Page 1

CONTROL VALVE

HANDBOOK

Fifth Edition

Page 2

Emerson Automation Solutions

Flow Controls

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

Neither Emerson, Emerson Automation Solutions, nor any of their afliated entities assumes

responsibility for the selection, use or maintenance of any product. Responsibility for proper

selection, use, and maintenance of any product remains solely with the purchaser and end user.

The contents of this publication are presented for informational purposes only, and while every

effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use

or applicability. All sales are governed by our terms and conditions, which are available upon

request. We reserve the right to modify or improve the designs or specications of such products

at any time without notice.

Fisher is a mark owned by one of the companies in the Emerson Automation Solutions business

unit of Emerson Electric Co. Emerson and the Emerson logo are trademarks and service marks

of Emerson Electric Co. All other marks are the property of their respective owners.

© 2005, 2019 Fisher Controls International LLC. All rights reserved.

D101881X012/ Sept19

Page 3

Preface

Control valves are an increasingly vital component of modern manufacturing around

the world. Properly selected and maintained control valves increase efciency,

safety, protability, and ecology.

The Control Valve Handbook has been a primary reference since its rst printing in

1965. This fth edition presents vital information on control valve performance and

the latest technologies.

Chapter 1 offers an introduction to control valves, including denitions for common

control valve and instrumentation terminology.

Chapter 2 develops the vital topic of control valve performance.

Chapter 3 covers valve and actuator types.

Chapter 4 describes digital valve controllers, analog positioners, boosters, and other

control valve accessories.

Chapter 5 is a comprehensive guide to selecting the best control valve for an

application.

Chapter 6 addresses the selection and use of special control valves.

Chapter 7 explains desuperheaters, steam conditioning valves, and turbine bypass

systems.

Chapter 8 details typical control valve installation and maintenance procedures.

Chapter 9 contains information on control valve standards and approval agencies

across the world.

Chapter 10 identies isolation valves and actuators.

Chapter 11 covers discrete automation.

Chapter 12 discusses various process safety instrumented systems.

Chapter 13 provides useful tables of engineering reference data.

Chapter 14 includes piping reference data.

Chapter 15 is a handy resource for common conversions.

The Control Valve Handbook is both a textbook and a reference on the strongest link

in the control loop: the control valve and its accessories. This book includes extensive

and proven knowledge from leading experts in the process control eld, including

contributions from the ISA.

Page 4

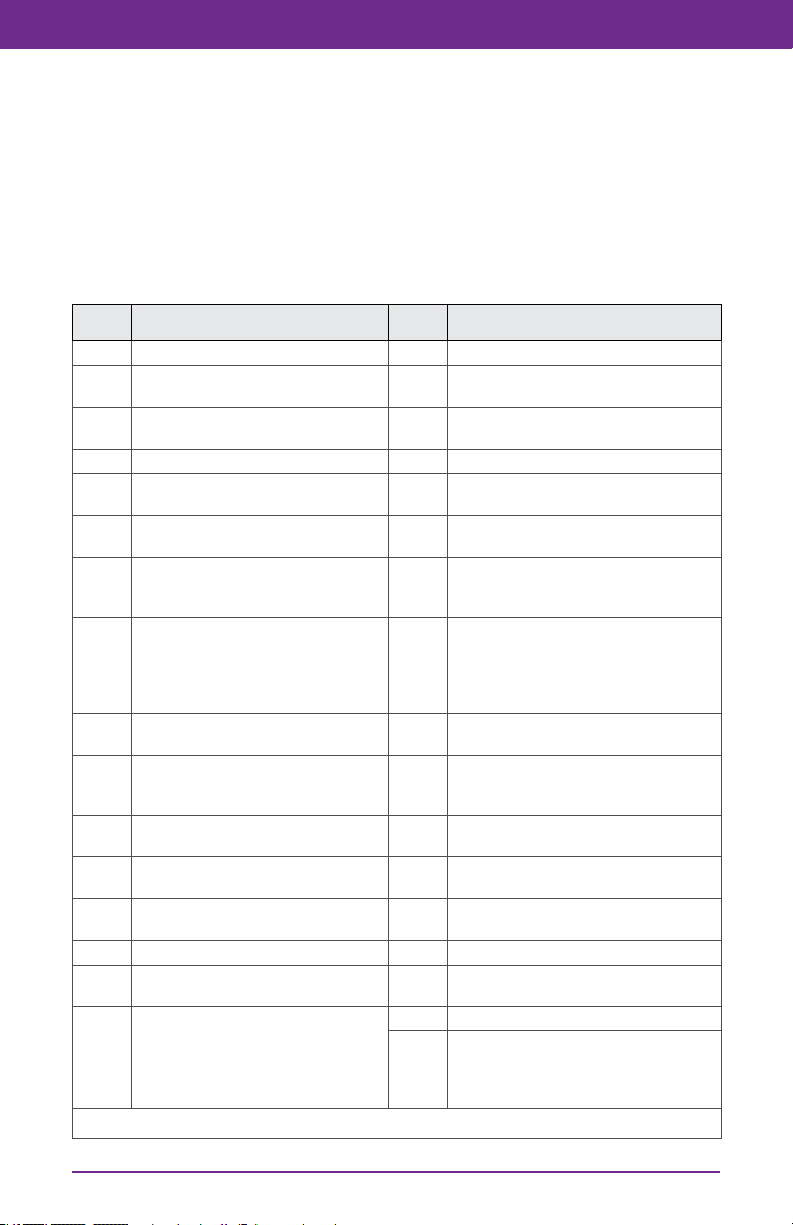

Table of Contents

Page 5

Control Valve Handbook | Table of Contents

Chapter 1: Introduction to Control Valves ............................................. 14

1.1 What is a Control Valve? .............................................................................. 15

1.2 Sliding-Stem Control Valve Terminology .....................................................15

1.3 Rotary Control Valve Terminology ...............................................................21

1.4 Control Valve Functions and Characteristics Terminology ............................23

1.5 Process Control Terminology .......................................................................25

Chapter 2: Control Valve Performance .................................................. 32

2.1 Process Variability ....................................................................................... 33

2.1.1 Deadband ................................................................................................................ 35

2.1.1.1 Causes of Deadband .........................................................................................................35

2.1.1.2 Effects of Deadband .........................................................................................................36

2.1.1.3 Performance Tests ............................................................................................................36

2.1.1.4 Friction ............................................................................................................................36

2.1.2 Actuator and Positioner Design ................................................................................ 37

2.1.3 Valve Response Time ................................................................................................ 38

2.1.3.1 Dead Time .......................................................................................................................38

2.1.3.2 Dynamic Time ..................................................................................................................38

2.1.3.3 Solutions ..........................................................................................................................39

2.1.3.4 Supply Pressure ................................................................................................................40

2.1.3.5 Minimizing Dead Time .....................................................................................................40

2.1.3.6 Valve Response Time ........................................................................................................41

2.1.4 Valve Type and Characterization ............................................................................... 41

2.1.4.1 Installed Gain ...................................................................................................................43

2.1.4.2 Loop Gain ........................................................................................................................43

2.1.4.3 Process Optimization .......................................................................................................44

2.1.5 Valve Sizing .............................................................................................................. 45

2.2 Economic Results ........................................................................................46

2.3 Summary .................................................................................................... 48

Chapter 3: Valve and Actuator Types ..................................................... 50

3.1 Control Valve Styles .................................................................................... 51

3.1.1 Globe Valves ............................................................................................................ 51

3.1.1.1 Single-Port Valve Bodies ...................................................................................................51

3.1.1.2 Post- and Port-Guided Valve Bodies ...................................................................................52

3.1.1.3 Cage-Style Valve Bodies ....................................................................................................52

3.1.1.4 Double-Ported Valve Bodies ..............................................................................................53

3.1.1.5 Three-Way Valve Bodies....................................................................................................53

3.1.2 Sanitary Valves ........................................................................................................ 54

3.1.3 Rotary Valves ........................................................................................................... 54

3.1.3.1 Buttery Valve Bodies .......................................................................................................54

3.1.3.2 Segmented Ball Valve Bodies ............................................................................................55

5

Page 6

Control Valve Handbook | Table of Contents

3.1.3.3 High-Performance Buttery Valve Bodies ..........................................................................55

3.1.3.4 Eccentric Plug Valve Bodies ...............................................................................................56

3.1.3.5 Full-Port Ball Valve Bodies .................................................................................................57

3.1.3.6 Multi-Port Flow Selector ...................................................................................................57

3.2 Control Valve End Connections ................................................................... 57

3.2.1 Screwed Pipe Threads .............................................................................................. 57

3.2.2 Bolted Gasketed Flanges ........................................................................................... 58

3.2.3 Welded End Connections .......................................................................................... 58

3.2.4 Other Valve End Connections ................................................................................... 59

3.3 Valve Body Bonnets .....................................................................................59

3.3.1 Extension Bonnets.................................................................................................... 60

3.3.2 Bellows Seal Bonnets ................................................................................................ 61

3.4 Control Valve Packing..................................................................................61

3.4.1 PTFE V-Ring .............................................................................................................. 62

3.4.2 Laminated and Filament Graphite ............................................................................ 62

3.4.3 U.S. Regulatory Requirements for Fugitive Emissions ................................................ 62

3.4.4 Global Standards for Fugitive Emissions .................................................................... 63

3.4.5 Single PTFE V-Ring Packing ....................................................................................... 65

