Fisher 25119 Parts Manual

Spray Valve and Accessories

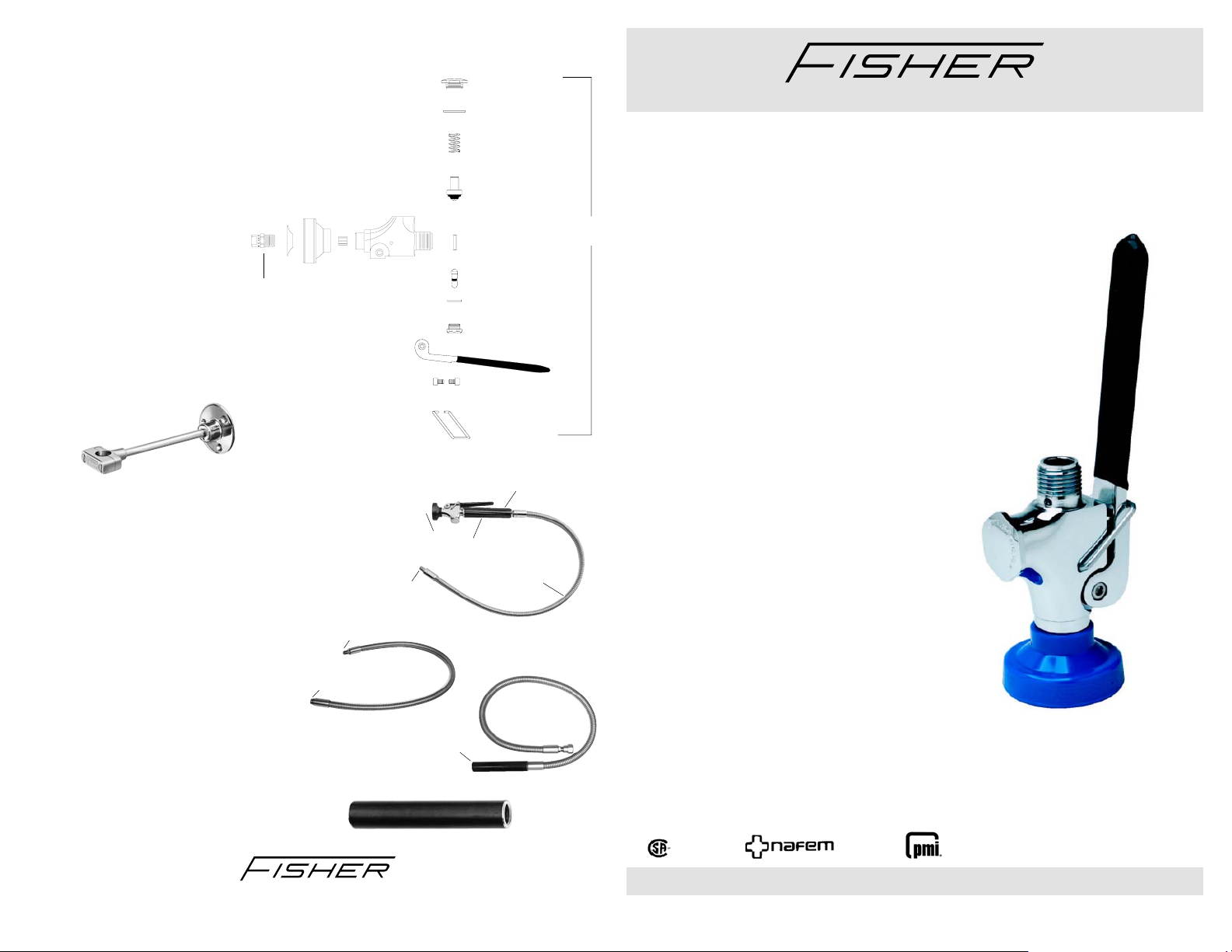

Model 2949

Spray Valve

Cast red brass construction with polished

chrome fi nish. Inlet thread size fi t Fisher and

all other pre-rinse units. Squeeze lever is

insulated for operator safety. Large, vinyl dish

guard bumper accommodates optional snap-in

scrubbing brush.

2949-3001

Nozzle for

2949 Spray

Valve

Model 2902-12

Wall Bracket

Designed to brace riser pipe, Chrome plated

fi nish, Adjustable - 2 1/4” to 12”. (Cut off

adjusting rod for correct length.

