MC-5000

MAY 10, 2017

FIREYE

MODULAR

MicroM

FLAME SAFEGUARD CONTROLS

APPROVED

WARNING: Selection of this control for a particular application should be made by a competent professional, licensed by a state or other government agency . Inappropriate application

of this product could result in an unsafe condition hazardous to life and property.

DESCRIPTION

The Fireye MicroM Series Flame Safeguard Control is a compact, microprocesso r based, modular

burner management system designed to provide automatic ignition and continuous flame monitoring

for commercial sizes of heating and process equipment firing any type of fuel.

The MicroM is designed to be backward compatible with existing TFM, UVM and M-Series II controls. The MicroM MEC120 and MEC230 chassis with the appropriate MEP100, MEP200 and

MEP500 series programmers provide operation similar to its predecessors and is usually directly

interchangeable. The MEC320 and MEC480 chassis with the appropriate MEP300, MEP400 and

MEP600 series programmers provide additional enhancements such as early spark termination, pilot

proving, and interrupted pilot.

The advantages of the MicroM are zero dependence on discrete components previously used for timing functions. The MicroM, through the use of micro-controller technology, incorporates smart diagnostic LED's, smart reset function for multi-burner applications, optional alpha-numeric display

output (ED510), and serial communications via a Modbus or E500 Communication Interface. The

MicroM system also provides additional amplifier selections. Along with the standard UV and

Flame Rod amplifiers are UV self-check, Infrared, Cadmium Sulfide and a dry contact amplifier for

use with the Fireye Phoenix scanner. All amplifiers are available with flame failure response times of

0.8 seconds or 3 seconds nominal (4 second maximum) and each provide a set of test jacks with a

uniform range of 0-10 VDC for the measurement of flame signal intensity.

A complete MicroM system includes the appropriate flame detector, plug-in amplifier and programmer modules which connect into a standard chassis and wiring b ase. Interchangeable programmer

and amplifier modules allow for complete versatility in selectio n of control function, timing and

flame scanning means. Functions such as relight, recycle, non-recycle, two stage capability, nonrecycle air flow, proof of air flow open at start, purge timing, early spark termination, pilot proving

and pilot cutoff are determined by the appropriate programmer module. Type of flame scanner (UV,

Repetitive UV Self-Check, Flame Rod, IR or Cadmium Sulfide or dry contact) and the flame failure

response time (FFRT) are determined by the amplifier module. Optional plug-in daughter boards

provide additional features such as remote reset, alpha-numeric display and serial communications.

The MicroM programmers are micro-controller based modules that control the sequence of operation and also interface with plug-in amplifiers, meter boards, display drivers and external communication devices. The programmers are available in an assortment of configurations necessary to

resolve the application requirement. Current families of programmers for use with the MEC120 and

1

MEC230 type chassis include the MEP100, MEP 200 and MEP500 series. Programmers for use with

NOTE: The individual MicroM modules, i.e. MEC chassis, MEP programmers and amplifiers are

not interchangeable with M-Series II modules, i.e. MC chassis, MP programmers and amplifiers.

?

the MEC320 and MEC480 type chassis include the MEP300, MEP400 and MEP600 series.

Some programmer modules are equipped with a series of dipswitches to select Purge Timing, Pilot

Trial for Ignition (PTFI) timing, Proof of Air flow open at start, Po st Purge, Recycle and Non-Recycle operation. LED indicators on the programmer modules indicate the current operating status of the

control and during a lockout condition displays the fault as a cod ed sequence, simplifying the troubleshooting of a shutdown.

In the event of pilot ignition failure, or following a safety shutdown, the control locks out, activati ng

an alarm circuit and displays the cause of lockout on the integrated LED’s and on the optional ED510

display. Unless otherwise specified, manual reset is required. Remote reset is available on the

MEC120R, MEC120RC, MEC320RD, MEC230RC, MEC320R, MEC320RC and MEC320RD

chassis. A detailed description of the various programmer, amplifier and chassis modules is found

later in this document. A “run-check” switch, provided to assist in testing size, position and stabilization of the pilot, is provided on some sp ecific m ode ls and all MEP5 00 and MEP600 series p rogram mers.

Modular MicroM controls incorporate a safety checking circuit that is operative on each start. If

flame (real or simulated) is detected prior to a start or during purge, the fuel valves will not be energized and the unit will lock out.

The modular MicroM controls use the same wiring base as the Fireye UVM, TFM and M- Series II

controls and are designed to be interchangeable with most models with litt le or no rewiring. See

INSTALLATION OF CONTROL, SCANNERS AND FLAME DETECTORS (page 8 and 47) for

temperature and wiring requirements.

SPECIFICATIONS

Supply: 120 VAC (min. 102, max. 132) 50/60 Hz. (MEC1XX, MEC3XX)

230 VAC (min. 196, max. 253) 50/60 Hz. (MEC2XX, MEC4XX)

Power Consumption:12 VA (Operating)

Shipping Weight (Appr ox): 3 lbs (1.4 kg)

Operating Temperature:-40°F (-40°C) to 140°F (60°C)

Table 1: AMBIENT TEMPERATURE LIMITS

Control 140°F 60°C - 40°F - 40°C

Scanner UV1A, UV2, UV8A,

45UV3, UV90

45UV5-1007, 45UV5-1009;

55UV5-1007, -1009

Photocell 45CM1 (OBSOLETE) 165°F 74°C - 40°F - 40°C

Flame Rod

(Tip 2460 F)

48PT2 140°F 60°C -40°F -40°C

CSIA5 140°F 60°C -40°F -40°C

MAXIMUM MINIMUM

200°F 93°C - 40°F - 40°C

200°F 93°C - 40°F - 40°C

1500°F 816°C - 40°F - 40°C

2

Table 2: LOAD RATINGS: All Ratings are 120V, 60 Hz

Fireye Terminal Typical Load Maximum Rating @120V 60 Hz

3 or 4

Individual or combined

5 Main Fuel Valve(s)

8 Motor or contactor

A Alarm

Table 3: ALTERNATIVE LOAD RATINGS:

COMBINATION NUMBER PILOT FUEL TERMINAL 3IGNITION TERMINAL 4 MAIN VALVE TERMINAL

Pilot valve(s)

Solenoid valve

Ignition Transformer

Minimum load requirement = 100mA

125 VA pilot duty (solenoid valve) plus

250 VA (Transformer)

125 VA pilot duty (solenoid) or

25 VA pilot duty (solenoid) and

400 VA (opening) motorized, 250 VA hold

Terminal 8 rated to energize and de-energize 9.8 FLA,

58.8 LRA on safety lockout.

125 VA, pilot duty

5

1 C

2 B

3 NO LOAD

4 E

5 NO LOAD

6 D

7 D

8 NO LOAD

Table 4: COMPOSITION OF EACH COMBINATION

ABCDE

4.5A Ignition 50 VA Pilot Duty

plus 4.5A ignition

180 VA Ignition

plus motor values with: 600VA

inrush., 360 VA

open, 250 VA

hold

NO LOAD E

NO LOAD E

NO LOAD E

A E

A E

A E

A D

A D

2A Pilot Duty 65 VA Pilot Duty

plus Motor valves

with: 3850 VA

in rush., 700 VA

open, 250 VA

hold

3

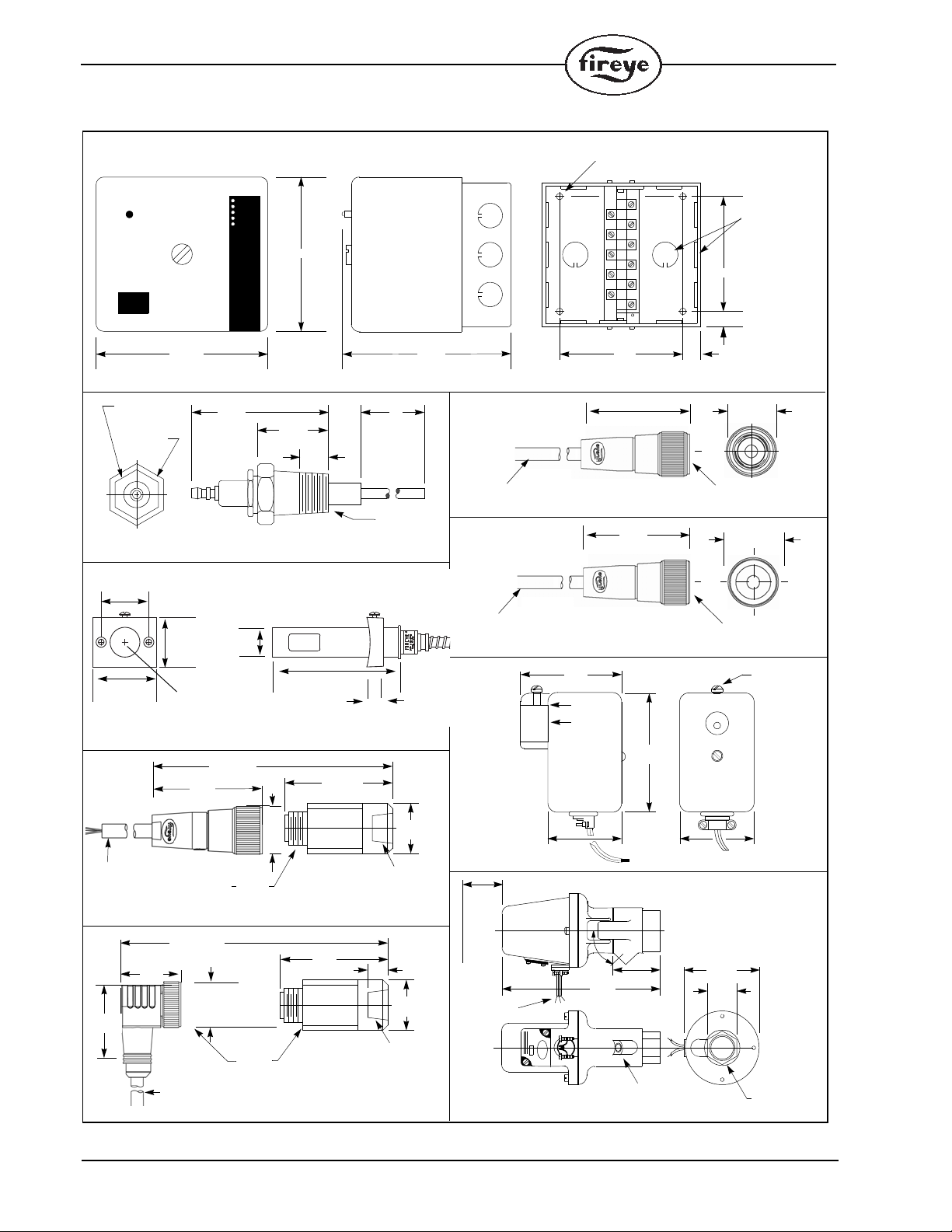

HOLE FOR

3/4”

