Page 1

Instruction Manual

D200129X012

2506/2516 Receiver/Controller

Fisher™ 2506 and 2516 Receiver/Controllers

June 2017

Contents

Introduction 2.................................

Scope of Manual 2.............................

Description 2.................................

Specifications 2...............................

Educational Services 4.........................

Installation 5..................................

Mounting the Controller 5......................

Actuator Yoke Mounting 6..................

Wall Mounting 6...........................

Actuator Diaphragm Case Mounting 7........

Pipestand Mounting 8......................

2500 Controller/Transmitter and

2506/2516 Receiver/Controller Mounting 9.

Connections 11...............................

Supply Connection 12......................

Output Connections 12.....................

Instrument Connection 12..................

Vents 12.................................

Remote Set Point Connection 13.............

Startup 13.....................................

Adjustments 14................................

Set Point Adjustment 14........................

Remote Set Point Adjustment 15................

Proportional Band Adjustment 15................

Reset Adjustment

(2516 Receiver/Controller Only) 15............

Anti‐Reset Windup Valve Adjustment

(2516F Receiver/Controller Only) 15...........

Calibration 16..................................

Principle of Operation 17........................

2506 Receiver/Controllers 17...................

2516, 2516F Receiver/Controllers 18.............

Maintenance 19................................

Changing Controller Action 19..................

Troubleshooting 20............................

Testing Relay Deadband 21.....................

Replacing Receiver/Controller Parts 21............

Bellows Replacement 21....................

Changing the Relay 22......................

Changing Proportional or Reset Valve 22......

Parts Ordering 22...............................

Parts Kits 23...................................

Parts List 23...................................

Receiver/Controller Common Parts 23............

Anti‐Reset Windup Valve for 2516F Only 26.......

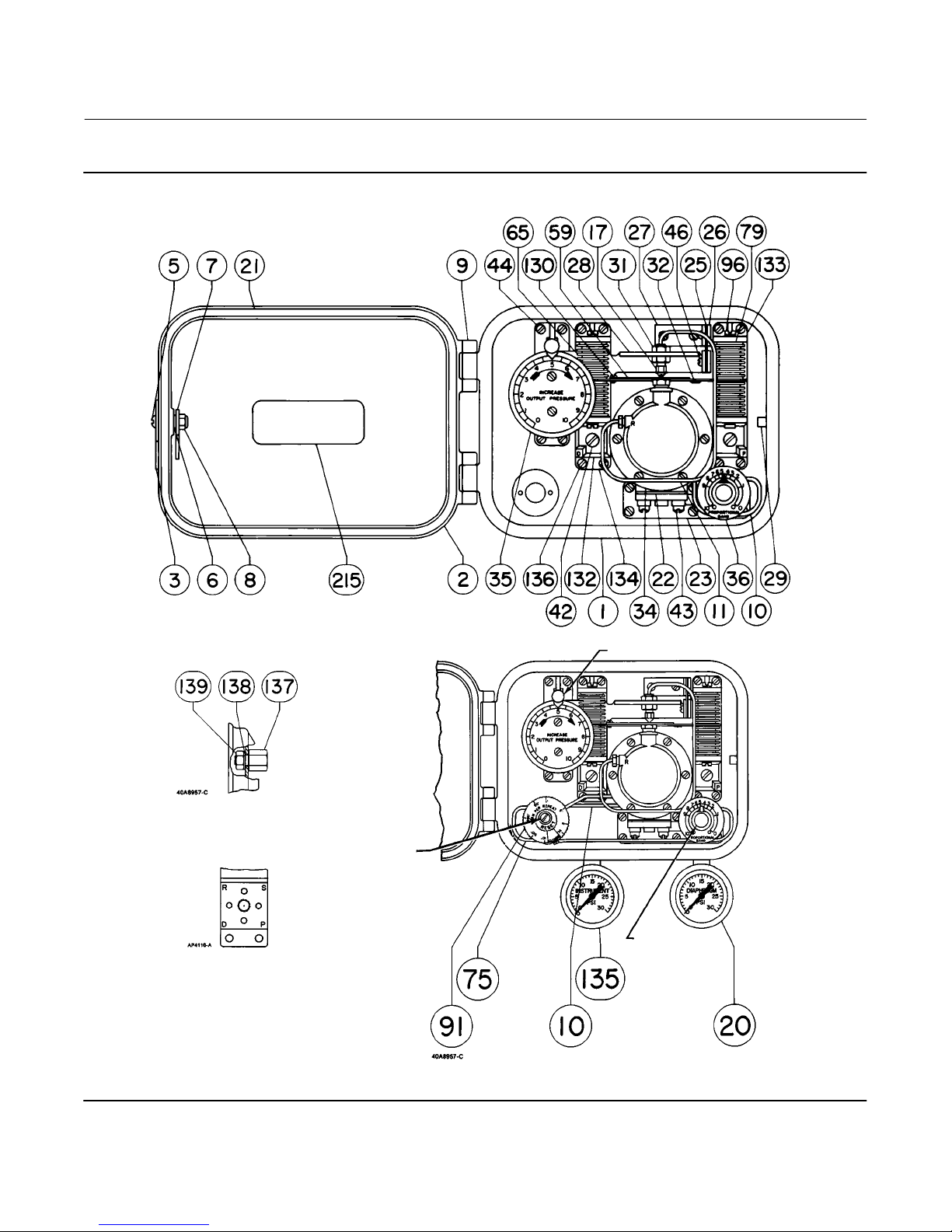

Figure 1. Fisher 2506 Receiver‐Controller

W4687

Figure 2. Fisher 2516 Receiver‐Controller

W4688

2516F Reset and Anti‐Reset Windup

Valve Assembly 26..........................

Mounting Parts 27.............................

Yoke Mounting 27.........................

Wall Mounting 27..........................

Case Mounting 27.........................

Pipestand Mounting 27.....................

2500 Controller/Transmitter and 2506/2516

Receiver/Controller Mounting 27..........

www.Fisher.com

Page 2

2506/2516 Receiver/Controller

June 2017

Instruction Manual

D200129X012

Introduction

Scope of Manual

This manual provides installation, startup, calibration, maintenance, and parts ordering information for 2506 and

2516 receiver/controllers. Figure 1 shows a 2506 receiver/controller. Figure 2 shows a 2516 receiver/controller.

A 2506/2516 receiver/controller is often used with a 2502 controller/transmitter. For information about 2502

controller/transmitters or associated equipment such as pressure regulators, sensors, accessories, or related control

devices, see the appropriate instruction manual, or contact your Emerson sales office

Do not install, operate, or maintain a 2506/2516 receiver/controller without being fully trained and qualified in valve,

actuator, and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is

important to carefully read, understand, and follow all contents of this quick start guide, including all safety cautions

and warnings. If you have any questions about these instructions, contact your Emerson sales office or Local Business

Partner before proceeding.

or Local Business Partner.

Description

See table 2.

The receiver/controllers described in this manual provide:

D Proportional‐only control: 2506 (with snap action: 2506S)

D Proportional‐plus‐reset control (2516)

D Proportional‐plus‐reset‐plus‐anti‐reset windup control (2516F)

See figures 9, 10, and 11.

The receiver/controller takes a pneumatic input signal from either a 2500 controller/transmitter or a control device.

The unit then provides a pneumatic output signal that operates a final control element.

When a 2506 receiver/controller is used to provide proportional‐only control, the pneumatic output signal from the

unit can also be piped to a remote receiving indicator or recording device. This provides a visual indication of

receiver/controller action.

The INCREASE OUTPUT PRESSURE adjustment is used to increase or decrease the output pressure in relationship to the

input pressure. Changing this adjustment changes the position of the nozzle in relationship to the beam/flapper

assembly. In turn, the amount of supply pressure released by the relay is changed and the pneumatic output signal

that operates a final control element is affected.

If a remote set point signal is used, it is piped to the remote set point connection and into remote set point bellows.

The remote signal expands the bellows and moves the beam/flapper assembly. This affects the controller output in the

same way a change in the INCREASE OUTPUT PRESSURE adjustment affects the output.

Specifications

Specifications are shown in table 1.

2

Page 3

Instruction Manual

D200129X012

Table 1. Specifications

2506/2516 Receiver/Controller

June 2017

Available Configurations

For additional information, refer to table 2

(1)

2506: A receiver/controller

that is set for either

proportional or snap action (S) control or for either

direct or reverse (R) action

2516: A 2506 that also provides proportional‐plusreset control

2516F: A 2516 that also provides anti‐reset windup

control

Input Signal Range

From a transmitter or control device, a signal of 0.2 to

1.0 bar (3 to 15 psig) or 0.4 to 2.0 bar (6 to 30 psig) is

required depending on receiver/controller range

Refer to the receiver/controller nameplate for specific

range.

Output Signal Range

(2)

See table 3

Output Action

Direct Action: An increasing fluid, interface level, or

density increases output pressure or,

Reverse Action: An increasing fluid, interface level, or

density decreases output pressure

Supply Medium

Air or Natural Gas

Supply medium must be clean, dry, and noncorrosive

Per ISA Standard 7.0.01

A maximum 40 micrometer particle size in the air

system is acceptable. Further filtration down to 5

micrometer particle size is recommended. Lubricant

content is not to exceed 1 ppm weight (w/w) or

volume (v/v) basis. Condensation in the air supply

should be minimized

Per ISO 8573-1

Maximum particle density size: Class 7

Oil content: Class 3

Pressure Dew Point: Class 3 or at least 10_C less than

the lowest ambient temperature expected

Steady State Air Consumption

(2)

See table 3

Proportional Band Reset, and Anti‐Reset Windup

See table 2 and the Changing Controller Action

procedure

Performance

Hysteresis: 0.6 percent of output pressure change at

100 percent of proportional band for 2506

proportional receiver/controllers only

Standard Supply and Output Pressure Gauge

Indications

See table 3

Remote Set Point Signal Range

From a control device, provide a remote set point

signal that is 0.2 to 1.0 bar (3 to 15 psig) or 0.4 to 2.0

bar (6 to 30 psig) that matches the receiver/controller

input signal range

Supply Pressure

(3)

Normal Operating Pressure: See table 3

Maximum Pressure to Prevent Internal Part Rupture:

3.4 bar (50 psig)

-continued-

Standard Tubing Connections

All connections are 1/4 NPT internal

Hazardous Area Classification

2506 receiver/controllers comply with the

requirements of ATEX Group II Category 2 Gas and

Dust

Operative Ambient Temperature Limits

(3)

Standard: -40 to 71°C (-40 to 160°F)

High Temperature: -18 to 104°C (0 to 220°F)

3

Page 4

2506/2516 Receiver/Controller

June 2017

Table 1. Specifications (continued)

Instruction Manual

D200129X012

Approximate Weight

4.54 kg (10 Pounds)

4 of the PED Directive 2014/68/EU. It was designed

and manufactured in accordance with Sound

Engineering Practice (SEP) and cannot bear the CE

marking related to PED compliance.

