Models 244EH and 244ER

PC-Programmable Temperature

Transmitt e rs

00809-0100-4737

English

Rev. EA

Product

Manual

Models 244EH and 244ER

PC-Programmable

Temperature Transmitters

NOTICE

Read this manual before working with the product. For personal a nd system safety, and

for optimum product performance, make sure you thoroughly unders tand the contents

before installing, using, or maintaining this product.

Within the United States, Rosemount Inc. has two toll-free assistance numbers:

Customer Central

Technical support, quoting, and order-related questions.

1-800-999-9307 (7:00 am to 7:00 pm CST)

North American Response Center

Equipment service needs.

1-800-654-7768 (24 hours—includes Canada)

Outside of the United States, contact your local Rosemount representative.

Rosemount Models 244EH and 244ER Smart Temperature Transmitters may be protected by one or more

U.S. Patents pending. Other foreign patents pending.

Rosemount and the Rosemount logotype are registered trademarks of Rosemount Inc.

Noryl and Lexan are registered trademarks of General Electric.

Microsoft, Windows, Windows 95, and Windows NT are registered trademarks of Microsoft Corp.

MINIGRABBER is a trademark of PamonaElectronics.

WAGO is a registered trademark of Kontakttechnik GmbH.

Cover photo: 644-244C901

Rosmeount Inc.

8200 Market Boulevard

Chanhassen, MN 55317

USA

Tel 1-800-999-9307

Fax (952) 949-7001

© Rosemount Inc., 2000

Fisher-Rosemount Limited

Heath Place

Bognor Regis

West Sussex PO22 9SH

England

Tel 44 (1243) 863 121

Fax 44 (1243) 867 5541

T

N

I

E

D

R

P

IN

U.

A.

S.

¢00809-0100-4737f¤

00809-0100-4737 Rev EA 10/00

The products described in this document are NOT designed for nuclear-qualified

applications. Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

For informationon Rosemount nuclear-qualified products, contact your local Rosemount

Sales Representative.

Fisher-Rosemount

Singapore Pte Ltd.

1 Pandan Crescent

Singapore 128461

Tel (65) 777-8211

Fax 65 777-0947

AP.RMT-Specialist@frco.com

Fisher-Rosemount

satisfies all obligations

coming fromlegislation

to harmonise product

requirements in the

European Union.

Product documentation available at...

www.rosemount.com

Table of Contents

SECTION 1

Introduction

SECTION 2

Installation

SafetyMessages.....................................1-1

Transmitter Overview.................................1-1

ManualOverview....................................1-2

Considerations ......................................1-3

General..........................................1-3

Mechanical.......................................1-3

Electrical ........................................1-3

Environmental....................................1-3

SafetyMessages.....................................2-1

Warnings........................................2-1

ToolsneededforInstallation ...........................2-2

Mounting...........................................2-3

SpecialMountingConsiderations.....................2-4

InstallationProcedures................................2-5

Transmitter.......................................2-5

ConfigurationSoftware.............................2-9

Model 244EC Configuration Interface ................2-11

FieldWiring.......................................2-12

SensorConnections...............................2-13

FailureMode.......................................2-16

ChangingSwitchPositions .........................2-16

SECTION 3

Operation

SECTION 4

Maintenance and

Troubleshooting

SafetyMessages.....................................3-1

Warning.........................................3-1

Power Supply .......................................3-1

Surges/Transients..................................3-1

Grounding .......................................3-2

Configuration.......................................3-2

ConfiguringaSingleTransmitter .....................3-3

ConfiguringSeveralTransmittersIdentically............3-4

ViewingtheProcessVariable........................3-5

Intermittent Sensor Algorithm ..........................3-5

CaseExamples....................................3-6

Intermittent Sensor Algorithm and Damping.............3-7

Intermittent Sensor Detect (Advanced Feature)...........3-8

Implementation ...................................3-9

SafetyInformation...................................4-1

Warning.........................................4-1

Troubleshooting .....................................4-1

Model 244EH software version 5.5.1 ..................4-1

1

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

APPENDIX A

Reference Data

APPENDIX B

Approvals

APPENDIX C

Models 644 and 244E

Temperature Transmitters

Manual Supplement

Transmitter Specification .............................A-1

Functional.......................................A-1

Performance.....................................A-2

Physical........................................ A-5

Model 244EC Configuration Interface ................ A-5

OrderingInformation................................ A-6

Ordering Flameproof and Explosion-proof Approvals

forTemperatureAssemblies........................ A-8

DimensionalDrawings...............................A-9

Transmitter...................................... A-9

Enclosure and Model 244EC Configuration Interface..... A-9

SafetyMessages.................................... B-1

Hazardous Locations Installations ...................... B-1

LocationsCertifications.............................. B-2

InstallationDrawings................................ B-4

Old Transmitter..................................... C-2

Transmitter Design................................ C-2

SensorWiringDiagrams........................... C-2

SpecialMountingConsiderations.................... C-2

New Transmitter.................................... C-3

Transmitter Design................................ C-3

SensorWiringDiagrams........................... C-3

SpecialMountingConsiderations.................... C-3

HART Communicator (Model 644H only) .............C-3

Specifications...................................... C-4

2

Section

1 Introduction

SafetyMessages ................................page1-1

TransmitterOverview.............................page1-1

ManualOverview ................................page1-2

Considerations ..................................page1-3

SAFETY MESSAGES Procedures and instructions in this manual may require special

precautions to ensure the safety of the personnel performing the

operations. Information that raises potential safety issues is indicated

by a warning symbol ( ). Refer to the safety messages listed at the

beginning of each section before performing an operation preceded by

this symbol.

Failure to follow these installation guidelines could result in death or

serious injury.

• Make sure only qualified personnel perform the installation.

TRANSMITTER OVERVIEW Thank you for choosing the Model 244E. Features of the Model 244EH

and Model 244ER transmitters include:

• Configuration using the Model 244EC Configuration Interface

and a Microsoft

and 244ER Configuration Software

• The ability to convert RTD and thermocouple inputs to 4–20 mA,

2-wire outputs that are less susceptible to electrical noise

• The capability to linearize RTD and thermocouple inputs

with temperature

• Electrical input-output isolation

• Electronics that are completely encapsulated in epoxy and

enclosed in a metal housing, making the transmitter extremely

durable and ensuring long-term reliability

• A compact size and two housing options allowing mounting

flexibility for the control room or the field

Rosemount Inc. has a full range of compatible connection heads,

sensors, and thermowells to provide complete assemblies for process

temperature measurements. Refer to Volume 1 of the Rosemount

Temperature Sensors and Assemblies Product Data Sheet (document

number 00813-0100-2654) for thread mount sensors and accessories, or

refer to Volume 2 (document number 00813-0100-2654) for DIN-style

sensors and accessories.

®

Windows®-based PC running the Models 244EH

1-1

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

MANUAL OVERVIEW This manual is designed to assist in the installation, operation, and

maintenance of Rosemount

®

Model 244EH and 244ER PC

Programmable Temperature Transmitters and the Model 244EC

Configuration Interface.

Section 2: Installation

• Tools for installation

• Mounting

• Installation

• Field wiring

Section 3: Operation

• Power Supply

• Configuration

Section 4: Maintenance and Troubleshooting

• Software Troubleshooting

Appendix A: Reference Data

• Specifications

• Dimensional drawings

• Ordering information

Appendix B: Approvals

• Locations certifications

• Installation drawings

Appendix C: Models 644 and 244E Temperature Transmitters Manual

Supplement

• Comparison between new and old Models 644 and 244E

• Specifications

1-2

CONSIDERATIONS

General Electrical temperature sensors such as RTDs and thermocouples

produce low-level signals proportional to their sensed temperature. The

Models 244EH and 244ER transmitters convert the low-level sensor

signal to a standard 4–20 mA dc signal that is relatively insensitive to

lead length and electrical noise. This current signal is then transmitted

to the control room via two wires.

Mechanical When choosing an installation location and position, take into account

the need for access to the transmitter.

Wiring Connections

Make wiring connections through the cable entry in the side of the

connection head. Be sure to provide adequate clearance for

cover removal.

Electrical Proper electrical installation is necessary to prevent errors due to

sensor lead resistances and electrical noise. Shielded cable should be

used in electrically noisy environments.

Environmental The transmitter electronics module is permanently sealed within the

housing, resisting moisture and corrosive damage. Verify that the

operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

1-3

Section

2 Installation

SafetyMessages ................................page2-1

ToolsneededforInstallation.......................page2-2

Mounting . ......................................page2-3

InstallationProcedures ...........................page2-5

FieldWiring.....................................page2-12

FailureMode ....................................page2-16

SAFETY MESSAGES Instructions and procedures in this section may require special

precautions to ensure the safety of the personnel performing the

operations. Information that raises potential safety issues is indicated

by a warning symbol ( ). Please refer to the following safety messages

before performing an operation preceded by this symbol.

Warnings

Explosions could result in death or serious injury.

• Do not remove the enclosure cover in explosive atmospheres when the circuit

is live.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certification.

• Enclosure covers must be fully engaged to meet explosion-proof requirements.

Process leaks could result in death or serious injury.

• Installand tighten thermowellsor sensors before applying pressure, or process

leakage may result.

• Do not remove the thermowell while in operation. Doing so may cause process

fluid leaks.

Electrical shock could cause death or serious injury.

• If the sensor is installed in a high-voltage environment and a fault condition or

installation error occurs, high voltage may be present on transmitter leads

and terminals.

• Use extreme caution when making contact with leads and terminals.

