FERITSCOPE® FMP30 Measurement of the Ferrite Content

in Austenitic and Duplex Steel

Coating Thickness Material TestingMicrohardnessMaterial Analysis

2

FERITSCOPE® FMP30

Measurement of the Ferrite Content

Chemical, energy and processing plants are often

subject to heat, aggressive media and high pressure.

These circumstances demand steel with high corrosion

and acid resistance that are resilient even at high

temperatures. If the ferrite content is too low, then

the welded material is susceptible to hot-cracking, if

the ferrite content is too high, the toughness, ductility

as well as the corrosion resistance of the steel are

reduced. For duplex steel, a ferrite deficit in the area

of the weld seam results in stress corrosion cracking

and reduction in strength.

The FERITSCOPE FMP30 measures the ferrite content

in austenitic and duplex steel according to the mag netic induction method. All magnetizable structure

sections are measured i. e., in addition to deltaferrite also strain-induced martensite, for example,

or other ferritic phases.

It is suited for measurements according to the BaslerStandard and according to DIN EN ISO 17655.

Areas of application are onsite measurements, e. g.

of austenitic platings as well as weld seams in stainless

steel pipes, containers, boilers or other products made

of austenitic or duplex steel.

Duplex steel is used increasingly in the chemical

and petrochemical industries, e. g., for boilers and

pipelines. A ferrite deficit in the weld seam area leads

to strength reduction, an excess ferrite content to a

reduction in toughness and ductility.

In particular when welding duplex steel, the ferrite

content in the welding area can easily assume unfavor-

able values either due to unsuitable welding filler

materials or through poor heat input or heat removal.

Only an onsite measurement can provide the assur-

ance that the processing did not change the opti-

mum ferrite content in an unfavorable manner at

the expense of mechanical or corrosion-resistance

properties.

