Page 1

Voyager 3000

10-November-1997

SCSI RAID Storage Array

User’s Manual

MAN-VRA3000UG-1

Revision A4_1

Page 2

Contents

Chapter One...........................................................................................................................1-1

Introduction.......................................................................................................................1-1

Voyager 3000 Family...................................................................................................1-1

VRA-3001T-XX-Y .................................................................................................1-2

VRA-3002T-XX-Y .................................................................................................1-3

VRA-3001R-XX-Y.................................................................................................1-5

VRA-3002R-XX-Y.................................................................................................1-6

Options....................................................................................................................1-7

System Features............................................................................................................1-7

Device Carrier.........................................................................................................1-7

Cooling....................................................................................................................1-7

RAID Controller......................................................................................................1-7

Power Supplies........................................................................................................1-8

SCSI Connectors .....................................................................................................1-8

RAID Basics.................................................................................................................1-9

RAID 0....................................................................................................................1-9

RAID 1 / 0+1...........................................................................................................1-9

RAID 3..................................................................................................................1-10

RAID 5..................................................................................................................1-10

Required Number of Drives and Net Capacity......................................................1-10

Chapter Two...........................................................................................................................2-1

Installation and Setup........................................................................................................2-1

Unpacking and Initial Setup.........................................................................................2-1

Recommendations for installation of rackmount systems in 19” racks........................2-1

Ambient Temperature..............................................................................................2-1

Air Flow ..................................................................................................................2-1

Mechanical Loading................................................................................................2-1

Electrical Considerations.........................................................................................2-2

Grounding ...............................................................................................................2-2

Setting the host SCSI Ids..............................................................................................2-3

Setting the target SCSI Ids ...........................................................................................2-3

Setting the target SCSI Ids on a VRA-3001 system.................................................2-3

Setting the target SCSI Ids on a VRA-3002 system.................................................2-5

Cabling and Termination Issues...................................................................................2-8

Components .................................................................................................................2-9

Power Supplies........................................................................................................2-9

Devices....................................................................................................................2-9

Power Option Board..............................................................................................2-10

Controller ..............................................................................................................2-10

Advanced Cooling Modules..................................................................................2-12

Component Insertion and removal .............................................................................2-13

Drive Insertion.......................................................................................................2-13

Drive Removal ......................................................................................................2-13

PSU Insertion and Removal ..................................................................................2-14

Controller Insertion and Removal..........................................................................2-14

Chapter Three.........................................................................................................................3-1

EMU .................................................................................................................................3-1

Environmental Monitoring Unit Configurations..........................................................3-1

Introduction.............................................................................................................3-1

ii

Page 3

EMU Features .........................................................................................................3-1

System Configurations.................................................................................................3-2

Setting up the EMU.................................................................................................3-3

Available EMU information....................................................................................3-5

Interpreting the EMU LED Feedback......................................................................3-6

Connecting the EMU ...................................................................................................3-7

Chapter Four..........................................................................................................................4-1

RAID controller configuration ..........................................................................................4-1

Controller Description..................................................................................................4-1

Controller Configuration..............................................................................................4-1

Accessing the VOYAGER 3000 Menus.......................................................................4-2

Connecting a Monitor .............................................................................................4-2

Creating a logical volume........................................................................................4-6

Creating a Second Logical Volume............................................................................4-11

Adding a Global Spare...............................................................................................4-12

Partitioning a Logical Volume ...................................................................................4-13

Mapping Host LUNs..................................................................................................4-14

De-assigning LUN Mapping......................................................................................4-16

Scan New SCSI Drives...............................................................................................4-16

View and Edit logical drives......................................................................................4-17

View and Edit SCSI Drives........................................................................................4-17

View and Edit SCSI Channels....................................................................................4-18

View and Edit Configuration Parameters ................................................................... 4-20

View and Edit Peripheral Devices..............................................................................4-21

System Functions.......................................................................................................4-21

Down Loading New Firmware ...................................................................................4-21

View System Information...........................................................................................4-22

Quick Installation.......................................................................................................4-22

Chapter Five...........................................................................................................................5-1

Front Panel Operation .......................................................................................................5-1

Creating a New Logical Drive......................................................................................5-1

Viewing Disks Assigned to a Logical Drive.................................................................5-2

Assigning a Spare Drive...............................................................................................5-3

Mapping a Logical Drive to a Host Channel and LUN ...............................................5-3

Deleting a Logical Drive .........................................................................................5-4

Setting the SCSI Channels ...........................................................................................5-4

Channel Terminator Setting ...................................................................................5-5

SCSI Reset at Power-Up Setting .............................................................................5-6

Sequential Drive Spin-Up Setting ...........................................................................5-6

Data Cache Setting..................................................................................................5-6

Viewing Connected Drives...........................................................................................5-6

Adding New Drives into Current List ..........................................................................5-7

Issuing a Reset..............................................................................................................5-7

Serial Number ..............................................................................................................5-7

Download Firmware.....................................................................................................5-7

iii

Page 4

Figures

Figure 1-1 VRA-3001T-XX-Y Single Tower.........................................................................1-2

Figure 1-2 Internal bus configuration of VRA-3001T-XX-Y.................................................1-3

Figure 1-3 VRA-3002T-XX-Y Twin Tower ..........................................................................1-3

Figure 1-4 VRA-3002T-XX-Y SCSI target interconnects......................................................1-4

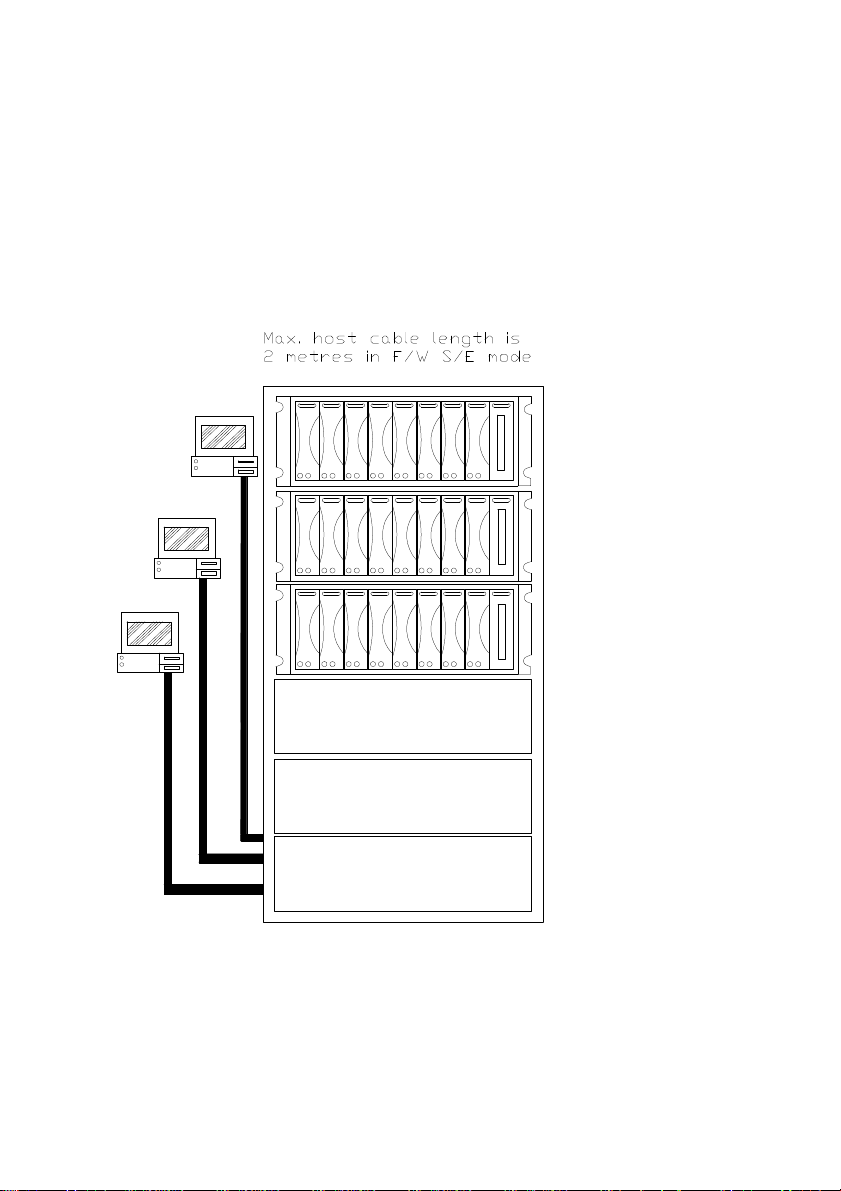

Figure 1-5 VRA-3001R-FW-Y example configuration..........................................................1-5

Figure 1-6 VRA-3002R-FW-Y example configuration..........................................................1-6

Figure 1-7 Device Carrier ......................................................................................................1-7

Figure 1-8 PSU mounted in removable canister.....................................................................1-8

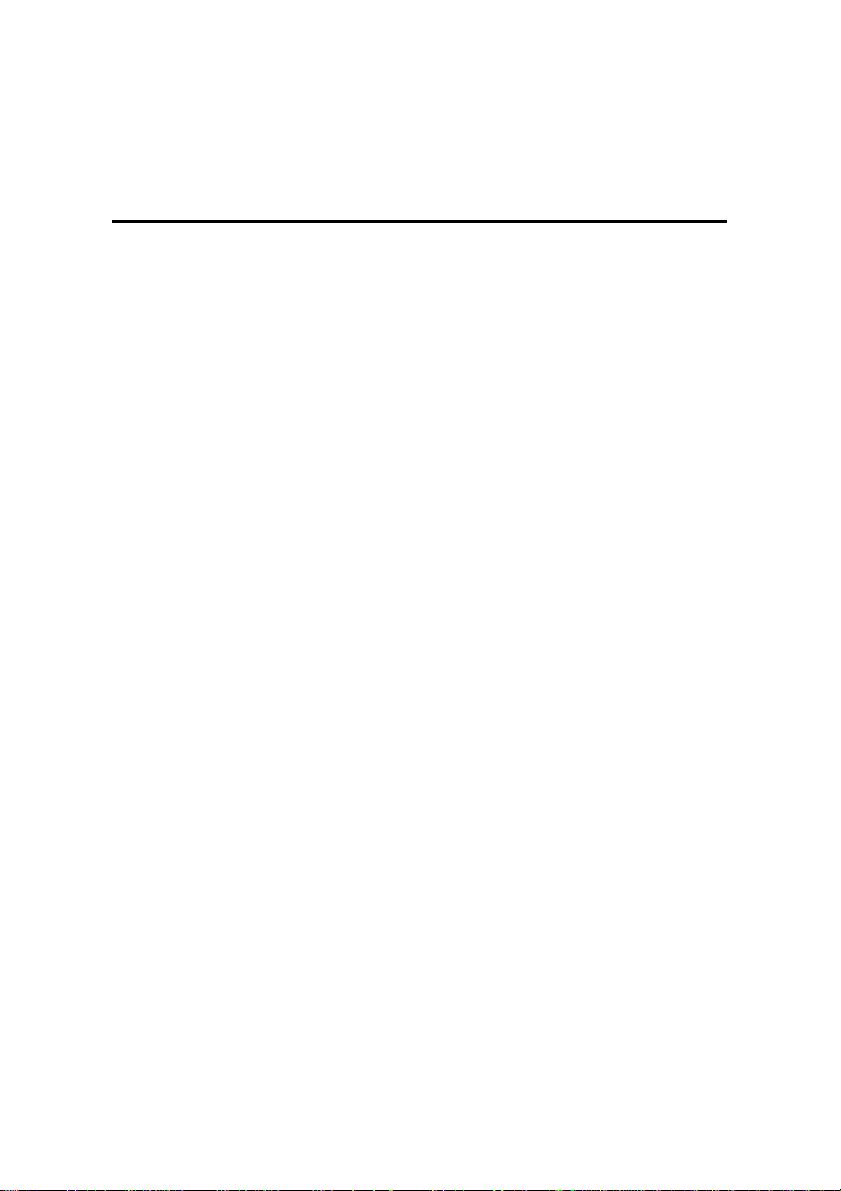

Figure 2-1 Grounding shelves within a 19" cabinet...............................................................2-2

Figure 2-2 Rear view of rack showing ground point..............................................................2-3

Figure 2-3 Rear view of single tower showing host connections............................................2-4

Figure 2-4 Rear view showing ACMs, cowl and shield.........................................................2-4

Figure 2-5 Setting the Target Bus SCSI IDs...........................................................................2-5

Figure 2-6 Setting the RAID Target Bus SCSI IDs................................................................2-5

Figure 2-7 Location of DPS1 on VRA-3002 second backplane.............................................2-6

Figure 2-8 SCSI ID Switch (DPS1)........................................................................................2-7

Figure 2-9 Removal and insertion of a Power Supply Unit...................................................2-9

Figure 2-10 Device carrier .....................................................................................................2-9

Figure 2-11 RAID Controller...............................................................................................2-11

Figure 2-12 Main board access............................................................................................2-11

Figure 2-13 Installing SIMMs..............................................................................................2-12

Figure 2-14 Removing the back face plate...........................................................................2-12

Figure 2-15 Rear view of ACM assembly............................................................................2-13

Figure 3-1 Single shelf EMU configuration...........................................................................3-2

Figure 3-2 Dual shelf EMU configuration .............................................................................3-2

Figure 3-3 Location of EMU within the shelf........................................................................3-3

Figure 3-4 EMU PCB layout..................................................................................................3-3

Figure 3-5 Connecting the EMUs together ...........................................................................3-7

Figure 4-1 Front view of controller (within a canister) ..........................................................4-1

Figure 4-2 Logical View of VOYAGER 3001.......................................................................4-2

Figure 4-3 Windows Program Manager.................................................................................4-3

Figure 4-4 Windows Terminal Program (Main Menu)...........................................................4-3

Figure 4-5 Setting Windows Terminal Emulation..................................................................4-4

Figure 4-6 Setting Windows Terminal Preferences................................................................4-4

Figure 4-7 Windows Terminal Preferences Screen ................................................................4-5

Figure 4-8 Windows Terminal Communications Settings......................................................4-5

Figure 4-9 Windows Terminal Communication Settings.......................................................4-6

Figure 4-10 Initial Screen.......................................................................................................4-7

Figure 4-11 Main Menu Screen .............................................................................................4-7

Figure 4-12 Verifying Drive Configuration ...........................................................................4-8

Figure 4-13 View and edit Logical Drives Screen..................................................................4-8

Figure 4-14 Creating a logical drive.......................................................................................4-9

Figure 4-15 Selecting the logical drive's RAID level .............................................................4-9

Figure 4-16 Selecting drives for inclusion in a RAID set.....................................................4-10

Figure 4-17 Setting the maximum drive capacity. ...............................................................4-10

Figure 4-18 Logical drive creation confirmation screen.......................................................4-10

Figure 4-19 Progress of RAID set creation...........................................................................4-11

Figure 4-20 Creating a RAID 1 volume...............................................................................4-11

iv

Page 5

Figure 4-21 Selecting two drives to form a RAID 1 set .......................................................4-11

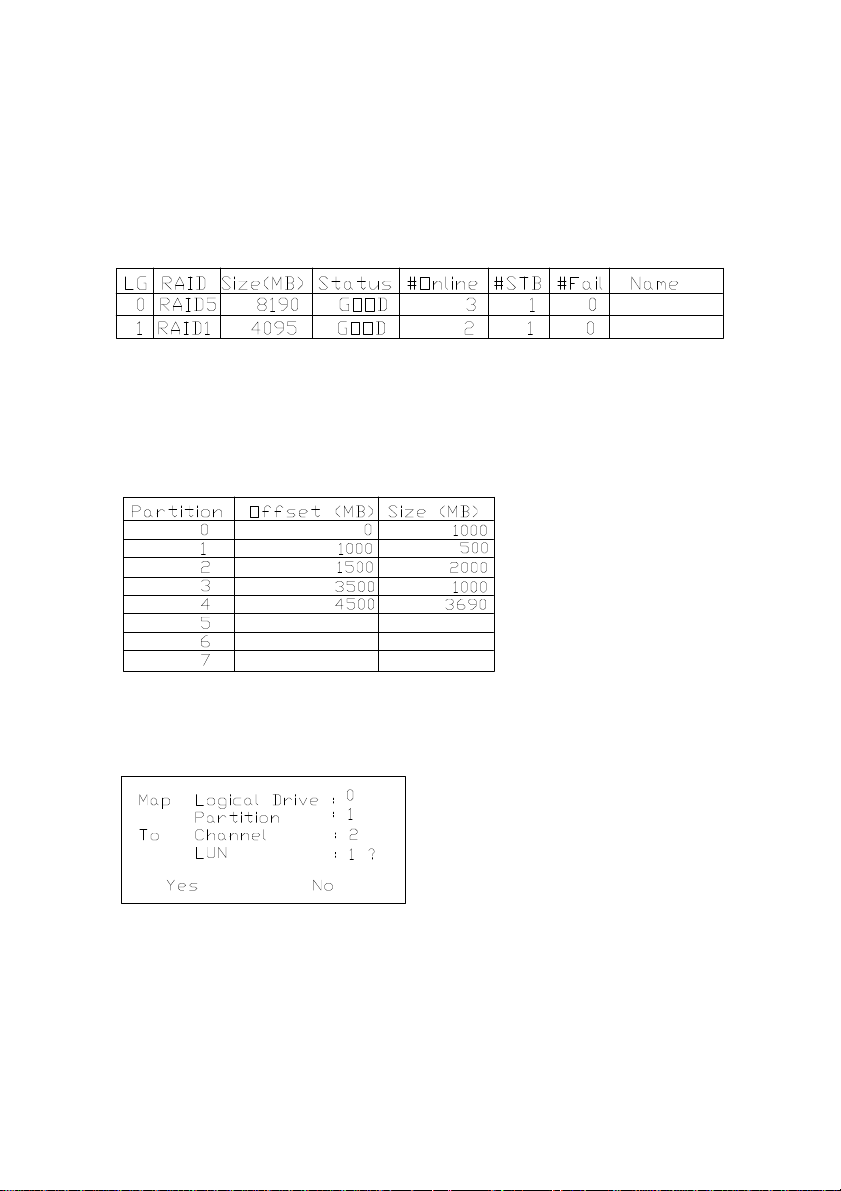

Figure 4-22 Viewing all Logical Drives..............................................................................4-12