Declaration of SEP

Fisher Controls International LLC declares this

product to be in compliance with Article 3 paragraph

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 - Process Instrument Terminology.

1. Receiver/controllers are field adjustable between direct or reverse action. If the receiver/controller is set for reverse action at the factory, an R suffix will appear in the type number. Receiver/

controllers are field‐adjustable between proportional and snap action. If the receiver/controller is set for snap action at the factory, an S suffix appears in the type number.

2. Normal m

3. The pressure/temperature limits in this document, and any applicable standard or code limitation should not be exceeded.

3

/hr at 0°C, 1.01325 bar absolute (Scfh at 60°F, 14.7 psia).

However, the product may bear the CE marking to

indicate compliance with other applicable EC

Directives.

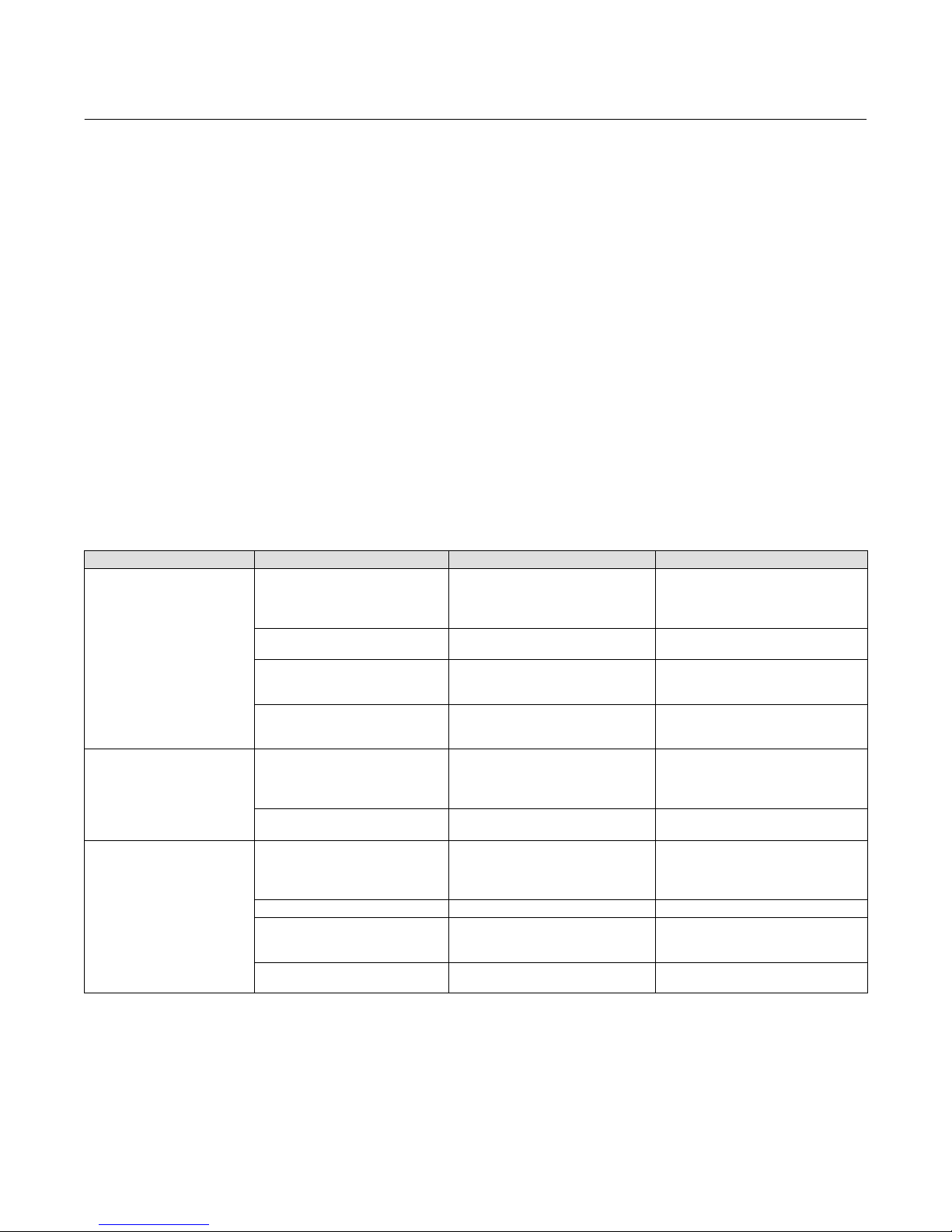

Table 2. Additional Information

Control Mode

Proportional control (2506) Proportional Band: Adjustable from 0 to 100% of transmitter signal.

Snap action control

(2506S)

Proportional‐plus‐reset

control (2516)

Proportional‐plus‐reset

with differential relief

control (2516F)

1. Proportional control is continuously active between 0 and 100 percent of the transmitter signal span. Differential gap provides snap action between 0 and 100 percent of the transmitter

signal. Do not use reset controllers in snap action.

(1)

Snap Action: Control output is at 0 or 100% of input supply pressure. Switching depends on

position of sensor and is adjustable.

Proportional Band: Adjustable from 0 to 200% of transmitter signal. Recommended setting

is from 20 to 200%.

Reset: Adjustable form 0.01 to 74 minute per repeat with standard reset valve setting.

Proportional Band: Adjustable from 0 to 200% of transmitter signal. Recommended setting

is from 20 to 200%.

Reset: Adjustable from 0.01 to 74 minute per repeat with standard reset valve setting.

Differential Relief: Provides relief when output pressure falls or when output pressure rises

depending on valve adjustment.

Action (Full Output Change) Output Signal

0.2 to 1.0 bar (3 to 15 psig) or

0.4 to 2.0 bar (6 to 30 psig)

0 to 1.4 bar (0 to 20 psig) or

0 to 2.4 bar (0 to 35 psig)

0.2 to 1.0 bar (3 to 15 psig) or

0.4 to 2.0 bar (6 to 30 psig)

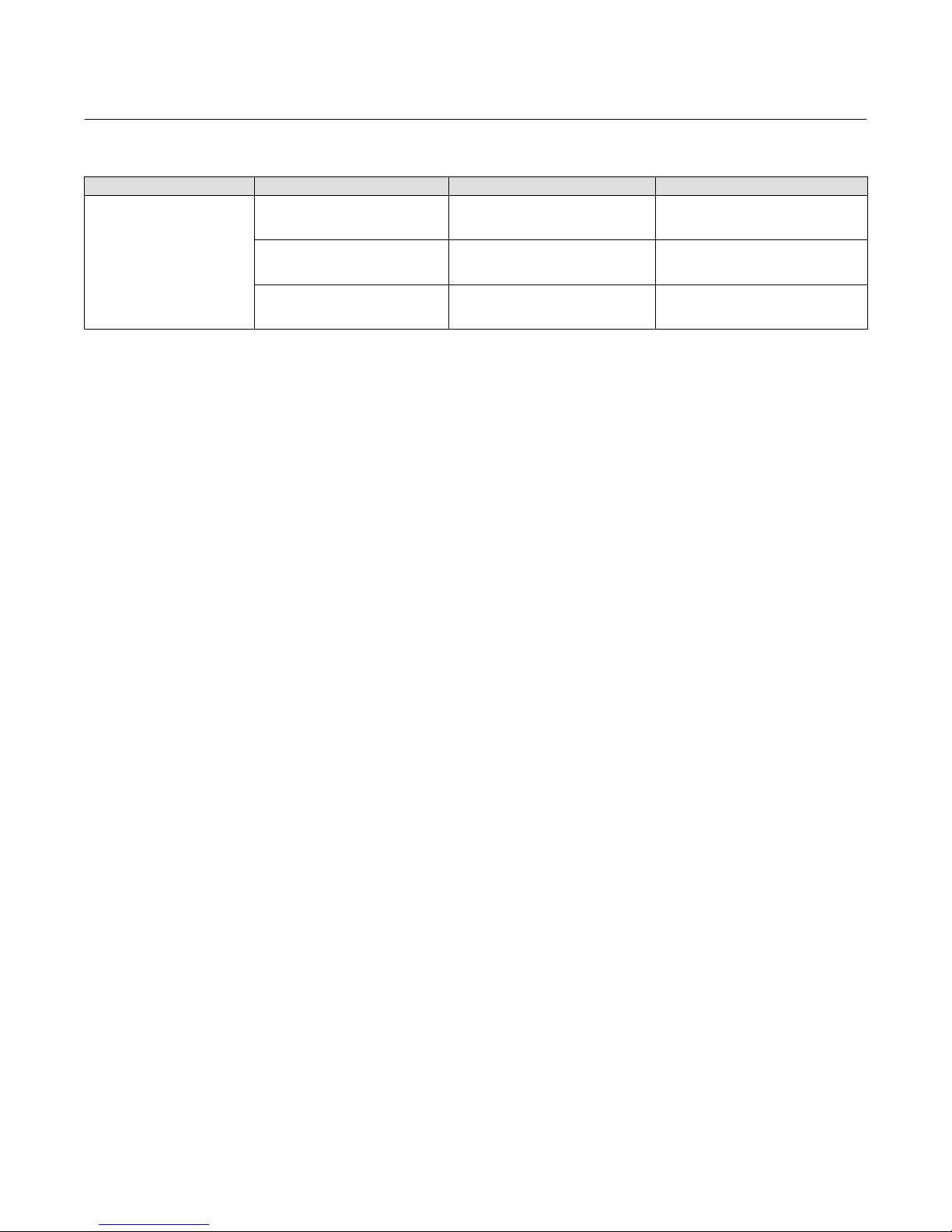

Table 3. Supply Pressure Data

OUTPUT SIGNAL RANGE

0.2 to 1.0 bar (3 to 15 psig) 0 to 30 psig 1.4 20 4.2 scfh

0.4 to 2.0 bar (6 to 30 psig) 0 to 60 psig 2.4 35 7 scfh

1. Consult your Emerson sales office for gauges calibrated in other units of measurement.

2. Control and stability may be impaired if this pressure is exceeded.

3. At zero or maximum proportional band or span setting.

4. At setting in middle of proportional band or span range.

5. If air consumption is desired in normal m

3

/hr at 0°C and 1.01325 bar, multiply scfh by 0.0268.

