Page 1

73550

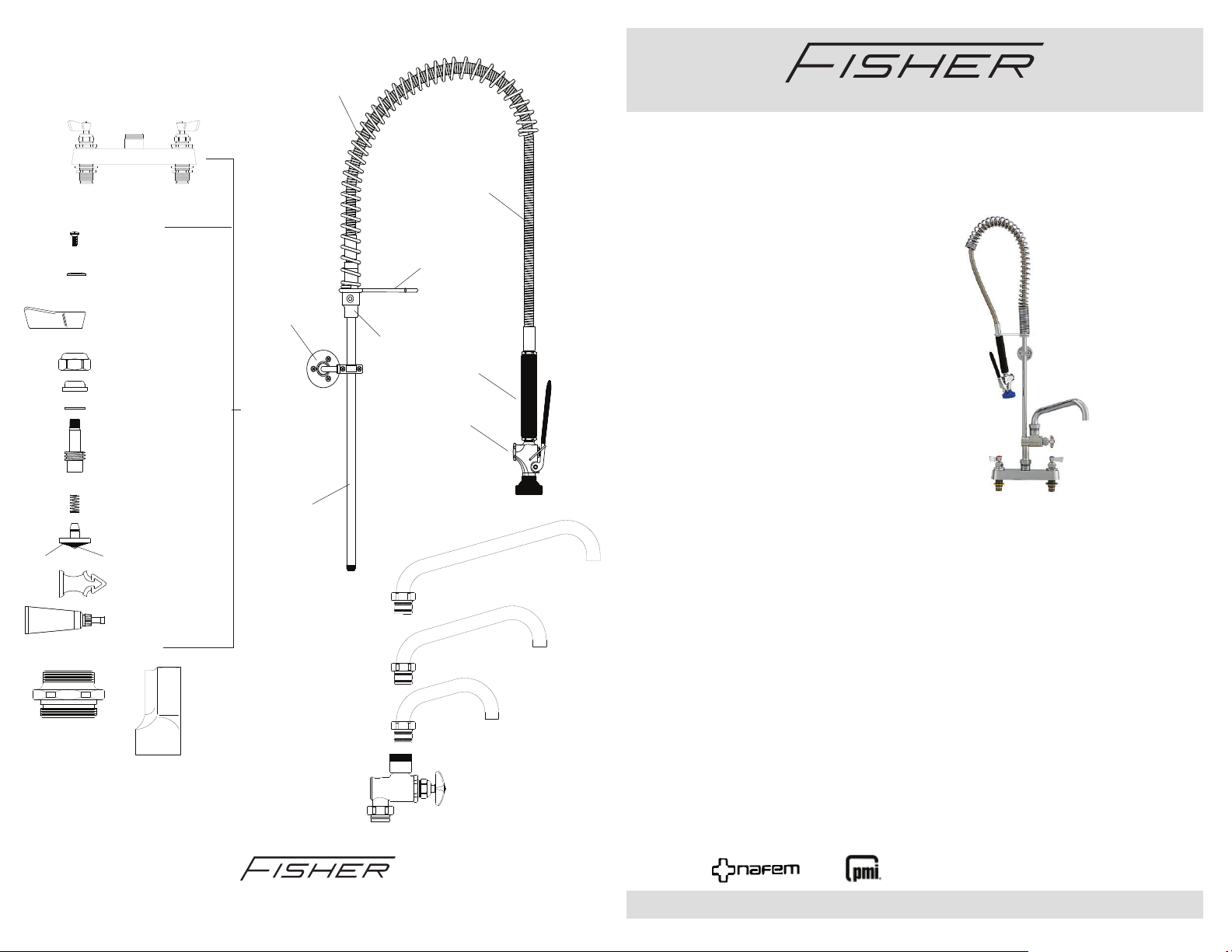

SEAT WASHER

RH STEM ADAPTER

LH STEM ADAPTER

73570

OR

73569

Replacement Parts for Pre-Rinse Units

2924-6000

GOOSENECK

SPRING

5200-CV

CONTROL VALVE

2000-7500

SCREW

2925-6300

HOSE HOOK

72813

2949

ULTRA SPRAY VALVE

1000-7502

SCREW

LEVER HANDLE

LH CHECK STEM

RH CHECK STEM

5000-2100

3/4” ELBOW

2000-8000

RED BUTTON

AND

2000-8001

BLUE BUTTON

2000-2301

2000-3002

BIBB CAP

73657

DUCK GASKET

73741

WASHER

2000-3406

OR

2000-3407

2000-6000

SPRING

73453

RETAINER

ASSEMBLY

73521

LUBE

2992

PST

2902-12

WALL BRACKET

5000-0012

RH CHECK STEM

REPAIR KIT

OR

5000-0013

LH CHECK STEM

REPAIR KIT

2927-4300

16” RISER

5000-0020

14” SWING SPOUT

5000-0001

10” SWING SPOUT

5000-0002

7” SWING SPOUT

CHEM TEE

2914

36” SS HOSE

2913

INSULATED

HANDLE

fisher manufacturing company

PRTB-CTA-8DLL

Product Installation Guide

Since 1936, Fisher Manufacturing Company has

manufactured heavy-duty, high quality plumbing

products and hardware specialties for the food service

industry. For three generations, the Fisher family has

adhered to a strict dedication of and overall value.