Figure 4-23 Adding Global Spare drive..............................................................................4-12

Figure 4-24 Allocating Capacities to partitions....................................................................4-13

Figure 4-25 Logical Drive Partition Table ...........................................................................4-13

Figure 4-26 Allocating capacities to partitions ....................................................................4-13

Figure 4-27 Mapping Host LUNs .......................................................................................4-14

Figure 4-28 LUN Partition table .........................................................................................4-14

Figure 4-29 Selecting a Volume for LUN mapping .............................................................4-15

Figure 4-30 Selecting a partition for LUN mapping ............................................................4-15

Figure 4-31 Mapping Logical Volume 0 Partition 1 to Channel 2 LUN 1...........................4-15

Figure 4-32 Logical mapping of all partitions......................................................................4-16

Figure 4-33 List and status of drives on system...................................................................4-16

Figure 4-34 Scanning SCSI drives......................................................................................4-16

Figure 4-35 View and edit scsi drives..................................................................................4-17

Figure 4-36 View and edit SCSI channels............................................................................4-18

Figure 4-37 View and edit SCSI target ................................................................................4-19

Figure 4-38 View and edit configuration parameters...........................................................4-20

Figure 4-39 Uploading the code using ZMODEM protocol.................................................4-21

Figure 4-40 View system information..................................................................................4-22

Figure 4-41 Quick Installation .............................................................................................4-22

v

Page 6

Tables

Table 1-1 Voyager 3000 Tower configurations......................................................................1-1

Table 1-2 Voyager 3000 Rackmountable configurations.......................................................1-1

Table 1-3 Voyager 3000 Fault Tolerant configurations .........................................................1-1

Table 1-4 Host Connection Codes .........................................................................................1-2

Table 1-5 RAID 0 layout........................................................................................................1-9

Table 1-6 RAID 0+1 layout....................................................................................................1-9

Table 1-7 RAID 3 layout......................................................................................................1-10

Table 1-8 RAID 5 layout......................................................................................................1-10

Table 1-9 Minimum drives necessary for a RAID set..........................................................1-10

Table 2-1 SCSI ID switch settings for the second backplane in a VRA-3002 configuration. 2-8

Table 2-2 Cable Lengths Vs Transfer Rates...........................................................................2-9

Table 2-3 Device carrier Device Part Numbers....................................................................2-10

Table 2-4 Power Option Board Switch Definitions..............................................................2-10

Table 3-1 EMU Switch Settings.............................................................................................3-4

Table 3-2 ID settings for the EMU........................................................................................3-4

Table 3-3 Power Sequencing Signals.....................................................................................3-5

Table 3-4 Read Only Memory locations within the EMU......................................................3-5

Table 3-5 Read/Write locations within the EMU...................................................................3-5

Table 3-6 Devices/events monitored by the EMU..................................................................3-6

Table 3-7 Interpreting the EMU LED feedback.....................................................................3-6

Table 4-1 RS232 Terminal Settings.......................................................................................4-2

vi

Page 7

Scope

This manual details the installation and configuration of Eurologic’s Voyager 3000 RAID

storage arrays.

vii

Page 8

Disclaimer

EUROLOGIC reserves the right to make changes to this manual and the equipment described

herein without notice. EUROLOGIC has made all reasonable efforts to insure that the

information in this manual is accurate and complete. However, EUROLOGIC shall not be

liable for any technical or editorial errors or omissions made herein or for incidental, special,

or consequential damage of whatsoever nature resulting from the furnishing of this manual, or

operation and performance of equipment in connection with this manual.

All Trademarks acknowledged.

viii

Page 9

Warranty

BASIC WARRANTY—In the absence of any optional warranty or continuing provisions by

formal agreement, EUROLOGIC warrants its products in accordance with the schedules listed

below. Purchaser hereafter mentioned refers at all times to the customer who purchased

EUROLOGIC product(s).

VOYAGER WARRANTY—EUROLOGIC warrants Voyager products of its manufacture to

be free from defect in material and workmanship for a period of one year from the date of

shipment. During this period, if the customer experiences difficulties with a EUROLOGIC

Voyager system and is unable to resolve the problem via phone with EUROLOGIC Technical

Support a Return Material Authorization (RMA) will be issued for the faulty component.

Following receipt of an RMA, the Purchaser is responsible for returning the product to

EUROLOGIC, freight prepaid. EUROLOGIC, upon verification of warranty, will repair or

replace at its option the Voyager component in question, and will then return the product to

the Purchaser, freight prepaid.

CABLE WARRANTY—All EUROLOGIC provided cables are warranted for ninety (90)

days from the time of shipment. Questionable cables should be returned to EUROLOGIC,

freight prepaid where they will be repaired or replaced by EUROLOGIC at its option and

returned to the Purchaser, freight prepaid.

GENERAL TERMS—The above warranties shall not apply to expendable components such

as fuses, bulbs, and the like, nor to connectors, adapters, and other items not a part of the

basic product. EUROLOGIC shall have no obligation to make repairs or to cause replacement

required through normal wear and tear or necessitated in whole or in part by catastrophe, fault

or negligence of the user, improper or unauthorized use of the product, or use of the product in

such a manner for which it was not designed, or by causes external to the product, such as, but

not limited to, power failure or air conditioning. EUROLOGIC's sole obligation hereunder

shall be to repair or replace any defective product, and, unless stated, pay return transportation

costs for such replacement. Purchaser shall provide labor for removal of the defective

product, shipping charges for return to EUROLOGIC and installation of its replacement. Onsite services are not a part of this warranty. Above warranties are subject to change without

notice.

RETURNED MATERIAL—Warranty claims must be received by EUROLOGIC within the

applicable warranty period. A replaced product, or part thereof, shall become the property of

EUROLOGIC and shall be returned to EUROLOGIC at Purchaser's expense. All returned

material must be accompanied by a Return Materials Authorization (RMA) number assigned

by EUROLOGIC. For RMA numbers contact EUROLOGIC at :

Telephone + 353 -1-2958366

FAX + 353-1-2958433

e-mail rma@eurologic.com

ix

Page 10

THE EXPRESSED WARRANTIES SET FORTH IN THIS AGREEMENT ARE IN LIEU OF

ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION, ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, AND ALL SUCH OTHER WARRANTIES ARE HEREBY

DISCLAIMED AND EXCLUDED BY EUROLOGIC. THESE STANDARD EXPRESS

WARRANTIES ARE IN LIEU OF ALL OBLIGATIONS OR LIABILITIES ON THE PART

OF EUROLOGIC FOR DAMAGES, INCLUDING BUT NOT LIMITED TO SPECIAL,

INDIRECT OR CONSEQUENTIAL DAMAGES ARISING OUT OF OR IN CONNECTION

WITH THE USE OR PERFORMANCE OF THE PRODUCT.

x

Page 11

Chapter One

Introduction

Voyager 3000 Family

The Voyager 3000 is a cost effective open architecture RAID solution. All Voyager 3000

systems include 8MB EDO cache memory, redundant power supplies (PSUs) and dual

advanced cooling modules (ACM’s) per shelf as standard. The Voyager 3000 series is

available in tower, rackmount and fault tolerant solutions1 . The model number and

descriptions are shown in Table 1-1, Table 1-2 and Table 1-3. The XX suffix refers to the host

connection and a key is shown in Table 1-4. The “Y” suffix refers to the power supply voltage

where a value of “1” is the 110V option and a value of “2” is the 220/240V option.

Components such as disk drives, power supplies and controllers are housed in easily

removable canisters which make up the base building blocks of the system. A shelf consists of

nine bays housing nine of these canisters. A shelf is mounted vertically in the single and dual

tower configurations and horizontally in the case of rackmounted systems.

The Voyager 3000 includes an integrated RAID controller which is independent of the host

system and only requires a host SCSI bus for connectivity.

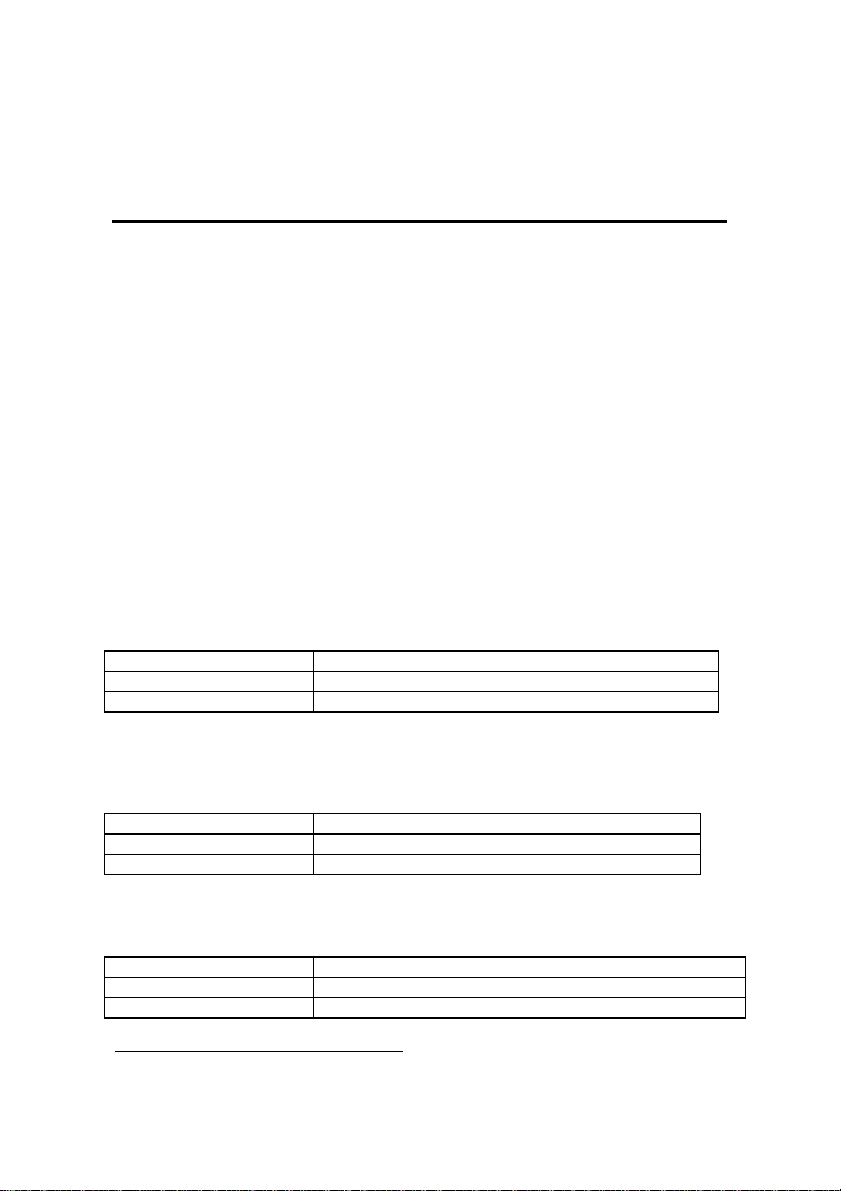

The Voyager 3000 tower configurations are:

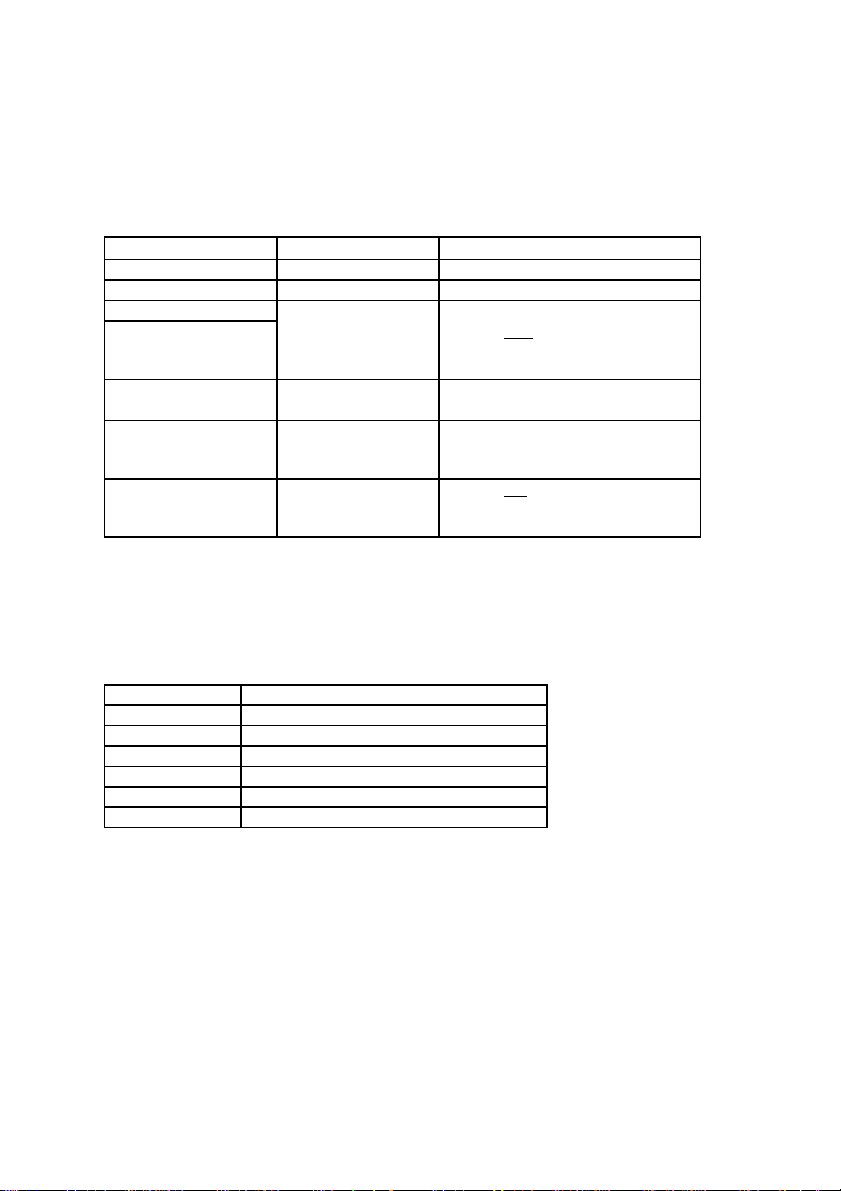

Table 1-1 Voyager 3000 Tower configurations

Model Number Description

VRA-3001T-XX-Y Single tower RAID, 6 storage bays, 1 controller, 1 host

VRA-3002T-XX-Y Twin tower RAID, 13 storage bays, 1 controller, 1 host

The Voyager 3000 rackmountable configurations are:

Table 1-2 Voyager 3000 Rackmountable configurations

Model Number Description

VRA-3001R-XX-Y Single shelf RAID, 6 storage bays, 1 controller, 1 host

VRA-3002R-XX-Y Twin shelf RAID, 13 storage bays, 1 controller, 1 host

The Voyager 3000 fault tolerant solutions are:

Table 1-3 Voyager 3000 Fault Tolerant configurations

Model Number Description

VRA-3002TFT-XX-Y Twin tower RAID, 12 storage bays, 2 controllers, 1 host

VRA-3002RFT-XX-Y Rackmount shelf RAID, 12 storage bays, 2 controllers, 1 host

1

This a future option. Contact Eurologic for availability.