STANDARD SUPPLY AND

OUTPUT PRESSURE GAUGE

INDICATIONS

(1)

NORMAL OPERATING

SUPPLY PRESSURE

Bar Psig Minimum

(2)

AIR CONSUMPTION AT NORMAL

OPERATING SUPPLY PRESSURE

(3)

(5)

(5)

Maximum

27 scfh

42 scfh

Educational Services

For information on available courses for 2506 or 2516 receiver/controllers as well as a variety of other products,

contact:

Emerson Automation Solutions

Educational Services - Registration

Phone: 1-641-754-3771 or 1-800-338-8158

E-mail: education@emerson.com

emerson.com/fishervalvetraining

(4)

(5)

(5)

4

Page 5

Instruction Manual

D200129X012

2506/2516 Receiver/Controller

June 2017

Installation

WARNING

To avoid personal injury or property damage resulting from the sudden release of pressure:

D Always wear protective clothing, gloves, and eyewear when performing any installation procedures to avoid personal

injury.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

D If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

CAUTION

Do not use sealing tape on pneumatic connections. This instrument contains small passages that may become obstructed

by detached sealing tape. Thread sealant paste should be used to seal and lubricate pneumatic threaded connections.

Mounting the Controller

Note

If a separate receiver/controller unit has been ordered for field installation with an existing valve/actuator assembly or 2500

controller/transmitter, additional mounting parts may be required. Find the mounting description in the parts list at the end of this

manual. Then, order any additional parts.

Figures 3 through 8 show dimensions and connection locations used when you install a receiver/controller.

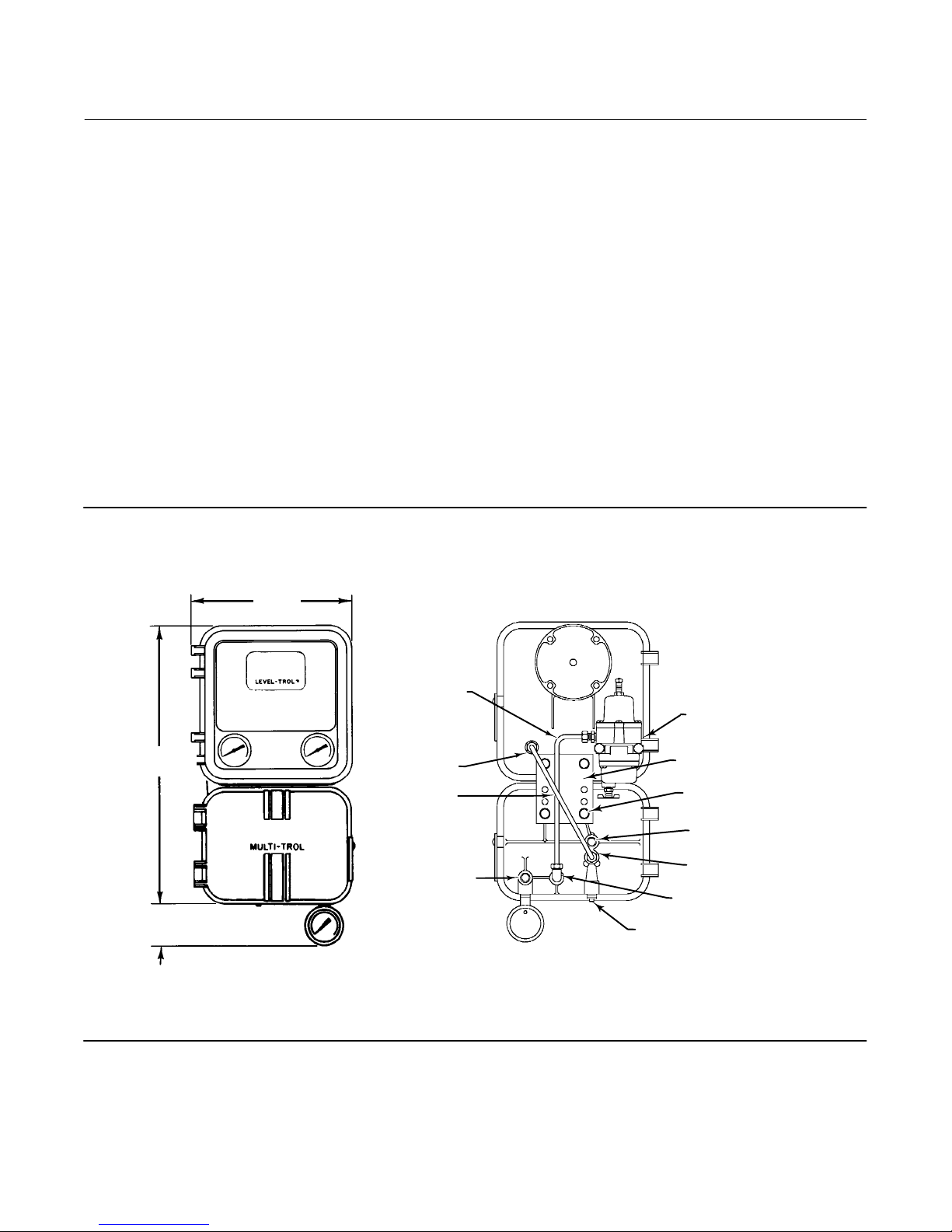

Figure 3. Dimensions and Location of Connections

235

(9.25)

171

(6.76)

232

(9.12)

FRONT VIEW

BELLOWS VENT OR

REMOTE SET POINT

CONNECTION

OUTPUT CONNECTION

(MARKED DIAPHRAGM)

44

(1.75)

70

(2.75)

SUPPLY

CONNECTION

57

(2.25)

70

(2.75)

MOUNTING

HOLES (2 PLACES)

5/16‐18 UNC

41

(1.62)

INSTRUMENT

CONNECTION

CASE VENT

TAPPED

VENT FOR

VENT LINE

(OPTIONAL)

AD4913‐H

A3844‐1

BOTTOM VIEW

REAR VIEW

mm

(INCH)

5

Page 6

2506/2516 Receiver/Controller

June 2017

Instruction Manual

D200129X012

Actuator Yoke Mounting

See figure 4 for a typical mounting plate. Key numbers are shown in figure 5.

1. Locate the mounting plate (key 164, figure 5). Select appropriate mounting holes in the mounting plate for the

receiver/controller. Then, align the mounting holes in the mounting plate with the mounting holes in the

receiver/controller case.

2. Place the two cap screws (key 48) through the mounting plate from “back to front”. Engage the cap screw threads

in the mounting holes in the receiver/controller case and tighten the cap screws to attach the mounting plate to the

back of the receiver/controller.

3. Place cap screws (key 39) through the yoke mounting holes in the mounting plate from “front to back”. Place a

spacer (key 174) over the threads of the cap screws extending from the mounting plate to properly separate the

mounting plate and the lower yoke boss of the actuator (figure 5).

4. Attach the mounting plate with receiver/controller to the lower yoke boss of the actuator yoke. Be sure the spacers

support the mounting plate. Be sure the receiver/controller is parallel with the actuator yoke and then tighten the

cap screws into the yoke boss.

5. If supply pressure is piped through a filter/regulator, bolt the regulator directly to the upper yoke boss using the cap

screws (key 85). Provide appropriate piping from the filter/regulator output connection to the receiver/controller

supply connection.

Figure 4. Mounting Plate for Yoke Mounting, Wall

Figure 5. Yoke Mounting

Mounting

13

8 HOLES

11/16 DIAMETERS

(17)

(0.50)

35

(1.38)

IC2218‐E

83

(3.25)

57

(2.25)

(0.69)

(0.50)

38

(1.50)

17

(0.56)

13

(0.69)

14

14

(0.58)

17

102

(4.00)

mm

(INCH)

SPACER (KEY 174)

CAP SCREW AND

LOCKWASHER

(KEYS 39 AND 83)

38b39604‐A

AD44913‐H

A3848‐1

Wall Mounting

See figure 6 for key number locations. The mounting plate is shown in figure 4.

REGULATOR OUTPUT

(SUPPLY CONNECTION

ON OPPOSITE SIDE)

MOUNTING PLATE

(KEY 164)

CAP HEAD SCREW

(KEY 48)

6

Page 7

Instruction Manual

D200129X012

2506/2516 Receiver/Controller

June 2017

Figure 6. Wall Mounting

MOUNTING

PLATE (KEY 164)

AD4913‐H

A3847‐1

194

(7.62)

SIDE VIEW

SPACER

(KEY 78)

CAP SCREW AND

LOCKWASHER

(KEYS 39 AND 83)

SPACER (KEY 174)

mm

(INCH)

1. Install lock washers (key 83) on the cap screws (key 39). Then, insert the cap screws through the mounting plate

from “back to front”. Place a spacer (key 174) over the threads of each cap screw as it extends from the mounting

plate. The spacers are required to properly separate the receiver/controller from the mounting plate. Then, thread

the cap screws into the mounting holes in the receiver/controller case and tighten.

2. Install lock washers (key 83) on the cap screws (key 48). Then, insert the cap screws through the mounting plate

from “front to back”. Place a spacer (key 174) over the threads of each cap screw as it extends from the mounting

plate. The spacers are required to properly separate the mounting plate from the wall mounting position. Then,

thread the cap screws into holes prepared at the wall mounting position and tighten.

