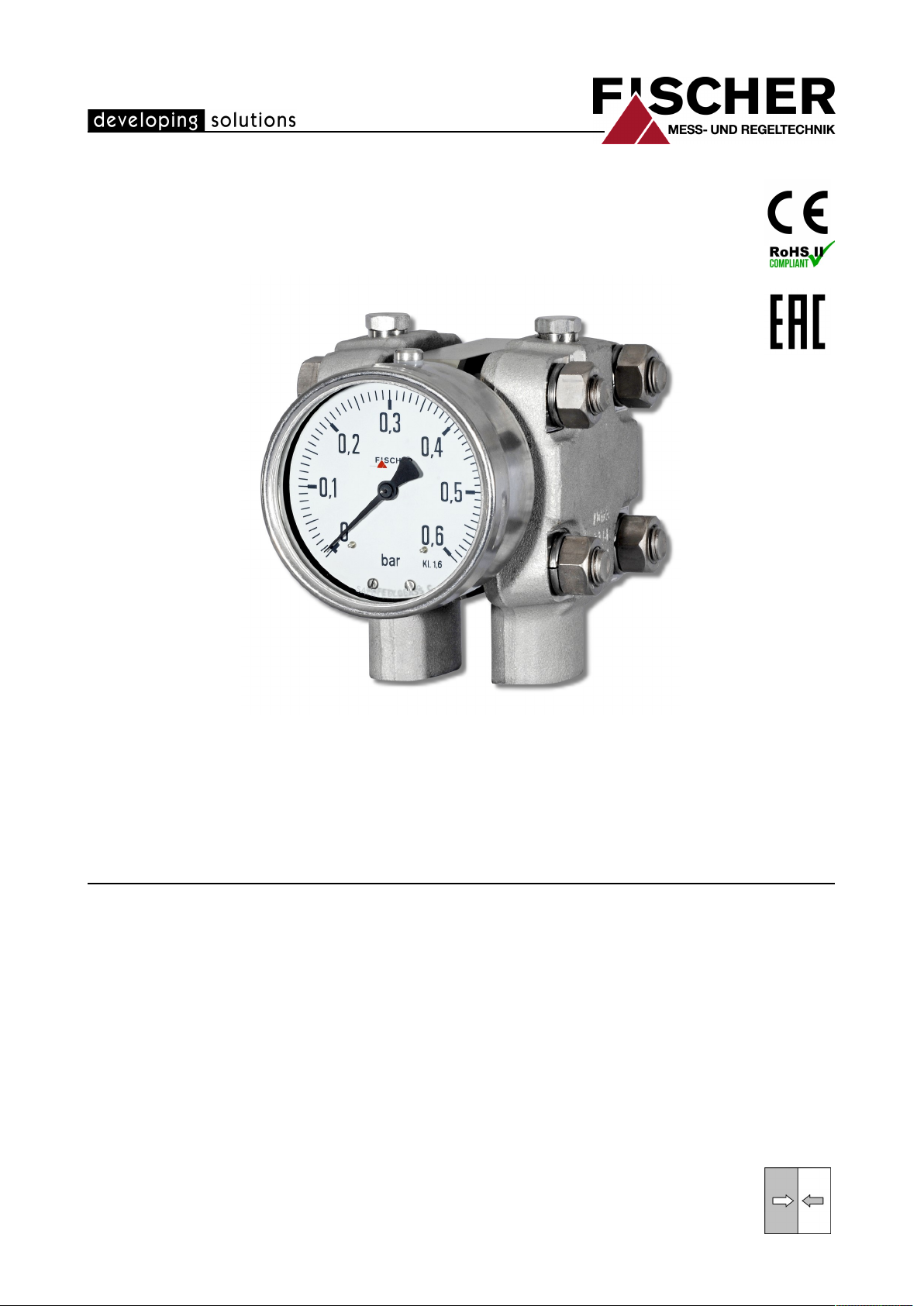

FISCHER DA01 VUW, DA01 VUW ATEX, DA03 0A Series, DA03 1C Series, DA03 1B Series Operating Manual

...Page 1

Operating manual

DA01 VUW

Differential pressure measuring device

Pressure levels PN250/PN400

Standard version

09015042 • BA_EN_DA01_VUW • Rev. ST4-A • 02/18

*09015042*

Page 2

| Masthead FISCHER Mess- und Regeltechnik GmbH

Masthead

Manufacturer:

Technical editorial team:

FISCHER Mess- und Regeltechnik GmbH

Bielefelderstr. 37a

D-32107 Bad Salzuflen

Telefon: +49 5222 974 0

Telefax: +49 5222 7170

eMail: info@fischermesstechnik.de

web: www.fischermesstechnik.de

Documentation representative: S. Richter

Technical editor: R.Kleemann

All rights, also those to the translation, reserved. No part of these instructions

may be reproduced or processed, duplicated or distributed using electronic systems or any other form (print, photocopy, microfilm or another process) without

the written consent of the company FISCHER Mess- und Regeltechnik GmbH,

Bad Salzuflen.

Reproduction for internal use is expressly allowed.

Brand names and procedures are used for information purposes only and do

not take the respective patent situation into account. Great care was taken

when compiling the texts and illustrations; nevertheless, errors cannot be ruled

out. The company FISCHER Mess- und Regeltechnik GmbH will not accept any

legal responsibility or liability for this.

Subject to technical amendments.

© FISCHER Mess- und Regeltechnik 2018

Version history

Rev. ST4-A 11/15 Version 1 (first edition)

2 / 32 BA_EN_DA01_VUW

Page 3

FISCHER Mess- und Regeltechnik GmbH Table of Contents

Table of Contents

1 Sicherheitshinweise ....................................................................................................................................... 4

1.1 General .....................................................................................................................................................4

1.2 Personnel Qualification.............................................................................................................................4

1.3 Risks due to Non-Observance of Safety Instructions ...............................................................................4

1.4 Safety Instructions for the Operating Company and the Operator............................................................4

1.5 Unauthorised Modification ........................................................................................................................4

1.6 Inadmissible Modes of Operation .............................................................................................................4

1.7 Safe working practices for maintenance and installation work .................................................................5

1.8 Pictogram explanation ..............................................................................................................................5

2 Product and functional description ..............................................................................................................6

2.1 Delivery scope ..........................................................................................................................................6

2.2 Equipment versions ..................................................................................................................................6

2.3 Function diagram ....................................................................................................................................11

2.4 Design and mode of operation................................................................................................................11

3 Assembly.......................................................................................................................................................12

3.1 General information ................................................................................................................................12

3.2 Process connection ................................................................................................................................12

3.3 Electrical connections .............................................................................................................................13

