Page 1

ControlWave Designer Programmer’s Handbook

ControlWave™ Designer Programmer’s

Handbook

D301426X012

January 2022

Remote Automation Solutions

Page 2

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

Application Safety Considerations

Protecting Operating Processes

A failure of this application – for whatever reason – may leave an operating process without appropriate

protection and could result in possible damage to property or injury to persons. To protect against this, you

should review the need for additional backup equipment or provide alternate means of protection (such as alarm

devices, output limiting, fail-safe valves, relief valves, emergency shutoffs, emergency switches, etc.).

CAUTION

When implementing control using this product, observe best industry practices as suggested by applicable and

appropriate environmental, health, and safety organizations. While this product can be used as a safety component in

a system, it

NOT intended or designed to be the ONLY safety mechanism in that system.

2 Contents

Page 3

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

Contents

Introduction ..................................................................................................................... 1

ControlWave Product Line 1

Manuals You Should Read Before You Read This One 1

What is Covered in this Manual? 1

What Related Documentation is Available? 2

ACCOL III Function Block Library ........................................................................................ 5

Alarm Configuration ......................................................................................................... 9

What are Alarms? 9

Where can I get detailed information about these function blocks? 11

Configuring an Analog Alarm 12

Using the ALARM_ANALOG function block 13

Configuring a Logical Alarm 17

Using the ALARM_LOGICAL_ON function block 17

Configuring a Change of State Alarm 19

Application Licensing ...................................................................................................... 23

Granting a License for a Controller to Run a Standard Application 23

Removing an Application License from a Controller: 24

Viewing a History of Dongle Issue / Remove Operations: 25

Application Parameters ................................................................................................... 27

Archive Configuration ..................................................................................................... 29

What Are Archive Files? 29

Archive configuration involves four basic steps: 30

What can be done with the data from the Archive File(s)? 31

Step 1. Define Archive Files(s) in the Flash Configuration Utility 31

Step 2. In Your ControlWave Designer Project, Identify the variables you want to archive in the

Archive List 36

Step 3. Create an Output List for Accessing the Most Recent Archive Record (OPTIONAL) 37

Step 4. Configure the ARCHIVE Function Block 38

Array Configuration ......................................................................................................... 41

Audit Configuration ........................................................................................................ 43

Step 1. Set parameters in the Flash Configuration Utility 43

Step 2. In ControlWave Designer, identify Variables for which you want to maintain Audit Logging46

Step 3. Configure an AUDIT Function Block 47

BSAP Addressing and Networks ....................................................................................... 49

What is BSAP? 49

Adding A ControlWave to an OpenBSI BSAP Network in the RTU Wizard 51

Setting the BSAP Local Address and EBSAP Group 52

What is Client/Server Communication? 53

BSAP - Underlying Technical Details (For ADVANCED USERS) 53

BSAP Master Port ............................................................................................................ 55

Configuring A BSAP Master Port 56

BSAP Slave Port ............................................................................................................... 61

Configuring a BSAP Slave Port 61

Communication Ports ..................................................................................................... 67

Contents iii

Page 4

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

How do I configure the Ports on the ControlWave? 81

What are the factory default settings for communication ports? 81

How can the port configuration be changed? 92

Dialing - An Overview 92

Serial Port Sharing between the BSAP Slave and Custom Slave Protocols: 92

Compiling ....................................................................................................................... 95

Conditional Logic ............................................................................................................ 97

DataView ...................................................................................................................... 101

Before you begin: 101

Calling up ControlWave Data in DataView 102

Debugging – An Overview ............................................................................................. 105

Starting Debug Mode 105

Using the Watch Window 105

Using the Cross-Reference Window 107

On-line Editing with Patch POU 108

Using the Force/Overwrite Options 109

Setting a Breakpoint 110

Exiting Debug Mode 112

Downloading ................................................................................................................ 113

Two Methods Available for Downloading 113

Downloading from within ControlWave Designer 114

Downloading Your ControlWave Project from Within ControlWave Designer 117

Downloading using the OpenBSI ControlWave Downloader 119

Starting the ControlWave Downloader 121

Using the ControlWave Downloader 122

Creating Download Scripts for Batch Downloading of ControlWave Controllers 123

Expanded BSAP (EBSAP) Communications ..................................................................... 127

Expanded BSAP – The Concept 128

General Requirements for Expanded BSAP (EBSAP): 129

Creating an EBSAP Master 130

OpenBSI Workstation is EBSAP Master 130

ControlWave-series Controller is the EBSAP Master 131

Configuring the Control and Status Arrays 132

Defining the Virtual Nodes 141

Defining the EBSAP Slave Nodes 142

Example 1 – OpenBSI Workstation is EBSAP Master to 1000 ControlWave controllers 143

Example 2 – ControlWave Controller is EBSAP Master to 300 ControlWave EBSAP Slaves 146

Flash Configuration Utility – An Overview ...................................................................... 149

Starting the Flash Configuration Utility 149

Flash File Access ............................................................................................................ 155

Viewing a List of Files in the Flash File Area: 156

Uploading a File from the ControlWave to Your OpenBSI Workstation: 156

Copying a File from the OpenBSI Workstation to Your ControlWave: 157

Deleting a File from the ControlWave User Flash Files Area: 157

Refreshing the List of Files: 158

Function Blocks – Creating ............................................................................................ 159

Function Block Parameter Name Prefixes ....................................................................... 165

Historical Data .............................................................................................................. 167

iv Contents

Page 5

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

What is Historical Data Used For? 167

What types of Historical Data can be saved in the ControlWave Controller? 167

How is Audit Trail and Archive Data Retrieved from the ControlWave Controller? 168

I/O Configurator............................................................................................................ 169

Tables of Board Types 174

Analog Boards 179

Digital Boards 183

High Speed Counter (HSC) Boards 185

Remote I/O Status Board 186

System Controller Board 186

CWM_RTU Board 187

Notes About Ethernet I/O Boards 187

HART Interface Board (CWM_HIB) 193

I/O Mapping .................................................................................................................. 197

Common Device Map 197

Local I/O - ControlWave 198

Ethernet I/O 206

ControlWave I/O Expansion Rack Boards 218

Local I/O – ControlWave MICRO-series 229

Local I/O – ControlWave GFC-CL and ControlWave XFC 242

Local I/O – ControlWave Express and ControlWave GFC 248

Local I/O – ControlWave CW10, CW30, CW35 256

I/O – ControlWave CW_31 261

ControlWave MICRO I/O Expansion Rack 269

I/O Simulator ................................................................................................................ 283

What is the I/O Simulator? 283

Starting the I/O Simulator 283

Analog Boards 287

Digital Boards 288

Counter Boards 288

Viewing the Board Configuration Status 289

Configuring a Pin 289

Viewing Simulated Alarms 290

Shutting Down the I/O Simulator 290

Troubleshooting Tip 290

IP Addressing and Networks .......................................................................................... 293

What is the Format of IP Addresses? 293

Adding a ControlWave to an IP Network with the RTU Wizard 298

Setting up IP Ports in the Flash Configuration Utility 299

Recommended Ranges for IP Addresses 299

IP Parameters ................................................................................................................ 301

IP Ports - Ethernet ......................................................................................................... 307

IP Ports – PPP ................................................................................................................ 309

IP Routes ....................................................................................................................... 311

Libraries ........................................................................................................................ 315

Memory Usage .............................................................................................................. 319

Some Background - What is Memory? 319

What is Downloading? 319

Types of Memory in the ControlWave Process Automation Controller (CW PAC) 320

Contents v

Page 6

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

What happens in the event of a power failure or the power switch is turned off? 323

What happens in the event of a watchdog condition? 323

What happens on restart after a power failure or watchdog? 324

Variations when using ControlWave MICRO/EFM 327

Variations when using ControlWave GFC/GFC-CL, XFC, Corrector, Express or ExpressPAC 328

Variations when using ControlWave_10/ _30/ _35 (CW_10, CW_30, CW_35) 329

Memory Allocation Issues 330

Determining POU Size at Compilation Time 330

Resolving “Not Enough Memory” Messages 330

Modbus Configuration .................................................................................................. 335

Configuring Your ControlWave Controller as a Modbus Master Device 335

Configuring Your ControlWave Controller as a Modbus Slave or Enron Modbus Slave Device 339

Modbus Ports ................................................................................................................ 341

Configuring Modbus Ports 341

Reset ControlWave Utility ............................................................................................. 343

Security ........................................................................................................................ 345