3. Provide appropriate piping from the filter/regulator output connection to the receiver/controller supply

connection.

Actuator Diaphragm Case Mounting

To mount a receiver/controller to the diaphragm casing of a standard diaphragm actuator, remove two hex nuts and

hex head cap screws securing the upper and lower diaphragm casings. If necessary, refer to the appropriate actuator

instruction manual to locate the hex head cap screws and nuts.

See figure 7 for key number locations.

Figure 7. Case Mounting

CAP HEAD SCREW

(KEY 39)

CAP HEAD

SCREW

(KEY 48)

mm

(INCH)

MOUNTING

BRACKET

(KEY 164)

AD4913‐H

A3846‐1

121

(4.75)

86

(3.38)

7

Page 8

2506/2516 Receiver/Controller

June 2017

Instruction Manual

D200129X012

1. Locate the receiver/controller mounting holes in mounting bracket (key 164, figure 7).

2. Place the two cap screws (key 48) through the receiver/controller mounting plate holes from “back to front''.

Engage the threads in the receiver/controller mounting holes and tighten the cap screws to attach the mounting

plate to the back of the receiver/controller.

3. Locate the receiver/controller mounting position on the horizontal edge of the diaphragm case. A typical Fisher

diaphragm actuator features upper and lower diaphragm casings held together with hex head cap screws and hex

nuts. Remove the hex nuts from two hex head cap screws joining the upper and lower casing. Then, remove the cap

screws.

4. Engage the cap screw threads in the mounting holes in the receiver/controller case and tighten the cap screws to

attach the mounting plate to the back of the receiver/controller.

5. Place the mounting bracket over the empty casing holes. Insert the casing cap screws through the mounting

bracket, upper casing, and lower casing. Add the nuts and tighten to secure the mounting bracket with

receiver/controller to the casing.

6. If supply pressure is piped through a filter/regulator, the regulator may be attached in one of two locations:

D Attach the regulator directly to the upper yoke boss using the cap screws (key 85) for yoke mounting.

D Attach the regulator to the casing using a mounting bracket (key 177). The mounting bracket for the regulator is

the same as the mounting bracket for the receiver/controller. Follow steps 1 through 4 to mount the regulator.

7. Connect the filter/regulator output connection to the receiver/controller supply connection.

Pipestand Mounting

See figure 8 for key number locations.

Figure 8. Pipestand Mounting

MOUNTING PLATE

2

NOTES:

1 PIPE CLAMP INCLUDES NUTS

2 FILTER/REGULATOR MOUNTING AREA

AD4913‐H

A3845‐1

1. Locate the mounting plate (key 164). Select appropriate mounting holes in the mounting plate for the

receiver/controller. Then, align the mounting holes in the mounting plate with the mounting holes in the

receiver/controller case.

2. Place the two cap screws (key 48) through the mounting plate from “back to front”. Place a spacer (key 174) over

the threads of each cap screw as it extends from the mounting plate. The spacers are required to properly separate

the receiver/controller from the mounting plate.

(KEY 164)

SPACE SPOOL

(KEY 78)

157

(61.9)

CAP SCREW AND LOCKWASHER

(KEYS 39 AND 83)

PIPE CLAMP

(KEY 175)

51 j PIPE

(2.00)

1

mm

(INCH)

8

Page 9

Instruction Manual

D200129X012

2506/2516 Receiver/Controller

June 2017

3. Attach the mounting plate with receiver/controller to a 2‐inch (nominal) pipe with pipe clamps (key 175). Each pipe

clamp includes two nuts. Tighten clamp nuts.

4. If supply pressure is piped through a filter/regulator, the regulator may be attached to the mounting plate using cap

screws (key 85), lock washers (key 84), and hex nuts (key 40).

5. Provide appropriate piping from the filter/regulator output connection to the receiver/controller supply

connection.

2500 Controller/Transmitter and 2506/2516 Receiver/Controller Mounting

If the controller/transmitter and receiver/controller are ordered simultaneously, the factory will mount them together

before shipment (figure 9). For examples of typical transmitter/receiver mounting arrangements, see figures 10

and 11.

If the receiver/controller is ordered separately for use with a 2500 controller/transmitter, it may not have the required

mounting parts. If mounting parts are required, consult the parts list under the specific mounting application.

See figure 9 for key number locations.

Figure 9. Fisher 2500 Controller‐Transmitter and 2506/2516 Receiver‐Controller Mounting

AR5748‐B

3V7594‐B

B2115‐1

406

(16.00)

60

(2.37)

235

(9.25)

FRONT VIEW

TUBING

(KEY 169)

TRANSMITTER

OUTPUT

TUBING

(KEY 168)

OUTPUT

CONNECTION

(MARKED

DIAPHRAGM)

REAR VIEW

1/4 NPT SUPPLY

(ON REGULATOR)

MOUNTING PLATE (KEY 164)

CAP SCREW AND LOCKWASHER

(KEYS 39 AND 83)

BELLOW VENTS OR REMOTE

SETPOINT CONNECTION

INSTRUMENT INPUT

CONNECTION

SUPPLY CONNECTION

1/4 NPT REMOTE

LEVEL INDICATOR

mm

(INCH)

1. Install lock washers (key 83) on the cap screws (key 39). Then, insert the cap screws through the mounting plate

from “back to front”. Thread the cap screws into the mounting holes in the receiver/controller case and tighten.

9

Page 10

2506/2516 Receiver/Controller

June 2017

Instruction Manual

D200129X012

2. Install lock washers (key 83) on the cap screws (key 48). Then, insert the cap screws through the mounting plate

from “back to front”. Thread the cap screws into the mounting holes in the controller/transmitter.

3. If supply pressure is piped through a filter/regulator, bolt the regulator to the back of the controller/transmitter.

4. Provide appropriate piping connections between the units as shown in figures 10 or 11.

Figure 10. Typical Transmitter with Receiver and Control Valve Installation Assembly

NOTE:

1 SEE FIGURE 9 FOR REAR VIEW

DF5357‐A

A3701‐2

SUPPLY

2500 CONTROLLER/

TRANSMITTER

2506/2516 RECEIVER/

CONTROLLER

FROM DIAPHRAGM

CONNECTION TO

ACTUATOR

DIAPHRAGM

ACTUATOR

CONTROL VALVE

1

1

1

10

Page 11

Instruction Manual

D200129X012

2506/2516 Receiver/Controller

Figure 11. Typical Transmitter and Receiver Installation with an Indicator and Remote Set Point Connection

June 2017

CONTROLLER/

TRANSMITTER

SUPPLY

4

CONTROLLER SUPPLY

NOTES:

1 PIPING FROM TRANSMITTER OUTPUT TO PANEL INDICATOR

2 PIPING FROM TRANSMITTER OUTPUT TO PANEL RECEIVER/CONTROLLER INSTRUMENT INPUT. SEE FIGURE 3 FOR CONNECTION LOCATION

3 PIPING FROM PANEL LOADER TO RECEIVER/CONTROLLER REMOTE SET POINT CONNECTION. SEE FIGURE 3 FOR CONNECTION LOCATION.

4 SEE FIGURE 3 FOR CONNECTION LOCATION.

DF5379‐A

A3702‐2

RECEIVER/

2500

CONTROLLER/

TRANSMITTER

2

INDICATOR

1

PANEL

LOADER

REMOTE

SET POINT

ADJUSTMENT

SUPPLY

CENTRALIZED

CONTROL PANEL

3

CONTROLLER OUTPUT PIPING

2506/2516 REMOTE

RECEIVER/CONTROLLER

DIAPHRAGM ACTUATOR

CONTROL VALVE

4

Connections

WARNING

The controller is capable of providing full supply pressure to connected equipment. To avoid personal injury or property

damage caused by parts bursting from system overpressure, make sure the supply pressure never exceeds the maximum

safe working pressure of any connected equipment.

CAUTION

Do not use sealing tape on pneumatic connections. This instrument contains small passages that may become obstructed

by detached sealing tape. Thread sealant paste should be used to seal and lubricate pneumatic threaded connections.

To complete the installation of a receiver/controller, make connections with tubing and fittings between the

receiver/controller and the actuator. The fittings, tubing, and mounting parts required depend on the type number

and optional equipment such as filter, regulator, and bypass valve.

11

Page 12

2506/2516 Receiver/Controller

June 2017

Instruction Manual

D200129X012

All pressure connections on 2506/2516 receiver/controllers are 1/4 NPT internal fittings (figures 3 and 9). Use 1/4‐inch

piping or 3/8‐inch tubing to these connections.

If remote venting is required, see the Vents subsection below.

Supply Connection

WARNING

Severe personal injury or property damage may occur if the instrument air supply is not clean, dry and oil free or

non‐corrosive gas. While use and regular maintenance of a filter that remove particles larger than 40 micrometers in

diameter will suffice in most applications, check with an Emerson Automation Solutions field office and industry

instrument air quality standards for use with corrosive gas or if you are unsure about the proper amount or method of air

filtration or filter maintenance.

If the existing supply is corrosive, make sure the tubing and instrument components that contact the corrosive medium are

of suitable corrosion‐resistant materials, or change to a noncorrosive supply medium.

WARNING

Personal injury or property damage may occur from bursting parts due to overpressuring any system component. To avoid

injury or damage, provide pressure‐relieving or pressure‐limiting devices if supply or input pressure could exceed the

maximum allowable pressures listed in table 3.

It is recommended that supply pressure pass through a filter/regulator combination such as a Fisher 67CFR. See table 3

for recommended supply pressures to the receiver/controller.

Typical supply pressure for the 67CFR is clean dry air or a gas at a pressure of 2.5 bar (35 psig) to a maximum of 17 bar

(250 psig). For specific regulator limits, see the appropriate regulator instruction manual.

Output Connections

See figure 3.

Use 3/8‐inch tubing between the actuator and the receiver/controller. Connect the output (diaphragm) connection to

the appropriate actuator connection.

Instrument Connection

See figure 3.

Use 3/8‐inch tubing to connect the output from the control device to the INSTRUMENT connection on the

receiver/controller.