4 Commissioning.............................................................................................................................................15

4.1 General ...................................................................................................................................................15

4.2 Venting of the pressure lines ..................................................................................................................15

4.3 Zero point correction...............................................................................................................................16

4.4 Switch point setting.................................................................................................................................16

5 Servicing .......................................................................................................................................................17

5.1 Maintenance ...........................................................................................................................................17

5.2 Transport ................................................................................................................................................17

5.3 Service....................................................................................................................................................17

5.4 Disposal ..................................................................................................................................................17

6 Technical Data .............................................................................................................................................. 18

6.1 Allgemeines ............................................................................................................................................18

6.2 Input variables ........................................................................................................................................19

6.3 Operating conditions...............................................................................................................................19

6.4 Construction design ................................................................................................................................20

7 Order Codes..................................................................................................................................................27

7.1 accessories.............................................................................................................................................29

8 EU Declarations of conformity ....................................................................................................................30

9 EAC Declaration ...........................................................................................................................................32

BA_EN_DA01_VUW 3 / 32

Page 4

1 | Sicherheitshinweise FISCHER Mess- und Regeltechnik GmbH

1 Sicherheitshinweise

1.1 General

WARNING

This operating manual contains instructions fundamental to the installation, operation and maintenance of the device that must be observed unconditionally. It

must be read by the assembler, operator and the specialized personnel in

charge of the instrument before it is installed and put into operation.

This operating manual is an integral part of the product and therefore needs to

be kept close to the instrument in a place that is accessible at all times to the responsible personnel.

The following sections, in particular instructions about the assembly, commissioning and maintenance, contain important information, non-observance of

which could pose a threat to humans, animals, the environment and property.

The instrument described in these operating instructions is designed and manufactured in line with the state of the art and good engineering practice.

1.2 Personnel Qualification

The instrument may only be installed and commissioned by specialized personnel familiar with the installation, commissioning and operation of this product.

Specialized personnel are persons who can assess the work they have been

assigned and recognize potential dangers by virtue of their specialized training,

their skills and experience and their knowledge of the pertinent standards.

1.3 Risks due to Non-Observance of Safety Instructions

Non-observance of these safety instructions, the intended use of the device or

the limit values given in the technical specifications can be hazardous or cause

harm to persons, the environment or the plant itself.

The supplier of the equipment will not be liable for damage claims if this should

happen.

1.4 Safety Instructions for the Operating Company and the Operator

The safety instructions governing correct operation of theinstrument must be

observed. The operating company must make them available to the installation,

maintenance, inspection and operating personnel.

Dangers arising from electrical components, energy discharged by the medium,

escaping medium and incorrect installation of the device must be eliminated.

See the information in the applicable national and international regulations.

Please observe the information about certification and approvals in the Technical Data section.

1.5 Unauthorised Modification

Modifications of or other technical alterations to the instrument by the customer

are not permitted. This also applies to replacement parts. Only the manufacturer

is authorised to make any modifications or changes.

1.6 Inadmissible Modes of Operation

The operational safety of this instrument can only be guaranteed if it is used as

intended. The instrument model must be suitable for the medium used in the

system. The limit values given in the technical data may not be exceeded.

The manufacturer is not liable for damage resulting from improper or incorrect

use.

4 / 32 BA_EN_DA01_VUW

Page 5

FISCHER Mess- und Regeltechnik GmbH Sicherheitshinweise | 1

1.7 Safe working practices for maintenance and installation work

The safety instructions given in this operating manual, any nationally applicable

regulations on accident prevention and any of the operating company's internal

work, operating and safety guidelines must be observed.

The operating company is responsible for ensuring that all required maintenance, inspection and installation work is carried out by qualified specialized personnel.

1.8 Pictogram explanation

DANGER

Type and source of danger

This indicates a direct dangerous situation that could lead to death or serious

injury (highest danger level).

a) Avoid danger by observing the valid safety regulations.

WARNING

Type and source of danger

This indicates a potentially dangerous situation that could lead to death or serious injury (medium danger level).

a) Avoid danger by observing the valid safety regulations.

CAUTION

Type and source of danger

This indicates a potentially dangerous situation that could lead to slight or serious injury, damage or environmental pollution (low danger level).

a) Avoid danger by observing the valid safety regulations.

NOTICE

Note / advice

This indicates useful information of advice for efficient and smooth operation.

BA_EN_DA01_VUW 5 / 32

Page 6

2 | Product and functional description FISCHER Mess- und Regeltechnik GmbH

Large measuring cell Ø130 Small measuring cell Ø75

NG100

NG160

(mbar ranges) (bar ranges)

