since the last release of MRMS IC. Click Next after you

review the changes.

Click I Agree

Figure 1-2. Read Me Page

4. Review the license agreement and click the I Agree button to

proceed with the installation or Cancel to abort the installation

process.

Figure 1-3. License Agreement page

Issued: May-2012 Getting Started 1-3

Page 8

ControlWave MRMS-IC Configuration Manual (D5140)

Figure 1-4. Installation in Progress

5. The installation begins. If you see the following message box,

click OK to confirm that you have the proper OpenBSI version

installed.

Click OK

Figure 1-5. Confirm OpenBSI Version

6. At the completion of the installation, click Next.

1-4 Getting Started Issued: May-2012

Page 9

Click Next

ControlWave MRMS-IC Configuration Manual (D5140)

Figure 1-6. Installation Completion

7. Now click Finish to exit the installer.

Click Finish

Figure 1-7. Exit the Installer

Issued: May-2012 Getting Started 1-5

Page 10

ControlWave MRMS-IC Configuration Manual (D5140)

1.4 Starting MRMS-IC Software

You start the MRMS_IC software by invoking the proper TechView

file. There are two ways to do this:

Starting MRMS_IC from

the Start Programs

Menu

Starting MRMS_IC from

an icon

1.4.1 MRMS_IC IP Startup

For an IP connection, click: Start > Programs > MRMS_IC >

MRMS_IC_IP_tvs

For a serial connection, click: Start > Programs > MRMS_IC >

MRMS_IC_Serial_tvs

From a desktop icon, similar to those below, or from the

\MRMS_IC\SUPPORT folder, double-click the IP or serial TVS file,

depending upon your type of connection.

Figure 1-8. MRMS_IC TVS file icons

For IP communication, see Section 1.4.1 MRMS_IC IP Startup.

For serial communication see Section1.4.2 MRMS_IC Serial Startup.

Note: Although you can view data through an IP connection, the

MRMS-IC application only allows configuration changes when

you establish a physical serial connection to serial

communication port 1 on the ControlWave Micro.

Once you start the TVS file for IP operation, TechView opens the

Runtime Configuration Parameters dialog box:

Figure 1-9. IP Runtime Parameters

1. Ignore the number of runs; this parameter does not apply for

1-6 Getting Started Issued: May-2012

Page 11

MRMS-IC.

2. Enter the IP address of the ControlWave Micro IP port to

which you are connected.

3. Click OK.

4. Log onto the ControlWave Micro as described in Section 1.4.3.

1.4.2 MRMS_IC Serial Startup

Once you start the TVS file for serial operation, TechView opens the

Runtime Configuration Parameters dialog box:

ControlWave MRMS-IC Configuration Manual (D5140)

Figure 1-10. Serial Runtime Parameters

1. Ignore the number of runs; this parameter does not apply to

MRMS-IC.

2. Enter the BSAP local address of the ControlWave Micro to

which you are connected.

3. Select the serial communication port on the PC which you are

using to communicate with the ControlWave Micro.

4. Select the baud rate on the serial communication line.

5. Click OK.

6. Log onto the ControlWave Micro as described in Section 1.4.3.

1.4.3 Logging Onto the ControlWave Micro

In the SignOn to RTU dialog box, enter a Username / Password

combination that allows full access to the ControlWave Micro, then

click the SignOn button.

Issued: May-2012 Getting Started 1-7

Page 12

ControlWave MRMS-IC Configuration Manual (D5140)

y

Figure 1-11. Logging onto the ControlWave Micro

1.5 Accessing Pages of the MRMS_IC Application

To access various pages of the MRMS_IC application, click on the tab

for the function you want to configure, then click on the buttons which

appear on that tab. By default, the I/O tab appears first.

Click on the tab you want to access, then

click on an

of the buttons for that tab

Tabs

Buttons

Figure 1-12. Tabs and Buttons in MRMS_IC

The next several chapters describe the functions available on each tab of

the application.

1-8 Getting Started Issued: May-2012

Page 13

ControlWave MRMS-IC Configuration Manual (D5140)

You need not configure all the features of the application; only those

that you need for your particular purpose and measurement needs.

1.6 Entering Data in Fields of the MRMS_IC Application

Whenever you select a field and enter data, or select from a drop-down

menu, you must press the [Enter] key to confirm and save your choice.

To exit a field without entering data, press the [Esc] key.

Issued: May-2012 Getting Started 1-9

Page 14

This page is intentionally left blank

Page 15

ControlWave MRMS-IC Configuration Manual (D5140)

Chapter 2 – Configuring Inputs and Outputs (I/O Tab)

This chapter discusses configuring the MRMS-IC application to accept

field inputs and outputs (I/O). This is accomplished from the MRMSIC’s I/O tab.

Note: Although you can view data through an IP connection, the

MRMS-IC application only allows configuration changes when

you establish a physical serial connection to serial

communication port 1 on the ControlWave Micro.

In This Chapter

2.1 I/O Tab ............................................................................................. 2-1

2.2 I/O Usage ......................................................................................... 2-2

2.2.1 Discrete Inputs (DI) .............................................................. 2-5

2.2.2 Discrete Outputs (DO) .......................................................... 2-5

2.2.3 Analog Inputs (AI) ................................................................. 2-6

2.2.4 Analog Outputs (AO) ............................................................ 2-7

2.2.5 High Speed Counters (HSC) ................................................ 2-8

2.2.6 Ultrasonic Flow Meters (UFM) ............................................. 2-9

2.2.7 Multi-variable Transmitters (Transducers) ......................... 2-10

2.3 Local DLM ...................................................................................... 2-12

2.4 Customer Modbus Slave ............................................................... 2-14

2.4.1 Signal List Grid ................................................................... 2-17

2.4.2 Floating Point Format ......................................................... 2-19

2.5 Ultrasonic Data .............................................................................. 2-20

2.6 Load/Save Configuration ............................................................... 2-25

2.6.1 Performing Array Read or Write Operations. ..................... 2-26

2.6.2 Creating a Recipe ............................................................... 2-27

2.6.3 Changing Floating Point Format of Values in the Recipe .. 2-28

2.6.4 Saving the Recipe .............................................................. 2-28

2.6.5 Recalling a Saved Recipe, and Sending Its Values to the

Controller .......................................................................... 2-29

2.7 Generic Modbus Master ................................................................ 2-29

2.8 Time Set/Daylight Saving Time ..................................................... 2-29

2.1 I/O Tab

Click the I/O tab to display the various I/O options you can configure.

We’ll discuss each of these in the sections that follow.

To configure an

I/O function or

feature, click on

its button.

Figure 2-1. I/O Tab in MRMS-IC

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-1

Page 16

ControlWave MRMS-IC Configuration Manual (D5140)

2.2 I/O Usage

When you click the button on

the I/O tab, the I/O Usage page displays a graphical representation of

the ControlWave Micro, showing each of the I/O modules detected by

the MRMS-IC. If MRMS-IC cannot detect a particular module or an I/O

slot is empty, its graphic shows “Not Present.” MRMS-IC only uses

Mixed I/O modules.

Click on the graphical

representation of a module

to configure its I/O.

I/O modules

Figure 2-2. I/O Usage Screen Showing I/O Modules Detected

When you move the cursor over the CPU module, an Expansion

Communication (ECOM) module, or any I/O module, you’ll see a

yellow box on the screen. To configure I/O, follow these steps:

1. From the I/O tab, click the I/O Usage button.

2. Position the cursor over the I/O module you want to configure; a

yellow box indicates the cursor position on any configurable

module.

3. Click on the module you want to configure. This opens a screen

showing the possible choices for I/O. The Mixed I/O Module

shows multiple types of I/O (see Figure 2-3).

2-2 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

Page 17

ControlWave MRMS-IC Configuration Manual (D5140)

Figure 2-3. Mixed I/O Module

4. The I/O assignments in the MRMS-IC application are fixed

based on the I/O slot. Because you can have an expanded

communication module (ECOM) in either I/O slot 1 or 2, I/O

designations begin with the right-most slot and go in reverse

order. In other words, the mixed I/O module in I/O slot 6 holds

user DI1, whereas the mixed I/O module in I/O slot 1 holds user

DI6.