2-1

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

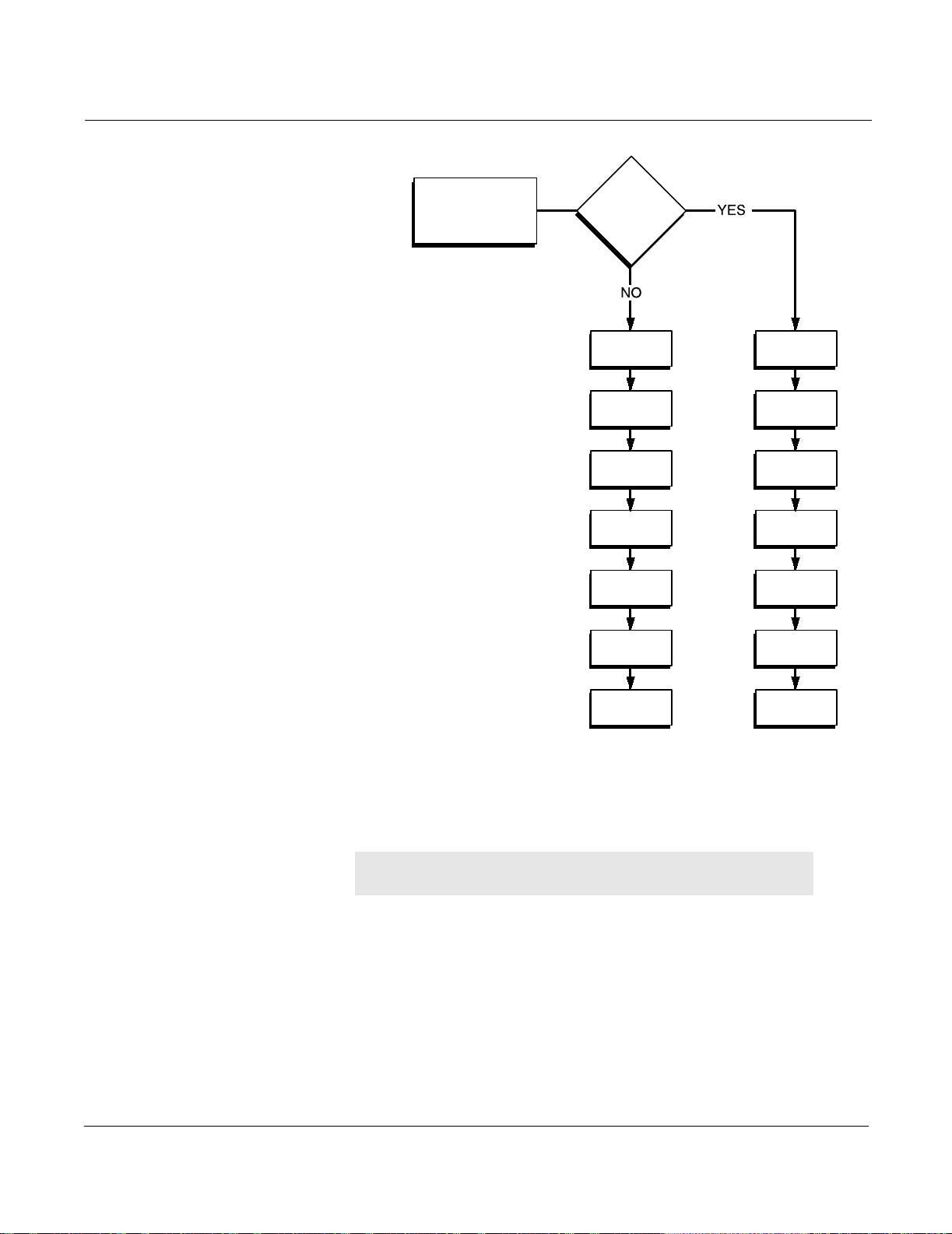

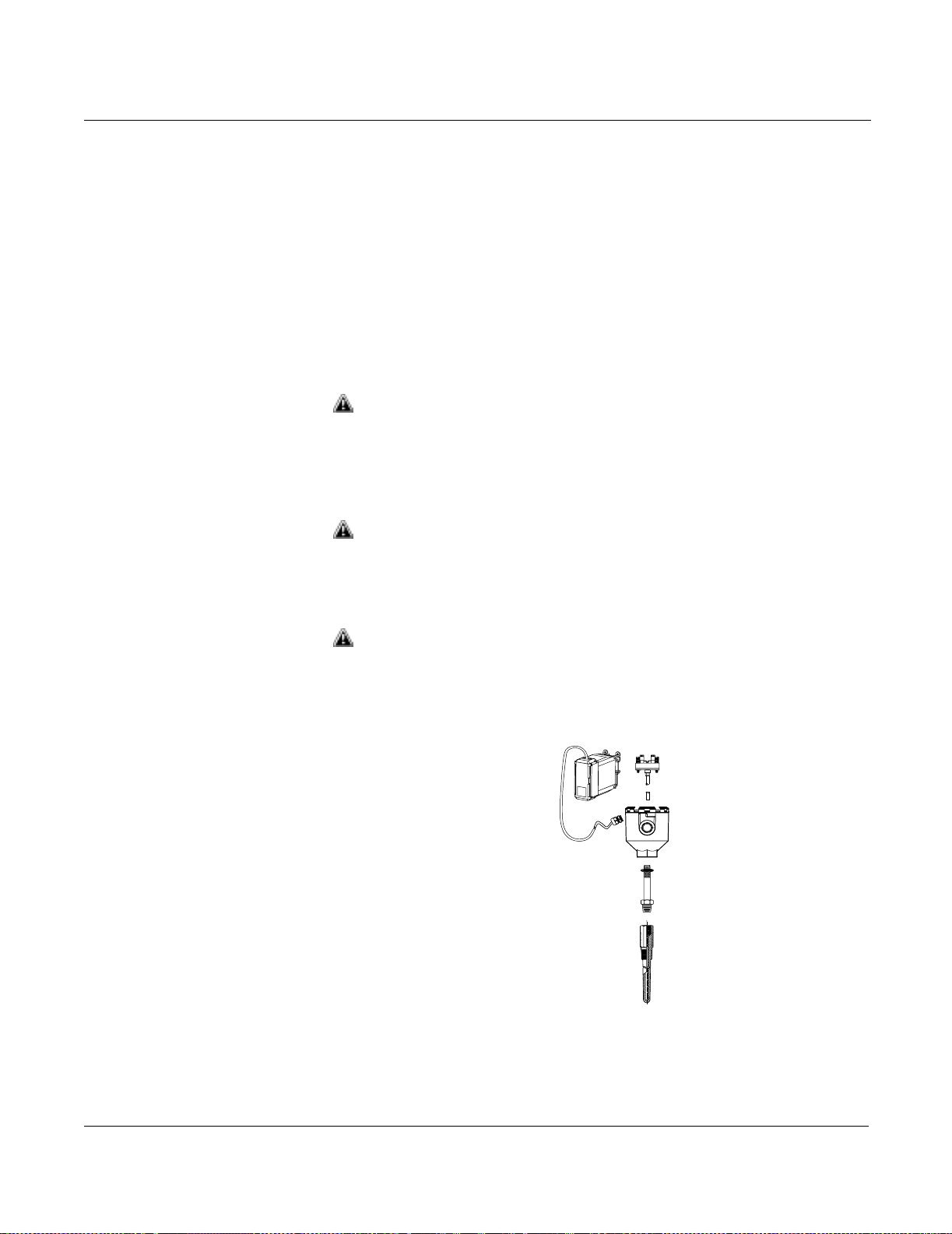

Figure 2-1. Transmitter

Installation Flowchart

Begin Here

Transmitter

Configured?

Configure

Transmitter

Set Sensor

Type

SetNumber

of Wires

Set50/60 Hz

Filter

Set Units

Set Range

Values

Field

Install

Set Failure

Mode Switch

Mount

Transmitter

Wire

Transmitter

Power

Transmitter

Check for

Leaks

TOOLS NEEDED FOR INSTALLATION

2-2

Set

Damping

The tools needed for installation are as follows:

Models 244EH and 244ER:

Model 244EC Configuration Interface:

Model 244EH and 244ER C onfiguration Software:

• Transmitter

• Mounting apparatus

• Transmitter

• 9-pin connector cable

• MINIGRABBER

•PC

• Windows-based software

Done

244-244_02A

™

clips

MOUNTING The Model 244EH installs in a connection head or universal head

mounted directly on a sensor assembly, apart from a sensor assembly

using a universal head, or to a DIN rail using an optional mounting

clip. The Model 244ER mounts directly to a wall or to a DIN rail.

The Models 244EH and 244ER transmitters will operate within

specifications for ambient temperatures between –40 and 185 °F

(–40 and 85 °C).

In a direct mounting configuration using a Model 244EH transmitter,

process heat is transferred from the thermowell to the transmitter via

the connection head. If the expected connection head temperature is

near or beyond specification limits, consider the use of additional

thermowell lagging, an extension nipple, or a remote mounting

configuration to isolate the transmitter from excessive temperatures.

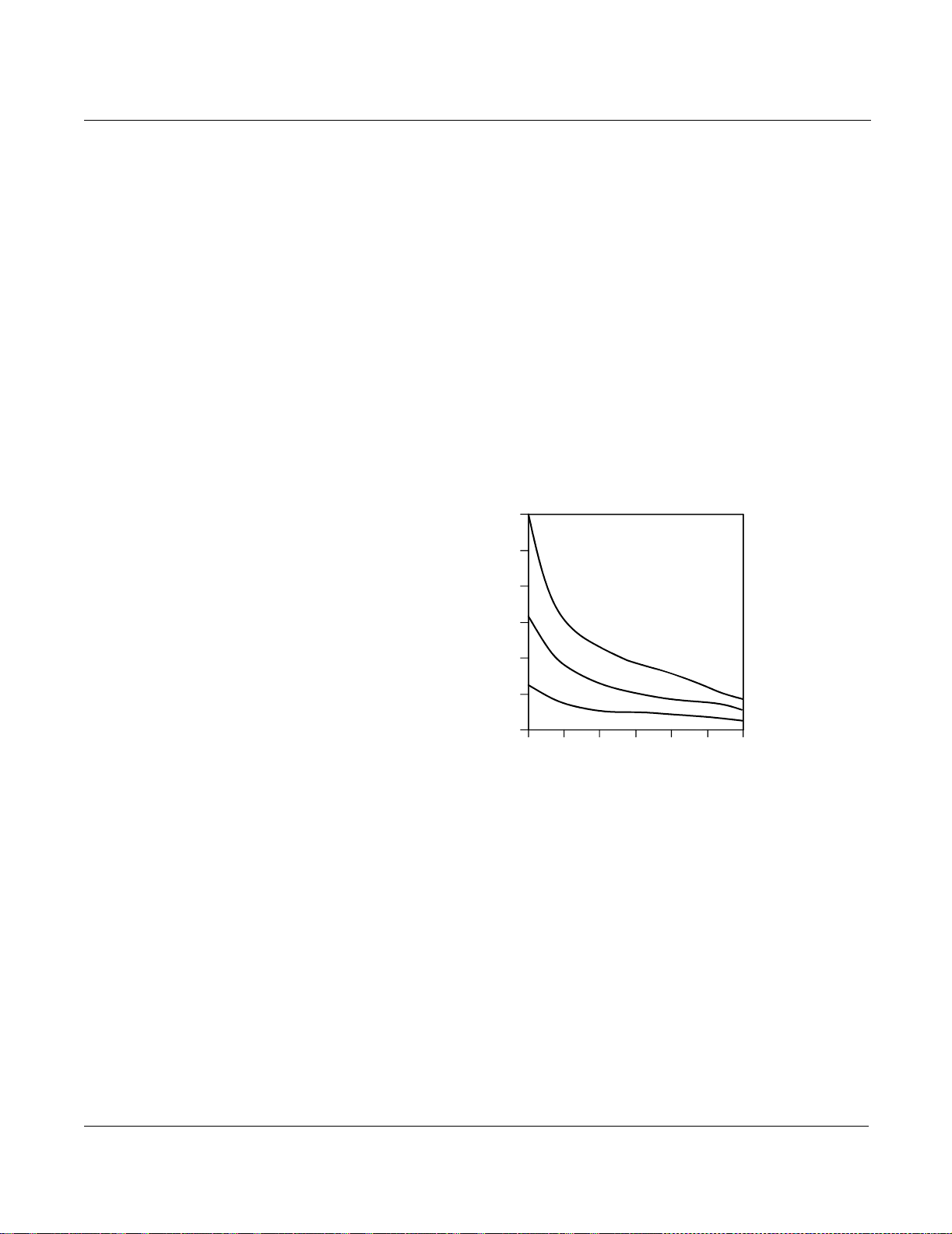

Figure 2-2 provides an example of the relationship between transmitter

housing temperature rise and extension length. Use Figure 2-2 as a

guide for determining adequate thermowell extension length.