Other Security-Related Issues 351

Security Protocols (CHAP and PAP) ................................................................................ 355

Security Protocols (CHAP and PAP) Used on PPP Links 355

Challenge Handshaking Authentication Protocol (CHAP) 355

Password Authentication Protocol (PAP) 358

System Tasks (Warm/Cold Starts) .................................................................................. 361

System Variables ........................................................................................................... 363

Using the System Variable Wizard 363

System Variable Mapping Charts 367

Static Memory Area: 393

Using the System Variable Viewer 396

Variable Extension Wizard ............................................................................................. 399

Before You Begin 399

Starting the Variable Extension Wizard 399

Using the Variable Extension Wizard 400

Marking a Variable for Report by Exception (RBE) Collection 403

Configuring a Variable as an Alarm 404

Creating / Editing a List 406

Setting initial values for Manual or Alarm Inhibit/Enable Flags 408

Assigning Units Text (Analog Variables ONLY) 409

Assigning ON/OFF Text (BOOL Variables ONLY) 410

Creating Descriptive Text for the Variable 411

Saving the Initialization Files and Exiting the Wizard 412

Format of Initialization Files 412

Troubleshooting Tips 417

Variables and Data Types .............................................................................................. 419

Global Variables Vs. Local Variables 419

Variable Addressing 420

System Variables 421

Data Types 421

Notes about STRING variables ......................................................................................................... 422

Variable Naming Conventions ....................................................................................... 423

vi Contents

Page 7

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

Versions and Compatibility ............................................................................................ 425

Virtual Ports .................................................................................................................. 441

VSAT Slave Port – Configuration .................................................................................... 443

Configuring Flash Parameters 443

Configuring System Variables 444

VSAT Master Ports 446

Web Pages – Notes About Using .................................................................................... 447

Other Notes About Using Web Pages 448

Calling Up Web_BSI Pages 449

Creating Your Own Web Pages to Use with the ControlWave 451

Appendix A: Troubleshooting Tips ................................................................................. 453

Using the Debug Information Tool 458

Other Debugging Tools (BTCP Spy, DLM Monitor) 462

Appendix B: ControlWave Designer Compatibility Issues ................................................ 463

Bringing an Older ControlWave Project into a Newer Version of ControlWave Designer 463

Warning - I/O Configurator and Multiple Copies of ControlWave Designer 464

Index .......................................................................................................................... 465

Contents vii

Page 8

Page 9

Introduction

ControlWave Product Line

Unless otherwise noted, the information in this manual applies to any controller in the

ControlWave product line, including:

ControlWave Process Automation Controller

ControlWave Low Power (LP) Controller

ControlWave Redundant Controller

ControlWave MICRO Controller

ControlWave Electronic Flow Meter (EFM)

ControlWave Gas Flow Computer (GFC)

ControlWave Gas Flow Computer Plus (GFC Plus)

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

ControlWave Explosion-Proof Gas Flow Computer (XFC)

ControlWave Express / Express Process Automation Controller

ControlWave Corrector

Manuals You Should Read Before You Read This One

Before you read this document, we strongly recommend you read, and try out, the

example presented in the Getting Started with ControlWave Designer Manual (part

number D301416X012). It is designed to explain various concepts to first-time

ControlWave users.

In addition, please review the quick setup guide for your particular controller (see next

page for the proper document) which contains notes about how to initially set up your

ControlWave Controller, and how to configure certain parameters for first-time use.

The ControlWave Designer Programmer’s Handbook (which you are reading right now)

builds on the information contained in these other documents, so it is essential that you

are familiar with the material included in them.

What is Covered in this Manual?

The ControlWave Designer Programmer’s Handbook is intended to provide you the

information you need to get the most out of your ControlWave Designer software. It

includes:

Introduction 1

Page 10

ControlWave Designer Programmer’s Handbook

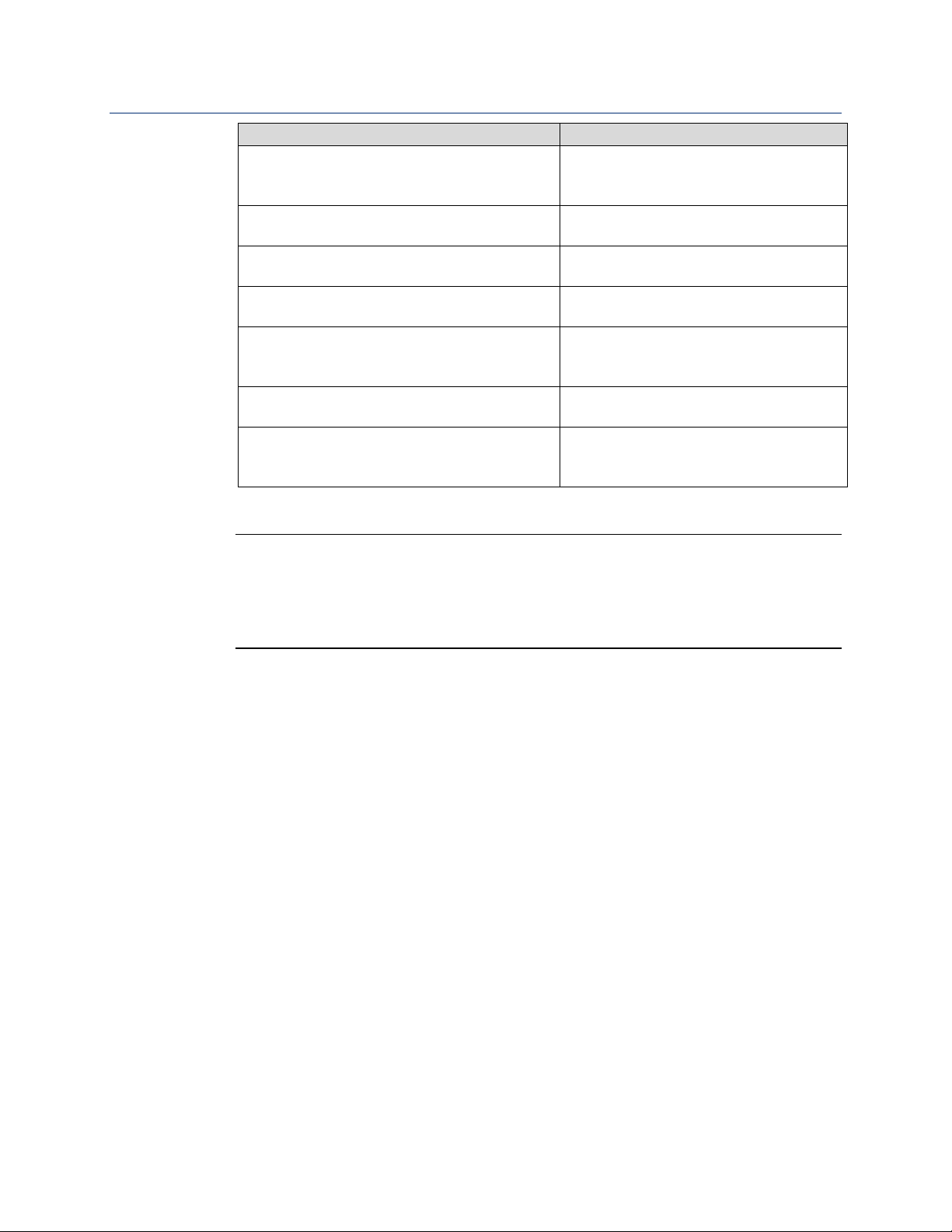

For information on this…

Please consult this…

ControlWave Designer

Getting Started with ControlWave Designer

IEC 61131 terminology and languages

Online help in ControlWave Designer,

Flash Configuration

Chapter 5 of the OpenBSI Utilities Manual

Web Pages

Web_BSI Manual (part number

Converting ACCOL II source files (*.ACC)

ACCOL Translator User’s Guide (part number

ControlWave Process Automation

ControlWave Quick Setup Guide (part number

ControlWave Low Power (LP) Controller

ControlWave LP Quick Setup Guide (part

ControlWave I/O Expansion Rack

ControlWave I/O Expansion Rack Quick Setup

ControlWave Redundant Controller

ControlWave Redundancy Setup Guide (part

ControlWave Gas Flow Computer (GFC)

ControlWave Gas Flow Computer (GFC)

D301426X012

January 2022

Examples of how to configure various sub-systems of ControlWave software, which

are commonly required in process control applications, such as: alarming, and

historical data collection.

Instructions for how to create your own function blocks, and how to create a library of

them, so they can be re-used in other projects.