5. Configuration is limited based on the I/O type. Refer to the sub-

sections that follow.

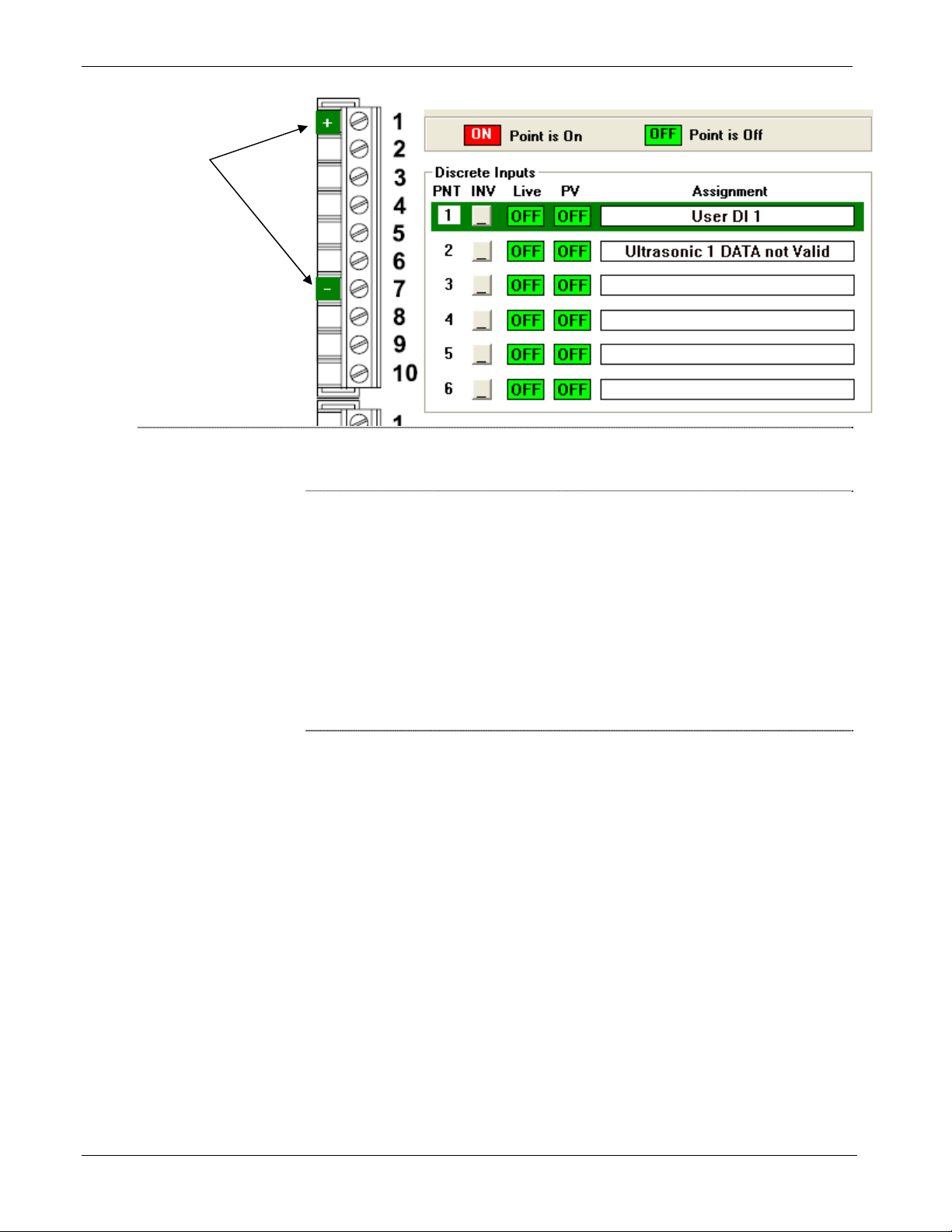

Note: You may have noticed that when the cursor is left hovered over

an IO point, the graphics to the left display the applicable

connection points for direct and remote IO.

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-3

Page 18

ControlWave MRMS-IC Configuration Manual (D5140)

Graphic displays

location of

physical I/O

connections for

an I/O point,

when you hover

the cursor over

the PNT.

Figure 2-4. Connection Points for Physical I/O

Notes:

The MRMS-IC application only uses Mixed I/O modules.

Depending upon your particular configuration, you might not use all

the inputs or outputs in a particular meter run or station.

If you have I/O that comes from an ultrasonic flow meter or a multi-

variable transmitter that communicates with the MRMS-IC through

a communication port, instead of an I/O module, you configure it

from the UFM or Transducer pages, discussed later in this chapter.

To return to the I/O Usage page from any page underneath it, click

the Go Back link.

2-4 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

Page 19

2.2.1 Discrete Inputs (DI)

Discrete inputs (DIs) include the following fields:

Field Description

PNT

INV If you click this box for a given I/O point so that “Y” is

Live

ControlWave MRMS-IC Configuration Manual (D5140)

This read-only field displays the I/O point number.

displayed, MRMS-IC inverts the real-live field value and

uses the inverted value as the process value. For

example, if the Live value of discrete I/O point 5 is OFF,

and INV is selected for that point, PV is set ON and that’s

what MRMS-IC uses for control and processing.

This read-only field shows the actual ON/OFF status of

this discrete input point.

PV

Assignment

2.2.2 Discrete Outputs (DO)

Discrete outputs (DOs) include the following fields:

Field Description

PNT

Points that are ON show in red.

Points that are OFF show in green.

This read-only field shows the value of the process

variable (PV) used in MRMS-IC. This matches the Live

value unless you invert the input using INV.

Points that are ON show in red.

Points that are OFF show in green.

This read-only field shows details of the fixed I/O

assigned to this point.

This read-only field displays the I/O point number.

PV

Assignment

This read-only field shows the value of the process

variable (PV) MRMS-IC will output to the field device.

This read-only field shows details of the fixed I/O

assigned to this point.

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-5

Page 20

ControlWave MRMS-IC Configuration Manual (D5140)

A

2.2.3 Analog Inputs (AI)

Analog inputs (AIs) include the following fields:

Field Description

PNT

This read-only field displays the I/O point number.

PV

Zero

Span Enter the value that, when added to the Zero value,

Units

Assignment

Use Stacked DP

Transmitter / Use

Single DP Transmitter

Only button

This read-only field shows the calculated value of the

analog input process variable (PV) based on the

configured Zero and Span.

If the value shows in red, the value is

questionable

connection, a communication problem with the field

device, data timeout or some other problem that could

cause the value to be invalid.

Enter the value that the process variable should read

when the AI field input is 4mA. Press [Enter] to save

your selection.

represents what the process variable should display

when the AI field input is 20m

your selection.

For example, if Zero is 5 and Span is 20, then:

If the AI field input is:

4mA 5

20mA 25

12mA 15

The engineering units for this process variable. Click in

the field and select the proper units from the drop-down

menu. Press [Enter] to save your selection.

This read-only field shows details of the fixed I/O

assigned to this point.

This button toggles I/O assignments based on whether

you use a single DP transmitter, or stacked DP

transmitters.

To use stacked, click the Use Stacked DP Transmitter

and assignments change to stacked; the label on the

button then changes to Use Single DP Transmitter

Only.

To use a single DP transmitter, click the Use Single DP

Transmitter and assignments change to single; the label

on the button then changes to Use Stacked DP

Transmitter.

. This could indicate no

. Press [Enter] to save

PV will be:

2-6 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

Page 21

2.2.4 Analog Outputs (AO)

Analog outputs (AOs) include the following fields:

Field Description

PNT

ControlWave MRMS-IC Configuration Manual (D5140)

This read-only field displays the I/O point number.

PV

Zero

Span Enter the value that, when added to the Zero value,

Units

Assignment

This read-only field shows the calculated value of the

analog output process variable (PV) based on the

configured Zero and Span. This value will be sent to the

field device.

