Page 1

00809-0100-4263

Product Discontinued

English

Rev. AA

Model 444 Alphaline®

Temperature

Transmitters

Page 2

Page 3

Product Manual

1

Model 444 Alphaline

®

Temperature Transmitters

NOTICE

Read this manual before working with the product. For personal and system

safety, and for optimum product performance, make sure you thoroughly

understand the contents before installing, using, or maintaining this product.

Within the United States, Rosemount Inc. has two toll-free assistance numbers.

Customer Central: 1-800-999-9307 (

Technical support, quoting, and order-related questions.

North American 1-800-654-7768 (

Response Center: Equipment service needs.

For equipment service or support needs outside the United States, contact your

local Rosemount representative.

7:00 a.m. to 7:00 p.m. CST)

24 hours a day – Includes Canada)

Rosemount Inc.

8200 Market Boulevard

Chanhassen, MN 55317 USA

Tel 1-800-999-9307

Telex 4310012

Fax (612) 949-7001

00809-0100-4263

© Rosemount Inc. 1998.

http://www.rosemount.com

N

I

R

P

IN

U.

S.

The products described in this document are NOT designed for nuclearqualified applications.

Using non-nuclear qualified products in applications that require nuclearqualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local

Rosemount Sales Representative.

SNF-0004

Ros

emount, the Rosemount logotype, and Alphaline are registered trademarks of Rosemount Inc.

Chromel and Alumel are trademarks of Hoskins Mfg. Co.

Cover Photo: 444-005AC

Fisher-Rosemount satisfies all obligations coming from legislation

to harmonize product requirements in the European Union.

T

E

D

A.

Page 4

Page 5

Table of Contents

SECTION 1

Introduction

SECTION 2

Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Mechanical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Mounting Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Access Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Housing Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Terminal Side of Electronics Housing . . . . . . . . . . . . . . . . . 2-2

Circuit Side of Electronics Housing . . . . . . . . . . . . . . . . . . 2-2

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Sensor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

RTD Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Thermocouple or Millivolt Inputs . . . . . . . . . . . . . . . . . . . . 2-6

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Multi-Channel Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Surges/Transients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Temperature Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Moist or Corrosive Environments . . . . . . . . . . . . . . . . . . . . . . . 2-9

Hazardous Location Installation . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Intrinsically Safe Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

SECTION 3

Calibration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Calibrating a RTD Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Calibrating a Thermocouple Transmitter

Using a Compensated Thermocouple Simulator . . . . . . . . . . . 3-5

Using an Ice Bath . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Calibrating a Low-Power Transmitter . . . . . . . . . . . . . . . . . . . . . . 3-8

Calibrating a Millivolt Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

i

Page 6

SECTION 4

Maintenance and

Troubleshooting

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Hardware Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Disassembly Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Reassembly Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Interchangeability of Parts

Mechanical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Electrical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Burnout Protection Adjustments . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Repair and Warranty Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

SECTION 5

Specifications

and Reference Data

SECTION 6

Options

APPENDIX A

Approval Drawings

APPENDIX B

T emperature Sensor

Reference Information

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

LCD Meter Specifications

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Physical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Analog Meter Specifications

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Physical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

LCD / Analog Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

ii

Page 7

Section

1 Introduction

OVERVIEW

This manual is designed to assist in installing, operating, and

maintaining Rosemount

Transmitters.

Section 2 Installation

provides mechanical, electrical, and environmental considerations to

guide you through a safe and effective transmitter installation.

Section 3 Calibration

provides different Model 444 calibration procedures.

Section 4 Maintenance and Troubleshooting

provides hardware diagnostics, maintenance tasks, basic hardware

troubleshooting techniques, and considerations for returning materials.

Section 5 Specifications and Reference Data

provides functional, performance, and physical transmitter

specifications; also includes transmitter dimensional drawings,

ordering information, and spare parts.

Section 6 Options

provides a listing of transmitter options and a description of each.

Appendix A Approval Drawings

contains approval drawings for Canadian Standards Association (CSA)

and Factory Mutual (FM) instrinsic safety installation.

Appendix B Temperature Sensor Reference Information

provides reference information regarding the application of various

Rosemount temperature sensors.

®

Model 444 Alphaline® Temperature

1-1

Page 8

Rosemount Model 444 Alphaline Temperature Transmitters

1-2

Page 9

Section

2 Installation

OVERVIEW

This section includes the following transmitter installation

information:

• General Considerations

• Mechanical Considerations

Mounting Stability

Access Requirements

• Electrical Considerations

Power Supply

Field Wiring

Sensor Connections

Grounding

Multi-Channel Installations

Surges/Transients

• Environmental Considerations

Temperature Environment

Moist or Corrosive Environments

Hazardous Location Installation

Intrinsically Safe Installation

• Installation Procedure

Mechanical

Electrical

GENERAL

CONSIDERATIONS

Failure to follow these installation guidelines may result in

death or serious injury. Make sure only qualifiedpersonnel

perform the installation.

Explosions can cause death or serious injury. Verify that the

operating atmosphere of the transmitter is consistent with

the appropriate hazardous locationscertifications.

Use the Rosemount Model 444 Alphaline Temperature Transmitter

when the temperature measurement point is remote from the control,

readout, or recording point, or where the measurement point is exposed

to environmental conditions that would be harmful to unprotected

signal conditioning equipment.

Electrical temperature sensors such as RTDs and thermocouples

2-1

Page 10

Rosemount Model 444 Alphaline Temperature Transmitters

produce low-level signals proportional to their sensed temperature. Model 444

temperature transmitters convert the low-level sensor signal to a standard 4–20

mA dc signal that is relatively insensitive to lead length and electrical noise.

This current signal is then transmitted to the control room via two wires.

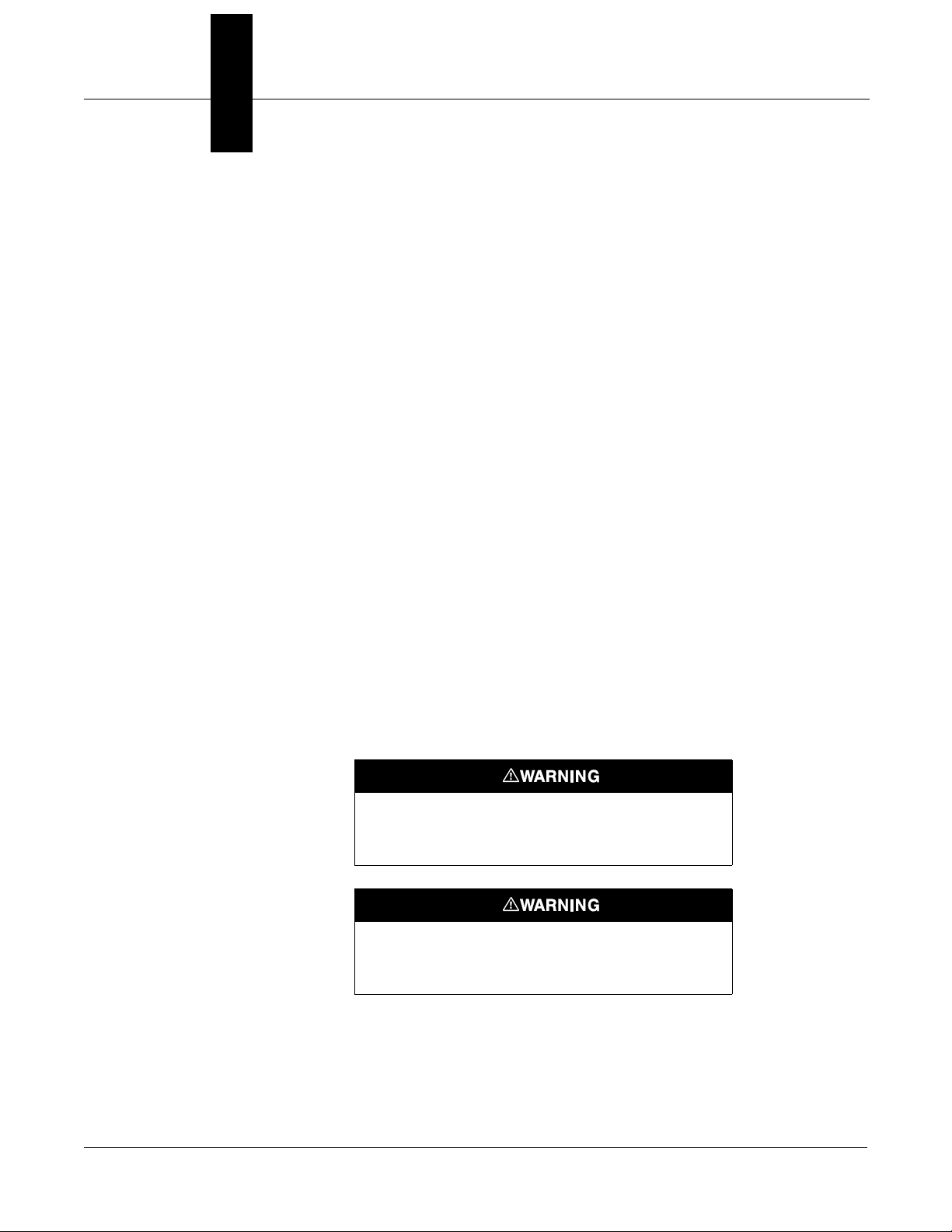

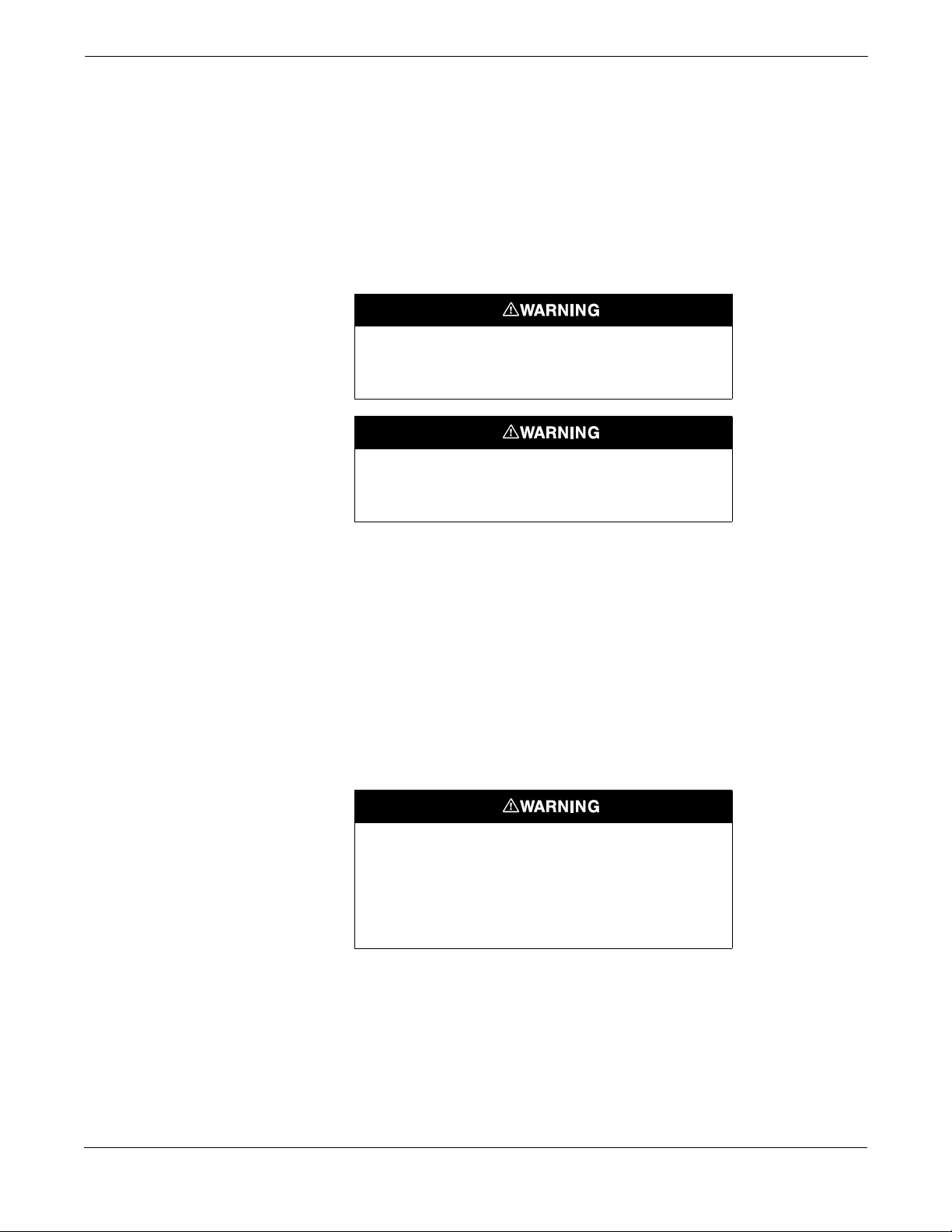

Figures 2-1, and 2-2 show recommended mounting configurations for

transmitter and sensor assemblies. See Section 6 Options for information

regarding Model 444 transmitter accessories.