3.4.6 ENVIRO-SEAL PTFE Packing....................................................................................... 65

3.4.7 ENVIRO-SEAL Duplex Packing ................................................................................... 67

3.4.8 ISO-Seal PTFE Packing .............................................................................................. 67

3.4.9 ENVIRO-SEAL Graphite ULF ....................................................................................... 67

3.4.10 HIGH-SEAL Graphite ULF ........................................................................................ 67

3.4.11 ISO-Seal Graphite Packing ...................................................................................... 67

3.4.12 ENVIRO-SEAL Graphite for Rotary Valves ................................................................. 67

3.4.13 Graphite Ribbon for Rotary Valves .......................................................................... 67

3.4.14 Sliding-Stem Environmental Packing Selection........................................................ 67

3.4.15 Rotary Environmental Packing Selection ................................................................. 69

3.5 Characterization of Cage-Guided Valve Bodies ............................................ 69

3.6 Valve Plug Guiding ......................................................................................70

3.7 Restricted-Capacity Control Valve Trim .......................................................70

3.8 Actuators .................................................................................................... 71

3.8.1 Diaphragm Actuators .............................................................................................. 71

3.8.2 Piston Actuators ...................................................................................................... 72

3.8.4 Rack-and-Pinion Actuators ....................................................................................... 73

3.8.5 Electric Actuators ..................................................................................................... 73

Chapter 4: Control Valve Accessories .................................................... 74

4.1 Environmental & Application Considerations ............................................... 75

4.2 Positioners ..................................................................................................75

4.2.1 Pneumatic Positioners .............................................................................................. 75

6

Page 7

Control Valve Handbook | Table of Contents

4.2.2 Analog I/P Positioners .............................................................................................. 76

4.2.3 Digital Valve Controllers ........................................................................................... 77

4.2.3.1 Diagnostics ......................................................................................................................77

4.2.3.2 Two-Way Digital Communication .....................................................................................78

4.3 I/P Transducers ............................................................................................ 78

4.4 Volume Boosters ......................................................................................... 78

4.5 Safety Instrumented Systems (SIS) .............................................................. 80

4.5.1 Partial Stroke Testing ............................................................................................... 80

4.6 Controllers ..................................................................................................81

4.7 Position Transmitters ..................................................................................83

4.8 Limit Switches .............................................................................................83

4.9 Solenoid Valves ........................................................................................... 83

4.10 Trip Systems .............................................................................................. 84

4.11 Handwheels ..............................................................................................84

Chapter 5: Control Valve Sizing ............................................................. 86

5.1 Control Valve Dimensions ...........................................................................88

5.1.1 Face-to-Face Dimensions for Flanged, Globe-Style Valves .......................................... 88

5.1.2 Face-to-Face Dimensions for Butt Weld-End, Globe-Style Valves ................................ 90

5.1.3 Face-to-Face Dimensions for Socket Weld-End, Globe-Style Valves ............................ 91

5.1.4 Face-to-Face Dimensions for Screwed-End, Globe-Style Valves .................................. 92

5.1.5 Face-to-Centerline Dimensions for Raised-Face, Globe-Style Angle Valves ..................... 92

5.1.6 Face-to-Face Dimensions for Separable Flange, Globe-Style Valves ............................ 93

5.1.7 Face-to-Face Dimensions for Flanged and Flangeless Rotary Valves ........................... 93

5.1.8 Face-to-Face Dimensions for Single Flange and Flangeless Buttery Valves ................... 94

5.1.9 Face-to-Face Dimensions for High-Pressure, Offset Buttery Valves ........................... 94

5.2 Control Valve Seat Leakage Classications ................................................... 95

5.3 Class VI Maximum Seat Leakage Allowable ..................................................96

5.4 Control Valve Flow Characteristics...............................................................96

5.4.1 Flow Characteristics ................................................................................................. 96

5.4.2 Selection of Flow Characteristics .............................................................................. 97

5.5 Valve Sizing .................................................................................................97

5.7 Equation Constants ....................................................................................99

5.8 Sizing Valves for Liquids .............................................................................100

5.8.1 Determining Piping Geometry Factor and Liquid Pressure-Recovery Factor .................. 100

5.8.2 Determining the Pressure Drop to Use for Sizing ..................................................... 101

5.8.3 Calculating the Required Flow Coefcient ............................................................... 101

5.8.4 Liquid Sizing Sample Problem ................................................................................. 102

5.9 Sizing Valves for Compressible Fluids.........................................................104

5.9.1 Determining Piping Geometry Factor and Pressure Drop Ratio Factor at Choked Flow ................. 105

7

Page 8

Control Valve Handbook | Table of Contents

5.9.2 Determining Pressure Drop Ratio to Use for Sizing and Expansion Factor ................... 105

5.9.3 Calculating Flow Coefcient ................................................................................... 105

5.9.4 Compressible Fluid Sizing Sample Problem No. 1 .................................................... 106

5.9.5 Compressible Fluid Sizing Sample Problem No. 2 .................................................... 107

5.10 Representative Sizing Coefcients ...........................................................109

5.10.1 Representative Sizing Coefcients for Single-Ported, Globe-Style Valves................. 109

5.10.2 Representative Sizing Coefcients for Rotary Valves ............................................. 110

5.11 Actuator Sizing........................................................................................111

5.11.1 Globe Valves ........................................................................................................ 111

5.11.1.1 Unbalance Force ..........................................................................................................111

5.11.1.2 Force to Provide Seat Load ............................................................................................112

5.11.1.3 Packing Friction ............................................................................................................112

5.11.1.4 Additional Forces ..........................................................................................................112

5.11.2 Actuator Force Calculations ................................................................................. 114

5.12 Actuator Sizing for Rotary Valves ............................................................. 114

5.12.1 Torque Equations ................................................................................................. 114

5.12.2 Breakout Torque .................................................................................................. 114

5.12.3 Dynamic Torque .................................................................................................. 114

5.13 Typical Rotary Valve Torque Factors .........................................................115

5.13.1 Torque Factors for V-Notch Ball Valve with Composition Seal ................................ 115

5.13.2 Torque Factors for Buttery Valve with Composition Seal ...................................... 115

5.13.2.1 Maximum Rotation ......................................................................................................115

5.14 Cavitation and Flashing ...........................................................................116

5.14.1 Choked Flow Causes Flashing and Cavitation ........................................................ 116

5.14.2 Valve Selection for Flashing Service ....................................................................... 117

5.14.3 Valve Selection for Cavitation Service ................................................................... 118

5.15 Noise Prediction ...................................................................................... 118

5.15.1 Aerodynamic ....................................................................................................... 118

5.15.2 Hydrodynamic ..................................................................................................... 120

5.16 Noise Control ..........................................................................................120

5.17 Noise Summary ......................................................................................123

5.18 Packing Selection ....................................................................................124

5.18.1 Packing Selection Guidelines for Sliding-Stem Valves............................................. 125

5.18.2 Packing Selection Guidelines for Rotary Valves ...................................................... 126

5.19 Valve Body Materials ...............................................................................127

5.19.1 Designations for Common Valve Body Materials ................................................... 129

5.20 Pressure-Temperature Ratings ................................................................. 130

5.20.1 Standard Class ASTM A216 Grade WCC Cast Valves ................................................ 130

5.20.2 Standard Class ASTM A217 Grade WC9 Cast Valves .............................................. 131

5.20.3 Standard Class ASTM A351 Grade CF3 Cast Valves ................................................ 132

5.20.4 Standard Class ASTM A351 Grades CF8M and CG8M Valves .................................. 133

8

Page 9

Control Valve Handbook | Table of Contents

5.21 Non-Metallic Material Abbreviations .......................................................135

5.22 Non-Destructive Test Procedures ............................................................ 135

5.22.1 Magnetic Particle (Surface) Examination .............................................................. 135

5.22.2 Liquid Penetrant (Surface) Examination ............................................................... 136

5.22.3 Radiographic (Volumetric) Examination ............................................................... 136

5.22.4 Ultrasonic (Volumetric) Examination .................................................................... 136

Chapte 6: Special Control Valves ......................................................... 138

6.1 High-Capacity Control Valves ....................................................................139

6.2 Low-Flow Control Valves ...........................................................................140

6.3 High-Temperature Control Valves .............................................................140

6.4 Cryogenic Service Valves ...........................................................................141

6.5 Valves Subjected to Cavitation and Fluids with Particulate .........................141

6.6 Customized Characteristics, Noise-Abatement, and Cavitation-Mitigation

Trims ..............................................................................................................142

6.7 Control Valves for Nuclear Service in the U.S. ............................................142

6.8 Valves Subjected to Sulde Stress Cracking ............................................... 143

6.8.1 Pre-2003 Revisions of NACE MR0175 ...................................................................... 143

6.8.2 NACE MR0175/ISO 15156 ........................................................................................ 144

6.8.3 NACE MR0103 .......................................................................................................... 145

Chapter 7: Steam Conditioning ........................................................... 146

