Page 1

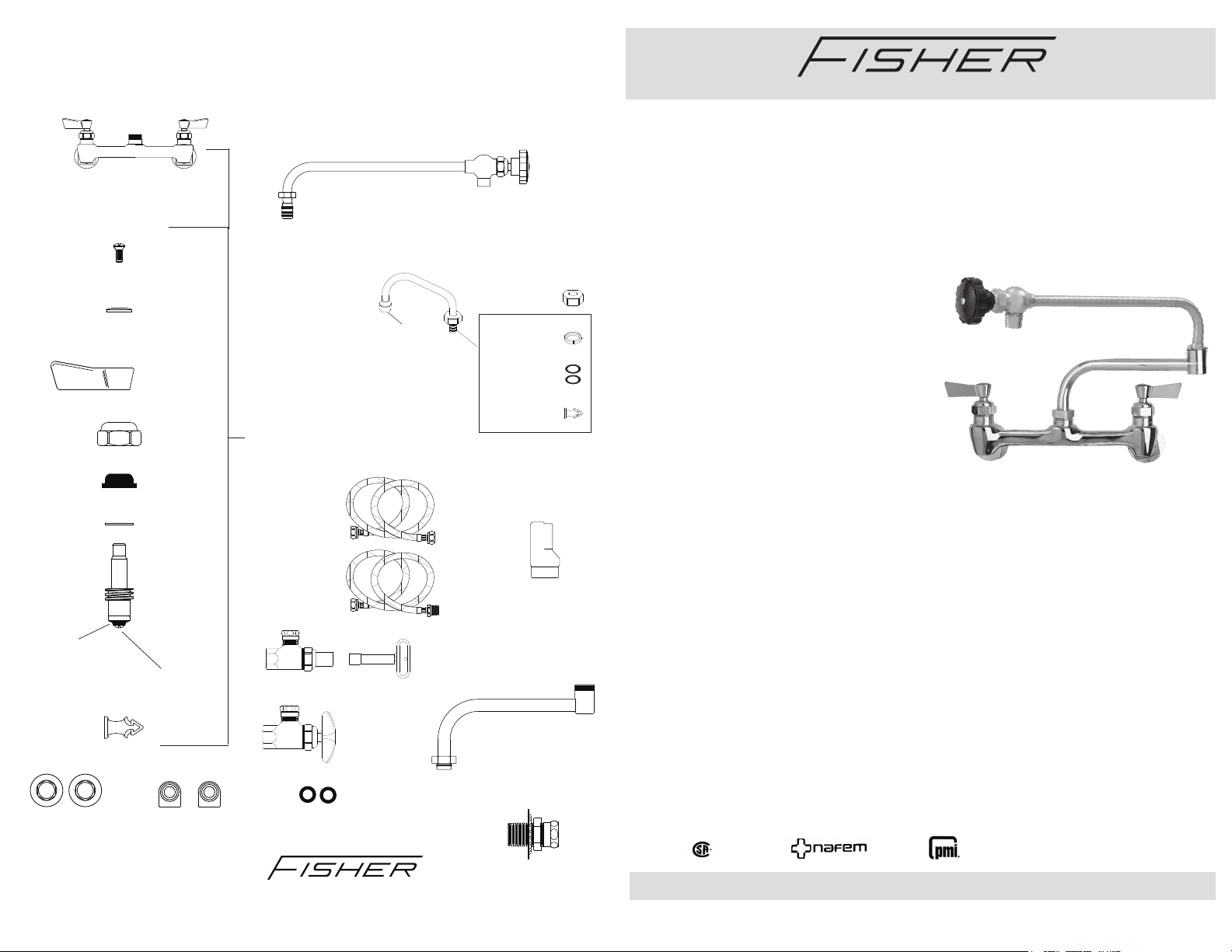

2000-5003

SEAT WASHER

3200-2306

ECCENTRIC

FLANGES

Replacement Parts for Wall Mount Faucets

8” ADJ. WALL CONTROL VALVE

3200

4000-0001

SPOUT 11CS 5.00 GPM

2000-7500

SCREW

2000-8000

RED BUTTON

AND

2000-8001

BLUE BUTTON

2000-2301

LEVER HANDLE

3000-0000

RH SWIVEL STEM

2000-3002

BIBB CAP

73657

DUCK GASKET

2000-5000

WASHER

3000-0010

LH SWIVEL STEM

OR

3000-0011

RH SWIVEL STEM

1000-7502

SCREW

73521

LUBE

3200-2307

1/2” ECCENTRICS

Part No. - 74719 REV.B

REPAIR KIT

OR

3000-0001

LH SWIVEL STEM

REPAIR KIT

10022 (36””)