Figure 2-2. Model 244EH Connection

Head Temperature Rise vs. Extension

Length

60

50

40

8

1

5°

5

4

30

20

10

2

0

Temperature Rise Above Ambient (°C)

75 100 125 150 175 200 225

C

0

5

P

°C

0

r

o

c

e

s

e

r

s

o

s

T

cess

s

e

m

p

em

T

Pr

o

c

°

C

P

Extension Length (mm)

T

e

m

p

e

r

a

t

u

p

er

e

r

a

t

u

r

e

r

e

at

u

r

e

3044-0123A

Example

The transmitter specification limit is 85 °C. If the ambient temperature

is 55 °C and the process temperature to be measured is 800 °C, the

maximum permissible connection head temperature rise is the

transmitter specification limit minus the ambient temperature

(85 –55 °C), or 30 °C. In this case, an extension of 100 mm meets this

requirement, but 125 mm provides a margin of 8 °C, thereby reducing

any temperature effects in the transmitter.

2-3

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

Special Mounting Considerations

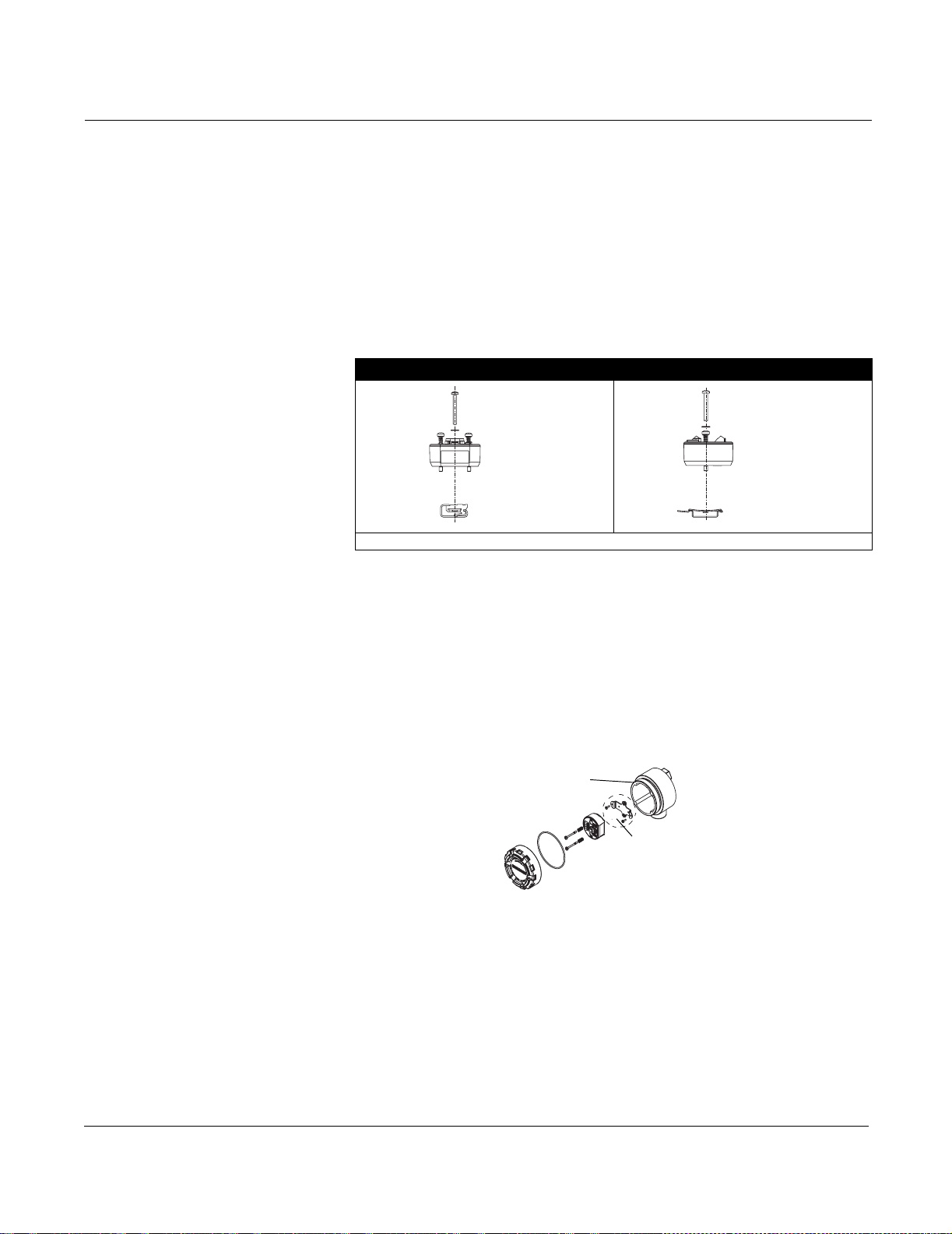

Figure 2-3. Assembling Rail Clip

Hardware to a Model 244EH

Special mounting hardware is available for mounting a

Model 244EH head mount transmitter to a DIN rail, or assembling

a new Model 244EH to an existing threaded sensor connection head

(former option code L1).

Mounting a Model 244EH to a DIN Rail

To attach a head mount transmitter to a DIN rail, assemble the

appropriate rail mounting kit (part number 00644-5301-0010) to the

transmitter as shown in Figure 2-3, then follow the procedure under

“Rail Mount Transmitter with Integral Mount Sensor” on page 2-7.

G-Rail (asymmetric) Top Hat Rail (symmetric)

Mounting

Hardware

Transmitter

Rail Clip

Note: Kit includes Mounting Hardware and both types of rail kits.

Mounting

Hardware

Transmitter

Rail Clip

Retrofitting a Model 244EH for Use in an Existing Threaded Sensor

Connection Head

644-5302B01A, D02A

Figure 2-4. Assembling Model

244EHforUseinanExistingL1

Connection Head

To mount a Model 244EH in an existing threaded sensor connection

head (former option code L1), order the Model 244EH retrofit kit (part

number 00644-5321-0010). The retrofit kit includes a new mounting

bracket and all associated hardware necessary to facilitate the

installation of the Model 244EH in the existing head.

Existing Threaded Sensor

Connection Head

(Former option code L1)

Kit includes replacement

bracket and screws.

644-5321A01A

2-4

INSTALLATION

C

PROCEDURES

Transmitter Refer to the appropriate procedure and the accompanying illustrations

when installing the transmitter.

Head Mount Transmitter with DIN Plate Style Sensor

The least complicated assembly uses:

• an integral mount sensor with flying leads

• an integral DIN style connection head

•a standard extension

•a threaded thermowell

Refer to Volume 2 of the Rosemount Sensors Product Data Sheet

(document number 00813-0101-2654) for complete sensor and

mounting accessory information.

To complete the assembly, follow the steps described below.

1. Attach the thermowell to the pipe or process container wall. Install

and tighten the thermowell before applying pressure.

2. Set the transmitter failure mode switch

(see Figure 2-13 on page 2-16).

3. Assemble the transmitter to the sensor. Push the transmitter

mounting screws through the sensor mounting plate and insert the

snap rings (optional, part number 00644-4432-0001) into the

groove of each transmitter mounting screw.

4. Insert the transmitter-sensor assembly into the connection head.

Thread the transmitter mounting screw into the connection head

mounting holes.

5. Assemble the extension to the connection head. Insert the

assembly into the thermowell.

6. Attach a cable gland into the shielded cable.

7. Insert the shielded cable leads into the connection head through

the cable entry. Connect and tighten the cable gland.

8. Connect the shielded cable leads to the transmitter power

terminals. Avoid contact with leads and terminals.

9. Install and tighten the connection head cover. Enclosure covers

must be fully engaged to meet explosion-proof requirements.