Vents

WARNING

If a flammable or hazardous gas is used as supply pressure medium, personal injury or property damage could result from

fire or explosion caused by the accumulated gas. Injury or property damage could also result from contact with flammable

12

Page 13

Instruction Manual

D200129X012

or hazardous gas. The case and cover assembly does not form a gas‐tight seal and flammable or hazardous gas could leak

from this unit. Therefore, if the receiver/controller unit is enclosed, install a remote vent line to remove part of the exhaust

gas to a properly ventilated area. However, a remote vent line cannot be relied upon to remove all hazardous gas. Vent line

piping should comply with local and regional codes and should be as short as possible. Select vent line piping with

adequate inside diameter and install with few bends to reduce case pressure buildup.

2506/2516 Receiver/Controller

June 2017

See figure 3 for vent locations.

A receiver/controller may be ordered with one of two vent configurations:

D Standard, with 1/4‐inch case vent open. The standard receiver/controller case (key 1) is not drilled and tapped for

the optional tapped vent.

D Optional, with tapped vent, for applications requiring vent line attachment to receiver/controller case. The optional

receiver/controller case features a tapped vent for applications requiring a remote vent line. The standard case vent

should be sealed with a machine screw.

An air vent plug (key 137) with gasket (key 138) and hex nut (key 139) can be added to the tapped vent. The air vent

plug provides a 1/4 NPT internal fitting.

D Receiver/controllers feature an open bellows vent/remote set point connection. An external vent assembly (key

128) is recommended if the remote set point connection is not made. The external vent assembly can be driven

into the open bellows vent.

Protect all vents against the entrance of any foreign material that could plug them. Check the vents periodically to be

certain they are not plugged.

Remote Set Point Connection

WARNING

Severe personal injury or property damage may occur if the instrument air supply is not clean, dry and oil free or

non‐corrosive gas. While use and regular maintenance of a filter that remove particles larger than 40 micrometers in

diameter will suffice in most applications, check with an Emerson Automation Solutions field office and industry

instrument air quality standards for use with corrosive gas or if you are unsure about the proper amount or method of air

filtration or filter maintenance.

See figure 3.

The remote set point connection is made at the tapped bellows vent/remote set point connection on the rear of the

receiver/controller case. A vent assembly (key 128) is recommended if the remote set point connection is not made.

To make a remote set point connection, remove the vent assembly from the connection. Install piping from the

remote set point loader or regulator.

When a panel loader or regulator is used for remote set point adjustment, as shown in figure 11, an adjustable output

range of 0.2 to 1 bar (3 to 15 psig) or 0.4 to 2 bar (6 to 30) is required to match the receiver/controller output range.

Use clean, dry air or a non‐corrosive gas for supply pressure to the remote set point bellows.

Startup

It is important that the output range of the transmitter or other device used as the input to the receiver/controller be

adjusted so that its output range corresponds to the input signal range of the receiver/controller. Be sure the

receiver/controller action (direct or reverse) is correct for the application.

13

Page 14

2506/2516 Receiver/Controller

June 2017

To start the system:

D For all receiver/controllers, perform steps 1 and 2.

1. See table 3 for specific pressure limits. Be sure the correct supply pressure is available. If necessary, adjust the

regulator to 1.4 bar (20 psig) for a 0.2 to 1 bar (3 to 15 psig) or 2.4 bar (35 psig) for a 0.4 to 2 bar (6 to 30 psig)

receiver/controller range.

2. Turn on the supply pressure to the receiver/controller.

D To make the proper level or output pressure setting for a 2506 receiver/controller, go to step 3. To make the proper

level or output pressure setting for a 2516 receiver/controller, go to step 9.

D For the 2506 receiver/controller:

3. Set the proportional band adjustment at 15 percent (1.5 on the adjustment dial). At this setting, a 0.1 bar (1.8 psig)

input pressure causes a 12 psig output pressure change. Operate the receiver/controller with the proportional band

setting as small as possible.

4. Provide an input pressure equal to the output pressure of the transmitter at a value desired or halfway between the

transmitter output range. For example, on a receiver/controller, if the desired control point is halfway between the

ends of the displacer, provide an input of 0.6 bar (9 psig) which is halfway between 0.2 and 1 bar (3 and 15 psig)

transmitter output range.

5. Set the output pressure adjustment to give a controller output that is halfway between its output range.

6. Vary the input pressure to be sure the full controller output pressure range is produced within the specified input

pressure range.

7. Lock the output pressure adjustment and connect the receiver/controller to the final control element.

8. If the proportional band setting is too narrow, causing instability, widen the proportional band just enough to

stabilize control. After making this adjustment, it may be necessary to reset the output pressure slightly to produce

the proper control range.

Instruction Manual

D200129X012

D For the 2516 receiver/controller:

9. Set the proportional band adjustment dial at 0 percent (minimum proportional band).

10. Set the reset adjustment to the fastest speed (0.005 minutes‐per‐repeat).

11. Provide an input pressure equal to the output pressure of the transmitter at a value desired or halfway between the

transmitter output range. For example, on a receiver/controller, if the desired control point is halfway between the

ends of the displacer, provide an input of 0.6 bar (9 psig) which is halfway between 0.2 and 1 bar (3 and 15 psig)

transmitter output range.

12. Adjust the output pressure dial to give a controller output somewhere within the output range of the

receiver/controller.

13. Lock the output pressure dial and connect to the final control element.

14. If the proportional band is too narrow causing instability, widen the proportional band or slow the reset just enough

to stabilize control.

Adjustments

To adjust the receiver/controller, open the cover and locate the appropriate adjustment. See figures 14, 15, and 16 for

the location of adjustments.

Set Point Adjustment

To adjust the level set point, loosen the knurled knob and rotate the knob around the INCREASE OUTPUT PRESSURE or

RAISE LEVEL dial. To raise fluid or interface level or increase density, rotate the knob in the direction of the arrow.

14

Page 15

Instruction Manual

D200129X012

To lower level or decrease density, rotate the knob in the opposite direction. The INCREASE OUTPUT PRESSURE or

RAISE LEVEL dial is graduated (in percent) to show approximate indications of the receiver/controller set point. When

making adjustments, do not rely only on the dial setting. Monitor the process fluid level to be sure the

receiver/controller attains the desired set point.

For differential gap receiver/controllers, the level setting adjustment determines the location of the gap within the

range of the sensing element.

2506/2516 Receiver/Controller

June 2017

Remote Set Point Adjustment

On a receiver/controller with remote set point adjustment capability, adjust the set point by changing the pressure to

the remote set point connection. Increase the remote set point signal pressure to decrease the receiver/controller set

point (for a direct acting receiver/controller) or increase the receiver/controller set point (for a reverse acting

receiver/controller).

Proportional Band Adjustment

For proportional and proportional‐plus‐reset receiver/controllers, the proportional band adjustment determines the

amount of change in the input pressure required to change the controller output signal from one limit of the output

signal range to the other limit (without the effect of reset action).

Proportional band is expressed as a percent of the sensing element range. That is, with a proportional band of 100

percent, an input pressure change equal to the sensing element span would change the controller output from one

limit to the other. With a proportional band of 50 percent, an input pressure change equal to one half the sensing

element range would change the controller output from one limit to the other.

The proportional valve dial is graduated from 0 to 10. A setting of 10 on the dial represents a proportional band of 100

percent; 5 represents a proportional band of 50 percent.

The receiver/controller is designed for a maximum proportional band of 200 percent. The effective band is determined

by the location of the adjustable nozzle assembly (key 17, figure 14) in the slot in the level set arm (key 28). Most

applications require a maximum band of 100 percent so, at the factory, a receiver/controller unit is set to the 100

percent value. This setting places the nozzle at a point that is halfway between the bellows assemblies. To adjust the

proportional band, rotate the adjustment counterclockwise to broaden the setting. Rotate the adjustment clockwise

to narrow the setting.

In some applications, a 200 percent proportional band range may be required. To obtain the 200 percent range, move

the nozzle assembly to the extreme right end of the slot in the level set arm.

For differential gap receiver/controllers, the proportional band adjustment determines the width of the differential

gap. This is the difference between the input pressures at which the controller output switches from zero to full supply

pressure and back to zero.

Reset Adjustment (2516 Receiver/Controller Only)

On proportional‐plus‐reset receiver/controllers, the reset adjustment determines the time in minutes required for the

reset action to produce a change in output pressure equal to the change that has occurred due to proportional band

action.

To adjust the reset action, rotate the adjustment clockwise to decrease, or counterclockwise to increase the minutes

per repeat. Increasing the minutes per repeat provides a slower reset action.

Anti‐Reset Windup Valve Adjustment (2516F Receiver/Controller Only)

The anti‐reset windup valve provides differential pressure relief. Its adjustment control extends from the back of the

receiver/controller case (figure 16).

15

Page 16

2506/2516 Receiver/Controller

June 2017

Instruction Manual

D200129X012

The factory sets this valve to relieve when the differential pressure between the proportional and reset bellows reaches

5 psi. To set the valve to relieve when the differential pressure is as low as 2 psig, turn the adjustment screw clockwise.

To set the valve to relieve when the differential pressure is as high as 7 psig, turn the adjustment screw

counterclockwise. The minimum differential setting yields the minimum differential set point overshoot during

startup.

Depending on the characteristics of the process, the anti‐reset windup valve can be positioned so that the arrow on

the case points to the letters RE or, to the letter P on the back of the manifold. If the arrow points to P, the valve opens

when receiver/controller output pressure rises. If the arrow points to RE, the valve opens when receiver/controller

output pressure falls.

Calibration

WARNING

The following calibration procedures require taking the controller out of service. To avoid personal injury and property

damage caused by an uncontrolled process, provide some temporary means of control for the process before taking the

receiver/controller out of service. Also refer to the Warning at the beginning of the Maintenance section.

See figure 14 for key number and adjustment locations.

When performing the following calibration procedures, open loop conditions must exist and make provisions to

monitor the output pressure. One way to obtain an open loop is to disconnect the controller output signal line and

install a pressure gauge.

Note

When calibrating a combined controller arrangement such as the 2500 with the 2506 or 2516 (figure 9), calibrate the 2500

controller/ transmitter first.