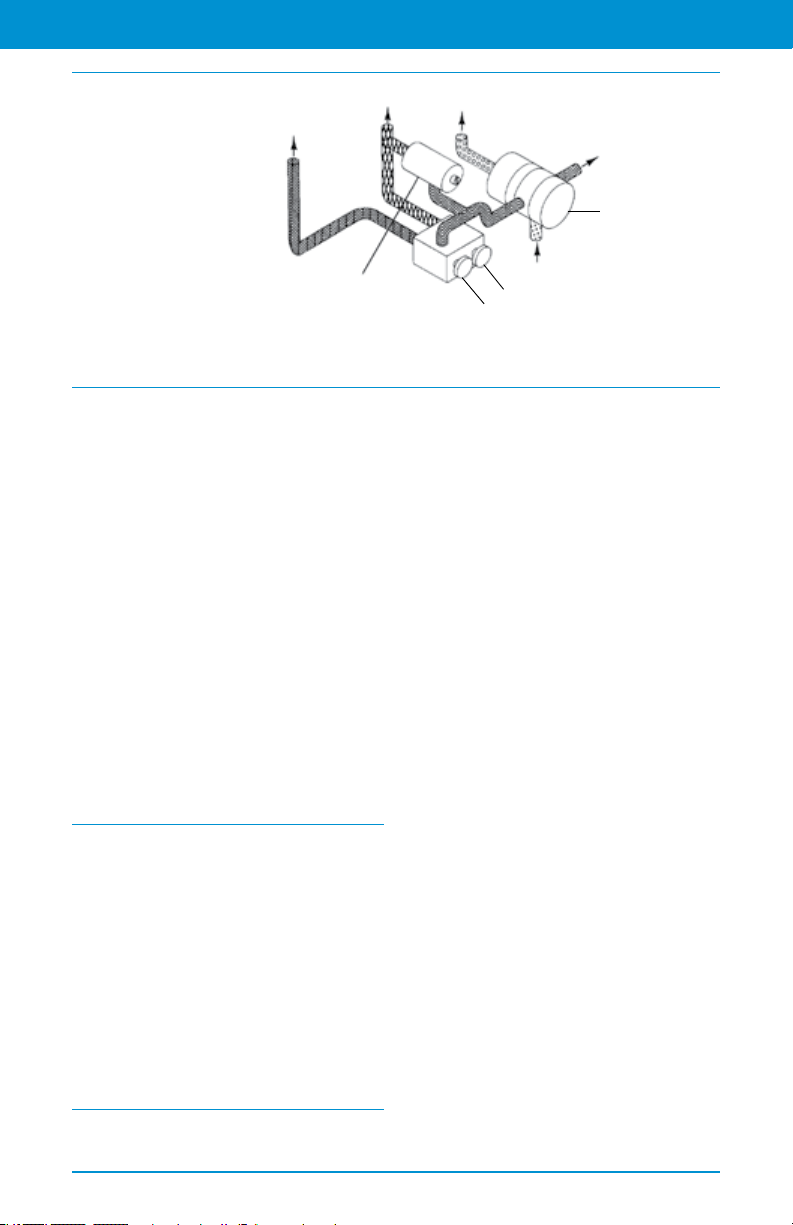

7.1 Understanding Desuperheating ................................................................147

7.1.1 Technical Aspects of Desuperheating ...................................................................... 147

7.2 Typical Desuperheater Designs ..................................................................150

7.2.1 Fixed-Geometry Nozzle Design ............................................................................... 150

7.2.2 Variable-Geometry Nozzle Design .......................................................................... 151

7.2.3 Self-Contained Design ............................................................................................ 151

7.2.5 Geometry-Assisted Wafer Design ........................................................................... 152

7.3 Understanding Steam Conditioning Valves................................................153

7.4 Steam Conditioning Valves ........................................................................153

7.4.1 Steam Attemperator .............................................................................................. 155

7.4.2 Steam Sparger ....................................................................................................... 155

7.6 Turbine Bypass System Components .........................................................156

7.6.1 Turbine Bypass Valves............................................................................................. 156

7.6.2 Turbine Bypass Water Control Valves ...................................................................... 156

7.6.3 Actuation............................................................................................................... 157

Chapter 8: Installation and Maintenance ............................................. 158

8.1 Proper Storage and Protection .................................................................. 159

9

Page 10

Control Valve Handbook | Table of Contents

8.2 Proper Installation Techniques ..................................................................159

8.2.1 Read the Instruction Manual .................................................................................. 159

8.2.2 Be Sure the Pipeline Is Clean ................................................................................... 159

8.2.4 Use Good Piping Practices ...................................................................................... 160

8.2.5 Flushing/Hydro/Start-Up Trim ................................................................................ 161

8.3 Control Valve Maintenance........................................................................161

8.3.1 Reactive Maintenance ............................................................................................ 162

8.3.2 Preventive Maintenance ......................................................................................... 162

8.3.3 Predictive Maintenance .......................................................................................... 162

8.3.4 Using Control Valve Diagnostics ............................................................................. 162

8.3.4.1 Instrument Air Leakage ..................................................................................................163

8.3.4.2 Supply Pressure ..............................................................................................................163

8.3.4.3 Travel Deviation and Relay Adjustment ...........................................................................163

8.3.4.4 Instrument Air Quality ....................................................................................................164

8.3.4.5 In-Service Friction and Friction Trending ..........................................................................164

8.3.4.6 Other Examples ..............................................................................................................164

8.3.5 Continued Diagnostics Development ...................................................................... 164

8.4 Service and Repair Parts ............................................................................165

8.4.1 Recommended Spare Parts .................................................................................... 165

8.4.2 Using Original Equipment Manufacturers (OEM) Parts ............................................ 165

8.4.3 Consider Upgrades for the Valve Trim ..................................................................... 165

8.5 Actuator Maintenance ............................................................................... 165

8.5.1 Spring-and-Diaphragm Actuators ......................................................................... 165

8.5.2 Piston Actuators .................................................................................................... 166

8.5.3 Stem Packing ......................................................................................................... 166

8.5.4 Seat Rings .............................................................................................................. 166

8.5.4.1 Replacing Seat Rings ......................................................................................................166

8.5.4.2 Connections: Plug-to-Stem, Ball-to-Shaft, and Disk-to-Shaft...........................................167

8.5.5 Bench Set ............................................................................................................... 167

8.5.6 Valve Travel ............................................................................................................ 167

Chapter 9: Standards and Approvals ................................................... 168

9.1 Control Valve Standards ............................................................................169

9.1.1 American Petroleum Institute (API) ......................................................................... 169

9.1.2 American Society of Mechanical Engineers (ASME) ................................................. 169

9.1.3 European Committee for Standardization (CEN) ..................................................... 169

9.1.3.1 European Industrial Valve Standards ...............................................................................169

9.1.3.2 European Material Standards .........................................................................................170

9.1.3.3 European Flange Standards ............................................................................................170

9.1.4 Fluid Controls Institute (FCI) ................................................................................... 170

9.1.5 Instrument Society of America (ISA) ....................................................................... 170

9.1.6 International Electrotechnical Commission (IEC) ..................................................... 171

10

Page 11

Control Valve Handbook | Table of Contents

9.1.7 Manufacturers Standardization Society (MSS) ........................................................ 171

9.1.8 NACE International ................................................................................................. 171

9.2 Product Approvals for Hazardous (Classied) Locations .............................172

9.2.1 Hazardous Location Approvals and Denitions ....................................................... 172

9.3 Classication Systems ...............................................................................172

9.3.1 Class/Division System ............................................................................................. 172

9.3.2 Zone System .......................................................................................................... 173

9.3.3 Equipment Groups ................................................................................................. 174

9.3.4 Equipment Subgroups ............................................................................................ 174

9.3.4.1 Group II (Commonly referred to as the “Gas Group”) .......................................................174

9.3.4.2 Group III (Commonly referred to as the “Dust Group”) ....................................................174

9.3.5 Type of Protection .................................................................................................. 175

9.3.5.1 Electrical Equipment .......................................................................................................175

9.3.5.2 Non-Electrical Equipment ...............................................................................................176

9.3.6 Level of Protection .................................................................................................. 177

9.3.7 Equipment Protection Level (EPL) ............................................................................ 177

9.4 Temperature Code ....................................................................................178

9.5 Nomenclature ...........................................................................................179

9.5.1 Class/Division System ............................................................................................. 179

9.5.2 Zone System .......................................................................................................... 179

9.5.3 Wiring Practices ..................................................................................................... 179

9.5.4 European Union (EU) – ATEX Directive 2014/34/EU ................................................ 180

9.6 Protection Techniques and Methods .........................................................181

9.6.1 Explosion-Proof or Flame-Proof Technique .............................................................. 181

9.6.2 Intrinsically-Safe Technique .................................................................................... 181

9.6.3 Non-Incendive or Type n Technique......................................................................... 182

9.6.4 Increased Safety ..................................................................................................... 182

9.6.5 Dust Ignition-Proof or Enclosure Dust-Proof............................................................ 183

9.7 Enclosure Ratings ......................................................................................183

Chapter 10: Isolation Valves ............................................................... 186

10.1 Basic Valve Types .....................................................................................187

10.1.1 Gate Valves .......................................................................................................... 187

10.1.2 Globe Valves ........................................................................................................ 188

10.1.3 Check Valves ........................................................................................................ 191

10.1.4 Bypass Valves ....................................................................................................... 192

10.1.6 Pinch Valves ......................................................................................................... 193

10.1.7 Ball Valves ............................................................................................................ 194