MECHANICAL

CONSIDERATIONS

Mounting Stability

Access

Requirements

Housing Rotation You may rotate the transmitter in 90-degree increments to improve field access

Terminal Side of

Electronics Housing

Circuit Side of

Electronics Housing

You can attach the transmitter directly to the sensor assembly as shown in

Figures 2-1 and 2-2. An optional mounting bracket permits the transmitter to be

mounted remotely from the sensor(s), either on a flat surface or attached to a

two-inch pipe (See Figure 2-11 on page 2-13). The choice of mounting method

must take into account a number of factors:

Mounting stability is an important consideration. The transmitter, though

rugged, may require supplementary support under high-vibration conditions,

particularly if extensive thermowell lagging or long extension fittings are used.

In such instances, the pipestand mounting technique shown in Figure 2-11 on

page 2-13 is preferable.

When choosing an installation location and position, take into account the need

for access to the transmitter.

to both compartments.

Make wiring connections through the conduit openings on the terminal side of

the electronics housing. Mount the transmitter so the terminal side is accessible,

and be sure to provide adequate clearance for cover removal.

The transmitter electronics are installed in the circuit side of the transmitter

housing. In case of electronic malfunction, provide adequate clearance for

circuit-side cover removal. Also, be sure to account for additional clearance if a

meter is to be installed. For more information regarding the meter option, refer

to Section 6 Options.

2-2

Page 11

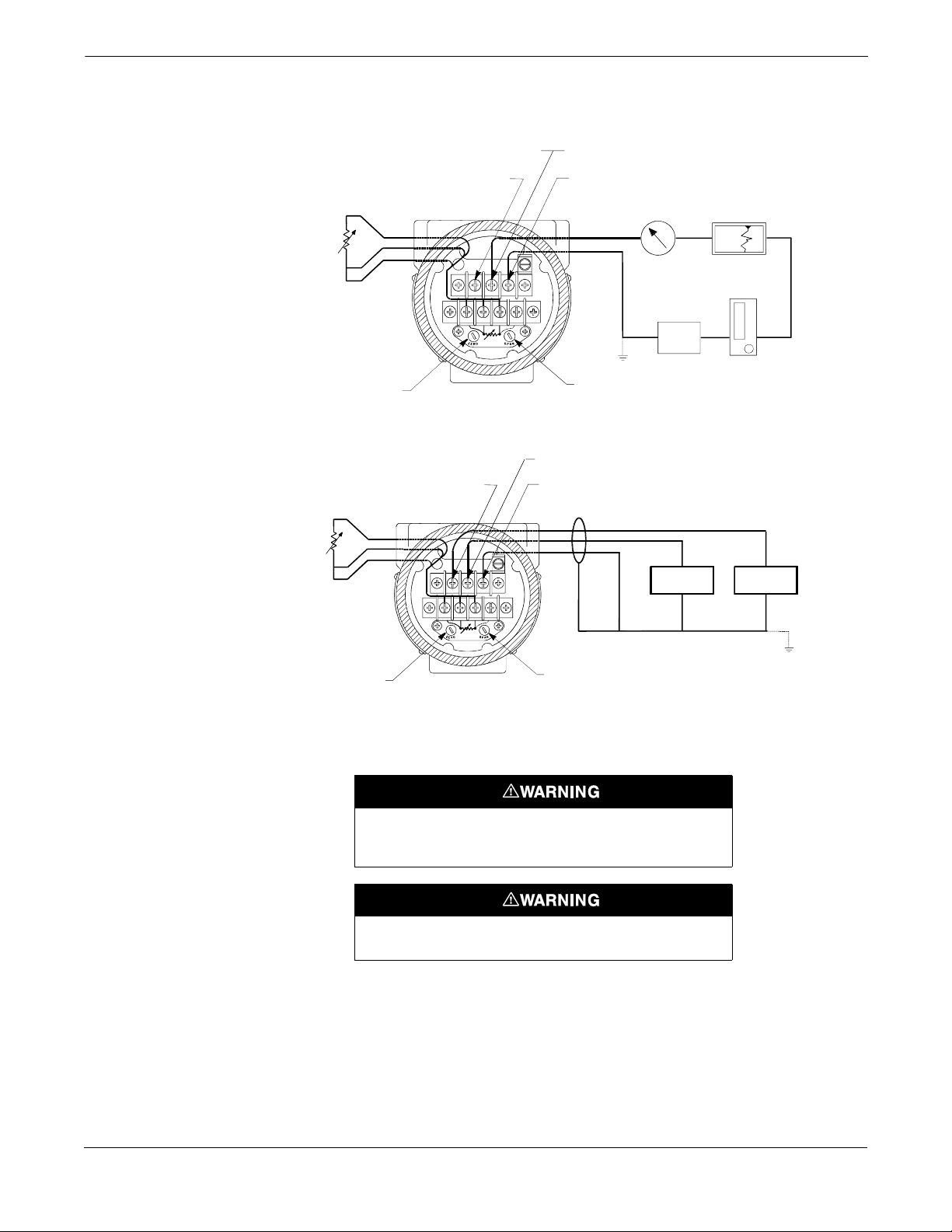

FIGURE2-1. Recommended

Process Mounting.

Installation

Thermowell

NOTE

Dimensionsare in inches (millimeters).

FIGURE2-2. Recommended

Process Mounting with

Drain Seal.

Thermowell

Hex

Extension

Nipple

Extension

Length

Union or Coupling

Sensor Hex

Transmitter

Conduit for

Field Wiring

(dc Power)

3.2

(81.3)

444-0200C

Extension

Nipple

Union or Coupling

Sensor Hex

Drain Seal

Conduit for

Field Wiring

(dc Power)

Coupling

Close Nipple

Street Ell

Transmitter

Terminal

Side

444-0200F

2-3

Page 12

Rosemount Model 444 Alphaline Temperature Transmitters

ELECTRICAL

CONSIDERATIONS

Po wer Supply

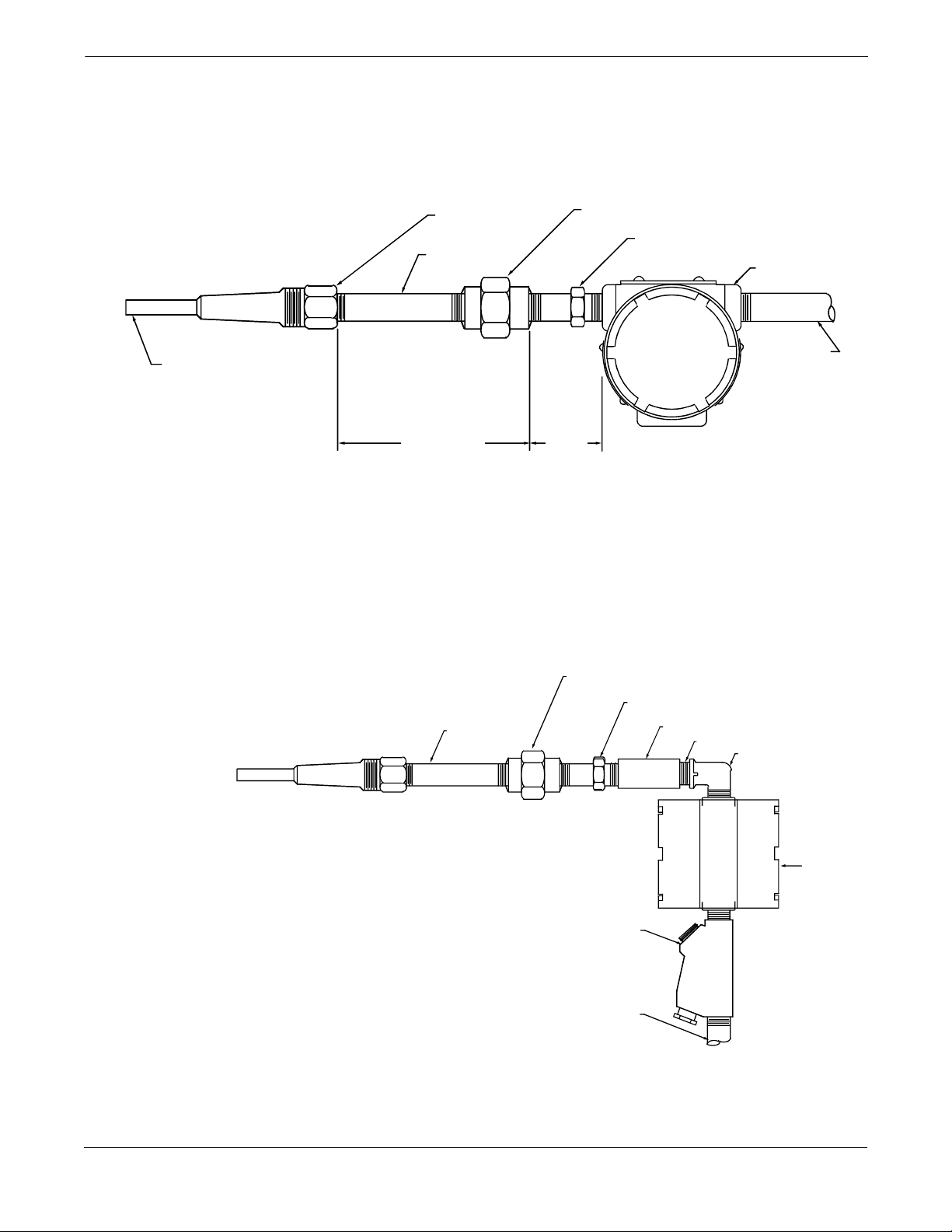

FIGURE 2-3. Model 444

Load Limits.

This section contains information that you should consider when preparing to

install Model 444 transmitters. Read this section carefully before going on to the

installation procedures. Metal conduit should be used to enclose cabling for best

results in electrically noisy environments.

The dc power supply should provide power with less than 2% ripple. The input

voltage versus load limitation relationship for 4–20 mA transmitters is shown in

Figure 2-3. Figure 2-4 shows field wiring for a standard Model 444 transmitter.

Figure 2-5 shows field wiring for Models 444LL and 444LM low-power voltage

output units, which require 100K ohms minimum load. The total R-load is the

sum of the resistance of the signal leads and the load resistance of the controller,

indicators, and related devices. Note that the resistance of intrinsic safety

barriers, if used, must be included in the total load.

Power Supply Load Limitations

R

LOAD(MAX.)

1650

1500

1000

500

Load (Ohms)

0

Voltage

Too Low

12 20 30 40

=503 (V

Power Supply (V dc)

(MIN.)

Operating

Region

– 12)

Field Wiring

Explosions mayresult in death or serious injury.

Do not remove the instrument cover in explosive

atmospheres when the circuit is alive.

High voltage that may be present on leads can cause

electrical shock.Avoid contact with leads and terminals.

Do not apply high voltage (e.g. ac line voltage) to the

transmitter terminals. Abnormally high voltage can damage

the unit.