1/4-18 NPT

1/2-14 NPT

1/4-18 NPT

1/2-14 NPT

Inner thread Outer thread Cutting ring-

screw connection

12 mm tube

Flange connection

based on DIN 615018

with internal thread G½

G½ G½ G½ G½

G½

2 Product and functional description

2.1 Delivery scope

• Differential pressure measuring device DA01

• Operating Manual

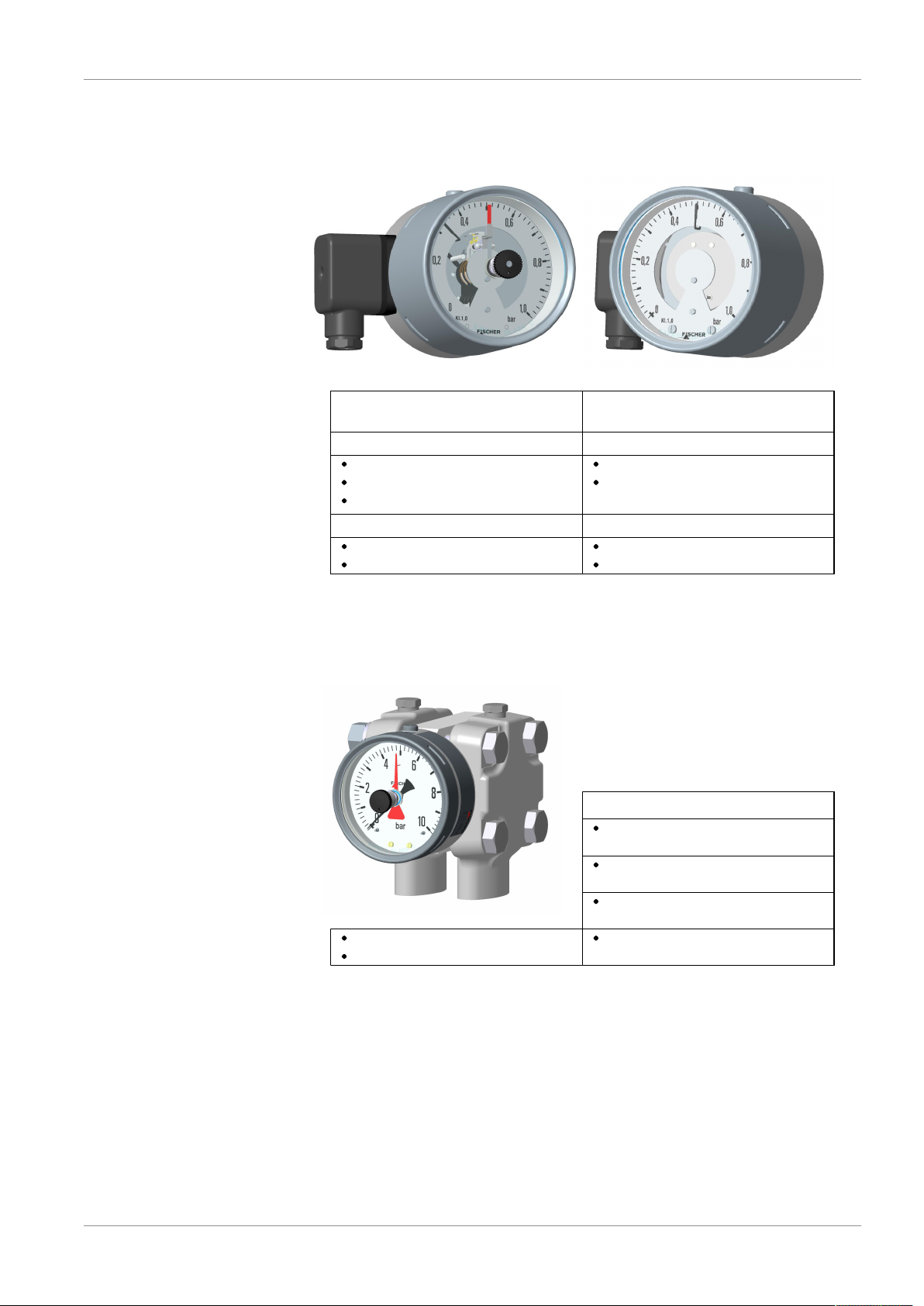

2.2 Equipment versions

The following illustrations depict typical combinations of the measuring cell,

measured value display and contact elements. However, these can be freely

combined according to the order code. Wherever this is not possible, this is

clearly stated.

For instance, a small measuring cell with an NG160 display and a contact element is also available.

Fig.1: Device overview

2.2.1 Process connection

Fig.2: Options for the process connection

6 / 32 BA_EN_DA01_VUW

Page 7

FISCHER Mess- und Regeltechnik GmbH Product and functional description | 2

Low-action contacts

Snap-actiocontacts

Inductive contacts

KINAX 3W2 708-226D0

KINAX 3W2 708-226E0

for standard devices

Snap-action contacts

Inductive contacts

for ATEX devices

KINAX 3W2 708-226D0

KINAX 3W2 708-226E0

Rotation angle encoder in accordance

with data sheet KE09

Limit switch in accordance with

data sheet KE##

Marker needle

Trailing needle

Fluid fillings

Unit without contacts

Paraffin oil, glycerine, silicon oil

Unit with inductive contacts

Paraffin oil, silicon oil

Unit with low-action contacts

Paraffin oil, silicon oil

Units with magnetic spring contacts

Silicon oil

2.2.2 Nameplate

2.2.3 Contact elements

Fig.3: Contact elements

2.2.4 Special functions

Fig.4: Special functions

BA_EN_DA01_VUW 7 / 32

Page 8

2 | Product and functional description FISCHER Mess- und Regeltechnik GmbH

Wall mounting Pipe mounting

Panel mounting set type 1 Panel mounting set type 2

with panel mounting set with front ring

available

on request

2.2.5 Assembly

Fig.5: Assembly

The panel installation fittings can only be used in devices with a small measuring cell (Ø75) and a display in the NG100 bayonet ring casing.

WARNING

Panel mounting set

Due to the heavy weight, the operator needs to install a support construction for

installation of the front panel.