Page 12

Voyager 3000 User Guide

Table 1-4 Host Connection Codes

FW Fast Wide single ended

FWD Fast wide differential

UW Ultra SCSI wide

UD Ultra SCSI wide differential

VRA-3001T-XX-Y

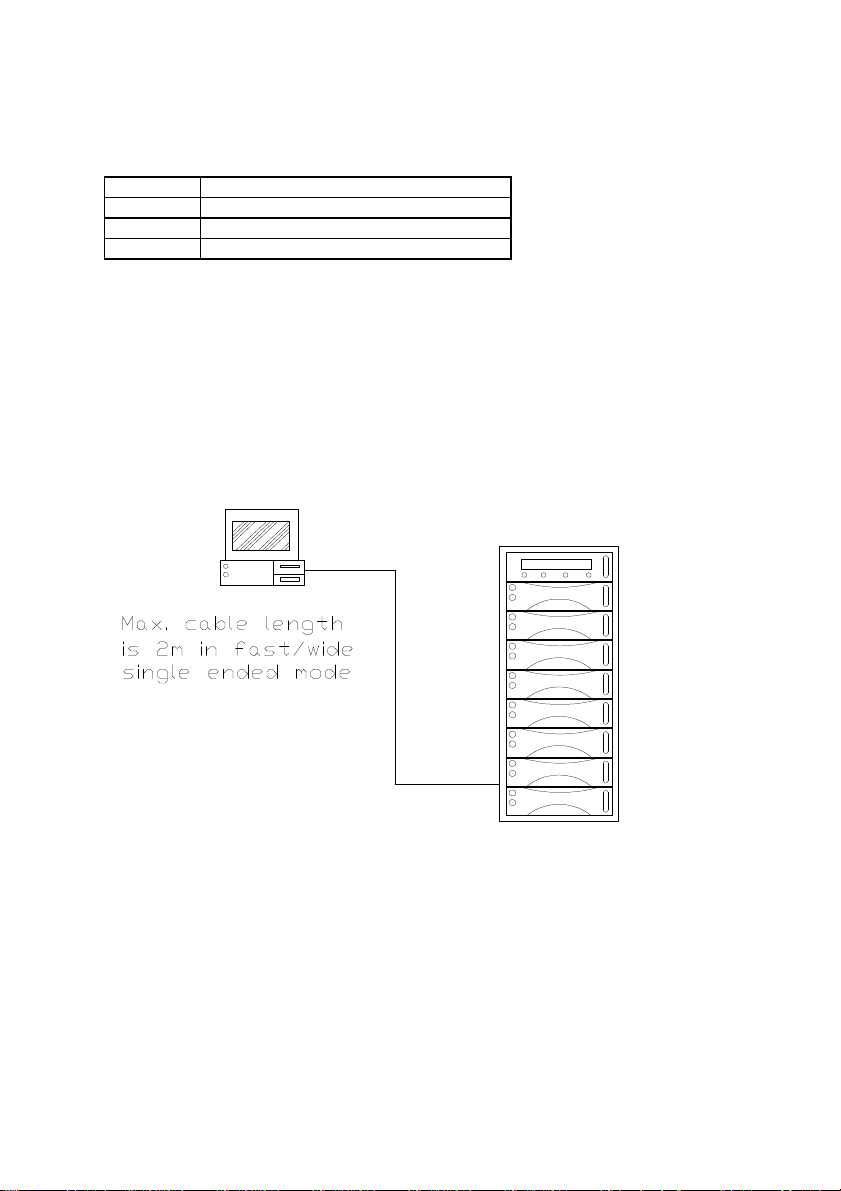

The VRA-3001T-XX-Y is typically used as an entry level RAID system where a large data

capacity is not required. The RAID controller is separate to the host system and is platform

independent. It is mandatory that a SCSI bus is available at the host side which will connect to

the host interface of the controller. A maximum external cable length between the VRA3001T-XX-Y and the host system is two metres in fast/wide single ended mode. Figure 1-1

shows the VRA-3001T-XX-Y configured as a single tower unit connected to a single host

system.

Figure 1-1 VRA-3001T-XX-Y Single Tower

The drives are connected to the RAID controller via two drive interfaces as shown in Figure 1-

2. The top three drives are connected to the first drive channel and the bottom three drives are

connected to the second drive channel.

1-2

Page 13

Introduction

Figure 1-2 Internal bus configuration of VRA-3001T-XX-Y

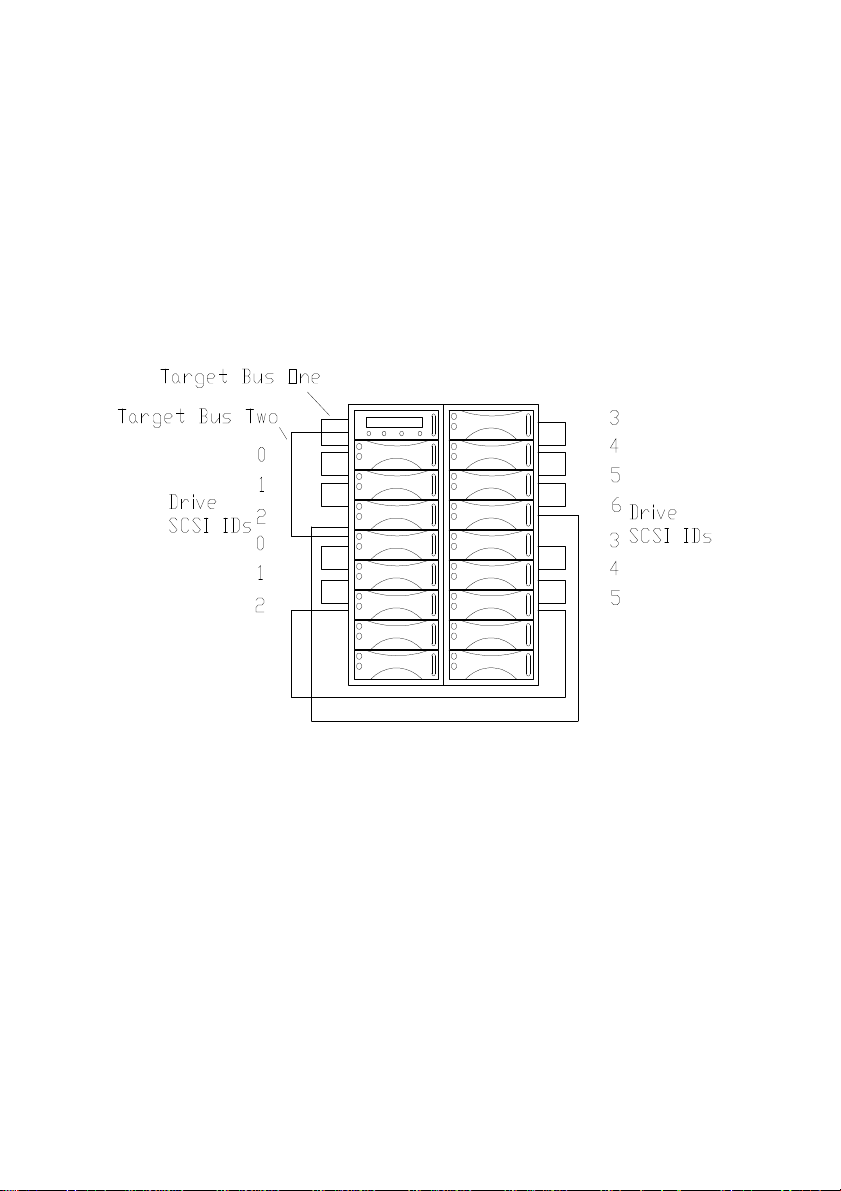

VRA-3002T-XX-Y

This is a twin tower RAID configuration made up of a single controller and 13 drives as

shown in Figure 1-3.

Figure 1-3 VRA-3002T-XX-Y Twin Tower

1-3

Page 14

Voyager 3000 User Guide

This system will typically be used in similar situations to that described within the VRA3001T-XX-Y section on page 1-2 but with larger capacity requirements.

The VRA-3002T-XX-Y is configured as two SCSI buses. The first SCSI channel is connected

to the top three drives in the first shelf (left hand side) which are set up as SCSI Ids 0à2. The

cable is then routed to the top four drives in the second shelf. These drives are set up as SCSI

Ids 3à6. The second channel is connected to the bottom three drives in the first shelf which

are configured as SCSI Ids 0à2 and looped to the second shelf to connect to the bottom three

drives which are set up at SCSI Ids 3à5. Refer to Figure 1-4 for a schematic view of the

interconnects. Each of the systems described are also available with differential host SCSI

buses giving an overall host cable length of 25 metres.

Figure 1-4 VRA-3002T-XX-Y SCSI target interconnects

1-4

Page 15

Introduction

VRA-3001R-XX-Y

This system will be used in a rackmount configuration and will normally be part of an

expandable system. Customers can add rackmount systems subject to cabinet limitations.

Figure 1-5 shows three systems mounted in a standard 19” cabinet. Each shelf is similar in

configuration to the VRA-3001T-XX-Y described earlier and is made up of six storage bays, a

single host connection and one RAID controller. The shelves take 3 U of cabinet space. Each

system is connected to a shelf via its own SCSI bus.

Figure 1-5 VRA-3001R-FW-Y example configuration

1-5

Page 16

Voyager 3000 User Guide

VRA-3002R-XX-Y

This system is similar to the VRA-3002T-XX-Y and is used for expandable storage. Each

shelf has a measurement of 3 U and may easily be integrated into a standard 19” rackmount

system. The system is made up of twin shelves, 13 storage bays, a single host connection and

one RAID controller. Figure 1-6 shows two hosts connected to two VRA-3002R-XX-Y

systems. In this and the previous case the hosts are completely separate entities and do not

share the data in any way.

Figure 1-6 VRA-3002R-FW-Y example configuration

1-6

Page 17

Introduction

Options

RCM-RC1-CD Vision Software - Availability to be announced

VSA-401TE-Y Single tower expansion kit for VRA-3001T - 1 shelf, 7

storage bays

VSA-401RE-Y Single rackmountable expansion kit for VRA-3001R - 1

shelf, 7 storage bays

MEM-72P016MEDO-60 16 MB EDO SIMM module for Voyager 3000 series

MEM-72P032MEDO-60 32 MB EDO SIMM module for Voyager 3000 series

System Features

Device Carrier

Front loaded components such as the RAID controller and disk drives are housed in easily

removable device carriers. The device carrier is the basic building block of the series. The

device carriers are of high quality anodised metal construction. This allows for rapid heat

dissipation and conforms to the stringent requirements of CE, UL and FCC standards.

Figure 1-7 shows the device carrier.

Figure 1-7 Device Carrier

Cooling

All models feature two Advanced Cooling Modules (ACMs) per shelf. The modules are

mounted at the rear of the unit. One ACM is capable of cooling an entire shelf in the event of

a module failure.

RAID Controller

The VOYAGER 3000 controller’s main features are:

• Five operating modes:

Non-RAIDDisk Spanning

RAID-0 Striping

RAID-1 Mirroring

RAID-3 Block Striping w/ Dedicated Parity

RAID-5 Multiple Block Striping w/ Distributed Parity

1-7

Page 18

Voyager 3000 User Guide

• Comprehensive failure management including:

Automatic bad sector reassignment

Hot-swapping

Global and Local Spare drive operation

Background rebuilding

• Works with any operating system without additional software drivers.

• Four types of daughter board:

--ELRC-9021WS: Wide, single-ended, 1 SCSI channel

--ELRC-9021WD: Wide, differential, 1 SCSI channel

--ELRC-9051UW: Ultra wide single-ended, 1 SCSI channel

--ELRC-9051UD: Ultra wide differential, 1 SCSI channel

• Up to 8 logical drives, each with independent RAID mode.

• Up to 8 partitions per logical drive2.

• Compatible and will automatically match any SCSI hard disks with SCSI-1, SCSI-2 or

Fast SCSI specification.

• Full SCSI-2 implementation including Tagged Command Queuing and Multi-Threaded

I/O.

• Uses 486 CPU with all executable firmware downloaded into high-speed DRAM.

• Firmware resides in easy-to-update Flash Memory.

• Up to 32 Mbytes of intelligent Read-Ahead/Write-Back cache.

• Front panel LCD and push buttons for configuration and message display.

• RS-232 interface for monitoring and configuration via a terminal.

Power Supplies

The VOYAGER 3000 uses two high performance power supply units per backplane. A single

power supply is rated at 180 Watts. Each power supply is rated at greater than 500,000 hours

MTBF with a second power supply providing full redundancy capabilities. The Power supply

units are housed in bays 8 through 9 within the cabinet and are mounted in removable shuttles

for ease of maintenance. Figure 1-8 shows a Power Supply Unit housed in the canister.

Figure 1-8 PSU mounted in removable canister

SCSI Connectors

SCSI connectors are of two types -

1. 68 Way MicroD High Density connectors for connection to external hosts.

2. SCA2 for internal peripheral connections.

2

A total maximum of eight logical drives are allowed e.g. 1 logical drive with eight partitions, 2 logical drives

with 4 partitions each etc.

1-8

Page 19

Introduction

The industry standard SCA2 connector is used to interface between the device and the

backplane. SCA features staggered contact pins and insertion guidance. All signals such as

SCSI, Ids, Power etc. are carried through the SCA. This lowers cost, enhances reliability and

fully conforms to the Ultra SCSI specification.

RAID Basics

RAID stands for Redundant Array of Independent Disks3. Some of the advantages of using a

RAID storage subsystem are:

• Provides disk spanning by weaving all connected drives into one single volume.

• Increases disk access speed by breaking data into several blocks for reading/writing it to

several drives in parallel. With RAID, storage speed increases as more drives are added.

Without RAID, the speed slows down as more drives are installed.

• Provides fault-tolerance by mirroring or parity operation.

RAID 0

Block Striping - Data is broken into logical blocks, the size of a SCSI disk block, and striped

across several drives.

Drive 0 Drive 1 Drive 2 Drive 3 Drive 4

A0 A1 A2 A3 A4

B0 B1 B2 B3 B4

C0 C1 C2 C3 C4

D0 D1 D2 D3 D4

Table 1-5 RAID 0 layout

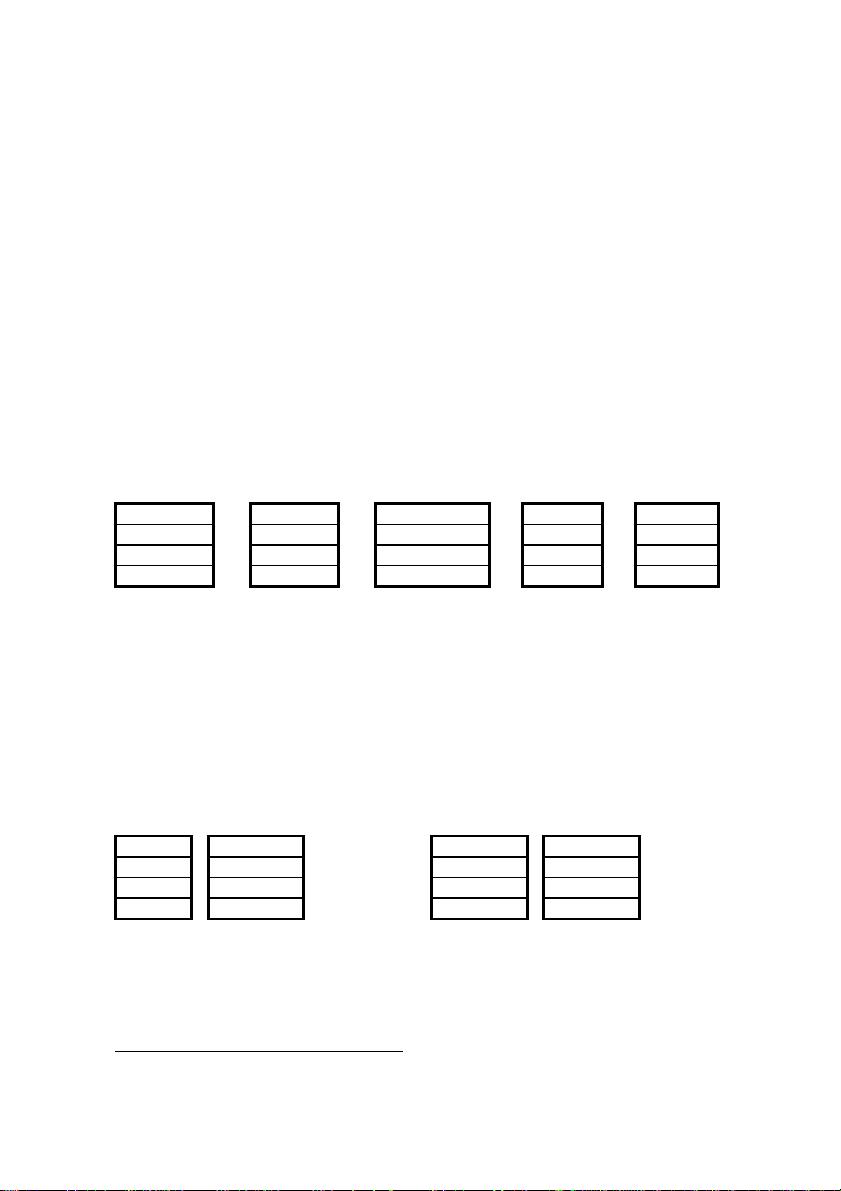

RAID 1 / 0+1

Mirroring and Striping - Copy of the same data is recorded into sets of striping drives. In the

event of failure, the duplicate set continues operation. Two drives implies a pure RAID 1

solution without the possibility of striping the mirrored drives. The equivalent capacity will be

that of a single drive. Four drives will appear with the layout as shown in Table 1-6 with the

equivalent capacity of two drives. Six drives will have the equivalent capacity of three drives

and so on. An even number of drives is required for this RAID level.