All power to the transmitter is supplied over the signal wiring. Signal wiring

need not be shielded, but use twisted pairs for best results. Do not run

unshielded signal wiring in conduit or open trays with power wiring, or near

heavy electrical equipment. To power the transmitter, connect the positive power

lead to the terminal marked “+” and the negative power lead to the terminal

marked “–” (see Figures 2-4 and 2-5). Tighten the terminal screws to ensure

adequate contact. No additional power wiring is required.

2-4

Page 13

FIGURE 2-4. Field Wiring for

the StandardModel 444

Transmitters.

Meter Connections

and S ignal

Test Points

(+)

{

(–) (–)

(+)

{

dc Power

Installation

FIGURE 2-5. Field Wiring for

Low-Power Model

444 Transmitters

(444LL and LM).

RTD Input

(typical)

Zero Adjust

RTD Input

Zero Adjust

Output Voltage (+)

Optional

Ground

Span Adjust

(+) dc Power

(–) Common

Shield

Span Adjust

–+–+

Power

Supply

+

++––

444-0000C02A

Output Load Limitation

Minimum Load = 100K

AtoD

Converter

Optional

Ground

444-0000A02A

Sensor

Connections

RTD Inputs

Explosion mayresult in death or serious injury. Do not

remove the instrument cover in explosive atmos pheres

when the circuit is alive.

Highvoltagethatmaybe present on leads can causeelectrical

shock. Avoid contact with the leads and the terminals.

Various RTD configurations are used in industry; each configuration offers a

specific solution for compensating the effects of lead wire resistance. They

include 3- and 4-wire designs. The correct installation for each of these RTDs is

shown in Figures 2-6a and b on page 2-6.

If the transmitter is mounted remotely from the RTD, operation will be

satisfactory, without recalibration, for lead wire resistances of up to 2 ohms per

lead (equivalent to 200 feet of 20 AWG wire). In this case, the leads between the

RTD and transmitter should be shielded.

2-5

Page 14

Rosemount Model 444 Alphaline Temperature Transmitters

The correct connections for a compensation loop RTD and a 2-wire RTD are

shown in Figure 2-6c and Figure 2-6d, respectively. In a 2-wire RTD, however,

both leads are in series with the sensor element, so significant errors (0.1 °C)

could occur if the lead lengths are greater than one foot. For longer runs when

using a 2-wire RTD, attach a third lead and connect as shown in Figure 2-6a.

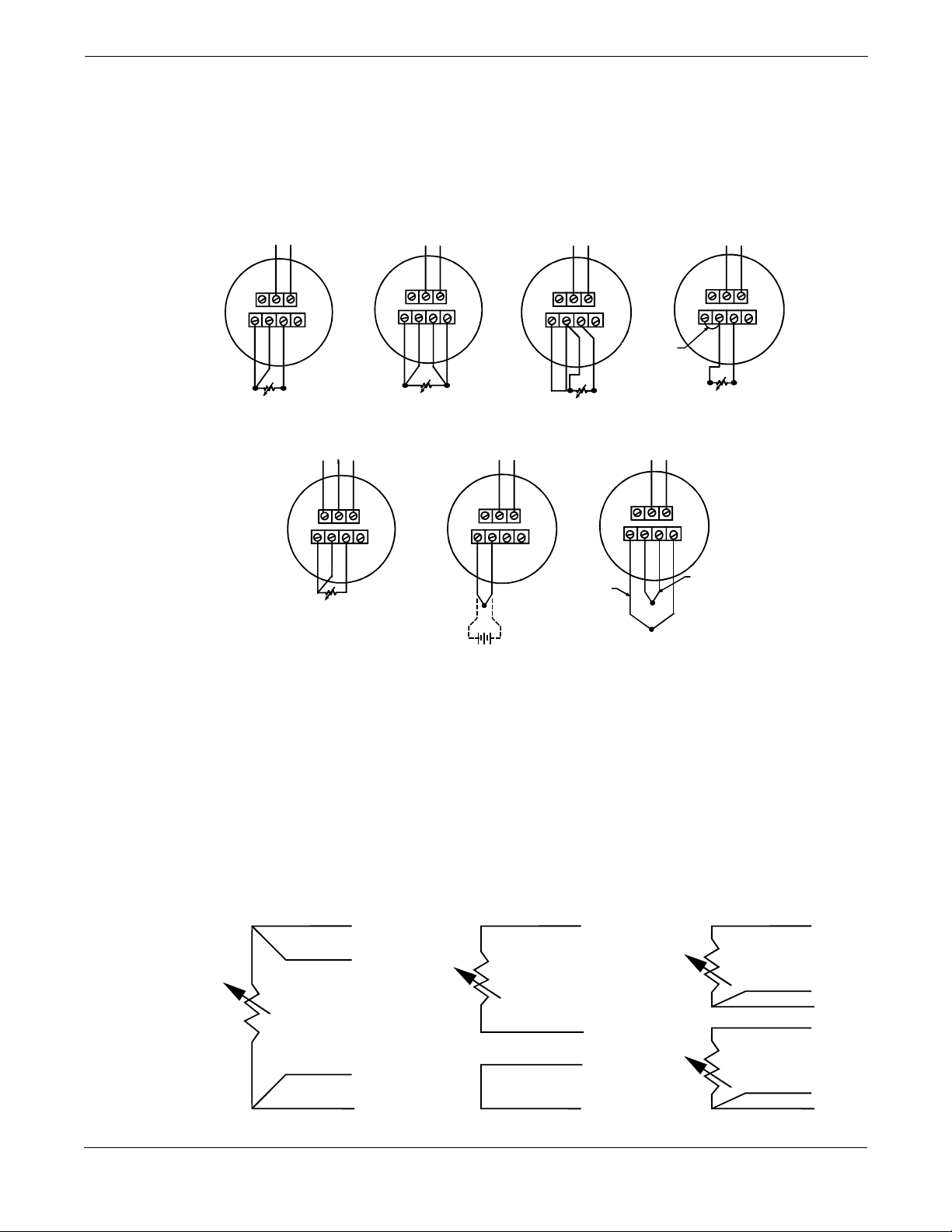

FIGURE 2-6.Sensor Wiring Diagrams.

Signal

–+

Red

Red

White

Model 444 with 3-Wire RTD

Figure 2-6a

Signal

+ Output Common –

Red

Model 444LL or 444LM

with 3-Wire RTD

Figure 2-6e

Signal

–+

Red

Red

White

Model 444 with 4-Wire RTD

Figure 2-6b

Red

White

Model 444MV with Millivolt

Input or Model444T Series

with Grounded or

Ungrounded Thermocouple

White

Signal

–+

Figure 2-6f

Model 444 with

Comp. Loop RTD

Figure 2-6c

–+

High T/C

–+

Signal

–+

Red

Jumper

White

Model 444 with 2-Wire RTD

Black

Black

Signal

++ ––

Model 444MV used as

DifferentialMillivolt

Transmitter (T/C Junctions

must be ungrounded)

Figure 2-6g

Figure 2-6d

–+

Low T/C

Signal

White

Red

–+

444-0203A;B;C;D

FIGURE 2-7.Characteristics of Thermocouple and RTD Input Wires.

Thermocouple Type Positive Lead Negative Lead

J Iron (Magnetic) Constantan (Non-magnetic)

K Chromel (Non-magnetic) Alumel (Magnetic)

T Copper (Yellow color) Constantan (Silver color)

E Chromel (Shiny metal) Constantan (Dull metal)

R Platinum 1 3% Rhodium Platinum

S Platinum 10% Rhodium Platinum

Single Element RTD Compensation Loop RTD Dual E lement RTD

Red

Red

White

White

2-6

Red

White

Black

Black

Red

White

White

Black

Green

Green

444-0207A

Page 15

Installation

Thermocouple or

Millivolt Inputs

Grounding

In the case of thermocouples, make connections between the sensor and the

transmitter with thermocouple wire. For process mounting applications, connect

the thermocouple directly to the transmitter. For installations where the

transmitter is mounted remotely from the sensor, use appropriate thermocouple

extension wire. As with all low-level signal wiring, shielding is recommended for

long runs. Make input connections for the Model 444MV Millivolt Transmitter

using copper wires. The correct connections for thermocouple and millivolt

inputs are shown in Figures 2-6f and g.

The transmitter will operate with the current signal loop either floating or

grounded. However, many types of readout devices are affected by the extra

noise in floating systems. If operation appears noisy or erratic, grounding the

current signal loop at a single point may solve the problem. The negative

terminal of the power supply is the best place to ground the loop. Alternately,

either side of the readout device could be grounded. Do not ground the current

signal loop at more than one point.

Thermocouple and millivolt transmitters are isolated, so the input circuit also

may be grounded at any single point (when a grounded thermocouple is used,

this point is the grounded junction), and the signal loop may be grounded at any

point.

The 444RL transmitter is not isolated, so there can be no grounds in the RTD

circuit. Since RTDs must be well-insulated from ground in order to give correct

temperature readings, this is not normally an installation limitation. The

positive side of the power supply should not be grounded for use with RTD input

transmitters. The 444RI9 should be used with grounded RTDs.

Multi-Channel

Installations

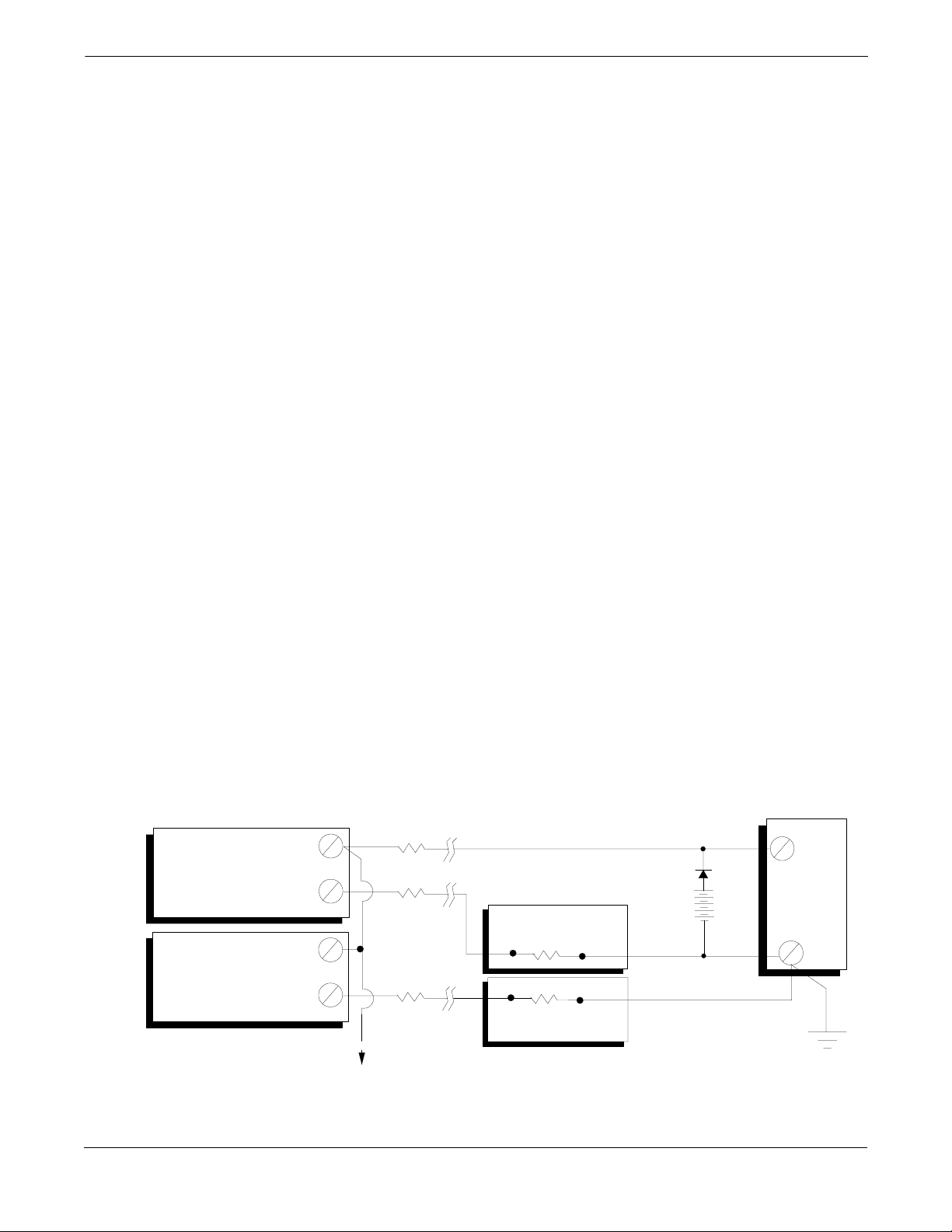

FIGURE 2-8. Multi-Channel

Installation.