2.2.6 Equipment features (overview)

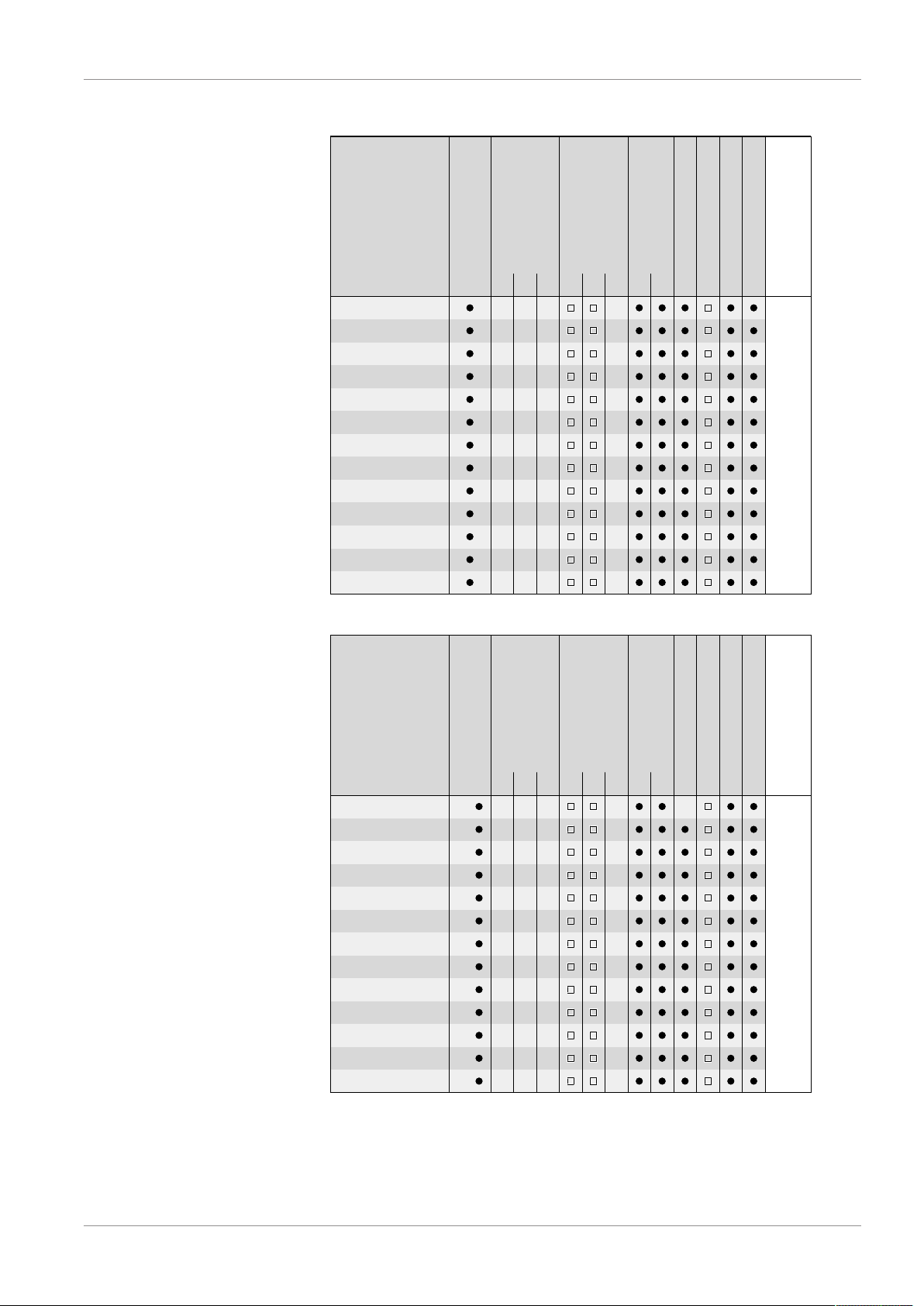

The following shows the configuration possibilities of the DA01 depending on

the measuring cell used and the pressure level.