Enter the value that the process variable should read

when the AO field output is 4mA. Press [Enter] to save

your selection.

represents what the process variable should display

when the AO field output is 20mA. Press [Enter] to save

your selection.

For example, if Zero is 5 and Span is 20, then:

If PV is:

5 4mA

25 20mA

10 8mA

The engineering units for this process variable. Click in

the field and select the proper units from the drop-down

menu. Press [Enter] to save your selection.

This read-only field shows details of the fixed I/O

assigned to this point.

The AO field output is:

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-7

Page 22

ControlWave MRMS-IC Configuration Manual (D5140)

2.2.5 High Speed Counters (HSC)

High speed counters (HSC) include the following fields:

Field Description

PNT

This read-only field displays the I/O point number. The

number varies depending upon the type of I/O module.

Counts

Time Stamp

Assignment

Use AutoAdjust / Use

Single HSC Input button

This read-only field displays the number of counts since

the last power cycle.

This read-only field displays the timestamp of the last

sample from the HSC module. The timestamp is the

number of milliseconds since boot.

This read-only field shows details of the fixed I/O

assigned to this point.

This button toggles I/O assignments based on whether

you use a single HSC input, or you use Auto Adjust

which requires two HSC inputs.

To use auto adjust, click the Use AutoAdjust and

assignments change to show two HSC inputs; the label

on the button then changes to Use Single HSC Input.

To use a single HSC input, click the Use Single HSC

Input and assignments change to a single HSC; the

label on the button then changes to Use AutoAdjust.

2-8 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

Page 23

ControlWave MRMS-IC Configuration Manual (D5140)

2.2.6 Ultrasonic Flow Meters (UFM)

If you have one or more ultrasonic flow meters, click the UFMs link on

the top of the I/O Usage page to call up the UFM page.

Figure 2-5. Ultrasonic Flow Meter (UFM) Configuration

Configure the following fields for your ultrasonic flow meter.

Field Description

Enabled/Disabled

Port

Address Enter the address of the UFM here. Press [Enter] to

Type

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-9

Click this button to enable communication from this UFM

to the MRMS-IC.

Use the dropdown menu to specify the ControlWave

Micro serial communication port which connects to this

UFM. Press [Enter] to save the selection.

save the selection.

Use the drop-down menu to select the type of UFM.

Press [Enter] to save your selection.

Page 24

ControlWave MRMS-IC Configuration Manual (D5140)

2.2.7 Multi-variable Transmitters (Transducers)

If you have one or more multi-variable transmitters, click the

Transducers link on the top of the I/O Usage page to call up the

Transducers page.

The Transducers page shows the first three multi-variable transmitters

(MVTs). If you want to view a different group of three MVTs, click the

button corresponding to the range of MVTs (1-3 or 4-6) on the top of

the screen.

Figure 2-6. Transducers Page (Multi-Variable Transmitters)

Each MVT includes the following fields:

Field Description

Enabled/Disabled

Communication

Protocol

(BSAP/MODBUS)

Port

2-10 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

Click this button to enable communication from this

MVT to the MRMS-IC.

Click the BSAP/MODBUS button to toggle the method

used to communicate with this MVT between BSAP

protocol and MODBUS protocol.

Use the dropdown menu to specify the ControlWave

Micro serial communication port which connects to this

MVT. Press [Enter] to save the selection.

Page 25

ControlWave MRMS-IC Configuration Manual (D5140)

Address Enter the address of the MVT here. Press [Enter] to

save the selection.

Xmtr Type

Register Set

Comm Stats

% Good

Good Polls

Bad Polls

Reset

Current Status

Tag Name

Serial Number

Time Stamp

DP

SP

Use the drop-down menu to select the type of data

coming from this MVT. Choose either:

: Data from this type:

Type

GP/T gage pressure and temperature

DP/P/T differential pressure, static pressure, and

temperature

T temperature

Press [Enter] to save your selection.

This field applies only to MODBUS communication.

Click either 7xxx or 4xxxx to select the MODBUS

register set used by this MVT.

This read-only field shows the percentage of

successful communication transactions with this MVT.

This read-only field shows the number of good poll

messages in communications with this MVT.

This read-only field shows the number of bad poll

messages in communications with this MVT.

This button resets the communication statistics in the

%Good, Good Polls, and Bad Polls fields.

These read-only fields display the most recent status

messages from this MVT.

This read-only field shows the tag name from this

MVT. (BSAP only)

This read-only field shows the serial number from this

MVT. (MODBUS only)

This read-only field shows the time stamp of the most

recent value received from this MVT.

This read-only field shows the most recent differential

pressure reading from this MVT.

This read-only field shows the most recent static

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-11

Page 26

ControlWave MRMS-IC Configuration Manual (D5140)

A

FT

Units

Zero

Span

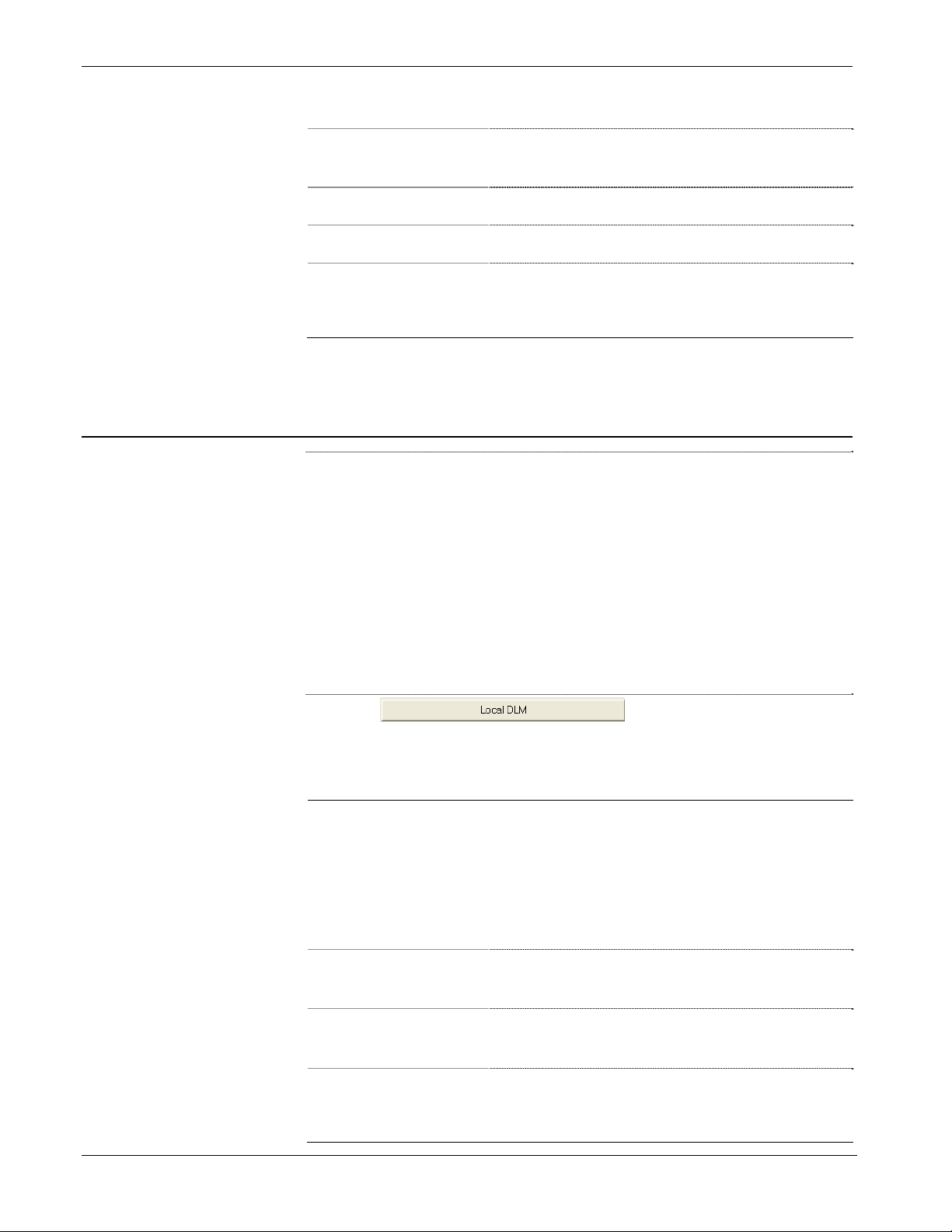

2.3 Local DLM

Notes:

The local Data Line Monitor (DLM) provides details about low-

level communication messages sent through a selected serial port

used by the MRMS-IC.

pressure reading from this MVT.