Transmitter

No. 1

Transmitter

No. 2

If using shielded wire, connect the shield of the sensor-to-transmitter cable to

the shield of the transmitters-to-receiver cable. Ground the shielding only at the

signal loop ground.

Figure 2-8 illustrates how several transmitters can be connected to a single

master power supply. In this instance, the system can be grounded only at the

negative power supply terminal. Since several channels are dependent on one

supply, an uninterruptible power supply or backup battery should be considered

if loss of all channels would pose operational problems. The diodes shown in

Figure 2-8 prevent unwanted charging or discharging of the battery.

ToAdditional

Transmitters

Readout or

Controller No. 1

Readout or

Controller No. 2

+

Backup

Battery

–

dc

Power

Supply

+

–

444-0202A

2-7

Page 16

Rosemount Model 444 Alphaline Temperature Transmitters

Surges/Transients

ENVIRONMENTAL

CONSIDERATIONS

Temperature

Environment

The transmitter will withstand electrical transients of the energy level usually

encountered in static discharges or induced switching transients. However, highenergy transients, such as those induced in wiring from nearby lightning strikes,

can damage both the transmitter and the sensor.

To protect against high-energy transients, install Model 444 transmitters in

conjunction with the Rosemount Model 470 Transient Protector. The Model 470

prevents damage from transients induced by lightning, welding, heavy electrical

equipment, or switch gears. Refer to the Model 470 Transient Protector product

data sheet, pub. no. 00813-0100-4191 for more information.

The transmitter will operate within specifications for ambient temperatures

between –25 and 85 °C. It will function, but not necessarily within specifications,

in ambient temperatures between

–40 and 100 °C.

Aside from ambient temperature variations, heat from the process is transferred

from the thermowell to the transmitter housing. If the process temperature is

near or beyond specification limits, use excess thermowell lagging or an

extension nipple to protect the transmitter from the high temperature condition.

See Figure 2-10.

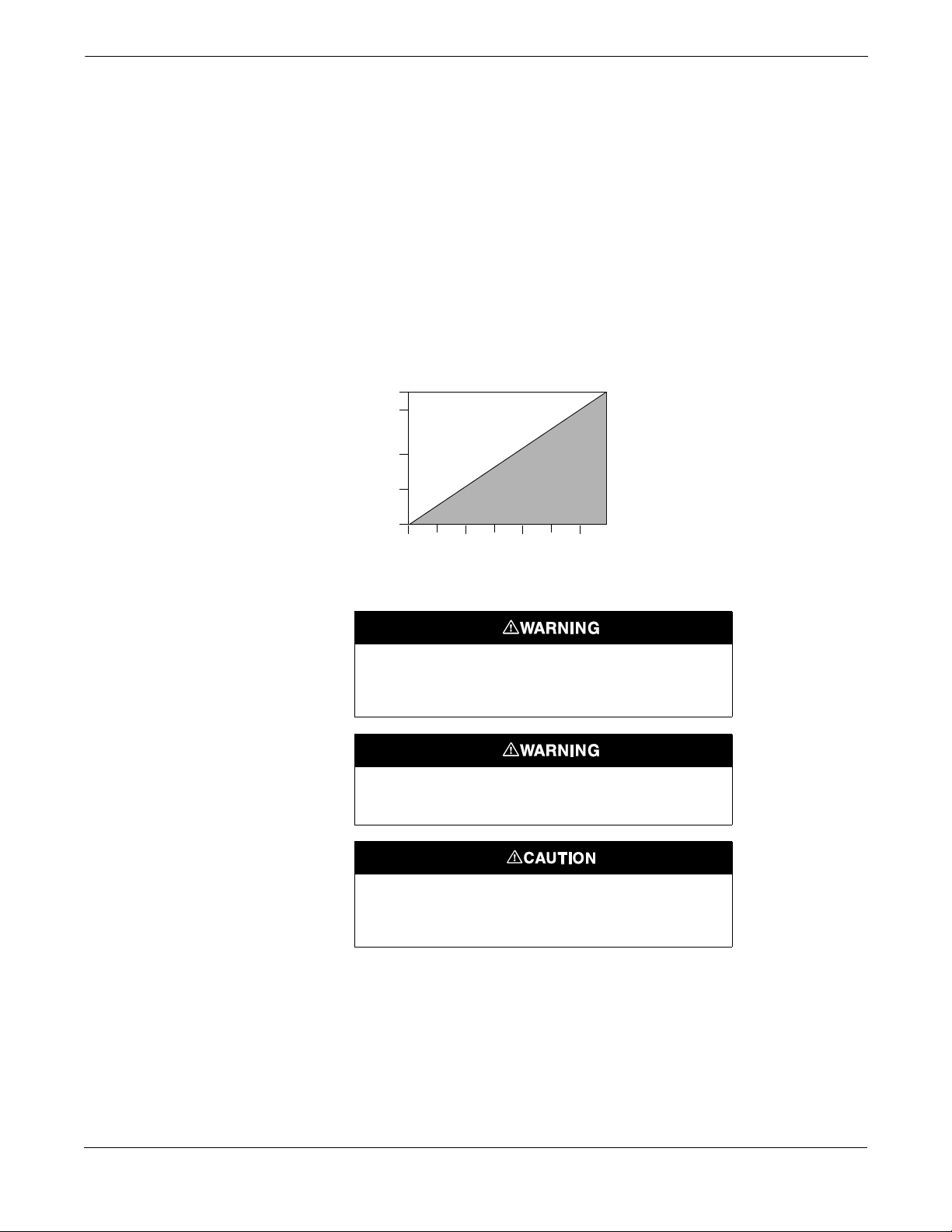

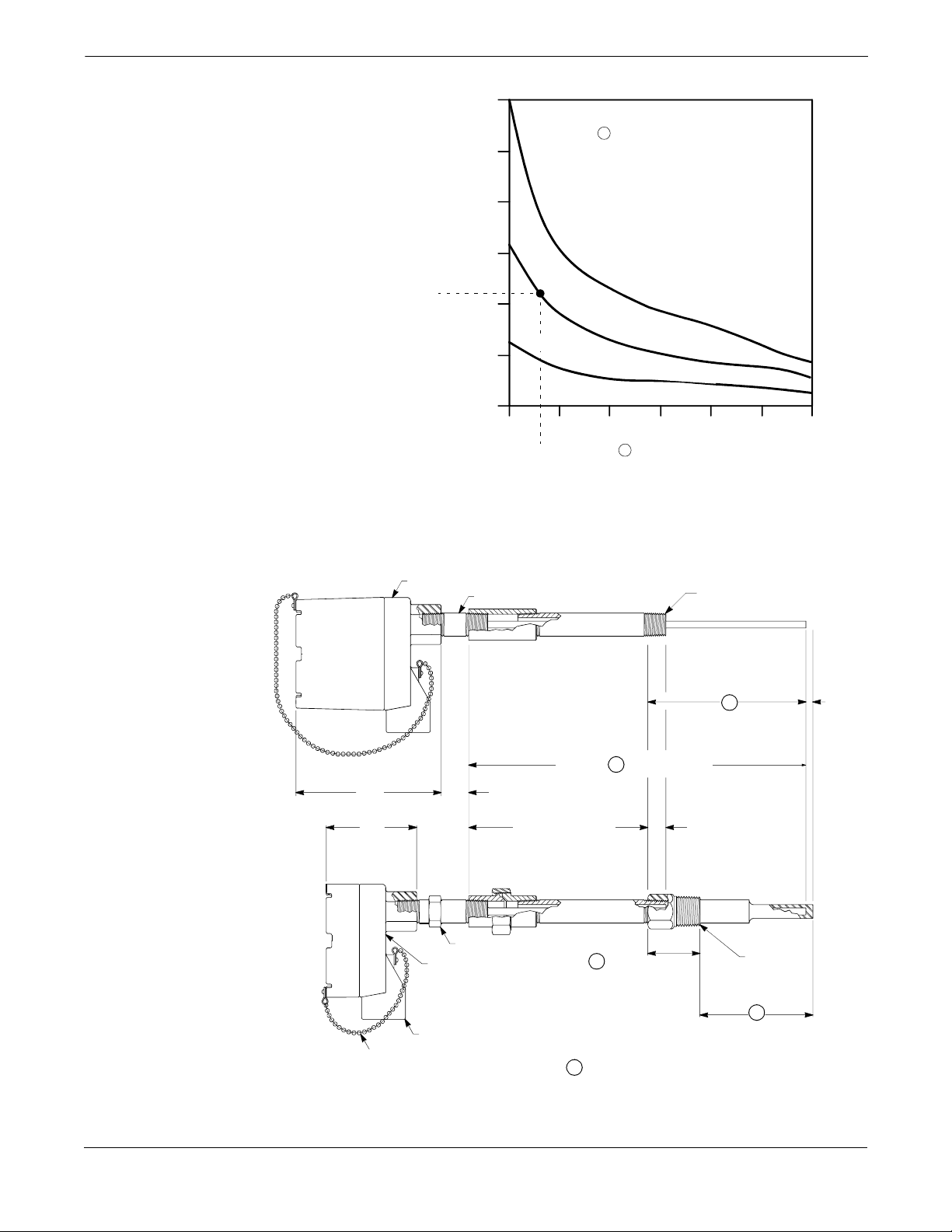

EXAMPLE:

Suppose the maximum ambient temperature is 40 °C and the temperature to

be measured is 540 °C. The maximum allowable housing temperature rise is

the rated temperature specification limit minus the existing ambient

temperature (85 – 40), or 45 °C. As shown in Figure 2-9, an “E” dimension of

3.6 inches will result in a housing temperature rise of 22 °C. An “E”

dimension of 4 inches would therefore be the minimum recommended length,

and would provide a safety factor of about about 25 °C. A longer “E”

dimension, such as 6 inches, would be desirable in order to reduce errors

caused by transmitter temperature effect, although in that case the

transmitter would probably require extra support. If a thermowell with

lagging is used, the “E” dimension may be reduced by the length of the

lagging.

2-8

Page 17

Installation

FIGURE 2-9. Model 444

Transmitter Housing

Temperature Rise.

FIGURE 2-10. Sensor

Assembly Dimensional

Drawings.

HOUSING

RISE

ABOVE

AMBIENT

°C (°F)

60

(108)

50

(90)

40

(72)

30

(54)

22

20

(36)

10

(18)

Connection Head with Extended Cover

25

0

3 4 5 6 7 8 9

Bayonet Spring Loaded Sensor

Transmitter Housing Temperature Rise

E

vs. Length for a Test Installation

8

1

5

°

C

(

1

540

°

C

(

1000

0

3.6

°

C

(

4

8

2°

°

F)

O

v

e

nT

E

5

0

0

°

F

)

O

v

e

n

T

e

F

)

O

v

e

n

T

e

m

pe

e

mp

e

r

a

t

u

r

e

Length in Inches

½–14 NPT Thread

m

p

e

r

a

tu

r

e

r

a

t

ur

e

3044-0123A

NOTE

Dimensions are in inches (millimeters).

5.5

(140)

3.5

(89)

Chain

Sensor Installed in

Connection Head

(Extended Cover)

with Coupling and

Nipple Extension

1.0

(25)

2.2

(56)

Spring Loaded Sensor

Connection Head with

Flat Cover

¾–14 NPT

Nominal Fitting

Sensor Installed in

ConnectionHead(Flat

Cover)withUnionand

Nipple Extension and

Thermowell

Sensor Length (Ref.)