For a direct action receiver/controller:

1. Adjust the INCREASE OUTPUT PRESSURE adjustment to mid‐range on the scale.

2. Turn the proportional band adjustment to 100 percent of the scale range.

3. For the 2516 only, turn the reset valve adjustment fully clockwise.

4. Adjust the input pressure to 0.6 bar (9 psig) for a 0.2 to 1 bar (3 to 15 psig) or 1.2 bar (18 psig) for a 0.4 to 2 bar (6 to

30 psig) receiver/controller.

5. For the 2516 only, turn the reset valve adjustment fully counterclockwise (to the CLOSED position). This locks 0.6

bar (9 psig) or 1.2 bar (18 psig) in the reset bellows.

6. If the output pressure is 0.6 bar (9 psig) for a 0.2 to 1 bar (3 to 15 psig) or 1.2 bar (18 psig) for a 0.4 to 2 bar (6 to 30

psig) receiver/controller, go to step 8. If not, continue with step 7.

7. If the output pressure span is too low, move the nozzle down towards the flapper, if output pressure is too high,

move the nozzle up. Continue by trial and error until the desired setting is obtained.

8. Adjust the input pressure to 1 bar (15 psig) for a 0.2 to 1 bar (3 to 15 psig) or 2 bar (30 psig) for a 0.4 to 2 bar (6 to

30 psig) receiver/controller.

16

Page 17

Instruction Manual

D200129X012

2506/2516 Receiver/Controller

June 2017

9. The output pressure should be 1 bar (15 psig) for a 0.2 to 1 bar (3 to 15 psig) or 2 bar (30 psig) for a 0.4 to 2 bar (6 to

30 psig) receiver/controller. If output pressure is within application tolerance, proceed to step 12. If not, continue

with step 10.

10. If the output pressure span is narrow, move the nozzle slightly to the left or, if the output pressure span is too wide,

move it to the right and repeat steps 4 and 6 through 10.

11. Repeat the steps until the receiver/controller is within application requirements.

12. Reconnect the receiver/controller to the control loop and see the Adjustment section.

Principle of Operation

The 2506/2516 uses a basic pressure balance relay system. The relay is connected so that supply pressure is fed to the

inlet side of the relay valve and the fixed restriction. From this restriction, the air pressure bleeds into the relay

chamber on one side of the large diaphragm and also to the nozzle. As long as there is no pressure change on either

diaphragm, the relay valve remains in equilibrium with both inlet and exhaust ends closed. The area ratio of the large

diaphragm to the small diaphragm is 3 to 1. A 12 psi pressure change on the small diaphragm is balanced by a 4 psi

change in the large diaphragm.

The following descriptions show how the relay works with the standard proportional, proportional‐plus‐reset, and

proportional‐plus‐reset with anti‐reset windup receiver/controllers.

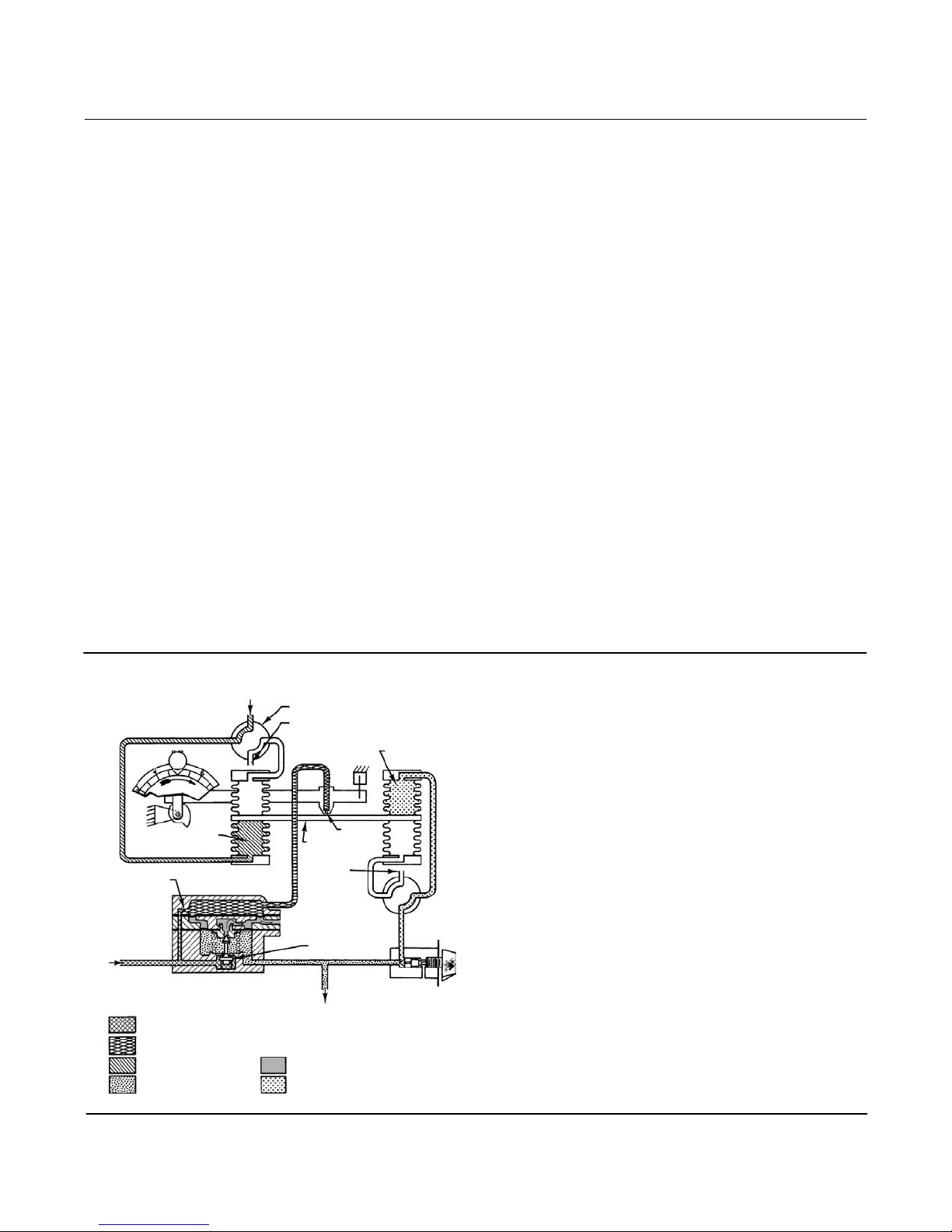

2506 Receiver/Controllers

See figure 12.

Figure 12. Fisher 2506 Direct Action Receiver / Controller Schematic

SENSING BELLOWS

RESTRICTION

SUPPLY

SUPPLY PRESSURE

RELAY LOADING PRESSURE

TRANSMITTER INPUT

OUTPUT PRESSURE

BD2388‐F

A3849

TRANSMITTER INPUT

REVERSING SWITCH

BELLOWS VENT OR REMOTE SETPOINT CONNECTION

PROPORTIONAL BELLOWS

NOZZLE

BEAM/FLAPPER

ASSEMBLY

VENT

RELAY INNER

VALVE

OUTPUT PRESSURE TO

CONTROL VALVE

RELAY BLEED PRESSURE

PROPORTIONAL PRESSURE

17

Page 18

2506/2516 Receiver/Controller

June 2017

Instruction Manual

D200129X012

As long as the process level remains constant, the transmitter input pressure to the receiver/controller remains

constant. Inside the receiver/controller, the bellows beam/flapper assembly remains in a steady‐state position.

The position of the bellows beam allows the supply pressure to bleed through the nozzle as fast as it enters the relay

through the fixed restriction. A change in transmitter input pressure repositions the beam/flapper assembly with

respect to the nozzle.

On a direct action receiver/controller, an increase in transmitter input pressure causes a pressure increase in the

sensing bellows assembly, tending to push the beam toward the nozzle. This restricts the escape of supply pressure

through the nozzle, thus increasing the pressure on the large diaphragm in the relay. This opens the relay valve to the

supply pressure allowing an increase in output pressure to the control valve.

A decrease in transmitter input pressure decreases the pressure in the input bellows assembly by moving the beam

away from the nozzle. This allows the supply pressure to bleed through the nozzle faster than it can enter through the

fixed restriction in the relay. The relay valve opens, exhausting the output pressure which vent through the relay

exhaust port. This action decreases output pressure to the control valve.

2516, 2516F Receiver/Controllers

The action of a proportional‐plus‐reset controller (figure 13) is similar to that of a proportional controller except that

feedback from the controller output pressure is piped to a reset bellows as well as to the proportional bellows.

Figure 13. Fisher 2516 and 2516F Direct Action Receiver‐Controller Schematic

REMOTE SETPOINT

BELLOWS

SENSING BELLOWS

RESTRICTION

SUPPLY

SUPPLY PRESSURE

RELAY LOADING

PRESSURE

TRANSMITTER INPUT

B2116

TRANSMITTER INPUT

2516 RECEIVER/CONTROLLER

REVERSING SWITCH

BELLOWS VENT OR REMOTE

SETPOINT CONNECTION

BEAM/FLAPPER

ASSEMBLY

OUTPUT PRESSURE

TO CONTROL VALVE

OUTPUT PRESSURE

RELAY BLEED PRESSURE

PROPORTIONAL BELLOWS

NOZZLE

BEAM/FLAPPER

ASSEMBLY

RESET

BELLOWS

RESET BELLOWS

RESET VALVE

OUTPUT

PRESSURE

PROPORTIONAL

VALVE

PROPORTIONAL PRESSURE

RESET PRESSURE

RESET RELIEF

VALVE SPRING

RESET

VALVE

PROPORTIONAL VALVE

RELIEF VALVE

DIAPHRAGM

2516F RECEIVER/CONTROLLER

ADJUSTING

SCREW

DIFFERENTIAL

RELIEF VALVE

You can adjust the reset valve on the 2516 and 2516F to channel some or all of the proportional pressure into the reset

bellows that opposes the proportional bellows action. This arrangement automatically reduces the effect of any

proportional overcorrection by a set amount per time interval, as long as there is a deviation from the control point.