This read-only field shows the most recent

temperature reading from this MVT.

This read-only field shows the engineering units for this

variable.

This read-only field shows the value for this variable

when the MVT receives a 4mA field input.

This read-only field shows the value that, when added

to the Zero value, represents what the process

variable should display when the field input to the MVT

is 20mA.

Typically, you would only use the local DLM if you are a very

advanced user and need to perform communication troubleshooting

for a particular port.

The local DLM only displays the first 80 characters of a message.

The local DLM only captures messages approximately every half

second, therefore, it can miss some messages.

Click the button on the I/O tab to

activate the Data Line Monitor function. The DLM includes the

following fields:

Field Description

Monitor Port

TX Data

Use the dropdown menu to select the ControlWave

Micro serial communication port you want the DLM to

monitor. Press [Enter] to save the selection.

Note:

the monitor port, you can copy data from the window to

the clipboard. You can then paste this data into

another file for off-line review.

This read-only field shows the most recent message

transmitted through this port.

fter you collect the data, if you select “None” for

RX Data

window The window shows successive messages detected by

2-12 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

This read-only field shows the most recent message

received through this port.

the DLM. Most recent messages appear at the top;

you can use the scroll bar to adjust the window to

show earlier messages.

Page 27

ControlWave MRMS-IC Configuration Manual (D5140)

Figure 2-7. Local DLM

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-13

Page 28

ControlWave MRMS-IC Configuration Manual (D5140)

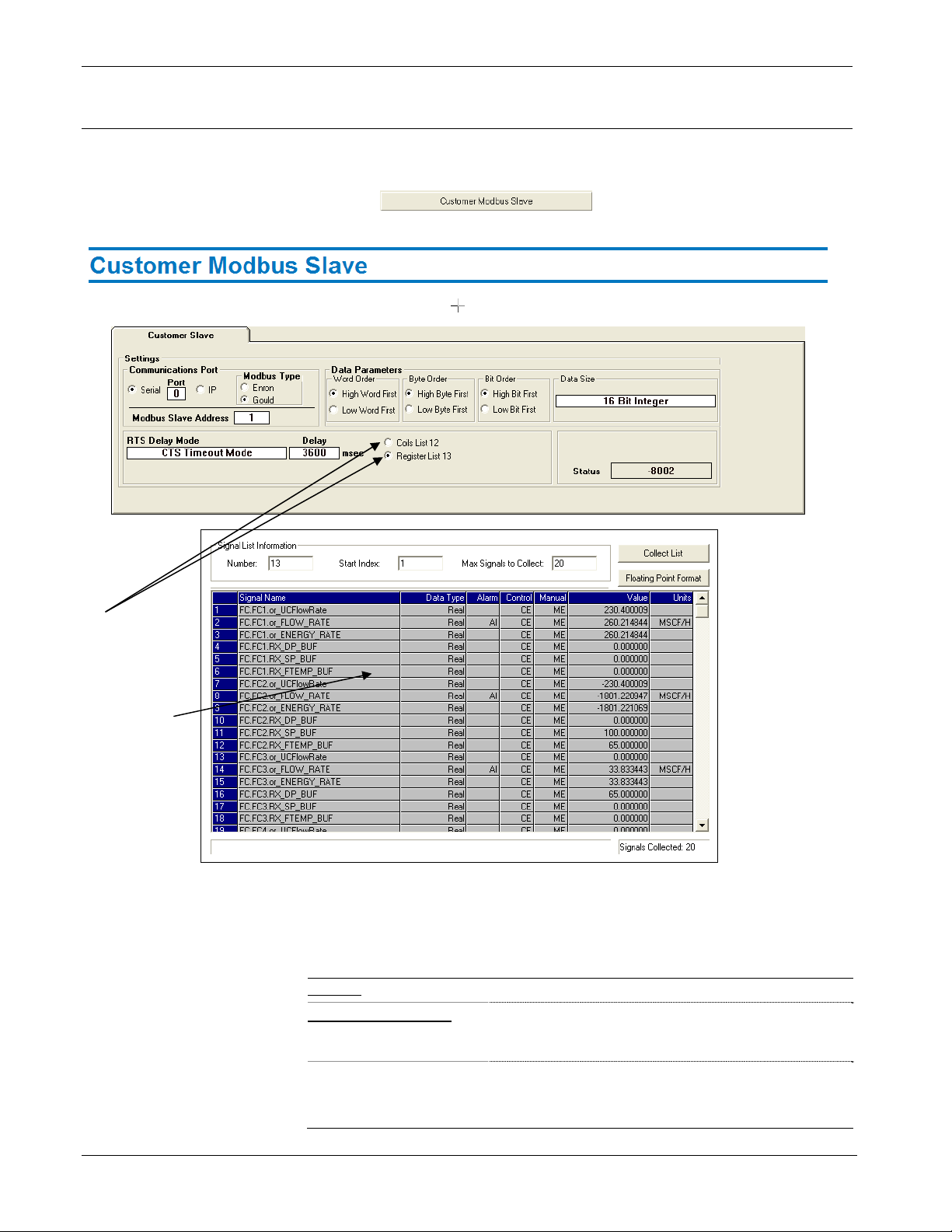

2.4 Customer Modbus Slave

MRMS-IC supports a single Modbus slave session you can configure to

provide a Modbus slave interface to the controller.

Click the button on the I/O tab to bring up

the Customer Modbus Slave page.

You can

view either

coils or

registers in

the Signal

List grid.

Figure 2-8. Customer Slave Page

This page includes the following fields:

Field Description

Settings

Communications Port

Serial Click the Serial selection to use serial Modbus

2-14 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

Modbus communications can use either serial or IP

communications.

communication, and specify the port you want to

use. (See Port).

Page 29

ControlWave MRMS-IC Configuration Manual (D5140)

Field Description

Port

IP Click the IP selection to use IP Modbus (Open

Modbus Slave Address

Modbus Type

Specify the serial communication port on the

ControlWave Micro you want to use for Modbus slave

communication. Use the following code:

Enter this

1 COM1

2 COM2

3 COM3

4 COM4

5 COM5

6 COM6

7 COM7

8 COM8

9 COM9

10 COM10

11 COM11

Press [Enter] to save the selection.

Modbus) communication.

Enter the Modbus slave address. If the local slave

address you enter has already been assigned to

either the SCADA Enron Modbus slave interface, or

any of the other Customer Modbus Slave sessions,

you will see a Loc Addr Conflict message. Modify

the Modbus Slave Address as required to resolve

the conflict.

: To select this serial CW Micro port:

Enron If you want to communicate using Enron Modbus,

click this selection.

Gould If you want to communicate using Gould Modbus,

click this selection.

Data Parameters

Word Order Choose the data word order to match the data word

order used by the Modbus Master that

communicates with this Modbus Slave.

High Word First

Low Word First

Byte Order Choose the data byte order to match the data byte

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-15

Click this to specify that the high word is first.

Click this to specify that the low word is first.

Page 30

ControlWave MRMS-IC Configuration Manual (D5140)

Field Description

High Byte First

order used by the Modbus Master that

communicates with this Modbus Slave.

Click this to specify that the high byte is first.

Low Byte First

Bit Order Choose the data bit order to match the data bit order

High Bit First

Low Bit First

Data Size

Click this to specify that the low byte is first.

used by the Modbus Master that communicates with

this Modbus Slave.

Click this to specify that the high bit is first.

Click this to specify that the low bit is first.