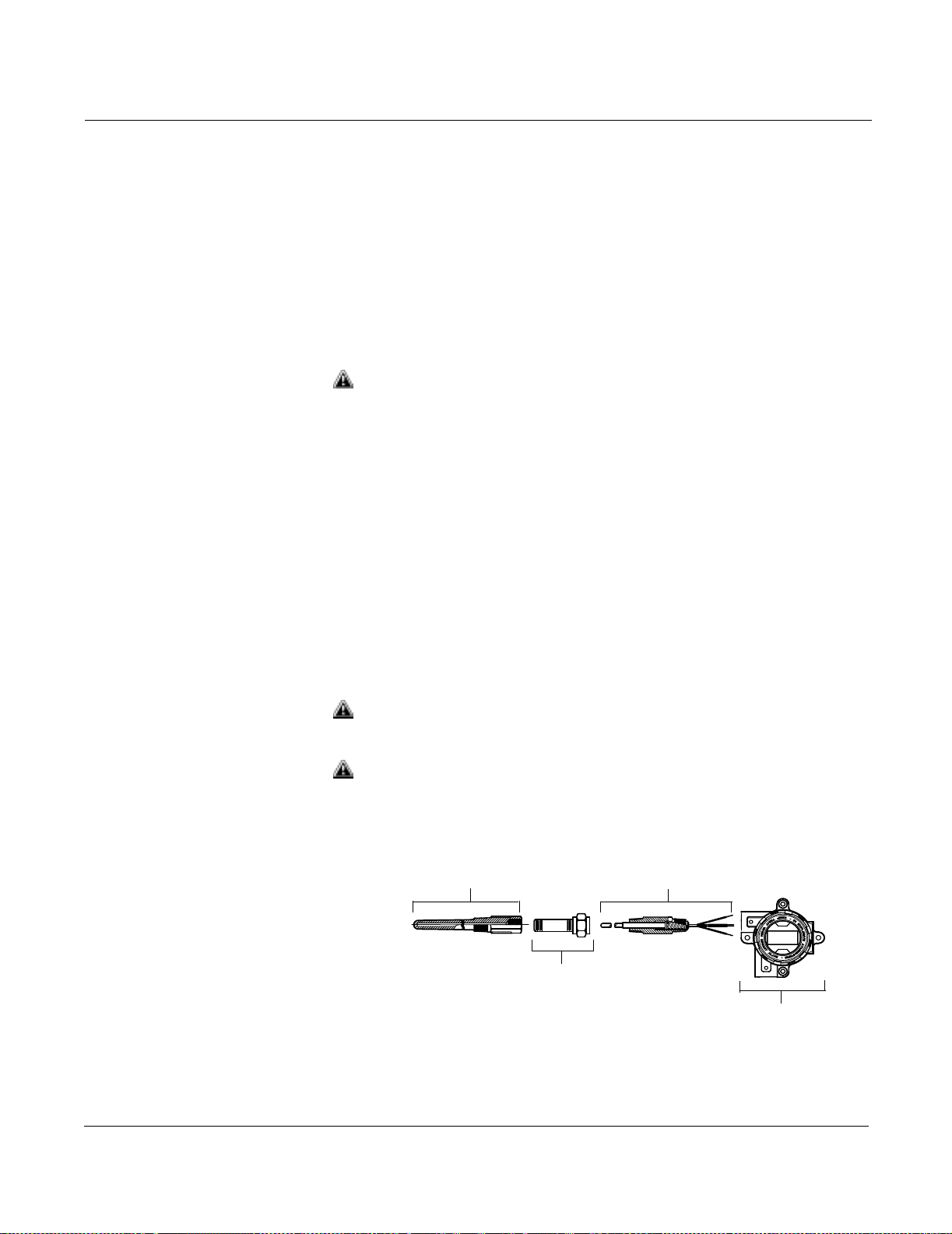

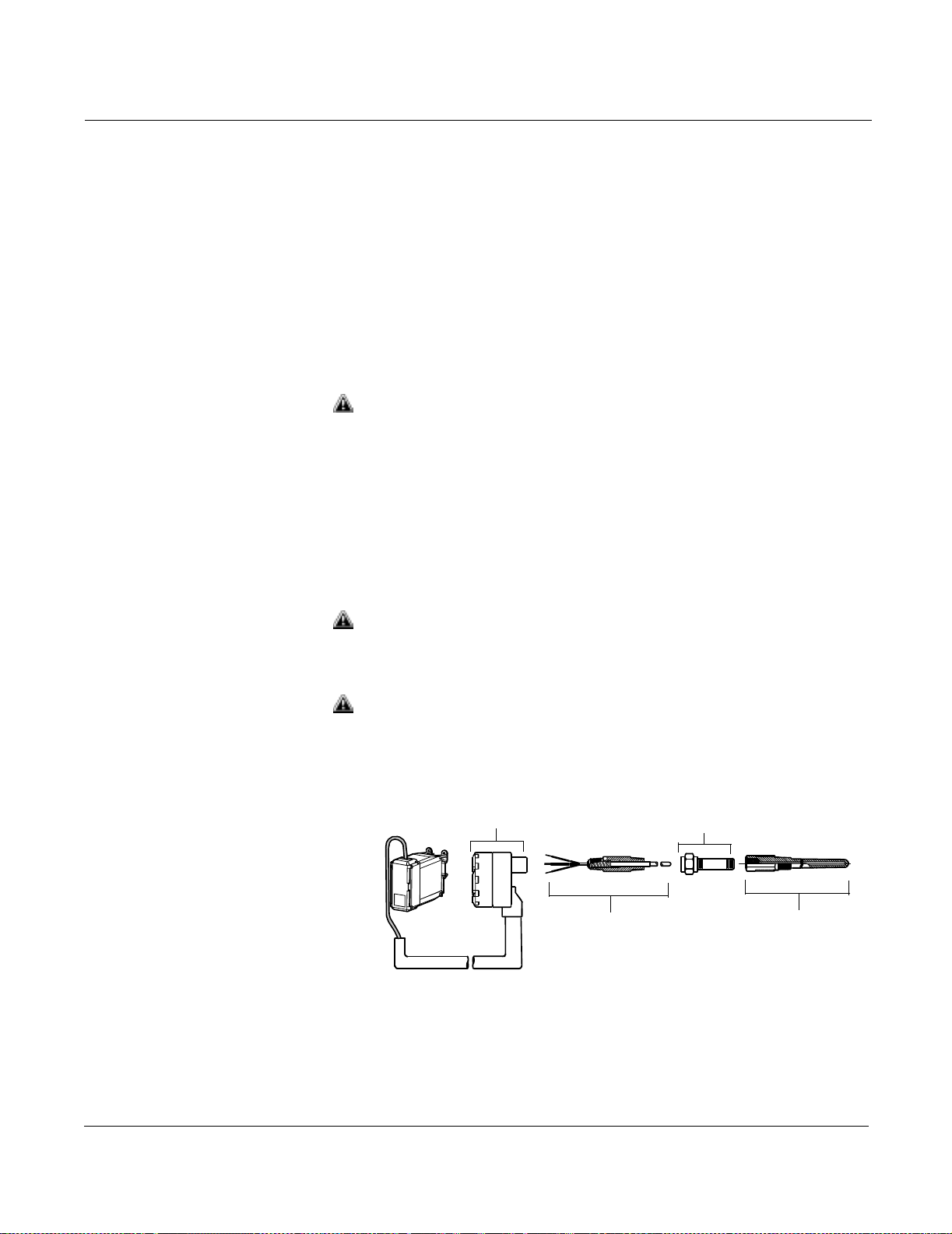

Figure 2-5. Typical Model 244EH

Mounting Configuration Using Integral

Mount Sensor and Assembly

Model 244EH

Transmitter

Integral Mount Sensor

with Flying Leads

onnection

Head

Threaded

Thermowell

Threaded Extension

644-0000B04A

2-5

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

Head Mount Transmitter with Threaded Sensor

The least complicated assembly uses:

• a threaded sensor with flying leads

• the universal connection head

• a union and nipple extension assembly

•a threaded thermowell

Refer to Volume 1 of the Rosemount Sensors Product Data Sheet

(document number 00813-0100-2654) for complete sensor and

mounting accessory information.

To complete the assembly, follow the steps as described below.

1. Attach the thermowell to the pipe or process container wall. Install

and tighten thermowells before applying pressure.

2. Attach necessary extension nipples and adapters. Seal the nipple

and adapter threads with silicone tape.

3. Screw the sensor into the thermowell. Install drain seals if

required for severe environments or to satisfy code requirements.

4. Set the transmitter failure mode switch

(see Figure 2-13 on page 2-16).

5. Pull the sensor wiring leads through the extensions and adapters

into the universal head. Mount the transmitter in the universal

head by threading the transmitter mounting screws into the

universal head mounting holes.

6. Mount the assembly into the thermowell. Seal adapter threads

with silicone tape.

7. Install conduit for field wiring to the conduit entry of the universal

head. Seal conduit threads with silicone tape.

8. Pull the field wiring leads through the conduit into the universal

head. Attach the sensor and power leads to the transmitter. Avoid

contact with leads and terminals.

9. Install and tighten the universal head cover. Enclosure covers

must be fully engaged to meet explosion-proof requirements.

Figure 2-6. Typical Model 244EH

Transmitter Mounting Configuration

Using Threaded Style Sensor

and Assembly

2-6

Threaded Thermowell

Standard

Extension

Threaded Style Sensor

Universal Head

644-0000A04A

Rail Mount Transmitter with Integral Mount Sensor

The least complicated assembly uses:

• an integral mount sensor with terminal block

• an integral DIN style connection head

•a standard extension

•a threaded thermowell

Refer to Volume 2 of the Rosemount Sensors Product Data Sheet

(document number 00813-0101-2654) for complete sensor and

mounting accessory information.

To complete the assembly, follow the procedure described below.

1. Attach the transmitter to a suitable rail or panel.

2. Attach the thermowell to the pipe or process container wall. Install

and tighten the thermowell before applying pressure.

3. Attach the sensor to the connection head and mount the entire

assembly to the thermowell.

4. Attach sufficient lengths of sensor lead wire to the sensor terminal

block.

5. Attach and tighten the connection head cover. Enclosure covers

must be fully engaged to meet explosion-proof requirements.

6. Run sensor lead wires from the sensor assembly to the transmitter.

7. Set the transmitter failure mode switch

(see Figure 2-13 on page 2-16).

8. Attach the sensor and power leads to the transmitter. Avoid

contact with leads and terminals.

Figure 2-7. Typical Rail Mount

Transmitter Mounting Configuration

Using Integral Mount Sensor

and Assembly

Rail Mount Transmitter

Sensor Leads

with Cable Gland

Integral Mount Sensor

with Terminal Block

Connection Head

Standard Extension

Threaded Thermowell

644-0000C04A

2-7

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

Rail Mount Transmitter with Threaded Sensor

The least complicated assembly uses:

• a threaded sensor with flying heads

• a threaded sensor connection head

• a union and nipple extension assembly

•a threaded thermowell

Refer to Volume 1 of the Rosemount Sensors Product Data Sheet

(document number 00813-0100-2654) for complete sensor and

mounting accessory information.

To complete the assembly, follow the procedure described below.

1. Attach the transmitter to a suitable rail or panel.

2. Attach the thermowell to the pipe or process container wall. Install

and tighten the thermowell before applying pressure.

3. Attach necessary extension nipples and adapters. Seal the nipple

and adapter threads with silicone tape.

4. Screw the sensor into the thermowell. Install drain seals if

required for severe environments or to satisfy code requirements.

5. Screw the connection head to the sensor.

6. Attach the sensor lead wires to the connection head terminals.

7. Attach additional sensor lead wires from the connection head to

the transmitter.

8. Attach and tighten the connection head cover. Enclosure covers

must be fully engaged to meet explosion-proof requirements.

9. Set the transmitter failure mode switch

(see Figure 2-13 on page 2-16).

10. Attach the sensor and power leads to the transmitter. Avoid

contact with leads and terminals.

Figure 2-8. Typical Rail Mount

Transmitter Mounting Configuration

Using Threaded Style Sensor

and Assembly

2-8

Rail M ount

Transmitter

Threaded Sensor

Connection Head

Threaded

Style Sensor

Standard

Extension

Threaded

Thermowell

644-0000A04B

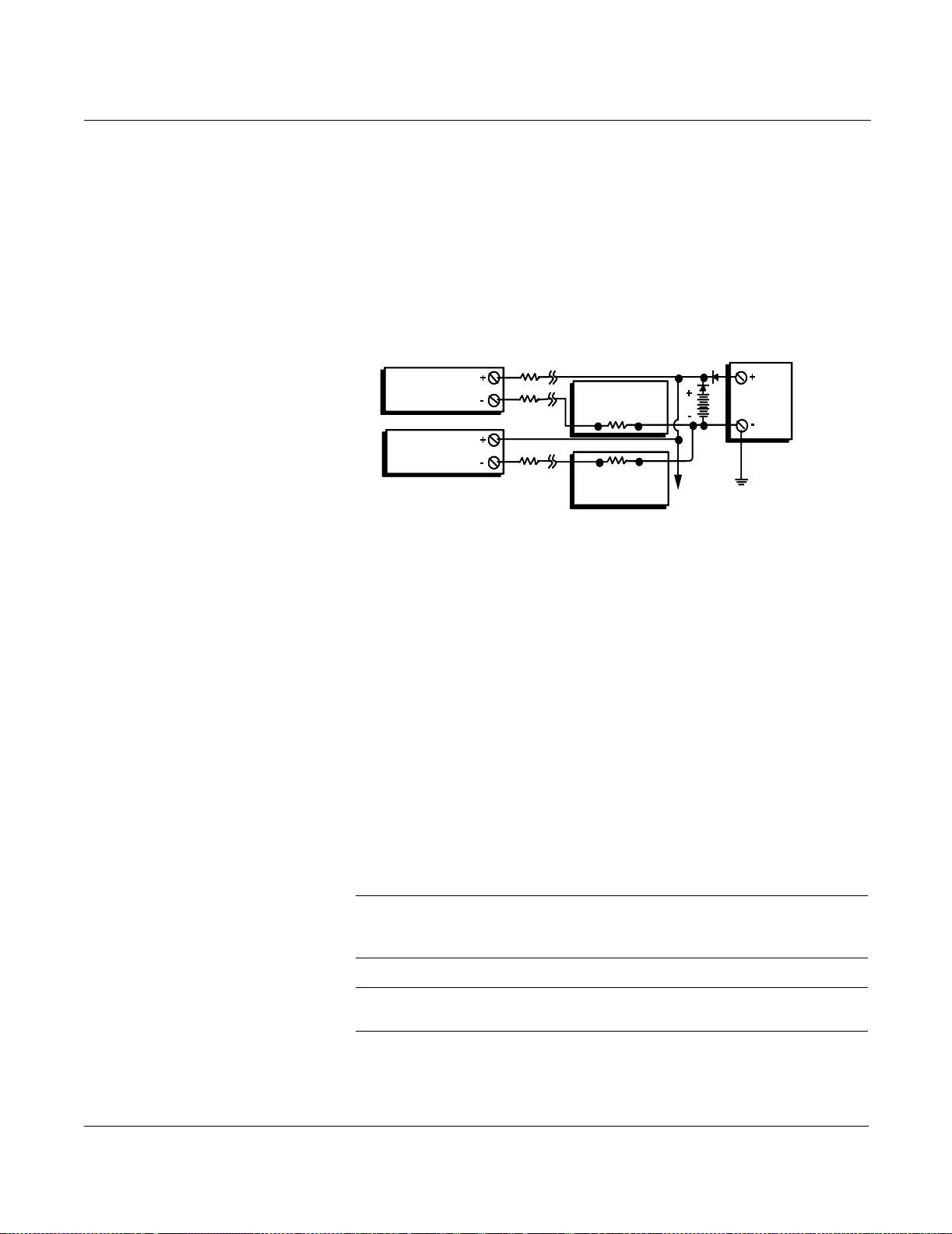

Figure 2-9. Multichannel Installations

Multichannel Installations

Several transmitters can be connected to a single master power supply

as shown in Figure 2-9. In this case, the system may be grounded only

at the negative power supply terminal. In multichannel installations

where several transmitters depend on one power supply and the loss of

all transmitters would cause operational problems, consider a back-up

battery or power supply that cannot be interrupted. The diodes shown

in Figure 2-9 prevent unwanted charging or discharging of the

back-up battery.