Table 1-6 RAID 0+1 layout

Set 1 Set 2

Drive 0 Drive 1 Drive 0 Drive 1

A0 A1 A0 A1

A2 A3 A2 A3

A4 B0 A4 B0

B1 B2 B1 B2

3

RAID Advisory Board Definition

1-9

Page 20

Voyager 3000 User Guide

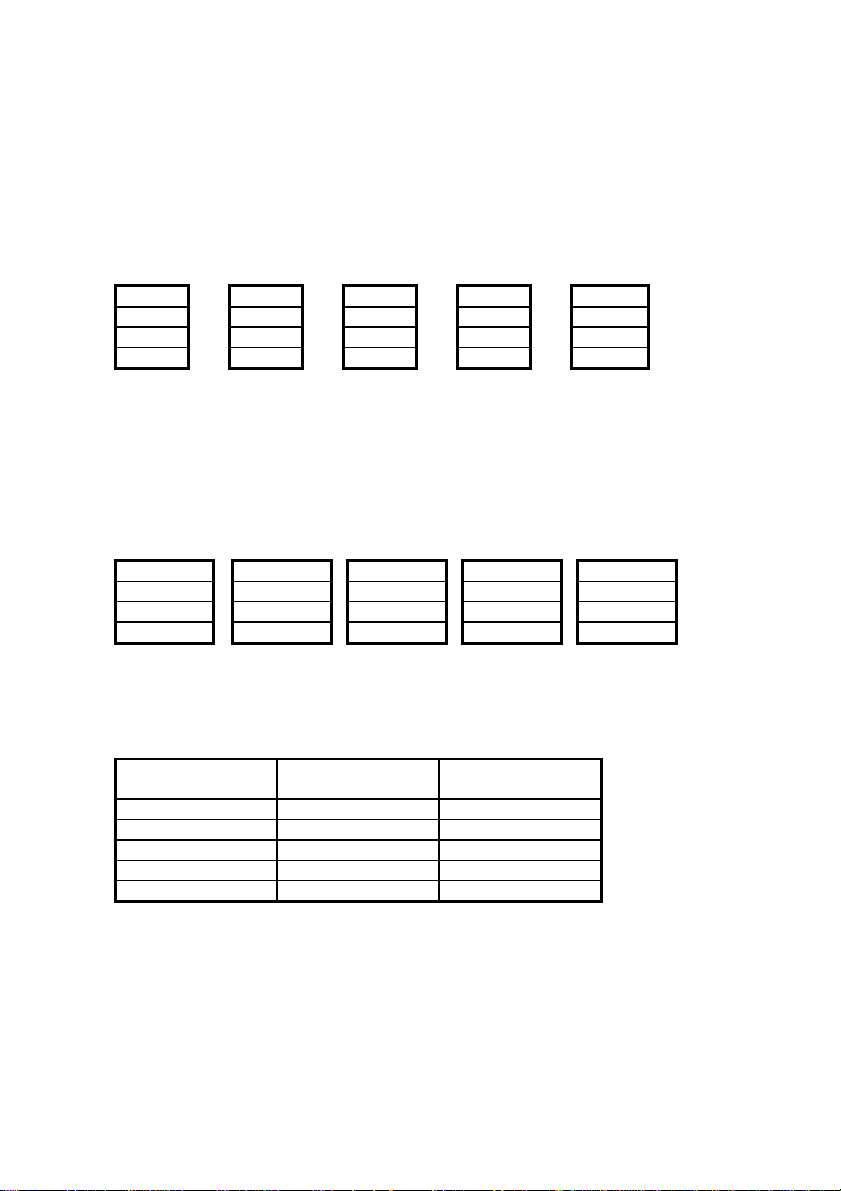

RAID 3

Block Striping with Dedicated Parity - Data is broken into logical blocks, the size of a SCSI

disk block, and striped across several drives. One drive is dedicated to parity. In the event of

failure, original data is re-generated from the parity information.

Table 1-7 RAID 3 layout

Drive 0 Drive 1 Drive 2 Drive 3 Drive 4

A0 A1 A2 A3 P

A4 B0 B1 B2 P

B3 B4 C0 C1 P

C2 C3 C4 D0 P

RAID 5

Multiple Block Striping with Distributed Parity - Sets a given number of logical blocks as a

unit for striping across several drives. For small read/write operations, one drive may be

activated for improved small record access speed. In this case we can process multiple I/O

requests simultaneously. Parity information is interleaved across the drive array. In the event

of failure, original data is regenerated from the parity information.

Table 1-8 RAID 5 layout

Drive 0 Drive 1 Drive 2 Drive 3 Drive 4

A0-A1 A2-A3 A4-B0 B1-B2 P

B3-B4 C0-C1 C2-C3 P C4-D0

D1-D2 D3-D4 P E0-E1 E2-E3

E4-F0 p F1-F2 F3-F4 G0-G1

Required Number of Drives and Net Capacity

The following table gives a summary of the minimum number of drives required and the

capacity available for the different types of RAID operation:

Table 1-9 Minimum drives necessary for a RAID set

OPERATION MIN. DRIVES

REQUIRED

RAID 0 2 T

RAID 1 2 T / 2

RAID 0 + 1 4 T / 2

RAID 3 3 T x (n - 1) / n

RAID 5 3 T x (n - 1) / n

CAPACITY

AVAILABLE

T = Sum of the capacity of all connected drives

n = Number of connected drives

1-10

Page 21

Chapter Two

Installation and Setup

Unpacking and Initial Setup

On receipt of the system visually inspect the exterior of the packaging for any signs of

damage. If any damage is found the carrier and Eurologic must be notified immediately who

will advise you of the appropriate action. The cartons are sealed via packaging tape which

should be cut open in the normal manner. Remove the top foam layer from each box and

exercise caution when lifting out the components. At this point the contents should be verified

against the packing list and Eurologic should again be notified immediately if any

discrepancies exist. The devices and power supply units are packaged in anti-static packaging

and anti-static precautions must be observed prior to removal. The devices and power supply

units can now be inserted into the tower or shelf.

Prior to applying system power verify that the SCSI IDs are set up correctly as described in

Setting the SCSI IDs and that there is no conflict with any other devices on the SCSI bus.

Verify that the external cabling considerations have been met as described in Cabling and

termination issues.

Recommendations for installation of rackmount systems in

19” racks

It is essential that the following guidelines be complied with to ensure the safe and efficient

operation of VOYAGER 3000 rackmount computer equipment. Eurologic’s rackmount

systems may be installed in closed or open rackmount systems by observing the

environmental, electrical and mechanical precautions listed.

Ambient Temperature

Installation of rackmount systems in standard 19” cabinetry may lead to a differential between

the room ambient temperature and the internal ambient temperature of the rack environment.

The maximum operating temperature of the Voyager 3000 is 40 degrees centigrade, however

it is not recommended that the system is continuously run at these elevated temperatures.

Consideration should therefore be given to ensuring that the room ambient is compatible with

these specifications.

Air Flow

To ensure that the internal heat build up is adequately dissipated into the room environment,

air flow should in no way be restricted. It is essential that no vents or ducts are blocked, that

the system is a minimum of 1 metre away from a solid surface such as a wall or partition.

Airflow through the VOYAGER 3000 shelves is from front to rear.

Mechanical Loading

Consideration should be given to the loading of the cabinet. To maintain a low centre of

gravity (thus reducing the likelihood of instability) racks should be installed (where possible)

from the bottom of the cabinet upwards. This is essential to ensure personnel safety.

Page 22

Voyager 3000 User Guide

Electrical Considerations

Circuit Overloading

Care should be taken to ensure that the current does not exceed the rating of the power source

circuitry. This includes cabling, power distribution units, filters and any other components

through which the main A/C flows. The power requirements of the Voyager 3000 shelf is

1Amp @200Volts and 2A @100Volts4 and must be added to the power demands of any other

electrical devices installed in the cabinet to arrive at a total power consumption figure. In

addition surge currents must be catered for. Disk devices normally consume twice the amount

of current at start up time as they do during steady state operation.

Grounding

Eurologic recommends that all rackmounted shelves be grounded to a common point in the

cabinet in a radial topology as shown in Figure 2-1.

Figure 2-1 Grounding shelves within a 19" cabinet

4

This figure may vary slightly depending on the redundancy mechanisms incorporated, the number of device

bays occupied and the device type occupying the bays.

2-2

Page 23

Installation and Setup

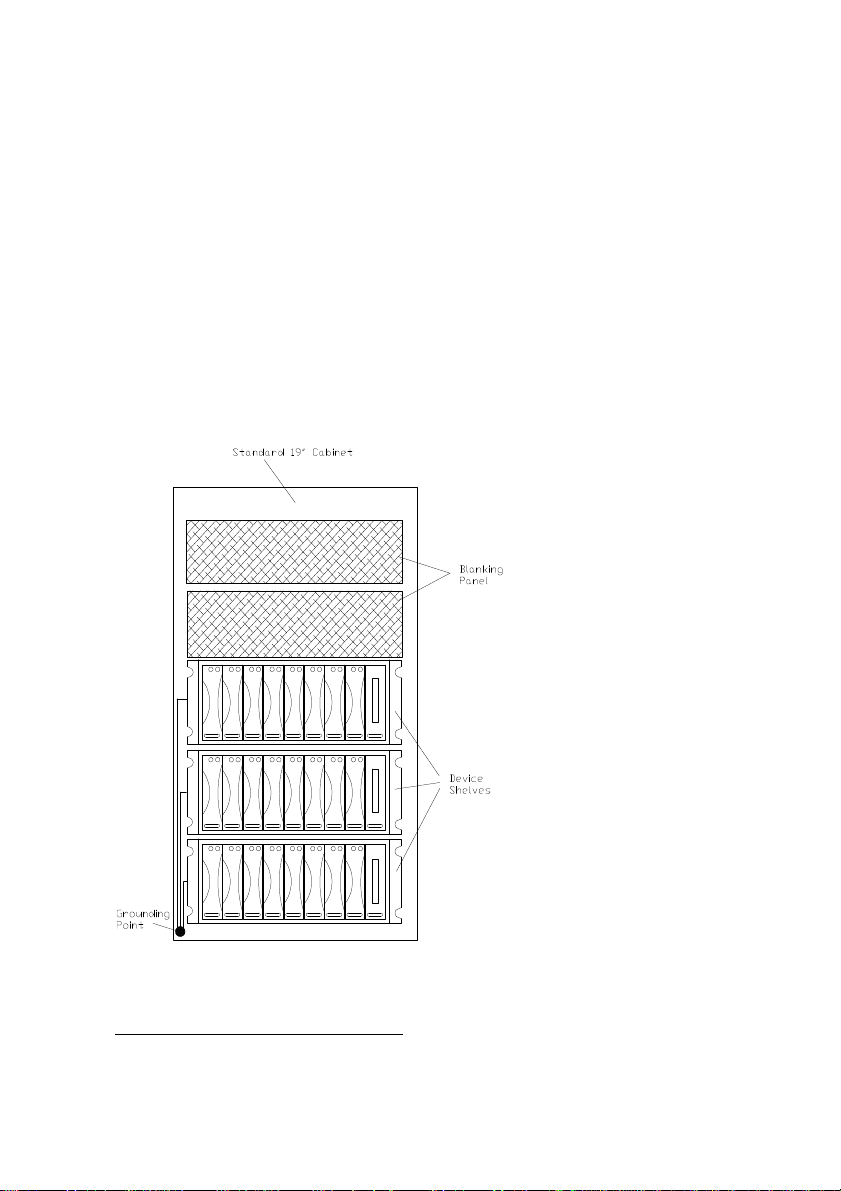

A ground point for securing the braid is provided at the rear of the rack and is shown in Figure

2-2.

Figure 2-2 Rear view of rack showing ground point

Setting the host SCSI Ids

For information relating to setting up the host ID refer to page 4-18.

Setting the target SCSI Ids

This section refers to configuration of the SCSI target bus IDs on the backplane. These are

factory set when the system is shipped and should not normally be altered.

Setting the target SCSI Ids on a VRA-3001 system

There are two single switches mounted on the backplane and they are used to set the SCSI IDs

of both target buses . The switches which are accessible from the rear of the units sets the base

SCSI ID's for each bus.

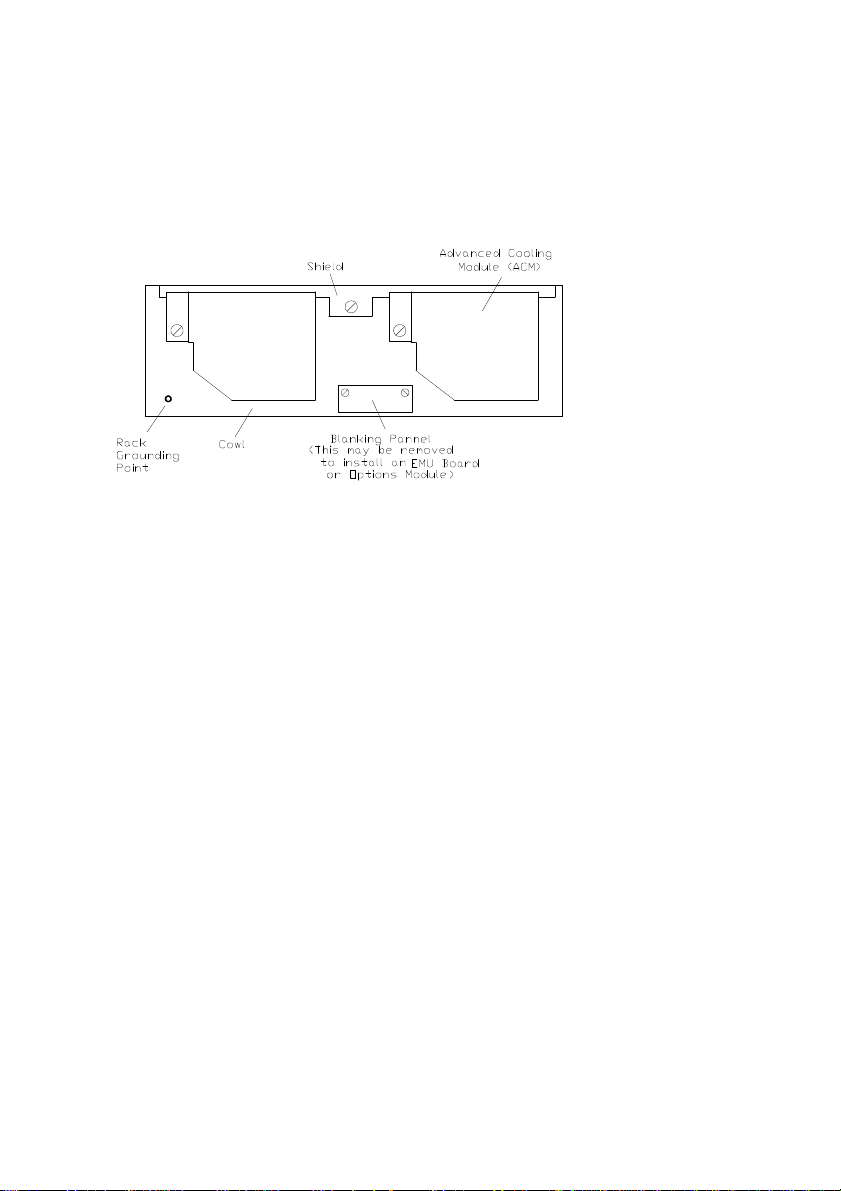

To access the switch perform the following sequence of steps:

1. Remove the back face plate by removing the two Philips head screws as shown in Figure

2-3

2-3

Page 24

Voyager 3000 User Guide

Figure 2-3 Rear view of single tower showing host connections

2. Refer to Figure 2-4 and remove the ACMs by unscrewing the large single screw, swinging

back and unclipping the snap on wiring connector.

Figure 2-4 Rear view showing ACMs, cowl and shield

3. Remove the shield by unscrewing the large flathead screw from the cowl.

2-4

Page 25

Installation and Setup

The switches are now accessible at the middle of the backplane on the right hand side when

looking at the rear of the system as shown in Figure 2-5.

Figure 2-5 Setting the Target Bus SCSI IDs

The SCSI Ids may be set to have a base address of either 0 or 3. Setting the switch to the left

(when viewed from the rear) will cause the drives associated with that switch to occupy SCSI

Ids 0à 2. Setting the switch to the right will cause the drives to occupy SCSI Ids 3à5. Figure

2-6 shows both target buses set to a base address of 0. This is the factory default setting and

Figure 2-6 Setting the RAID Target Bus SCSI IDs

should not normally be altered.

Setting the target SCSI Ids on a VRA-3002 system

The first shelf (right hand side when viewed from the rear) in the VRA-3002 is configured the

same as the VRA-3001 shelves. The second shelf is configured as two separate busses and

linked externally via the bulkhead connectors. Figure 1-4 gives a schematic view of the

cabling interconnections.

2-5

Page 26

Voyager 3000 User Guide

Figure 2-7 Location of DPS1 on VRA-3002 second backplane

Switch positions 1-4 are used to set the starting ID for the first device (bay 0) on the bus.

Devices in bays 1,2 and 3 will automatically increment this ID by one in turn5. For example if

the device in bay 0 is set to be at SCSI ID 3 then the device in bay 1 will automatically appear

as ID 4, the device in bay 2 will appear as ID 5 and the device in bay 3 will appear as ID 6.