Select the appropriate data format for Modbus

Register data from the drop down menu. The

available selections are:

Single Bit – Each Register will include a single bit

Byte Data – Each Register will include a single byte

16 Bit Integer – Each Register will include a single

16-bit integer

32 Bit Int., 1 Reg., Cnt*1, Adr*1 – Each Register

will include a 32-bit double integer.

32 Bit Float, 1 Reg., Cnt*1, Adr*1 – Each Register

will include a 32-bit floating point number

32 Bit Int., 2 Reg., Cnt*2, Adr*2 – Two registers will

be used for each 32-bit double integer. The

MODBUS Master must poll two registers for each 32

bit integer.

32 Bit Float, 2 Reg., Cnt*2, Adr*2 – Two registers

will be used for each 32-bit floating point number.

The MODBUS Master must poll two registers for

each 32 bit number.

32 Bit Int., 2 Reg., Cnt*2, Adr*1 - Two registers will

be used for each 32-bit double integer. The

MODBUS Master must poll a single register for each

32 bit integer.

32 Bit Float, 2 Reg., Cnt*2, Adr*1 - Two registers

will be used for each 32-bit floating point number.

The MODBUS Master must poll a single register for

each 32 bit number.

Press [Enter] to save the selection.

If you don’t make a selection, the field shows Not Set.

2-16 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

Page 31

ControlWave MRMS-IC Configuration Manual (D5140)

A

Field Description

RTS Delay Mode

Select from one of two modes for the Ready-to-Send

(RTS) delay mode.

Message Delay Mode raises RTS, a delay timer starts. The length of the

delay is determined by the value in the Delay Time

field. No message is sent until after this delay

expires. The value of CTS does not affect the

operation of this mode.

CTS Timeout Mode - After the Modbus slave port

raises RTS, it uses the Delay Time value as the

maximum time to wait for CTS to be received from

the master. If the Modbus slave port receives CTS at

any time before this time expires, the port starts to

transmit the message. If the Modbus slave port does

not receive a CTS from the master prior to the

expiration of the Delay Time, it does not respond to

the master and instead reports an error.

Press [Enter] to save the selection.

Delay msec Specify the Delay (in milliseconds) used by the RTS

Delay Mode and CTS Timeout Mode.

Coils List 12

Each Modbus slave session has two dedicated lists,

one for Modbus Registers and the other for Modbus

Coils. To display coils in the signal list grid, click this

button. See Section 2.4.1 for instructions on using

the signal list grid.

fter the Modbus Slave port

Register List 13

Status

2.4.1 Signal List Grid

The Signal List grid displays lists of variables included in the MRMSIC application.

Each Modbus slave session has two dedicated lists,

one for Modbus Registers and the other for Modbus

Coils. To display registers in the signal list grid, click

this button. See Section 2.4.1 for instructions on

using the signal list grid.

This read-only field displays a status code indicating

the health of the Modbus slave communications.

If you see any code other than 0 here or see an error

message above the code, see Appendix E – Errors

and Troubleshooting for more information.

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-17

Page 32

ControlWave MRMS-IC Configuration Manual (D5140)

Figure 2-9. Signal List Grid Control

Field Description

Signal List Information

The list window shows the contents of lists within the

application.

Number

Max Signals to Collect

Start Index

Collect List

Floating Point Format

Signal Name

Data Type

Alarm

Specifies the number of the list. In some cases,

pushing a button elsewhere on the page fills in this

number; in other cases, you must enter a list number

directly.

Specifies the number of list items to retrieve into the

grid control. Depending upon how many list items

are collected, you may need to use a scroll bar to

view them.

Normally, the signal list grid displays variables

beginning with the first variable in the list. If you want

to skip further into the list, enter the number of the

first list item you want to see in this field, and the grid

starts displaying from that item forward.

Click this button to force the Signal List grid to collect

the specified list now.

Click this to specify the Floating Point Format dialog

box. See Figure 2-10

Shows the variable name for this list item, or its

descriptor.

Shows the variable type, such as Real or Boolean.

If this variable is an alarm, and this shows “AI” it

indicates the variable is alarm inhibited. If this shows

“AE” it indicates that the variable is alarm enabled.

Control

2-18 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

If this shows “CI” it indicates the variable is control

inhibited. If this shows “CE” it indicates that the

variable is control enabled.

Page 33

ControlWave MRMS-IC Configuration Manual (D5140)

Field Description

Manual

If this shows “MI” it indicates the variable is manual

inhibited. If this shows “ME” it indicates that the

variable is manual enabled.

Value

Units

Signals Collected

Shows the current value of the variable.

Shows the engineering units (if specified) for this

variable.

Displays a count of the number of variables collected

into the signal list grid.

2.4.2 Floating Point Format

The floating point format is the way floating point (real) numbers

display within a screen in the MRMS-IC application.

To change this format, you click the button on a

page, to call up the Float Format dialog box.

Figure 2-10. Floating Point Format dialog box

Field Description

Width

Precision

Exponent

OK

Cancel

Choose the total number of characters in the field

(including the decimal point) used to display a

floating point number.

Choose the number of places to the right of the

decimal point which the floating point number should

show.

Select one of these formats:

e show number in exponential notation

f show number in floating point notation

g allow application to choose the “best fit” format

for this number.

Click this to save your entries and exit the dialog

box.

Click this to discard your entries and exit the dialog

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-19

Page 34

ControlWave MRMS-IC Configuration Manual (D5140)

Field Description

2.5 Generic Modbus Master

Click the button on the I/O tab to

activate the Generic Modbus page. There are multiple pages for Modbus

Master 1 (MB1) to Modbus Master 5 (MB5). You click on a tab to call

up the appropriate Modbus Master.

box.

Figure 2-11. Generic Modbus Master

This page includes the following fields:

Field Description

Settings

Communications Port

Modbus communications can use either serial or IP

communications.

2-20 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

Page 35

ControlWave MRMS-IC Configuration Manual (D5140)

Field Description

Serial Click the Serial selection to use serial Modbus

communication, and specify the port you want to

use. (See Port).

Port

IP Click the IP selection to use IP Modbus (Open

Specify the serial communication port on the

ControlWave Micro you want to use for Modbus

master communication. Use the following code:

Enter this

1 COM1

2 COM2

3 COM3

4 COM4

5 COM5

6 COM6

7 COM7

8 COM8

9 COM9

10 COM10

11 COM11

Press [Enter] to save the selection.

Modbus) communication.

: To select this serial CW Micro port:

IP Address

Modbus Slave Address

Data Parameters

Word Order Choose the data word order to match the data word

High Word First

Low Word First

Byte Order Choose the data byte order to match the data byte

If you want to use IP Modbus (Open Modbus), enter

the IP address of the port used by this master.

Enter the Modbus slave address. If the local slave

address you enter has already been assigned to

either the SCADA Enron Modbus slave interface, or

any of the other Customer Modbus Slave sessions,

you will see a Loc Addr Conflict message. Modify

the Modbus Slave Address as required to resolve

the conflict.

order used by the Modbus Slave that communicates

with this Modbus Master.

Click this to specify that the high word is first.

Click this to specify that the low word is first.

order used by the Modbus Slave that communicates

with this Modbus Master.

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-21

Page 36

ControlWave MRMS-IC Configuration Manual (D5140)

Field Description

High Byte First

Click this to specify that the high byte is first.

Low Byte First

Bit Order Choose the data bit order to match the data bit order

High Bit First

Low Bit First

Data Size

Click this to specify that the low byte is first.

used by the Modbus Slave that communicates with

this Modbus Master.

Click this to specify that the high bit is first in a byte

of data..

Click this to specify that the low bit is first in a byte of

data.

Select the appropriate data format for Modbus

Register data from the drop down menu. The

available selections are:

Single Bit – Each Register will include a single bit

Byte Data – Each Register will include a single byte

16 Bit Integer – Each Register will include a single

16-bit integer

32 Bit Int., 1 Reg., Cnt*1, Adr*1 – Each Register

will include a 32-bit double integer.