Transmitter

No. 1

R

R

Lead

Lead

Backup Battery

Readout or

Controller

No.1

dc

Power

Supply

Transmitter

No. 2

R

Lead

Configuration Software System Requirements

For the configuration software to function properly, the following

minimum PC requirements must be observed.

• 80386 or faster processor

• 1 MB free disk space

• 3.5-inch floppy disk drive

• Mouse or other pointing device

• 256 color display (recommended settings are 16-bit color at

1024 × 728 screen resolution)

• Microsoft Windows 3.1, Windows for Workgroups 3.11,

Windows 95, or Windows NT.

The configuration software is available in English, French, German,

Italian, Spanish, Chinese, Japanese, and Korean language versions.

The configuration software automatically selects the appropriate

language based on the language version of Windows.

Readoutor

Controller

No. 2

To Additional Transmitters

3044-0131A

NOTE

Close all currently running applications before starting the

installation procedure.

NOTE

Windows 98 is not compatible with this software.

2-9

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

Choose the procedure that matches the operating system you are using.

Procedure for Windows 3.1 or Windows for Workgr ou ps 3.11

1. If you do not have Win32s installed, install it now. Follow the

instructions on the diskette label.

2. Insert the Models 244EH and 244ER Configuration Software

diskette into your floppy disk drive.

3. In the File Manager, choose RUN from the FILE menu.

4. The RUN dialog box appears. In the COMMAND LINE text box,

type <drive>:\setup. Substitute the letter of your floppy disk drive

(usually a or b) for <drive>. Click OK.

5. The WELCOME window appears. Click OK.

6. The SELECT DESTINATION DIRECTORY window appears. To

accept the default installation directory, click OK. To specify a

different installation directory, either type a new directory path in

the DESTINATION DIRECTORY text box or select one from the list.

Click OK.

7. The COMM SETTINGS window appears. In the COMM PORT

drop-down box, choose the communication port to which you

intend to connect the Model 244EC. Click OK.

8. The SELECT PROGRAM MANAGER GROUP window appears. To

accept the default Program Manager group name, click OK. To

specify a different group name, either type a new name in the

GROUP NAME text box or select one from the list. Click OK.

Procedure for Windows 95 or Windows NT

1. Insert the Models 244EH and 244ER Configuration Software

diskette into your floppy disk drive.

2. Click the START button on taskbar. Click RUN.

3. The RUN dialog box appears. In the OPEN text box, type

<drive>:\setup. Substitute the letter of your floppy disk drive

(usually a or b) for <drive>. Click OK.

4. The SELECT DESTINATION DIRECTORY window appears. To

accept the default installation directory, click OK. To specify a

different installation directory, either type a new directory path in

the DESTINATION DIRECTORY text box or select one from the list.

Click OK.

5. The COMM SETTINGS window appears. Choose the

communication port to which you intend to connect the

Model 244EC from the COMM PORT drop-down box. Click OK.

6. The SELECT PROGRAM MANAGER GROUP window appears. To

accept the default Program Manager group name, click OK. To

specify a different group name, either type a new name in the

GROUP NAME text box or select one from the list. Click OK.

2-10

Screen Conventions

The Models 244EH and 244ER Configuration Software follows the

Microsoft Windows screen conventions with the following exception:

Configuration parameters change color to indicate fields where

information has changed. Before placing a new transmitter into service,

or before returning a transmitter to service after changing

configuration information, verify that the values in the fields that have

been changed reflect the correct configuration parameters for your

application. For example, if you change the Sensor Type field to PT10 0–

Alpha 392, the Number of Wires, Units, 4 mA Point, and 20 mA Point

fields all change to reflect the default PT100–Alpha 392 sensor values.

Verify all information before placing the transmitter into service.

Model244EC Configuration Interface

The Model 244EC Configuration Interface is a portable, self-contained

link between your PC and a Model 244. The Model 244EC connects to a

PC serial port with a standard 9-pin interconnecting plug and connects

to a transmitter with two MINIGRABBER

The Model 244EC will also operate using a wall power adapter or a

single replaceable 9-volt battery.

Setting Up the Model 244EC Configuration Interface

All necessary power is provided through the configuration leads from

the Model 244EC to the transmitter. The sensor does not need to be

disconnected in order to configure the transmitter.

To set up the Model 244EC Configuration Interface and prepare it for

use, refer to Figure 2-10 on page 2-12 and follow the procedure

described below.

1. Install the 9-volt battery in the Model 244EC. Be sure the power

switch remains in the “OFF” position.

2. Attach the ribbon cable from the Model 244EC to the serial port of

your PC using the 9-pin interconnecting plug. If your PC has a

25-pin serial port, you will need a 25-pin to 9-pin adapter to

accommodate the connection.

NOTE

It is not necessary to power down your PC before you attach the

Model 244EC. However, if you are using a desktop model, you may wish

to power down to reduce the risk of electric shock or computer damage.

™

clips.

3. Attach the configuration leads to the Model 244EC using the

banana jacks provided. Be sure to observe proper polarity—attach

the red lead to the positive (+) jack on the Model 244EC and the

black lead to the negative (–) jack.

4. Attach the configuration leads to the configuration terminals

(labeled “PROG”) on the transmitter using the MINIGRABBER

clips provided. Be sure to observe proper polarity—attach the red

lead to the positive (+) terminal on the transmitter and the black

lead to the negative (–) terminal.

2-11

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

5. Turn on the Model 244EC using the power switch on the top side of

the housing.

NOTE

Verify that the Model 244EC “Low Battery” LED is not on before

initiating communication with the transmitter. If the low battery LED

is on, you will not be able to configure the transmitter.

6. Using your PC, open the Configuration Software program.

Access the online help if you have questions regarding the use

of the program.

Figure 2-10. Complete Transmitter

ConfigurationSystem

Model 244EC

Configuration

Interface

Model 244EH or 244ER

Windows-based PC Running

the Configuration Software

Transmitter

FIELD WIRING All power to the transmitter is supplied over the signal wiring. Use

ordinary copper wire of sufficient size to ensure that the voltage across

the transmitter power terminals does not drop below 12.0 V dc.

If the sensor is installed in a high-voltage environment and a fault

condition or installation error occurs, the sensor leads and transmitter

terminals could carry lethal voltages. Use extreme caution when

making contact with the leads and terminals.

NOTE

Do not apply high voltage (e.g., ac line voltage) to the transmitter

terminals. Abnormally high voltage can damage the unit. (Sensor and

transmitter power terminals are rated to 42.4 V dc.)

For multichannel installations, see “Multichannel Installations” on

page 2-9. The transmitters will accept inputs from a variety of RTD and

thermocouple types. Refer to Figure 2-12 on page 2-15 when making

sensor connections.

244-011AB

2-12

Figure 2-11. Transmitter Field

Wiring Diagrams

Use the following steps to wire the transmitter:

1. Connect the positive lead from the power supply to the transmitter

terminal marked “+” and the negative lead to the transmitter

terminal marked “–” (see Figure 2-11 and Figure 2-13).

2. Tighten the terminal compression screws to ensure adequate

contact. No additional power wiring is required.

3. After making connections, recheck the polarity and correctness of

connections, then turn the power on.

Model 244EH

Power

Supply

244-0000A02C

Model 244ER

Power

Supply

Note: Signal loop may be grounded at any point or left ungrounded.

Sensor Connections The Models 244E are compatible with a number of RTD and

thermocouple sensor types. Figure 2-12 shows the correct input

connections to the sensor terminals on the transmitter. To ensure

proper sensor connections, anchor the sensor lead wires into the

appropriate compression terminals and tighten the screws.

RTD or Ohm Inputs

The transmitters will accept a variety of RTD configurations, including

2-wire, 3-wire, 4-wire, and compensation loop designs. If the

transmitter is mounted remotely from a 3-wire or 4-wire RTD, it will

operate within specifications, without recalibration, for lead wire

resistances of up to 10 ohms per lead (equivalent to 1,000 feet of

20 AWG wire). In this case, the leads between the RTD and transmitter

should be shielded. If using only two leads, both RTD leads are in series

with the sensor element, so significant errors can occur if the lead

lengths exceed three feet of 20 AWG wire (approximately 0.05 °C/ft).

For longer runs, attach a third or fourth lead as described above.

644-0000A02D

2-13

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

Sensor Lead Wire Resistance Effect

RTD Input

When using a 4-wire RTD, the effect of lead resistance is eliminated

and has no impact on accuracy. However, a 3-wire sensor will not

fully cancel lead resistance error because it cannot compensate for

imbalances in resistance between the lead wires. Using the same

type of wire on all three lead wires will make a 3-wire RTD

installation as accurate as possible. A 2-wire sensor will produce the

largest error because it directly adds the lead wire resistance to the

sensor resistance. For 2- and 3-wire RTDs, an additional lead wire

resistance error is induced with ambient temperature variations.

The table and the examples shown below help quantify these errors.

Table 2-1. Examples of Approximate

Basic Error

Sensor Input Approximate Basic Error

4-wire RTD None (independent of lead wire resistance)

3-wire RTD ± 1.0 Ω in reading per ohm of unbalanced lead wire

resistance (Unbalanced lead wire resistance =

maximum imbalance between any two leads.)

2-wire RTD 1.0 Ω in reading per ohm of lead wire resistance

Examples of Approximate Lead Wire Resistance

Effect Calc ulations

Given:

Total cable length = 150 m

Imbalance of the lead wires at 20 °C = 0.5

Ω

Resistance/length (18 AWG Cu) = 0.025 Ω/Ω °C

α

Temperature coefficient of copper (

Temperature coefficient of platinum (

Change in Ambient Temperature (

RTD Resistance at 0 °C (R

) = 100 Ω (for Pt 100 RTD)

o

) = 0.0039 Ω/Ω °C

Cu

α

) = 0.00385 Ω/Ω °C

Pt

∆T

) = 25 °C

amb

• Pt100 4-wire RTD: No lead wire resistance effect.