Key

8 / 32 BA_EN_DA01_VUW

Page 9

FISCHER Mess- und Regeltechnik GmbH Product and functional description | 2

Measuring range

Measured value display

Ø100

Inductive contacts

Rotation angle transducer

Trailing needle

Marker needle

Remote seal

1 2 3 1 2

0 ... 0.6 bar

0 ... 1 bar

0 ... 1.6 bar

0 ... 2.5 bar

0 ... 4.0 bar

0 ... 6bar

0 ... 10 bar

0 ... 16 bar

0 ... 25 bar

-1 ... 0.6 bar

-1 ... 1.5 bar

-1 ... 3 bar

Snap-action contacts

-1 ... 5 bar

1 2 3

Low-action contacts

Pressure levelPN250/PN400

Measuring range

Measured value display

Ø160

Inductive contacts

Rotation angle transducer

Trailing needle

Marker needle

Remote seal

1 2 3 1 2

0 ... 0.6 bar

0 ... 1 bar

0 ... 1.6 bar

0 ... 2.5 bar

0 ... 4.0 bar

0 ... 6bar

0 ... 10 bar

0 ... 16 bar

0 ... 25 bar

-1 ... 0.6 bar

-1 ... 1.5 bar

-1 ... 3 bar

Snap-action contacts

-1 ... 5 bar

1 2 3

Low-action contacts

Pressure levelPN250/PN400

Small measuring cell Ø75

BA_EN_DA01_VUW 9 / 32

Fig.6: Small measuring cell Ø75 Measured value display Ø100

Fig.7: Small measuring cell Ø75 Measured value display Ø160

Page 10

2 | Product and functional description FISCHER Mess- und Regeltechnik GmbH

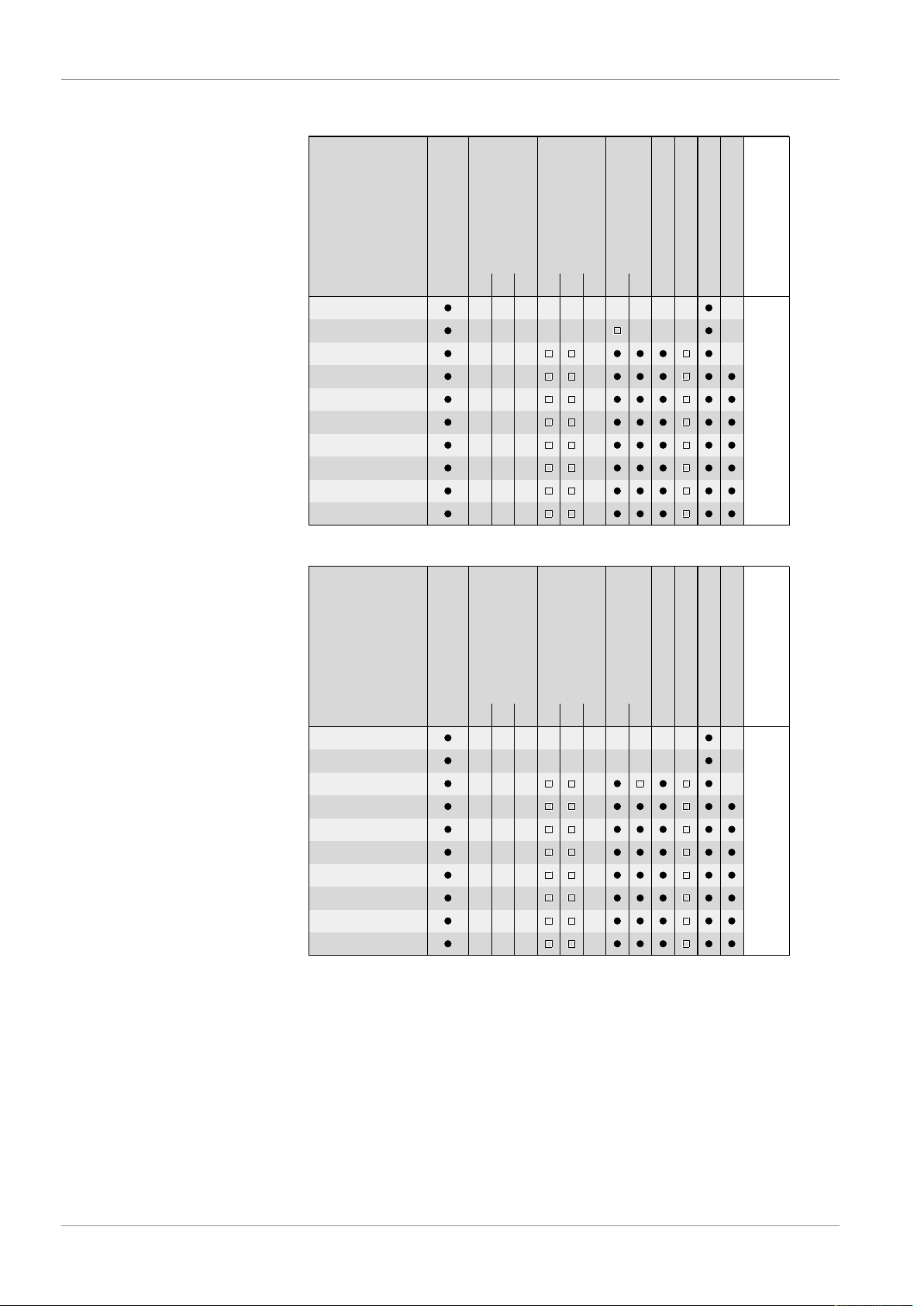

-100 ... +250 mbar

Measuring range

Inductive contacts

Rotation angle transducer

Trailing needle

Marker needle

Remote seal

1 2 3 1 2

0 ... 40 mbar

0 ... 60 mbar

0 ... 100 mbar

0 ... 160 mbar

0 ... 250 mbar

0 ... 400 mbar

-40 ... +60 mbar

-60 ... +100 mbar

-100 ... +150 mbar

Snap-action contacts

1 2 3

Low-action contacts

Pressure level

PN250

Measured value display

Ø100

-100 ... +250 mbar

Measuring range

Inductive contacts

Rotation angle transducer

Trailing needle

Marker needle

Remote seal

1 2 3 1 2

0 ... 40 mbar

0 ... 60 mbar

0 ... 100 mbar

0 ... 160 mbar

0 ... 250 mbar

0 ... 400 mbar

-40 ... +60 mbar

-60 ... +100 mbar

-100 ... +150 mbar

Snap-action contacts

1 2 3

Low-action contacts

Pressure level

PN250

Measured value display

Ø160

Large measuring cell Ø130

Fig.8: Large measuring cell Ø130 Measured value display Ø100

Fig.9: Large measuring cell Ø130 Measured value display Ø160

10 / 32 BA_EN_DA01_VUW

Page 11

FISCHER Mess- und Regeltechnik GmbH Product and functional description | 2

1

2

3

4

5

6

7

8

8

7

2.3 Function diagram

Fig.10: Function diagram

1 Motion train 2 Transfer lever

3 Measuring shaft 4 Pressure transfer fluid

5 Separating membrane 6 Connecting rod

7 Measuring diaphragm 8 Pressure chamber

2.4 Design and mode of operation

The pressures in the pressure chambers that are to be compared are each exerted onto a measuring membrane that can be rigidly connected using a connection rod. To compensate the static pressure, the space between the separating and measuring membrane is filled with a pressure transfer fluid.

During pressure equalisation, the two measuring membranes are in an idle position. In case of pressure difference, the force acting on the membranes causes

it to be moved towards the side of the lower pressure.

The connecting rod transfers the deflection of the measuring membranes onto

the transfer lever mounted to the measuring shaft. Proportional to the current

differential pressure, the measurement shaft makes a rotational movement that

the indicator translates into a rotation angle between 0 and 270°.

In the case of one-sided pressure by the measuring system above and beyond

the measuring range, the over-pressure guard will be activated which supports

the overlosaded membrane.

BA_EN_DA01_VUW 11 / 32

Page 12

3 | Assembly FISCHER Mess- und Regeltechnik GmbH

3 Assembly

3.1 General information

The device can be mounted in one of the following ways (see Assembly):

1. Wall mounting

The device is designed for installation onto flat assembly plates. The unit is

equipped with a wall mounting plate for this mounting type.

2. Pipe assembly

The device is equipped with a special pipe assembly set and is suitable for

mounting to a 2" pipe (DN50).

3. Panel mounting

Panel mounting is available in two installation models.

– Panel mounting fittings (Type 1)

This variant is only suitable for models with a small measuring system

(Ø75) and a bayonet ring casing NG100.

– Panel installation with front ring (Type 2)

All models are suitable for this variant. A suitable steel construction

must be used to ensure that the front plate can bear the weight of the

DA03. This is possible e.g. by means of a combination with the wall or

pipe assembly.

At the factory, the device is calibrated for vertical installation, but the installation

position is arbitrary. For any installation positions that are not vertical, the zeropoint signal can be corrected via the installed offset correction.

To ensure safety during installation and maintenance, we recommend installing

a suitable shut-off valve on the system (see accessories).

3.2 Process connection

• By authorized and qualified specialized personnel only.

• The pipes need to be depressurized when the instrument is being connected.

• Appropriate steps must be taken to protect the device from pressure surges.

• Check that the device is suitable for the medium being measured.

• Maximum pressures must be observed (cf. Tech. data)

All supply lines are arranged so that there are no mechanical forces acting on

the device.

The pressure lines must be kept as short as possible and installed without any

tight bends to avoid delays.

The pressure lines must be installed at an inclination so that when fluids are

measured no air pockets are created or when measuring gases, no water pockets are created. If the required inclination is not reached, water or air filters must

be installed at suitable places.

The pressure lines need to be vented for fluid measuring media. [}15].

If water is used as a measuring medium, the unit must be protected against

frost.

If the pressure sensing lines are already pressurised at the time of commissioning, zero-point control and adjustment cannot be performed. In such cases, the

device should be only connected to the mains without the pressure sensing

lines.

12 / 32 BA_EN_DA01_VUW

Page 13

FISCHER Mess- und Regeltechnik GmbH Assembly | 3

+

Higher pressure

lower pressure

1

2

3

4

5

6

M20 x 1.5

1

2

5

6

3

4

4

The process connections are marked with (+) and (-) symbols on the device.

The pressure lines must be mounted according to these symbols.

Differential pressure

Fig.11: Process connection

3.3 Electrical connections

• By authorized and qualified specialized personnel only.

• When connecting the unit, the national and international electro-technical

regulations must be observed.

• Disconnect the system from the mains, before electrically connecting the

device.

• Install the consumer-adapted fuses.

• Do not connect the connector if strained.

Only devices with contact elements are connected to the electrical supply. To

this end there is a cable socket on the side of the device, or a HAN plug in the

power plant version.

3.3.1 Cable socket / HAN plug

BA_EN_DA01_VUW 13 / 32

Fig.12: Cable socket

1 Lower part 2 Sealing ring EPDM

3 Middle part 4 Sealing ring EPDM

5 Lid 6 Lid screw

Fig.13: HAN connector

1 Cable screw connection M20 x 1.5 2 Sleeve housing Han 3A

3 Socket insert Han 7D 4 Pin insert Han 7D

5 Safety clip 6 Attachment casing Han 3D

Page 14

3 | Assembly FISCHER Mess- und Regeltechnik GmbH

1 2 3 4

1 2

1 2 3 4

1 2 3

1 2 3 4

-+-

+

1 2

Eb= 5 ... 25V

1 2 3

R

L

+

-

Eb= 12 ... 30V

1 2 3

R

L

+

-

~

+

-

~

+

-

2-Wire 3-Wire

3.3.2 Contact elements

Contact elements are supplied in accordance with data sheet KE. This illustrates all variants, their pin assignment and the technical data.