Length

X

E

V

(1)

+ 1.75 (44)

T

(1)

T

= 0.0 on Standard Assembly Thermowells

L

0.53 (13) Max.

Thread

Engagement

¾–14 NPT

on Thermowell

U

0.25

(6)

Sensors-0000A06A

2-9

Page 18

Rosemount Model 444 Alphaline Temperature Transmitters

Moist or Corrosive

Environments

HazardousLocation

Installation

The transmitter is designed to resist attack by moisture and other corrosives.

The coated circuit boards are mounted in a compartment completely sealed from

the conduit entrances. O-ring seals protect the interior when the covers are

installed. In humid environments, however, it is still possible for moisture

“breathing” to occur in conduit lines. If the transmitter is mounted at a low point

in the conduit run, the terminal compartment could fill with water, causing

electrical shorting. The transmitter should be mounted so moisture from the

conduit will not drain into the housing. In some instances a drain seal, installed

as shown in Figure 2-2 on page 2-3, is advisable.

Explosions mayresult in death or serious injury.Verify that

the operating atmosphere of the transmitter is consistent

with the appropriate hazardous locations certifications.

Explosions mayresult in death or serious injury.Both

transmitter covers must be fully engaged to meet explosionproof requirements.

Intrinsically Safe

Installation

The Model 444 is designed with an explosion-proof housing and circuitry

suitable for intrinsically safe and non-incendive operation. Individual

transmitters are clearly marked with a tag indicating the approvals they carry.

The various approvals are available as options. Refer to Section 5

Specifications and Reference Data for a complete listing of available

approvals.

To maintain certified ratings for installed transmitters, install in accordance

with applicable installation codes and approval drawings. Refer to Appendix A

Approval Drawings for Model 444 installation drawings. For future orders,

refer to the current product price list for the most up-to-date information on

these approvals.

For explosion-proof installations, installation location must

be m ade in accordance with Rosemount drawing 004440261, Rev. E.

For intrinsically safe installations, installation location must

be m ade in accordance with Rosemount drawing 004440034, Rev. C (CSA) or00444-0264, Rev. B (SAA).

You can use Intrinsically safe installations instead of explosion-proof

installations in hazardous areas. In such configurations, the transmitter and

sensor are located in a hazardous area, and the current signal leads are

connected to equipment in a non-hazardous area through intrinsic safety

barriers that limit the voltage and current fed into the hazardous area. Install in

accordance with the barrier manufacturer’s instructions for the specific barrier

used. For approval information, refer to Table 5-1 on page 5-4, and Table 5-2 on

page 5-5. For installation information, refer to the intrinsically safe barrier

systems reference drawings in Appendix A Approval Drawings.

2-10

Page 19

Installation

INSTALLATION

PROCEDURE

Installation consists of mounting the transmitter and sensor assembly and

making electrical connections. If mounting the transmitter directly to the sensor

assembly, use the process mounting technique shown in Figure 2-1 or Figure 2-2,

on page 2-3. For transmitter locations remote from the sensor, use conduit

between the sensor and transmitter. Transmitter hubs will accept male conduit

fittings with ½–14 NPT; ½–14 NPSM; or ½–14 taper thread per ANSIC 80.4.

Explosion mayresult in death or serious injury. Do not

remove the instrument cover in explosive atmos pheres

when the circuit is alive.

High voltage that may be present on leads may cause

electrical shock.Avoid contact with the leads and the

terminals.

Process leaks may result in death or serious injury.Install

and tighten thermowells or sensors before applying

pressure, or process leakage may result. Removing the

thermowell or sensor while in operation may cause process

fluid leaks.

Mechanical

Electrical

1. Mount the thermowell to the pipe or process container wall.

2. Attach any necessary extension nipples and adapters. Seal the nipple and

adapter threads with silicone or tape.

3. Screw the sensor into the thermowell.

4. Install drain seals if required for severe environments or to satisfy code

requirements (See Figure 2-2 on page 2-3).

5. Attach the transmitter to the thermowell assembly. Seal the adapter

threads with silicone or tape.

6. Install conduit for field wiring to the remaining conduit entry of the

transmitter. Seal conduit threads with silicone or tape.

7. Pull field wiring leads through the conduit into the terminal side of the

transmitter housing.

For explosion-proof installations, wiring connections must

be m ade in accordance with Rosemount drawing 004440261, Rev. E.

For intrinsically safe installations, wiring connections must

be m ade in accordance with ANSI/ISA-RP12.6, and

Rosemount drawing 00444-0034, Rev.C (CSA) or 004440264, Rev. B (SAA).

For all installations, wiring connections must follow the

National Electric Code.

2-11

Page 20

Rosemount Model 444 Alphaline Temperature Transmitters

Preliminary Checkout

1. For any Model 444 unit, first verify that the transmitter is calibrated to

the required range. Calibration is usually performed by substituting an

input in place of the sensor, and this is most conveniently accomplished

prior to sensor connection. Refer to the calibration procedures in Section

4 Maintenance and Troubleshooting.

Input Connections

2. Model 444RL: Connect the RTD leads as shown in Figure 2-6a, b, c, d, or

e depending upon the lead compensation method used.

Model 444T series: Connect the thermocouple leads as shown in Figure

2-6f. Polarity is important; be sure to identify the leads accurately. The

negative lead is usually red; if there is no color coding, the characteristics

provided in Figure 2-7 may be helpful.

Model 444MV: If using the transmitter as a millivolt-to-milliampere

converter, use ordinary copper leads for input connections as shown in

Figure 2-6f. If using the transmitter with two thermocouples to measure

differential millivolt, connect the thermocouples as shown in Figure 2-6g.

The “high” thermocouple causes the transmitter output to increase when

its temperature increases relative to the “low” thermocouple. Grounded

thermocouples cannot be used for differential measurements.

Models 444LL and LM: In these low-power option packages, the RTD

leads are connected the same as in the conventional RTD arrangements

shown in Figure 2-6a, b, c, and d.

Output Connections

3. For all 4–20 mA models, use ordinary copper wire of sufficient size to

assure that the voltage across the transmitter power terminals does not go

below 12 V dc (See Figure 2-3). For multi-channel or intrinsically safe

installations, see applicable paragraphs in this section.

Model 444RL: Connect current signal leads as shown in Figure 2-6a, b, c,

or d.

Model 444T series: Connect current signal leads as shown in Figure 2-6f.

Model 444MV: Connect current signal leads as shown in Figure 2-6f or g.

Models 444LL and LM: Connect current signal leads as shown in Figure

2-6e.

Final Checkout

4. For all models, recheck the polarity and correctness of connections; then

turn the power on.

2-12

Page 21

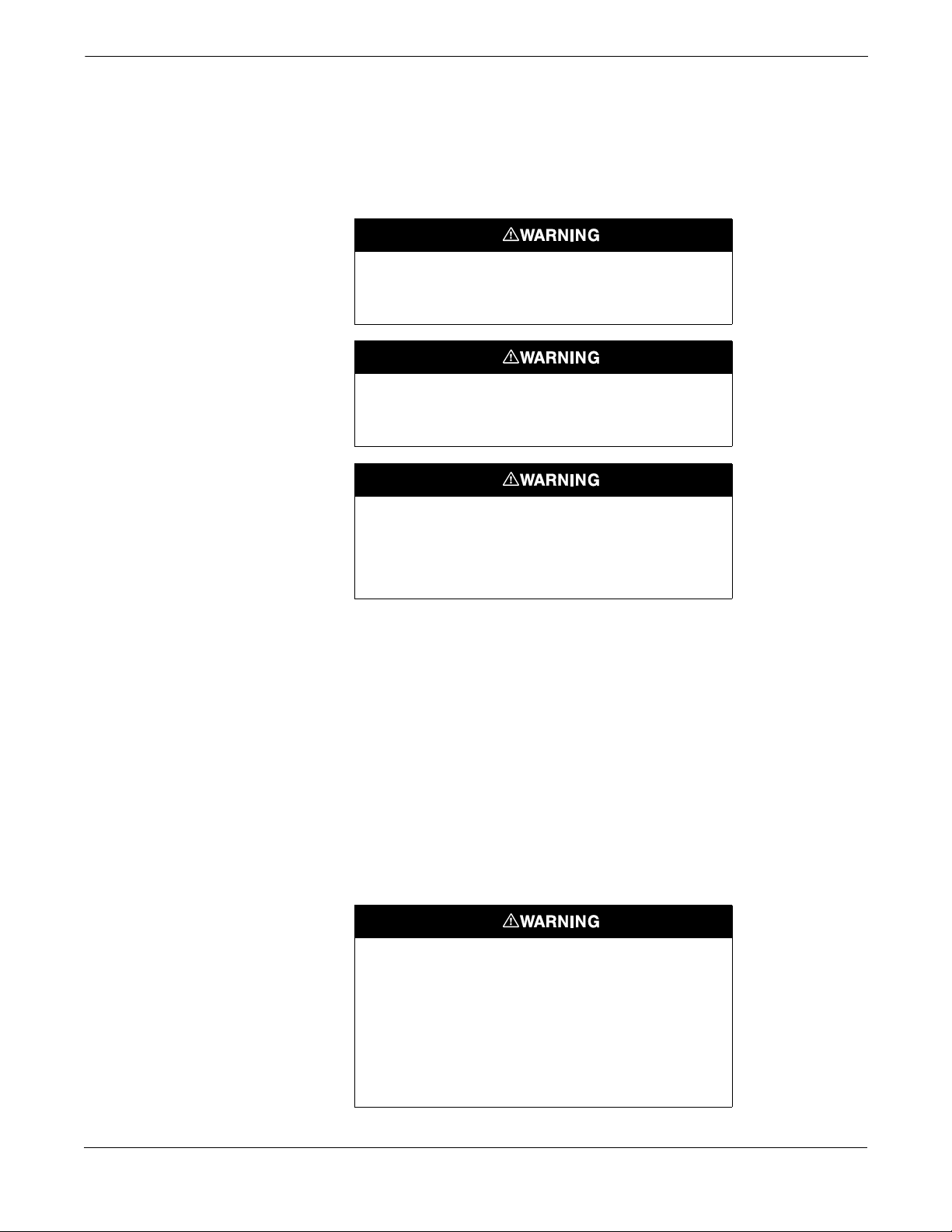

FIGURE 2-11. Model 444

with

Optional Mounting Bracket.

Installation

PIPESTAND MOUNTING

Clearance Hole

for ¼-inch Bolt

(eight places)

NOTE

Dimensions are in inches (millimeters).

FIGURE 2-12. Model 444

Dimensional Drawings

4.5 Max.

(114)

Transmitter can be Rotated 90°

Mounting Bracket

¼–20 3½-inch

5

/16 –18 U-bolt for

2-inch Pipe (2)

Permanent Tag

(Optional)

Bolt (4)

PANEL OR SURFACE MOUNTING

5.00 (127)

7.5 (191) Max. with Optional

Meter

Meter Housing

5

/16 -inch Bolts

(four required,

not furnished)

2.81 (81)

4.5 Max.

(114)

Hole for

5

/16 -inch

Bolts

(four

places)

0.75 (19)

Clearance for

Cover Removal

(Typical)

444-1151G, 1151F04A

4.5 Max.

Nameplate

Explosion Proof or

Intrinsic Safety L abel

(Optional)

0.375 (10) Min. Dp.

NOTE

Dimensions are in inches (millimeters).

(114)

Mounting Holes

¼–20 UNC–2B

(four places)

½–14 NPT per

ANSI C80.4 for

Conduit or Sensor

Connection

(two places)

0.87 (22)

1.7

(44)

(117)

Terminal

Connections

this Side

0.36 (9)

0.72 (18)

4.2

Terminal

Circuitry

this Side

444-51LTE 05A, 51LTG05A, 51LTF 05A

2-13

Page 22

Rosemount Model 444 Alphaline Temperature Transmitters

2-14

Page 23

Section

3 Calibration

OVERVIEW

SAFETY MESSAGES

Each transmitter is factory calibrated to the temperature range shown

on the nameplate. If calibration to a specific range is not specified on

the purchase order, the transmitter is calibrated to maximum span

with a base temperature of 0 °C, and the “Calibration” entry on the

transmitter nameplate is left blank. For more specific calibration

information and a complete breakdown of transmitter parts, refer to

Section 5 Specifications and Reference Data.