•Pt100 3-wire RTD:

Imbalance of Lead Wires

Basic Error

Error due to amb. temp. variation

----------------------------------------------------------------- -=

×()

α

PtRo

()∆T

()× Imbalance of Lead Wires()×

α

Cu

-------------------------------------------------------------------------------------------------------------------------=

amb

()Ro()×

α

Pt

Lead wire imbalance seen by the transmitter = 0.5

Basic error

--------------------------------------------------------------------------------- 1.3 °C==

0.00385 Ω / Ω°C()100 Ω()×

0.5 Ω

Ω

2-14

Error due to amb. temp. var. of 25 °C±

0.0039 Ω / Ω°C()25 °C()× 0.5 Ω()×

-------------------------------------------------------------------------------------------------------

0.00385 Ω / Ω°C()100 Ω()×

0.13 °C±==

•Pt100 2-wire RTD:

Lead Wire Resistance

Basic Error

Error due to amb. temp. variation

----------------------------------------------------------=

×()

α

PtRo

()∆T

()× Lead Wire Resistance()×

α

Cu

-----------------------------------------------------------------------------------------------------------------=

amb

()Ro()×

α

Pt

Lead wire resistance seen by the transmitter = 150 m × 2 wires ×

Ω/m = 7.5 Ω

0.025

Figure 2-12. Sensor Wiring Diagrams

Basic error

Error due to amb. temp. var. of 25 ° C±

-------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------- 19.5 °C==

0.00385 Ω / Ω°C()100 Ω()×

0.0039 Ω / Ω°C()25 °C()× 7.5 Ω()×

0.00385 Ω / Ω°C()100 Ω()×

7.5 Ω

1.9 °C±==

Thermocouple or Millivolt Inputs

For integral mounting applications, the thermocouple can be

connected directly to the transmitter. If mounting the transmitter

remotely from the sensor, use appropriate thermocouple extension

wire. Make connections for millivolt inputs with copper wire. Use

shielding for long runs of wire.

Model 244E Sensor Connections

1

2-wire

RTD

and V

* Rosemount Inc. provides 4-wire sensors for all single element RTDs. You can use these

RTDs in 3-wire configurations by leaving the unneeded leads disconnected and insulated

with electrical tape.

** The transmitters must be configured for a 3-wire RTD in order to recognize an RTD with a

compensation loop.

3-wire

RTD

and V

*

RTD with

Comp.

Loop

12341234 1234 12341234

**

4-wire

RTD

and V

T/C

and mV

644-0000B01A

2-15

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

Figure 2-13. Transmitter Power,

Sensor, and Configuration Terminals

Model 244EH Model 244ER

12 34

Sensor

Terminals

Configuration

Terminals

Failure Mode

Switch

Power Terminal

Sensor Terminal

Failure Mode Switch

Power/Configuration

Terminals

FAILURE MODE The Models 244EH and 244ER features software driven alarm

diagnostics and an independent circuit. These features are designed to

provide separate backup alarm output in case the microprocessor,

electronics, hardware, or software fails. The alarm levels are user

selectable using the Failure Mode Switch. The position of the jumper

determines the direction in which the output is driven (HI or LO) in

case of alarm. The jumper switch feeds into the Digital-to-Analog (D/A)

converter, which drives the proper alarm output even if the

microprocessor fails.

The values to which the transmitter drives its output in failure mode

depend on whether it is factory configured to standard or

NAMUR-compliant operation. See “Failure Mode” on page A-2 for

these parameters.

To determine the failure mode configuration of a transmitter, review

the low and high alarm levels on the SERVICE menu provided by the

configuration software.

244-1260B02D, 1105E01B

Changing Switch Positions To change the failure mode on the Model 244EH or 244ER transmitter,

follow the steps described below.

1. If the transmitter is mounted in an enclosure, remove the

enclosure cover.

2. Locate the orange failure mode switch. The switch is located near

the power terminals on the Model 244EH and in the center of the

front panel on the Model 244ER (see Figure 2-13).

3. Move the switch to the desired alarm setting. To set the failure

mode to high alarm, position the switch toward the “HI” mark on

the terminal block; to set the failure mode to low alarm, position

the switch in the opposite direction.

4. Replace the enclosure cover (if applicable). Enclosure covers must

be fully engaged to meet explosion-proof requirements.

2-16

Section

3 Operation

SafetyMessages ................................page3-1

Power Supply . . . . . . . . . . . . . ......................page3-1

Configuration ...................................page3-2

IntermittentSensorAlgorithm .....................page3-5

SAFETY MESSAGES Instructions and procedures in this section may require special

precautions to ensure the safety of the personnel performing the

operations. Information that raises potential safety issues is indicated

by a warning symbol ( ). Please refer to the following safety messages

before performing an operation preceded by this symbol.

Warning

If the transmitter is installed in a measurement loop,disconnect power to the transmitter

before beginning to se t up the Model 244EC Configuration Interface.If the Model 244EC

connects to a transmitter while the transmitter is powered in a measurement loop, the

Model 244EC will shunt the electrical current, possibly resulting in a dangerous situation

within the measurement loop.

PO WER SUPPL Y The dc power supply should provide power with a ripple that is less

than two percent of the nominal supply voltage. The total resistance

load is the sum of the resistance of the signal leads and the lead

resistance of any controller, indicator, or related piece of equipment in

the loop. Note that the resistance of intrinsic safety barriers, if used,

must be included.

Surges/Transients The transmitter will withstand electrical transients of the energy level

usually encountered in static discharges or induced switching

transients. However, high-energy transients, such as those induced by

lightning strikes, welding, heavy electrical equipment, or switch gears,

can damage both the transmitter and the sensor.

To protect against high-energy transients, install Models 244E into a

suitable connection head with the Rosemount Model 470 Transient

Protector. The Model 470 prevents damage from transients induced by

lightning, welding, heavy electrical equipment, or switching gears.

Refer to the Model 470 Transient Protector Product Data Sheet

(document number 00813-0100-4191) for more information.

3-1

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

Grounding The transmitter will operate with the current signal loop either floating

or grounded. However, the extra noise in floating systems affects many

types of readout devices. If the signal appears noisy or erratic,

grounding the current signal loop at a single point may solve the

problem. The best place to ground the loop is at the negative terminal

of the power supply.

The transmitter is electrically isolated to 500 V ac rms, so the input

circuit also may be grounded at a single point. When using a grounded

thermocouple, the grounded junction serves as this point. Do not

ground the current signal loop at more than one point.

NOTE

Do not ground the signal wire at both ends.

CONFIGURATION The Models 244EH and 244ER are designed to be configured using a

Model 244EC Configuration Interface connected to a Microsoft

Windows-compatible PC running the Models 244EH and 244ER

Configuration Software program. Configuration parameters include:

•Sensor type

• Number of wires

• 50/60 Hz filter selection

• Engineering units

• Upper and lower range values

• Damping value

•Tag

• Intermittent Sensor Detect

3-2

Each configuration parameter is explained in the on-line help provided

with the software. To access the on-line help, either click the HELP

button on the main configuration window (see Figure 3-1) or choose a

topic from the HELP menu.

Configuring a Single Transmitter

Figure 3-1. Models 244EH and 244ER

Configuration Software Main

ConfigurationWindow

NOTE

See “Configuration Software” on page 2-9 for instructions on how to

install the configuration software.

To configure a single Model 244EH or 244ER transmitter, perform the

following procedure:

1. Disconnect power to the transmitter if the transmitter is installed

in a measurement loop.

NOTE

Configuring a transmitter while it is powered in a measurement loop

could cause the Model 244EC to shunt the current.

2. Set up the transmitter configuration system (see “Model 244EC

Configuration Interface” on page 2-11) and open the program.

3. Select READ FROM XMTR from the menu bar to initiate the

transmitter configuration. The main configuration window will

appear (see Figure 3-1).

4. Set the configuration parameters. To view a complete list of

options for each parameter, click the drop-down arrow in any

parameter box. For example, on the main configuration screen,

click the arrow in the UNITS box to view a list of available units.

NOTE

The configuration of the Intermittent Sensor Detect feature of the

Model 244E Temperature Transmitter with version 5.5.1 software

cannot be changed with the Model 244EC version 2.0 or earlier. For

more information see Section 4: Maintenance and Troubleshooting.

244E-244DF01

3-3

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

NOTE

Each configuration parameter is explained in detail in the on-line help

provided with the software. To access help, click the HELP button on

the main configuration window (see Figure 3-1).

5. Click the SEND TO XMTR button to upload configuration

information to the transmitter. The software will indicate whether

the configuration is successful or unsuccessful. If the configuration

succeeds, then go to step Step 6. If the configuration does not

succeed, then refer to Section 4: Maintenance and Troubleshooting

for a list of possible causes and repeat Step 5 until the transmitter

configuration is successful.

6. Click the SAVE TO FILE button to save the configuration

information for use with other transmitters.

NOTE

To ease the process of later finding a specific configuration file, name

saved files according to a logical system and preserve the default .244

filename extension.

7. Click the CANCEL button to close the main

configuration window.

Configuring Several Transmitters Identically

To configure several Model 244E transmitters identically, perform the

following procedure:

1. Configure a single transmitter according to “Configuring a Single

Transmitter” on page 3-3 and save the configuration to a file.

2. Select OPEN from the FILE menu to open the saved

configuration file.

3. Connect a new transmitter to the Configuration Interface.

4. Click the SEND TO XMTR button to upload the configuration

information to the transmitter. The software will report whether

the configuration is successful or unsuccessful. If the configuration

succeeds, then go to Step 5. If the configuration does not succeed,

then refer to Section 4: Maintenance and Troubleshooting for a list

of possible causes and repeat Step 4 until the transmitter

configuration is successful.

5. Repeat Steps 3 and 4 until all transmitters are configured.

6. Click the CANCEL button to close the main configuration screen.

3-4

Viewing the Process Variable

Figure 3-2. Viewing the Process

Variable with the 244EC

With version 2.0 and later of the Model 244EC Configuration Interface,

users can view the measured temperature (PV) by selecting SERVICE

from the menu bar of the main configuration window (see Figure 3-2).

In order to view a valid PV, a temperature sensor must be connected to

the Model 244E transmitter, and the transmitter must be configured

properly for that sensor type. The PV will be automatically updated on

the Model 244EC screen approximately two times per second.

INTERMITTENT SENSOR ALGORITHM

244E-244EC01

The electronics of the Model 244E transmitter contains an intermittent

sensor algorithm that monitors the input signal during operation. The

signal diagnostics routine, which occurs at each temperature update

(every 500 milliseconds), eliminates output pulsing in an intermittent

open sensor condition. Further, it validates the input signal before the

digital-to-analog (D/A) conversion takes place.

If the process temperature changes, the intermittent sensor algorithm

causes the transmitter to respond according to one of the three cases

described below. Threshold value is the maximum change in reading (as

a percentage of output range) within one update cycle (500 ms). The

threshold value of the Model 244E is 2% of output range.

3-5

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

Case Examples Case 1: Open Sensor

If the algorithm detects an open sensor, the transmitter immediately

goes into alarm (high or low, depending on the position of the failure

mode switch).

Case 2: Temperature Change Greater than the

Threshold Value(2% of Output Range)

If the algorithm detects a process temperature change (∆T) greater

than the threshold value (2 % of the output range), but which is not a

true open sensor condition, the transmitter will go into a hold period.