10.1.8 Buttery Valves .................................................................................................... 194

10.1.9 Plug Valves ........................................................................................................... 195

11

Page 12

Control Valve Handbook | Table of Contents

Chapter 11: Solenoid Valves ................................................................ 210

11.1 Solenoid Valves ....................................................................................... 211

Chapter 12: Safety Instrumented Systems ........................................... 214

12.1 Safety and Layers of Protection ...............................................................215

12.2 Safety Instrumented Systems (SIS) .......................................................... 216

12.3 Safety Standards .....................................................................................217

12.4 Safety Integrity Level (SIL) .......................................................................217

12.5 Probability of Failure Upon Demand ........................................................ 218

Final Elements, Proof Testing, and Partial Stroke Testing Techniques ...............219

12.6

12.7 Partial Stroke Testing ..............................................................................219

12.8 Online Testing Methods for the Final Element..........................................220

12.9 Digital Valve Controller Use for Partial Stroke Testing ..............................220

12.10 High-Integrity Pressure Protection System (HIPPS) ...............................221

12.11 Functionality of the HIPPS ....................................................................221

12.12 Testing Requirements ...........................................................................221

Chapter 13: Engineering Data ............................................................. 224

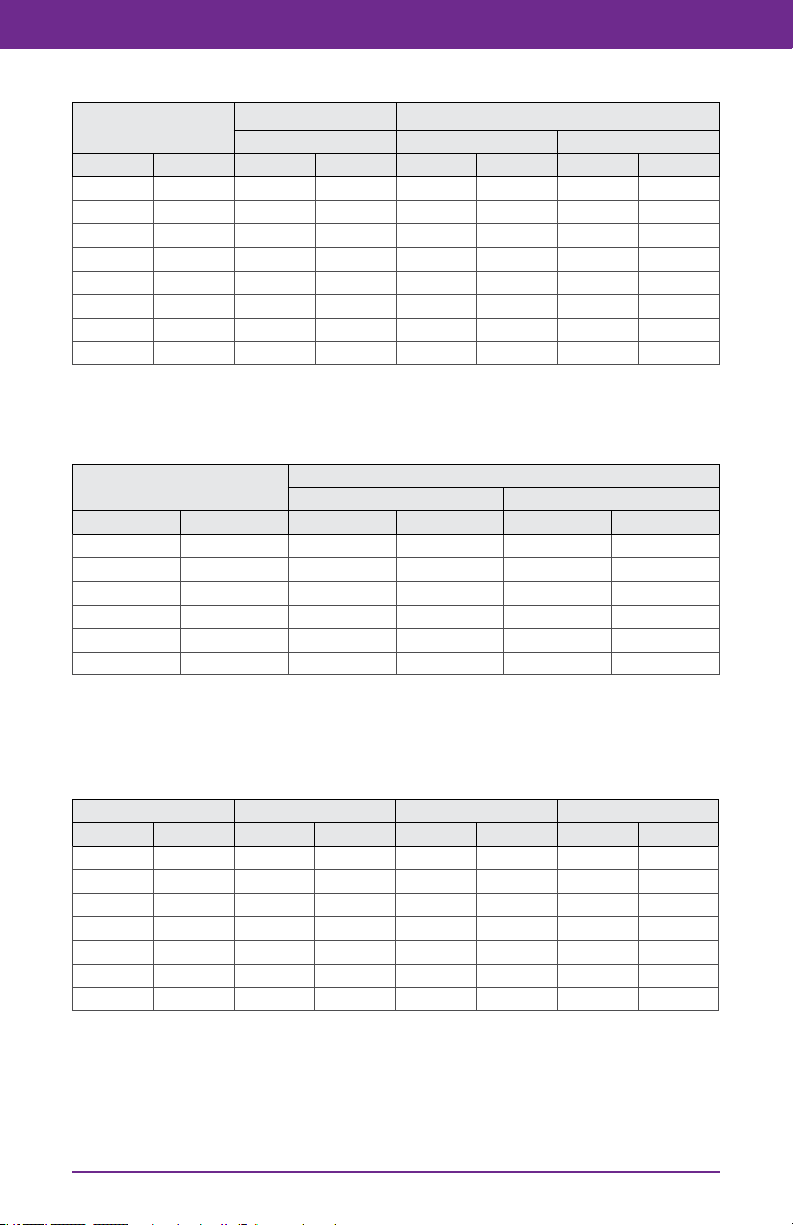

13.1 Standard Specications for Pressure-Retaining Valve Materials ................225

13.2 Valve Material Properties for Pressure-Containing Components .............. 232

13.3 Physical Constants of Hydrocarbons ........................................................234

13.4 Specic Heat Ratio ..................................................................................237

13.5 Physical Constants of Various Fluids ........................................................238

Refrigerant 717 (Ammonia) Properties of Liquid and Saturated Vapor ..............240

13.6

13.7 Properties of Water .................................................................................247

13.8 Properties of Saturated Steam .................................................................248

13.9 Properties of Superheated Steam ............................................................ 257

Chapter 14: Pipe Data ......................................................................... 266

14.1 Pipe Engagement ....................................................................................267

14.2 Carbon and Alloy Steel - Stainless Steel ....................................................267

14.3 American Pipe Flange Dimensions ...........................................................275

14.3.1 Diameter of Bolt Circles ....................................................................................... 275

14.3.2 Number of Stud Bolts and Diameter ..................................................................... 276

14.3.3 Flange Diameter .................................................................................................. 277

14.3.4 Flange Thickness for Flange Fittings ...................................................................... 278

14.4 Cast Steel Flange Standards ..................................................................... 280

14.4.1 Cast Steel Flange Standard for PN 10 .................................................................... 280

14.4.2 Cast Steel Flange Standard for PN 16 .................................................................... 281

12

Page 13

Control Valve Handbook | Table of Contents

14.4.3 Cast Steel Flange Standard for PN 25 .................................................................... 282

14.4.4 Cast Steel Flange Standard for PN 40 .................................................................... 283

14.4.5 Cast Steel Flange Standard for PN 63 .................................................................... 284

14.4.6 Cast Steel Flange Standard for PN 100 .................................................................. 284

14.4.7 Cast Steel Flange Standard for PN 160 .................................................................. 285

14.4.8 Cast Steel Flange Standard for PN 250 .................................................................. 285

14.4.9 Cast Steel Flange Standard for PN 320 .................................................................. 286

14.4.10 Cast Steel Flange Standard for PN 400 ................................................................ 286

Chapter 15: Conversions and Equivalents ............................................ 288

15.1 Length Equivalents ..................................................................................289

15.2 Whole Inch to Millimeter Equivalents ......................................................289

15.3 Fractional Inch to Millimeter Equivalents .................................................290

15.4 Additional Fractional Inch to Millimeter Equivalents ................................291

15.5 Area Equivalents ......................................................................................293

15.6 Volume Equivalents .................................................................................293

15.7 Volume Rate Equivalents ......................................................................... 293

15.8 Mass Conversion–Pounds to Kilograms ................................................... 294

15.9 Pressure Equivalents ...............................................................................294

15.10 Pressure Conversion–Pounds Per Square Inch to Bar .............................295

15.11 Temperature Conversion Formulas ........................................................ 296

15.12 Temperature Conversions .....................................................................296

15.13 API and Baumé Gravity Tables and Weight Factors ................................ 299

15.14 Other Useful Conversions ...................................................................... 301

15.15 Metric Prexes and Sufxes ...................................................................302

Index .................................................................................................. 304

13

Page 14

Chapter 1

Introduction to Control Valves

Page 15

Control Valve Handbook | Chapter 1: Introduction to Control Valves

See Additional Resources »

1.1 What is a Control Valve?

Modern processing plants utilize a vast

network of control loops to produce an

end product for market. These control

loops are designed to keep a process

variable (i.e. pressure, ow, level,

temperature, etc.) within a required

operating range to ensure a quality end

product is produced. Each of these loops

receives and internally creates

disturbances that detrimentally affect

the process variable (PV). Interaction

from other loops in the network also

provide disturbances that inuence the

process variable. See Figure 1.1.

Manipulated

Variable

Control

Valve

Figure 1.1 Feedback Control Loop

Process

Controller

To reduce the effect of these load

disturbances, sensors and transmitters

collect information about the process

variable (PV) and its relationship to some

desired set point. A controller processes

this information and decides what must

be done to get the process variable back

to where it should be after a load

disturbance occurs. When all the

measuring, comparing, and calculating

are done, some type of nal control

element must implement the strategy

selected by the controller.

The most common nal control element

in the process control industries is the

control valve. The control valve

manipulates a owing uid, such as gas,

steam, water, or chemical compounds to

compensate for the load disturbance and

keep the regulated process variable as

close as possible to the desired set point.

Controlled

Variable

Sensor

Transmitter

The control valve is a critical part of the

control loop. Many people who talk

about control valves are really referring

to a control valve assembly. The control

valve assembly typically consists of the

valve body, the internal trim parts, an

actuator to provide the motive power to

operate the valve, and a variety of

additional valve accessories, which can

includes, transducers, supply pressure

regulators, manual operators, snubbers,

or limit switches.

There are two main types of control

valve designs, depending on the action

of the closure member: sliding-stem or

rotary. Sliding-stem valves, as seen in

Figure 1.2 and 1.3, use linear motion to

move a closure member into and out of

a seating surface. Rotary valves, as seen

in Figure 1.13 and 1.17, use rotational

motion to turn a closure member into

and out of a seating surface.