SIGHTING

PIPE

SCREW,

1/4”-20 THD

2” (51) CLEARANCE REQUIRED TO REMOVE

2”

(51)

1/2”-14

STRAIGHT PIPE THD

8 1/4”

(210)

45

O

3/8”-18 NPT FOR

PURGE AIR CONNECTION

4” (102)

1 11/16”

HEX

(43)

1”-11 1/2 NPT

FOR SIGHT

TUBE

UV2 UV SCANNER

UV SELF-CHECK

SCANNER

TYPE 45UV5

MODEL 1009

UV1A UV SCANNER

72” LEAD

2 7/8”

(73)

2”

(50.8)

1 5/8”

(41)

3 1/4”

(82)

UV SCANNER

Type: 45UV3

Model: 1050

2 3/8”

(60.3)

1 3/16”

(30)

1/2”

(12.7)

”L”

1/2”-14 NPT

13/16” HEX

(20.6)

15/16” HEX

(23.8)

”L” LENGTH AS SPECIFIED: 12”, 18”, 24” (304.8, 457.2, 609.6)

69ND1 FLAME ROD

2 1/2”

(63.5)

5.04”:(128)

WHEN ASSEMBLED

1 1/4”

DIA.

1.063”

DIA.

HEAT INSULATOR

.345” (8.7)

TC-ER CABLE

1/2”-14

TAPERED

PIPE THD

1/2”-14

STRAIGHT PIPE THD

48PT2-1000 SERIES INFRARED SCANNER

2 1/2”

(63.5)

3.96” (100.6)

WHEN ASSEMBLED

1 1/4”

DIA.

1.02” DIA.

(26.0)

HEAT INSULATOR

.345” DIA. (8.7) TC-ER CABLE

1/2”-14

TAPERED

PIPE THD

2.13”

(54.0)

1.46”

(37.1)

13/32” (10)

48PT2-9000 SERIES INFRARED SCANNER

UV90 SCANNER

5 3/16”

5 3/16”

MOUNTING BASE

5 5/16”

4”

4”

1/2”’

1/2”

3/16” DIA. MOUNTING

HOLES (4)

KNOCKOUTS (12)

FOR 1/2”

CONDUIT

μΜ

All dimensions in inches (millimeters in parentheses).

S1

7

S2

8

3

2/N

5

A

4

1

6

3/16” MOUNTING

HOLES

(4)

0.880"

(22.3MM)

1.90

(48.2MM)

1.406"

(35.7MM)

1.48"

(37.6MM)

0.875"

(37.6MM)

3.75"

(95.7MM)

0.5"

(12.7MM)

UV90 MOUNTING BLOCK

(Included with Scanner)

2.58”

(50.8)

36” (1m APPROX.)

TC-ER CABLE

3/8” PIPE THREAD

1.06” DIA.

(27.0)

2.53”

(64.3)

1/2-14 STRAIGHT

FEMALE PIPE THREAD

1.06” DIA

(27.0)

36” TC-ER CABLE (UV-1A-3)

72” TC-ER CABLE (UV-1A-6)

2.5”

(63.6)

4

APPROVALS

WARNING: This equipment is a Class B digital apparatus which complies with the Radio

Interference Regulations, CRC c.1374.

CAUTION: Published load ratings assume that no control be required to handle inrush

current more often than once in 15 seconds. The use of control switches, solenoids, relays,

etc. which chatter will lead to premature failure. It is important to run through a test

operation (with fuel shut off) following the tripping of a circuit breaker, a blown fuse, or

any instance of chattering of any external current consuming devices.

WARNING: Selection of programmer and amplifier type for a particular application should

be made by a competent professional, such as a Boiler/Burner technician licensed by a state

or government agency, engineering personnel of the burner, boiler or furnace manufacturer

(OEM) or in the performance of duties based on the information from the OEM.

WARNING: This equipment generates and can radiate radio frequency energy, and if not

installed and used in accordance with the instruction manual may cause interference to

radio communications. It has been tested and found to comply with the limits for a Class A

computing device pursuant to Subpart J of part 15 of FCC Rules, which are designed to provide reasonable protection against such interference when operated in a commercial environment. Operation of this equipment in a residential area is likely to cause interference in

which case the user, at his own expense, will be equipped to take whatever measures that

may be required to correct the problem.

In order for the MicroM to gather and retain statistical and historic data such as burner

hours, burner cycles, system hours and average flame signal, it is necessary that Terminal 1

be powered at all times. Removing power from Terminal 1 at the end of the firing cycle

causes all data gathered during the previous 16 hours or last 9 cycles to be lost. For conversions or upgrades from older TFM or M-Series II controls that use MART1 amplifiers, it is

necessary that Terminal 1 be directly powered with 120 VAC.

?

Underwriters Laboratories Inc.:

MCCZ File MP 1537

Controls, Primary Safety - Listed

MCCZ2 File MP1537

Controls, Primary Safety - Component

MCCZ7 File MP1537

Controls, Primary Safety Certified for Canada

MCCZ8 file MP1537

Controls, Primary Safety Certified for Canada - Component

Factory Mutual System (FM) Approved

UL approval does not apply to 230VAC operations.

5

ORDERING INFORMATION

MicroM Chassis Types (For use with MEP1XX, MEP2XX, and MEP5XX, includes dust cover)

MEC120 120 VAC input with standard plug-in board.

MEC120R 120 VAC input with remote reset capability.

MEC120D 120 VAC input with alpha-numeric display interface to ED510.

MEC120RD 120 VAC input with alpha-numeric display interface to ED510 and remote reset capability.

MEC120C 120 VAC input with interface to E500 Communication Interface and Modbus capability.

MEC120RC 120 VAC input with remote reset capability, alpha-numeric display interface to ED510, interface to E500 Communica-

MEC230 230 VAC input with standard plug-in board.

MEC230RC 230 VAC input with remote reset capability, alpha-numeric display interface to ED510, and Modbus capability.

MEC320 120 VAC input with standard plug-in board.

MEC320R 120 VAC input with remote reset capability.

MEC320D 120 VAC input with alpha-numeric display interface to ED510.

MEC320RD 120 VAC input with alpha-numeric display interface to ED510 and remote reset capability.

MEC320C 120 VAC input with interface to E500 Communication Interface and Modbus capability.

MEC320RC 120 VAC input with remote reset capability, alpha-numeric display interface to ED510, interface to E500 Communica-

MEC320TS 120 VAC input with display interface to ED510, Modbus interface and auxiliary relay output with dry contact for con-

MEC480 230 VAC input with standard plug-in board.

MEC480RC 230 VAC input with remote reset capability, alpha-numeric display interface to ED510, and Modbus capability.

tion Interface and Modbus capability.

MicroM Chassis Types (For use with MEP3XX, MEP4XX, and MEP6XX, includes dust cover)

tion Interface and Modbus capability.

troller interface (MED8).

MicroM Programmer Models (For use with MEC120 and MEC 230 Chassis)

MEP100 Relight operation, 10 sec. PTFI.

MEP101 Relight operation, allow flame signal until 60 seconds after interlock closed.

MEP102 Non-recycle on flame fail, 5 second PTFI.

MEP103 Fixed 10 second SISP*, 10 second MTFI, re-try once on igniter failure, fixed 30 second post purge.

MEP104 Non-recycle on flame fail, 10 second PTFI.

MEP105 Non-recycle on flame fail, lockout on air-flow open with flame present, 10 second PTFI.

MEP106 Same as MEP100. 12 second pre-purge, added reset from lockout via line voltage.

MEP107 Same as MEP100. Force 5 minute purge delay after main flame fail.

MEP108 Same as MEP100 with 0 second purge, 15 second PTFI, non-recycle on flame fail. Not FM approved.

MEP109 Immediate ignition and pilot, 10 second fixed PTFI, 10 second MTFI, intermittent pilot, non-recycle on flame fail.

MEP100P Relight operation, 10 sec PTFI, fixed 15 second post purge.

MEP130 Same as MEP100, 30 second PTFI. Not FM approved.

MEP230 Selectable purge timing (7, 30, 60, 90 sec.) 10 sec PTFI timing, recycle/non-recycle, post purge, prove air open at start.

MEP230H Same as MEP230 with 8 second pilot stabilization.

MEP235 Same as MEP230 with lockout on air flow open 10 seconds after the start of a cycle, selectable recycle/nonrecycle lockout

MEP236 Same as MEP230 with additional 6 second igniter on time with main fuel. To be used with intermittent pilot only.

MEP237 Same as MEP230 with fixed PTFI timing and check/run switch. Used with MEDC2 amplifier to provide operation with 85

MEP238 Same as MEP230. Ignition de-energized 3 seconds after pilot flame detected. Provides 8 second pilot stabilization period.

MEP290 Same as MEP230 except selectable post purge is 0 or 90 seconds.

MEP560 Same as MEP230H, 10 second main trial for ignition, run-check switch.

MEP561 Same as MEP560 without 8 second pilot stabilization. Selectable purge time of 7s, 10s, 15s, 30s.

MEP562 Same as MEP560, lockout on loss of air flow, non-recycle operation only.

MEP564 Same as MEP560. Selectable purge time of 7s, 30s, 60s, 240s.

MEP536 Same as MEP230, 10 second main trial for ignition, run-check switch, will not lockout on air flow open during purge.

MEP537 Same as MEP536 except provides one recycle on main flame failure.

*Spark Igniter Sensing Period

on air flow open after flame is proven and dedicated lockout after loss of flame.

Series (Phoenix) and 95 Series (InSight) scanners.

6

MicroM Programmer Models (For use with MEC320 and MEC 480 Chassis)

MEP300 Relight operation, 10 sec. fixed PTFI, 5 sec.pilot proving period, 5 second MTFI. lockout on flame fail during PTFI, pilot

MEP304 Non-recycle on flame fail, 5 sec. purge, 10 sec.fixed PTFI, 5 sec. pilot proving, 10 sec.MTFI, interrupted pilot, early

MEP335 Non-recycle on flame fail, 30 second purge, 35 second hot surface ignition on terminal 4, 3 second PTFI on terminal 3,

MEP397 Recycle on main flame fail, 15 sec. purge, 7 second fixed PTFI, 5 sec. pilot proving 5 sec. MTFI, early spark termination

MEP437 Recycle once on main flame failure, selectable 5 or 10 sec. fixed PTFI, selectable interrupted or intermittent pilot, 5 sec.