SUPPLY LINE

1/2” F X 1/2”F

10049 (24”)

10006 (36””)

SUPPLY LINE

1/2” M X 1/2”F

2200-5000

ECCENTRIC GASKETS

MANUFACTURING COMPANY

PO BOX 60, TULARE, CA 93275

(800)421-6162, FAX: (800)832-8238

www.fi sher-mfg.com

ANGLE STOP

WITH KEY

ANGLE STOP

WITH CROSS

HANDLES

1792

1790-1

12564

2.2 GPM

AERATOR

15621

SPOUT NUT

2002

SNAP RING

1600-5000

SPOUT

O-RING

10456

LUBE

19119

SWIVEL SPOUT

RETRO-FIT KIT

2400-2103

ELBOWS

3000-0003

DOUBLE JOINT

SPOUT 7 1/2”

OR

4000-0002

DOUBLE JOINT

SPOUT 14”

2200-0000

SLIP JOINT KIT

FISHER MANUFACTURING COMPANY

FAHB-PFDJ-8AWLL

Product Installation Guide

Since 1936, Fisher Manufacturing Company has manufactured heavy-duty, high quality plumbing products

and hardware specialties for the food service industry.

For three generations, the Fisher family has adhered

to a strict dedication of and overall value. When you

install Fisher products… you install the best. Our

hardware is manufactured with the standardization

of internal mechanisms. All chrome plating is triple

plated copper, nickel and chrome for durability. Every piece of equipment we make is rigorously tested

in both our modern in-house testing center and in

actual field situations under extreme conditions.

Every detail is thoroughly checked. Before we make

our products available to you, they pass each and

every test. You get proven performance. Guaranteed.

Limited One Year Warranty

Fisher Manufacturing Company warrants its products and parts thereof (except as noted below) against

defects in materials or workmanship for a period of

one year after the date of original purchase. During

this period Fisher Manufacturing Company will

replace a defective product or part without charge

to you, provided that the entire product is delivered

to Fisher Manufacturing Company. All transportation and insurance charges for shipping the product

to and from Fisher Manufacturing Company must

be borne by you. Charges for transportation and

insurance may, at the option of Fisher Manufacturing Company, be refunded depending upon our

investigation of the warranty claim. This warranty does not cover external finish (except at date

of original purchase) or labor costs not specifically authorized by Fisher Manufacturing Company.

A full and complete copy of our One Year limited

warranty is available upon request.

WARNING:

Proposition 65 requires that we provide you with the

following notice: “This product Contains A Chemical

Known To The State Of California To Cause Birth

Defects Or Other Reproductive Harm.”

FISHER MANUFACTURING COMPANY, TOLL FREE: 800-421-6162, FAX:800-832-8238

www.fi sher-mfg.com

#4230 - FAUCET 8AWLH 11CS07DJ

#4231- FAUCET 8AWLH 11CS13DJ

ANSI/A112.18.1M, ANSI/NSF 61.