1.2 Sliding-Stem Control Valve Terminology

The following terminology applies to the

physical and operating characteristics of

standard sliding-stem control valves

with diaphragm or piston actuators.

Some of the terms, particularly those

pertaining to actuators, are also

appropriate for rotary control valves.

Many of the denitions presented are in

accordance with ANSI/ISA-75.05.01,

Control Valve Terminology, although

other popular terms are also included.

Additional explanation is provided for

some of the more complex terms.

Additional sections in this chapter follow

that dene specic terminology for

rotary control valves, general process

control, and control valve functions and

characteristics.

15

Page 16

Control Valve Handbook | Chapter 1: Introduction to Control Valves

Actuator Stem Force: The net force

from an actuator that is available for

actual positioning of the valve plug,

referred to as valve travel.

Angle Valve: A valve design in which the

inlet and outlet ports are perpendicular

to each other. See also Globe Valve.

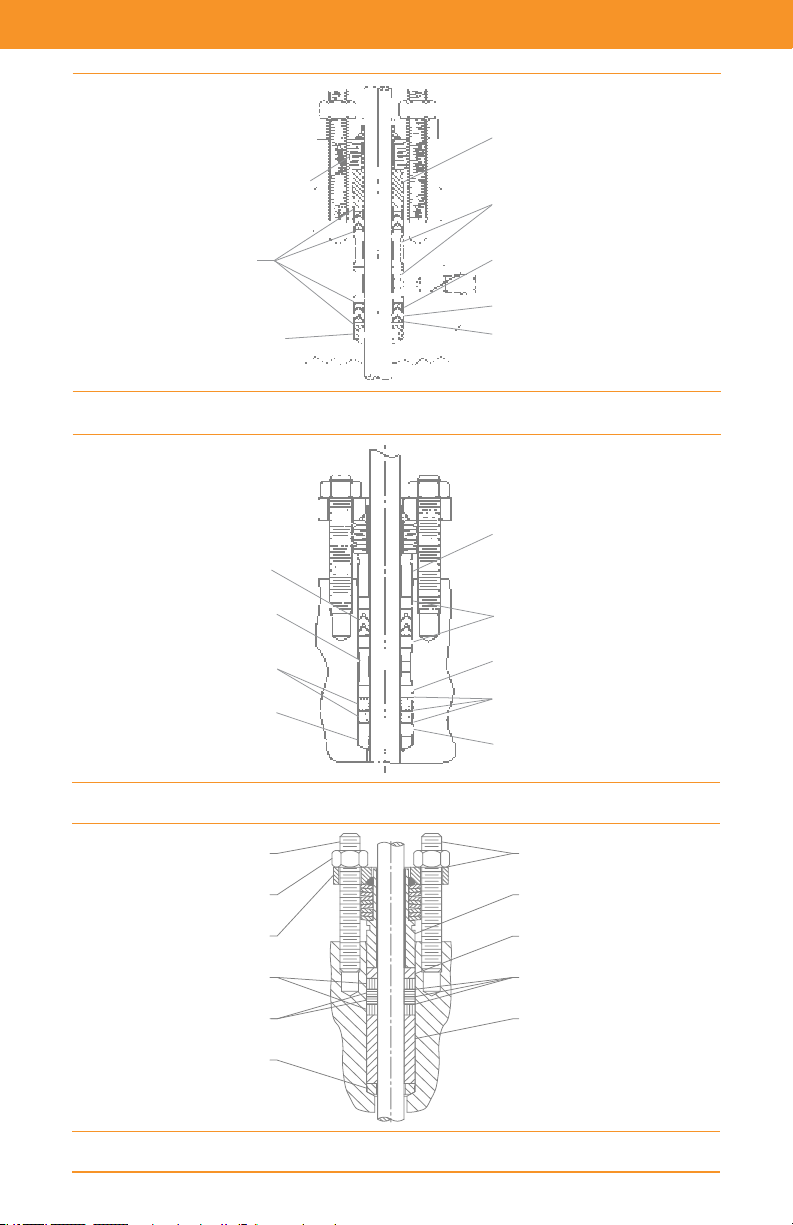

Figure 1.2 Sliding-Stem Control Valve

1. Bonnet

2. Packing Box

3. Cage or Seat

Ring Retainer

4. Valve Stem

1

2

3

6

5. Valve Plug

6. Valve Body

7. Seat Ring

8. Port

4

5

Figure 1.4 Angle Valve

Bellows Seal Bonnet: A bonnet that

uses a bellows for sealing against

leakage around the closure member

stem. See Figure 1.5.

Bonnet: The portion of the valve that

contains the packing box and stem seal

and can provide guiding for the valve

7

8

stem. It provides the principal opening

to the body cavity for assembly of

internal parts or it can be an integral part

of the valve body. It can also provide for

the attachment of the actuator to the

Figure 1.3 Sliding-Stem Control Valve

Actuator Spring: A spring, or group of

springs, enclosed in the yoke or actuator

casing or piston cylinder that moves the

actuator stem in a direction opposite to

that created by loading pressure.

Actuator Stem: The part that connects

the actuator to the valve stem and

transmits motion (force) from the

actuator to the valve.

Actuator Stem Extension: An extension

of the piston actuator stem to provide a

means of transmitting piston motion to

the valve positioner.

valve body. Typical bonnets are bolted,

threaded, welded, pressure sealed, or

integral with the body. This term is often

used in referring to the bonnet and its

included packing parts. More properly,

this group of component parts should

be called the bonnet assembly.

Bonnet Assembly (Commonly Bonnet,

more properly Bonnet Assembly): An

assembly including the part through

which a valve stem moves and a means

for sealing against leakage along the

stem. It usually provides a means for

mounting the actuator and loading the

packing assembly, and maintains proper

16

Page 17

Control Valve Handbook | Chapter 1: Introduction to Control Valves

See Additional Resources »

alignment of the plug to the rest of the

control valve assembly. See Figure 1.6.

1. Bonnet

1

2

3

4

5

Figure 1.5 Bellows Seal Bonnet

1

2

3

4

Figure 1.6 Bonnet Assembly

2. Packing

3. Packing Box

4. Bellows

5. Valve Stem

1. Bonnet

2. Packing

3. Packing Box

4. Valve Stem

Bottom Flange: A part that closes a

valve body opening opposite the bonnet

opening. It can include a guide bushing

and/or serve to allow reversal of the

valve action.

Bushing: A device that supports and/or

guides moving parts such as valve stems

and plugs.

Cage: A part of the valve trim that

surrounds the closure member and can

provide ow characterization and/or a

seating surface. It also provides stability,

guiding, balance, and alignment, and

facilitates assembly of other parts of the

valve trim. The walls of the cage contain

openings that usually determine the

ow characteristic of the control valve.

See Figure 1.7.

Closure Member: The movable part of

the valve that is positioned in the ow

path to modulate the rate of ow

through the valve.

Closure Member Guide: That portion of

a closure member that aligns its

movement in either a cage, seat ring

(port guiding), bonnet, bottom ange,

stem or any two of these.

Cylinder: The chamber of a piston

actuator in which the piston moves.

Cylinder Closure Seal: The sealing

element at the connection of the

piston actuator cylinder to the yoke.

Diaphragm: A exible, pressure

responsive element that transmits

force to the diaphragm plate and

actuator stem.

Diaphragm Actuator: A uid-powered

device in which the uid, usually

compressed air (see Loading Pressure),

acts upon a exible component, the

diaphragm to produce a force to move

the closure member.

Diaphragm Case: A housing,

consisting of top and bottom

section, used for supporting a

diaphragm and establishing one or

two pressure chambers.