Since the addresses of the devices in the first backplane is set to occupy SCSI Ids 0à2 for

each bus, the default setting for the devices in the second backplane is set to be at a base

address of 3. As there are four switches the switch positions are arranged to allow 16 possible

Ids from 0 à 15.

Switch positions 5-8 are used to set the starting address of the fifth device on the bus (bay 4)

and in a similar manner devices in bays 6,7 and 8 will also be automatically incremented. The

default setting for the second bus is also to start at a base address of 3. Figure 2-8 shows how

to set up the SCSI IDs using switch DPS1.

5

If the starting address is at 15 then the subsequent Ids will roll over so that the second drive

will take SCSI ID 0, the third drive ID 1 etc.

2-6

Page 27

Figure 2-8 SCSI ID Switch (DPS1)

Installation and Setup

SW-1 of DPS1 corresponds to the L.S.B. of the ID of the device in bay 0, whilst SW- 4

corresponds to the MSB of the ID of the device in bay 3. SW- 5 of DPS1 corresponds to the

L.S.B. of the device in bay 4, whilst SW- 8 corresponds to the MSB of the ID of the device in

bay five.

Table 2-1 shows the switch settings along with their corresponding Ids, the default6 settings

are shown in bold text.

6

There is normally no need to change the factory default settings.

2-7

Page 28

Voyager 3000 User Guide

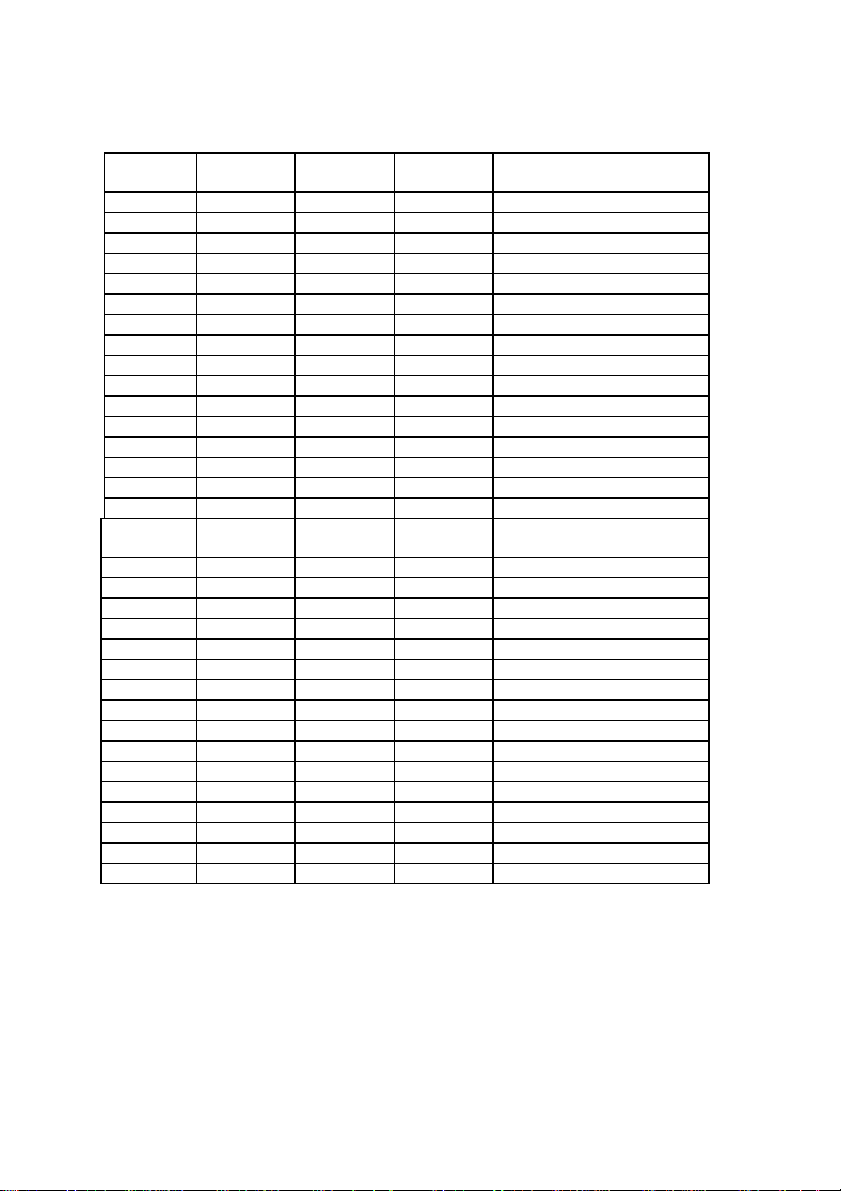

Table 2-1 SCSI ID switch settings for the second backplane in a VRA-3002 configuration.

DPS1 Sw1

(ID Bit0)

Off Off Off Off 0

On Off Off Off 1

Off On Off Off 2

On On Off Off 3

Off Off On Off 4

On Off On Off 5

Off On On Off 6

On On On Off 7

Off Off Off On 8

On Off Off On 9

Off On Off On 10

On On Off On 11

Off Off On On 12

On Off On On 13

Off On On On 14

On On On On 15

DPS1 Sw5

(ID Bit0)

Off Off Off Off 0

On Off Off Off 1

Off On Off Off 2

On On Off Off 3

Off Off On Off 4

On Off On Off 5

Off On On Off 6

On On On Off 7

Off Off Off On 8

On Off Off On 9

Off On Off On 10

On On Off On 11

Off Off On On 12

On Off On On 13

Off On On On 14

On On On On 15

DPS1 Sw2

(ID Bit1)

DPS1 Sw6

(ID Bit1)

DPS1 Sw3

(ID Bit2)

DPS1 Sw7

(ID Bit2)

DPS1 Sw4

(ID Bit3)

DPS1 Sw8

(ID Bit3)

Bay 0 Device SCSI ID

Bay 4 Device SCSI ID

Cabling and Termination Issues

SCSI requires that cable lengths be no greater than 6 metres at 5MHz clock rates and no

greater than 3 metres at 10MHz clock rates when used in SCSI -2 single ended mode.

Differential mode allows cable lengths of up to 25 metres. See the note below for Ultra SCSI.

This is summarised in Table 2-2.

2-8

Page 29

Installation and Setup

Note Ultra SCSI has very stringent requirements regarding cable length.

Any cables connected to Ultra devices must conform to Ultra SCSI

specifications. When there are excess of 4 devices cable length should be no

is that for any Ultra SCSI system the initiator and target will try to transfer data at

Ultra SCSI rates during the initialisation process regardless of the number of devices

and cable length. When Ultra SCSI cable length restrictions can be violated (in the case

of buses with more than 4 devices) the transfer rate must be reduced at the initiator side.

Table 2-2 Cable Lengths Vs Transfer Rates

Length in Metres Transfer Speed

6 Metres 5 MHz (10 MB/S for wide (16 bit) SCSI-2, 5MB/S for narrow SCSI-2)

3 Metres 10 MHz (20 MB/S for wide (16 bit) SCSI-2, 10MB/S for narrow SCSI-2)

3 Metres 20 MHz (4 devices or less) Ultra SCSI single ended

1.8 Metres 20 MHz (greater than 4 devices) Ultra SCSI single ended

25 Metres SCSI-2 Differential mode

greater than 1.8 metres for single ended Ultra SCSI. The implication of this

Components

Power Supplies

The Power Supplies are housed in removal canisters and are supplied as such. To replace a

power supply simply press the button as shown in Figure 2-9 and withdraw the carrier. The

PSU is hot pluggable7. Refer to the heading on page 2-14 for more details.

Figure 2-9 Removal and insertion of a Power Supply Unit

Note: The Power Supplies are not Auto Sensing and there are two different

types depending on the AC Input. Power Supplies for the US market are

clearly marked with a label stating 115V.

Devices

Devices are housed in two types of canisters. The top LED in the device carrier indicates SCSI

activity on the device and is green. The bottom LED is red and indicates a fault condition.8 A

front view of the device carrier is shown in Figure 2-10.

Figure 2-10 Device carrier

7

To allow correct functionality of the power supply circuitry, please ensure that at least one minute has

elapsed between removal and re-insertion of the power supply unit.

2-9

Page 30

Voyager 3000 User Guide

SCA attachment

To connect an SCA device to a device carrier simply insert the SCA device and connect it via

the 4 screw holes provided on the underside of the device carrier. There are also device

carriers for other devices. Table 2-3 shows the carrier part numbers.

Table 2-3 Device carrier Device Part Numbers

Description Part Number

Device carrier Standard 3.5” non SCA wide drive VOY-W-AA

Device carrier Standard 3.5” non SCA narrow drive VOY-N-AA

Device carrier Standard 3.5” SCA drive VOY-SCA-AA

Device carrier for Barracuda 4 drive VOY-SCB-AA

Power Option Board

The Power Option Board provides RS-232 communication between the controller and a

terminal. It also has a four way DIP switch The relevant switch settings are shown in

Table 2-4.

Table 2-4 Power Option Board Switch Definitions

SW1-4 SW1-2 SW1-3 SW1-1

Sync Link

(default is off)

SW1-4 is used to configure the spindle synchronisation line across both SCSI buses. The

default setting is off. SW1-2 and SW1-3 are used to provide Termination Power and will

normally be set to on. SW1-1 is used to delay the spin up cycle and is normally set to on. The

power sequence delay will cause the second group of drives (the bottom 3 drives in each shelf)

to spin up after the first group of drives in the case of a single power supply. In the case of

dual power supply configurations no delay will take place regardless of this setting.

Termination Power enable

(default is on)

Delay Enable

(default is on)

Controller

To remove the controller shut down the system and remove the device immediately under the

controller. This will grant access to the controller removal level attached to the underside of

the controller. Grasp the handle and depress the release button on the right hand side of the

carrier and pull with a steady slow action towards you. This will allow the controller to be

withdrawn in a controlled manner.

The controller may be removed from the carrier by turning the carrier upside down and

removing the eight countersunk screws. This will withdraw the controller complete with the

backplane interface board.

8

Note that the EMU in conjunction with SAFTE or a RAID controller must be installed to convey this fault

information

2-10

Page 31

Installation and Setup

Power

Socket

Channel 0

CPU

Figure 2-11 RAID Controller

Access to the controller is obtained by removing the four screws at the side of the top panel.

This will allow access to the main board. Removing the piggy-backed channel cards reveals

Figure 2-12 Main board access

Simm

Module

the topography of the main board as shown in Figure 2-12.

SIMM Installation

Note the following guidelines with regards to DRAM:

• Minimum DRAM required is 4 MBytes installed in SIMM socket

• EDO RAM is recommended for enhanced performance.

2-11

Page 32

Voyager 3000 User Guide

• Use 72-pin 60 Ns DRAM or EDO SIMM.

• Maximum DRAM size is 32 MBytes in one 32 MByte SIMM.

Installation of SIMMs is accomplished by the following steps:

1. Power off the system and disconnect the power connector.

2. Refer to Figure 2-13 Insert the DRAM SIMM vertically with the key to the left (1). Then,

push towards the back until the hooks on both sides of the socket snap into place (2) as shown

below.

Figure 2-13 Installing SIMMs

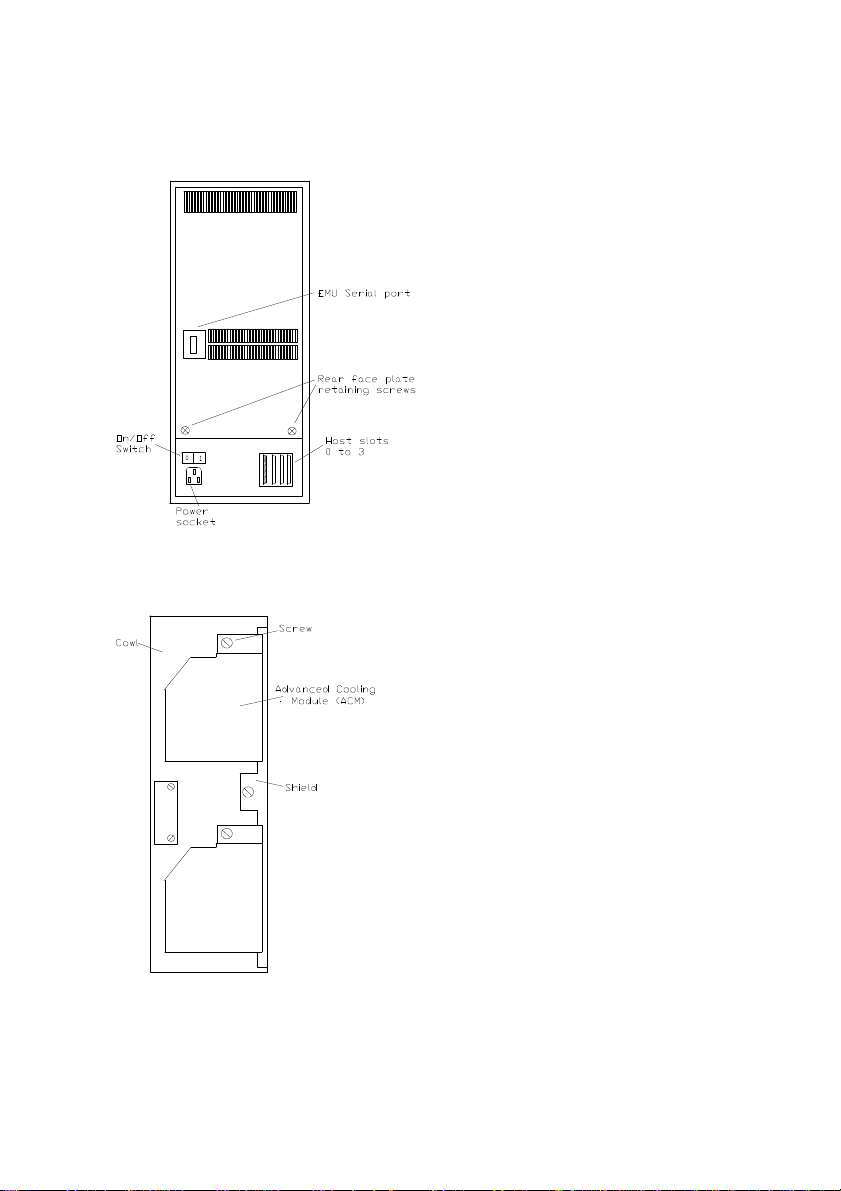

Advanced Cooling Modules

The Advanced Cooling Modules are accessed from the rear of the cabinet. The ACMs are

supplied as complete units. Do not attempt to disassemble beyond the FRU level. To remove

an ACM perform the following sequence of steps:

1.Remove the back face plate by removing the two lower Philips head screws as shown in

Figure 2-14.

Figure 2-14 Removing the back face plate

2-12

Page 33

Installation and Setup

Refer to Figure 2-15 and remove the ACMs by unscrewing the large single screw, swinging

back and unclipping the snap-on wiring connector.

Figure 2-15 Rear view of ACM assembly

Installation of an ACM is simply a reversal of the above procedure.

Component Insertion and removal

Drive Insertion

Push the device firmly into the device bay slot. Do not attempt to slam it into position. Ensure

that the button at the front of the carrier is fully extended after device insertion. Failure to do

so may result in an incorrectly latched device. In situations where the button is not fully

extended it may be necessary to apply additional pressure.

SCA devices are hot swappable within the system. The only requirement is that there must be

no I/O activity to the device being removed. If the drive has failed and has been dropped by

the controller then no I/O will take place to that unit and swapping is permissible. This

conforms to case 4 of Hot Plugging as defined in the SCSI specification.

Drive Removal

Prior to complete removal of the carrier from the VOYAGER 3000 system you must ensure

that the drive has fully spun down as centrifugal forces may damage the device. You must

ensure that adequate shock and anti-static precautions are complied with.

9 SPI Rev 14 Annex A

2-13

9

Page 34

Voyager 3000 User Guide

PSU Insertion and Removal

The VOYAGER 3000’s power supply is designed for hot pluggable operation. To achieve this

temperature sensitive current limiting is used. As the temperature to the devices increase the

current limiting function decreases. This will prevent undesirable surges. If removing and

replacing the same PSU please ensure that at least one minute has elapsed between removal

and re-insertion which will allow components to cool to ambient temperature.

Controller Insertion and Removal

To insert the controller push the device firmly into the device bay slot. Do not attempt to slam

it into position. To remove refer to the paragraph heading marked

Controller on page 2-10.

2-14

Page 35

Environmental Monitoring Unit

Chapter Three

EMU

Environmental Monitoring Unit Configurations

Introduction

The Environmental Monitoring Unit ( EMU ) is a multifunction plug-in daughter card that

allows a user to monitor the operational status of a Voyager 3000 system. There is one EMU

per storage shelf. The module provides visual and audible feedback of events to the user. In

addition the EMU provides addressable memory locations which may be read or written to.

This allows more comprehensive monitoring and reporting to intelligent agents such as

Eurologic’s Vision software. The EMU specification is based on the SAFTE ( SCSI Accessed

Fault Tolerant Enclosures ) specification, and contains many of the features detailed there.