Only a few calibration laboratories have the kind of precision

temperature baths necessary for accurate direct calibration of a

temperature sensor or sensor/transmitter system. As a result, the

transmitter is normally calibrated by substituting a resistance decade

box for an RTD or a compensated thermocouple simulator for a

thermocouple.

This section contains the following transmitter calibration information:

• Calibrating a RTD Transmitter

• Calibrating a Thermocouple Transmitter

• Calibrating a Low-Power Transmitter

• Calibrating a Millivolt Transmitter

This section contains procedures that require removing the transmitter

covers and making electrical connections. The following safety

messages apply to all such procedures.

Explosion mayresult in death or serious injury. Do not

remove the instrument cover in explosive atmos pheres

when the circuit is alive.

High voltage that may be present on leads can cause

electrical shock.Avoid contact with the leads and the

terminals.

3-1

Page 24

Rosemount Model 444 Alphaline Temperature Transmitters

CALIBRATING A

RTD TRANSMITTER

Calibration Procedure To calibrate a model 444RL or 444RL___B0912, perform the following procedure:

Calibration Equipment Required:

Readout Resistor. The transmitter test terminals give a 40–200 mV signal. The

Models 444RL and444RL ___B0912 have a jumper-selectable 4–20 mA test

output option (2-board sets). If this is not suitable for the test equipment

available, a ±0.1% tolerance, 0.5 W precision wirewound resistor is needed.

Suggested values include a 100-ohm resistor to give a 0.4 to 2 volt output; or 500

ohms for 2 to 10 volts.

Voltmeter (such as a 5-digit DVM). Voltage rating is dependent upon the test

signal. Accuracy is ±0.01%; resolution is 1 mV.

dc Power Supply. Power capability is 24 V dc at 35 mA.

Resistance Decade Box. Precision type, 5-dial, with largest dial providing 100-

ohm steps. Accuracy is ±0.02 ohm. The decade box should be periodically

calibrated against a 5-dial Wheatstone bridge.

Lead Simulation Resistors. If the transmitter is to be mounted remote from the

RTD, and the lead resistance between the transmitter and the RTD is greater

than 2 ohms per lead (equivalent to 200 ft of 20 AWG wire), the transmitter

should be trimmed with simulated lead resistances for best accuracy. This

requires wirewound resistors with resistance values equal to the nominal lead

resistance of the RTD.

1. The Models 444RL and 444RL ___B0912 have a jumper-selectable 4–20

mA test output option. If a 4–20 mA test output is required, reposition the

test terminal output jumper on the range board (the default setting is 40–

200 mV). Refer to steps 2 through 4 of the disassembly procedure, on page

4-4, for information on removing the circuit board assembly.

Place the jumper in the position labelled “A” for a 4–20 mA test output. See

Figure 3-1. Refer to steps 5 through 12 of the reassembly procedure, on

page 4-5, for information on reinstalling the circuit board assembly.

2. Remove the cover from the terminal side of the transmitter housing.

3. If an RTD is already connected, remove all RTD lead connections.

4. Attach the calibration test equipment as shown in Figure 3-2. Use

miniature banana plugs to make terminal connections. Use simulated lead

resistors only if necessitated by long lead wire lengths, as discussed above.

3-2

NOTE

If using RTD configurations other than the 3-wire design shown in Figure 3-2,

refer to Figure 2-6 on page 2-6 for the correct wiring.

5. If trimming the transmitter to a new range, you may have to reposition the

Coarse Zero Jumper on the Range Board. If so, see the disassembly

procedure on page 4-4. Position the jumper in the location shown in Table

3-1. (A transmitter with a Base Temperature outside the regions shown in

Table 3-1 is a special design, and does not contain a Coarse Zero Jumper.)

Reassemble the circuit boards.

Page 25

Calibration

6. Determine the RTD resistance at the desired base and full scale

temperatures. For Calibration Code 1 (see Table 5-3, on page 5-9), these

resistances are listed in Table B-1.

7. Turn the power on.

8. Set the decade box to the resistance corresponding to the desired base

temperature. Adjust the zero potentiometer until the output is 4 mA.

Remember that recovery time of the unit from an underscale condition is

longer than from an over-scale condition. Therefore, set the box to a higher

resistance than that desired, then bring it down to the correct value.

9. Set the decade box to the resistance corresponding to the desired full scale

temperature. Adjust the span potentiometer until the output is 20 mA.

10. Repeat steps 8 and 9 until you obtain the 4 and 20 mA readings without

readjusting the span and zero potentiometers. Complete this process more

quickly by noting the full scale reading before readjusting the span pot,

using the span pot to overshoot the desired reading by 20%, and then

using the zero pot to readjust the full scale reading to 20 mA.

EXAMPLE:

To calibrate the Model 444RL1U1 for a range of 100 to 150 °F (38 to 66 °C),

first consult Table 3-1, and plug the jumper into pins Z2. From Table B-1,

trim points are 114.68 and 125.37 ohms corresponding to 100 °F and 150 °F

respectively. After adjusting the base to 4 mA, and setting the decade to full

scale resistance, output equals 22.5 mA, or 2.5 mA greater than desired. Set

the span pot to an output lower than 20 mA by the amount equal to 20% of

2.5 equals 0.5 mA, or 19.5 mA. Reset the zero pot so the output equals 20 mA.

Repeat steps 8 and 9 and this procedure until readjustments are no longer

necessary.

TABLE 3-1. Coarse Jumper

Location, Model 444R.

11. Disconnect the decade box and the readout resistor. Reconnect the RTD

and power leads. Replace the terminal cover.

12. Mark the correct range in the “Calibration” space on the nameplate

.

Base Temperature

Region

°C °F 444RL1 444RL2 444RL3

–50 to 0

0to50

50 to 100

100 to 150

NOTE

If the base temperature is at a dividing point between regions, use the

lowerjumper position optimum performance; i.e.,uselocationZ1 rather

than Z2 for Model 444RL1 with a base temperature of 0 °C.

–58 to 32

32 to 122

122to212

212to302

Jumper Location

Z1

Z2

Z3

Z4

Z1

Z1

Z2

Z2

Continuously

adjustable

(no jumper)

3-3

Page 26

Rosemount Model 444 Alphaline Temperature Transmitters

FIGURE 3-1.Location of

Test Input and Burnout

Protection Jumper on Model

444RL Range Board.

Test Output

Jumper Position

BurnoutProtection

Jumper Position

444-0002ACCA

FIGURE 3-2. RTD

Transmitter Calibration

Diagram.

Decade Box

DVM

Transmitter

Lead Simulator Resistors

(If required)

Power

Supply

Readout

Resistor

DVM

Alternate Readout

444-0215A

3-4

Page 27

CALIBRATING A

THERMOCOUPLE

TRANSMITTER

Calibration

Using a

Compensated

Thermocouple

Simulator

Calibration Procedure 1. Remove the cover from the terminal side of the transmitter housing.

Calibration Equipment Required

Compensated Thermocouple Simulator. Precision voltage source providing

conformity to NIST Monograph 125 thermocouple curves. Reflect accuracy of

simulator to desired calibration span. A simulator accuracy four times better

than the transmitter is recommended (0.05% of calibrated span or 0.005mV

whichever is greater). Simulator inaccuracies greater than this will degrade

system accuracy and factory calibration is recommended.

Voltme t er. Such as a 5-digit DVM. Accuracy is ±0.01%; resolution is 1 mV.

dc Power Supply. Power capability is 24 Vdc at 35 mA.

Thermocouple Wire.Use the same type as that used in the construction of the

thermocouple.

Readout Resistor. The transmitter test terminals give a 40–200 mV signal. If

this is not suitable for the test equipment available, a ±0.1% tolerance, 0.5 W

precision wirewound resistor is needed. Suggested values include a 100-ohm

resistor to give a 0.4 to 2 volt output; 250 ohms for 1 to 5 volts; or 500 ohms for

2 to 10 volts.

2. If a thermocouple is already connected, remove all thermocouple lead

connections.

3. Connect the equipment as shown in Figure 3-4. Be sure to maintain

polarity from the transmitter to the thermocouple simulator. Make

terminal connections using miniature banana plugs.

4. If trimming the transmitter to a new range, you may have to reposition the

Coarse Zero Jumper on the Range Board. If so, see the Disassembly

Procedure on page 4-4. Position the jumper in the location shown in Table .

(A transmitter with a base temperature outside the regions shown in Table

is a special design and does not contain a Coarse Zero Jumper. Also, Model

444 TR and TS transmitters do not have Coarse Zero Jumpers.)

Reassemble the circuit boards.

5. Determine the base and full scale temperatures.

6. Turn the power on.

7. Refer to the thermocouple simulator instructions for setting the

thermocouple type and engineering units. Set the simulator to the base

(zero) temperature and adjust the zero pot until the output is 4 mA (or 40

mV at the test terminals).

8. Set the simulator to the full scale temperature and adjust the span pot

until the output is 20 mA (or 200 mV at the test terminals).

9. Repeat steps 7 and 8 until you obtain the 4 and 20 mA readings without

readjusting the pots. Use the “overshoot” technique described in step 9 of

the RTD calibration procedure, if desired.

10. Disconnect the simulator leads. Reconnect the thermocouple and power

leads, if required. Replace the terminal side housing cover.

11. Mark the new range in the “Calibration” space on the nameplate.

3-5

Page 28

Rosemount Model 444 Alphaline Temperature Transmitters

TABLE 3-2. Coarse Zero

Jumper Location, Model

444TJ, TK, TF, TT, and MV

Range Code 1.

Transmitter Base Region

°C °F mV

–50to50

50 to 100

NOTE

Range Codes 2 and 3 are continuously adjustable over the range

showninTable1.(NoCoarseZeroJumper)

FIGURE 3-3.Location of

Burnout Protection Jumper

on Model 444T Range

Board.

–58to122

122to302

-2 to 3

3to8

Coarse Zero

Jumper Location

Z1

Z2

FIGURE 3-4. Compensated

Thermocouple Simulator

Calibration Diagram.

Thermocouple

Simulator

Burnout R2, R3

Protection Resistors

.

Thermocouple

Wire

+

–

444-0010ACCA

–

DVM

+

+

Readout Resistor

+

–

Power

Supply

–+–

Transmitter

(Alternate Readout)

DVM

444-0216A

3-6

Page 29

Calibration

UsinganIceBath

Calibration Procedure 1. Remove the cover from the terminal side of the transmitter housing.

Calibration Equipment Required

Millivolt Source. Precision voltage source providing outputs from –10 to 100

mV. Reflect accuracy of four times better that the 444 transmitter is

recommended (0.05% of calibrated span or 0.005 mV which ever is greater).

Voltme t er. Such as a 5-digit DVM. Accuracy is ±0.01%; resolution is 1 mV.

dc Power Supply. Power capability is 24 V dc at

35 mA.

Thermocouple Wire.Use the same type as that used in the construction of the

thermocouple.

Readout Resistor. The transmitter test terminals give a 40–200 mV signal. If

this is not suitable for the test equipment available, a ±0.1% tolerance, 0.5 W

precision wirewound resistor is needed. Suggested values include a 100-ohm

resistor to give a 0.4 to 2 volt output; 250 ohms for 1 to 5 volts; or 500 ohms for

2 to 10 volts.

Ice Bath. For highest accuracy, a stirred ice bath (such as a Rosemount 911A)

should be used, as well as ice made from deionized or distilled water.

Input Monitor Voltmeter. Use to monitor source when required. Resolution of

±0.001 mV for ranges up to 100 mV. This can be the same as voltmeter used to

measure transmitter output if rangeability and resolution are sufficient for

both levels.