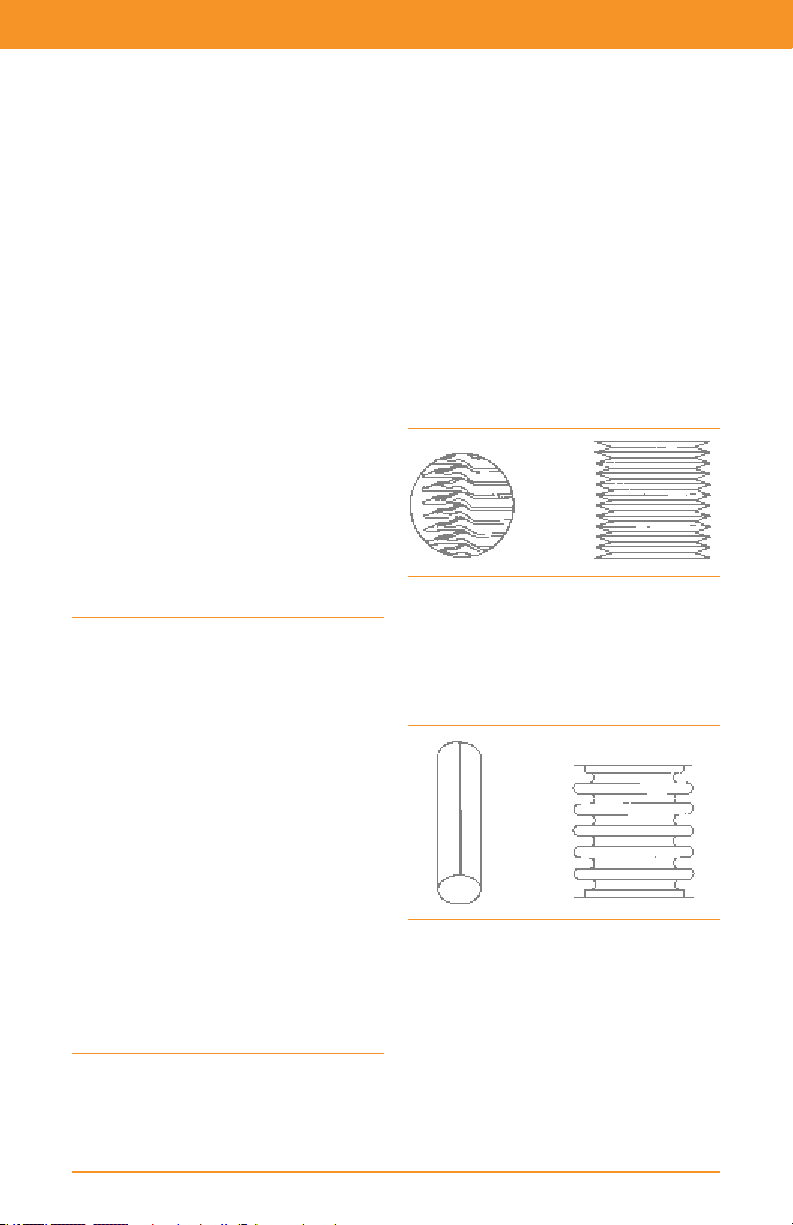

Figure 1.7 Cages (left to right): Linear, Equal-Percentage, Quick-Opening

17

Page 18

Control Valve Handbook | Chapter 1: Introduction to Control Valves

Diaphragm Plate: A rigid plate

concentric with the diaphragm for

transmitting force to the actuator stem.

Direct-Acting Actuator: An actuator,

in which the actuator stem extends

with increasing loading pressure. See

Figure 1.9.

Extension Bonnet: A bonnet with

greater dimension between the

packing box and bonnet ange for hot

or cold service.

Figure 1.8 Three-Way Globe Valve

1

3

Globe Valve: A valve with a linear

motion closure member, one or more

ports, and a body distinguished by a

globular shaped cavity around the port

region. Globe valves can be further

classied as: two-way single-ported

(Figure 1.3); two-way double-ported;

angle-style, or three-way (Figure 1.8).

Loading Pressure: Fluid, usually

compressed air, applied to the diaphragm

or piston in a pneumatic actuator.

Offset Valve: A valve construction

having inlet and outlet line connections

on different planes, but 180 degrees

opposite each other.

Packing Box (Assembly): The part of

the bonnet assembly used to seal

against leakage around the closure

member stem. Included in the complete

packing box assembly are various

combinations of some or all of the

following component parts: packing,

2

4

5

6

7

8

10

Figure 1.9 Direct-Acting Actuator

18

1. Loading Pressure Connection

2. Diaphragm Case

3. Diaphragm

4. Diaphragm Plate

5. Actuator Spring

6. Actuator Stem

7. Spring Seat

8. Spring Adjuster

9

11

9. Stem Connector

10. Valve Stem

11. Yoke

Page 19

Control Valve Handbook | Chapter 1: Introduction to Control Valves

See Additional Resources »

packing follower, packing nut, lantern

ring, packing spring, packing ange,

packing ange studs or bolts, packing

ange nuts, packing ring, packing wiper

ring, felt wiper ring, Belleville springs,

anti-extrusion ring. See Figure 1.11.

Piston: A rigid movable pressure

responsive element that transmits force

to the piston actuator stem.

1

2

3

4

6

Figure 1.10 Piston-Type Actuator

5

1. Loading Pressure

Connection

2. Piston

3. Piston Seal

7

4. Cylinder

5. Cylinder Closure

Seal

6. Seal Bushing

7. Stem Connector

Piston-Type Actuator: A uid powered

device in which the uid, usually

compressed air, acts upon a movable

piston to provide motion of the actuator

stem and provide seating force upon

closure. Piston-type actuators are

classied as either double-acting, so that

full power can be developed in either

direction, or as spring-fail so that upon

loss of supply power, the actuator moves

the valve in the required direction of

travel. See Figure 1.10.

Port: The ow control orice of a

control valve.

Retaining Ring: A split ring that is used to

retain a separable ange on a valve body.

Reverse-Acting Actuator: An actuator

in which the actuator stem retracts with

increasing loading pressure. Reverse

actuators have a seal bushing installed in

the upper end of the yoke to prevent

leakage of the loading pressure along

the actuator stem. See Figure 1.12.

Rubber Boot: A protective device to

prevent entrance of damaging foreign

material into the piston actuator

seal bushing.

Seal Bushing: Top and bottom bushings

that provide a means of sealing the

piston actuator cylinder against leakage.

Synthetic rubber O-rings are used in the

bushings to seal the cylinder, the actuator

stem, and the actuator stem extension.

Seat: The area of contact between the

closure member and its mating surface

that establishes valve shutoff.

Seat Load: The net contact force

between the closure member and seat

with stated static conditions. In practice,

7

8

Figure 1.11 Packing

1

2

3

4

5

6

3

4

5

9

PTFE Packing

1. Upper Wiper

2. Packing Follower

3. Female Adaptor

4. V-Ring

5. Male Adaptor

6. Lantern Ring

7. Washer

8. Spring

9. Box Ring/Lower

Wiper

1

2

4

1

3

1

2

1

Graphite Packing

1. Filament Ring

2. Laminated Ring

3. Lantern Ring

4. Zinc Washer

4

4

19

Page 20

Control Valve Handbook | Chapter 1: Introduction to Control Valves

the selection of an actuator for a given

control valve will be based on how much

force is required to overcome static,

stem, and dynamic unbalance with an

allowance made for adequate seat load.

Seat Ring: A part of the valve body

assembly that provides a seating surface

for the closure member and can provide

part of the ow control orice.

Separable Flange: A ange that ts over

a valve body ow connection. It is

generally held in place by means of a

retaining ring.

Spring Adjuster: A tting, usually

threaded on the actuator stem or into

the yoke, to adjust the spring

compression (see bench set in Control

Valve Functions and Characteristics

Terminology).

Spring Seat: A plate to hold the spring

in position and to provide a at surface

for the spring adjuster to contact.

Static Unbalance: The net force produced

on the valve stem by the process uid

pressure acting on the closure member

and stem with the uid at rest and with

stated pressure conditions.

Stem Connector: The device that

connects the actuator stem to the

valve stem.

Trim: The internal components of a valve

that modulate the ow of the controlled

uid. In a globe valve body, trim would

typically include closure member, seat

ring, cage, stem, and stem pin.

Trim, Soft-Seated: Valve trim with an

elastomeric, plastic, or other readily

deformable material used either in the

closure component or seat ring to

provide tight shutoff with minimal

actuator forces.

Valve Body: The main pressure

boundary of the valve that also provides

the pipe connecting ends, the uid ow

passageway, and supports the seating

surfaces and the valve closure member.

Among the most common valve body

constructions are: single-ported valve

bodies having one port and one valve

plug; double-ported valve bodies having

3

4

1

6

7

8

10

11

Figure 1.12 Reverse-Acting Actuator

20

1. Loading Pressure Connection

2. Diaphragm Case

3. Diaphragm

2

4. Diaphragm Plate

5

9

12

5. Seal Bushing

6. Actuator Spring

7. Actuator Stem

8. Spring Seat

9. Spring Adjuster

10. Stem Connector

11. Valve Stem

12. Yoke

Page 21

Control Valve Handbook | Chapter 1: Introduction to Control Valves

See Additional Resources »

two ports and one valve plug; two-way

valve bodies having two ow

connections, one inlet and one outlet;

three-way valve bodies having three ow

connections, two of which can be inlets

with one outlet (for converging or mixing

ows), or one inlet and two outlets (for

diverging or diverting ows). The term

“valve body”, or even just “body”, is

frequently used in referring to the valve

body together with its bonnet assembly

and included trim parts. More properly,

this group of components should be

called the valve body assembly.

Valve Body Assembly (Commonly Valve

Body or Valve, more properly Valve Body

Assembly): An assembly of a valve body,

bonnet assembly, bottom ange (if

used), and trim elements. The trim

includes the closure member, which

opens, closes, or partially obstructs one

or more ports.

Valve Plug (Plug): A term frequently

used to reference the valve closure

member in a sliding-stem valve.

Valve Stem: In a linear motion valve, the

part that connects the actuator stem

with the closure member.

Yoke: The structure that rigidly connects

the actuator power unit to the valve.

1.3 Rotary Control Valve Terminology

The following terminology applies to the

physical and operating characteristics of

rotary control valves with diaphragm or

piston actuators. The closure members

(i.e. balls, disks, eccentric plugs, etc.) in

rotary designs perform a function

comparable to the valve plug in a

sliding-stem control valve. That is, as

they rotate they vary the size and shape

of the ow stream by opening more or

less of the seal area to the owing uid.

Many of the denitions presented are in

accordance with ISA S75.05, Control

Valve Terminology, although other

popular terms are also included. Terms

pertaining to actuators are also

appropriate for rotary control valves.