MEP696 Provides 30 sec. pre-purge, lockout on airflow after 10 sec., 10 sec. PTFI, 5 sec. pilot proving, early spark termination,

MEP697 Provides dip-switch selectable pre-purge, selectable air flow proving at startup, selectable post purge, selectable 5/10

MEUV1 UV amplifier, 0.8 second FFRT, uses UV1A, UV2, UV8A, UV90 and 45UV3-1050 scanners.

MEUV4 UV amplifier, 3 second FFRT, uses UV1A, UV2, UV8A, UV90 and 45UV3-1050 scanners.

MEUVS1 UV Self-Check amplifier, 0.8 second FFRT, uses 45UV5-1009 scanner.

MEUVS4 UV Self-Check amplifier, 3 second FFRT, uses 45UV5-1009 scanner.

MERT1 Flame Rod amplifier, 0.8 second FFRT, uses 69ND1.

MERT4 Flame Rod amplifier, 3 second FFRT, uses 69ND1.

MEIR1 Infrared amplifier, 0.8 second FFRT, uses 48PT2 scanner.

MEIR4 Infrared amplifier, 3 second FFRT, uses 48PT2 scanner.

MECD1 Cadmium sulfide amplifier, 0.8 second FFRT, uses CS1A5 scanner.

MECD4 Cadmium sulfide amplifier, 3 second FFRT, uses CS1A5 scanner.

MEDC2 Contact input amplifier for use with MEP237 to provide operation with 85 Series (Phoenix) and 95 Series

proving and MTFI. Recycle on air flow open. No post purge. Reset on line voltage.

spark termination.

5 second pilot proving period, intermittent pilot, 15 second post purge. Manual reset only.

and interrupted pilot. Recycle on air flow failure. No post purge, run/check switch. Reset on line voltage.

MTFI, selectable purge time to 240 seconds, main valve proof of closure, 15 sec. post purge. Reset on line voltage.

5 sec. MTFI, interrupted pilot, selectable recycle/non-recycle on flame fail, 60 sec. post purge, selectable baud rate for

communications, output for external controller operation.

sec. PTFI, 5 sec. pilot proving early spark termination, 5 sec. MTFI, interrupted pilot, selectable recycle/non recycle on

flame fail, output for external controller operation.

MicroM Amplifier Models:

(InSight) scanners

Optional Plug-In Board Modules:

MED1 Standard local reset switch.

MED2 Same as MED1 with display output.

MED3 Same as MED1 with remote reset.

MED4 Same as MED1 with display output and remote reset.

MED5 Same as MED1 with display output and RS485 communications.

MED6 Same as MED1 with display output, remote reset and RS485 communications.

MED7 Same as MED1 with RS485 communications.

MED8 Same as MED1 with display output, RS485 Modbus interface and auxiliary relay output

with normally closed dry contact for controller interface.

MED9 Same as MED1 with display output, RS485 Modbus interface and auxiliary relay output

with normally open dry contact for controller interface.

Wiring Base (Common for all Controls):

61-3060 Closed wiring base, surface mounting.

61-5042 Open wiring base, cabinet mounting.

7

Accessories

CAUTION: The UV1A, UV2, UV8A, UV90 and 45UV3 ultra-violet flame scanners and associated amplifier modules are non self-checking UV systems and should be applied only to

burners that cycle often (e.g.: a minimum of once per 12 hours) in order for the safety checking circuit to be exercised. If component checking is required during burner operation for

constantly fired burners, utilize the self-checking ultra-violet flame scanners (45UV5) with

associated amplifier module (MEUVS1, MEUVS4) or the infrared flame scanner (48PT2)

with associated AutoCheck amplifier (MEIR1, MEIR4).

ED510 Two line by 16 character, back lit LCD display with keypad.

ED580-2, -4, -8 Remote display cable with RJ45 connection in 2, 4 or 8 foot long lengths. To be used with the appropriate daughter

EC485 RS232 to RS485 converter with power supply and RJ12 jack.

UC485 USB to RS485 converter. Supplied with USB cable.

SMDK-1004 Serviceman’s display kit used for diagnosing MicroM system. Consists of ED510 equipped with back plate, MED

129-145-1, -2, -3 ED510 remote display mounting kit with 4’, 8’ or 2’ cable respectively. Provides NEMA 4 protection.

IT1000 Monitoring device using cellular networks. Provides various reporting methods

board.

daughter board and ED580-4.

FLAME SCANNERS

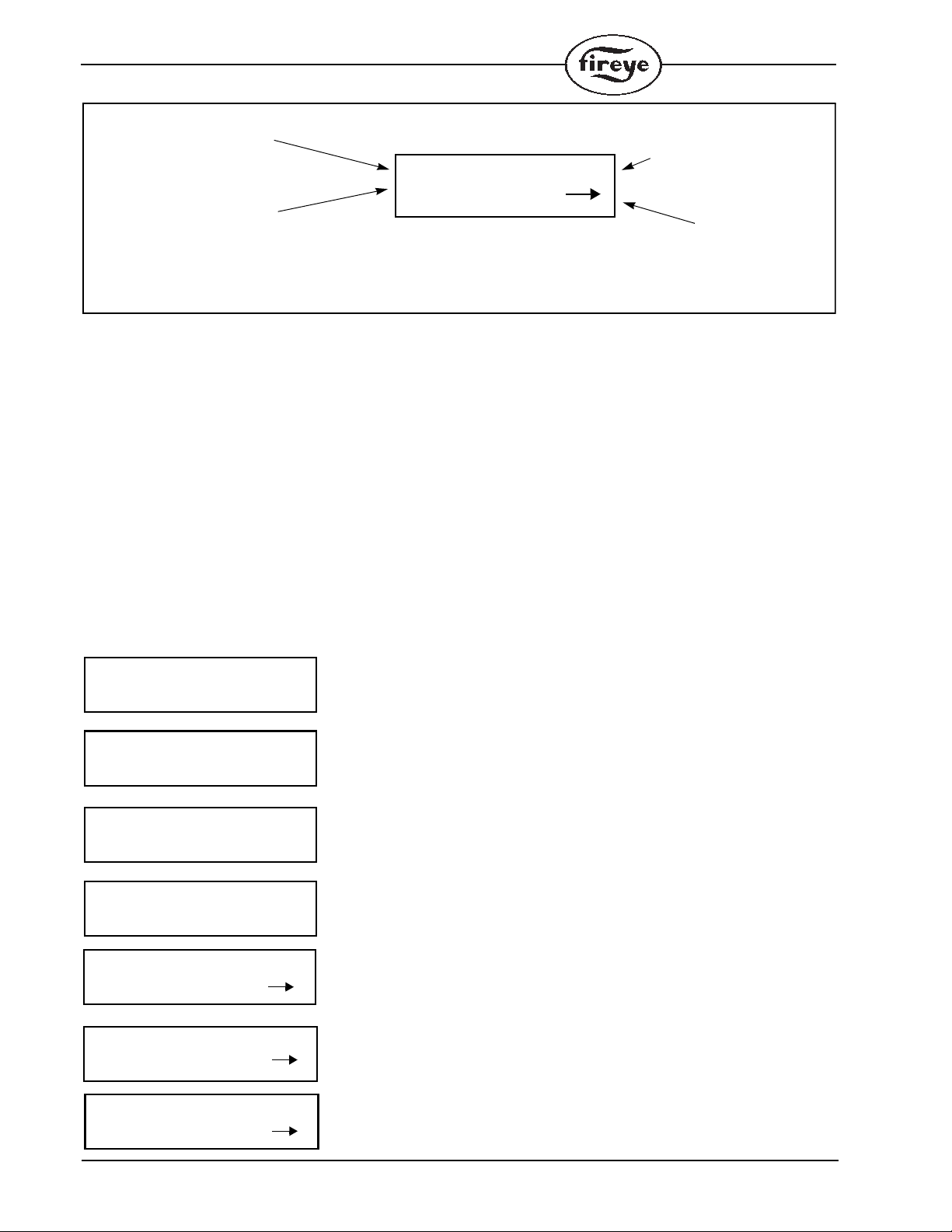

For a complete system, choose one of each of the following:

- Chassis - Flame Detector

- Programmer Module - Wiring Base

- Amplifier Module

8

INSTALLATION OF CONTROL, SCANNERS AND FLAME DETECTORS

WARNING: Installer must be trained and qualified. Follow the burner manufacturer’s

instructions, if supplied. Otherwise, proceed as follows:

WARNING: Controls require safety limits utilizing isolated mechanical contacts.

Electronic limit switches may cause erratic operation and should be avoided.

Care must be taken to NOT route the high energy ignition wire in close proxim-

ity to the flame sensor wiring, particularly when using MERT amplifier.

Wiring Base

Mount the wiring base on the burner or on a panel. The location should be free from excessive vibration and within the specified ambient temperature rating. The base may be mounted in any angular

position.

All wiring should comply with applicable electrical codes, regulations and local ordinances. Use

moisture resistant wire suitable for at least 90 degrees C. Good electrical wiring practice should be

followed to ensure an adequate ground system. Refer to Fireye Service Note SN-100 separately and

General Grounding Rules later in this document for grounding methods.

A good ground system should be provided to minimize the effects of AC qu ality problems. A properly designed ground system meeting all the safety requirements w ill ensure that any AC voltage

quality problems, such as spikes, surges and impulses have a low impedance path to ground. A lo w

impedance path to ground is required to ensure that large currents involved with any surge voltages

will follow the desired path in preference to alternative paths, where extensive damage may occur to

equipment.

Circuit recommendations are found on pages 38 through 43. Consult the factory for assistance with

non-standard applications.