18

Page 19

Instruction Manual

D200129X012

2506/2516 Receiver/Controller

June 2017

The 2516F receiver/controller also features an anti‐reset windup valve. This valve provides differential pressure relief to

prevent proportional pressure from exceeding reset pressure by more than a set value. The proportional valve output

pressure registers on one side of the diaphragm chamber and the reset valve output pressure registers on the other

side diaphragm. A sudden increase in the output pressure causes a rapid pressure increase in the proportional bellows

and in the proportional side of the diaphragm chamber. If the diaphragm pressure of the relief valve exceeds that of

the spring side by the amount of the relief pressure setting, the relief diaphragm moves off the orifice in the

differential relief valve. This allows the pressure on the proportional side of the diaphragm to bleed into the reset

system. This action provides quick relief of excessive proportional pressure and reduces the time required by the

system to return to the control point. A user can reverse the differential relief action to relieve on decrease output

pressure.

Maintenance

Receiver/controller parts are subject to normal wear and may require inspection or replacement. The frequency of

inspection and parts replacement depends upon the severity of the service conditions. When inspection or repairs are

needed, disassemble only those parts necessary to accomplish the job.

Select the appropriate maintenance procedures and perform the appropriate steps. Each procedure requires that

supply pressure and process pressure be shut off before beginning maintenance.

Establish a maintenance cycle to regularly clean the vents (figure 3). Also, establish a maintenance cycle to clear the

relay orifice (key 88, not shown) by pushing in the plunger of the core assembly (key 89).

WARNING

The following maintenance procedures require taking the controller out of service. To avoid personal injury and property

damage caused by an uncontrolled process:

D Always wear protective clothing, gloves, and eyewear when performing any maintenance operations to avoid personal

injury.

D Provide some temporary means of controlling the process before taking the receiver/controller out of service.

D Release any trapped pressure from the controller and vent supply pressure before disassembly.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Changing Controller Action

See figure 14 for key number locations, unless otherwise directed.

Note

Do not switch the 2516 receiver/controller to snap (S) action.

To change controller action, reposition one or both switch plates (key 132), which are mounted on the left or right

bellows assemblies (key 134 or 133 respectively). When either switch plate (key 132) is removed, the raised letters D,

R, S, and P are visible on the bellows frame located under the switch plate (figure 14).

19

Page 20

2506/2516 Receiver/Controller

June 2017

Instruction Manual

D200129X012

These letters correspond to: direct (D), reverse (R), snap (S), and proportional (P) control action. To obtain the type of

control desired, position the switch plates so that the proper letter appears in the cut‐out corner, as explained below:

D The bellows assembly on the left provides either direct or reverse action. The receiver/controller (2506 or 2516) can

be changed between direct and reverse action by repositioning the switch plate (key 132) on the left. Direct action

(D) is when increasing transmitter input pressure increases receiver/controller output pressure. To obtain direct

action, position the switch plate so the D is visible. Reverse action (R) is when decreasing transmitter input pressure

increases receiver/controller output pressure. To obtain reverse action, position the switch plate so the R is visible.

D The bellows assembly on the right provides either proportional (P) or snap (S) action depending on the switch plate

position. For all types of receiver/controllers, to obtain proportional action, position the switch plate so the P is

visible. For 2506 receiver/controllers, to obtain snap action, position the switch plate so the S is visible.

Troubleshooting

As an aid to troubleshooting, see table 4 for a listing of some common operating faults, their probable cause, and

suggested procedures for correcting the faults.

Table 4.Troubleshooting Chart

Fault Possible Cause Check Correction

1. Process wanders or cycles

around set point.

Note: 1.2 is for the 2500 and

2506/16 combination.

2. Receiver/controller

controlling off set point or

switching point.

3. Receiver/controller cannot

obtain full output range.

1.1 Proportional band or specific

gravity adjustment incorrect, or

improperly tuned control loop.

1.2 Input signal varying to the

2506/16.

1.3 Supply pressure varying, or

incorrect supply pressure setting.

1.4 Relay malfunction. 1.4 Check for relay malfunction by

2.1 Supply pressure not set

correctly.

2.2 Leak in the receiver/controller

loop.

3.1 Supply pressure not set

correctly.

3.2 Nozzle adjustment. 3.2 Insure the nozzle is not loose. 3.2 Perform calibration procedures.

3.3 Relay malfunction. 3.3 Check for relay malfunction by

3.4 Leaking controller/transmitter

loop.

1.1 Insure that the prestartup

procedures are completed correctly.

Tune control loop.

1.2 Use a pressure gauge to monitor

input stability.

1.3 Use input pressure gauge to

monitor stability. Make sure regulator

supply pressure is within limits.

using the testing relay deadband

procedure.

2.1 Make sure regulator supply

pressure is set correctly. Make sure

regulator supply pressure is within

limits.

2.2 Use soap and water to check for

internal and external leaks.

3.1 Make sure supply pressure is set

correctly. Make sure regulator supply

pressure is within limits.

using the testing relay deadband

procedure.

3.4 Use soap and water to check for

internal and external leaks.

-continued-

1.1 If stable control cannot be attained,

and all other elements are functionally

correct, examine other possible causes

related to the controller/transmitter.

1.2 Apply stable input pressure source.

Tune the 2500 controller/transmitter.

1.3 Apply correct supply pressure. It is

recommended to use one regulator per

instrument.

1.4 Depress plunger to clean out the

fixed restriction. Replace relay using the

procedure in the maintenance section.

2.1 Reset the regulator pressure.

If the problem recurs, replace or rebuild

the regulator. Provide a regulator input

pressure within regulator limits.

2.2 Replace or repair leaking parts as

necessary.

3.1 Reset the regulator pressure.

If problem recurs, replace or rebuild the

regulator. Provide a regulator input

pressure within regulator limits.

3.3 Depress plunger to clean out the

fixed restriction. Replace relay using the

procedure in the maintenance section.

3.4 Replace or repair leaking parts as

necessary.

20

Page 21

Instruction Manual

D200129X012

2506/2516 Receiver/Controller

June 2017

Table 5.Troubleshooting Chart (continued)

Fault Possible Cause Check Correction

4. Receiver/controller remains

at full or zero output pressure.

4.1 Supply or output pressure

gauge malfunction.

4.2 Flapper adjustment. 4.2 Insure the flapper is not loose on

4.3 Relay malfunction. 4.3 Check for relay malfunction by

4.1 Insure the pressure gauges are

registering correctly.

the torque tube shaft. Insure the

flapper is centered on the nozzle.

using the testing relay deadband

procedure.

4.1 Replace pressure gauges.

Use corrective action given for section 3

of this table.

4.2 Replace or tighten flapper assembly

as necessary and/or center flapper on

nozzle.

4.3 Depress plunger to clean out the

fixed restriction. Replace relay using the

procedure in the maintenance section.

Testing Relay Deadband

1. Replace the PROPORTIONAL BAND adjustment assembly with a 1/8 NPT pipe plug according to the sections for

changing proportional, reset, or anti‐reset windup valves.

2. Turn on the supply pressure and set it to 1.4 bar or 2.4 bar (20 or 35 psig) according to supply pressure

requirements of the receiver/controllers.

3. By changing the process variable and adjusting the INCREASE OUTPUT PRESSURE control, set the output pressure

to 15 or 30 psig. While monitoring the output pressure, slowly change the process until an output pressure change

just begins. Record the value of the process variable at this detection point.

4. Change the process variable in the opposite direction until another output pressure change just begins. Again,

record the value of the process variable. If the difference between the two values (the deadband) is more than 0.2

percent of the maximum displacer length, the relay must be repaired or replaced.

5. See the relay removal and replacement procedures and, if necessary, the relay disassembly and assembly

procedures if the relay is to be repaired.

6. Turn off the supply pressure, remove the pipe plug, and install the PROPORTIONAL BAND adjustment assembly.

Replacing Receiver/Controller Parts

See figure 14 for key number locations, unless otherwise indicated.

Bellows Replacement

Use the following bellows replacement procedure to replace defective bellows or change the output signal range.

Removal

1. Remove the relay tubing assembly (key 11), the INCREASE OUTPUT PRESSURE plate (key 35), and the attached

restriction plug orifice assembly (key 11).

2. Take out the four bellows screws (key 96). These are special screws with air passages in them so, be careful not to

lose them.

3. Compress the bellows (both are key 65) slightly and slip them out of the bellows frame (keys 133 or 134).

4. Unscrew the bellows from the beam (key 59). A gasket (key 79) fits between the end of the bellows and the bellows

frame.

5. Inspect each bellows and gasket and, if necessary, replace them.

Replacement

1. First install the bellows gasket (key 79), then install each bellows (key 59) by screwing it onto the beam (key 59).

2. Compress the bellows slightly and slip them into the bellows frame (key 133 or 134).

21

Page 22

2506/2516 Receiver/Controller

June 2017

3. Secure the screws (key 96) and replace the tubing.

4. Check all tubing connections and the bellows screws for leaks. Tighten as necessary and proceed to the Calibration

section.

5. If a bellows assembly (key 65) with a different range is installed, replace the gauges (key 20 or 135) with those with

an appropriate measurement capability.

Instruction Manual

D200129X012

Changing the Relay

Remove the relay to replace it.

Removal

1. Disconnect the tubing (key 11) from the relay.

2. Remove two relay mounting screws, the relay, and the relay gasket (keys 43, 34, and 22).

Replacement

1. Install a new gasket (key 22), the replacement relay (key 34), and secure with two mounting screws (key 43).

2. Connect the tubing (key 11) to the relay.

3. See the testing relay deadband procedures in this section.

4. If the deadband is within tolerance, see the Calibration section.

Changing Proportional or Reset Valve

1. Disconnect the appropriate tubing(s) from the proportional or reset valve.

2. Removing the valve assembly:

a. Remove the proportional valve assembly by unscrewing it from the relay base. Install the replacement assembly.

b. Remove the reset valve assembly by unscrewing the two machine screws (key 182, not shown) located behind

the reset valve on the back of the case. Install the replacement assembly.

Parts Ordering

Whenever corresponding with your Emerson sales office or Local Business Partner, include the receiver/controller type

number and the serial number. The serial number can be found on the nameplate.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Automation Solutions should

not, under any circumstances be used in any Fisher instrument. The use of components not manufacture by Emerson

Automation Solutions may void your warranty, might adversely affect the performance of the instrument, and could cause

personal injury or property damage.