Function Code

32 Bit Float, 1 Reg., Cnt*1, Adr*1 – Each Register

will include a 32-bit floating point number

32 Bit Int., 2 Reg., Cnt*2, Adr*2 – Two registers will

be used for each 32-bit double integer. The

MODBUS Master must poll two registers for each 32

bit integer.

32 Bit Float, 2 Reg., Cnt*2, Adr*2 – Two registers

will be used for each 32-bit floating point number.

The MODBUS Master must poll two registers for

each 32 bit number.

32 Bit Int., 2 Reg., Cnt*2, Adr*1 - Two registers will

be used for each 32-bit double integer. The

MODBUS Master must poll a single register for each

32 bit integer.

32 Bit Float, 2 Reg., Cnt*2, Adr*1 - Two registers

will be used for each 32-bit floating point number.

The MODBUS Master must poll a single register for

each 32 bit number.

Press [Enter] to save the selection.

If you don’t make a selection, the field shows Not Set.

Select the Modbus function from the drop-down menu.

2-22 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

Page 37

ControlWave MRMS-IC Configuration Manual (D5140)

Field Description

Press [Enter] to save the selection.

RTS Delay Mode

Delay msec Specify the Delay (in milliseconds) used by the RTS

Time Out msec

Select from one of two modes for the Ready-to-Send

(RTS) delay mode.

Message Delay Mode - After the Modbus Master

port raises RTS, a delay timer starts. The length of

the delay is determined by the value in the Delay

field. No message is sent until after this delay

expires. The value of CTS does not affect the

operation of this mode.

CTS Timeout Mode - After the Modbus Master port

raises RTS, it uses the Delay value as the maximum

time to wait for CTS to be received from the slave. If

the Modbus Master port receives CTS at any time

before this time expires, the port starts to transmit

the message. If the Modbus master port does not

receive a CTS from the slave prior to the expiration

of the Delay it does not respond to the slave and

instead reports an error.

Press [Enter] to save the selection.

Delay Mode and CTS Timeout Mode. Press [Enter]

to save the selection.

Specify the time (in milliseconds) that the Modbus

master must wait for a response from the Modbus

slave before the master declares that the slave timed

out. Press [Enter] to save the selection.

Collection Rate msec

Start Register

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-23

Specify the interval (in milliseconds) between poll

attempts by the Modbus master. Press [Enter] to

save the selection.

Specify the starting address for coil or register

operations. The address transmitted to the Slave is

one less than the value specified here. For example,

the address 7031 is sent as 7030 for Function code

Page 38

ControlWave MRMS-IC Configuration Manual (D5140)

Field Description

3. Press [Enter] to save the selection.

Register Count

Disabled/Enabled If this shows Disabled, click on it to enable the

Status

List Number

Specify the number of coils or registers the Master

should read. The value can range from 1 to 2000 for

coils or 1 to 125 for 16-bit registers, or 1 to 62 for 32bit registers. Press [Enter] to save the selection.

Modbus Master.

This read-only field displays a status code indicating

the health of the Modbus master communications.

If you see any code other than 0 here or see an error

message above the code, see Appendix E – Errors

and Troubleshooting for more information.

Shows the number of the list you can open in

DataView to see the collected Modbus data.

2-24 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

Page 39

2.6 Load/Save Configuration

The Load/Save Configuration feature provides a way to save and restore

MRMS-IC configuration data. It uses the Data Array Save/Restore

utility and the recipe utility to accomplish the read/write operations.

Click the button on the I/O

tab to activate the Load/Save Configuration page.

ControlWave MRMS-IC Configuration Manual (D5140)

Figure 2-12. Load/Save Configuration

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-25

Page 40

ControlWave MRMS-IC Configuration Manual (D5140)

2.6.1 Performing I/O Array Operations.

1. Enter a valid username/password combination for the controller

that has full privileges in the RTU User Name and RTU

Password fields.

Figure 2-13. Array Read / Write

2. To read values from the I/O array in the controller and store

those values in a PC disk file, click Save I/O Configuration to

Disk.

3. The Data Array Save/Restore utility starts.

Note: Allow the Data Array/Save Restore utility to run by itself; you

need not enter any values unless it generates an error.

2-26 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

Page 41

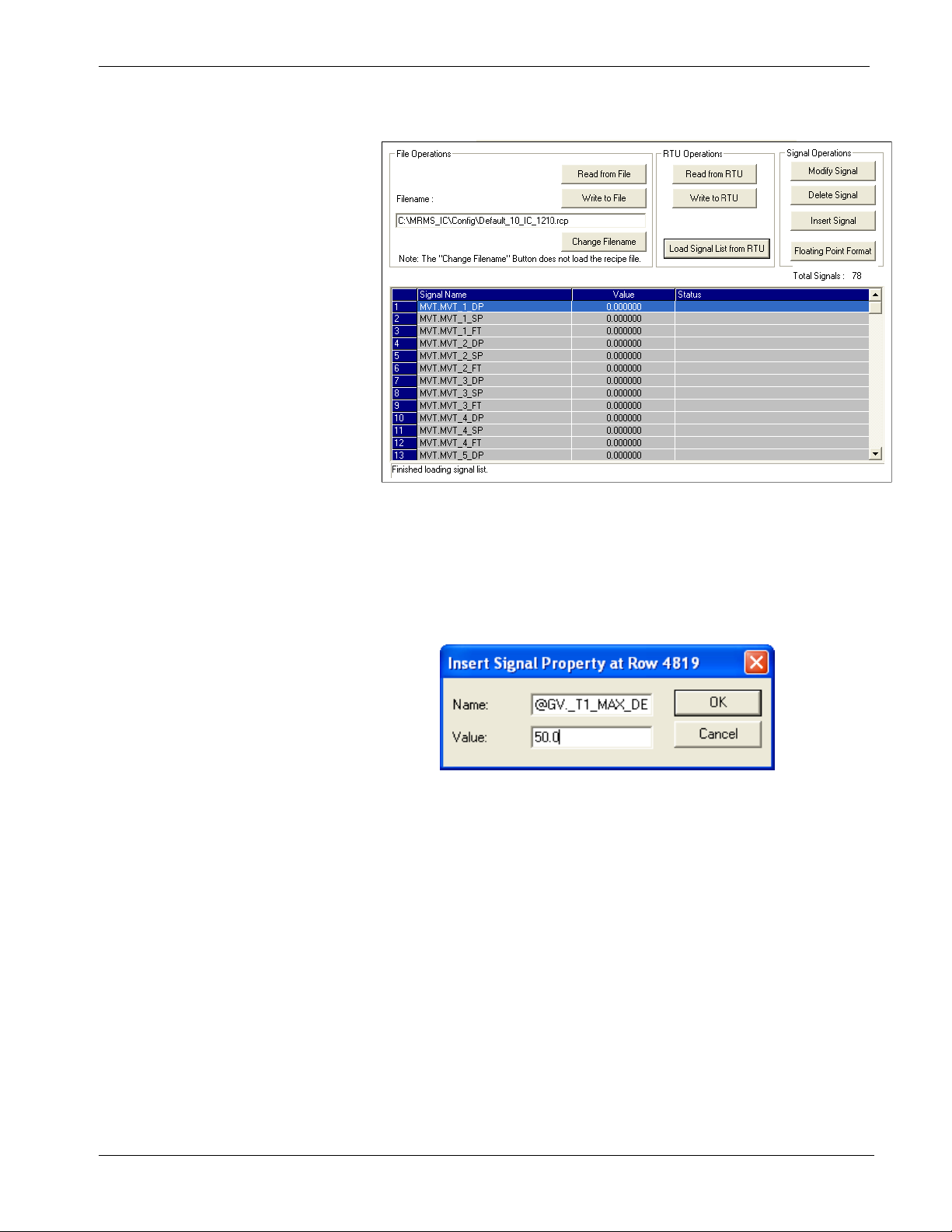

2.6.2 Creating a Recipe

ControlWave MRMS-IC Configuration Manual (D5140)

Figure 2-14. Recipe

To create a recipe you must first specify the variables you want included

in the recipe. One way to do this is to either right-click on the grid in the

center of the Recipe page and choose "Insert Signal" from the pop-up

menu, or click the Insert Signal button.