Notes about how to use OpenBSI, and BSAP, or IP, to include your ControlWave in a

network.

Explanations about how ControlWave memory works, and how I/O points can be

configured.

Discussions of communication options, as well as how to download your ControlWave

project into the ControlWave controller.

What Related Documentation is Available?

(part D301416X012)

Projects, Project Tree, POUs, Tasks,

Resources

ACCOL3 library

PROCONOS library

ActiveX controls used with ControlWave

into ControlWave Projects

Controller

ControlWave MICRO Controller ControlWave Micro Quick Setup Guide (part

ControlWave Electronic Flow Meter (EFM) ControlWave Electronic Flow Meter (EFM)

accessible through the question mark [?]

menu item.

(part number D301414X012) contains full

details on flash configuration.

D301418X012).

D301417X012)

D301415X012)

number D301422X012)

Guide (part number D301423X012)

number D301424X012).

number D301425X012)

Instruction Manual (part number

D301383X012)

2 Introduction

Instruction Manual (part number

(D301387X1012)

Page 11

ControlWave Designer Programmer’s Handbook

For information on this…

Please consult this…

ControlWave Explosion-Proof Gas Flow

ControlWave Explosion-Proof Gas Flow

ControlWave Express

ControlWave Express RTU Instruction Manual

ControlWave Express PAC

ControlWave Express PAC Instruction Manual

ControlWave Corrector

ControlWave Corrector Instruction Manual

ControlWave Gas Flow Computer Plus

ControlWave Gas Flow Computer Plus

ControlWave Ethernet I/O

ControlWave Ethernet I/O Instruction Manual

D301426X012

January 2022

Computer (XFC)

ControlWave Industrial Ethernet Real

Time Switches

Computer (XFC) Instruction Manual (part

number D301396X012)

(part number D301386X012)

(part number D301384X012)

(part number D301382X012)

Instruction Manual (part number

D301389X012)

(part number D301395X012)

ControlWave Industrial Ethernet Real-time

Switches Instruction Manual (part number

D301390X012)

Note:

Because the existing ControlWave install-base includes customers with older hardware

and software, for support purposes this manual includes references to older un-supported

operating systems and devices.

Introduction 3

Page 12

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

4 Introduction

Page 13

ControlWave Designer Programmer’s Handbook

Function block or

Minimum Firmware

Description

AGA3

2.00.00

Computes natural gas volume flow rate through an orifice plate in

Computes mass and volume flow rate for fluids (gases or liquids) in

AGA3I

1.00.00

Computes natural gas volume flow rate according to the Factors

AGA3SELECT

5.50.00

Combines the functions of the AGA3I and AGA3TERM function

AGA3TERM

2.00.00

Computes natural gas volume flow rate through an orifice plate in

AGA5

2.00.00

Performs AGA-5 calculations for conversion of computed gas

AGA7

2.00.00

Performs AGA-7 calculations for base volume rate.

AGA8_DET2017

6.00.00

Computes Base compressibility, Flowing compressibility and

AGA8DETAIL

2.00.00

Computes Base compressibility, Flowing compressibility and

AGA8_GRS2017

6.00.00

Computations for natural gas mixtures according to the Gross

ACCOL III Function Block Library

The ACCOL III Function Block Library is a set of functions and function blocks created by

Emerson and included with ControlWave Designer. ACCOL III function blocks are designed

to provide ControlWave Designer with the capabilities of ACCOL II modules used in our

previous ACCOL II language. This library also includes several newer functions which were

not available in ACCOL II.

Note

Other function block libraries are available for liquids calculations, and NIST23 calculations.

Contact Emerson Remote Automation Solutions division for more information.

For instructions on how to use any of these function blocks, please consult the online help

in ControlWave Designer.

D301426X012

January 2022

Function

AGA3DENS 4.10.00

Revision Required

thousands of cubic feet per hour (MSCFH) according to American

Gas Association (AGA) Report #3 1985 Edition.

lbs/hour and cubic ft per hour, for orifice plates, with flange taps

ONLY, according to the method explained in the American Gas

Association (AGA) Report #3 of August, 1992, 3rd Edition (Part 1

and Part 4).

Method in AGA Report #3.

blocks into a single function block.

thousands of cubic feet per hour (MSCFH) according to AGA

Report #3 1985 Edition. Allows factor substitution and display.

volume to energy equivalents.

Supercompressibility for natural gas mixtures, according to the

Detail Characterization Method in the 2017 AGA Report 8 Part 1.

AGA8GROS 1.00.00 Computations for natural gas mixtures according to the Gross

ACCOL III Function Block Library 5

Supercompressibility for natural gas mixtures, according to the

Detail Characterization Method in AGA Report 8.

Characterization method in AGA Report 8.

Characterization method in the 2017 AGA Report 8 Part 1.

Page 14

ControlWave Designer Programmer’s Handbook

Function block or

Minimum Firmware

Description

AGA8_PART2

6.00.00

Performs calculations specified by 2017 AGA Report 8 Part 2,

AGA10

4.50.00

Computations for natural gas mixtures according to AGA Report

ALARM

4.70.00

Used to batch process alarms defined in the Variable Extension

ALARM_ANALOG

1.00.00

Monitors a process variable and sends a notification message to a

ALARM_LOGICAL_ON

1.00.00

Monitors a Boolean process variable and sends a notification

ALARM_LOGICAL_OFF

1.00.00

Monitors a Boolean process variable and sends a notification

ANOUT

1.00.00

Converts and scales signals for hardware analog output.

ARCHIVE

1.00.00

Provides historical storage of signal values.

ARRAY_ANA_GET

4.50.00

Function. Returns the REAL value of the specified array element.

ARRAY_ANA_SET

4.50.00

Function. Writes a REAL value to the specified array element.

ARRAY_LOG_GET

4.50.00

Function. Returns the BOOL value of the specified array element.

ARRAY_LOG_SET

4.50.00

Function. Writes a BOOL value to the specified array element.

AUDIT_SELECTED

5.40.00

Allows you to log events for value changes of individual variables or

AUTOADJUST

2.00.00

Performs adjusted volume and self check calculations for an

BTI

4.70.00

Allows CW_10, CW_30, and CW_35 controllers with the BBTI

CALC_DENSITY

June 22, 2009 library or

Calculates the mass density of a gas using the real gas relative

CLIENT

2.00.00

Communicates with other ControlWave controllers that have

COMMAND

1.00.00

Pulse Delayed Output.

COMPARATOR

1.00.00

Analog signal comparison.

CRC

2.00.00

Calculates CRC of data stored in an array.

CUSTOM

1.00.00

Custom Communications Interface.

DACCUMULATOR

1.00.00

Performs Double Precision Arithmetic.

DEMUX

1.00.00

Copies a signal value into a list of signals.

D301426X012

January 2022

Function

ALARM_STATE 1.00.00 Monitors a Boolean process variable and sends a notification

Revision Required

Thermodynamic Properties of Natural Gas and Related Gases,

GERG–2008 Equation of State.

Number 10.

Wizard.

remote computer when the variable’s value exceeds user defined

limits.

message to a remote computer when the variable is TRUE.

message to a remote computer when the variable is FALSE.

message to a remote computer when the variable changes state.

AUDIT 1.00.00 Provides historical storage of alarms and events.

log customized events. The customized events can include

standard value change information, alternate values, or NOTE

events. You can use the AUDIT_SELECTED FB independently of the

AUDIT FB.

Invensys Auto-adjust Turbine Meter.

AVERAGER 1.00.00 Computes the time-average and integral.

board to collect data from the Bristol TeletransTM Model 3508

Transmitter.

newer.

DB_LOAD 4.00.00 Loads variable information (LISTS) from a text file.

density (specific gravity)

implemented the Server Function Block.

DIAL_CTRL 4.00.00 Establishes a dial-up connection on a given port, or interface to a

6 ACCOL III Function Block Library

Page 15

ControlWave Designer Programmer’s Handbook

Function block or

Minimum Firmware

Description

modem.

DIFFERENTIATOR

1.00.00

Differentiates an analog signal.

DISPLAY

4.20.00

Provides support for the keypad display.

ENCODE

1.00.00

Set/Read System Time, Julian /Wall Time Conversions.

EVP

4.50.00

Calculates the equilibrium vapor pressure for a liquid.

FIELDBUS

5.10.00

Interfaces with Foundation Fieldbus devices via a bridge server.

FILE_CLOSE

2.20.00

Function – End access to a flash file.

FILE_DELETE

2.20.00

Function – Remove a file from flash.