Model 2911

Hose and Spray Assembly

Overall length 46”. Note: Upon request, optional

adapter for inlet is available to fi t other pre-rinse

units.

Stainless Steel

Armor Clad Flex Hose

Model 2914 - “A” = 36”

(Fits Model 2010 Pre-rinse Unit)

Model 2916 -25 1/2” - “A” = 25 1/2”

(Fits Model 2211 Pre-rinse Unit)

Model 2916 - 15 1/2” - “A” = 15”

(Fits Model 2916 - 15 1/2” Pre-rinse Unit)

Model 2918 - 44” Replacement

Pre-rinse hose with T&S adapter.

Also available in 68” for T&S sprays.

Model 2913

Insulated Handle

3/4” 14 Female

1/4” NPT Male

Stainless Steel

1/4” NPT Male

Fisher Handle

Thread

2912-2501

Squeeze Lever

Dish Guard

Bumper

Vinyl Insulation

2914

Fisher and T&S

Valve Thread

1000-3301

Bonnet Nut

1000-5001

Bonnet Washer

2912-6000

Spring

1000-0001

Retainer Disk Assy

2922-5000

Handle Gasket

1000-0003

Lift Pin Sa

2909-5000

Gasket

2909-3400

Lift Pin Guide

2912-7501

Screws

2909-6000

Clip

3/4” Insulated

Handle

200 P.S.I.

3- Ply Hose Liner

Stainless Steel

Cover

2918

T&S Spring Stop

Thread

3/4” 14 Female

11355

Spray Valve

Repair Kit

fisher manufacturing company

Pre-Rinse Units

Product Installation Guide

Since 1936, Fisher Manufacturing Company has

manufactured heavy-duty, high quality plumbing

products and hardware specialties for the food service

industry. For three generations, the Fisher family has

adhered to a strict dedication of and overall value.

When you install Fisher products… you install the best.

Our hardware is manufactured with the standardization

of internal mechanisms. All chrome plating is triple

plated copper, nickel and chrome for durability.

Every piece of equipment we make is rigorously

tested in both our modern in-house testing center and

in actual fi eld situations under extreme conditions.

Every detail is thoroughly checked. Before we make

our products available to you, they pass each and

every test. You get proven performance. Guaranteed.

Limited One Year Warranty

Fisher Manufacturing Company warrants its products

and parts thereof (except as noted below) against

defects in materials or workmanship for a period of

one year after the date of original purchase. During

this period Fisher Manufacturing Company will

replace a defective product or part without charge to

you, provided that the entire product is delivered to

Fisher Manufacturing Company. All transportation and

insurance charges for shipping the product to and from

Fisher Manufacturing Company must be borne by you.

Charges for transportation and insurance may, at the

option of Fisher Manufacturing Company, be refunded

depending upon our investigation of the warranty claim.

This warranty does not cover external fi nish (except at

date of original purchase) or labor costs not specifi cally

authorized by Fisher Manufacturing Company.

A full and complete copy of our One Year

limited warranty is available upon request.

WARNING:

Proposition 65 requires that we provide you with the

following notice: “This product Contains A Chemical

Known To The State Of California To Cause Birth

Defects Or Other Reproductive Harm.”