9

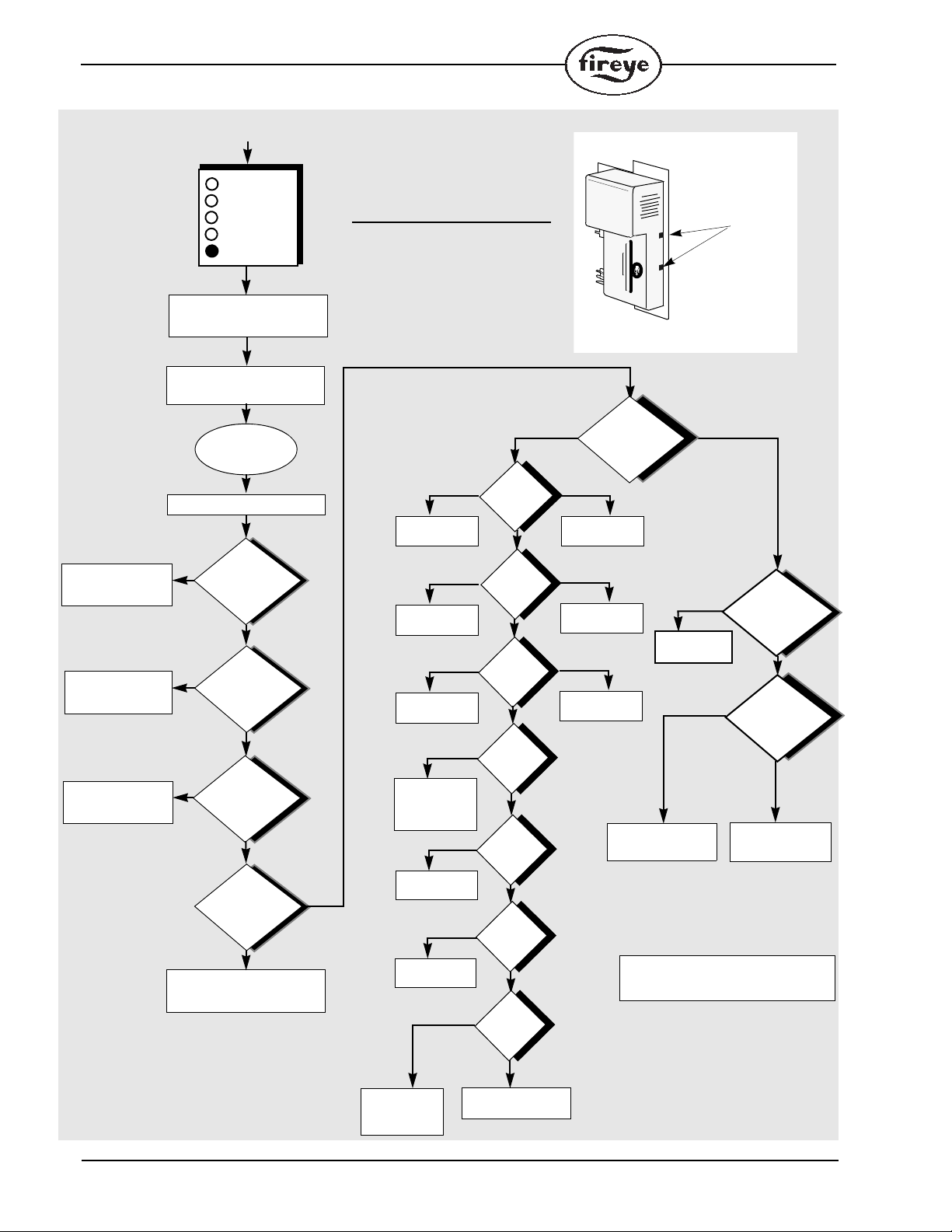

INSTALLING THE PROGRAMMER AND AMPLIFIER MODULES

WARNING: Remove power from the control before proceeding.

PROGRAMMER

AMPLIFIER

WARNING: Turn off the power when installing or removing the control.

WARNING: Disconnect power before servicing.

FIGURE 1. .

Select the appropriate programmer and amplifier modules for your application. R emove the dust

cover from the chassis. Insert the amplifier module into the slot in the corner of the chassis and gently push the module into position. Insert the pro gramme r module int o the slot at the right sid e of the

chassis and gently push the module into position.

NOTE: Refer to programmer dipswitch settings on page 11 for the proper setting of the dipswitches

for those programmers with this feature.

Replaceable Fuse

The chassis modules are designed with a field replaceable fuse. The fuse is located on the printed circuit board below the transformer. In the event the fuse becomes OPEN, the Operating Control, PTFI,

and Flame LED’s will light. However , KL or KF (Wiring Arrangements section on pages 33 through

38) will not be energized and the control will lock out and indicate Lockout, Check Blown Fuse. The

fuse will blow as a result of an overload condition on Terminals 3, 4, or 5. To replace the fuse,

remove power from the system and using a small screwdriver or similar tool, install a Fireye replacement fuse (P/N 23-197).

FOR MEC230, ORDER FIREYE REPLACEMENT FUSE P/N 23-198 .

10

FIGURE 2.

Replaceable

Fuse Location

PROGRAMMER DIPSWITCH SETTINGS

NOTE: The dipswitch settings become permanently stored within the programmer’s eeprom memory

after 8 hours of continuous electrical operation.

The first 8 hours of continuous operatio n is determined from the value of system hours being accumulated by the MicroM. System hours are stored to memory (eeprom) automatically every 1,000

minutes or at the occurrence of a lockout. Therefore, any lockout that occurs during the first 8 hours

will cause the system hour value to become the time when the last lockout occurred. If power is

removed and restored, the continuous 8 hours feature will be reduced by the time when the lockout

occurred.

This allows sufficient opportunity to make the appropriate selection, test and checkout the system.

Once stored, the settings cannot be altered.

The MEP200 and MEP500 series programmers have a series of 6 dipswitches (see Figure 3) whic h

allow the user to program the purge timing, trial for ignition timing, enable post purge, enable proof

of air flow open at start and select recycle/non-recycle operation.

MicroM Programmer Dip Switch Configuration

(see bulletin MC-3200 for MEP696 settings)

SWITCH FUNCTION NOTES

654321 STD MEP561MEP564

CC

CO

OC

OO

C

O

C

C

O

C

O

Note: C refers to switch closed position, closed position is when the switch is toward the printed

7

30

60

90

DISABLED POST*

15 SECONDS

5 PTFI

10

DISABLE PROVE AIR

ENABLE

77

10 30

15 60

30 240

PURGE

TIMEO

FLOW OPEN

AT START

RECYCLE

NON-RECYCLE

PURGE

TIME

SECONDS

* The MEP290

Programmer

module has

selectable post purge

of 90 seconds.

circuit board. O refers to switch open position or when the switch is moved away from the printed

circuit board. Indicating arrow on top of programmer cover points toward closed position.

11

FIGURE 3.

LED

INDICATORS

SWITCHES

(shown in closed or OFF position)

DIP

Once the switches are set, they become permanently stored after 8 hours of continuou s operation or

they can be manually set through the use of the optional ED510 display. Refer to the section using

the optional ED510 display for detailed information.

Where applicable, each MicroM programmer is shipped with dip-s witch 6 set to non-recycle on

flame fail, dipswitch 4 set to 5 second PTFI ti me, an d dipswitches 1 & 2 set to the longest purge

time.

Dipswitch Definitions

Purge Time: Begins after power is detected on T erminal #7 (limit control) and Terminal #6 (running

interlock switch) and no flame (real or simulated) is detected.

Post Purge: If enabled, Terminal #8 (blower motor or contactor) will remain energized for 15 seconds after terminal #7 or Terminal #6 is detected as open.

PTFI Time: The maximum length of time that Terminal #3 and Terminal #4 will be energized after

the pre-purge period to detect pilot flame. For all programmers, the MicroM forces a 3 second delay

before advancing to the next logic module (Stabilization, MTFI or Auto) after flame is detected

during the PTFI period. This is to allow establishment of a pilot and stabilization of the fuel flow.

Prove Air Flow Open: After power is detected on Terminal #7 (limit control) and before energizing

Terminal #8 (blower mo tor or contactor) no power must be detected on Terminal #6 (running interlock switch). If power is detected on Terminal #6, the MicroM will hold for 60 seconds after which

safety lockout will occur. On recycle operation, if this is enabled, T erminal #8 will be de-energized to

allow Terminal #6 to open.

Recycle / Non-Recycle: Applies to flame failure during the Run condition. If a flame failure occurs,

the control will de-energize Terminals #3 and #5 and if Recycle is selected a new prepurge period

will begin. Lockout will occur immediately and the alarm will energize 15 seconds after flame failure if Non-Recycle is selected. Unless otherwise stated (see Programmer Description), the MicroM

recycles on all occurrences of air flow failure. The MEP235 and MEP562 will always initiate a lockout on flame failure.

LED INDICATOR LIGHTS

All MicroM Programmer Modules have 5 LED lights to indicate the operating status of the control

and also to display the coded sequence under locked out conditions. The function of the lights under

a normal operating condition is:

Operating Control: This LED is energized whenever the burner control switch and all other various

limit switches are closed and power is applied to Terminal #7.

Interlock or Air Flow: This LED is illuminated whenever power is detected on Terminal #6, indicating the air flow switch or other running interlock is closed. If the operating control is closed and

the running interlock switch remains open, this LED will flash at a 1 second rate indefi nitely for t he

MEP100 and MEP200 family. Lockout will occur if the switch remains open for 10 minutes in the

MEP500 family. This LED will blink when configured as a flame switch and flame detected.

12

LOCKOUT CODES

PTFI: This LED is illuminated only during the pilot trial for igni tion period and the stabilization

period when so equipped.

Flame: This LED is on whenever a flame signal is detected, and the control is not in a locked out

state.

Alarm: This LED flashes when an alarm condition is detected and is used as an address indicator

(see communication).

During an alarm condition, the Alarm LED is made to flash at approximately a 1 second rate. The

remaining four LEDs are illuminated as a coded sequence identifying the reason for the lockout. For

instance, for a LOCKOUT - FLAME FAIL- PTFI, the INTERLOCK, PTFI and FLAME LED’s will

all be lit steady, with the Alarm LED flashing. This remains true if power is removed and then

restored in a locked out condition.

While in the Idle or Off state, the LEDs are made to flash sequentially to show the operational status

of the control every minute. The LEDs can be tested by pressing and releasing the Reset push button,

while in the Idle or Off state.

MSGN DESCRIPTION OP

CTRL

DEC HEX

6 6 Lockout Line Frequency Noise Detected

7 7 Lockout Flame Fail - PTFI

15 0F Lockout Fault Unknown

16 10 Lockout Amplifier High Count Fail

19 13 Lockout Flame Fail - MTFI

20 14 Lockout False Flame - STANDBY

21 15 Lockout Intrlck Open

22 16 Lockout Intrlck Closed

24 18 Lockout Chassis Opto

37 25 Lockout Flame Fail - AUTO

39 27 Lockout Fuel Valve State Change

54 36 Lockout Check Chassis

55 37 Lockout Check Programmer

56 38 Lockout Check Amplifier

58 3A Lockout Amplifier Auto Check Fail

59 3B Lockout Check BLOWN FUSE

76 4C Lockout Check Scanner

N/A N/A System Error

AIRFLOW

INTLCK

PTFI FLAME ALARM

= NOT LIGHTED

= LIGHTED

= FLASHING

All LED’s Flashing indicates defective programmer.