9

Page 2

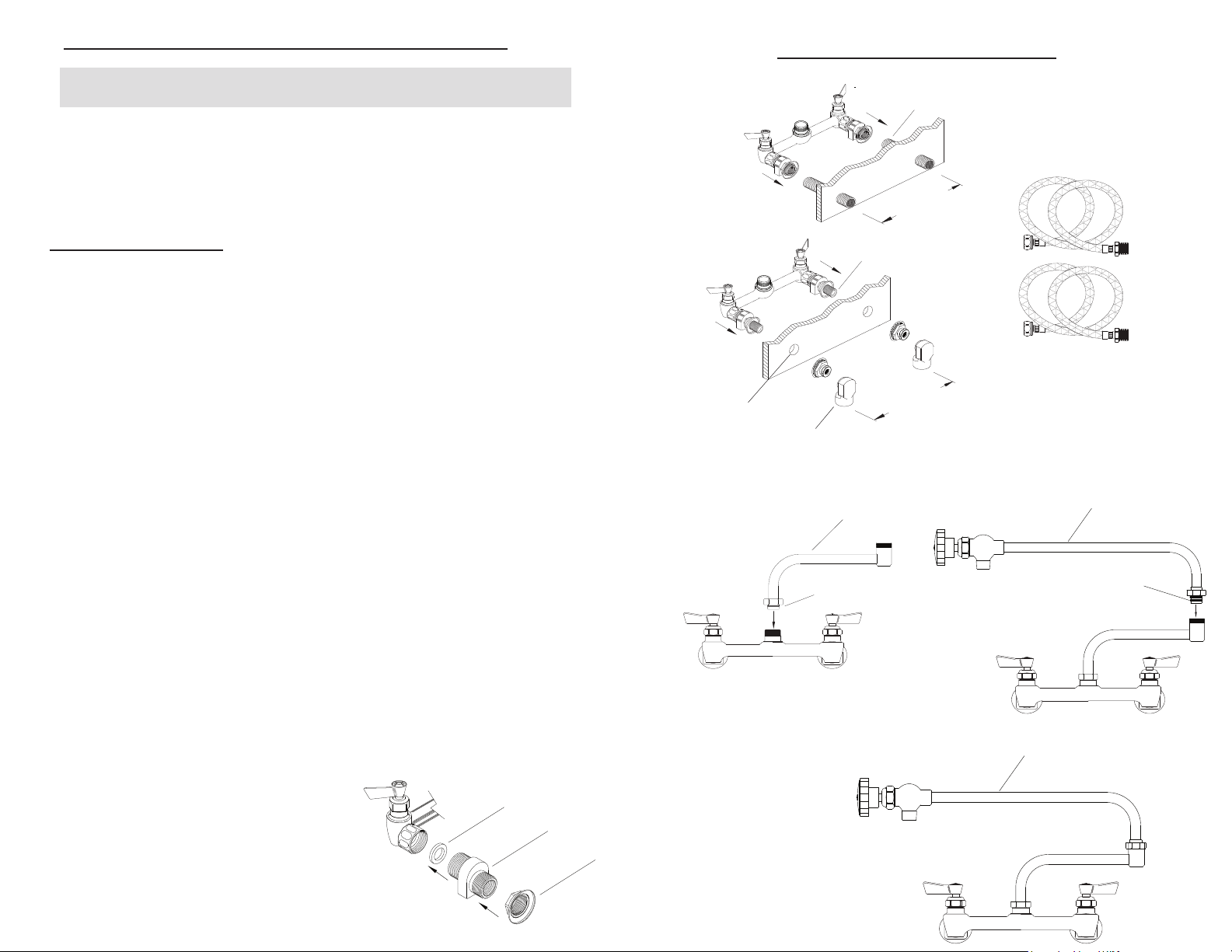

Installation Instructions for Wall Mount Faucet

Installation Instructions Continued

BE SURE TO CHECK WITH YOUR LOCAL DEPARTMENT HAVING

JURISDICTION REGARDING BACKFLOW PREVENTION.

Installation Notes:

• Be sure water supply is shut-off before beginning.

• Use pipe thread sealant on all threaded joints such as PST or Tefl on tape.

• Check the packaging for missing items BEFORE beginning installation. If

items are missing, contact your supplier.

Installation Instructions

Step 1.

Insert and center the gasket into the female swivel inlets of the 8” control valve body. Loosely mount

the eccentrics and fl ange onto the control valve body.

Step 2.

Mount control valve body to either a wall with a male supply nipples, or backsplash with nipples (not

included). Be sure to use pipe thread sealant on the supply nipple threads. Adjust the eccentrics as

needed in order to mount the control valve level. Once level, tighten the eccentrics

Step 3.

Apply O-ring lube to the O-rings on the DJ spout. Mount the DJ spout and tighten the nut onto the

faucet spout outlet.

Step 4.

Apply O-ring lube to the O-rings on the control spout. Make sure the white snap ring is in place

before mounting the control spout. Mount the control spout and tighten the control spout nut onto the

DJ spout outlet.

Step 5.

Turn on water supply and check for leaks.

Step 2

Ø 7/8”

Step 3

Elbows

(Not Included)

DJ Swing Spout

Apply O-ring

Lube Here

1/2” NPT Supply

Nipples (Not Included)

7 3/4” - 8 1/4”

[196.9mm] - [209.6mm]

1/2” NPT Supply

Nipples (Not Included)

7 3/4” - 8 1/4”

[196.9mm] - [209.6mm]

Step 4

Supply Lines

(Not Included)

Control Spout

Apply O-ring

Lube Here

Step 1

Control Spout

Step 5

Gasket

Eccentric

Flange

Loading...

Loading...