FILE_OPEN

2.20.00

Function – Start access to an existing flash file or create a new one.

FILE_READ_STR

2.20.00

Function – Read a line from a file and load into a string.

FILE_WRITE

2.20.00

Function – Send a buffer of binary data to a flash file.

FILE_WRITE_STR

2.20.00

Function – Send a formatted string to a flash file.

FPV

2.00.00

Computes Super Compressibility Factor (FPV) of a gas per AGA

GENERIC_SERIAL

2.00.00

Generic Serial communications serves as a means to buffer user

GPA8173

4.50.00

Converts the mass of natural gas liquids to equivalent liquid

GSV

4.50.00

Converts the gross standard volume for a liquid.

HART

5.00.00

Interface to HART field devices via serial port or I/O board.

HILOLIMITER

1.00.00

Compares a signal against a high and low limit.

HILOSELECT

1.00.00

Finds highest and lowest REAL values in a signal list.

HSCOUNT

1.00.00

High Speed Counter.

HWSTI

4.80.00

Honeywell Smart Transmitter Interface

IEC62591

5.50.00

Allows a ControlWave Micro controller with an IEC62591 Interface

INTEGRATOR

1.00.00

Computes an integral approximation.

ISO5167

2.00.00

Calculates flow rate for Orifice plates, Nozzles, Venturi tubes, and

LEAD_LAG

1.00.00

Adds a controlled delay effect.

LICENSE

4.90

Determines application licenses for the RTU.

LIQUID_DENSITY

4.50.00

Calculates the density of liquid at flowing conditions.

LISTxxx

1.00.00

Define/Expand a list.

MUX

1.00.00

Extracts the value of a signal from a list of signals

PDO

1.00.00

Pulse Duration Output.

PID3TERM

1.00.00

3 Mode PID Control.

PORTATTRIB

4.40.00

Allows the user to set the port characteristics online (except for the

PORT_CONTROL

4.20.00

Communications port manual control.

D301426X012

January 2022

Function

FILE_DIR 2.20.00 Function Block – Get a listing of files. Retrieve file attributes.

FILE_READ 2.20.00 Function – Read binary data from file.

FUNCTION 1.00.00 Table lookup and interpolation with arrays.

Revision Required

Report NX-19.

defined data through a serial port.

volumes at base conditions.

LIST_ELE_NAME 3.00.00 Returns the variable name for a given list element.

ACCOL III Function Block Library 7

module to communicate to IEC62591 wireless devices.

Venturi-nozzle Primary Devices per ISO 5167-1980 (E), 1980

edition

MODE).

Page 16

ControlWave Designer Programmer’s Handbook

Function block or

Minimum Firmware

Description

R_INT

1.00.00

Function to Truncate to Integer.

RBE

4.40.00

Supports Report by Exception

REDUN_SWITCH

2.00.00

Function to perform programmed fail-over to Redundant Standby.

REG_ARRAY

1.00.00

Register Arrays – For HMI Access.

SCHEDULER

3.00.00

Equalizes the elapsed running time of a number of external

SEQUENCER

1.00.00

Provides sequential output control.

SERVER

2.00.00

Communicates with other ControlWave controllers that have

STEPPER

1.00.00

Sequence up to 255 Boolean Outputs.

STORAGE

04.40

Stores and retrieve historical data.

TCHECK

4.70.00

Provides status checking and data processing for a 3508 Teletrans

USERS_ACTIVE

5.20

Returns information on all currently signed-in users.

USERS_DEFINED

5.20

Allows encrypted access to the security configuration of the

V_ATTRIB_GET

04.50

This function returns the value of the specified attribute of a

V_ATTRIB_SET

04.50

This function sets the value of the specified attribute of a variable.

VAR_ATTRIB_GET

2.10.00

Retrieves the value of an attribute for a variable.

VAR_ATTRIB_SET

2.10.00

Sets the value of an attribute for a variable.

VAR_CI_PROC

2.10.00

Performs the CI (Control Inhibit) processing for the given variable.

VAR_FETCH

3.00.00

This function block fetches complete information about a variable

VAR_SEARCH

3.00.00

This function searches the PDD for variables, both with a given

VIRT_PORT

2.20.00

This function block creates a virtual port by defining a connection

VLIMIT

1.00.00

Limit an input’s rate of change.

VMUX

3.00.00

Extracts the value of a signal from a list of signals and ramps the

WATCHDOG

5.60

Activates a watchdog output based on user-defined criteria.

XMTR

4.70.00

Provides read/write access to the memory of a TeleTrans

D301426X012

January 2022

Function

R_RND 1.00.00 Function to Round to nearest Integer.

RBE_DISABLE 5.60.00 Disables selected RBE variables to prevent RBE reporting from

TOT_TRND 1.00.00 Computes totals from input and slope of input.

Revision Required

them.

devices.

implemented the Client Function Block.

Transmitter.

ControlWave.

variable.

given its name.

index, and by name.

to a terminal server.

output to match the input.

Transmitter, or other compatible device.

8 ACCOL III Function Block Library

Page 17

Alarm Configuration

What are Alarms?

Alarms are messages generated by the controller

when one or more process variables changes, and

that change violates some pre-defined limit or state.

There are three types of alarms:

Analog Alarms– These alarms are generated when

an analog variable (type REAL, INT, etc.) exceeds a

pre-defined

message is generated when the variable returns to

within the pre-defined limit.

established around the alarm limits so that variables

can fluctuate slightly near the alarm limit without

constantly going into and out of an alarm state, and

thereby flooding the system with repetitive alarms.

Analog alarms are configured using the

ALARM_ANALOG function block.

alarm limit. A return-to-normal

Deadbands can be

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

Logical Alarms – These alarms are generated when a

variable of type BOOL enters its 'in-alarm' state. A

return-to-normal message is generated when the

variable returns to its opposite (non-alarm) state The

user chooses which state is the 'in alarm' state by the

choice of alarm function block. If its 'in-alarm' state

occurs when the BOOL variable becomes TRUE, then

the ALARM_LOGICAL_ON function block should be

used. if the variable's 'in-alarm' state occurs when the

BOOL variable becomes FALSE, then the

ALARM_LOGICAL_OFF function block should be used.

Note: The ALARM_LOGICAL_ON and

ALARM_LOGICAL_OFF function blocks are identical

except that the ALARM_LOGICAL_ON function block

generates an alarm when the associated process

variable (iaAlarmVar) is TRUE, whereas the

ALARM_LOGICAL_OFF function block generates an

alarm when the associated process variable

(iaAlarmVar) is FALSE.

Alarm Configuration 9

Page 18

ControlWave Designer Programmer’s Handbook

Alarm Variable

This is the actual process variable which is to be monitored by the alarm

Alarm Priority

The alarm priority is basically a number which indicates the importance

Priority

Value

Meaning

Operator

1

Operator guide alarms are used to indicate everyday

Non-Critical

2

Non-critical alarms are used to indicate problems,

Critical

3

Critical alarms are used to indicate dangerous

Descriptive

Text

Up to 64 characters of descriptive text may be stored along with any

Disable

Alarm processing for a particular process variable can be turned OFF.

Status

Every alarm function block maintains error and status information.

D301426X012

January 2022

Change-of-State Alarms – These alarms are

generated whenever a variable of type BOOL

changes state. In this case, there is no such thing as

a return-to-normal condition. Change-of-State

alarms are configured using the ALARM_STATE

function block.

All three types of alarms have various inputs and

outputs associated with them. These inputs and

outputs are configured within the alarm function

block. The following information is common to all

three types of alarms:

function block. Analog (REAL, INT, etc.) can only be monitored via the

ALARM_ANALOG function block. Boolean variables can be monitored

by either the ALARM_LOGICAL_ON, ALARM_LOGICAL_OFF, or

ALARM_STATE function block(s).

of the alarm. There are four priorities supported in the system:

Event 0 Event alarms are used to indicate normal, everyday

occurrences.

Guide

occurrences which are slightly more important than

events.

which, while not serious enough to cause damage to

a plant or process, require corrective action.

problems that require immediate attention and/or

corrective action.

The choice of which alarm priorities are to be assigned to a particular

alarm variable is entirely at the discretion of the user.

alarm message. This text may be changed dynamically by control logic.

This prevents any alarm messages for that process variable from being

generated. This might be used in the case of system maintenance or

troubleshooting.

