Page 1

Engineering Manual

& Design Guide

Airstroke

®

actuators/Airmount

®

isolators

IRSTROKEIRSTROKE

R

R

IISSOLAOLA TORSTORS

IRMIRMOUNTOUNTIRMOUNT

IRSTROKE

ACTUAACTUA TORSTORS

ISOLATORS

ACTUA TORS

EMDG 198

EMDG 198

Page 2

2

Table of Contents and Introduction...............................2

Advantages of Airstroke Actuators...............................3

Advantages of Airmount Isolators.................................4

Air Spring Bellows Construction ...................................5

End Closure Options

Crimped bead plates..................................................6

Crimped bead plates mounting hardware .................7

Steel bead rings.........................................................8

Aluminum bead rings.................................................9

The four types of bead rings and

mounting hardware................................................10

Rolled plates............................................................11

How to use the Static Data Chart

For Airstroke Actuation......................................12&13

For Airmount Isolation..............................................13

Internal Rubber Bumpers..............................................13

Basic Parameters Applicable to Both Airstroke

Actuators and Airmount Isolators

Media.......................................................................14

Pressure ..................................................................14

Temperature ...........................................................14

Contaminants...........................................................14

Storage....................................................................14

Airstroke Actuation

Selection..................................................................15

Down and Up Stops.................................................15

Return......................................................................15

Guiding ....................................................................15

Angular Capability....................................................15

Horizontal Misalignment..........................................16

Design Envelope......................................................16

Stacking...................................................................16

Fail-Safe Devices.....................................................16

Vacuum....................................................................16

Inflation Pressure Chart...........................................17

Airstroke Actuator Problem Solvers...........18,19 & 20

Airmount Vibration Isolation

Selection Procedure and Isolation Formula.......21-22

Dynamic Spring Rate Formula ................................22

Natural Frequency Formula.....................................22

Center of Gravity......................................................23

Lateral Rates and Stability.......................................23

Triple Convoluted and Reversible

Sleeve Type Parts .................................................24

Design Envelope......................................................24

Safety Stops ............................................................24

Initial Installation......................................................24

Startup and Shutdown/Resonance

and Amplification ...................................................24

Isolating an Unbalanced Mass ................................24

Low Pressure Operation..........................................24

Effect of an Auxiliary Reservoir ...............................24

Damping ..................................................................25

Plumbing Systems...................................................25

Isolation Chart..........................................................26

Airmount Isolation Problem Solvers...................27-28

Miscellaneous Applications

Shock Impact Isolation.............................................29

Protective Boot and Flexible Connector..................29

Vacuum Pump.........................................................29

Inflatable Chuck.......................................................29

Cam Follower...........................................................29

Miscellaneous Problem Solvers.........................30-31

Airstroke/Airmount Selection Guide......................32-33

Individual Air Spring Data Pages............................34-98

Index & Work Sheets

Order Number to Style Number

to Page Number.........................................100-101

Airstroke Design Parameter Worksheet................103

Airmount Design Parameter Worksheet................105

Style Number to Page Number..............................107

TABLE OF CONTENTS

Firestone developed the air spring in the late 1930’s as a

more efficient spring (vibration isolator) for use in vehicle

suspensions. Airide®springs, as they were named, provided the means for a suspension to reduce the amount of

road shock and vibration transmitted into the vehicle.

Millions of miles of actual use have proven the dependability and effectiveness of the air suspension concept using

Airide®springs by Firestone.

Airstroke

®

actuators, Airmount®isolators, and Airide

®

springs are Firestone registered trademark names

for one

product

: the air spring. The use of the air spring (actuator,

industrial isolator and vehicular isolator, respectively) determines which name is applied to it. All of the parts in this

catalogue may be used as Airstroke actuators (except the

1X84D-1 and 2M1A) or Airmount isolators, with two exceptions: Triple convoluted and reversible sleeve type air

springs (except the 1M1A-0) should not be used as

Airmount isolators without consulting Firestone.

Individual Airstroke actuators and Airmount isolators are

capable of generating a force or supporting a load of up to

100,000 pounds, and a stroke capability of up to 14 inches

is possible. Included in this engineering manual are

detailed operating characteristics for many of the standard

Firestone air springs, along with technical details and procedures for using these products.

PLEASE NOTE:

The information contained in this publication is intended to provide a general guide to the characteristics and applications of these products. The

material, herein, was developed through engineering design and development, testing and actual applications and is believed to be reliable and

accurate. Firestone, however, makes no warranty, express or implied, of

this information. Anyone making use of this material does so at his own

risk and assumes all liability resulting from such use. It is suggested that

competent professional assistance be employed for specific applications.