EMU Features

• Monitors presence and status of Fans and Power Supply Units ( PSU ) .

• Monitors presence of SCSI devices.

• Monitor UPS status and presence.

• Indicates error conditions visually and audibly.

• Adjustable over-temperature warning.

• Stores insertion counts for all removable devices - PSU, Fan or SCSI Device

• Communication via serial RS232 port or via I2C bus.

• Fully compatible with Eurologic’s Vision software.

The EMU is a flexible unit which may be configured in a variety of ways. It connects to a host

system via an RS-232 link. Up to eight EMUs may be cascaded together in a Master/Slave

configuration. Each EMU is set up to have a distinct ID. A device having an ID of 0 will be a

Master, all other devices are designated as Slaves. Multiple EMUs are daisy chained together

via an I2C bus.

The EMU stores data in a non-volatile EEPROM memory so it is possible to track changes in

the system even if power has been removed. On power up the EMU compares the physical

system configuration to that stored in memory and notes any changes. These changes will be

reported to the Host. It is the responsibility of the Host to process this information.

3-1

Page 36

Voyager 3000 User Guide

System Configurations

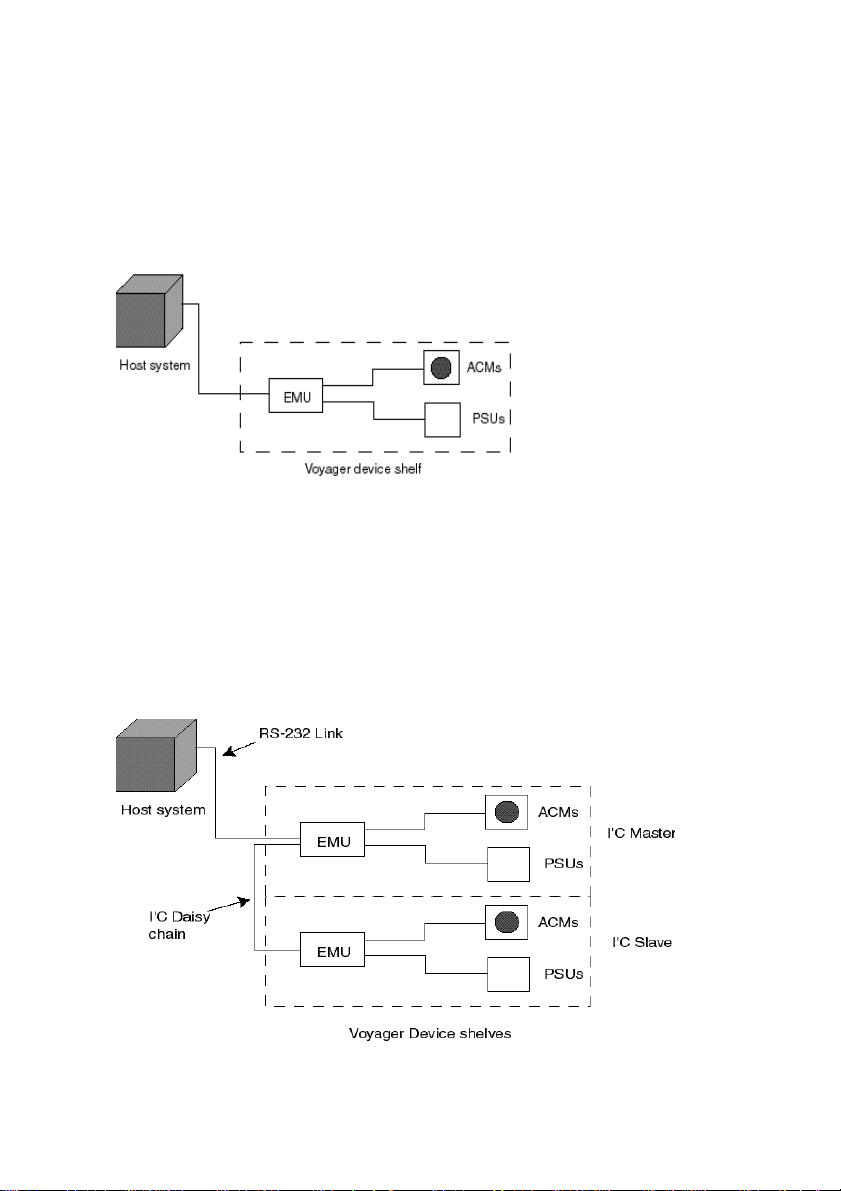

Single Shelf configuration

Figure 3-1 shows how a single shelf Voyager 3000 system is configured with an EMU. The

system is set up with a device ID of 0 ensuring that it functions as a master device.

Figure 3-1 Single shelf EMU configuration

Dual shelf configuration

In a dual shelf configuration the Host connects to the I2C Master via RS232 serial link. Data

from the second EMU is requested via the I2C bus and is passed to the Host via the RS232

link. The I2C Master has sufficient memory to store global system information and its own

status information, the slave will store its own status information. An unique I2C address is

assigned to each EMU with the address 0 reserved for the master. The EMU currently has

provision to support up to eight shelves.

Figure 3-2 Dual shelf EMU configuration

3-2

Page 37

Environmental Monitoring Unit

Setting up the EMU

The EMU is physically located at the rear of the device shelf. A magnified view of the EMU is

shown in Figure 3-3.

Figure 3-3 Location of EMU within the shelf

A view of the PCB layout is shown in Figure 3-4.

Figure 3-4 EMU PCB layout

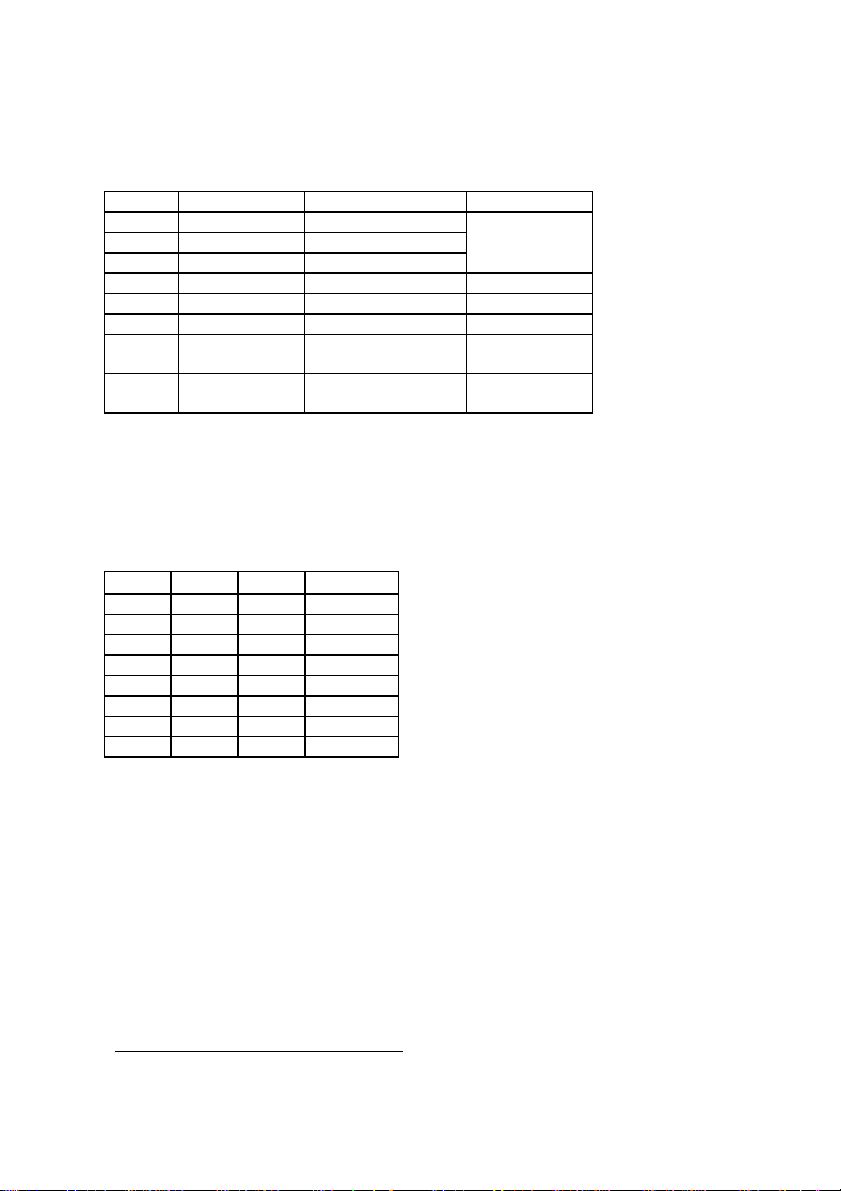

The switch settings for the Dip. Switches shown in Figure 3-4 above are given in Table 3-1

3-3

Page 38

Voyager 3000 User Guide

Table 3-1 EMU Switch Settings

Switch Signal Name Description Default Setting

SW1 ID2 Address Bit 2 Setting is

SW2 ID1 Address Bit 1 position

SW3 ID0 Address Bit 0 dependent

SW4 Sync Spindle Sync Off

SW5 DLYSEN Drive Spinup Enable On

SW6 DLYSON Drive Spinup Delay Off

SW7 Term Pwr 1 Termination Power

On

Enable Bus One

SW8 Term Pwr 1 Termination Power

On

Enable Bus Two

SW1àSW3 are used to set the I2C bus ID. A device with address 0 is designated as the

master. Any other ID caused the EMU to appear as a slave device. Table 3-2 lists the ID

setting for the EMU.

Table 3-2 ID settings for the EMU

SW1 SW2 SW3 EMU ID

Off Off Off 0 (Master)

Off Off On 1

Off On Off 2

Off On On 3

On Off Off 4

On Off On 5

On On Off 6

On On On 7

SW4 is used to enable drive spindle synchronization.

SW5 and SW6 are used to control drive spinup sequencing.

If SW6 is set off then SW5 will control drive sequencing. If SW5 is off then power up

sequencing is disabled. If SW5 is set to on then power up sequencing will be enabled if only

one PSU is available10 otherwise no power sequencing will occur.

If SW6 is on then delayed power sequencing will always occur regardless of the setting of

SW5. Table 3-3 summarizes these signals

10

This situation may occur if a PSU has failed or the system has been set up with only one PSU configured.

3-4

Page 39

Environmental Monitoring Unit

Table 3-3 Power Sequencing Signals

SW5 SW6 Action

Off Off No delayed power sequencing

On Off Power sequencing if only 1 PSU is available

X On Delayed power sequencing

X = Don’t Care

SW7 enables SCSI Termination power for bus one and SW8 enables SCSI Termination power

for bus two.

Available EMU information

More comprehensive information is provided to intelligent agents such as Eurologic’s Vision

software. Configuration, warning and status Information is available from all EMU’s. The

single EMU Storage System will provide the data shown in Table 3-4 and Table 3-5.

Table 3-4 Read Only Memory locations within the EMU

Data Name Number of Information Bytes

EMU Part No. 4 bytes

EMU Firmware Rev 2 bytes

EMU Serial No. 4 bytes

EMU Power Cycle Count 2 bytes

Status Byte 2 bytes

EMU Available 2 bytes

EMU Attention 2 bytes

Local Temp 2 bytes

EMU Data 8 bytes

Fan Insertion Count 2 bytes per Fan

PSU Insertion Count 2 bytes per PSU

SCSI Device Insertion Count 2 bytes per SCSI Devices

Table 3-5 Read/Write locations within the EMU

Data Name Number of Information Bytes

Master 12 bytes

Alarm Temperature 2 bytes

Critical Temperature 2 bytes

Action Byte 2 bytes

SCSI Device Status 2 bytes

Power Supply Control & Status 2 bytes

Fan Status 2 bytes

3-5

Page 40

Voyager 3000 User Guide

Each slave EMU will have the same data available to the Master and Host as is shown in

Table 3-4 and Table 3-5. Table 3-6 shows a summary of the status that is monitored by the

EMU.

Table 3-6 Devices/events monitored by the EMU

Connection Status monitored Method used

FANS Connected Loopback circuit.

Speed OK Squarewave proportional to speed.

PSU Connected Loopback circuit.

Voltage Good Valid if both 12V and 5V good

Temperature Within range

SCSI Devices Connected

Battery Backup or

UPS

IDs

On Battery Power

2 Minute reserve

warning

signals are active. Voltages

monitored internally by the PSU.

Temperature trip points set in oC by

EMU circuitry.

Loopback circuit.

Read ID settings serially from

backplane.

Internal and external logic level

connectors.

Interpreting the EMU LED Feedback

When a failure occurs an audible alarm will sound from the buzzer and the EMU LED will

flash at regular intervals. Table 3-7 shows how to recognize failures.

Table 3-7 Interpreting the EMU LED feedback

No of Flashes Interpretation

1 Fan One Failure

2 Fan Two Failure

3 Fan Three Failure

4 Fan Four Failure

5 Alarm Temperature

5 Critical Temperature reached or exceeded

If a device failure occurs then the bottom light indicator will display RED indicating which

device has failed. If a Power Supply failure occurs then the indicator will display RED.

The Silence Switch is used only to silence the alarm buzzer - it does not stop the error LED

from flashing. Multiple failures are shown as multiple sequences of LED flashes, for example

if the first two fans fail, then the LED will flash once, followed by two flashes and it will

continue to display this sequence.

3-6

Page 41

Environmental Monitoring Unit

Connecting the EMU

This section describes the procedure for connecting the EMU to the host system. It is possible

to have up to eight EMUs connected together in a daisy chain configuration. The first EMU

on the chain must be connected to the host system using the serial RS232 cable provided. The

EMU ID for the first shelf in the chain must be set as ID 0 so that the system will see it as the

master. All other EMUs connected on the chain will be seen by the system as slaves.

The EMUs should be daisy chained together using the EMU cable provided (3 connectors).

The top connector of the EMU cable should be attached to the 3-pin connector on the EMU.

The middle connector of the EMU cable should be connected to the next shelf on the chain.

To the bottom connector on the EMU cable connect the second EMU cable provided. Connect

the middle connector of the second EMU cable to the third EMU on the chain. Continue this

procedure until all the EMUs (up to a max. of 8) have been connected together.

Figure 3-5 shows how to connect the EMUs together.

Figure 3-5 Connecting the EMUs together

3-7

Page 42

Voyager 3000 User Guide

This page is intentionally left blank.

3-8

Page 43

Chapter Four

RAID controller configuration

Controller Description

The VOYAGER 3000 is a SCSI to SCSI RAID controller specifically designed to provide

RAID 0, 1, 0+1, 3 or 5 capability to any host system equipped with a SCSI interface. It is

totally independent of the host system's operating system with all the RAID functions

performed by the controller hardware. In effect, it endows the host system with the high speed

and fault-tolerant disk storage operation of RAID technology. The VOYAGER 3000 has

comprehensive drive failure management that allows automatic reassignment to reserve blocks

when a bad sector is encountered during a write. Hot-swapping is supported through

automatic disconnection of a failed drive and detection of a fresh drive followed with

background rebuilding of the data. The controller also supports spare drive operation. All

these failure recovery procedures are transparent to the host system.

The controller is housed in a removable device canister which allows for minimum Mean

Time to Repair (MTTR) periods. It is configured as one host bus with up to two target buses

of 3-7 drives on each bus.

Figure 4-1 Front view of controller (within a canister)

The controller hardware is pre-configured when it leaves the factory but it is the responsibility

of the user to configure the logical volumes according to the capacities and RAID levels.