Improper configuration is indicated by negative status values, and will

prevent execution of the alarm function block. Positive values indicate

the variable is in an alarm state. A value of ‘0’ indicates there are no

10 Alarm Configuration

Page 19

ControlWave Designer Programmer’s Handbook

configuration errors, and the variable is NOT in an alarm state. For a full

Alarm

Sequence #

An alarm sequence number is assigned to each alarm message to

Global

Sequence #

A global sequence number is assigned to each audit record, archive

D301426X012

January 2022

description of status values, see the on-line help files.

uniquely identify it within the Alarm System. Alarm sequence numbers

range from 0 to 65,535 and are shared among all alarm function blocks

in the alarm system to maintain proper ordering of messages.

record, or alarm message to uniquely identify it within the ControlWave

controller. Global sequence numbers range from 0 to 65,535 and are

shared by all of these sub-systems to maintain proper ordering of

messages.

The remaining inputs/outputs configured within the Alarm function block vary depending

upon the type of alarm function block being used.

Note

Some parameters in the alarm function block may not be required, depending upon your

specific application. In addition, if you do NOT intend to change the value of a particular

input value, and its parameter only supports a single data type (i.e., its parameter name

does NOT have an “ia” or “iany” prefix), you can enter it as a constant, instead of assigning

a variable name.

Alternatively, the OpenBSI Alarm Router can be used to view alarms, and offers an

interface to custom alarm applications. See the Open BSI Utilities Manual (part number

D301414X012) for information on Alarm Router.

Where can I get detailed information about these function blocks?

On-line help is provided within ControlWave Designer for every ACCOL3 function block. To

access this, you can right click on the ACCOL3 library icon, and choose

Library…” from the pop-up menu.

Important

This section describes the standard method for alarm configuration. Beginning with

OpenBSI Version 5.4, an alternate way to create alarms is to use the Variable Extension

Wizard and the ALARM function block for batch processing. The Variable Extension Wizard

configures the alarms in the controller, but they do NOT appear within your project. For

information on this method, see the Variable Extension Wizard section, later in this

manual.

“Help on ACCOL 3

Alarm Configuration 11

Page 20

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

Configuring an Analog Alarm

For this example, let’s say we have a tank full of water which must be maintained at a

certain temperature range. A temperature transmitter is mounted on the tank to measure

the current temperature of the water, and it has been decided that the water temperature

should be kept between 40.0

that range indicates an alarm condition.

The figure, below, shows a plot of the value of the variable measuring Celsius temperature

in the tank, as it fluctuates over time. Four alarm limits and two deadbands have been

defined. Starting from the left of the graph, the value of the variable increases until it

reaches 70.0

0

C, the high alarm limit (see Item 1). At this point a high alarm message is

generated, and the variable is considered to be in a ‘high alarm’ state.

The value of the variable continues to increase. When it passes the high-high alarm limit of

0

90.0

C a ‘high-high’ alarm message is generated (see Item 2). At this point, the variable is

considered to be in a high-high alarm state.

0

C and 70.00 Celsius. Any temperature reading outside of

The value of the variable then starts to decrease. Although the value passes below 90.0

it is still considered to be in a ‘high-high’ alarm state because there is a 10.0

0

high

0

C,

deadband in effect (deadbands are shown as shaded areas on the graph.) When the

variable value falls lower than 80.0

deadband of 10.0

0

C) the variable is no longer in a ‘high-high’ alarm state (See Item 3). It is

0

C point (90.00 C high alarm limit minus the high

still however in a ‘high’ alarm state.

12 Alarm Configuration

Page 21

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

As the value of the variable decreases below 70.00 C, it remains in a ‘high’ alarm state until

its value falls below 60.0

0

C (70.00 C alarm limit, minus a 10.00 C high deadband). (See Item

4). At this point, the variable is in its normal range, and a ‘return-to-normal’ alarm message

is sent.

Then, however, the value of the variable continues to drop. When it reaches 40.0

0

C, a ‘Low

Alarm’ message is generated (See Item 5).

The variable remains in a ‘Low Alarm’ state until the variable value drops to 20.0

0

C. (See

Item 6). This causes a ‘Low Low Alarm’ message to be generated.

The variable remains in a ‘Low-Low Alarm’ state until the variable rises above 30.0

0

(20.0

C low-low alarm limit plus low deadband of 10.00 C). (See Item 7). The variable is still

0

C,

in a ‘Low Alarm’ state, however.

Once the variable rises above 50.0

0

C (40.00 C low alarm limit + low deadband of 10.00 C), it

has left the low-alarm state, and a ‘return to normal’ alarm message is sent (See Item 8).

As long as the variable remains in the normal range (between 40.0 and 70.0

0

C), no more

alarm messages will be generated.

Using the ALARM_ANALOG function block

Where you insert your ALARM_ANALOG function block depends upon the overall

construction of your project:

The ALARM_ANALOG function block can only detect an alarm condition when it is executed.

Therefore, when constructing your project, you should think about how and when you

want to execute the function block.

You might choose to place the ALARM_ANALOG function block in the same POU which

holds primary control logic for the process variable. This is always required if the

variable being monitored is not global. Typically, the ALARM_ANALOG function block

would be placed at the end of the POU. If you require timestamps to reflect the exact

moment the alarm condition occurred, you could place the ALARM_ANALOG function

block immediately following the logic which manipulates the process variable.

Alternatively, you could place the ALARM_ANALOG function block in a separate POU,

which could even be executed at a different task interval. This approach may be

convenient if you want to organize your project such that all alarm function blocks are

in the same place.

Step 1. Following the considerations discussed above, insert an ALARM_ANALOG function

block into your program. A separate ALARM_ANALOG function block is required

for every analog variable you want to configure as an alarm.

Alarm Configuration 13

Page 22

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

Step 2. Based on our example of monitoring water temperature in a tank, assign

meaningful variable names, and where applicable, initial values to each of the

parameters of the ALARM_ANALOG function block.

The actual process variable being monitored for alarm conditions must be assigned

to the iaAlarmVar parameter. In this case we will call it WATER_TEMP since that is

the process I/O variable from the temperature transmitter.

Now we need to assign alarm limits and deadbands based on our previous discussion of

the proper range for the water temperature.

Important

You must use the same variable type for alarm limits and alarm deadbands as you use for

your alarm variable. For example, if the alarm variable is defined as type REAL, then every

alarm limit and alarm deadband for that ALARM_ANALOG function block must also be

defined as type REAL. Type mismatches of any kind will prevent the ALARM_ANALOG

function block from working and will generate errors on the odiStatus parameter.