Creep and magnetic spring contacts

The terminal numbers always correspond to the contact number an are assigned to the target indicators from left to right. Up to three contacts can be

used. There are assigned to the target indicators as follows:

1. For 2 contacts

Contact 1: left target indicator

Contact 2:right target indicator

2. For 3 contacts

Contact 1: left target

Fig.14: Contacts

Contact 2: middle target

Contact 3: right target

Inductive contacts

In the case of inductive contacts, the switch function is not only determined by

the slot type initiator but also by the switch amplifier. Up to max two contacts

can be used. There are assigned to the target indicators as follows:

Contact 1: left target indicator

Fig.15: Inductive contacts

Contact 2:right target indicator.

3.3.3 Rotation angle transducers KINAX 3W2

The rotation angle encoder serves to record angular positions, to prepare and

provide the measured values as electrical output signals 0/4…20mA for the

following device. Rotation angle encoder is supplied in accordance with data

sheet KE09. This contains further information about the pin assignment and the

technical data.

Fig.16: Rotation angle transducers connection

14 / 32 BA_EN_DA01_VUW

Page 15

FISCHER Mess- und Regeltechnik GmbH Commissioning | 4

Venting screw

Closing screw0.8 x 4

Venting screws

5

Seal (FKM)

4 Commissioning

4.1 General

All electrical supply, operating and measuring lines, and the pressure connections must have been correctly installed before commissioning. All supply lines

are arranged so that there are no mechanical forces acting on the device.

Check that all pressure connections are free of leaks before commissioning.

In models filled with fluid, the venting valve on the upper side of the bayonet

casing must be opened before commissioning! To do this, turn the venting

screw anticlockwise as far as it will go.

Fig.17: Venting valve

4.2 Venting of the pressure lines

WARNING

Risk connected to pressure

Never remove the venting screw if the unit is still pressurised! Close the shut-off

valves of the flanged fittings or depressurize the system.

The pressure lines need to be vented for before commissioning on devices that

work with fluid media. Proceed as follows:

• Remove the venting screws of the two pressure chambers.

• Carefully increase the system pressure until the fluid level is 5 mm below

the sealing surface of the threaded borehole.

• Close the device with the venting screws

Fig.18: Venting with fluid media

BA_EN_DA01_VUW 15 / 32

Page 16

4 | Commissioning FISCHER Mess- und Regeltechnik GmbH

Without fluid filling With fluid filling

Closing screw 11

1.2 x 7

1

2

3

4

5

6

4.3 Zero point correction

The differential pressure measuring units are set in the factory before delivery

so that they do not usually need to be adjusted at the assembly site. If this is

still necessary, proceed as follows:

• Depressurize the measuring chamber (+) und (-) side or only exert the existing static system pressure.

• Remove the closing screw The zero point correction screw is located behind.

• Set the measurement value pointer to the scale zero point using the zero

point correction screw.

• Mount the closing screw

Fig.19: Zero point correction screw

4.4 Switch point setting

There is an adjustment lock attached to the front pane of the measuring unit on

units with contact elements. This means that the contacts attached to the target

indicators can be set to any point along the scale.

To facilitate switching precision and the service life of the mechanical measuring system, the switching points should lie between 10% and 90% of the measuring range.

Fig.20: Switch point setting

1 Adjustment key 2 Adjusting lock

3 Axle 4 Drive arm

5 Set-point display 6 Actual value display

Adjustment sequence:

16 / 32 BA_EN_DA01_VUW

• Press the axle inwards until the drive arm reaches behind the setting pin of

the target value indicator.

• Set the target value indicator to the required switch point by turning the setting key.

• Relieve the axle.

• The switch-point setting can be secured against unintentional adjustment by

removing the attachment screw and the adjustment key.

Page 17

FISCHER Mess- und Regeltechnik GmbH Servicing | 5

5 Servicing

5.1 Maintenance

The instrument is maintenance-free. We recommend the following regular inspection to guarantee reliable operation and a long service life:

• Check the function in combination with downstream components.

• Check the leak-tightness of the pressure connection lines.

• Check the electrical connections.

The exact test cycles need to be adapted to the operating and environmental

conditions. In combination with other devices, the operating instructions for the

other devices also need to be observed.

5.2 Transport

The measuring device must be protected against impacts. It should be transported in the original packaging or a suitable transport container.

5.3 Service

All defective or faulty devices should be sent directly to our repair department.

Please coordinate all shipments with our sales department.

WARNING

Process media residues

Process media residues in and ondismantled devices can be a hazard to

people, animals and the environment. Take adequate preventive measures. If

required, the devices must be cleaned thoroughly.

Return the device in the original packaging or a suitable transport container.

5.4 Disposal

WARNING

Incorrect disposal may pose a risk to the environment.

Please help to protect the environment by always disposing of the work pieces

and packaging materials in compliance with the valid national waste and recycling guidelines or reuse them.

BA_EN_DA01_VUW 17 / 32

Page 18

6 | Technical Data FISCHER Mess- und Regeltechnik GmbH

6 Technical Data

6.1 Allgemeines

EXECUTION Nominal

pressure

DA01 V … PN250 Ø75 Measuring ranges: 0…0.6 bar to 0…25 bar

DA01 U … PN400 Ø75 Measuring ranges: 0…0.6 bar to 0…25 bar

DA01 W … PN250 Ø130 Measuring ranges: 0…40 mbar to 0…400 bar

Measuring

cell

Application information

Remote seals:

It is possible to attach remote seals for all measuring ranges. The remote seals need to be designed for the displacement volume, the

length of the cable and the application temperature.

Remote seals:

It is possible to attach remote seals for all measuring ranges. The remote seals need to be designed for the displacement volume, the

length of the cable and the application temperature.

Limitations:

Drag indicator measuring ranges ≥ 60 mbar

Contacts / Transmitter measuring ranges ≥ 100 mbar

Remote seals:

It is possible to attach remote seals for measuring ranges ≥ 160 mbar.

The remote seals need to be designed for the displacement volume,

the length of the cable and the application temperature.

18 / 32 BA_EN_DA01_VUW

Page 19

FISCHER Mess- und Regeltechnik GmbH Technical Data | 6

6.2 Input variables

Measuring variable

Differential pressure in gaseous and fluid aggressive media.