All MicroM chassis are shipped with a convenient peel off label that can be applied to any

surface (inside cover) for future reference.

13

DIAGNOSTIC MESSAGES - TROUBLESHOOTING GUIDE

POSSIBLE CAUSE SOLUTION

Check Programmer Voltage on Terminal 5 at improper time. Inspect wiring to main fuel valve

Welded watchdog relay Replace MEC chassis

Internal diagnostic failure Replace MEP programmer

Check Chassis Voltage on Terminal 3 or 4 at improper time. Inspect wiring to pilot valve and igniter.

Welded watchdog relay Replace MEC chassis

Chassis Opto Opto-Coupler(s) short circuited Replace MEC chassis

Amplifier High Count Fail Amplifier signal level high Replace Amplifier module

Amplifier Auto Check Fail Flame signal too high Use orifice in sight pipe

Internal Amplifier diagnostic fault Replace Amplifier module

Check Scanner Defective shutter Inspect scanner wiring, replace scanner

UV tube false firing Replace UV tube or scanner

Check Blown Fuse No power detected on terminal 3 Inspect defective pilot valve or igniter

Defective fuse Replace fuse

Line Frequency Noise Detected Spikes detected on AC mains Check for SCR motors or DC drives

Inspect ground system

Fuel Value State Change Terminal 5 (main fuel) detected on during PTFI Check external wiring or replace MEC chassis

Check Amplifier Amplifier not passing diagnostic tests Replace Amplifier module

System Error Noise transient Check high energy ignition noise location. Be

sure it is not arcing to chassis or wrapped

with scanner wiring.

PROGRAMMER DESCRIPTION

For replacement of UVM, TFM and M-II type controls, refer to the cross-reference provided at the end of

this section.

MEP100 SERIES

MEP100 and MEP101

These programmers provide relight operation, in the event of a flame failure, pilot trial for ignition is

reinitiated. The MEP101 will not lock out if flame signal is present during the Idle or Off cycle. With

flame signal present, lockout will occur 60 seconds after the start of a cycle and the air flow switch is

closed.

Pilot Ignited Burners

Refer to typical wiring arrangement beginning on page 38.

Normal Operation

With power applied and the limit operating control circuit (1-7) closed, the Operating Control LED

illuminates, the burner motor circuit is energized (Terminal 8).

After the air flow proving switch (7-6) closes, the interlock (air flow) LED is illuminated and a short

time delay period (3-5 seconds) begins.

At the expiration of the safe start check period, a 10 second pilot trial for ignition (PTFI) period is

initiated, illuminating the PTFI Led. Power is applied to Terminal 3, energizing the pilot gas valve

and to Terminal 4, energizing the spark ignition.

At the detection of pilot flame, the FLAME LED is illuminated, and the programmer holds that position for 3 seconds to allow the to pilot stabilize.

Power is then applied to Terminal 5 energizing the main fuel valve and removing power from Terminal 4, turning off the spark igniter.

When the operating control opens, the control de-energizes Terminal 3 and Terminal 5 and the pro-

14

grammer reverts back to an Idle state.

Safety Shutdown

In the event pilot flame is not detected at the end of the 10 second PTFI period, the pilot gas valve

and spark ignition are de-energized. A safety lockout occurs which de-energizes the burner motor

and energizes the lockout alarm relay circuit, lighting the Alarm LED, 15 seconds after the safety

lockout occurs. Manual reset is required.

In the event of a flame failure during a firing period, the main fuel valve is de-energized (Terminal 5)

and the spark ignition is re-energized (Terminal 4), the PTFI period begins again as described above

under Normal Operation.

In the event of the interlock switch opening, the main fuel valve and pilot valve are de-energized.

The control reverts back to the Idle state and begins again a new cycle starting with the safe start

check period.

Direct Spark Ignited Burners

Refer to typical wiring arrangement illustrated on pages 40 and 41.

Normal Operation

With power applied and the limit operating control circuit (1-7) closed, the Operating Control LED

illuminates, the burner motor circuit is energized (Terminal 8).

The interlock proving switch (7-6) closes, the INTRLCK LED is illuminated and a short time delay

period (3 seconds) begins (safe start check period).

At the expiration of the safe start check period, a 10 second PTFI period is initiated. The PTFI Led is

illuminated, power is applied to Terminal 3, energizing the main fuel valve and to Terminal 4, energizing the spark ignition.

At the detection of main flame, the FLAME LED is illuminated, and the programmer holds that position for 3-5 seconds to allow the main flame to stabilize.

Power is then removed from Terminal 4, turning off the spark igniter.

When the operating control opens, the control de-energizes Terminal 3 and Terminal 5 and the pro-

grammer reverts back to an Idle state. Terminal 8 is immediately de-energized.

Safety Shutdown

In the event the main flame is not detected at the end of a 10 second PTFI period, the main fuel valve

and spark ignition are de-energized. A safety lockout occurs which de-energizes the burner motor

and energizes the lockout alarm relay circuit, lighting the Alarm LED, 15 seconds after the safety

lockout occurs. Manual reset is required.

In the event of a flame failure during a firing period, the secondary fuel valve (if used) is de-energized and the spark ignition is re-energized, the PTFI period begins again as described ab ove under

Normal Operation.

In the event of the interlock switch opening, the main fuel valve and pilot valve are de-energized.

The control reverts back to the Idle state and begins again a new cycle starting with the safe start

check period.

MEP102 & MEP104

The MEP102 and MEP104 programmers operate the same as the MEP100, except th e PTFI time is

limited to 5 seconds and 10 seconds respectively, the relight feature is eliminated and instead, the

control will enter safety lockout on flame failure. Recycle to the start of safe start check period to

begin a new cycle will occur on air flow switch opening.

MEP103

The MEP103 programmer implements a fixed 10 second spark igniter sensing period (SISP) used to

detect spark, followed by a 10 second main trial for ignition (MTFI). Safety lockout occurs on flame

failure during the main firing period (AUTO). Recycle occurs on air flow switch opening. If spark is

not detected during the spark igniter sensing period the cont rol makes one attempt to establish pilot

15

TIMING CHART

TYPE MEP100

PROGRAMMING SEQUENCE

L1/7

ON

INTERLOCK

AIR FLOW

PROVEN

FIRING

PERIOD

L1/7

OFF

PTFI

10 SEC

SAFE

START

CHECK

PERIOD

8

T

E

R

M

I

N

A

L

S

3

4

5

following a post purge of 30 seconds and a safe start check. Failure to ignition spark on the second

attempt results in safety lockout.

MEP100P

The MEP100P programmers provides a fixed 15 second post purge period upon detection of the

operating Control (1-7) or Air Flow switch (7-6) opening.

MEP100 as FLAME SWITCH (refer to Figure 11)

For systems that require flame switch operation, that is, relay KF will togg le on with flame signal

and off without flame signal, the MicroM provides this function when equipped with an MEP100

programmer. To operate as a flame switch, Terminals 1 and 6 MUST be powered with 120 VA C

while T erminal 7 MUST be left unpowered. Terminals 3, 4, and 5 will provide an isolated (KL relay

not energized) set of contacts with Terminal 3 being the common input , Terminal 4 will be normally

closed and Terminal 5 will be normally open. If Terminal 7 is powered or if Terminal 6 is non-

powered and a flame signal is present, the MicroM will lockout after 1 minute and Terminals 4

and 5 will no longer switch with flame signal. Refer to Figure 11 for configuration wiring. Air

Flow LED will blink while flame is detected.

MEP200 SERIES

16

Terminal #5 is energized 3 seconds after flame is detected.

Re-ignited PTFI on flame fail after Terminal 5 energized.

Recycle on loss of interlock (air flow) after flame proven.

MEP101

Same as MEP100 but will tolerate flame signal during “Off” cycle.

MEP102

PTFI time limited to 5 seconds, lockout on flame fail.

MEP104

PTFI time limited to 10 seconds, lockout on flame fail.

The MEP200 Series programmers come equipped with a bank of dipswitches that allow user selectable prepurge timing, selectable PTFI timing, selectable post purge, selectable air flow proven open

at start, and selectable recycle/non-recycle operation. Refer to PROGRAMMER DIPSWITCH SETTINGS for detailed information.

Recycle operation refers to flame failure during the main (AUTO) firing period. In the event of a

main flame failure, power is removed from Terminal 3 and Terminal 5. If selected by the dipswitch,

the control will enter a post purge period for 15 seconds and revert back to the Idl e state where the

pre-purge period begins.

TIMING CHARTS

TYPE MEP230

PROGRAMMING SEQUENCE

L1/7

ON

PURGE

COMPLETE

FIRING

PERIOD

L1/7

OFF

SELECTABLE PTFI

5 OR10 SEC

SELECTABLE

PURGE

7, 30, 60, 90 Seconds

8

T

E

R

M

I

N

A

L

S

3

4

5

SELECTABLE

POST PURGE

INTERLOCK

AIR FLOW

PROVEN

If non-recycle operation is selected, in the event of a main flame failure, power is removed from Terminal 3 and Terminal 5. The control will enter a forced post purge period of 15 seconds, after which

the Alarm LED is illuminated and the alarm relay is energized putting power on Terminal A.

The MEP230H programmer operates the same as the MEP230 with the exception of an additional 8

second pilot stabilization. After flame is detected during the trial for ignition period, the powering of

Terminal 5 is delayed for eight (8 ) seconds. Terminal 4 remains powered during the stabilization

period. This function is offered primarily for two-stage light oil burners, to assure a specific delay

between light off of the first and second stage, and to provide additional ignition timi ng to improve

flame stabilization.

The MEP290 programmer operates the same as the MEP230 with the exception t hat post purge is

selectable from 0 to 90 seconds.

MEP235

The MEP235 programmer operates the same as the MEP230 except flame failure during the firing

period causes lockout. Dipswitch #6 refers to Recycle/Non-Recycle on a loss of air flow (T erminal 6)

after flame is proven. The running interlock circuit (Terminal 6) must be proven closed within 10

seconds after start of a cycle.

MEP236

The MEP236 programmer provides a 3 second main flame stabilization period by keeping Terminal

#4 (igniter) energized while the main fuel valve (Terminal #5) opens. The MEP236 is to be used on

an intermittent pilot only.