Additional explanation is provided for

some of the more complex terms.

Additional sections in this chapter follow

that dene specic terminology for

general process control, and control

valve functions and characteristics.

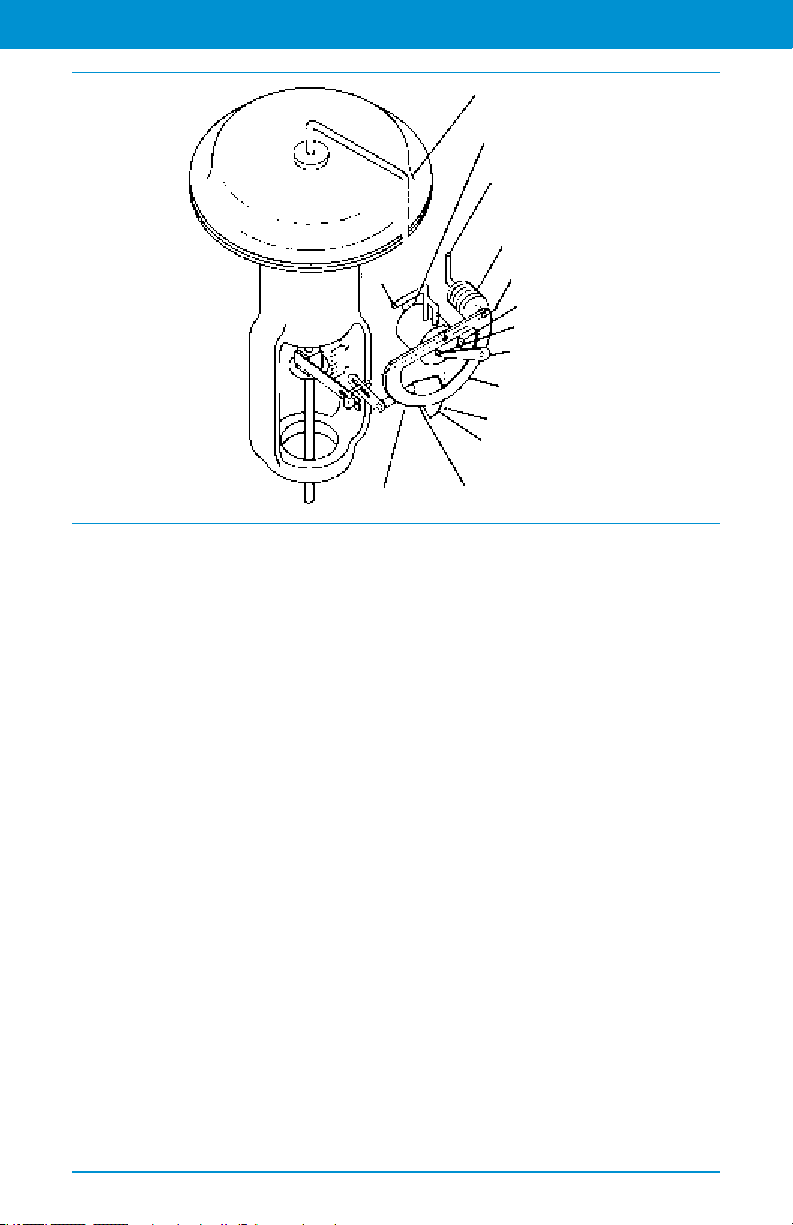

Figure 1.13 Rotary Control Valve

Actuator Lever: Arm attached to rotary

valve shaft to convert linear actuator

stem motion to rotary force (torque) to

position a disk or ball of a rotary valve.

The lever normally is positively

connected to the rotary by close

tolerance splines or other means to

minimize play and lost motion.

Ball, Full: The ow closure member of

rotary control valves using a complete

sphere with a cylindrical ow passage

through it. The ow passage equals or

matches the pipe diameter.

Ball, Segmented: The ow closure

member of rotary control valves using a

partial sphere with a ow passage

through it.

21

Page 22

Control Valve Handbook | Chapter 1: Introduction to Control Valves

opening. This allows the disk to be swung

out of contact with the seal as soon as it

is opened, reducing friction and wear.

Figure 1.14 Segmented Ball

Ball, V-Notch: The most common type

of segmented ball control valve. The

Figure 1.16 Eccentric Disk Valve

V-notch ball includes a polished or

plated partial sphere surface that rotates

against the seal ring throughout the

travel range. The V-shaped notch in the

ball permits wide rangeability and

produces an equal-percentage ow

characteristic.

Flangeless Valve: Valve style common

to rotary control valves. Flangeless

valves are held between ANSI/ASME-

class anges by long through-bolts

(sometimes also called wafer-style

valve bodies).

Plug, Eccentric: Style of rotary control

valve with an eccentrically-rotating plug

which cams into and out of the seat,

which reduces friction and wear. This

style of valve is well suited for erosive

applications.

Reverse Flow: Flow from the shaft/hub

Figure 1.15 V-Notch Ball

Disk, Conventional: The symmetrical

ow closure member used in the most

common varieties of buttery rotary

valves. Highly-dynamic torques normally

limit conventional disks to 60 degrees

maximum rotation in throttling service.

Disk, Dynamically-Designed: A

buttery valve disk contoured to reduce

dynamic torque at large increments of

rotation, thereby making it suitable for

throttling service with up to 90 degrees

of disk rotation.

Disk, Eccentric: Common name for valve

design in which the off-centered

positioning of the valve shaft/disk

connections causes the disk to take a

slightly eccentric (cammed) path on

side over the back of the disk, ball, or

plug. Some rotary control valves are

capable of handling ow equally well in

either direction. Other rotary designs

might require modication of actuator

linkage to handle reverse ow.

Rod End Bearing: The connection often

used between actuator stem and

actuator lever to facilitate conversion of

linear actuator thrust to rotary force

(torque) with minimum of lost motion.

Use of a standard reciprocating actuator

on a rotary valve body commonly

requires linkage with two rod end

bearings. However, selection of an

actuator specically designed for rotary

valve service requires only one such

bearing and thereby reduces lost motion.

Rotary Control Valve: A valve style in

which the ow closure member (full ball,

22

Page 23

Control Valve Handbook | Chapter 1: Introduction to Control Valves

See Additional Resources »

partial ball, disk or plug) is rotated in the

ow stream to control the capacity of

the valve. See Figure 1.17.

Seal Ring: The portion of a rotary

control valve assembly corresponding to

the seat ring of a globe valve. Positioning

of the disk or ball relative to the seal ring

determines the ow area and capacity of

the unit at that particular increment of

rotational travel.

Shaft: The portion of a rotary control

valve assembly corresponding to the

valve stem of a globe valve. Rotation of

the shaft positions the disk or ball in the

ow stream and controls ow through

the valve.

Sliding Seal: The lower cylinder seal in a

pneumatic piston-style actuator

designed for rotary valve service. This seal

permits the actuator stem to move both

vertically and laterally without leakage of

lower cylinder loading pressure, allowing

for a single rod end bearing.

Standard Flow: For those rotary control

valves having a separate seal ring or ow

ring, the ow direction in which uid

enters the valve body through the

pipeline adjacent to the seal ring and

exits from the side opposite the seal

ring. Sometimes called forward ow or

ow into the face of the closure

member. See also Reverse Flow.

Trunnion Mounting: A style of

mounting the disk or ball on the valve

shaft or stub shaft with two

diametrically opposed bearings.

1.4 Control Valve Functions and Characteristics Terminology

Bench Set: The calibration procedure of

an actuator spring so that it can use a

pressure range to fully stroke a valve to

its rated travel (see Inherent Diaphragm

Pressure Range).

Capacity: Amount of ow through a

valve (C

Clearance Flow: Flow that occurs below

the minimum controllable ow with the

closure member not fully seated.

Diaphragm Pressure Span: Difference

between the high and low values of the

diaphragm loading pressure range.

or Kv), under stated conditions.

v

13

14

Figure 1.17 Rotary Control Valve

1

3

5

11

8

10

12

9

2

4

6

7

1. Loading Pressure

Connection

2. Diaphragm Case

3. Diaphragm

4. Diaphragm Plate

5. Spring

6. Actuator Stem

7. Lever

8. Shaft

9. Tra vel Stop

10. Packing

11. Disk

12. Body

13. Seal

14. Seal Retainer

23

Page 24

Control Valve Handbook | Chapter 1: Introduction to Control Valves

Double-Acting Actuator: An actuator in

which pneumatic, hydraulic, or electric

power is supplied in either direction.

Dynamic Unbalance: The net force

produced on the valve plug in any stated

open position by the uid process

pressure acting upon it.

Effective Area: In an actuator, the part

of the diaphragm or piston area that

produces a stem force. The effective

area of a diaphragm might change as it

is stroked, usually being a maximum at

the start and a minimum at the end of

the travel range. Molded diaphragms

have less change in effective area than

at sheet diaphragms; thus, molded

diaphragms are recommended.

Fail-Closed: A condition wherein the

valve closure member moves to a closed

position when the actuating energy

source fails.

Fail-Open: A condition wherein the

valve closure member moves to an open

position when the actuating energy

source fails.

Fail-Safe: A characteristic of a valve and

its actuator, which upon loss of actuating

energy supply, will cause a valve closure

member to be fully closed, fully open, or

remain in the last position, whichever

position is dened as necessary to

protect the process and equipment.

action can involve the use of auxiliary

controls connected to the actuator.