14 Alarm Configuration

Page 23

ControlWave Designer Programmer’s Handbook

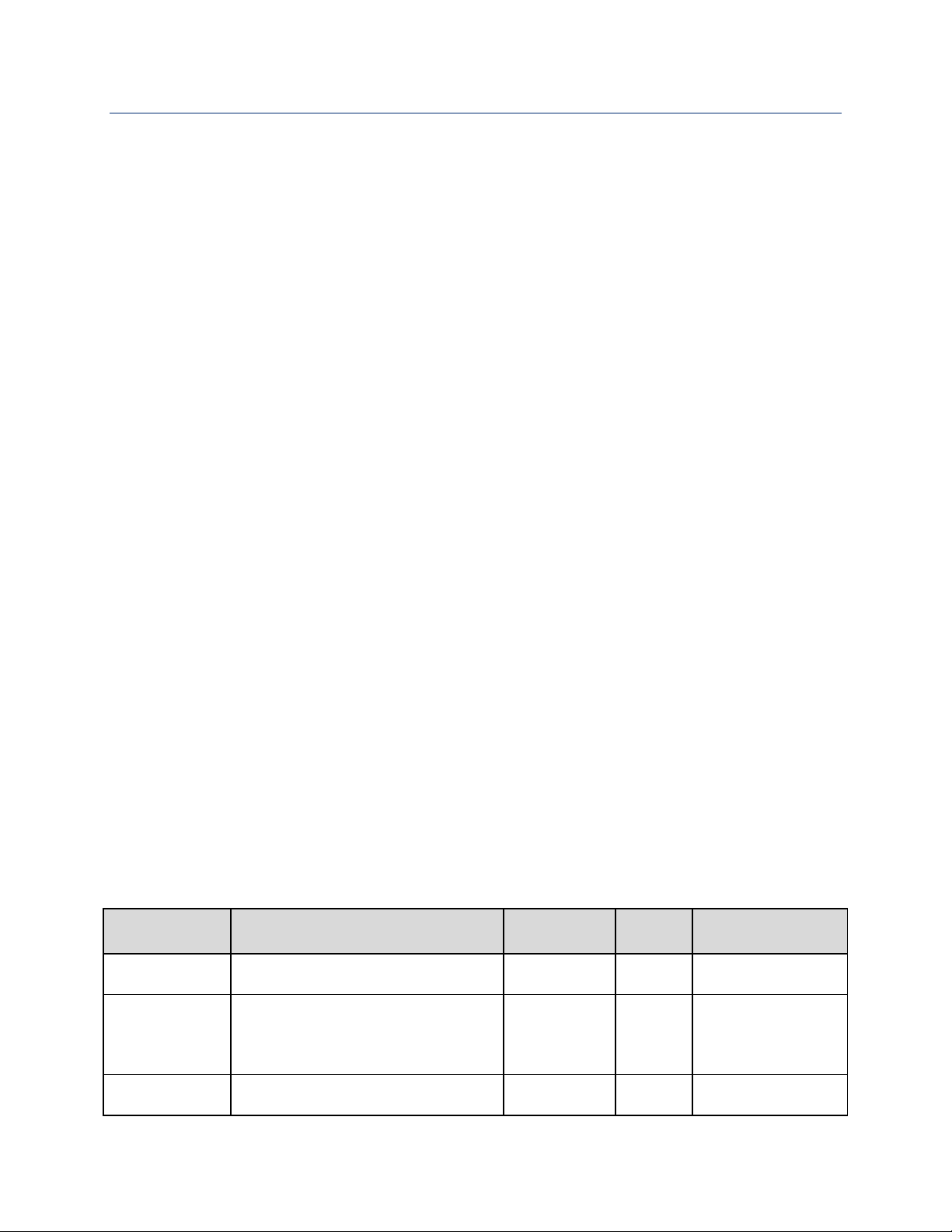

Parameter

Suggested Variable Name

Variable

Value

Notes

iaAlarmVar

WATER_TEMP

REAL, SINT,

None

The actual process

iaHiHiLimit

WATER_HH_LIMIT

REAL, SINT,

90.0

High-high alarm limit

Setting Alarm Limits (iaLoLimit, iaLoLoLimit, iaHiLimit, iaHiHiLimit)

We want to generate an alarm when the temperature goes out of the range 40.00 Celsius

to 70.0

0

Celsius, so 40.0 will be our low alarm limit (iaLoLimit parameter) and 70.0 will be

our high alarm limit (iaHiLimit parameter). We can also assign Low-Low and High-High

alarm limits to generate additional alarm messages if the variable goes much higher or

much lower than the Low and High limits. These are on the iaHiHiLimit and iaLoLoLimit

parameters, respectively. NOTE: You do not need to use all four limits. Only one alarm limit

is required to configure an analog alarm.

Setting Deadbands (iaHiDeadBand, iaLoDeadBand)

We strongly recommend that you define deadbands around your alarm limits. Two

deadbands are supported, iaHiDeadBand is applied to the high and high-high alarm limits,

and iaLoDeadBand is applied to the low and low-low alarm limits. Deadbands are ranges

above a low limit, or below a high limit, in which a return-to-normal message will NOT be

sent, even though a process variable has returned inside the range defined by the alarm

limits. This is to prevent the system from being flooded with alarm messages if a process

variable is fluctuating around the alarm limit. Without a deadband defined, every time the

process variable enters or leaves the normal range, a return-to-normal or alarm message

would be generated, thereby flooding the system with repetitive alarms, even though the

process variable has changed very little. For this example, we have chosen a deadband of

10.0 for both the low and high deadbands.

D301426X012

January 2022

Setting Alarm Priorities (iiLoPriority, iiLoLoPriority, iiHiPriority, iiHiHiPriority)

Alarm priorities indicate the severity of the alarm condition triggered by passing one of the

pre-defined alarm limits. For this example, passing either the low or high alarm limits is

considered NON-CRITICAL, and passing either the low-low or high-high alarm limits is

considered CRITICAL. The alarm priority has no effect on the operation of the alarm

system, and is defined strictly at the user’s discretion. Priorities are displayed as part of the

alarm message.

Units Text, Descriptive Text (istrUnitsText, istrDescText)

These parameters are strictly for the convenience of the user. They specify engineering

units for the alarm variable, and descriptive text for the alarm condition.

The table, below, summarizes the values for the various parameters used in this example:

Name

ibDisable WATER_TEMP_ALARM_DISABLE BOOL FALSE For disabling/ enabling

Type

INT, DINT,

USINT, UINT, or

UDINT

alarm processing.

variable measuring

temperature in the

tank.

Alarm Configuration 15

USINT, INT,

Page 24

ControlWave Designer Programmer’s Handbook

Parameter

Suggested Variable Name

Variable

Value

Notes

UINT, DINT, or

iaHiLimit

WATER_H_LIMIT

REAL, SINT,

70.0

High alarm limit

iaLoLimit

WATER_L_LIMIT

REAL, SINT,

40.0

Low alarm limit

iaLoLoLimit

WATER_LL_LIMIT

REAL, SINT,

20.0

Low low alarm limit

iaHiDeadBand

WATER_HDB

REAL, SINT,

10.0

High alarm deadband

iaLoDeadBand

WATER_LDB

REAL, SINT,

10.0

Low alarm deadband

iiPriority

CRITICAL_PRIORITY

INT 3 High-High Priority

iiHiPriority

NON_CRITICAL_PRIORITY

INT 2 High Priority

iiLoPriority

NON_CRITICAL_PRIORITY

INT 2 Low Priority

iiLoLoPriority

CRITICAL_PRIORITY

INT 3 Low-Low Priority

istrUnitsText

TEMP_UNITS

STRING

'DEG_C'

Engineering units (up

istrDescText

WATER_TEMP_DESC_TEXT

STRING

'WATER

Descriptive text (up to

odiStatus

WATER_TEMP_ALARM_STATUS

DINT

None

Status of the execution

ouiAlarmSeq

WATER_TEMP_ALARM_SEQ_NUM

UINT

None

Alarm sequence

ouiGlobalSeq

WATER_TEMP_GLOBAL_SEQ_NUM

UINT

None

Global sequence

D301426X012

January 2022

Name

Type

UDINT

USINT, INT,

UNIT, DINT or

UDINT

USINT, INT,

UINT, DINT or

UDINT

USINT, INT,

UINT, DINT or

UDINT

USINT, INT,

UINT, DINT or

UDINT

USINT, INT,

UINT, DINT or

UDINT

16 Alarm Configuration

to 6 characters)

TEMPERAT

URE'

64 characters)

of this function block.

number.

number.

Page 25

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

The configured alarm block appears, below:

Configuring a Logical Alarm

For this example, let’s say we have an electrical switch which turns ON in the event of a

compressor power failure. When the switch turns ON, we want to generate an alarm.

When the power is restored, the switch turns OFF and a return-to-normal message will be

generated.

Because the alarm condition occurs when the switch turns ON, we must use an

ALARM_LOGICAL_ON function block. (If we wanted to generate an alarm when the switch

turned OFF, we would have used an ALARM_LOGICAL_OFF function block.)

Using the ALARM_LOGICAL_ON function block

Where you insert your ALARM_LOGICAL_ON function block depends upon the overall

construction of your project:

The ALARM_LOGICAL_ON function block can only detect an alarm condition when it is

executed. Therefore, when constructing your project, you should think about how and

when you want to execute the function block.

You might choose to place the ALARM_LOGICAL_ON function block in the same POU

which holds primary control logic for the process variable. This is always required if the

variable being monitored is not global. Typically, the ALARM_LOGICAL_ON function

block would be placed at the end of the POU. If you require timestamps to reflect the

Alarm Configuration 17

Page 26

ControlWave Designer Programmer’s Handbook

Parameter

Suggested Variable Name

Variable

Value

Notes

ibDisable

POWERFAIL_ALARM_DISABLE

BOOL

FALSE

For disabling/ enabling

iaAlarmVar

COMPRESSOR_POWER_FAILURE

BOOL

None

The ON/OFF status of

iiPriority

CRITICAL_PRIORITY

INT 3 Priority of this alarm

istrOnText

POWER_FAIL_ONTEXT

STRING

'FAILED'

ON message text (up

istrOffText

POWER_FAIL_OFFTEXT

STRING

'NORMAL'

OFF message text (up

istrDescText

POWERFAIL_DESC_TEXT

STRING

'WATER

Descriptive text (up to

D301426X012

January 2022

exact moment the alarm condition occurred, you could place the

ALARM_LOGICAL_ON function block immediately following the logic which

manipulates the process variable.