When you install Fisher products… you install the best.

Our hardware is manufactured with the standardization

of internal mechanisms. All chrome plating is triple

plated copper, nickel and chrome for durability. Every

piece of equipment we make is rigorously tested in

both our modern in-house testing center and in actual

field situations under extreme conditions. Every detail

is thoroughly checked. Before we make our products

available to you, they pass each and every test. You get

proven performance. Guaranteed.

Limited One Year Warranty

Fisher Manufacturing Company warrants its products

and parts thereof (except as noted below) against

defects in materials or workmanship for a period of

one year after the date of original purchase. During

this period Fisher Manufacturing Company will

replace a defective product or part without charge to

you, provided that the entire product is delivered to

Fisher Manufacturing Company. All transportation and

insurance charges for shipping the product to and from

Fisher Manufacturing Company must be borne by you.

Charges for transportation and insurance may, at the

option of Fisher Manufacturing Company, be refunded

depending upon our investigation of the warranty claim.

This warranty does not cover external finish (except at

date of original purchase) or labor costs not specifically

authorized by Fisher Manufacturing Company.

A full and complete copy of our One Year limited

warranty is available upon request.

WARNING:

Proposition 65 requires that we provide you with the

following notice: “This product Contains A Chemical

Known To The State Of California To Cause Birth

Defects Or Other Reproductive Harm.”