Measurement of the ferrite

content of a weld seam

3

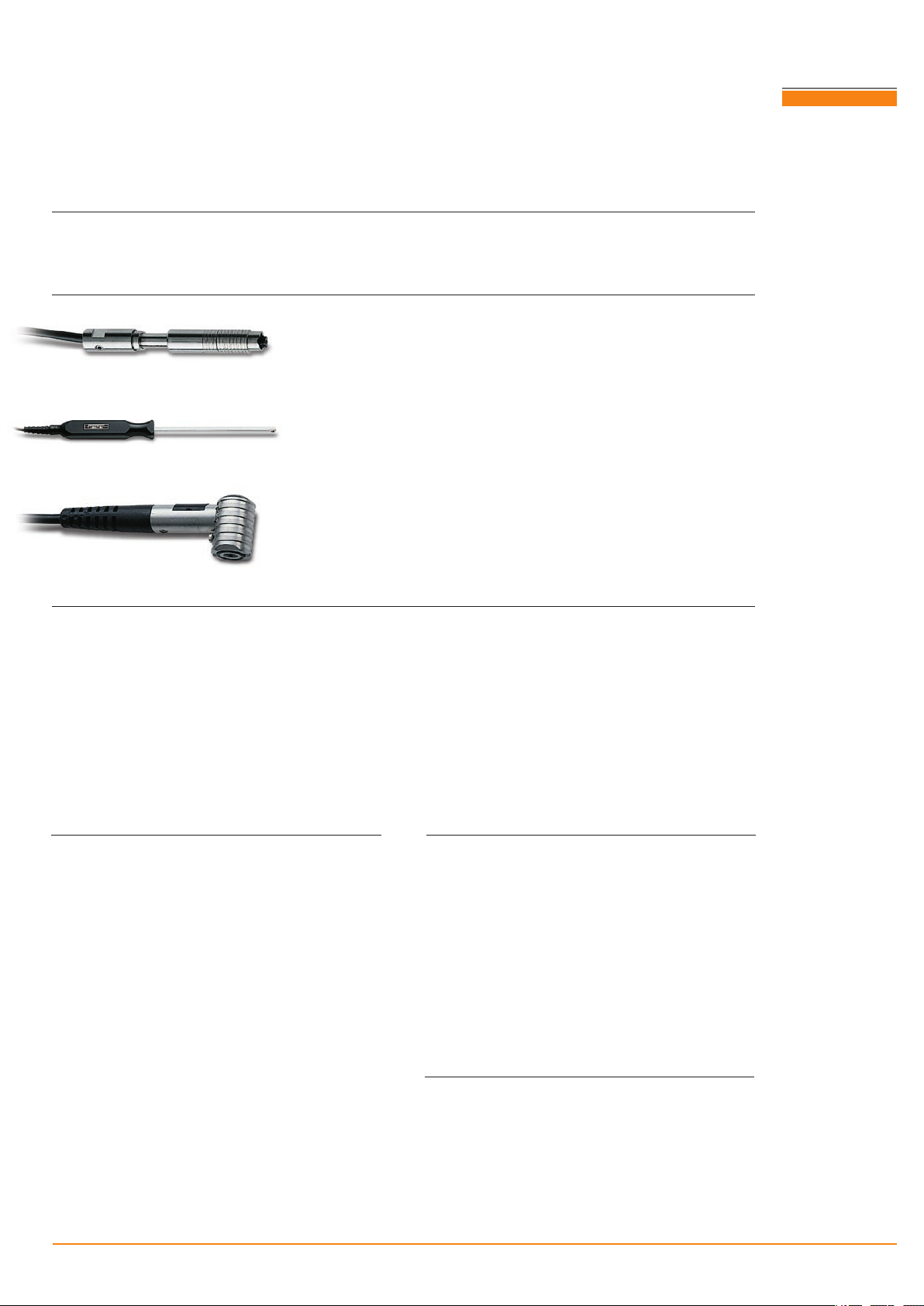

Simple and quick measurements

It is easy to measure the ferrite content accurately

when using the FERITSCOPE FMP30. Upon probe

placement on the surface of the specimen, the reading

is displayed automatically and stored in the instrument. The probe can also be placed onto hard to

reach areas. For such applications, the instrument

features an “external start” function to trigger the

measurements with the push of a button. This is ideal

for measurements in pipes, bore holes or grooves.

Finding weld seams in polished surfaces is made

easy through the “continuous display” instrument

function. When scanning the surface with the probe

with this function enabled, the continuous readings

are displayed only. A change in the ferrite content

reading indicates that the weld seam has been

found.

For easy ferrite content measurements along a weld

seam, the instrument offers the “continuous measurement capture” function. When scanning the weld seam

with the probe positioned, the continuous readings are

captured and stored. This provides a ferrite content

profile along the weld seam.

Measurement influencing factors do not significantly

affect the FERITSCOPE FMP30. Ferrite content measurements can be carried out regardless of the substrate material properties starting at a plating thickness of 3 mm.

Corrective calibrations with customer-specific calibration standards or correction factors (included)

can be used to take influences of the specimen

shape (strong curvature), plating and substrate

thicknesses into account. The calibration is always

stored measurement-application specific in the respective application memory.

Determination of the ferrite

content in the weld seam area

using the FERITSCOPE FMP30

4

FERITSCOPE® FMP30

FERITSCOPE® FMP30

Instrument features

User-friendly operation menu•

Multiple language selections•

Large, easy to read display•

Robust housing•

Non-destructive measurement of the ferrite content in

•

a range from 0.1 to 80 % Fe or 0.1 to 110 FN

Units of measurement switchable between WRC-FN •

and % Fe

Automatic probe recognition•

Sliding cover for keypad; however, On/Off and

•

evaluation keys remain accessible at all times

Protection of settings though lockable keypad•

Battery or line operation•

Automatic instrument shut-down or continuous op-

•

eration

Measurement capture

Fast measurement and data storage•

Automatic measurement acquisition upon probe

•

place ment or through “external trigger”