During the hold period, the transmitter determines whether or not this

temperature measurement is valid by using the three additional

measurement points. In the meantime, the output remains unchanged

at the initial reading (Time = 0 ms).

A) If these next three readings are within the new threshold value

(at Time = 500 ms), this measurement is validated. The output

changes to reflect this and the transmitter is no longer in a hold

period. In this case, the output delay is 1.75 to 2.00 seconds.

Step Changes Greater than Threshold Value

Input

Output without Algorithm

Output with Algorithm (Default)

0 500 1000 1500 2000 2500 3000 3500 4000

Time (in Microseconds)

B) If the reading drops back within the original threshold value (at

Time = 0 ms) during the hold period, the transmitter interprets the

reading(s) outside the threshold value as a spike, and the output

changes to reflect the latest reading. The transmitter is no longer in

a hold period, and the spike is not seen at the output.

Changes Greater than Threshold Value

Input

Output without Algorithm

Output with

Algorithm (Default)

0 500 1000 1500 200025003000 3500 4000

Time (in 500 ms increments)

C) If any of the next three measurements is outside the new

threshold value (at Time = 500 ms), the output remains unchanged

at the initial reading (Time = 0 ms). the transmitter remains in a

hold period until four consecutive measurements are within the

threshold value of the first in the series.

3-6

Step Changes Greater than Threshold Value

Input

Output without Algorithm

Output with Algorithm (Default)

0 5001000 1500 2000 2500 3000 3500 4000

Time (in 500 ms increments)

Total of All Step Changes

D) If an open sensor is validated at the end of the first update cycle

(Time = 500 ms), the output will go directly to alarm level. The

original spike (at Time = 0 ms) will not be seen at the output.

Open Sensor

Intermittent Sensor

Algorithm and Damping

Input

Output without Algorithm

Output with Algorithm (Default)

0 500 1000 1500 2000 2500 3000 3500 4000

False Output

Time (in 500 ms increments)

Alarm

Case 3: Temperature Change Within the

Threshold Value (2 % of Range)

If the transmitter detects an input change that is within the threshold

value, it reports the new value within one output cycle (500 ms).

If the transmitter has both intermittent sensor detect and damping

enabled, the output reading is calculated by the following formula:

2TU–

Damped Value P N–()

P = previous damped value

N = new sensor value

T = damping time constant

U = update rate

× N+=

------------------

2TU+

The transmitter outputs the corresponding value on the damping curve

within 1.75 to 2.0 seconds and updates the output reading every 500 ms

thereafter, according to the damping equation above. At the value to

which the damping time constant is set, the transmitter output is at

63% of the input change.

3-7

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

Figure 4-1 illustrates an example of intermittent sensor detect with

damping enabled. If the temperature undergoes a step change greater

than the threshold value, or from 100 degrees to 110 degrees, and the

damping is set to 5.0 seconds, the transmitter calculates a new reading

every 500 ms using the damping equation, but holds the output at

100 degrees for between 1.75 and 2.0 seconds. Within 1.75 and

2.0 seconds, the transmitter outputs the reading that corresponds to

the damping curve at that time (

), and continues to calculate and

update the output reading every 500 ms thereafter (

damping equation. After 5 seconds, the transmitter outputs

106.3 degrees, or 63% of the input change (

), and the output

continues to approach the input curve according to the equation above.

NOTE

If the damping time constant is set between 0 and 2 seconds, the

transmitter does not report the output change until the intermittent

sensor algorithm validates the input signal. After validating the input

signal, the transmitter outputs the value that corresponds to the

damping curve at that time.

Figure 3-3. Damping Function when

Input Change is Greater Than the

Threshold Value

) according to the

Intermittent Sensor Detect (Advanced Feature)

3-8

644-644_02A

NOTE

The Intermittent Sensor Detect feature is not available when using a

Model 244EH with software revision 5.5.1. To determine the software

version of a Model 244E temperature transmitter, first connect the

transmitter to the Model 244EC configurator, open the Model 244EC

software configuration tool, and then choose “service” from the Model

244EC software menu.

The Intermittent Sensor Detect feature is designed to guard against

process temperature readings caused by intermittent open sensor

conditions (an intermittent sensor condition is an open sensor condition

that lasts less than 0.7 seconds). By default, the transmitter is shipped

with the Intermittent Sensor Detect feature switched ON. In most

applications, this is the preferred setting. The Intermittent Sensor

Detect feature can be switched ON or OFF with the Model 244EC. The

setting of this feature cannot be changed when using a Model 244E

with version 5.5.1 software and a Model 244EC version 2.0 or earlier.

Transmitter Behavior with Intermittent Sensor Detect ON

When the Intermittent Sensor Detect feature is switched ON, the

transmitter can eliminate the output pulse caused by intermittent open

sensor conditions. Process temperature changes (∆T) within 2% of the

output range will be tracked normally by the transmitter’s output. A ∆T

greater than 2% of the output range will activate the intermittent

sensor algorithm. True open sensor conditions will cause the

transmitter to go into alarm.

Tr ansmitter Behavior with Intermittent Sensor Detect OFF

When the Intermittent Sensor Detect feature is switched OFF, the

transmitter tracks all process temperature changes, even if they are the

consequence of an intermittent sensor. The output delay due to the

intermittent sensor algorithm will be eliminated.

Implementation The Intermittent Sensor Detect feature can be turned ON or OFF using

a Model 244E transmitter with software version 5.4.1 or earlier with

the Model 244EC software configuration tool when the transmitter is

connected to the Model 244EC Configurator.

Turning the Intermittent Sensor Detect feature OFF does not affect the

time needed for the transmitter to output the correct alarm signal after

detecting a true open sensor condition. However, the transmitter may

briefly output a false temperature reading for less than 0.5 seconds in

either direction (see Figure 3-4) up to100% of output range.

Figure 3-4. Open Sensor Response

(Three Cases)

25

20

15

10

5

Transmitter Output (mA)

0

0

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

Normal open sensor responses

A false temperature output in

either direction up to the

threshold value (100 % of output

range if Intermittent Sensor Detect

is OFF) is possible when an open

sensor condition is detected.

Time (seconds)

High Alarm

Unless rapid response rate is necessary, the suggested setting of the

Intermittent Sensor Detect mechanism is ON.

644-644_03

3-9

Section

4 Maintenance and

Troubleshooting

SafetyInformation ...............................page4-1

Troubleshooting .................................page4-1

SAFETY INFORMATION Procedures and instructions in this manual may require special

precautions to ensure the safety of the personnel performing the

operations. Information that raises potential safety issues is indicated

by a warning symbol ( ). Refer to the safety messages listed at the

beginning of each section before performing an operation preceded by

this symbol.

Warning

• Failure to follow these installation guidelines could result in death or

serious injury.

• To clarify error messages that do not appear in this section, contact one of the

technical support managers listed at the beginning of this manual.

TROUBLESHOOTING To determine the software version of a Model 244E temperature

transmitter, first connect the transmitter to the Model 244EC

configurator, open the 244EC software configuration tool, and then

choose “Service “from the 244EC software menu.

Model 244EH software

version 5.5.1

The configuration of the Intermittent Sensor Detect feature of the

Model 244E Temperature Transmitter with version 5.5.1 or greater

software cannot be changed with the Model 244EC version 2.0.0 or

earlier. If you attempt to change the configuration of this feature and

then click the SEND TO XMTR button, the following screen will appear.

SCRNDUMP-244E-STATUS

4-1

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

The “Information Transmitter UNSUCCESSFUL” message appears

because the transmitter did not accept the change made in the

Intermittent Sensor Detect field. However, any other configuration

changes sent at the same time as the Intermittent Sensor Direct

change will be sent successfully. These other configuration changes can

be verified by clicking on the READ XMTR button.

TABLE 4-1. Models244EH and 244ER

TroubleshootingChart

Error Message Cause and Possible Solutions

Cannot Open 244E

Communications Device Driver

Cannot print Computer cannot find or does not recognize a printer

Cannot write to <filename> The disk is write-protected or full. Verify that the disk is

Error reading <filename> The file’s format may have been corrupted. Try reading a

Error writing to <filename> The disk may have been corrupted or the filename is not

Field device did not respond The transmitter did not respond to the inquiry made by the

Information transfer

UNSUCCESSFUL

Invalid user entry The entered values are not within the capabilities of the

Is not a proper 244E config file The file is not readable by the configuration software. Try

No response from transmitter The configuration software did not connect to a

WARNING—Battery low

indication received

The Models 244EH and 244ER Configuration Software is

not working properly. Reinstall the software.

connected to it. Verify that the computer is connected to a

suitable printer.

not write-protected and that there is sufficient free space

available.

backup of the file.

valid. Try saving under a different filename.

software. Verify all connections in the configuration

system. Verify that the transmitter is functional.

See “Model 244EH software version 5.5.1” on page 4-1.

Some configuration information was not properly

transmitted from the configuration program to the

transmitter.Verify all connections in the configuration

system.

transmitter.Check the transmitter specifications, then

adjust the range and damping values as necessary.

another file.

transmitter.Verify all connections in the configuration

system.

The battery for the configuration interface is running low

on voltage. Replace the battery.

4-2

Appendix

Appendix

A Reference Data

TransmitterSpecification..........................pageA-1

OrderingInformation .............................pageA-6

DimensionalDrawings............................pageA-9

TRANSMITTER SPECIFICATION

Functional Inputs

User selectable using the Model 244EC Configuration Interface and the

Models 244EH and 244ER configuration software; sensor terminals

rated to 42.4 V dc. See Table A-2 on page A-3.

Output

Two-wire 4–20 mA, linear with temperature for RTDs and

thermocouples, and linear with input for millivolts and ohms

Isolation

Input to output isolation tested up to 500 V ac rms (707 V dc) at

50/60 Hz

Power Supply

External power supply required. The transmitters operate on 12.0 to

42.4 V dc terminal voltage. Transmitter power terminals rated to

42.4 V dc.

Load Limitations

Maximum Load = 43.5 3 (Supply Voltage – 12.0)

1322

1000

750

500

250

Load (Ohms)

0

10

Ambient Temperature Limits

Operating Storage

–40 to 85 °C (–40 to 185 °F) –50 to 120 °C (–58 to 248 °F)

4–20 mA dc

12.0

20 30 40 42.4

Supply Voltage(V dc)

Operating

Region

244-24401A

A-1

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

Failure Mode

The values that the transmitter drives its output to in failure mode

depend on whether it is factory configured to standard or

NAMUR-compliant operation. The values for standard and

NAMUR-compliant are as follows:

TABLE A-1. Operation Parameters

Standard NAMUR-Compliant

Linear Output: 3.9 ≤ I ≤ 20.5 mA 3.8 ≤ I ≤ 20.5 mA

Fail High: 21 ≤ I ≤ 23 mA (default) 21 ≤ I ≤ 23 mA (default)

Fail Low: I ≤ 3.75 mA I ≤ 3.6 mA

Humidity Limits

0 to 99% relative humidity, non-condensing

Turn-on Time

Performance within specifications is less than 5.0 seconds after power

is applied to the transmitter

Update Ti me

Approximately 0.5 seconds

Performance The Models 244EH and 244ER maintain a specification conformance of

at least 3s.