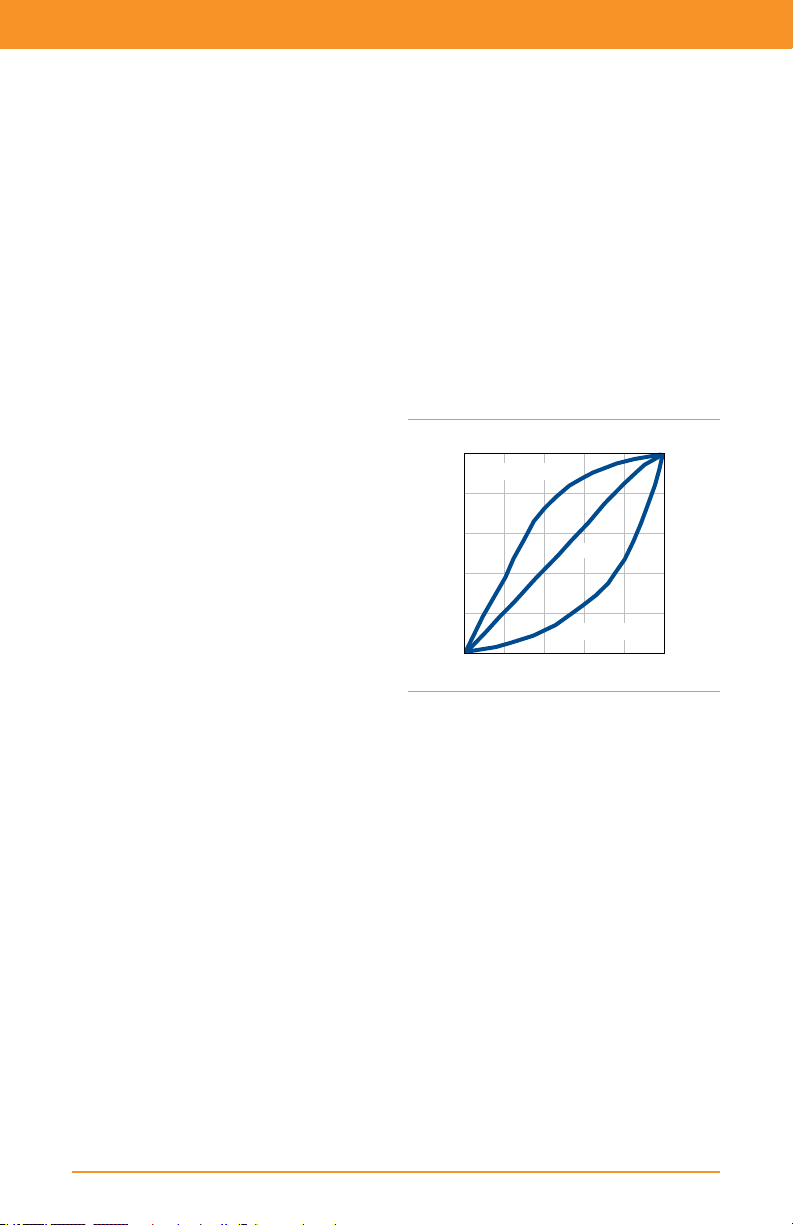

Flow Characteristic: Relationship

between ow through the valve and

percent rated travel as the latter is varied

from 0 to 100%. This term should always

be designated as either inherent ow

characteristic or installed ow

characteristic (See denitions in Process

Control Terminology Section).

Flow Coefcient (C

): A constant related

v

to the geometry of a valve, for a given

travel, that can be used to establish ow

capacity. It is the number of U.S. gallons

per minute of 16°C (60°F) water that will

ow through a valve with a one pound

per square inch pressure drop.

High-Recovery Valve: A valve design

that dissipates relatively little ow

stream energy due to streamlined

internal contours and minimal ow

turbulence. Therefore, pressure

downstream of the valve vena contracta

recovers to a high percentage of its inlet

value. Straight-through ow valves, such

as rotary ball valves, are typically

high-recovery valves.

Inherent Diaphragm Pressure Range:

The high and low values of pressure

applied to the diaphragm to produce

rated valve plug travel with atmospheric

pressure in the valve body. This range is

often referred to as a bench set range

because it will be the range over which

the valve will stroke when it is set on

the work bench.

Inherent Flow Characteristic: The

relationship between the ow rate and

the closure member travel as it is

moved from the closed position to

rated travel with constant pressure drop

across the valve.

Installed Diaphragm Pressure Range:

The high and low values of pressure

applied to the diaphragm to produce

rated travel with stated conditions in the

valve body. It is because of the forces

acting on the closure member that the

inherent diaphragm pressure range can

differ from the installed diaphragm

pressure range.

Installed Flow Characteristic: The

relationship between the ow rate and

the closure member travel as it is

moved from the closed position to

rated travel as the pressure drop across

the valve is inuenced by the varying

process conditions.

Low-Recovery Valve: A valve design

that dissipates a considerable amount of

ow stream energy due to turbulence

24

Page 25

Control Valve Handbook | Chapter 1: Introduction to Control Valves

See Additional Resources »

created by the contours of the ow path.

Consequently, pressure downstream of

the valve vena contracta recovers to a

lesser percentage of its inlet value than is

the case with a valve having a more

streamlined ow path. Although

individual designs vary, conventional

globe-style valves generally have low

pressure recovery capability.

Modied Parabolic Flow

Characteristic: An inherent ow

characteristic that provides equalpercentage characteristic at low closure

member travel and approximately a

linear characteristic for upper portions

of closure member travel.

Normally-Closed Valve: See Fail-Closed.

Normally-Open Valve: See Fail-Open.

Push-Down-to-Close (PDTC)

Construction: A globe-style valve

construction in which the closure

member is located between the

actuator and the seat ring, such that

extension of the actuator stem moves

the closure member toward the seat

ring, nally closing the valve. The term

can also be applied to rotary valve

constructions where linear extension of

the actuator stem moves the ball or disk

toward the closed position. Also called

direct-acting.

Push-Down-to-Open (PDTO)

Construction: A globe-style valve

construction in which the seat ring is

located between the actuator and the

closure member, so that extension of

the actuator stem moves the closure

member from the seat ring, opening the

valve. The term can also be applied to

rotary valve constructions where linear

extension of the actuator stem moves

the ball or disk toward the open

position. Also called reverse-acting.

Rangeability: The ratio of the largest

ow coefcient (C

ow coefcient (C

or Kv) to the smallest

v

or Kv) within which

v

the deviation from the specied ow

characteristic does not exceed the

stated limits. A control valve that still

does a good job of controlling when ow

increases to 100 times the minimum

controllable ow has a rangeability

of 100 to 1. Rangeability can also be

expressed as the ratio of the maximum

to minimum controllable ow rates.

Rated Flow Coefcient (C

coefcient (C

) of the valve at rated travel.

v

): The ow

v

Rated Travel: The distance of

movement of the closure member from

the closed position to the rated full-open

position. The rated full-open position is

the maximum opening recommended

by the manufacturers.

Relative Flow Coefcient (C

ratio of the ow coefcient (C

stated travel to the ow coefcient (C

): The

v

) at a

v

)

v

at rated travel.

Seat Leakage: The quantity of uid

passing through a valve when the valve

is in the fully closed position and

maximum available seat load is applied

with pressure differential and

temperature as specied.

Spring Rate (K

): The force change per

s

unit change in length of a spring. In

diaphragm actuators, the spring rate is

usually stated in pounds force per inch

compression.

Vena Contracta: The portion of a ow

stream where uid velocity is at its

maximum and uid static pressure and

the cross-sectional area are at their

minimum. In a control valve, the vena

contracta normally occurs just

downstream of the actual physical

restriction.

1.5 Process Control Terminology

The following terms and denitions not

previously dened are frequently

encountered by people associated with

25

Page 26

Control Valve Handbook | Chapter 1: Introduction to Control Valves

control valves, instrumentation, and

accessories. Some of the terms,

indicated with an asterisk (*), are

derived from the ISA standard, Process

Instrumentation Terminology, ISA 51.1.

Other popular terminology used

throughout the control valve industry is

also included.

Accessory: A device mounted to a

control valve assembly to complement

various functions or produce desired

actions, particularly actuation. (i.e.

positioners, supply pressure regulators,

solenoids, limit switches, etc.).

Actuator*: A pneumatic, hydraulic, or

electrically powered device that supplies

force and motion to open or close a valve.

Actuator Assembly: An actuator,

including all the pertinent accessories

that make it a complete operating unit.

ANSI: Abbreviation for American

National Standards Institute.

API: Abbreviation for American

Petroleum Institute.

ASME: Abbreviation for American

Society of Mechanical Engineers.

ASTM: Used to stand for American

Society for Testing and Materials. As

the scope of the organization became

international, the name was changed to

ASTM International. ASTM is no longer

an abbreviation.

Automatic Control System*: A control

system that operates without human

intervention.

Backlash: A form of deadband that

results from a temporary discontinuity

between the input and output of a

device when the input of the device

changes direction. (i.e. slack, or

looseness, of a mechanical connection).

Bode Diagram*: A plot of log amplitude

ratio and phase angle values on a log

frequency base for a transfer function. It