Terminal #5 is energized 3 seconds after flame is detected.

Selectable Recycle/Non-Recycle operation on loss of flame after Terminal 5 energized.

Recycle on loss of interlock (air flow) after flame proven.

Selectable air flow (interlock circuit) proven at start.

Selectable purge times are 7, 30, 60 and 90 seconds.

17

Terminal #5 is energized 3 seconds after the flame is detected.

TYPE MEP236

PROGRAMMING SEQUENCE

L1/7

ON

PURGE

COMPLETE

FIRING

PERIOD

L1/7

OFF

SELECTABLE PTFI

5 OR10 SEC

SELECTABLE

PURGE

8

T

E

R

M

I

N

A

L

S

3

4

5

SELECTABLE

POST PURGE

PILOT

IGNITER

MAIN VALVE

MFSP*

6 SEC

*MAIN FLAME STABILIZATION PERIOD

INTERLOCK

AIR FLOW

PROVEN

TYPE MEP230H

PROGRAMMING SEQUENCE

L1/7

ON

PURGE

COMPLETE

FIRING

PERIOD

L1/7

OFF

SELECTABLE PTFI

5 OR10 SEC

SELECTABLE

PURGE

8

T

E

R

M

I

N

A

L

S

3

4

5

SELECTABLE

POST PURGE

STABILIZATION PERIOD

8 SEC

INTERLOCK

AIR FLOW

PROVEN

Selectable Recycle/Non-Recycle operation on loss of flame after flame is proven.

Igniter remains on for 6 seconds after main valve opened.

Intermittent pilot only.

For interrupted pilot, use MEP536

Pilot Stabilization timing begins as soon as flame is proven.

Selectable Recycle/Non-Recycle operation on loss of flame after Terminal 5 is energized.

Selectable air flow (interlock circuit) proven at start.

MEP500 SERIES

18

Refer to typical wiring arrangement illustrated on page 40.

The MEP500 Series Programmers provide an additional relay used to control Terminal 4 separately.

This allows the implementation of a pilot stabilization period as well as main trial for ignition period.

They also come equipped with a bank of dipswitches that allow the user selectable prepurge timing,

selectable PTFI timing, selectable post purge, selectable air flow proven open at start, and selectable

recycle/non-recycle operation. Refer to PROGRAMMER DIPSWITCH SETTINGS for detailed

information.

TYPE MEP560

PROGRAMMING SEQUENCE

L1/7

PURGE

COMPLETE

FIRING

L1/7

SELECTABLE PTFI

5 OR10 SEC

SELECTABLE

PURGE

8

T

E

R

M

I

N

A

L

3

4

5

SELECTABLE

POST PURGE

STABLIZATION PERIOD

8 SEC

MTFI

10 SEC

INTERLOCK

AIR FLOW

PROVEN

TYPE MEP561

PROGRAMMING SEQUENCE

L1/7

ON

PURGE

COMPLETE

FIRING

PERIOD

L1/7

OFF

SELECTABLE PTFI

5 OR10 SEC

SELECTABLE

PURGE

7, 10, 15, 30 Seconds

8

T

E

R

M

I

N

A

L

S

3

4

5

SELECTABLE

POST PURGE

MTFI

10 SEC

INTERLOCK

AIR FLOW

PROVEN

A “run-check” switch is also provided to assist in testing size, position and stabilization of pilot in

conjunction with the flame detector,

For the MEP560 and MEP562, after pilot flame is detected, the control enters an 8 second pilot stabilization period with Terminal 3 and Terminal 4 energized. At the expiration of the stabilization

period, Terminal 5 is energized.

Pilot Stabilization timing begins as soon as flame is proven.

Selectable Recycle/Non-Recycle operation on loss of flame after Terminal 5 is energized.

Selectable air flow (interlock circuit) proven at start.

Recycle on loss of air flow (interlock circuit) after flame is proven.

Selectable purge times are 7, 10, 15 and 30 seconds.

10 second timing begins 3 seconds after flame is proven.

Selectable Recycle/Non-Recycle operation on loss of flame after Terminal 5 is energized.

Selectable air flow (interlock circuit) proven at start.

Recycle on loss of air flow (interlock circuit) after flame is proven.

19

Pilot stabilization timing begins as soon as flame is proven.

TYPE MEP562

PROGRAMMING SEQUENCE

L1/7

ON

PURGE

COMPLETE

FIRING

PERIOD

L1/7

OFF

PTFI

5 OR10 SEC

SELECTABLE

PURGE

8

T

E

R

M

I

N

A

L

S

3

4

5

SELECTABLE

POST PURGE

MTFI

10 SEC

STABLIZATION

8 SEC

PERIOD

INTERLOCK

AIR FLOW

PROVEN

TYPE MEP300

PROGRAMMING SEQUENCE

L1/7

ON

PURGE

COMPLETE

FIRING

PERIOD

L1/7

OFF

10 SEC

PTFI

5 SECOND

PURGE

8

T

E

R

M

I

N

A

L

S

3

4

5

POST PURGE

INTERLOCK

AIR FLOW

PROVEN

5 SEC

PILOT

PROVING

5SEC

MTFI

INTERMITTENT

PILOT

Lockout on loss of air flow (interlock circuit) after flame is proven.

Lockout on flame fail.

MEP300/MEP600 SERIES

This programmer type must be used with the MEC320 or MEC480 t ype chassis. Refer to typical

wiring arrangement illustrated on page 41.

The MEP300/MEP600 Series Programmers provide additional relays used to control Terminals

3 and 4 separately. This allows the implementati on of early spark termination, pilot proving period

and interrupted pilot operation. The MEP397, MEP696 and MEP697 programmers contain a “runcheck” switch to assist in testing size, position and stabilization of pilot in conjunction with the

flame detector.

The MEP696 and MEP697 provide a control line used to energized and de-energize a relay located

on the MED8 and MED9 daughter boards.

TIMING CHARTS

20

0 Second post purge on operating control open.

15 Second post purge on flame fail during PTFI, Proving and MTFI.

Lockout on flame fail during PTFI, Proving and MTFI.

Relight operation on main flame fail.

Recycle operation on air flow failure.

Reset from lockout from pushbutton or line voltage.

TYPE MEP304

PROGRAMMING SEQUENCE

L1/7

ON

PURGE

COMPLETE

FIRING

PERIOD

L1/7

OFF

10 SEC

PTFI

5 SECOND

PURGE

8

T

E

R

M

I

N

A

L

S

3

4

5

POST PURGE

INTERLOCK

AIR FLOW

PROVEN

5 SEC

PILOT

PROVING

10 SEC

MTFI

INTERRUPTED

PILOT

TYPE MEP335

PROGRAMMING SEQUENCE

L1/7

ON

PURGE

COMPLETE

FIRING

PERIOD

L1/7

OFF

35 SEC

HSI

30 SECOND

PURGE

8

T

E

R

M

I

N

A

L

S

3

4

5

15 SEC

POST PURGE

INTERLOCK

AIR FLOW

PROVEN

3 SEC

PTFI

5 SEC

PILOT

PROVING

INTERMITTENT

PILOT

0 Second post purge on operating control open. 15 Second post purge on flame fail.

Non-recycle operation on flame fail.

Recycle operation on air flow failure.

15 Second post purge

Non-recycle operation on flame failure.

Recycle operation on air flow failure.

Reset from lockout from pushbutton.

21

0 Second post purge on operating control open.

TYPE MEP397

PROGRAMMING SEQUENCE

L1/7

ON

PURGE

COMPLETE

FIRING

PERIOD

L1/7

OFF

7 SEC

PTFI

1 5 SECOND

PURGE

8

T

E

R

M

I

N

A

L

S

3

4

5

POST PURGE

INTERLOCK

AIR FLOW

PROVEN

5 SEC

PILOT

PROVING

5 SEC

MTFI

INTERRUPTED

PILOT

TYPE MEP696

PROGRAMMING SEQUENCE

L1/7

ON

PURGE

COMPLETE

FIRING

PERIOD

(AUTO)

L1/7

OFF

5/10 SEC

SELECTABLE

PTFI

30 SECOND

PURGE

8

T

E

R

M

I

N

A

L

S

3

4

5

SELECTABLE

POST PURGE

0/60 SEC

INTERLOCK

AIR FLOW

PROVEN

5 SEC

PILOT

PROVING

5 SEC

MTFI

INTERRUPTED

PILOT

MODULATE CONTACTS

15 Second post purge of flame fail during PTFI, Proving and MTFI.

Lockout on flame fail during PTFI, Proving and MTFI.

Relight operation on main flame fail.

Recycle operation on air flow failure.

Reset from lockout from pushbutton or line voltage.

22

Lockout on flame fail.

Lockout occurs if air flow terminal 6 is not proven 10 seconds into purge.

Modulate contacts on daughter board change state 1 second into Auto.

TYPE MEP697

PROGRAMMING SEQUENCE

L1/7

ON

PURGE

COMPLETE

FIRING

PERIOD

(AUTO)

L1/7

OFF

5/10 SEC

SELECTABLE

PTFI

SELECTABLE

PURGE

8

T

E

R

M

I

N

A

L

S

3

4

5

SELECTABLE

POST PURGE

INTERLOCK

AIR FLOW

PROVEN

5 SEC

PILOT

PROVING

10 SEC

MTFI

INTERRUPTED

PILOT

MODULATE CONTACTS

STANDOFF

PLUG-IN BOARD

(MED SERIES)

RELEASE

DIRECTION

WARNING: Remove power when servicing the control.

Lockout on flame fail.

Lockout on air flow switch opening while main flame energized.

Recycle/Non-recycle dipswitch controls lockout on air flow switch not closing 10 seconds into

purge.

Modulate contacts on daughter board change state 5 seconds into Auto.

OPTIONAL PLUG-IN BOARDS

Description

A family of optional plug-in boards are available separately for the MicroM chassis to provide

remote reset, remote alpha-numeric display and serial communications as a stand alone or in com bination. Refer to ORDERING INFORMATION for MicroM Chassis types for units that have preinstalled functions.

FIGURE 4. PLUG -IN BOARD LOCATION AND INSTALLATION

Installation

For upgrading standard units or for replacing the installed pl ug-in board, grasp plug-in board at the

top and pull away from the chassis, freeing the unit from the retaining standoff. Lift plug-in board up

and away from connector located on chassis board. Guide new plug-in bo ard into the same con nector

and push onto standoff.