Figure 2-15. Insert Signal Property dialog box

In either case, a dialog box opens and you can enter the variable's name.

If desired, you can also enter a value for the variable. Click OK when

you are finished. Repeat for each additional variable.

If you don't enter values for the variable when you insert it you can load

the current values in the MRMS-IC for all variables in the recipe by

clicking on Read From RTU.

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-27

Page 42

ControlWave MRMS-IC Configuration Manual (D5140)

Another way to specify variables for the recipe is to load the variables

from the list. To do this, click the Load Signal List from RTU button,

then specify the number of the signal list and click OK.

Figure 2-16. Signal List to Load

If, as you are creating the recipe, you decide you want to change a

variable or value for a particular entry, either right click on the entry

and choose "Edit Signal" from the pop-up menu, or click the Modify

Signal button. Make changes, as desired, and click OK.

If you want to delete a variable in the recipe, either right-click on the

line for that variable and choose "Delete Signal" from the pop-up

menu, or click the Delete Signal button. You will be prompted to

confirm the deletion.

For information on changing the floating point format of values in the

recipe, see Section 2.4.2.

2.6.3 Saving the Recipe

Type the path and filename for your recipe file in the "Filename" field

or click Change Filename to select a recipe from the default recipe

area. Standard recipe files are stored with a file extension of (.RCP).

You also have the option of saving the file as a .CFG file (which is

intended for use with Coastal Flow Measurement Inc. Flow-Cal™

software.)

Figure 2-17. Edit Signal Property

2-28 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

Page 43

ControlWave MRMS-IC Configuration Manual (D5140)

Figure 2-18. Saving the Recipe

Once you have specified the path and filename, click on the Write to

File button; answer Yes to the confirmation prompt, and the control

writes the recipe to the specified file.

2.6.4 Recalling a Saved Recipe, and Sending Its Values to the

Controller

To recall a recipe which you have saved previously, use the Change

Filename button to locate it, or type its path and filename in directly in

the "Filename" field. Finally, click the Read From File button, and the

recipe will be brought into the web page.

Once the recipe file has been loaded, you can send the recipe values to

the controller by clicking on the Write to RTU button; answer Yes to

the confirmation prompt, and the control writes the recipe to the

controller

2.7 Time Set/Daylight Saving Time

Click the button on the I/O tab to

open the Time Set/Daylight Saving Time page.

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-29

Page 44

ControlWave MRMS-IC Configuration Manual (D5140)

Figure 2-19. Time Set/Daylight Saving Time page

Field Description

Current RTU Date and

Time

Current PC Date and

Time

Clear Registers Click this button to set all six time registers (Year,

Load Registers with the

RTUs Date/Time

Load Registers with the

PCs Date/Time

Year

Month

Day

This read-only field shows the current date and time

setting at the controller.

This read-only field shows the current date and time

at the PC workstation.

Month, Day, Hour, Minutes and Seconds) to zero.

Click this button to store the controller time in the six

time registers.

Click this button to store the PC workstation time in the

six time registers.

This time register holds a year value. You can set it

by typing in a value, or you can load it by one of the

buttons.

This time register holds a month value. You can set

it by typing in a value, or you can load it by one of

the buttons.

This time register holds a day value. You can set it

by typing in a value, or you can load it by one of the

buttons.

2-30 Configuring Inputs and Outputs (I/O Tab) Issued: May-2012

Page 45

ControlWave MRMS-IC Configuration Manual (D5140)

Field Description

Hour

Minutes

Seconds

Set RTU Date/Time with

Register Values

This time register holds an hour value. You can set it

by typing in a value, or you can load it by one of the

buttons.

This time register holds a minute value. You can set

it by typing in a value, or you can load it by one of

the buttons.

This time register holds a seconds value. You can

set it by typing in a value, or you can load it by one

of the buttons.

Click this button to update the controller’s date and

time with the values currently in the time registers.

Issued: May-2012 Configuring Inputs and Outputs (I/O Tab) 2-31

Page 46

This page is intentionally left blank

Page 47

ControlWave MRMS-IC Configuration Manual (D5140)

Chapter 3 – Configuring Stations and Runs (Measurement

Tab)

Note: Although you can view data through an IP connection, the MRMS-

IC application only allows configuration changes when you

establish a physical serial connection to serial communication port

1 on the ControlWave Micro.

This chapter discusses configuring the stations and meter runs for the

MRMS-IC application as well as all the measurement functions for the

various meter runs. This is accomplished from the MRMS-IC

Measurement tab.

In This Chapter

3.1 Measurement Tab ........................................................................................................ 3-2

3.2 Status/Configuration ..................................................................................................... 3-3

3.2.1 Site Configuration Data Tab (Site Configuration) ..................................... 3-4

3.2.2 MVT Common Settings Tab (Site Configuration) ..................................... 3-7

3.2.3 Station Summaries Tab (Site Configuration) ............................................ 3-8

3.2.4 Station Configuration Tab (Station Configuration).................................. 3-10

3.2.5 Station Data Tab (Station Configuration) ............................................... 3-15

3.2.6 Run Config Tab (Run Configuration) ...................................................... 3-16

3.2.7 Alarm Configuration Tab (Run Configuration) ........................................ 3-21

3.2.8 Linearization Config Tab (Run Configuration) ........................................ 3-23

3.2.9 PV/GQ Averages Tab (Run Configuration) ............................................ 3-24

3.2.10 Orifice Tab (Run Configuration).............................................................. 3-25

3.2.11 Turbine Tab (Run Configuration) ............................................................ 3-29

3.2.12 Auto-Adjust Tab (Run Configuration) ..................................................... 3-32

3.2.13 Ultrasonic Tab (Run Configuration) ........................................................ 3-34

3.2.14 PD Tab (Run Configuration) ................................................................... 3-37

3.3 View Local Archives ................................................................................................... 3-39

3.3.1 Selecting Logs to View ........................................................................... 3-39

3.4 Collect Local Logs ...................................................................................................... 3-40

3.4.1 Selecting Archives for Collection ............................................................ 3-40

3.4.2 Collecting a Single Archive ..................................................................... 3-40

3.4.3 Collecting Multiple Archives .................................................................... 3-40

3.4.4 Log Collection Parameters ..................................................................... 3-40

3.5 View Audit Log ........................................................................................................... 3-43

3.5.1 Data Storage Parameters dialog box ..................................................... 3-44

3.5.2 Search Data Collection Criteria dialog box ............................................. 3-45

3.6 Maintenance Mode ..................................................................................................... 3-46

3.6.1 Site Tab .................................................................................................. 3-46

3.6.2 Station Tab ............................................................................................. 3-49

3.6.3 Run Tab .................................................................................................. 3-51

3.6.4 PVs Tab .................................................................................................. 3-53

3.6.5 AI Maintenance Tab................................................................................ 3-54

3.7 Gas Chromatograph Configuration ............................................................................ 3-56

3.7.1 General ................................................................................................... 3-56

3.7.2 Current Tab (Gas Chromatograph Configuration) .................................. 3-61

3.7.3 Component Tab (Gas Chromatograph Configuration) ........................... 3-65

3.7.4 Delta Limit Tab (Gas Chromatograph Configuration) ............................. 3-67

3.7.5 Normalization Tab (Gas Chromatograph Configuration) ........................ 3-68

Issued: May-2012 Configuring Stations and Runs (Measurement Tab) 3-1

Page 48

ControlWave MRMS-IC Configuration Manual (D5140)

3.7.6 Custom Tab (Gas Chromatograph Configuration) ................................. 3-69

3.8 Summary Pages ......................................................................................................... 3-70

3.8.1 Measurement Tab................................................................................... 3-70

3.8.2 Alarm Tab ............................................................................................... 3-71

3.9 Limits Page (Gas Composition Allowable Ranges) ................................................... 3-72

3.10 Daily Run Corrected and Uncorrected Volume .......................................................... 3-73

3.1 Measurement Tab

Click the Measurement tab to display the measurement options you can

configure. We’ll discuss each of these in the sections that follow.