#25003 - 3/4 PRERINSE SPGCT 8DLH 10SS

#49808 - 3/4 PRERINSE SPGCT 8DLH 14SS

PART NO. 74683

20788

ADD-ON-CONTROL

VALV E

MANFACTURING COMPANY

PO BOX 60, TULARE, CA 93275

(800)421-6162, FAX: (800)832-8238

www.fisher-mfg.com

KEEP THIS MANUAL FOR FUTURE REFERENCE

ANSI/A112.18.1M, ANSI/NSF 61.9

fisher manufacturing company - toll free: 800-421-6162 fax: 800-832-8238

REV. A

www.fi sher-mfg.com

Page 2

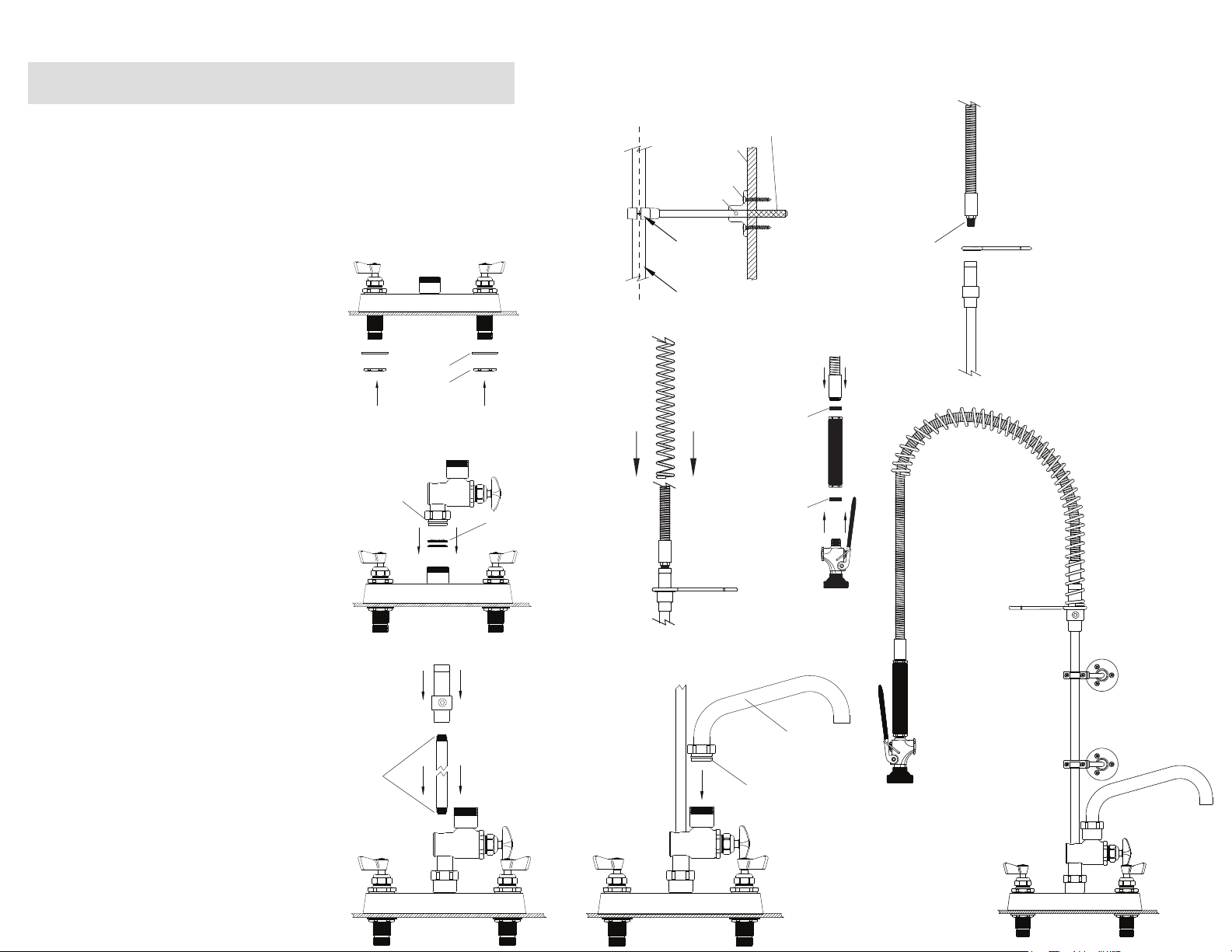

Installation Instructions for Pre-Rinse Units

BE SURE TO CHECK WITH YOUR LOCAL DEPARTMENT HAVING JURISDICTION

REGARDING BACKFLOW PREVENTION

Installation Notes:

• Be sure to shut off water supply before beginning.

• Use pipe thread sealant such as PST on all threaded joints.

• Check the packaging for missing items BEFORE beginning installation. If items are missing,

contact your supplier.

Installation Instructions Continued

Step 4

Excess Rod Length

Trim to Fit (optional)

Wall

Wall Screw

Set Screw

Step 5

Installation Instructions

1. Mount the control valve, placing the nuts and washer

on and control valve nipples and tighen. Connect the

water supply to water inlets.

2. Place the 2 serrated washers into the control valve

stacked on top of each other. Apply lube sealant to

the o-rings on the add on body. Insert the add-on

body into the control valve outlet. Position the addon body and tighten the nut.

3. Mount the pipe to hose adapter to the enclosed riser

using thread sealant. Mount the other end of the

riser to the female outlet of the add-on body

4. Proceed by installing the wall bracket with following

steps below.

a. Locate and drill a Ø7/16” hole in the wall directly

behind and about 3/4 the way up the riser pipe.

b. Loosely attach the front and back of the pipe

clamp onto the riser pipe.

c. Hold the wall bracket fl ange against the wall,

centered with the hole. Use the wall screws and a

screw driver to mount the fl ange to the wall.

d. Slide part, but not all, of the wall bracket rod non-

threaded end fi rst through the center hole of the

fl ange and into the wall.

e. Align the rod with the pipe clamp and thread the

rod into the pipe clamp. Be sure the rod is level

by adjusting the pipe clamp position.

f. Once level, fi x the rod in place by tightening both

the set screw located in the fl ange and the pipe

clamp screws.

5. Slip the hose hook over the pipe to hose adapter.

Apply thread sealant to the SS hose and attach the

SS hose to the pipe to hose adapter and tighten SS

hose.

6. Install gooseneck spring by slipping SS hose

through the spring. Spring will fi t over adapter which

holds it in an upright position. Note: Be sure spring is

installed as shown.

7. Place the handle gaskets inside the outlets of the

insulated handle. Attach the insulated handle to the

SS hose and to the spray valve.

8. Apply lube to the o-rings on swing spout, insert the

swing spout in to the add-on faucet outlet and

tighten the spout nut.

9. Turn on water supply and check for leaks.

Step 1

Step 2

Apply Lube

Step 3

Thread Sealant

Goes Here

Washer

Nut

Serrated Washer

Pipe

Clamp

Riser Pipe

Step 6 Step 7

Handle Gasket

Handle Gasket

Step 8

Swing Spout

Apply O-Ring

Lube Here

Thread Sealant

Goes Here

Step 9

Loading...

Loading...