23

Function

SERIAL COMMUNICATIONS

A

B

REMOTE DISPLAY

RJ45 JACK

REMOTE RESET

(RS485)

(+)

(-)

SERIAL COMMUNICATIONS

REMOTE DISPLAY

RJ45 JACK

RELAY CONTACTS

(RS485)

B

A

MED8 - Normally Closed

MED9 - Normally Open

(used only with MEP696/MEP697)

CAUTION: Remote reset is recommended only on a control solely for proved ignition programming (pilot ignited burner) or a control for use only with applications in which

unburned fuel cannot accumulate and that is intended for installation in inaccessible locations such as open-flame, ceiling-suspended gas heaters. The remote reset location must be

within sight and sound of the fired equipment.

Any MicroM chassis type with the appropriate plug-in board installed provides remote reset capabilities in the event of a lockout condition. A remote reset swit ch consists of a dry contact such as a

remote momentary push-button wired to the two (2) terminals located on the plug-in board as shown

in Figure 5. The reset switch will also force the MicroM to recycle if depressed and released during

the purge or run period.

A plug-in board (MED8) is pre-installed in the MEC320TS chassis to provide local reset, remote

alpha-numeric display, serial communications and normally closed relays.

FIGURE 5. REMOTE RESET

ADVANCED RESET FUNCTIONS

Multiple functions have been integrated into the reset push button located on the MicroM and provided by way of the remote reset terminals. Among these are reset/recycle, reset from lockout only,

recycle only and set unit address. The functions of the switch is determined by the length of time

the push button is depressed and released.

The MicroM allows the connection of the remote resets to be connected together, usually in a multiburner system where multiple MicroM’s are mounted in a common panel. The reset push button

located on the MicroM daughter board is in parallel with the remote reset terminals when provided

by the other MED daughter boards.

Normal Operation

If the push button is depressed and released for greater than 1/2 second but less than 3 seconds, the

24

MicroM will either reset if in lockout, or shutdown and revert back to the start of the cycle. If the

MicroM is in the Idle state, this action will cause the LED’s to sequence from the bottom to top and

serves as a LED test.

Smart Reset

If the push button is depressed and released greater than 3 seconds but less than 5 seconds, the

MicroM will reset from the lockout state only. This is especially useful where, through the use of

remote reset daughter boards, all reset inputs can be connected together to a common reset pushbutton or intelligent device (PLC). If the push button is depressed as described above it will only cause

the unit that is in lockout to reset and not effect any other units.

Smart Recycle

If the push button is depressed and released greater than 5 seconds but less than 7 seconds, all connected MicroM units will recycle back to the beginning of purge. All units that are in lockout will

remain in lockout.

Address Mode

If the unit is in the Idle or Standby mode and the push button is d epressed and released for greater

than 10 seconds, the unit address of the MicroM will be displayed on the LED’s in a binary format.

The range of the address is 0 to 31 and is used for Modbus or E500 communications. Because the

default address is 0 and since address 0 would mean no LED’s would be lit; the ALARM LED is

made to flash when the address is 0. The OP CTRL LED is the least significant bit while the FLAME

relay is the most significant bit. The ALARM LED is used to indicate if the address is greater than or

less than 16. If the ALARM LED is flashing, the address is less than 16 and conversely if the

ALARM LED is solid, the unit address is greater than 16. This only applies to the address. To increment the address on the control, depress and release the RESET push button and observe the LED

pattern. If the RESET switch is untouched for 30 seconds, the current address displayed will be

stored to memory and the MicroM will automatically exit the address mode.

LED

OP CNTRL 1 - ● - ● - ● - ● - ● - ● - ● - ● -

Air Flow 2 - - ●● --●● --●● --●● -

PTFI 4 ----●●●● ----●●●● -

FLAME 8 --------●●●●●●●● -

ALARM

REMOTE DISPLAY

BINARY

VALUE0123456789101112131415★16

16

✸✸✸✸✸✸✸✸✸✸✸✸✸✸✸✸✸

★ note: addresses 17-31 would repeat above pattern but with alarm LED steady on

The MicroM provides an interface to the optional ED510 displ ay module. The ED510 connects to

the MicroM through the plug-in board using a ED580 cable. The ED580 cable is available in 2, 4, or

8 foot lengths. Part number 129-145 -1 (4 ft.), -2 (8 ft.), -3 (2 ft.) is available for remote mounting the

ED510 Display Module and to provide NEMA 4 protection. ¤

The ED510 Display Module is a backlit, 2 line by 16 character LCD display with keypad to provide

both current operation and historical information of the MicroM. The ED510 contains a keypad consisting of three push keys, SCRL, RESET and MODE. Remote reset is available through the ED510

Keypad.

The ED510 displays current burner status, first out annunciation in the event o f a lockout conditi on,

historical burner information, detailed lockout inform ation of the last six (6) lockout conditions and

programmer configuration information. Through the display the ability to pro gram the unit address

for communications, as well as resetting the stored information (cycles, hours, and lockouts) to zero

is provided.

Depending on the information being displayed, data is displayed on the ED510 screen in th e follow ing locations:

25

At any time the MicroM is powered, the SCRL key is used to scroll through and display the total

PURGE 00:05

STARTING BURNER

OPERATING STATUS

(Standby, Purge, PTFI,

Auto, etc.)

ADDITIONAL INFORMATION

(Flame Signal Strength, Cause of current Lockout, etc.) OR

BURNER HISTORY (SCRL key required)

(Burner Cycles, Burner Lockouts, etc.) OR

SUB-MENU HEADINGS (SCRL and MODE keys required)

(Lockout History, Program Setup, etc.

ON OPERATING STATUS

TIMING

(During Purge or PTFI) OR

FLAME SIGNAL STRENGTH

(During PTFI, MTFI, or Auto)

ARROW displayed when

MODE key is required to

access sub-menus

(Lockout, History, Program

Setup, etc.)

AUTO 40

BNR HOURS 673

AUTO 40

BNR CYCLES 2784

AUTO 40

BNR LOCKOUTS 21

AUTO 40

SYS HOURS 1386

AUTO 40

LOCKOUT HISTORY

AUTO 40

PROGRAM SETUP

AUTO 40

SYSTEM INFO

number burner hours, burner cycles, burner lockouts and system hours on the bottom line of the

ED510 display. The top line will continue to show the current run mode of the control (e.g. PURGE,

AUTO, etc.) Following the historical information, the SCRL key will display three (3) sub-menus

providing the following information and/or functions:

— Lockout History (with burner cycle and burner hour time stamp).

— Program Setup (to display programmer type, purge timing, switch configuration, etc.)

— System Information (values of average pilot and main flame signal, and reset burner his-

tory).

The system sub-menus require the MODE key to gain access to the information associated with each

sub-menu. An arrow is displayed in the lower right hand corner of the display to indicate a system

sub-menu is available. Once within the sub-menu, pressing the SCRL key displays the next item

within the sub-menu, and pressing the MODE key will exit the sub-menu and return the display to

the top of the main menu.

Number of burner operating hours. (Terminal #5 energized).

Number of burner cycles.

26

Number of burner lockouts.

Number of hours the control has been powered.

Sub-menu to display the cause of the last 6 lockouts. The MODE key is required to

display the actual lockouts.

Sub-menu to display various operating parameters of the programmer and amplifier. The MODE key is required to enter the sub-menu.

Sub-menu to display information pertaining to the operation of the control. The

MODE key is required to enter the sub-menu

LOCKOUT HISTORY

The sub-menu “LOCKOUT HISTORY” will display the last six (6) lockouts, along with the burner

cycle and burner hour when the lockout occurred. When the MODE key is pressed, the screen will

display the most recent lockout condition and the number of that lockout (e.g. LO # 127 represents

the 127th lockout of that control). The SCRL key will display the Burner Hour, followed by the

Burner Cycle when the lockout occurred. The SCRL key will advance to the next lockout, and repeat

the sequence listed above. The MODE key will exit the sub-menu.

PRESS SCREEN DISPLAYS DESCRIPTION

SCRL AUTO 45

LOCKOUT HISTORY

MODE LO #127 PTFI

FLAME FAIL

SCRL LO #127 PTFI

@ BNR HOURS 136

SCRL LO #127 PTFI

@ BNR CYCLE 744

SCRL LO #126 PURGE

AIR FLOW OPEN

MODE AUTO 45

FLAME SIGNAL

Scrolling through the historical information.

The latest (most recent) lockout condition. This is the 127th lockout of

the control. History indicates the lockout occurred during PTFI.

The last lockout occurred after 136 hours of burner operation.

The last lockout occurred at burner cycle 744.

The second latest lockout condition. This is the 126th lockout of the control. History indicates the lockout occurred during purge.

Screen has returned to the normal run message.

PROGRAM SETUP

The sub-menu “PROGRAM SETUP” allows the user to review the various operational settings of

the programmer module (e.g. programmer type, purge timing, etc.). The MODE key is used to enter

the “PROGRAM SETUP” sub-menu, and the SCRL key is used to advance through the sub-menu.

MODE AUTO 45 Programmer Type is an MEP230.

PROGRAMR MEP230

SCRL AUTO 45 Software Engineering code of the programmer module is code 5.

ENGR CODE NO. 5

SCRL AUTO 45 Amplifier module is an EUV1 or an ERT1.

AMP. TYPE= MEUV

SCRL AUTO 45 Flame Failure Response Time (FFRT) is 3 seconds.

FLAME FAIL TIME = 3s

SCRL AUTO 45 Purge timing (selected by the dipswitches) is 7 seconds.

PURGE TIME = 7s

SCRL AUTO 45 Prove 7-6 open to start is disabled (selected by dipswitches).

PROVE 7-6 OPEN = N

SCRL AUTO 45 Post purge time is 0 seconds (selected by dipswitches).

POST PURGE = 0s

SCRL AUTO 45 Control recycles on flame fail (selected by dipswitches).

TYPE RECYCLE

SCRL AUTO Unit Address is 00. Refer to section on communications.

27

UNIT ADDRESS 00

SCRL PRESS RESET TO Force storage of dipswitch settings before 8 hours time-out.

ACCEPT SETTINGS

MODE AUTO 45 Mode key returns to normal run message.

SYSTEM INFO

The sub-menu “SYSTEM INFO” allows the user to review information pertaining to the operation of

the control (e.g. average main flame signal strength, status of the high fire and low fire end switches,

etc.). The MODE key is used to enter the “SYSTEM INFO” sub-menu, and the SCRL key is used to

advance.

Press Screen Displays Description

SCRL AUTO 45 SCRL key advances through the historical information until

SYSTEM INFO > “System Info” is displayed. Pressing and releasing

the MODE Key enters the sub-menu.