Controller Configuration

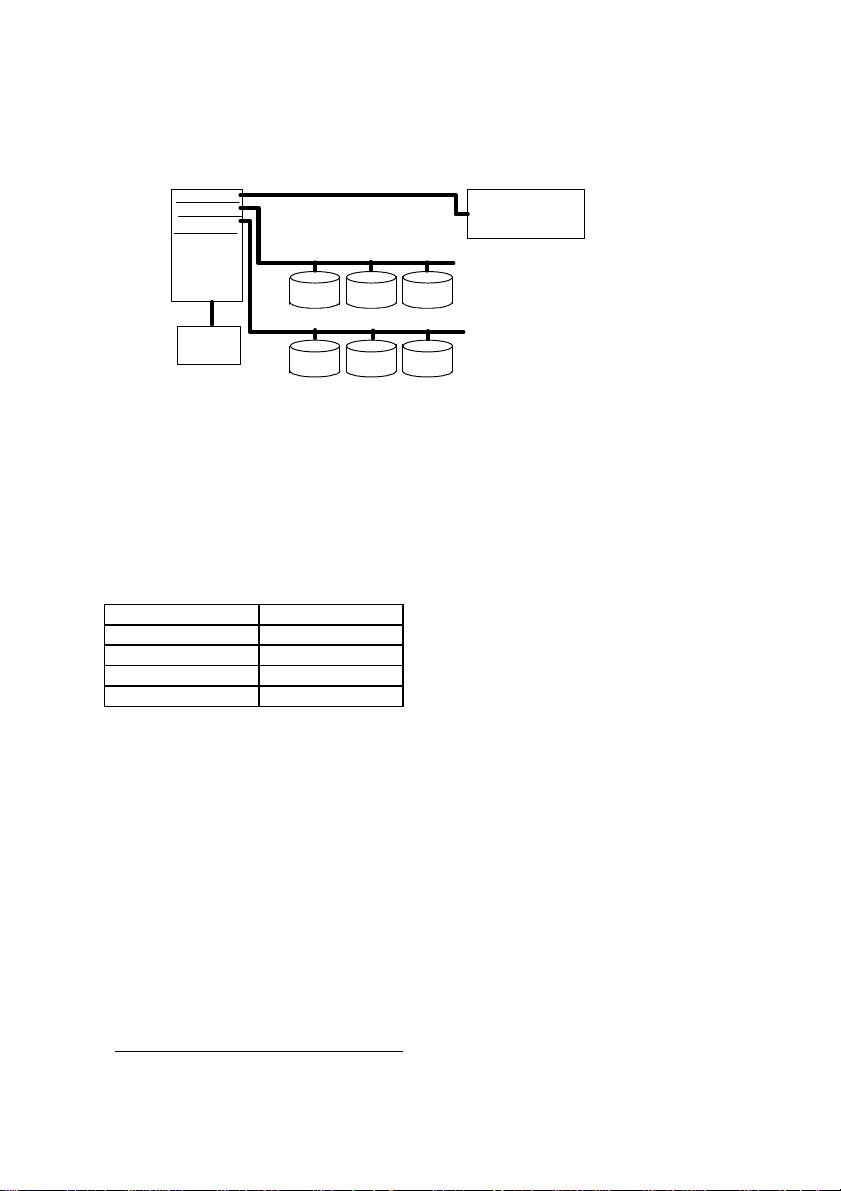

This section covers configuration issues involved with the RAID system. Figure 4-2 shows a

logical view of a Voyager 3001 configuration. In this case there are three SCSI buses

connected to the controller across the three channels. Channel 2 makes up the host SCSI bus

with channels 0 and 1 making up the target buses.

Page 44

Voyager 3000 User Guide

Figure 4-2 Logical View of VOYAGER 3001

Channel

Channel 1

Channel 0

Controller

Power

Supply

2

Host SCSI

Drive SCSI

Drive SCSI

Host

System

Top 3 drives on

VRA-3001

Bottom 3 drives on

VRA-3001

Accessing the VOYAGER 3000 Menus

Connecting a Monitor

The VOYAGER 3000 is shipped with a serial cable for making the connection from the

options board at the rear of the system to an external monitor. To use the monitor utility, run

the cable from the VOYAGER 3000 to your monitor. The terminal should be configured as

shown in Table 4-1 and set up for VT100 emulation.

Table 4-1 RS232 Terminal Settings

Parameter Value

Baud Rate 9600

Data Bits 8

Stop Bits 1

Parity None

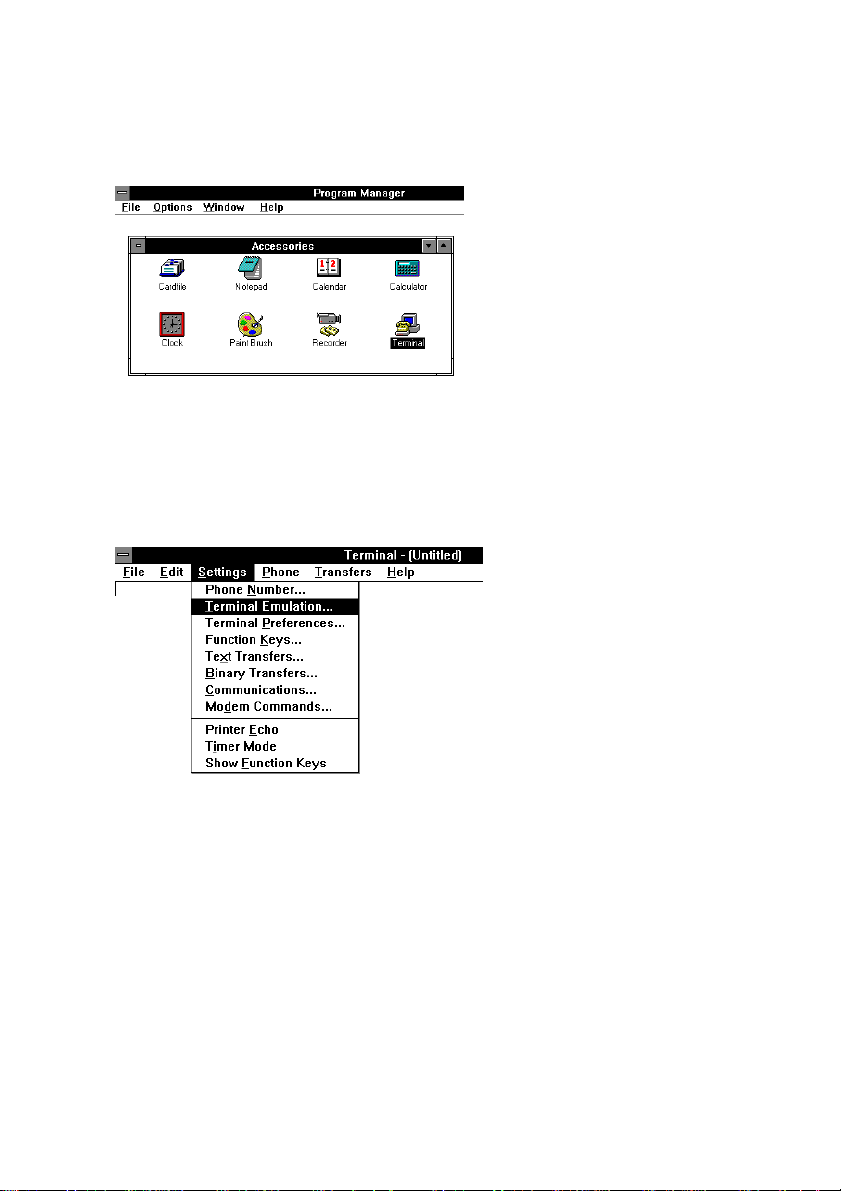

Emulating a Monitor

If you do not have a dedicated monitor at your disposal, you can still access the VOYAGER

3000 monitor utility by using a PC and communications software to emulate a monitor. In this

example, we will use the Microsoft Windows V3.X11 Terminal program.

11

Windows 95 users can use HyperTerminal

4-2

Page 45

RAID Controller Configuration

Figure 4-3 Windows Program Manager

First connect the VOYAGER 3000 to the serial port of your PC with the cable supplied. Then

load Windows, open the Accessories window and double-click on the Terminal icon.

Before you can view the monitor utility, you will have to configure the software to emulate a

Figure 4-4 Windows Terminal Program (Main Menu)

monitor. Start by clicking on Settings/Terminal Emulation.

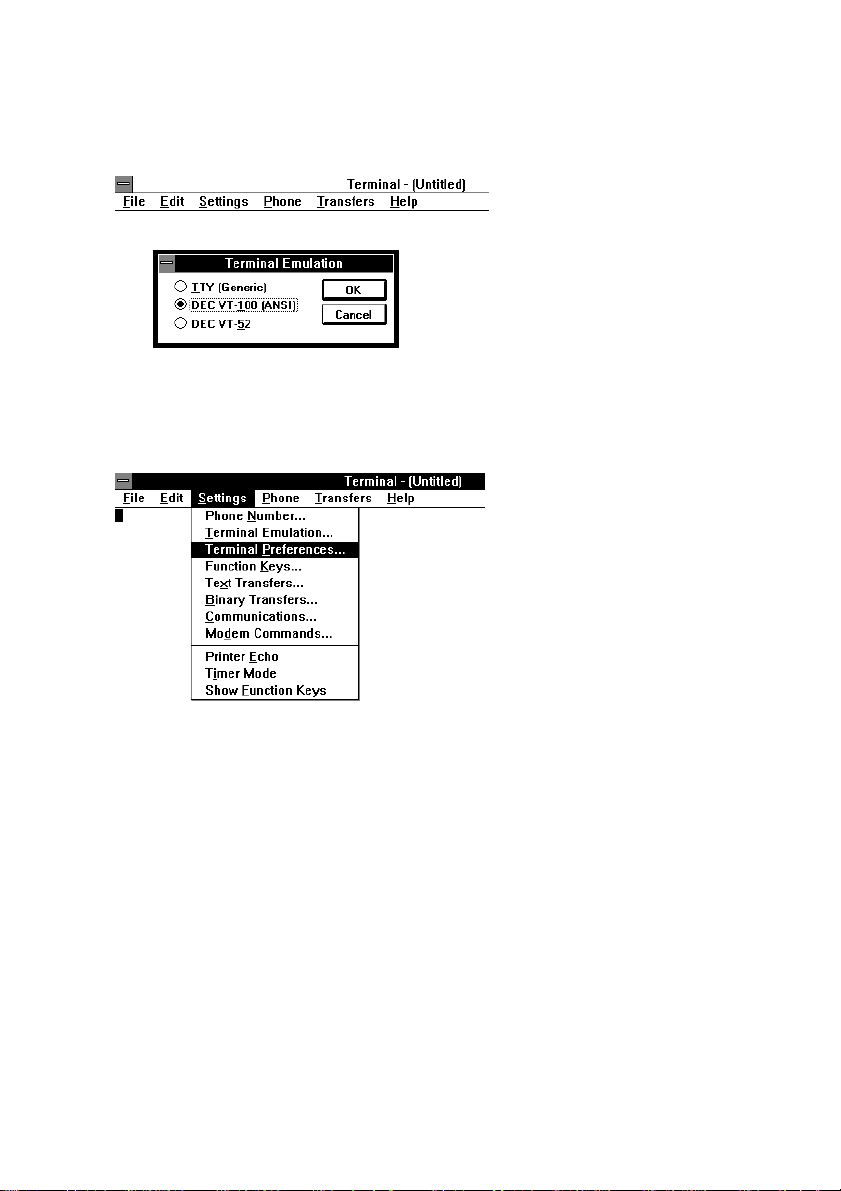

Select the DEC VT-100 emulation.

4-3

Page 46

Voyager 3000 User Guide

Figure 4-5 Setting Windows Terminal Emulation

The next step is to set up the terminal preferences

Figure 4-6 Setting Windows Terminal Preferences

De-select Use Function, Arrow and Ctrl Keys for Windows check box as shown in Figure 4-

7.

4-4

Page 47

RAID Controller Configuration

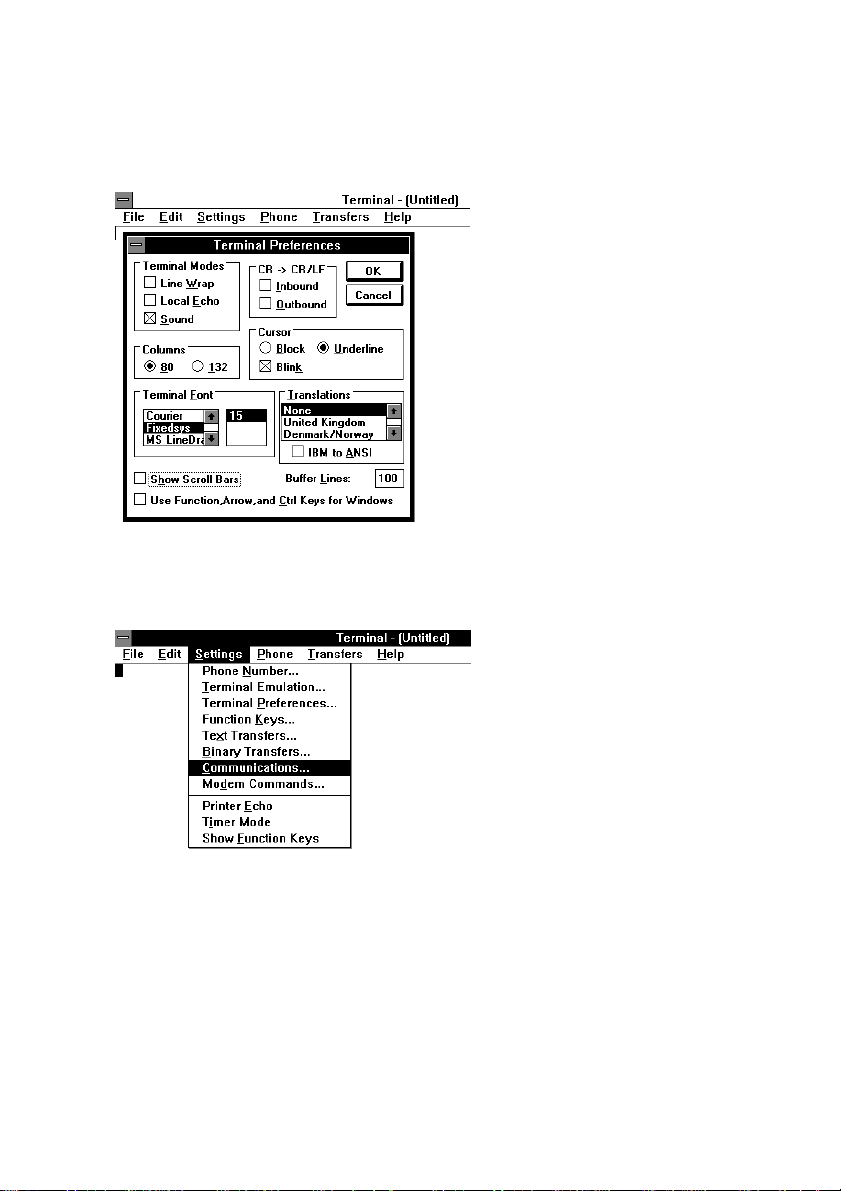

Figure 4-7 Windows Terminal Preferences Screen

and then click on Settings, Communications

Figure 4-8 Windows Terminal Communications Settings

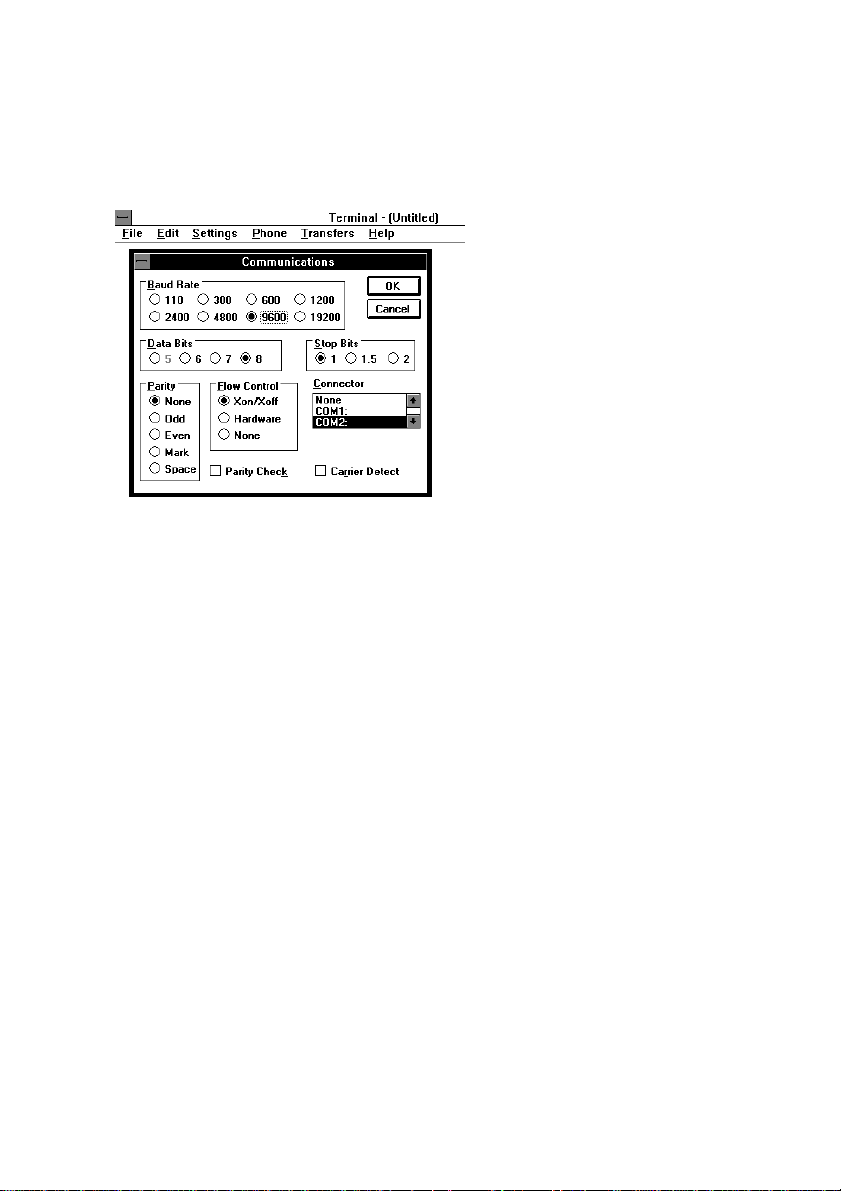

Select the appropriate COM port. In our example we have connected to the second serial port

so we use COM2. Set the baud rate to 9600, data bits to 8, stop bits to 1, parity to none and

flow control to Xon/Xoff.