Alternatively, you could place the ALARM_LOGICAL_ON function block in a separate

POU, which could even be executed at a different task interval. This approach may be

convenient if you want to organize your project such that all alarm function blocks are

in the same place.

Step 1. Following the considerations discussed above,

insert an ALARM_LOGICAL_ON function block

into your program. A separate

ALARM_LOGICAL_ON (or ALARM_LOGICAL_OFF)

function block is required for every variable you

want to configure as a logical alarm.

Step 2. Based on our example of detecting a change of

state of a pump, assign meaningful variable

names, and where applicable, initial values to

each of the parameters of the

ALARM_LOGICAL_ON function block.

The actual process variable being monitored for alarm conditions must be assigned to the

iaAlarmVar parameter. In this case we will call it COMPRESSOR_POWER_FAILURE since

that is the process I/O variable from the switch.

Name

The table, below, summarizes the values for the various parameters used in this example.

Type

alarm processing.

the switch used to

indicate power failure

of the compressor.

NOTE: Alarms are only

generated when

iaAlarmVar is ON.

condition.

to 6 characters)

to 6 characters)

TEMPERAT

URE'

64 characters)

18 Alarm Configuration

Page 27

ControlWave Designer Programmer’s Handbook

Parameter

Suggested Variable Name

Variable

Value

Notes

odiStatus

POWERFAIL_ALARM_STATUS

DINT

None

Status of the execution

ouiAlarmSeq

POWERFAIL_ALARM_SEQ_NUM

UINT

None

Alarm sequence

ouiGlobalSeq

POWERFAIL_GLOBAL_SEQ_NUM

UINT

None

Global sequence

D301426X012

January 2022

Name

Type

of this function block.

number

number

The configured alarm block appears, below:

Configuring a Change of State Alarm

For this example, let’s say we have a pump which is critical to the operation of a water

plant. Whenever it starts or stops, we want to generate an alarm message. NOTE: In

change-of-state alarms, there is NO return-to-normal state; every change from ON-to-OFF

or OFF-to-ON generates an alarm message.

Using the ALARM_STATE function block

Where you insert your ALARM_STATE function block depends upon the overall

construction of your project:

The ALARM_STATE function block can only detect an alarm condition when it is

executed. Therefore, when constructing your project, you should think about how and

when you want to execute the function block.

You might choose to place the ALARM_STATE function block in the same POU which

holds primary control logic for the process variable. This is always required if the

variable being monitored is not global. Typically, the ALARM_STATE function block

would be placed at the end of the POU. If you require timestamps to reflect the exact

moment the alarm condition occurred, you could place the ALARM_STATE function

block immediately following the logic which manipulates the process variable.

Alternatively, you could place the ALARM_STATE function block in a separate POU,

which could even be executed at a different task interval. This approach may be

Alarm Configuration 19

Page 28

ControlWave Designer Programmer’s Handbook

Parameter

Suggested Variable Name

Variable

Value

Notes

ibDisable

DISABLE_WATERPMP_STATALRM

BOOL

FALSE

For disabling/ enabling

iaAlarmVar

WATER_PUMP_STATUS

BOOL

None

The ON/OFF status of

iiPriority

CRITICAL_PRIORITY

INT 3 Priority of this alarm

istrOnText

WATER_PUMP_ONTEXT

STRING

'ACTIVE'

ON message text (up

istrOffText

WATER_PUMP_OFFTEXT

STRING

'IDLE'

OFF message text (up

istrDescText

WATER_PUMP_DESC_TEXT

STRING

'WATER

Descriptive text (up to

odiStatus

WATER_PUMP_ALARM_STATUS

DINT

None

Status of the execution

ouiAlarmSeq

WATER_PUMP_ALARM_SEQ_NUM

UINT

None

Alarm sequence

ouiGlobalSeq

WATER_PUMP_GLOBAL_SEQ_NUM

UINT

None

Global sequence

D301426X012

January 2022

convenient if you want to organize your project such that all alarm function blocks are

in the same place.

Step 1. Following the considerations

discussed above, insert an

ALARM_STATE function block into

your program. A separate

ALARM_STATE function block is required

for every variable you want to configure

as a change-of-state alarm.

Step 2. Based on our example of detecting a change of state of a water pump, assign

meaningful variable names, and where applicable, initial values to each of the

parameters of the ALARM_STATE function block.

The actual process variable being monitored for alarm conditions must be assigned to the

iaAlarmVar parameter. In this case we will call it WATER_PUMP_STATUS.

Name

The table, below, summarizes the values for the various parameters used in this example:

Type

alarm processing.

the water pump.

condition.

to 6 characters)

to 6 characters)

PUMP

STATE

CHANGE'

64 characters)

of this function block.

number

20 Alarm Configuration

number

Page 29

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

The configured alarm block appears, below:

Alarm Configuration 21

Page 30

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

22 Alarm Configuration

Page 31

ControlWave Designer Programmer’s Handbook

Application Licensing

Certain standard applications sold by Emerson Remote Automation Solutions are licensed

to prevent unauthorized duplication. When you purchase the application(s), you will

receive a license key (also known as a USB dongle), that will allow you to manage which

controllers will be license recipients for the standard applications.

Note:

Only ControlWave-series controllers with firmware 04.90 or newer support application

licensing.

Granting a License for a Controller to Run a Standard Application

D301426X012

January 2022

1.

2.

Start Programs OpenBSI Tools ControlWave Tools Application Licensing

Install the dongle in your PC’s USB port, and allow it to be recognized.

Start the Application Licensing Tool, using the following sequence:

3. The Application Licensing Tool will read the dongle, and display the following

information:

Application A list of all the standard application licenses originally issued via this

dongle.

RTU State The license status of a particular controller for a particular standard

application. If the controller has not been queried yet, this will

display ‘Unknown’.

Ordered The total number of licenses included on this dongle, for a given

application, when it left the factory.

Available The total number of licenses, for a given application, which have

not yet been issued to controller(s).

Application Licensing 23

Page 32

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

4. Select the controller to which you want to issue the license, using the [Browse] button.

(If communication is via NetView, the controller must exist in the current NETDEF file;

otherwise select the locally connected ‘RTU’.)

5. Enter a valid username / password combination for that controller, and click on the

[Query RTU License State] button.

6. The application window will be updated to show which applications have been

licensed for this controller. Select the application you want to issue to the controller.

There must be at least 1 or more listed in the

7. Click on [Issue License]. The license will be granted to the controller, and the

“Available” count will be decremented by 1.

8. Repeat this process for any other controllers you want to issue licenses to. When

finished, click on

[Exit].

“Available” field.

Removing an Application License from a Controller:

You might want to remove a license from a controller, for example, if you have to take it

out of service, for repairs, and want to use its license in a replacement unit. Follow the

steps, below:

1. Install the dongle in your PC’s USB port, and allow it to be recognized.

2. Start the Application Licensing Tool, using the following sequence:

Start Programs OpenBSI Tools ControlWave Tools Application Licensing

24 Introduction

Page 33

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

3. The Application Licensing Tool will read the dongle, and display the following

information:

Application A list of all the standard application licenses originally issued via this

dongle.

RTU State The license status of a particular controller for a particular standard

application. If the controller has not been queried yet, this will display ‘Unknown’.

Ordered The total number of licenses included on this dongle, for a given

application, when it left the factory.

Available The total number of licenses, for a given application, which have not yet

been issued to controller(s).

4. Select the controller for which you want to revoke the license, using the [Browse]

button. (If communication is via NetView, the controller must exist in the current

NETDEF file; otherwise select the locally connected ‘RTU’.)

5. Enter a valid username / password combination for that controller, and click on the

[Query RTU License State] button.

6. The application window will be updated to show which applications have been

licensed for this controller. Select the application you want to remove from the

controller.

7. Click on [Remove License]. The license will be removed from the controller, and

restored onto the dongle. The

“Available” count will be incremented by 1.

Viewing a History of Dongle Issue / Remove Operations:

The Application Licensing Tool maintains, on the dongle, a list of the last 150 license

operations. To view this history, click on

[View Event Log].

Application Licensing 25

Page 34

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

26 Introduction

Page 35

Application Parameters

Goal Idle

This is a goal expressing the percentage of time the ControlWave CPU

Idle Min Ticks

This is the minimum number of 1 millisecond clock ticks to be left between

Minimum Idle

If this percentage of free CPU time is not maintained within the

The Application Parameters page is accessible from the "Application Parameters" tab in the

Flash Configuration Utility. For instructions on calling up the Flash Configuration Utility,

see Flash Configuration – An Overview, later in this manual. These parameters apply only to

ControlWave-series units that are configured as IP nodes.