22

Page 23

Instruction Manual

D200129X012

2506/2516 Receiver/Controller

June 2017

Parts Kits

Key Description Part Number

Receiver/Controller Repair Kits

Contains keys 17, 19, 21, 24, 38, and 45

Standard Temperature R2506X00L12

High Temperature R2506X00H12

Relay Replacement Kit

Contains key 22 (43 for 2500 and 2502)

and the relay assembly (key 34)

Standard Temperature RRELAYX0L22

High Temperature RRELAYX0H22

2506/2516 Controller Cover Gasket Kit

Contains qty. 5 cover gaskets, key 21 R2506CVR012

Parts List

Note

Contact your Emerson sales office for Part Ordering information.

Key Description

1 Controller case (controller back), die cast aluminum

for 2506, 2516

Standard: W/open case vent (no optional

tapped vent for vent line)

Optional: W/tapped vent for vent line

(case vent sealed with machine screw)

Additional option: Case pressure‐tested

to 0.1 bar (2 psig). Contact your Emerson

sales office to order pressure testing.

Label (key 179) is added to the case.

1 Controller case (controller back), die cast Aluminum

for 2516F, w/open case vent (no optional

tapped vent for vent line)

2 Controller cover, die cast

3 Door handle, steel pl

4 Door handle shaft, stainless steel

(not shown)

5 Machine screw, steel pl

6 Washer, stainless steel

7 Door hook, steel pl

8 Elastic stop nut, steel pl

9 Hinge pin, stainless steel, (2 req'd)

10 Compensator tubing assembly, proportional,

stainless steel

11 Relay tubing assembly,

2506 and 2516, stainless steel

17 Orifice cap, brass

Receiver/Controller Common

Parts (figure 14)

Note

Case Vent Options:

•The standard receiver/controller case features an open case vent. The

case is not drilled for the optional tapped vent.

•All receiver/controller cases feature an open bellows vent/remote set

point connection. A external vent assembly (key 128) is recommended if

the remote set point connection is not made.

•The optional receiver/controller case features a tapped vent for

applications requiring a remote vent line. The standard case vent is

sealed w/a machine screw. An external connection (air vent plug, key

137) w/gasket (key 138) and hex nut (key 139) can be added to the

tapped vent.

Note

Gauges:

See key 135 for input (instrument) gauge or pipe plug.

20* Output (diaphragm) gauge

Triple scale

0 to 30 psig/0‐0.2 MPa/0‐2 bar

0 to 60 psig/0‐0.4 MPa/0‐4 bar

Dual scale

0 to 30 psig/0‐2 kg/cm

21* Cover gasket, chloroprene

22* Relay gasket,

Standard temperature, chloroprene

High temperature, silicone

23 Relay base, die cast zinc

24* Relay base gasket (not shown)

Standard temperature, chloroprene

High temperature, silicone rubber

25 Flexure strip, stainless steel

26 Flexure strip nut, steel (2 req'd)

27 Flexure strip base, steel

28 Level set arm, steel

29 Latch pin, steel

2

*Recommended spare parts

23

Page 24

2506/2516 Receiver/Controller

June 2017

Instruction Manual

D200129X012

Key Description

31 Nut, brass (2 req'd)

32 Flapper, K93602 nickel alloy

34 Relay assembly

Standard temperature

High temperature

35 Level adjustment assembly

35C Level adjustment dial (not shown), aluminum

Std, clockwise adjustment

Optional, counter‐clockwise adjustment

For use w/2500 controller

36 Proportional band assembly

41 Screw, steel pl (2 req'd)

42 Machine screw, steel pl (2 req'd)

43 Machine screw, steel pl (2 req'd)

44 Machine screw, steel pl (6 req'd)

46 Machine screw, stainless steel (4 req'd)

47 Spring (not shown)

56 Bellows stud, brass (2 req'd) (not shown)

59 Bellows beam, steel pl

65* Bellows assembly

Brass

Range:

0.2 to 1 bar (3 to 15 psig)

Gray color code

0.4 to 2 bar (6 to 30 psig)

Green color code

Stainless steel

Range:

0.2 to 1 bar (3 to 15 psig)

Gray color code

0.4 to 2 bar (6 to 30 psig)

Green color code

Key Description

91 Reset restriction valve assembly

2516

Standard temperature

High temperature

2516F

Standard temperature

96 Bellows screw (4 req'd)

brass

stainless steel

128 External vent assembly (not shown)

for bellows vent opening when remote

set point connection is not made

plastic/stainless steel

129* Switch plate gasket (2 req'd) (not shown)

Standard temperature, nitrile

High temperature, silicone

130 Machine screw, steel pl

132 Switch plate, die cast zinc (2 req'd)

133 Right bellows frame, die cast zinc

134 Left bellows frame, die cast zinc

135* Input (instrument) gauge

Triple Scale

0 to 30 psig/0‐0.2 MPa/0‐2 bar

0 to 60 psig/0‐0.4 MPa/0‐4 bar

Dual Scale

0 to 30 psig/0‐2 kg/cm

Note

Gauges:

See key 20 for output (diaphragm) gauge.

2

Note

Bellows Assembly:

Select specific bellows assembly by application pressure range.

75 Reset tubing assembly, stainless steel

77* Bellows frame gasket (2 req'd) (not shown)

Standard temperature, chloroprene

High temperature, silicone

79* Bellows gasket (4 req'd)

Standard temperature, chloroprene

High temperature, silicone

24

135 Pipe plug (not shown), brass

Use instead of input gauge

136 Machine screw, steel pl (18 req'd)

137 Air vent plug, brass

For use w/optional case (key 1) featuring

tapped vent

138* Vent plug gasket, chloroprene

For use w/key 137

139 Hex nut, steel pl

For use w/key 137

179 Label, paper

For case (back), if pressure‐tested.

See key 1

186 Anti‐reset windup valve assembly

See following list for individual parts

215 Nameplate

*Recommended spare parts

Page 25

Instruction Manual

D200129X012

Figure 14. Fisher 2506 and 2516 Receiver‐Controller Assemblies

2506/2516 Receiver/Controller

June 2017

C0670‐2

30A8956‐B

USE W/THREADED CASE VENT

VIEW A

WITH SWITCH PLATE REMOVED

2506 ASSEMBLY

SETPOINT ADJUSTMENT

RESET VALVE

ADJUSTMENT

PROPORTIONAL

BAND VALVE

ADJUSTMENT

2516 ASSEMBLY

25

Page 26

2506/2516 Receiver/Controller

June 2017

Instruction Manual

D200129X012

Key Description

Anti‐Reset Windup Valve for

2516F Only (figure 15)

192 Lower valve body assembly

193* O‐ring, nitrile (3 req'd)

194 Diaphragm assembly, rubber

195 Spring, steel

196 Upper body half, aluminum

197 Adjustment screw, brass

198 Spring seat, aluminum

199 Machine screw, stainless steel (4 req'd)

200 Machine screw, stainless steel (2 req'd)

Figure 15. Fisher 2516F Anti‐Reset Windup Valve

Assembly

Key Description

2516F Reset and Anti‐Reset

Windup Valve Assembly

(figure 16)

181 Relief tubing assembly

182 Machine screw, steel pl (2 req'd)

183* O‐ring, Nitrile

184 Manifold, aluminum

185 Manifold nipple, aluminum

186 Differential relief valve

Figure 16. Fisher 2516F Reset and Anti‐Reset Windup

Valve Assembly

RESET VALVE

ADJUSTMENT

21A6447‐A

SECTION A‐A

ADJUSTMENT

SCREW

15A7608‐B

A3841

RECEIVER/

CONTROLLER

BACK

ANTI‐RESET WINDUP ADJUSTMENT

26

*Recommended spare parts

Page 27

Instruction Manual

D200129X012

2506/2516 Receiver/Controller

June 2017

Mounting Parts

Key Description

Yoke Mounting (figures 3 and 4)

39 Cap screw (2 req'd)

48 Cap screw (2 req'd)

For 513, 657, 667

For 480

78 Spacer (2 req'd)

For 480

164 Mounting bracket

174 Spacer Spool (2 req'd)

Regulator mounting. To upper yoke boss

85 Cap screw (2 req'd)

Key Description

Regulator mounting. To actuator case (not shown)

40 Hex nut (2 req'd)

84 Lock washer (2 req'd)

85 Cap screw (2 req'd)

176 Cap screw (2 req'd)

177 Bracket

Pipestand Mounting (figure 8)

39 Cap screw, (2 req'd)

78 Spacer, (2 req'd)

83 Lock washer (2 req'd)

164 Mounting plate, steel pl

175 Pipe clamp (2 req'd)

(includes 2 hex nuts for each clamp)

Regulator mounting. To mounting plate

(not shown)

40 Hex nut (2 req'd)

84 Lock washer (2 req'd)

85 Cap screw (2 req'd)

Wall Mounting (figure 6)

39 Cap screws, (2 req'd)

78 Spacer, (2 req'd)

83 Lock washer (2 req'd)

164 Mounting plate, steel pl

174 Spacer, (2 req'd)

Regulator mounting

165 Nipple, to join regulator to

receiver/controller supply

connection

178 Street Elbow, for supply connection

to regulator

Case Mounting (figure 7)

39 Cap screw (2 req'd)

48 Cap screw (2 req'd)

164 Mounting bracket, steel pl

2500 Controller/Transmitter and

2506/2516 Receiver/Controller

Mounting (figure 9)

39 Cap screw (4 req'd)

83 Lock washer (4 req'd)

164 Mounting plate, steel pl

Regulator mounting on 2506, 2516. With separate supply sources

and separate regulators

165 Nipple, to join regulator to receiver/controller

supply connection

Regulator mounting on 2506, 2516. With common supply source

and separate regulators

165 Nipple, to join regulator to receiver/controller

supply connection

166 Nipple, to join tee (key 167) to

controller/transmitter regulator

167 Tee (common supply connection at

controller/transmitter regulator)

172 Connector to tee (key 167)

173 Street Elbow, for receiver/controller

regulator supply connection

27

Page 28

2506/2516 Receiver/Controller

June 2017

Instruction Manual

D200129X012

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

28

E 1978, 2017 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...