Stability

±0.1% of span or 0.1 °C, whichever is greater, over 12 month period

Power Supply Effect

Less than ±0.005% of span per volt

Vibration Effect

The transmitters tested to the following specifications with no effect on

performance:

Frequency Vibration

10 to 60 Hz 0.21 displacement

60 to 2000 Hz 3 g peak acceleration

CE Electromagnetic Compatibility Compliance Testing

The Models 244EH and 244ER meet all requirements listed under IEC

61326: Amendment 1, 1998.

A-2

Accuracy

TABLE A-2. Model 244E Input Options and Accuracy.

Sensor

Options

2-, 3-, 4-wire RTDs °C °F °C °F

Pt 100 IEC 751, 1995 (α = 0.00385) –200 to 850 –328 to 1562 10 18 0.05% of span + 0.15 °C or 0.2 °C

Pt 100 JIS 1604, 1981 (α = 0.003916) –200 to 645 –328 to 1093 10 18 0.05% of span + 0.15 °C or 0.2 °C

Pt 200 IEC 751, 1995 (α = 0.00385) –200 to 850 –328 to 1562 10 18 0.01% of span or 0.4 °C

PT 500 IEC 751, 1995 (α = 0.00385) –200 to 850 –328 to 1562 10 18 0.01% of span or 0.3 °C

Pt 1000 IEC 751, 1995 (α = 0.00385) –200 to 300 –328 to 572 10 18 0.01% of span or 0.3 ° C

Ni 120 Edison Curve No. 7 –70to300 –94 to 572 10 18 0.01% of span or 0.2 °C

Cu 10 Edison Copper Winding No. 1 –50to250 –58 to 482 10 18 0.5% of span or 1.5 °C

Thermocouples

(3)

Type B

Type E NIST Monograph 175, IEC 584 –50 to 1000 –58 to 1832 25 40 0.1% of span o r 0.5 °C

Type jJ NIST Monograph 175, IEC 584 –180 to 760 –292 to 1400 25 40 0.1% of span or 0.5 °C

Type K NIST Monograph 175, IEC 584 –180 to 1372 –292 to 2502 25 40 0.1% of span or 1.0 °C

Type N NIST Monograph 175, IEC 584 –200 to 1300 –328 to 2372 25 40 0.1% of span or 1.0 °C

Type R NIST Monograph 175, IEC 584 0 to 1768 32 to 3214 25 40 0.1% of span or 1.0 °C

Type S NIST Monograph 175, IEC 584 0 to 1768 32 to 3214 25 40 0.1% of span or 1.0°C

Type T NIST Monograph 175, IEC 584 –200 to 400 –328 to 75 2 25 40 0.1% of span or 0.5 °C

DIN Type L DIN 43710 –200 to 900 –328 to 1652 25 40 0.1% of span or 0.5 °C

DIN Type U DIN 43710 –200 to 600 –328 to 1112 25 40 0.1% of span or 0.5 °C

Type

W5Re/W26Re

Millivolt Input –10 to 100 mV 3mV 0.025 mV + 0.003% of span

2-, 3-, 4-wire Ohm Input 0 to 2000 ohms 20 ohm 0.75 Ω + 0.03% of span

(1) No minimumor maximum span restrictions within the input ranges.Recommendedminimumspanwill holdnoisewithinaccuracyspecification with damping

at zero seconds.

(2) Total digital accuracy for thermocouple measurement: sum of digital accuracy +0.5 °C (cold junction accuracy)

(3) Accuracy for NIST Type B thermocouple is ±3.0 °C from 100 to 300 °C.

(2)

NIST Monograph 175, IEC 584 100 to 1820 212 to 3308 25 40 0.2% of span or 1.0 °C

Sensor

Reference

ASTME 988-96 0 to 2000 32 to 3632 25 40 0.1% of span or 1.0 °C

Input

Ranges

Recommended

Min. Span

(1)

Accuracy (whichever is greater)

When using a Pt 100 (

α = 0.00385) sensor input with a 75 to 150 °C

range, the accuracy will be 0.05% of span + 0.15 °C or 0.20 °C,

whichever is greater. Sample Calculation:[0.0005 (150-75) + 0.15] =

0.19 °C, which is less than 0.20 °C, so the accuracy equals 0.20 °C.

A-3

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

Ambient Temperature Effect Transmitters can be installed in locations where the ambient

temperature is between –40 and 85 °C (–40 and 185 °F). At the factory,

each transmitter is individually characterized over this ambient

temperate range. This special manufacturing technique is

accomplished through hot and cold temperature profiling with

individual adjustment factors programmed into each transmitter. The

transmitters automatically adjust for component temperature drift

caused by changing environmental conditions.

TABLE A-3. Models 244E Ambient Temperature Effects per 1 °C (1.8 °F)

Sensor Options

2-, 3-, 4-wire RTDs

PT 100 (α = 0.00385) 0.003 °C — — +0.001% of span

Pt 100 (α = 0 .003916) 0.003 °C — — 0.001% of span

Pt 200 0.004 °C — — 0.001% of span

Pt 500 0.003 °C — — 0.001% of span

Pt 1000 0.003 °C — — 0.001% of span

Ni 120 0.003 °C — — 0.001% of span

Cu 10 0.03 °C — — 0.001% of span

Thermocouples

Type B (100 °C ≤ reading <300°C) 0.064 °C –0.011 — 0.001% of span

(300 °C ≤ reading < 1000 °C) 0.040 °C –0.025 — 0.001% of span

(reading ≥ 1000 °C) 0.014 °C — — 0.001% of span

Type E 0.005 °C –0.00043 –0.0043 0.001% of span

Type J, K, DIN L 0.006 °C –0.00054 –0.0025 0.001% of span

Type N 0.007 °C –0.00036 — 0.001% of span

Type R, S (reading < 200 °C) 0.023 °C –0.0036 — 0.001% of span

(reading ≥ 200 °C) 0.016 °C — — 0.001% of span

Type T, DIN U 0.007 °C — –0.043 0.001% of span

Type W5Re/W26Re 0.023 °C –0.0036 — 0.001% of span

Millivolt Input 0.0005mV — — 0.001% of span

2-, 3-, 4-wire Ohm 0.0084 Ω — — 0.001% of span

(1) Change in ambient is with reference to the calibration temperature of the transmitter 68 °F (20 °C) from factory.

(1)

Fixed Value % of reading %ofSpan

(if reading > 0) (if reading is < 0)

0.016°C —

A-4

When using a Type J thermocouple with a –50 °C to 600 °C

temperature range at an ambient temperature of 60 °C and a reading of

–25 °C, the ambient temperature effect according to °C is: [fixed value

(a) + (% of reading (b) 3 reading) + (% of span (c) 3 span)] = [0.006 + (–

0.000025 3 (–25)) + (0.00001 3 650)] = 0.013 °C per °C. With the

ambient temperature 40 °C above reference condition temperature, the

total ambient temperature effect is: 40 3 0.013 = 0.52 °C.

When using a Type J thermocouple with a –50 °C to 600 °C

temperature range at an ambient temperature of 60 °C and a reading of

525 °C, the ambient temperature effect according to °C is:[fixed value

(a) + (% of reading (b) 3 reading) + (% of span (c) 3 span)] = [0.006 +

(0.0000054 3 525) + (0.00001 3 650)] = 0.015 °C per °C. With the

ambient temperature 40 °C above reference condition temperature, the

total ambient temperature effect is: 40 3 0.015 = 0.6 °C.

The worst case error would be: Reference Accuracy + CJC Accuracy +

Temp Effects = 0.65 °C + 0.5 °C + 0.52 °C = 1.67 °C. Total Probable

Error:

0.6520.520.52

++ 0.97°C=

2

Physical Electrical Connections

Power and Sensor Terminals

Model 244EH Compression screws permanently

fixed to terminal block

Model 244ER: Compression screw permanently

fixed to front panel

WAGO®spring clamp terminals are optional (option code G5)

Materials of Construction

Clips permanently fixed to

terminal block

Clips permanently fixed to

front panel

Model244EC Configuration Interface

Construction Material for the Electronics Housing and Terminal Block

Model 644H

Model 644R:

Noryl

Lexan

®

®

glass reinforced

polycarbonate

Mounting

The Model 244EH installs in a connection head or universal head

mounted directly on a sensor assembly, apart from a sensor assembly

using a universal head, or to a DIN rail using an optional mounting

clip. The Model 244ER mounts directly to a wall or to a DIN rail.

Weight

Code Options Add

Model 244EH HeadMount 78 (2.75)

J5, J6 UniversalHead 520 (18.43)

Model 644R Rail Mount 173 (6.10)

(1) All weights are in grams (ounces).

(1)

Enclosure Ratings

Option codes J5 and J6 are NEMA 4X, IP66, and IP68.

Option code J6 is CSA Enclosure Type 4X

Power Supply

9 V dc battery or wall adapter

Output voltage rating: 8to12Vdc

Output current rating: 100 mA minimum

Connector: 3.5 mm diameter male plug, positive tip, ne gative sleeve

To meet CSA ordinary location approval requirements, the wall power

adapter must be CSA listed with a Class 2 output. To meet FM ordinary

location approval requirements, the wall power adapter must be listed

by a Nationally Recognized Test Laboratory (such as FM or UL) with a

Class 2 output.

Ambient Temperature Limits

32 to 104 °F (0 to 40 °C)

Humidity Limits

0 to 99% relative humidity, non-condensing

A-5

Rosemount Models 244EH and 244ER PC-Programmable Temperature Transmitters

ORDERING INFORMATION

TABLE A-4. Model 244EH and 244ER Temperature Transmitter Ordering Information

• = Available

— = Not available

Model Product Description

244EH Head Mount Temperature Transmitter • —

244ER Rail Mount Temperature Transmitter — •

Code Hazardous Area Certifications

E5 FM Explosion-Proof Approval Yes • —

I5 FM Intrinsic Safety and Non-Incendive Approval No* • •

K5 FM Intrinsic Safety, Non-Incendive, and Explosion-Proof Approval Combination Yes • —

I6 CSA Intrinsic Safety and Non-Incendive Approval No* • •

C6 CSA Intrinsic Safety, Non-Incendive, and Explosion-Proof Approval Combination Yes • —

N1 CENELEC/BASEEFA Typen Approval Yes • —

ED CENELEC/KEMA Flameproof Approval Yes • —

I1 CENELEC/BASEEFA Intrinsic Safety Approval No* • •

E7 SAA Flameproof Approval.

N7 SAA Type N Approval.

I7 SAA Intrinsic Safety Approval.

NA No Approval No* • •

Consult factory for availability.

Consult factory for availability

Consult factory for availability.

EnclosurePurchase

Required?

Yes • —

Yes • —

No* • •

Head

Mount

Head

Mount

* Transmitters with intrinsic safety approvals can be ordered without enclosures. However, to meet intrinsic safety requirements, the transmitter must be installed in

an enclosure with IP20 or higher rating. Model 244EH transmitters ordered with enclosure options J5 or J6 meet this requirement.

Code Options

Assembly Options (Model 244EH Only)

X1 Assemble Transmitter to a Sensor Assembly (hand tight,

X2 Assemble Transmitter to a Sensor Assembly (hand tight, no

X3 Assemble Transmitter to a Sensor Assembly (wrench tight,

®

Teflon

(PTFE) tape where appropriate, fully wired) • —

Teflon

(PTFE) tape, unwired) • —

Teflon