Note:

Unless you are using redundancy or have a specific need to edit these parameters (for

example, if you are running an application with special memory requirements, or if you are

encountering performance problems related to CPU activity), leave these parameters at

their defaults. Users should exercise particular caution when modifying the application

parameters for memory. Making a significant change to these parameters without

understanding how the parameters interact could actually reduce the amount of available

memory, even though you have increased the values of the parameters. When changing

these parameters, use

only small incremental changes.

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

CPU:

should be idle. The default value is 30%. If this goal cannot be met, the

DEFAULT task period will automatically be adjusted to free up CPU time.

executions of the DEFAULT task. The default value is 2.

ControlWave CPU, an overload exception is reported. The default value is

5%.

Application Parameters 27

Page 36

ControlWave Designer Programmer’s Handbook

Prog RAM

In kilobytes, this is the amount of memory reserved (at system start) for

Data RAM

This is the size of storage reserved for variables in kilobytes. This can

Retain RAM

This is the size of storage space (in kilobytes) reserved at system start for

Unit A Addr

This must be an IP address corresponding to an Ethernet port on the A

Unit B Addr

D301426X012

January 2022

Memory:

storing the generated code for the ControlWave project. This value

should NOT be set significantly larger than the amount of memory

actually needed for the project, because any unused reserved memory

will be unavailable for data or other purposes. NOTE: If the system does

not have sufficient memory to hold the user requests, the requests will

be reduced proportionally. This defaults to 1024k in the ControlWave

and ControlWave MICRO, and 256k in the ControlWaveLP. This can range

from 10k to 1024k.

range from 10k to 1024k.This defaults to 256k in the ControlWave and

ControlWave MICRO, and 64k in the ControlWaveLP. NOTE: This amount

does not include historical data (audit/archive).

variables marked as ‘RETAIN’. The values of variables marked as ‘RETAIN’

are preserved in the event of a warm start download. This can range from

0k to 1024k, and defaults to 256k in the ControlWave and ControlWave

MICRO, and 64k in the ControlWaveLP.

Redundancy Transfer

controller in a redundant pair.

This must be an IP address corresponding to an Ethernet port on the B

controller in a redundant pair.

Variations when using the ControlWave I/O Expansion Rack

For the ControlWave I/O Expansion Rack, the 'Memory' and 'CPU' sections of the Application

Parameters page are omitted, and a 'Timeouts' section is added.

The "Power Fail Timeout" determines how outputs of the I/O rack should be set when power is

restored following a power failure, or under certain circumstances, during a restart following a

CPU watchdog.

"Host Comm Loss Timeout" specifies how the outputs of the I/O Rack should be affected in the

event of a communication failure with the host ControlWave controller.

For a full description of these options, please see the ControlWave I/O Expansion Rack Quick

Setup Guide (part number D301423X012).

28 Application Parameters

Page 37

Archive Configuration

What Are Archive Files?

Archive information is saved at the ControlWave-series controller in structures called

archive files. The archive files are essentially tables of data stored in rows and columns.

Each row has a timestamp, and sequence numbers, associated with it, and each column is

associated with a process variable. A row of process variable values, along with its

associated timestamp and sequence numbers is called a

A record constitutes a 'snapshot' of the values for those variables at that particular time.

Depending upon how you configure the archive file, the values saved may be just

instantaneous values, or they may be the result of calculations performed on data received

during the collection interval (integration, averaging, etc.)

Data is stored in the archive file either at a specified interval (periodic storage) or based on

settings in the ARCHIVE function block.

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

record.

Some Background - Archive Calculations (Weight Factors, Intervals, and Samples)

Optionally, calculations can be performed on the data prior to its being saved in the

archive file. These calculations could be averaging, integration, etc.

The calculations performed using the Archive system are particularly useful in fluid flow

applications, for fluids in either the gas or liquid state. The calculations are intended to

assist in meeting the requirements of the American Petroleum Institute Manual of

Measurement Standards, Chapter 21, by supporting some of the averaging techniques

described in that document. If desired, these same calculations may be utilized for other

applications (besides the fluid flow applications for which they were originally intended).

In the following explanations some mathematical terminology is used that is directly

connected to the execution rate of the ARCHIVE function block. The Archive will have been

declared to have a periodic type and an Interval of 1 day or less. Within this Periodic

Interval the ARCHIVE function block will be executed at an execution interval established

by the task execution.

Some of the calculations make use of a “Weight factor”. The weight factors are set as input

parameters of the ARCHIVE function block, and can be any REAL number values. The

weight factors are used to control whether a sample is used in the calculation performed.

The weight factors are typically used to control the number of samples included in the

averaging calculations, so that, for example, Pressure or Temperature is only averaged

when the weight factors indicate that it is valid to use the samples.

The averaging methods also provide an automatic switch from one type of averaging to

another anytime after the start of a periodic interval. If a periodic interval begins with

Weight Factor2 in a non-zero state then throughout the interval Weight Factor2 controls

the averaging – samples are only used if Weight Factor2 is not zero. If the Interval begins

with Weight Factor2 already zero then each sample is weighted using Weight Factor1, but

Archive Configuration 29

Page 38

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

if at any time during the interval Weight Factor2 becomes non-zero, all samples taken with

Weight Factor1 are discarded and a new average is started under control of Weight

Factor2. For the rest of the interval Weight Factor2 is in control and Weight Factor1 has no

more effect.

For example, if Weight Factor1 represents the delta time between ARCHIVE function block

executions, and Weight Factor2 represents the delta flow time between ARCHIVE function

block executions, then for those archive intervals where no flow time occurred, the result

is a straight time average. For those archive intervals where flow time has occurred, the

result is a flow time average.

Defining a Straight-time Average Archive

To set up a simple straight-time averaged archive, there are two methods available:

Method 1: Set Weight Factor1 to the delta time between ARCHIVE function block

executions each time the ARCHIVE function block is executed. (Note: The

delta time between each execution of the ARCHIVE function block must be

dynamically calculated by user-created logic in your program. Do NOT simply

enter a constant based on the rate of execution of the task, because that will

not account for any slippage in execution time.)

Method 2: Set Weight Factor1 to 1.0 each time the ARCHIVE function block is executed.

This provides an average based on the number of samples taken. (This is

equivalent to a time-based average.)

Archive configuration involves four basic steps:

1. Define the archive file(s) using the Flash Configuration Utility. This includes

specifying the number of rows (records) and columns, the types of calculations

performed, etc.

2. Identify in ControlWave Designer, every variable you want to have archived. This is

accomplished by including these variables in a LIST function block.

3. Create another LIST to hold the current archive record. (THIS IS OPTIONAL). This

allows the current archive record data to be used within your ControlWave project; if

you don’t want to do this, skip this step.

4. Configure an ARCHIVE function block in your ControlWave project. This function

must be executed frequently enough to collect an adequate number of samples.

30 Archive Configuration

Page 39

ControlWave Designer Programmer’s Handbook

D301426X012

January 2022

What can be done with the data from the Archive File(s)?

Once archiving has been fully configured, and the ControlWave project has been

downloaded and has been running, archive data will be collected, and the Archive File(s)

will be populated with data. There are various methods for extracting this Archive data:

The Archive Collection web page control may be used to display archive data. This web

page is included in the standard Web_BSI set, and allows you to display the archive

data in Microsoft® Internet Explorer.

The OpenBSI DataView utility can display archive data on the screen of your OpenBSI

Workstation.

The PocketBSI Data Viewer can display archive data on the PocketBSI AccessPack.

The OpenBSI Harvester can collect the archive data, and store it in files on the OpenBSI

Workstation, which the OpenBSI Data File Conversion Utility can export to human

machine interface (HMI) packages such as OpenEnterprise.

Step 1. Define Archive Files(s) in the Flash Configuration Utility

The individual columns of the archive file, and various parameters that define how

archiving is performed, are specified in the Archive page of the Flash Configuration Utility.

Changes made in the Archive page will NOT take effect until the unit has been powered off

and back on.

Archive Configuration 31

Page 40

ControlWave Designer Programmer’s Handbook

Number

This is a unique ID number for this Archive File. It can range from 1 to 32767.

Name

This is the archive file name. Up to 8 alphanumeric characters, beginning with

Records

This determines how many rows of 'snapshot' data will be retained in this

Columns

This is the number of columns in the Archive File. Each column corresponds to

Flash