2. Install the equipment as shown in Figure 3-5 and allow the thermocouple

junctions to stabilize at the ice point. Make terminal connections with

miniature banana plugs.

3. If trimming the transmitter to a new range, you may have to reposition the

Coarse Zero Jumper on the Range Board. If so, see the disassembly

procedure on page 4-4. Position the jumper in the location shown in Table .

(A transmitter with a base temperature outside the regions shown in Table

is a special design and does not contain a Coarse Zero Jumper. Also, Model

444 TR and TS transmitters do not have Coarse Zero Jumpers.)

4. Determine the thermocouple millivolt levels at the desired base and full

scale temperatures. See NIST Monograph 125 or

Table B-1.

5. Turn the power on.

6. Set the millivolt source until the monitoring voltmeter reads the emf

corresponding to the desired base temperature. Adjust the zero pot until

the output is 4 mA.

7. Set the millivolt source until the monitoring voltmeter reads the emf

corresponding to the desired full scale temperature. Adjust the span pot

until the output is 20 mA.

8. Repeat steps 6 and 7 until you obtain the 4 and 20 mA readings without

readjusting the pots. Use the “overshoot” technique described in step 9 of

the RTD calibration procedure, if desired.

9. Mark the correct range in the “calibration” space on the nameplate.

3-7

Page 30

Rosemount Model 444 Alphaline Temperature Transmitters

FIGURE 3-5. Ice Bath

Calibration Diagram.

Input

Monitor

DVM

Millivolt

Source

+

–

Thermocouple

Wire

–

DVM

+

+

Power

Supply

+

–

+

–

Ice B ath

+

DVM

(Alternate Readout)

–

–

444-0217A

CALIBRATING A

LOW-POWER

TRANSMITTER

Calibration Equipment Required

Voltme t er. Such as a 5-digit DVM. Accuracy is ±0.01%; resolution is 1 mV.

dc Power Supply. Power capability is 5 V dc at 1.5 mA for Model 444LL and 8 V

dc at 2 mA for Model 444LM.

Resistance Decade Box. Precision type, 5-dial, with largest dial providing 100-

ohm steps. Accuracy is ±0.02 ohm. The decade box should be periodically

calibrated against a 5-dial Wheatstone bridge.

Lead Simulation Resistors. If the transmitter is to be mounted remote from the

RTD, and the lead resistance between the transmitter and the RTD is greater

than 2 ohms per lead (equivalent to 200 ft of 20 AWG wire), the transmitter

should be trimmed with simulated lead resistances for best accuracy. This

requires wirewound resistors with resistance values equal to the nominal lead

resistance of the RTD.

Load Resistor. If the transmitter is to be operated with a load that is

significantly different from the DVM used for calibration, a load resistor can be

used for best calibration accuracy. A metal film, carbon comp, or wirewound

resistor, as well as a decade box can be used to simulate the actual load.

3-8

Page 31

Calibration Procedure The following steps describe the procedure for calibrating a low-power

transmitter, as shown in Figure 3-6:

1. Remove the cover from the terminal side of the transmitter housing.

2. If an RTD is already connected, remove all RTD lead connections.

3. Attach the calibration test equipment as shown in Figure 3-6. Make

terminal connections using miniature banana plugs. Use simulated lead

resistors only if necessitated by long lead wire lengths, as discussed above.

NOTE

If using RTD configurations other than the 3-wire design shown in Figure 3-2,

refer to Figure 2-6 on page 2-6 for the correct wiring.

4. Determine the RTD resistance at the desired base- and full-scale

temperatures. For Calibration Code 1 (see Table 5-5), obtain these

resistances from Table B-1.

5. Turn the power on.

6. Set the decade box to the resistance corresponding to the desired base

temperature. Adjust the zero potentiometer until the output is 0.8 V for

Model 444LL or 1.0 V for Model 444LM.

7. Set the decade box to the resistance corresponding to the desired full-scale

temperature. Adjust the span potentiometer until the output is 3.2 V for

Model 444LL or 5.0 V for Model 444LM.

8. Repeat steps 6 and 7 until you obtain both the zero- and full-scale readings

without adjusting the span and zero potentiometers. Complete this process

more quickly by noting the full-scale reading before readjusting the span

pot, using the span pot to overshoot the desired reading by 20%, and then

using the zero pot to readjust the full scale reading.

9. Disconnect the decade box and the readout. Reconnect the RTD and power

leads. Replace the terminal cover.

10. Mark the correct range in the “Calibration” space on the nameplate.

Calibration

FIGURE 3-6. Low-Power

Transmitter Calibration

Diagram.

Load Re sistors ➀

Decade Box

➀Transmitters are calibrated

at the factory with a 220 K V load.

(If required)

DVM

444LL and LM Transmitter

+

+

dcPower

Source

–

–

Lead S imulator Resistors

(If required)

444-0218A

3-9

Page 32

Rosemount Model 444 Alphaline Temperature Transmitters

CALIBRATING A

MILLIVOLT

TRANSMITTER

Calibration is identical to the thermocouple type (see Figure 3-5 on page 3-8),

except that a reference junction and ice bath are not used. The millivolt source is

connected directly to the transmitter input terminals with copper wire, and the

desired millivolt levels are entered directly. See Table 3-2 for Coarse Zero

Jumper locations.

3-10

Page 33

Section

4 Maintenance and

Troubleshooting

OVERVIEW

This section contains the following transmitter maintenance and

troubleshooting information:

Hardware Diagnostics

• Troubleshooting

• Repair

Disassembly Procedure

Reassembly Procedure

Interchangeability of Parts

Burnout Protection Adjustments

• Repair and Warranty Service

• Return of Materials

Use onlythe procedures and new parts specifically

referenced in this manual. Unauthorized procedures or

parts can affect product performance and the output signal

used to control a process, and may render the instrument

dangerous. Direct any questions concerning these

procedures or parts to Rosemount Inc.

HARDWARE

DIAGNOSTICS

TROUBLESHOOTING

If you suspect a malfunction, refer to Table 4-1 to verify that

transmitter hardware and process connections are in good working

order. Under each of the seven major symptoms, you will find specific

suggestions for solving the problem. Always deal with the most likely

and easiest-to-check conditions first.

This section offers tips for troubleshooting several kinds of potential

malfunctions. To determine a malfunction, use pin-like probes to break

through the protective coating to make measurements on a circuit

board.

4-1

Page 34

Rosemount Model 444 Alphaline Temperature Transmitters

TABLE 4-1. Transmitter

TroubleshootingSymptoms

andCorrectiveActions.

Symptom Potential Source Corrective Action

High Output Sensor Check for a sensor or thermocouple opencircuit. (RL, MV, T-Series with upscale burnout protection only)

Loop Wiring Check for dirty or defective terminals, interconnecting pins, or receptacles.

Electronics Assembly Check for dirty or defective interconnectingpins.

Erratic Output Loop Wiring Check foradequate voltage to the transmitter.

Electronics Assembly Check for dirty or defective interconnectingpins.

Low Output or

No Output

Excessive

Current

(over 30 mA)

Excessive

Output Shift

with Ambient

Temperature

UnitCannotbe

Trimmed to

Desired Base

Temperature

UnitCannotbe

Trimmed to

Desired Span.

Sensor Check RTD leadsto ensure that theyare not shortingtogether or to ground.(RL only)

Loop Wiring Check for adequate voltage tothe transmitter.(RL only)

Loop Wiring Check for short between current signal leads.

Electronics Assembly Check for defective components in amplifier or current control section.

Sensor Check for incorrect thermocouple typeor Incorrect thermocouplepolarity connection (T series only)

Electronics Assembly Check to ensure that the burnout -protection jumpers positioned correctly (MV, T series only).

Transmitter Check to ensure that unit iscapable of desired range.

Electronics Assembly Check to ensure that the range boardjumper is in the correct position.

Transmitter Check to ensure that unit iscapable of desired range.

Loop Wiring Check for adequate voltage tothe transmitter.

Electronics Assembly Check for defective components in amplifier or current control section.

Check for intermittent shorts, open circuits, and multiple grounds.

Check for dirty or defective terminals orinterconnectionpins.

Check for correct RTD lead connection. (RL only)

Check for open RTDlead on double-lead side. (RL only)

Check for intermittent shorts, open circuits, and multiple grounds. (MV, T series only)

Check for proper polarity at the signal terminal. (MV,T series only)

Check for dirty or defective terminals orinterconnectionpins.

Check to ensure that current signal leadsARE NOT connected to sensor terminals.

Check that sensor leads ARE NOT groundedwhen positive side of power supply is grounded (RL,

RL___B0912, LL, and LM)

Check for defective components in voltage regulator or dc-to-ac converter section (MV, T series only).

Check for defective components in amplifieror current control section(all models).

May require replacement electronicsassembly.

Check to ensure that the burnout -protectionjumpers positioned correctly.(MV, Tseries only).

Check for defective zero pot.

Check for defective components in voltage regulator section.

Check for defective span pot.

4-2

Page 35

REPAIR

Maintenance and Troubleshooting

Exposure to hazardous substances can cause death or

serious injury. If a hazardous substance is identified, a

Material Safety Data Sheet (MSDS), required by law to be

availableto people exposed to specific hazardous

substances, must be included with the returned materials.

In case of a failure, particularly one in which the transmitter’s output goes to

one extreme and stays there, the first step is to determine whether the fault lies

with the sensor(s) or the transmitter. Although only a careful calibration can

determine sensor shifts, catastrophic failures (such as an open or shorted sensor

element) can be checked with an ohmmeter at the time the transmitter is

disconnected from the sensor(s).

NOTE

The Resistance vs. Temperature and Millivolt vs. Temperature tables for the

standard Model 444 sensor input types are presented in Table B-1 in Appendix

B Temperature Sensor Reference Information.

RTD Test: A platinum RTD with an ice-point (°C) resistance of 100 ohms should

read approximately as shown in Table B-1 at other temperatures. The resistance

between the two leads on the same side of the sensing element should be low, a

few ohms at most. Resistance between any of the RTD leads and the sensor

sheath should be high

(1 megohm or greater).

Thermocouple Test: Thermocouple resistance should be low (10 ohms or less

for short runs of heavy wire). For longer runs of extension wire, resistance will

be roughly ten times the resistance of copper wire of the same diameter. If the

sensor and receiving equipment are functioning properly, the transmitter will

probably require repair.

The transmitter is designed for easy replacement of its plug-in, modular circuit

boards. A malfunction can be most easily isolated by substituting boards one at a

time until the unit functions properly.

It is recommended that customers return defective circuit boards to Rosemount

Inc. for repair (see “RETURN OF MATERIALS” on page 4-6). This ensures that

replacement parts meet the design criteria for the board and that the

malfunctioning board is completely checked and repaired.

Rosemount Inc. offers a circuit board repair/replacement program through its

many service centers. Please contact your Rosemount field sales office for price

and delivery information.

4-3

Page 36

Rosemount Model 444 Alphaline Temperature Transmitters

Disassembly

Procedure

Explosion can cause death or serious injury. Do not remove

the instrument cover in explosive atmospheres when the

circuit is alive.

High voltage that may be present on leads can cause

electrical shock. Makesure all powerto the transmitter is off

before wiring.

NOTE

The numbers in parentheses refer to parts shown in the Illustrated Parts List,

Table 5-7, in Section 5 Specifications and Reference Data.

1. Terminal blocks for making all field wiring electrical connections are

located in a compartment identified as “Terminal Side” on the nameplate.

The sensor terminals, power supply and signal-test terminals, as well as

the zero and span adjustments are accessible by removing the Electronics

Housing Cover (2) from the terminal side. The terminals are permanently

attached to the housing and must not be removed.

2. The transmitter electronics Circuit Board Assembly (5, 6, 7) is located in a

separate compartment, identified as “Circuit Side” on the nameplate.

Make sure power is off. Then remove Circuit Side Cover (2).

NOTE

On the standard RTD input (Model 444RL), fast turn-on (Model 444RL

___B0912), and low-power (Models 444LL and LM) units, boards 5 and 6 are

integrated into one board.