Enabled or disabled acoustic signal•

Overwriting of erroneous measurements or previ-

•

ously stored readings

Selectable tolerance limits•

Measurement data presentation as an analog bar •

with display of specification limits

Continuous display: Continuous display of the

•

reading when probe is placed on the specimen;

storing with externally triggered measurement

acquisition

Outlier rejection function for the automatic elimina- •

tion of erroneous measurements

Matrix measurement mode: Measurement data

•

storage in blocks that are set up in the application

in the form of a matrix. Block change manually or

automatically in the specified sequence

Measurement data averaging: Only the mean value

•

of a specified number of single readings is stored

Automatic block creation: Number of single read-•

ings per block

Area measurement: Continuous measurement acqui-

•

sition until the probe is lifted off; only the resultant

mean value is stored

Continuous measurement acquisition and storage

•

with the probe placed on the specimen

5

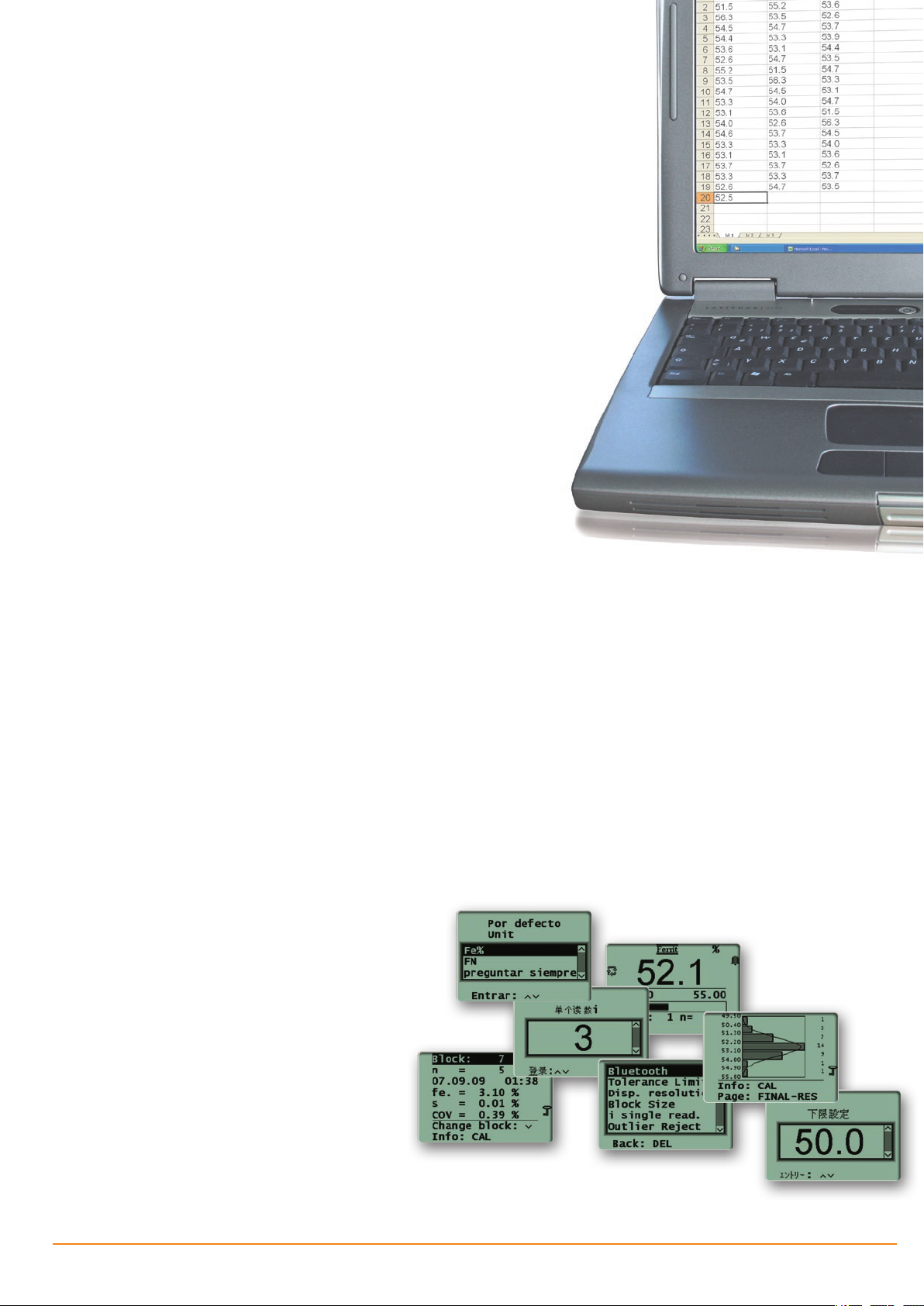

Simple and convenient evaluation of measurement

data through data transfer via Bluetooth® or cable

Data memory

Up to 20,000 readings and 100 applications for •

mea surement data and application-specific calibrations

Separation of the measurement data in up to 4,000 •

blocks

Date and time stamp for the blocks•

Evaluation

Statistical evaluation of measurement series with

•

mean value, standard deviation, max and min value,

range

Computation of the process capability indices c

•

and c

pk

Output of characteristic variance-analytical values•

Graphical measurement presentation as a histogram

•

with a Gaussian bell curve

Interfaces

USB port for data transfer to a PC or printer•

Optional Bluetooth•

®

module, interface for wireless

data transfer to a PC (up to 10 m)

Optional COM module, serial interface for data

•

transfer to a PC or printer (cable length up to 12 m)

Calibration

Only one calibration required for the entire rele-

•

vant measurement range from 0.1 to approx. 90 FN.

Adherence to the measurement accuracy specified

in standard AWS A4.2M

Calibration using calibration standards traceable

•

to TWI secondary standards or customer-specific

standards

Linking applications: Common normalization/

•

calibration of applications

p

Large, easy to read graphical display in several languages

6

FERITSCOPE® FMP30

Calibration and measurement method

Calibration / Standards

To obtain comparable measurement results, the instruments must be adjusted or calibrated using standards

that can be traced to internationally recognized

secondary standards. For this purpose, the IIW (Inter national Institute of Welding, UK) developed secondary standards that have been determined by the