The VOYAGER 3000 monitor utility provides complete control over the configuration and

operation of the controller. You may also use the utility to view the status of the controller’s

RAID sets and monitor the progress of create operations. It is also possible to use the monitor

utility to view the I/O performance of the system. Use the arrow keys to navigate through the

4-5

Page 48

Voyager 3000 User Guide

menus and press the v key to back up to previous levels. Entries are selected via the e

key.

Figure 4-9 Windows Terminal Communication Settings

Creating a logical volume

A "Logical Drive" is a set of drives grouped together to operate under a given RAID level and

appears as a single contiguous drive. The VOYAGER 3000 is capable of grouping connected

drives into 8 logical drives, each operating on the same or different RAID levels. The logical

drive can be further divided into a maximum of 8 "Partitions" (using terminal commands).

During operation, the host sees the logical drive or partition as one single drive. A total of 8

logical units is possible.

In this example we will show how to create a RAID level 5 set using a single tower

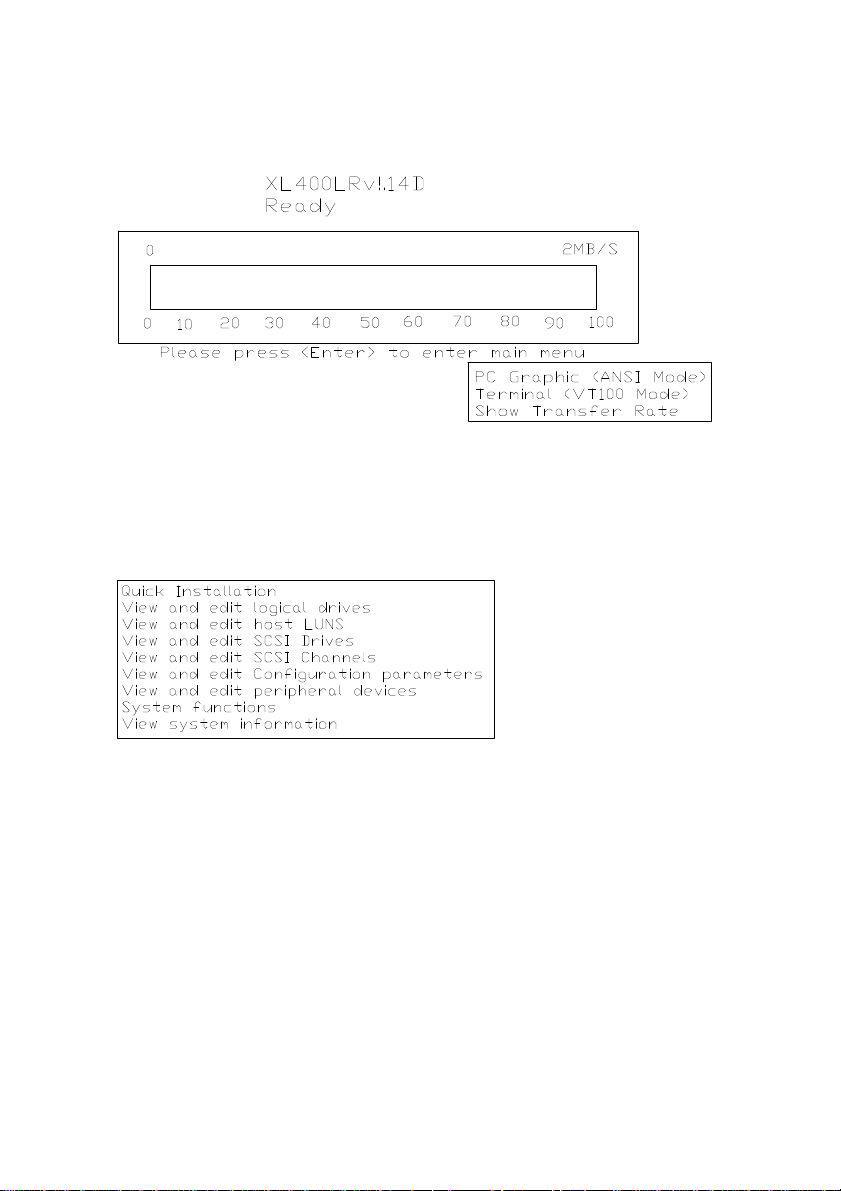

configuration. The initial screen is shown in Figure 4-10.

4-6

Page 49

RAID Controller Configuration

Figure 4-10 Initial Screen

Select Terminal (VT100) mode if following the instructions above and press e. This will

display the screen shown in Figure 4-11.

Figure 4-11 Main Menu Screen

In the example shown the physical configuration consists of a single tower with 6 disk drives.

The first task is to create a RAID set which is a logical drive as far as the host is concerned.

This logical drive will appear as a normal disk to the Operating System and will behave

similar to any other disk with the added benefits of enhanced reliability and performance.

Prior to creating the RAID set, verify that the configuration as seen by the RAID controller

4-7

Page 50

Voyager 3000 User Guide

matches the actual configuration. This is done by selecting view and edit SCSI drives from the

main menu as shown in Figure 4-12.

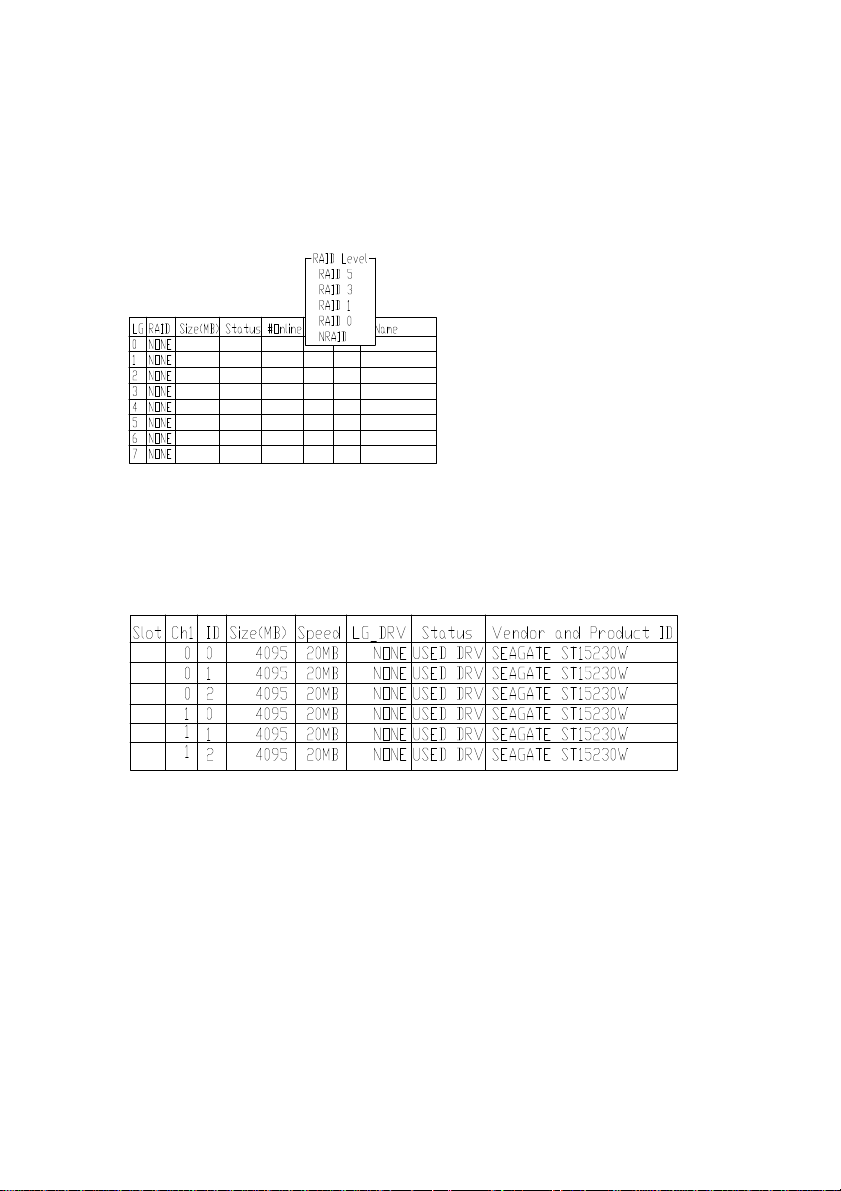

Figure 4-12 Verifying Drive Configuration

The controller displays six drives. Use the arrow keys to scroll down if necessary. The

information reported by the VOYAGER 3000 includes the Vendor and Product ID of the

drives as well as their capacity and RAID controller status. The example in Figure 4-12 shows

six drives connected to the two target buses. Each target bus is identified by its channel

number as shown in the second column of Figure 4-12.

In our example there are six Seagate drives of 4095 MB capacity. We will create a RAID level

five set on the three drives connected to channel zero and we will create a RAID level one set

on drives 0 and 1 of channel one. In addition we will create a Global Standby disk on drive 2

of channel 1. Enter the View and edit Logical Drives option from the main menu as shown in

Figure 4-13.

Figure 4-13 View and edit Logical Drives Screen

4-8

Page 51

RAID Controller Configuration

Pressing the e key will commence the operation of building a new logical drive. A

dialogue will appear asking to Create Logical Drive, answering YES to this prompt brings up

the screen shown in Figure 4-14 prompting the user to select the desired RAID level. Select

the RAID 5 option and press the e key.

Figure 4-14 Creating a logical drive

A list of drives which are available for RAID set inclusion appears as shown in Figure 4-15.

The drives can be tagged for inclusion by positioning the cursor on each drive and selecting

Figure 4-15 Selecting the logical drive's RAID level

by pressing the e key. This will mark them by inserting an asterisk (*) character beside

the drive’s entry in the table.

The example shown in Figure 4-16 includes three drives which will participate in a RAID

level 5 configuration.

4-9

Page 52

Voyager 3000 User Guide

Figure 4-16 Selecting drives for inclusion in a RAID set

After the drives are selected we back up through the menus by pressing the v key. The next

dialogue to appear prompts the user to assign the maximum capacity of the RAID set. In our

example we will use all of the available drive capacity which is 4095MB. To alter the capacity

press the e key and type in the desired value. Figure 4-17 shows the dialogue for

entering the drive capacity.

Figure 4-17 Setting the maximum drive capacity.

Pressing the v key will bring up the dialogue shown in Figure 4-18

Figure 4-18 Logical drive creation confirmation screen

Select Yes and press the e key. The status of the RAID set creation is shown to the user .

4-10

Page 53

RAID Controller Configuration

Figure 4-19 Progress of RAID set creation

Creating a Second Logical Volume

There are three drives left unassigned and we will use two of them to create a 2 drive RAID 1

set. This will become the second logical drive. To do this we take the View and Edit Logical

Drives option again from the Main Menu and highlight logical drive one position. As with

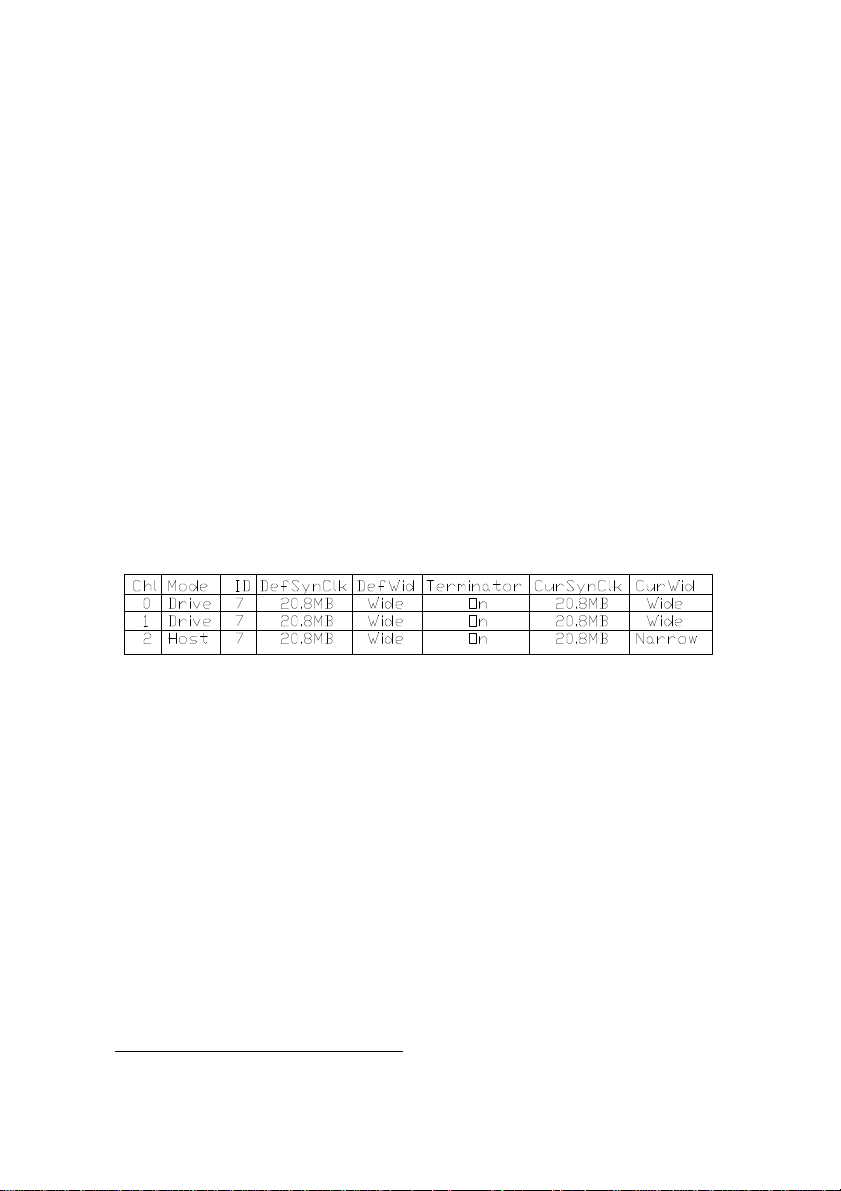

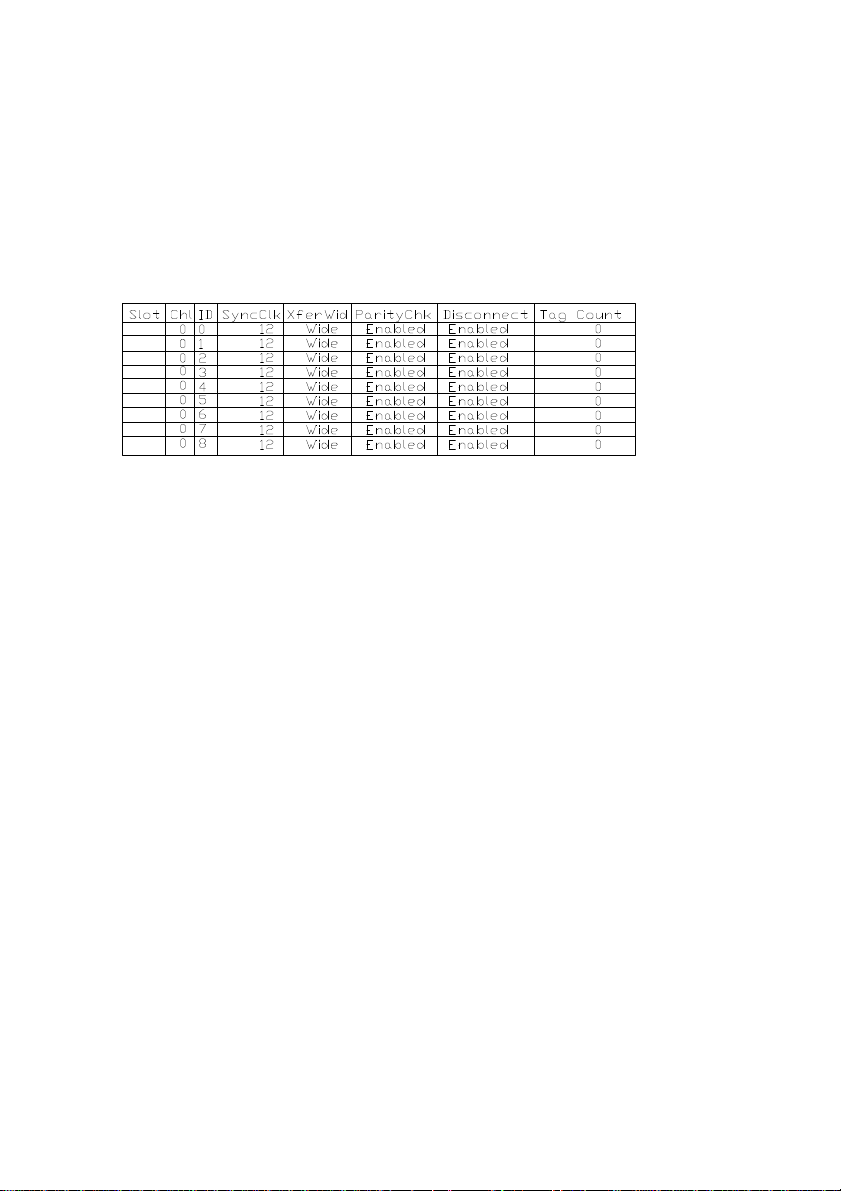

creating the first logical volume pressing e will bring up a dialogue box asking to Create