Copyright ©1998 Firestone Industrial Products Company

INTRODUCTION

Page 3

3

AD V ANTA GES OF FIREST ONE

AIRSTROKE

®

A CTU A T ORS

Why use an Airstroke actuator (rather than air or hydraulic cylinder)

for actuation?

LOW COST

Generally, initial cost is one-half or less than conventional pneumatic or hydraulic cylinders of the same force capabilities. This initial cost advantage is many times greater in

the larger sizes.

WIDE SIZE RANGE

Airstroke actuators are available in sizes ranging from 2.2 inches to 37 inches in diameter.

The force capability is 100,000 pounds. Strokes of up to 14 inches are possible.

DURABLE FOR LONG LIFE

Airstroke actuators are a further application of Firestone’s time proven Airide springs for

truck and bus suspensions. The long life and durability necessary for millions of miles of

heavy duty suspension use under adverse environmental conditions are also important

factors in machine design.

NO MAINTENANCE OR LUBRICATION REQUIRED

NO INTERNAL ROD OR PIST ON

Airstroke actuators have no internal rod, piston, or sliding seals as do conventional

cylinders. This allows for the design of Airstroke actuators into applications where dirt or

grit would destroy the seals on conventional cylinders.

FRICTION FREE FOR IMMEDIATE RESPONSE

Since Airstroke actuators have no sliding seals, there is no breakaway friction as with

conventional cylinders

FLEXIBLE MEDIA

An Airstroke actuator can do its work with either a liquid or gas (Please see page 14 for

acceptable media choices.)

ANGULAR CAPABILITY

An Airstroke possesses the unique capability of stroking through an arc without a clevis.

Angular motion of up to 30 degrees is possible, along with the design advantage of

generally less complex linkages.

SIDE LO ADING CAPABILITY

Airstroke actuators, within certain limits, are not

affected by side loads as are conventional cylinders. This misalignment capability eliminates

potential rod bending, scoring, and excessive seal

wear common to conventional cylinders.

COMPA CT STARTING HEIGHT

Airstroke actuators have a low profile compared to

conventional cylinders. Our smallest Airstroke

actuator (2.2 inch/dia.) collapses to just 1.1 inches

in height, while our largest triple convoluted

Airstroke (37 inch/dia.) will collapse to a very compact 5.5 inches.

FACT OR Y SEALED AND TESTED

Most Airstroke actuators feature Firestone’s proven

concept of crimped end plates. The crimped design

allows for preshipment testing and quicker installation on equipment.

PLEASE REFER TO PAGE

15

FOR A THOROUGH

DISCUSSION OF ACTUATION.

Page 4

4

Why use an Airmount isolator rather than a coil

spring or other type of isolator?

UNSURPASSED ISOLATION CAP ABILITY

Airmount isolators can provide the highest degree of isolation

of any type vibration isolator. System natural frequencies as

low as 60 cycles per minute (1 Hertz) are available. The

addition of an auxiliary reservoir can provide even lower system frequencies. In order to achieve similar results from a

conventional coil spring isolator, a real deflection of 9 inches

would be required.

CONST ANT ISOLATION EFFICIENCY

Airmount isolators are unique in that the system’s natural frequency does not change significantly with changes in load.

This unique feature, combined with accurate height control, will

allow the use of the same Airmount isolator at each mounting

point of an unevenly loaded machine.

A CCURATE HEIGHT CONTROL

Airmount isolators provide accurate height control through regulation of internal air pressure. This feature eliminates the

fatigue and permanent set found in the use of other types of

vibration isolators.

WIDE SIZE RANGE

Airmount isolators are capable of isolating loads of 100

pounds per mounting point to over 100,000 pounds per

mounting point.

COMPA CT INSTALLED HEIGHT

Airmount isolators can carry the loads and provide the isolation

described above at installed heights as low as 2.5 inches. Coil

springs providing equal isolation would require a free height of

5 to 25 inches.

EXTENDED EQUIPMENT LIFE

Airmount isolators extend equipment life through their superior

isolation capabilities.

EFFECTIVE NOISE REDUCTION

Airmount isolators reduce structurally transmitted noise.

Airmount isolators are also quiet in themselves, since there is

no spring chatter as found in conventional coil springs.

VERSA TILE

Airmount isolators can be used not only to protect structural

members from vibrating machinery, but are also widely used

to protect delicate equipment from structurally transmitted

vibration.

PLEASE REFER TO PAGE

21

FOR A THOROUGH

DISCUSSION OF VlBRATION ISOLATION.

AD V ANTA GES OF FIREST ONE

AIRMOUNT

®

ISOLAT ORS

Page 5

5

An air spring is a carefully designed rubber/fabric bellows

which contains a column of compressed air. The rubber bellows itself does not provide force or support load. This is done

by the column of air.