TWI (The Welding Institute, UK) according to the

method described in DIN EN ISO 8249 and

AWS A4.2M.

Helmut Fischer offers certified calibration standard sets

that are traceable to the TWI secondary standards for

corrective and master calibrations. The standards of

the Fischer calibration standard sets list in addition to

the ferrite numbers FN also the % Fe values.

Influences including the shape of the part to be

measured (strong curvature, thickness of the ferritecontaining coating, etc.) can be taken into account

through corrective calibrations with customer-specific

calibration standards or through correction factors

(included). The normalization and corrective calibration are stored application-specific in the respective

application memory of the instrument.

Magnetic induction method

The FERITSCOPE FMP30 measures according to the

magnetic induction method. A magnetic field generated by a coil begins to interact with the magnetic

portions of the specimen. The changes in the magnetic

field induce a voltage proportional to the ferrite content

in a second coil. This voltage is then evaluated. All

magnetic portions in the otherwise non-magnetic structure are measured, i. e., in addition to delta ferrite and

other ferritic portions also strain-induced martensite,

for example.

A specific advantage of the magnetic induction meth-

od for measuring the ferrite content is that a sigma

phase, i. e., a Fe-Cr precipitation, which has formed

due to excess ferrite content and unfavorable cooling

conditions, for example, is recognized correctly as

a non-ferritic structural component. In comparison,

erroneous interpretation of ferrite content is likely in

a metallographic section where a sigma phase is not

easily distinguished from a ferritic structure.

Fischer calibration standard set with certificate

7

Ordering Information

Standard content of shipment Order no.

FERITSCOPE FMP30 instrument, wrist strap, case, battery set, short form operating

instructions printed, operator’s manual and USB driver on CD, interface cable FMP/PC

Probes with a measurement range 0.1 – 80 % Fe or 0.1 – 110 WRC-FN

FGAB1.3 -F e For measurements on flat and curved areas 604-264

FGA06H- Fe For measurements on flat and curved

surfaces. Very robust through a

particularly wear-resistant probe tip

FGABI1.3-150-Fe

FGABI1.3-260-Fe

Ideal for measurements in pipes,

bore holes or grooves

Insertion diameter > 9 mm

Shank length = 150 mm or 260 mm

FGABW1.3-Fe Angle probe for measurements on flat

specimens or in pipes, bore holes and gaps

Calibration standard sets

Corrective calibration standard set CAL-SS % Fe-WRC 0.3/10 includes standards about:

0.4, 2 and 9 FN (0.4, 2.5 and 10.5 % Fe)