KEEP THIS MANUAL FOR FUTURE REFERENCE

PART NO. L9417

MANFACTURING COMPANY

PO BOX 60, TULARE, CA 93275

(800)421-6162, FAX: (800)832-8238

www.fisher-mfg.com

REV. A

ANSI/A112.18.1M, ANSI/NSF 61.9

fisher manufacturing company - toll free: 800-421-6162 fax: 800-832-8238

www.fi sher-mfg.com

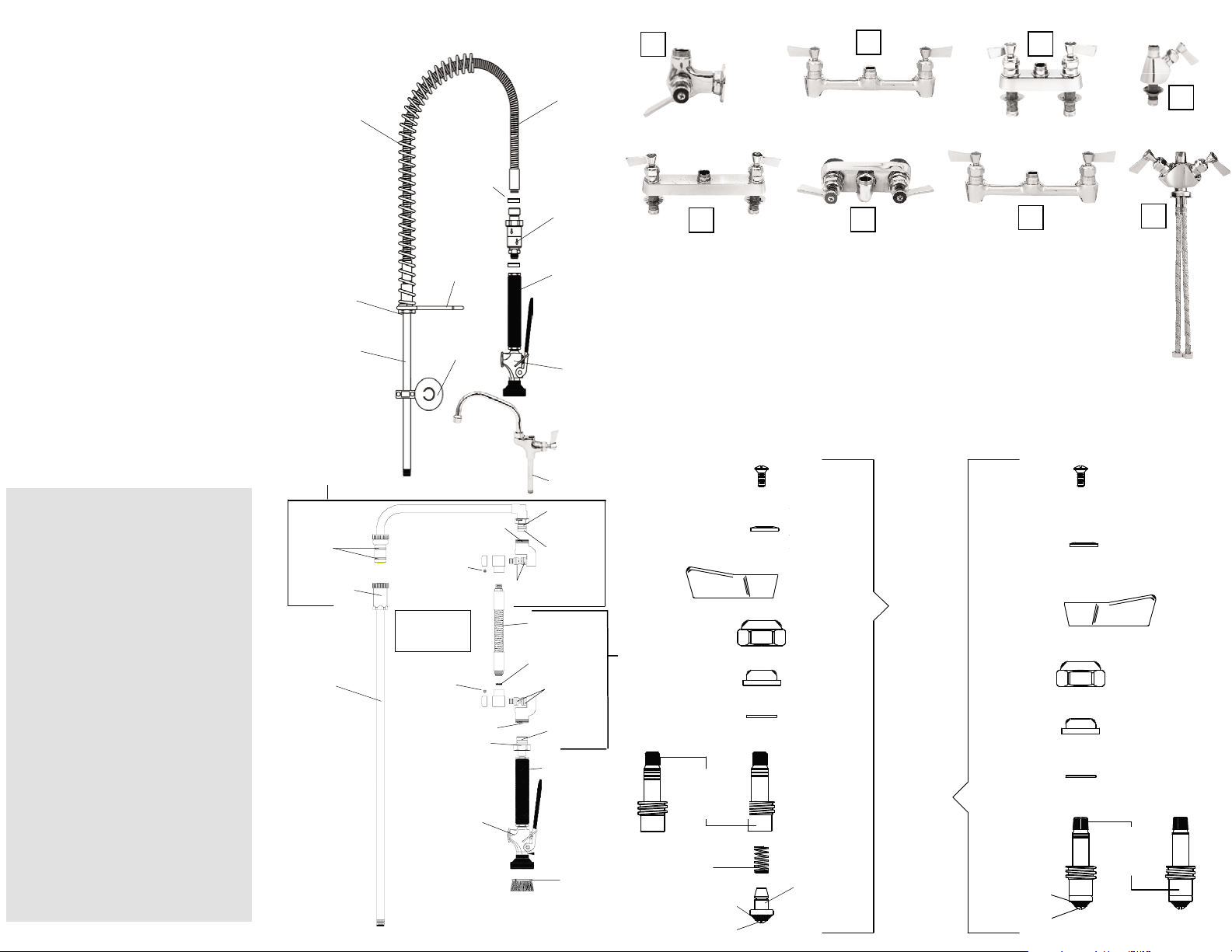

Installation Instructions for

All Models

#2924-6000

1. Install MIXING FAUCET.

2. Install 2927-4300 PIPE RISER and

2926-3300 PIPE TO HOSE ADAPTER.

Into mixing faucet. Note: Use pipe

Sealant compound on both joints.

3. Slip 2925-6300 HOSE HOOK over

2926-3300 ADAPTER.

4. Install 2914 FLEX HOSE into 2926-3300

ADAPTER. Note: Use pipe sealant

compound.

5. Install 2924-6000 SPRING GOOSENECK by slipping 2914 FLEX HOSE

through the spring. Spring will fit over

2926-3300 ADAPTER which holds it in

an upright position. Note: Be sure spring

is installed as shown. DO NOT INSTALL

SHORT BEND DOWN.

6. Install 2913 INSULATED HANDLE with

hex end toward spray valve. Note: Be

sure internal gaskets are in place for

both hose and spray valve end of

handle.

NOTICE TO PLUMBER:

It is not necessary to install check valves

in supply lines to prevent cross flow of hot

and cold water. All Fisher Mixing Faucets

are supplied with internal check valves.

To insure long, maintenance free service

and efficiency from your Fisher Pre-Rinse

unit, we note the following.