MODE AUTO 45 The average flame signal strength of the pilot flame = 22

AVG. PILOT FLM 22

SCRL AUTO 45 The average flame signal strength of the main flame = 40.

AVG. MAIN FLM 40

SCRL PRESS RESET TO Historical data will be cleared to 0. Must be done while

CLEAR HISTORY terminal I-7 is open.

MODE AUTO 45 Mode key returns to run message.

FLAME SIGNAL

COMMUNICATIONS

The protocol to be used is Modbus RTU. This is implemented by the master (PC, PLC, etc.) issuing a

poll to the slave (MicroM) and the slave responding with the appropriate message.

A typical format of a poll request is as follows:

DST FNC ADR

HI

DST refers to the logical address of the slave set but using reset pushbutton or ED510.

FNC is the function being requested. FNC 03 is a read request.

ADR is the message number or register number of the data being requ ested. In Modbus, register

addresses begin at 40001 but is interpreted as address 00.

DAT is the number of words being requested. A word is an integer consisting of 2 bytes.

The normal response from a slave is as follows:

DST FNC DBC DATA….

ADR

LO

DAT

HI

Hi/Lo

DAT

LO

CRC

LO

CRC

LO

CRC

HI

CRC

HI

28

DBC is the data byte count being returned. It must be two times the DAT number from the poll

request.

DATA is the data returned and is always a series of 2 byte integers. If 4 words were requested then

DBC would be 8 and there would be 8 data bytes or 4 data words containing the requested data.

The format of the data is 4800, N, 8, 1 meaning 4800 baud, no parity, and 1 stop bit.

Below is a table of currently available messages provided by the MicroM programmers, followed by

a description where necessary.

MESSAGE

ADDRESS

00 1-6 STATUS 83 (053H) = RUN;

01 1 MSGN Current message being displayed (see Table 3)

02 1 GSTAT Defines Timer Type

03 1 TIMER Time, Flame, Address

04 1 FLAME Flame Signal

05 1-3 LOGSTAT Current logic module, PURGE, PTFI, AUTO (See

06 1 INPUTS Input limits state

07 1 OUTPUTS Output relays state

08 2, 4 or 8 SYSMINS System on minutes

10 2 or 4 BNRMINS Burner on minutes

12 2 CYCLES Completed Burner Cycles

14 1 LOCKOUT COUNT Stored Lockout Count

15 1-6 LOCKOUT HISTORY Last 6 Lockouts, first word is most current lock-

21 1-2 DEVTYP Programmer device type, 5=EP, 6=EPD,

22 1 AMPTYP Amplifier Type;

23 1 PROGTYP Programmer Type (See Table 2)

24 2 FLAME SIGNAL

26 1-9 Combined Status See Description Below

35 6 Most Recent Lockout Data

41 6 2nd Most Recent Lockout

47 6 3rd Most Recent Lockout

53 6 4th Most Recent Lockout

59 6 5th Most Recent Lockout

65 6 6th Most Recent Lockout

WORDS

REQUESTED

RESPONSE VALUE

202 (0CAH) = LOCKOUT

Table 1)

out

7=MicroM

MECD=080H;

MEUV=090H;

MEIR=0A0H;

MERT=0B0H;

MEUVS=0C0H

AVERAGES

Data

Data

Data

Data

Data

PTFI and Auto Flame Signal Averages

Returns complete lockout description of stored

lockout history. Includes lockout message,

lockout module, @ burner hours, and @ burner

cycles

Messages 00, 05, 08, 10, 15, 21 and 26 are unique in that a limited number of successive registers

can be combined with these requests. For example, a request to message 00 can contain up to 6 data

words. The response to this would contain STATUS, MSGN, GSTAT, TIMER, FLAME and LOGSTAT. If the requested data word count (DAT) we re to be 2 then the response would contain STATUS and MSGN only. Message 15, last 6 lockouts, can return data ranging from 1 to 6, with 1

referring to the most recent lockout.

29

Message 26 returns the current operating status as well as stored burner hours and burner cycles as a

snapshot of the entire MicroM system. When all 9 words are requested, the data returned consists of

STATUS, MSGN, FLAME, INPUTS, OUTPUTS, BNRMINS, and BNRCYCS.

The MSGN being transmitted is a numerical value and must be interpreted by t he communicating

device, which actually is an advantage since this can be made to be whatever message text the end

user wants. In other words, it allows for programming custom messages without actually ch anging

the message in the programmer.

The MicroM stores its burner on time (Terminal 5 powered) and system on time (L1 powered) in

minutes. Internally, the programmer converts this to hours for display purposes, however the result is

rounded down. The information being supplied by Modbus will be the actual time in minutes and it

is up to the communicating device to do the conversion. Sin ce the maximum value stored in the

MicroM is 9,999,999 minutes, the maximum value in hex therefore, is 98967FH and comprises of

two data words. The maximum cycle count is 999,999 decimal or 0F423FH, still two data words. As

an example, the System on Minutes data is transmitted from the MicroM to the interface as high

word / low word as shown below:

MESSAGE ADDRESS 8 MESSAGE ADDRESS 9

HIGH WORD LOW WORD

HIGH BYTE LOW BYTE HIGH BYTE LOW BYTE

0 98H 96H 7FH

Note: Data from address 9 cannot be accessed directly.

All values are represented in a HEX or base 16 format.

GSTAT determines the type of value TIMER represents. TIMER can be a running timer such as is

used in purge, a flame signal or meaningless. Only the lower nibble of GSTAT has any value. If this

value is 0 then the TIMER value has no meaning. The value in TIMER is a background minute timer

in the MicroM and should be ignored. If GSTAT is between 4 and 7, the TIMER represents the current value flame signal. If GSTAT is a 1, 2, or 3 then TIMER represents a running timer value.

The baud rate of the MicroM is fixed at 4800 bits per second. The format of the data is 8 data bits, no

parity and 1 stop bit. Due to the RS485 format, the communication format is considered half-duplex.

That is, only one user is permitted on the communication lines at a time.

The information contained in INPUTS and OUTPUTS represents the status of the interlocks and

relays respectively. For the INPUTS, a 1 in the interlock position defines the interlock as being on or

energize where the 1 in any bit position in the OUTPUT register signifies the relay as being energized.

INPUTS

Term 5Term 3Term 6Term 7

Reset Scrl Mode RF Pilot Intrlck OpCntrl Ref

Reset, Scrl and Mode represent the keypad located on the ED510 display. A ‘0’ in any of these positions indicates the switch is depressed. A ‘1’ in the opto-coupler position indicates the opto-coupler

is on or interlock closed.

OUTPUTS

Term 8 Term A Term 3 Term 5 Term 4

N/A N/A N/A Blower Alarm Pilot Main Fuel MTFI

A ‘1’ in any terminal position indicates the relay is energized. Term 4 indicates the state of K1 relay,

located in the MEP500 series programmers.

30

It is suggested that repeated polling interval not be less than 200 mSec per request. Requesting

data such as burner minutes, system minutes and burner cycles be kept at a minimum due to

the amount of processing time required to gather that data.

Table 1: Logic Dispatch

LOGIC DISPATCHER

VALUE MicroM

HEX DEC

45H 69 MPOSTIDLE

46H 70 MPREPURGE1

47H 71 MPURGE

48H 72 MTFI

49H 73 MSTABLE

4AH 74 MTFMF

4BH 75 MAUTO

4CH 76 MSHTDWN1

4DH 77 MSHTDWN2

4EH 78 MIDLE

Logstat represents the current software module the Flame-Monitor is currently executing. They are

named as close to the logic module the actual burner sequence is in. For instance, in the Flame-Monitor, MPURGE represents High Fire Purge where MPOSTPURGE represents low fire start purge.

MSHUTDWN1 represents the post purge period after a complete cycle or the cool down period after

a lockout.

MIDLE or STANDBY is the period of time where the operating control is open or the control is in

lockout waiting for reset. On instances of false flame during the purge period, the cont rol algorithm

forces the control back to STANDBY until false flame ceases or lockout occurs.

MPREPURGE1 is the period of time prior to PURGE where the control checks the status of the air

flow interlocks or in the case of the Flame-Monitor, high fire proving switch (D-8). If found open,

the control will remain in this state until the respective switch closes or lockout occurs.

MTFI represents the pilot ignition stage of a burner sequence. MTFMF represents the main trial for

ignition period where main fuel is introduced along with pilot.

MAUTO is the run period of the burner sequence.

MPOSTIDLE and MSHTDWN2 are small periods of time where certain internal tests are conducted

and general cleanup before and after a cycle is performed.

PROGTYP is represented by 1 data word. The upper byte identifies the family and the lower byte

represents the programmer type within the family. The data represented by PROGTYP can be used

to guard against the wrong programmer being installed in a system.

31

Table 2: Program Module Identification

Programmer Module Identifier

MEP100 0H, 01H

MEP101 0H, 02H

MEP102 0H, 03H

MEP103 0H, 04H

MEP100P 0H, 05H

MEP109 0H, 06H

MEP130 0H, 08H

MEP104 0H, 09H

MEP105 0H, 0AH

MEP106 0H, 0BH

MEP107 0H, 0CH

MEP108 0H, 0DH

MEP230 1H, 01H

MEP230H 1H, 02H

MEP235 1H, 04H

MEP236 1H, 05H

MEP290 1H, 06H

MEP238 1H, 09H

MEP237 1H, 0AH

MEP560 2H, 01H

MEP561 2H, 02H

MEP562 2H, 03H

MEP536 2H, 04H

MEP537 2H, 05H

MEP300 0H, 01H

MEP304 0H, 09H

MEP397 0H, 0DH

32

Table 3: Message Description

DEC HEX MicroM Message

1 1 L1-7 OPEN

2 2 FALSE FLAME

3 3 STARTING BURNER

44

5 5 INTRLCK OPEN

6 6 LOCKOUT LINE FREQUENCY NOISE DETECTED

7 7 LOCKOUT FLAME FAIL - PTFI

8 8 UNIT ADDRESS

99 MTFI

10 0AH IGNITION TIMING

11 0BH

12 0CH FLAME SIGNAL

13 0DH CYCLE COMPLETE

14 0EH OFF

16 10H LOCKOUT AMPLIFIER HIGH COUNT FAIL

19 13H LOCKOUT FLAME FAIL – MTFI

20 14H LOCKOUT FALSE FLAME – STANDBY

21 15H LOCKOUT INTRLCK OPEN

22 16H LOCKOUT INTRLCK CLOSED

23 17H INTRLCK CLOSED (PROVING AIR FLOW OPEN AT START)