Corrective calibration standard set CAL-SS % Fe-WRC 1.5/30 includes standards about:

2, 9 and 33 FN (2.5, 10.5 and 30 % Fe)

604-300

604-303

604-254

604 -341

604-337

602-279

602-239

Corrective calibration standard set CAL-SS % Fe-WRC 10/80 includes standards about:

9, 33 and 110 FN (10.5, 30 and 80 % Fe)

Calibration standard set CAL-SS % Fe-WRC 0.3/80 includes standards about:

0.5, 2, 13, 33 and 90 FN (0.5, 2.5, 14.5, 30 and 63 % Fe)

Optional accessories

Adapter E-probe/F-socket 604 -214

AC adapter FMP 30-40 604-290

Instrument upgrade

Bluetooth

®

Module FMP30/40, interface for the wireless data transfer from

the instrument to a PC (max. 10 m)

Rechargeable battery set FMP (NiMH) 604-295

COM Module FMP30/40, serial inter -

Battery charger AA/Mignon 604-335

Bluetooth

®

USB stick, for retrofitting

604 -4 81

face (RS232) for data transfer to a PC

or printer (max. cable length 12 m)

the PC with Bluetooth interface

USB printer cable DK-FMP 604 -145

Printer F6100 604-291

Software MP-Name, Software

602-966

Spare parts

for naming of applications

Wrist strap FMP 604-150

Software PC-DATEX, Software for

data transfer to Excel spreadsheets

Software PC-DATACC, Software for

data transfer to Access data bases

602-465

603- 028

Interface cable FMP/PC 604 -146

Battery set FMP (Alkaline) 604-296

Instrument case FMP 604 -148

602-277

602- 776

604-480

604-500

FERITSCOPE® is a registered trademark of Helmut Fischer GmbH Institut für Elektronik und Messtechnik, Sindelfingen/Germany.

Bluetooth® is a registered trademark of Bluetooth SIG, USA.

Fischer Worldwide

Helmut Fischer GmbH

Institut für Elektronik und Messtechnik

71069 Sindelfingen, Germany

Tel. +49 70 31 30 30

mail@helmut-fischer.de

Fischer Instrumentation (GB) Ltd

Lymington / Hampshire SO41 8JD, England

Tel. +44 15 90 68 41 00

mail@fischergb.co.uk

Fischer Technology, Inc.

Windsor, CT 06095, USA

Tel. +1 860 683 07 81

info@fischer-technology.com

Helmut Fischer AG

CH-6331 Hünenberg, Switzerland

Tel. +41 41 785 08 00

switzerland@helmutfischer.com

Fischer Instrumentation Electronique

78180 Montigny le Bretonneux, France

Tel. +33 1 30 58 00 58

france@helmutfischer.com

Helmut Fischer S.R.L.

Tecnica di Misura, 20128 Milano, Italy

Tel. +39 0 22 55 26 26

italy@helmutfischer.com

Fischer Instruments, S.A.

08018 Barcelona, Spain

Tel. +34 9 33 09 79 16

spain@helmutfischer.com

Helmut Fischer Meettechniek B.V.

5627 GB Eindhoven, The Netherlands

Tel. +31 40 248 22 55

netherlands@helmutfischer.com

Fischer Instruments K.K.

Saitama-ken 340-0012, Japan

Tel. +81 4 89 29 34 55

japan@helmutfischer.com

Fischer Instrumentation (Far East) Ltd

Kwai Chung, N.T., Hong Kong

Tel. +852 24 20 11 00

hongkong@helmutfischer.com

Fischer Instrumentation (S) Pte Ltd

Singapore 658065, Singapore

Tel. +65 62 76 67 76

singapore@helmutfischer.com

Nantong Fischer Instrumentation Ltd

Shanghai 200333, P. R. China

Tel. +86 21 32 51 31 31

china@helmutfischer.com

Fischer Measurement Technologies (India) Pvt. Ltd

Pune 411036, India

Tel. + 91 20 26 82 20 65

india@helmutfischer.com

www.helmut-fischer.com

05-09

902-039 01/11

Coating Thickness Material TestingMicrohardnessMaterial Analysis

Loading...

Loading...