General

Small measuring cell

Ø75

Rated pressure of the measuring

system

Durability One-sided over-pressure-proof up to the

Measurement accuracy ±1.6 % of the measuring range

Temperature sensor 0.3 % / 10 °C

Zero-point adjustment ±25 % of the measuring range

Max. static operating pressure

rated pressure of the measuring system

resistance to under-pressure on the (+) and

(-) side

Measuring ranges

Measuring range Device model

V U W

0 … 0.6 bar ● ●

0 … 1 bar ● ●

0 … 1.6 bar ● ●

0 … 2.5bar ● ●

0 … 4.0 bar ● ●

0 … 6 bar ● ●

0 … 10 bar ● ●

0 … 16 bar ● ●

0 … 25 bar ● ●

-1 … 0.6 bar ● ●

-1 … 1.5 bar ● ●

-1 … 3 bar ● ●

-1 … 5 bar ● ●

Large measuring cell

Ø130

Measuring range Device model

V U W

0 … 40 mbar ●

0 … 60 mbar ●

0 … 100 mbar ●

0 … 160 mbar ●

0 … 250 mbar ●

0 … 400 mbar ●

0 … 600 mbar ●

6.3 Operating conditions

Permissible ambient temperature -20 … +80 °C

Admissible storage temperature -40 … +80 °C

Admissible media temperature Max. 100 °C

Type of protection: IP 65 acc. to EN 60529

BA_EN_DA01_VUW 19 / 32

Page 20

6 | Technical Data FISCHER Mess- und Regeltechnik GmbH

6.4 Construction design

Materials

Measured value display Material Material no.

EU AISI

Bayonet ring housing NG100, NG160 CrNi steel 1.4301 304

Process connection (all models) CrNi steel 1.4404 316L

Intermediate plate AlMgSiPb HARD-COAT

Seals (O-rings) FKM

Motion train CrNi steel

Dial face and needle Aluminium, painted, printed

Inspection disk Safety laminated glass

®

MB = Measurement

range

Materials (media-contacting)

Design of the measuring system (R) Material Material no.

EU AISI

Pressure caps CrNi steel 1.4404 316L

Separation membranes CrNi steel 1.4571 361Ti

Design of the measuring system (G) Material Material no.

EU AISI

Pressure caps CrNi steel 1.4404 316L

Separation membranes Hastelloy® C276

Process connection Material Material no.

EU AISI

Connecting piece and port CrNi steel 1.4404 316L

Cutting ring screw connections CrNi steel 1.4571

Assembly

Wall mounting Flanged assembly plate

Pipe mounting Flanged assembly plate and attachment bracket

Panel mounting set

type 1

Panel mounting set

type 2

Panel installation fittings for units with a small measuring

cell (Ø75) and NG100 bayonet ring casing.

Front ring and support construction

20 / 32 BA_EN_DA01_VUW

Page 21

FISCHER Mess- und Regeltechnik GmbH Technical Data | 6

6.4.1 Additional Attachments

6.4.1.1 Contact elements

Limit signal transmitters (contacts) and capacitive rotation angle transducers

with an output signal proportional to the angular position can be fitted into a

housing augmented by a corresponding bayonet ring connector.

A certain minimum pressure level is required to operate this kind of contact element, which is why there is a lower limit for the mbar measuring ranges. This

limit depends on the model type and is stated in the section ‚General‘.

The measuring deviation increases by ±0.5% per contact when the contacts are

driven and switched.

For more information and the order key, please refer to the data sheet:

• for limit switch in data sheet KE

• for rotation angle converter in the data sheet KE09

6.4.1.2 Fluid charging

Under aggravated operating conditions, such as vibrations and extreme pressure fluctuations, or in order to avoid condensation forming if used outdoors, the

casing can be filled with the following fluids depending in the type of contacts installed:

without contacts Glycerine, silicon oil

Low-action contacts Silicon oil

Magnetic spring contacts Silicon oil

Inductive contacts Paraffin oil

Rotation angle transducer no filling possible

6.4.1.3 Marker needle

A settable red marker can be attached to the scale to clearly show a certain

pressure (limit value).

6.4.1.4 Trailing needle

The railing needle is 'dragged' with the measured value indicator. As there is no

fixed connection between the two needles, one-off maximum values are stored.

The trailing needle can be reset using an adjusting dial in the window. Trailing

needles cannot be used in conjunction with contacts. A certain minimum pressure level is required to move the drag indicator, which is why there is a lower

limit for the mbar measuring ranges. This limit depends on the model type and

is stated in the section ‚General‘.

6.4.1.5 Shut-off fitting

3-spindle valve block PN 100, DN 5, can be directly flanged

• Type DZ3600SV2700

• Material 1.4571

• Functions: Shut-off, pressure compensation

BA_EN_DA01_VUW 21 / 32

Page 22

6 | Technical Data FISCHER Mess- und Regeltechnik GmbH

Cable socket

HAN 7D

6.4.2 Electrical connection

In the case of devices with additional electronic equipment, the connection is

realised using a cable socket attached to the side and/or with a Han 7D connector on th epower plant models. The pin assignment depends on the ordered

mode and is stated in the data sheet KE or KE09.

Fig.21: Cable socket

Cable socket

Number of screw terminals 6 + 2PE

Rated current See data sheet KE

Rated voltage 250 V

Cable diameter up to 1.5 mm2 with wire protection

Cable screw connection M20 x 1.5, terminal range 7 … 13 mm

HAN 7D

No. of crimp contacts 7 + PE

Rated current See data sheet KE

Rated voltage 50 V

Cable diameter 1 mm

Cable screw connection M20 x 1.5, terminal range 7 … 13 mm

2

22 / 32 BA_EN_DA01_VUW

Page 23

FISCHER Mess- und Regeltechnik GmbH Technical Data | 6

Small measuring system (Ø75)

Flange based on DIN EN 61518 Wall mounting plate

152

105

90

80

86.5

132

(with installed contacts)

112

213

(with installed contacts)

165

113

NG100 Ø101

NG160 Ø161

Ø9

41.3

54.4

80

132

152

R6

Ø9

Cable socket

G½

7/16 UNF

Round steel bracket

2'' pipe (DN50)

2" pipe mounting

Pipe mounting plate

Spacer sleeve

Attachment kit for

round steel bracket

(possible for all models)

The pipe assembly set

is also available as accessory.

6.4.3 Dimensional drawings

All dimensions in mm unless otherwise stated

Fig.22: Dimensional drawing (Small measuring system Ø75)

Fig.23: Pipe mounting

BA_EN_DA01_VUW 23 / 32

Page 24

6 | Technical Data FISCHER Mess- und Regeltechnik GmbH

Wall mounting plate

Flange based on DIN EN 61518

Large measuring system (Ø130)

170

60

200

100

R6

Ø11

200

119

149

(with installed contacts)

170

60

120

Ø11

170

100

277.5

229.5

175

NG100 Ø101

NG160 Ø161

(with installed contacts)

7/16 UNF

G½

54.4

41.3

Cable socket

Installation of front panel type 1

d2

d1

d3

120°

d4

d1

NG100

d2 d3 d4

101 132 116 4.8

Front ring

Bayonet ring

with connecting bracket

Holding plate

Assembly bracket

The front plate thickness

must be min. 2 mm.