3. Remove the three Circuit Board Assembly Screws (4).

4. Push equally on the zero and span adjustment pot shafts from the

terminal side. This will allow you to grasp and remove the Circuit Board

Assembly.

5. If troubleshooting is required, it is best to keep the Circuit Board

Assembly together for initial evaluation. Otherwise, the board assembly

may be disassembled by grasping the Output Board (5) around its

circumference and pulling it gently and evenly away from the other two

boards. Remove the Amplifier Board (6) in the same manner. Take care not

to bend the interconnection pins.

6. The adjustment pot shafts are sealed by two small O-rings (1D). Remove, if

necessary, by taking off the O-ring Retainer Plate (1B), which is held in

place by two small screws (1C).

7. The Nameplate (1E), Hazardous Service Certification Label (9), and

Instrument Tag (8) are held in place with Drive Screws (1F). Remove any

of these by gripping the head of the Drive Screw with pliers and carefully

turning counter-clockwise.

4-4

Page 37

Reassembly

Procedure

Maintenance and Troubleshooting

Explosions can cause death or serious injury. Both

transmitter covers must be fully engaged to meet explosionproof requirements.

1. Inspect all O-rings (1D,3) and replace if necessary. Lightly grease new Orings with silicone grease to guarantee an adequate seal.

2. If the O-ring Retainer Plate (1B) has been removed, be sure the correct

side is facing outward. The resistor symbol should be visible on RTD

Transmitters, while a thermocouple symbol should be visible on

Thermocouple or Millivolt transmitters.

3. Inspect threaded connections on the housing and covers to make sure a

minimum of five undamaged threads will be fully engaged. If the threads

are shiny, apply a thin layer of molybdenum disulphide thread coating

(such as Moly-Kote) to prevent galling of the aluminum threads.

4. If the Range Board (7A) requires a Coarse Zero Jumper (7B) check to make

sure it is in the correct location for the desired temperature range. See

Table 3-1, on page 3-3 or Table 3-2, on page 3-6.

5. Orient the Range Board (7A) and Amplifier Board (6) as shown in the

Illustrated Parts List. Taking care not to bend the pins, plug the Amplifier

Board into the Range Board. Press together until all three standoffs on the

Amplifier Board rest against the Range Board.

6. Orient the Output Board (5) so its standoffs line up with the standoffs of

the Amplifier/Range Board combination. Carefully and evenly, plug the

output board into the Amplifier/Range Board. Take care not to bend the

pins. Press together until all three standoffs on the Output Board rest

against the Amplifier Board.

7. The circuit board assembly may be bench-tested, or calibrated outside the

housing through the use of Test Terminal Strips (11 and 12). See the

discussion of Calibration and Troubleshooting in this section.

8. If the circuit board assembly has been calibrated outside the housing, be

very careful to ensure the zero and span adjustment pots are not moved

while inserting the circuit board assembly into the housing.

9. Orient the circuit board assembly so the pot shafts line up with the pot

holes in the housing.

10. Insert the circuit board assembly firmly into the housing.

11. Replace the three Circuit Board Assembly Screws (4).

12. Replace the transmitter covers (2). Tighten the covers hand-tight.

Interchangeability

of Parts

Use onlythe procedures and new parts specifically

referenced in this manual. Unauthorized procedures or

parts can affect product performance and the output signal

used to control a process, and may render the instrument

dangerous. Direct any questions concerning these

procedures or parts to Rosemount Inc.

4-5

Page 38

Rosemount Model 444 Alphaline Temperature Transmitters

Mechanical Parts • All mechanical hardware is interchangeable among units without regard

to model numbers.

• Nameplates are interchangeable only among units that share the same

input types (i.e. RTD, Thermocouple, or Millivolt).

Electrical Parts • Amplifier Board: Interchangeable among Models 444T and 444M.

• Output Board: 444T series (TE, TJ, TK, TT, TR, TS) and 444MV share a

common output board.

• Range Board: Interchangeable among units of the same input code (e.g.,

444RL1).

Burnout Protection

Adjustments

REPAIR AND

WARRANTY

SERVICE

The Model 444T series (TE, TJ, TK, TT, TR, TS) and Model 444MV have a

resistor network that drives the output either upscale or downscale if an open

occurs in the input circuit. This option is identified in the model number. To

convert from upscale to downscale, disassemble the circuit board assembly and

remove R3 (22 meg, ¼WCC resistor) from the range board. To convert from

downscale to upscale, replace R3. If no burnout protection is desired (as in some

instances where the source has a high input impedance), remove both R2 and

R3. See Figure 3-3, on page 3-6.

Model 444RL has a jumper on the range board to select burnout protection.

Placing the jumper in the “U” position will cause the output to be driven upscale

if the RTD opens. If the jumper is in the “D” position the output will be driven

downscale. See Figure 3-1, on page 3-3. Models 444LL and 444LM have inherent

upscale burnout protection that cannot be changed. Model 444RL also has a

jumper on the range board to specify mA output at the transmitter test

terminals. Setting the jumper at the “V” position produces a 40–200 mV output

at the test terminals. Setting the jumper at the “A” position produces a

4–20 mA output at the test terminals. See Figure 3-1, on page 3-4.

Repair and warranty service is available through the Rosemount Regional

Service Centers. Submit damage claims directly to the carrier.

RETURN OF

MATERIALS

4-6

Exposure to hazardous substances can cause death or

serious injury. If a hazardous substance is identified, a

Material Safety Data Sheet (MSDS), required by law to be

availableto people exposed to specific hazardous

substances, must be included with the returned materials.

To expedite the return process, call the Rosemount North American Response

Center toll-free at 800-654-RSMT (7768). This center, available 24 hours a day,

will assist you with any needed information or materials.

The center will ask for product model and serial numbers, and will provide a

Return Material Authorization (RMA) number. The center will also ask for the

name of the process material the product was last exposed to.

The Rosemount North American Response Center will detail the additional

information and procedures necessary to return goods exposed to hazardous

substances.

Page 39

Section

5 Specifications

and Reference Data

FUNCTIONAL

SPECIFICATIONS

Inputs

Models 444RL, LL, and LM

100 V R

Model 444T

Thermocouple types E,J,K,T,R, and S per NIST (grounded or

ungrounded).

Model 444MV

Millivolt input (grounded or ungrounded) source impedance less than

100 V.

R-numbers, specials

Special inputs other than standards, consult factory.

Spans

RTD

Platinum 45 to 135 °F (25 to75 °C).

Copper 180 to 540 °F (100 to 300 °C).

Nickel 45 to 360 °F (25 to 200 °C).

Thermocouples

Type J, K, E, T 180 to 540 °F (100 to 300 °C).

Type J 504 to 1458 °F (280 to 810 °C).

Type K, E 504 to 1510 °F (280 to 840 °C).

Type K 845 to 2540 °F (470 to 1410 °C).

Type R, S 1467 to 3000 °F (815 to 1670 °C).

Millivolt

5 to 15 mV.

15 to 45 mV.

Outputs

Linear with temperature for RTD inputs.

Linear with millivolt input signal for thermocouple or millivolt inputs;

thermocouple and millivolt models input/output isolated to 500 V dc.

Models 444RL, T, MV

4–20 mA.

Model 444LL

0.8–3.2 V dc.

Model 444LM

1.0–5.0 V dc.

platinum RTD per IEC 751.

0

125 to 380 °F (70 to 210 °C).

360 to 1080 °F (200 to 600 °C).

5-1

Page 40

Rosemount Model 444 Alphaline Temperature Transmitters

Output Limits (approximate)

Models 444RL, T, MV

Low: 3.9 mA dc.

High: 30.0 mA dc.

Model 444LL

Low: 0.1 V dc.

High: 4.2 V dc.

Model 444LM

Low: 0.125 V dc.

High: 6.2 V dc.

Power Supply

Models 444RL, T, and MV

12 to 45 V dc at terminals of transmitter.

Model 444LL

5 to 12 V dc (overvoltage protected to 24 V dc)

max current = 1.5 mA.

Model 444LM

8 to 12 V dc (overvoltage protected to 24 V dc)

max current = 2.0 mA.

Load Limits

Models 444RL, T, and MV

4–20 mA.

1650

1500

1000

500

Load (Ohms)

0

12 20 30 40

Maximum Load = 50 3 (Supply Voltage – 12)

4–20 mA dc

Voltage

Too Low

Operating

Region

Power Supply (V dc)

Span and Zero

Continuously adjustable, as defined in the ordering table. Adjustments are

accessible from the terminal side of the transmitter housing.

Tran smitter Temperature Limits

–13 to 185 °F (–25 °C to 85 °C), transmitter operates within specifications.

–40 to 212 °F (–40 °C to 100 °C), transmitter operates without damage.

–58 to 248 °F (–50 °C to 120 °C), storage.

–13 to 149 °F (–25 °C to 65 °C), transmitter operates within specifications for

meter option.

Loss of Input

Upscale burnout indication standard for RTD inputs, downscale burnout

indication optional. Upscale burnout indication standard for thermocouple and

millivolt inputs; downscale burnout indication or no indication optional.

Turn-on Time

2 seconds. No warm-up required.

5-2

Page 41

Specifications and Reference Data

PERFORMANCE

SPECIFICATIONS

Accuracy

±0.2% of calibrated span (or, for thermocouple and millivolt inputs, ±0.02

millivolts, whichever is greater). ±0.5% for copper, nickel, and isolated RTD

inputs, 0.1% for differential RTD inputs. Includes combined effects of

transmitter repeatability, hysteresis, linearity (conformity instead of linearity

for thermocouple input), and adjustment resolution. Does not include sensor

error.

Stability

±0.2% of calibrated span for six months.

Ambient Temperature Effect

Errors for 50 °F (28 °C) change in ambient temperature.

RTD Inputs

Zero: ±0.17 °C,

plus

Span: ±0.22%,

plus

Elevation/Suppression: ±0.083% of base temperature in °C.

T/C Inputs (Includes Effect of Cold Junction)

Zero: ±1.38 °C,

plus

Span: ±0.28% of span,

plus

Elevation/Suppression: ±0.11% of base

temperature in °C.

Millivolt Inputs

Zero: ±0.038 mV,

plus

Span: ±0.28% of span,

plus

Elevation/Suppression: ±0.11% of base input in mV.

Input Impedance (Thermocouple and mV Inputs)

More than 1 megohm—burnout resistors disconnected.

Power Supply Effect

±0.005% per volt.

Load Effect

No load effect other than the change in voltage supplied to the transmitter.

Vibration Effect

±0.05% of span per g to 200 Hz in any axis for 3 g’s up to 33 Hz, 2 g’s from 33 to

70 Hz and 1 g from 70 to 200 Hz.

Mounting Position Effect

None.

5-3

Page 42

Rosemount Model 444 Alphaline Temperature Transmitters

PHYSICAL

SPECIFICATIONS

Materials of Construction

Electronics Housing

Low-copper aluminum. (NEMA 4X). IP 54, IP 65, IP 66.

Housing Paint

Polyurethane.

Housing O-rings

Buna-N.

Sensor and Conduit Connections

1

/2-inch conduit on electronics housing. Screw terminals and integral test jacks

compatible with miniature banana plugs (Pomona 2944, 3690 or equal).

Weight

Transmitter: 3 lb (1.4 kg).

Transmitter with mounting bracket: 4 lb (1.8 kg).

Hazardous Location Certifications

Factory Mutual (FM) Approvals

E5 Explosion Proof: Class I, Division 1, Groups B, C, and D. Dust Ignition

Proof: Class II, Division 1, Groups E, F, and G; Class III, Division 1

hazardous locations. Indoor and outdoor use. NEMA Enclosure Type 4X.

Refer to Factory Mutual Explosion Proof Drawing 00444-0261.

I5 Intrinsic Safety: Class I, Division 1, Groups A, B, C, and D; Class II,

Division 1, Groups E, F, and G; Class III, Division 1 hazardous locations;

Intrinsically safe system only when applying Table 5-1 entity parameters.