Figure 3-1. Measurement Tab in MRMS-IC

Click on the

button to

configure or view

a particular

function

3-2 Configuring Stations and Runs (Measurement Tab) Issued: May-2012

Page 49

3.2 Status/Configuration

When you click the button on the

Measurement tab, MRMS-IC opens up a tree structure that shows the site

and lists the stations and meter runs.

ControlWave MRMS-IC Configuration Manual (D5140)

Calling up pages for

configuring the site,

station, or meter run

Double-click on items in the tree to bring up configuration pages for

the site, station, or meter run.

Click on the site name to call

up pages for

site. If no site name exists

yet, click on “Unnamed

Site.”

Click on the “Station n”

name to call up pages for

configuring the station.

Click on the “Run n” name

to call up pages for

configuring the meter run.

configuring the

Figure 3-2. Selecting the Site, Stations, and Runs

Issued: May-2012 Configuring Stations and Runs (Measurement Tab) 3-3

Page 50

ControlWave MRMS-IC Configuration Manual (D5140)

3.2.1 Site Configuration Data Tab (Site Configuration)

The Site Configuration Data tab shows basic information about the site.

Figure 3-3. Site Configuration data tab

Field Description

Site Name

Software

Program Name

Revision

PLC Firmware These fields refer to the ControlWave internal system

The site refers to the geographical location or an

organizational name associated with this MRMS-IC

controller. You might name the site after the RTU

node name or a place. Enter a name and press the

[Enter] key to save your entry.

This read-only field shows the name of the MRMS-IC

software installed on the RTU.

This read-only field shows the revision of the MRMSIC software running on the RTU.

The revision is in the format V.v Rnn

Where:

V is the major version number

v is the minor version number

Rnn is the revision build number, if this is

a revision release of the software.

firmware that controls operation the ControlWave

Micro.

3-4 Configuring Stations and Runs (Measurement Tab) Issued: May-2012

Page 51

ControlWave MRMS-IC Configuration Manual (D5140)

r

r

Major

Minor

OBSI Version Reserved for future use.

Load Versions The load version fields let you compare the revisions of

RAM: Name

RAM: Date

BOOTFILE: Name

BOOTFILE: Date

Status This read-only field shows Match if the name and date

PLC Time This read-only field shows the current date and time

This read-only field shows the major revision numbe

of the system firmware running in the ControlWave

Micro.

This read-only field shows the minor revision numbe

of the system firmware running in the ControlWave

Micro.

the ControlWave project stored in flash (ControlWave

bootproject) and the revision of the ControlWave

project currently executing in SDRAM.

This read-only field shows the name of the

ControlWave project executing in the ControlWave

Micro’s SDRAM.

This read-only field shows the date and time stamps of

the ControlWave project executing in the ControlWave

Micro’s SDRAM. Dates use the format mm/dd/yyyy

where mm is the two-digit month (01 to 12), dd is the

two-digit day (01 to 31), and yyyy is the four-digit year.

Timestamps are in the format hh:mm:ss where hh is

the 2-digit hour (0 to 23), mm is the 2-digit minute (0 to

59) and ss is the two-digit second (0 to 59).

This read-only field shows the name of the

ControlWave bootproject stored in FLASH at the

ControlWave Micro.

This read-only field shows the date and time stamps of

the ControlWave bootproject stored in FLASH at the

ControlWave Micro. Dates use the format mm/dd/yyyy

where mm is the two-digit month (01 to 12), dd is the

two-digit day (01 to 31), and yyyy is the four-digit year.

Timestamps are in the format hh:mm:ss where hh is

the 2-digit hour (0 to 23), mm is the 2-digit minute (0 to

59) and ss is the two-digit second (0 to 59).

of the ControlWave project executing in SDRAM is

identical to that for the bootproject stored in FLASH.

If this field shows Mismatch this indicates that the

ControlWave project executing in SDRAM is not the

same as the bootproject.

This is an error condition because if the unit restarts for

any reason, the bootproject overwrites the project

executing in SDRAM on restart and you will lose the

SDRAM project.

stamps of the ControlWave Micro’s real time clock.

Dates use the format mm/dd/yyyy where mm is the

two-digit month (01 to 12), dd is the two-digit day (01 to

31), and yyyy is the four-digit year. Timestamps are in

the format hh:mm:ss where hh is the 2-digit hour (0 to

23), mm is the 2-digit minute (0 to 59) and ss is the

two-digit second (0 to 59).

Issued: May-2012 Configuring Stations and Runs (Measurement Tab) 3-5

Page 52

ControlWave MRMS-IC Configuration Manual (D5140)

PLC Identification This read-only field identifies boot PROM firmware

Power These fields show information about power status at

installed in the ControlWave Micro. To use the

MRMS-IC application, your boot PROM firmware

must have the prefix CWM.

the ControlWave Micro.

DC

Detected I/O These fields show the types of I/O modules detected

Slot n

Total Points These fields show the total number of different types of

AIs

AOs

DIs

DOs

HSCs

RTDs

TCs

This read-only field shows the DC voltage level at

the ControlWave Micro’s power supply sequencer

module (PSSM).

by the MRMS-IC as being installed in the ControlWave

Micro.

This read-only field shows details of the installed I/O

module that the MRMS-IC detects in this ControlWave

Micro slot. The slot number from 1 to 14 refers to slots

in the base and expansion housings.

I/O points from all the I/O modules detected by the

MRMS-IC application.

This read-only field shows the total number of analog

inputs residing across all I/O modules detected by the

MRMS-IC application.

This read-only field shows the total number of analog

outputs residing across all I/O modules detected by the

MRMS-IC application.

This read-only field shows the total number of discrete

inputs residing across all I/O modules detected by the

MRMS-IC application. Note: This count includes all

possible DIs, including a DI/DO point configured as a

DO.

This read-only field shows the total number of discrete

outputs residing across all I/O modules detected by the

MRMS-IC application. Note: This count includes all

possible DOs, including a DI/DO point configured as a

DI.

This read-only field shows the total number of high

speed counter inputs residing across all I/O modules

detected by the MRMS-IC application.

This read-only field shows the total number of

resistance temperature device inputs residing across

all I/O modules detected by the MRMS-IC application.

This read-only field shows the total number of

thermocouple inputs residing across all I/O modules

detected by the MRMS-IC application.

3-6 Configuring Stations and Runs (Measurement Tab) Issued: May-2012

Page 53

ControlWave MRMS-IC Configuration Manual (D5140)

3.2.2 MVT Common Settings Tab (Site Configuration)

This page configures details for the multivariable transmitter/transducer

(MVT).

Figure 3-4. MVT Common Settings tab

Field Description

Collect Process

Variable (PV) Data

every msecs

Collect Diagnostic Data

every msecs

Indicate

Communications

Failure when No

Response after

msecs

Maximum Monitor

Count

Enter how often (in milliseconds) the ControlWave

Micro should collect process variable (PV) data. For

natural gas measurement in custody transfer

applications, the API requires updates no less

frequent than 1.0 seconds (1,000 milliseconds). The

ControlWave Micro can communicate with up to

eight (8) MVTs per second using a single RS-485

port at 19,200 baud. Press the [Enter] key to save

your entry.

Enter how often to collect diagnostic data from the

MVT (in milliseconds). You should not set the

interval of this collection to be very short, because it

may interfere with the higher priority PV data

collection. Press the [Enter] key to save your entry.

Enter the period (in milliseconds) that the MRMS-IC

application waits before declaring that a loss in

communications to the MVT constitutes a

communications timeout.

Enter the maximum number of polls that the MRMS-IC

application uses to count good/bad polls and

determine the %good.

Issued: May-2012 Configuring Stations and Runs (Measurement Tab) 3-7

Page 54

ControlWave MRMS-IC Configuration Manual (D5140)

3.2.3 Station Summaries Tab (Site Configuration)

Figure 3-5. Station Summaries tab