(only small measuring system Ø75 and NG100 display)

Fig.24: Dimensional drawing (Large measuring system Ø130)

Fig.25: Installation of front panel with panel fittings

24 / 32 BA_EN_DA01_VUW

Page 25

FISCHER Mess- und Regeltechnik GmbH Technical Data | 6

Installation of front panel type 2

Front ring

Bayonet ring

with connecting bracket

The front plate thickness must be min. 2 mm.

A suitable steel construction must be used to ensure

that the front plate can bear the weight of the DA03.

Examples:

d2

d1

d3

120°

d4

d1

NG100

NG160

d2 d3 d4

101 132 116 4.8

161 196 178 5.8

Assembly on a mounting plate Mounting to a 2'' pipe

Fig.26: Installation of front panel with front ring

BA_EN_DA01_VUW 25 / 32

Page 26

6 | Technical Data FISCHER Mess- und Regeltechnik GmbH

Contact elements

NG100 = 90

NG160 = 120

NG100 = 138

NG160 = 167.5

100 18 118

Shut-off fitting

~147

~155

Cutting ring connection G3/8

for 12 mm pipe

DA03

Process

1

2

3

2

13

~110

Valve open

108

54

(Connection clearance)

~73

with inner spindle thread

M10

42

Fig.27: Dimensional drawing contact devices

Fig.28: Shutoff valve DZ3600SV2700

26 / 32 BA_EN_DA01_VUW

Page 27

FISCHER Mess- und Regeltechnik GmbH Order Codes | 7

D A 0 1

1 2 5 6 7 8 9 10 11 12 13 14 15 163 4

0

Process connection

Output signal

Operating voltage

Measuring unit

Measured value display /

contact elements

Electrical connection

Assembly

Type

Measuring range

Code no.

7 Order Codes

Device model:

[1] Pressure level Measuring cell

V PN250 Ø75

U PN400 Ø75

W PN250 Ø130

Small measuring system

Ø75

Measuring range:

[2.3] Measuring range Device model

V U W

01 0 … 0.6 bar ● ●

02 0 … 1 bar ● ●

03 0 … 1.6 bar ● ●

04 0 … 2.5bar ● ●

05 0 … 4.0 bar ● ●

06 0 … 6 bar ● ●

07 0 … 10 bar ● ●

08 0 … 16 bar ● ●

09 0 … 25 bar ● ●

32 -1 … 0.6 bar ● ●

33 -1 … 1.5 bar ● ●

34 -1 … 3 bar ● ●

35 -1 … 5 bar ● ●

BA_EN_DA01_VUW 27 / 32

Page 28

7 | Order Codes FISCHER Mess- und Regeltechnik GmbH

Large measuring system

Ø130

[2.3] Measuring range Device model

V U W

57 0 … 40 mbar ●

58 0 … 60 mbar ●

59 0 … 100 mbar ●

60 0 … 160 mbar ●

82 0 … 250 mbar ●

83 0 … 400 mbar ●

C1 0 … 600 mbar ●

70 -40 … +60 mbar ●

72 -60 … +100 mbar ●

74 -100 … +150 mbar ●

76 -100 … +250 mbar ●

Design of the measuring system:

[4]

R Pressure chamber CrNi steel 1.4404 (AISI 316L)

Measuring membrane standard

G Pressure chamber CrNi steel 1.4404 (AISI 316L)

Measuring membrane Hastelloy C276

Process connection:

[5.6]

03 Flange connection based on DIN EN 61518

with internal thread G½

04 Connecting piece G½ with inside thread 1/4 -18 NPT

05 Connecting piece G½ with inside thread 1/2 -14 NPT

13 Connection shanks G½ with external thread G½

14 Connecting port G½ with outer thread 1/4-18 NPT

15 Connecting port G½ with outer thread 1/2-14 NPT

27 Cutting ring connection in brass for 12 mm pipe

Measured value display:

[7]

L Bayonet ring housing NG100

M Bayonet ring housing NG160

Assembly:

[8]

W Wall mounting

R Pipe mounting

T Panel installation fittings

(only a small measuring system Ø75, NG100 measured value display

without contact elements)

G Front ring for panel mounting

28 / 32 BA_EN_DA01_VUW

Page 29

FISCHER Mess- und Regeltechnik GmbH Order Codes | 7

Fluid filling:

[9]

0 Without fluid filling

1 Glycerine

4 Paraffin oil

5 Silicon oil

Special functions:

[10]

0 Without special function

1 Adjustable marker needle

2 Resettable drag needle

Contacts/transmitters:

[11]

0 No contacts/transmitters

1 Built-in contacts as per data sheet KE

2 Installed capacitive rotation angle encoder in accordance with data

sheet KE09

5 Built-in contacts with plug connector (power plant model)

[12]

0 Standard version

Limitations

A minimum operating pressure, which not all measuring ranges achieve, is required to activate a contact element or a drag indicator. Please also note the information about the equipment features [}8].

7.1 accessories

Order no. Planned measures Material

DZ3600SV2700 Triple valve block DN5 PN420

• Flange connection acc. to DIN EN 61518

• Cutting ring screw connections 12 mm pipe

• Including assembly set

Order no. Planned measures Type

05003065 Isolating unit amplifier 1-channel 24 V DC TS500Ex-ia-1R-5

05003066 Isolating unit amplifier 2-channel 24 V DC TS500Ex-ia-2R-5

05003083 Isolating unit amplifier 1-channel 230 V AC TS500Ex-ia-1R-0

05003084 Isolating unit amplifier 2-channel 230 V AC TS500Ex-ia-2R-0

05003070 Universal supplier isolator ST500Ex-10-5

05003086 Universal supplier isolator ST500Ex-10-0

1.4571

BA_EN_DA01_VUW 29 / 32

Page 30

8 | EU Declarations of conformity FISCHER Mess- und Regeltechnik GmbH

8 EU Declarations of conformity

Fig.29: CE_EN_DA01_10

30 / 32 BA_EN_DA01_VUW

Page 31

FISCHER Mess- und Regeltechnik GmbH EU Declarations of conformity | 8

Fig.30: CE_EN_DA01_20

BA_EN_DA01_VUW 31 / 32

Page 32

9 | EAC Declaration FISCHER Mess- und Regeltechnik GmbH

9 EAC Declaration

Fig.31: ЕАЭС N RU Д-DЕ.АЛ16.В.77754

32 / 32 BA_EN_DA01_VUW

Loading...

Loading...