1. Whenever possible install 2902-12

WALL BRACKET. This prevents the

bending of the pipe riser by the

operator.

2. The spray valve is provided with a

spring clip which when placed in the

squeeze handle notch allows the spray

to run freely. This allows the operator to

use both hands for pre-rinsing etc.

3. To avoid accidental flooding and

increase hose life, relieve pressure on

the hose during slack periods and at

closing time by first turning off mixing

faucet (or water supply) then squeezing

the lever handle.

Spring

Gooseneck

2926-3300

Pipe To Hose

Adapter

#2927-4300

3/8” Pipe

21” Riser

2020-0006

Ultra-Flex

Gooseneck

1000-5008

O-Ring

2929-2500

Packing Gland

2927-4301

31” Riser

2020-7000

2020-7000

Set Screw

Set Screw

ULTRA-FLEX

PRE-RINSE

UNIT

2020-7000

Set Screw

2949 Ultra-Spay Valve

2922-5000

Washer

2925-6300

Hose Hook

2902-12

Wall Bracket

2020-5003

Gasket

2020-5003

Gasket

2020-5004

Gasket

2020-5002

O-Ring

2916-15 ½

15 ½” Hose

2922-5000

Gasket

2913-3/8

3/8” Handle

#2914

Stainless Steel

36” Hose

OPTION

#2932-0002

In-Line

Dual Check

Valve

#2913

Insulated

Handle

2949

Ultra-Spray

Optional 2901

Add-On Faucet

2020-5004

Gasket

1700-5002

O-Ring

2020-5002

O-Ring

1700-5002

O-Ring

Optional

2949-9001

Brush

A

E

A #2700 – Single Wall Control Valve w/ 3/8”F outlet

Stem RH Swivel Repair Kit #3000-0000

B #13196 – 8” c/c Backsplash Control Valve w/ 3/8”F

outletand check valves

Hot Stem RH Check Repair Kit #2000-0004

Cold Stem LH Check Repair Kit #2000-0005

C #2500-CV – 4” c/c Deck Control Valve w/ 3/8”F outlet,

check valves

Hot Stem RH Check Repair Kit #2000-0004

Cold Stem LH Check Repair Kit #2000-0005

D #12890 – Single Deck Control Valve w/ 3/8”F outlet

Stem LH Swivel Repair Kit #3000-0001

2020-0004

Ultra-Swivel

W/Handle

2000-3406

LH Check Stem

2000-3407

RH Check Stem

2000-6000

Spring

2000-5003

Seat Washer

1000-7502

Screw

2000-7500

Screw

2000-8000

2000-8000

Red Button

Red Button

And

And

2000-8001

2000-8001

Blue Button

Blue Button

2000-2301

Handle

2000-3002

Bibb Cap

10464

Gasket

2000-5000

Washer

2000-0001

Retainer

Assembly

B

F

E #2300-CV – 8” c/c Deck Control Valve w/ 3/8”F outlet,

check valves

Hot Stem RH Check Repair Kit #2000-0004

Cold Stem LH Check Repair Kit #2000-0005

F #2600-CV – 4” c/c Backsplash Control Valve w/ 3/8” F

outlet, check valves

Hot Stem RH Check Repair Kit #2000-0005

Cold Stem LH Check Repair Kit #2000-0004

G #2200-CV – 8” adj Wall Control Valve w/ 3/8”F outlet and

check valves

Hot Stem RH Check Repair Kit #2000-0004

Cold Stem LH Check Repair Kit #2000-0005

H #13080 – Single Deck Dual Control Valve w/ 3/8” F outlet,

check valves

Hot Stem RH Check Repair Kit #2000-0004

2000-7500

Screw

2000-8000

Red Button

And

2000-0004

RH Check Stem

Repair Kit

Or

2000-0005

LH Check Stem

Repair Kit

3000-0000

3000-0000

RH Swivel Stem

RH Swivel Stem

Repair Kit

Repair Kit

Or

Or

3000-0001

3000-0001

LH Swivel Stem

LH Swivel Stem

Repair Kit

Repair Kit

2000-8001

Blue Button

2000-2301

Handle

2000-3002

Bibb Cap

10464

Gasket

2000-5000

Washer

C

G

2000-5003

Seat Washer

1000-7502

Screw

-

H

3000-0010

LH Swivel Stem

r

3000-0011

RH Swivel Stem

D

Loading...

Loading...