Firestone air springs are highly engineered elastomeric bellows with specially designed metal end closures. Our standard

two ply air spring bellows is actually made up of four layers:

a. An inner liner of calendered rubber.

b. One ply of fabric reinforced rubber.

c. A second ply of fabric-reinforced rubber (with the cords at

a specific bias angle to the first ply).

d. An outer cover of calendered rubber.

Many of our air springs are also available in high strength construction for higher pressures (see page

14

for more detailed

information). In this case, there are four plies of fabric-reinforced rubber, with an inner liner and outer cover.

The two ply air spring is standard. Where high strength construction is available, it is so noted in the selection guide

(page

32

), on the individual Data sheets, and in the index

(page

107

). If the high strength style number is omitted, then

it is not currently available in that particular part.

Each air spring bellows is identified by a style number. This

style number is molded into the bellows during the curing (or

vulcanization) process. Examples would be 16, 22, 313,

1T15M-6, etc... This identifies

only

the rubber/fabric bellows

and

not the complete assembly

. There are several different

end closure options available for most air springs; therefore,

please always specify both the style number and the complete

assembly order number (AON). An example would be: Style

#22, assembly order number W01-M58-6180. Both numbers

are given on the individual data sheets.

OUTER COVER

SECOND PLY

FIRST PLY

INNER LINER

AIR SPRING

BELLO WS CONSTRUCTION

Page 6

6

END CLOSURE OPTIONS

AIR INLET

1

/4" NPT is standard. 3/4" NPT is also available for most

parts. (See the data sheet order block on each specific

part).

BLIND NUT

3

/8-16 UNC thread x 5/8" deep (two or four per each plate

depending on part size). Used for mounting the part.

UPPER BEAD PLATE

(9 gauge carbon steel, .149"). Permanently crimped to

bellows to form an airtight assembly which allows for leak

testing before the unit leaves the factory. Zinc/chromate

plated for rust protection.

GIRDLE HOOP

Wire wound type shown, molded into the bellows.

BELLOWS

Wall gauge is approximately 1/4". See page 5 for detailed

information.

LOWER BEAD PLATE

Usually the same as upper bead plate, except without air

inlet.

Each individual air spring data sheet shows a cross sectional

view of the most popular end closure option for that part. For

convoluted air springs 16 inches in diameter and less, and for

the reversible sleeve air springs,

the Crimped Bead Plate

attachment is shown.

For convoluted air springs 17 inches in

diameter and larger,

a Bead Ring attachment is shown

. An air

spring of each variety, with proper terminology for each, is

shown on the following pages.

CONVOLUTED AIR SPRINGS

(#22 is shown)

REVERSIBLE SLEEVE

AIR SPRINGS

(1T15M-6 is shown)

AIR INLET

1

/4" NPT is standard. 3/4" NPT is also available for most parts. (See the data sheet order block on

each specific part).

BLIND NUT 3/8-16 UNC thread x 5/8" deep

(two or four

per each plate depending on part size). Used for mounting the part.

BEAD PLATE (9 gauge carbon steel, .149").

Permanently crimped to bellows to form an airtight assembly which allows for leak testing before the unit leaves the

factory. Zinc/chromate plated for rust protection.

BELLOWS Wall gauge is approximately 1/4"

. See page 5

for detailed information.

BELLOWS END CLOSURE— (steel) Permanently

molded into the bellows (Except for styles 1T19L-7,

1T19L-11).

PISTON May be made of aluminum, steel, plastic or

hard rubber. Held to the bellows by a bolt which screws

into the bumper stud. For mounting, a long bolt may be

used coming up through the mounting surface. Or, a

short bolt may be used to attach the piston to the lower

end closure and then use the threaded holes in the piston to secure the assembly to the mounting surface. (A

piston long bolt is usually not included).

BUMPER STUD A permanent part of the bellows end

closure (and bellows). It has two functions:

1. The optional rubber bumper snaps over the outside.

2. The inside is a threaded hole (see data sheets for

thread dimension and depth) used to secure the

piston to the bellows.

THREADED HOLE May be used for attachment to

mounting surface. Not included in some pistons (See

individual data sheets for specific part configuration.)

CRIMPED BEAD PLATES

Page 7

7

TANK VALVE One method for inflating air springs

(primarily used in Airmount isolator applications) is with

a tank valve: An air hose chuck is used (as inflating a

tire with an air line). Care must be taken to periodically

check the pressure within the air spring, because air

will slowly permeate through the rubber/fabric bellows

(See page 25).

CRIMPED BEAD PLATE

MOUNTING HARD W ARE

CRIMPED BEAD PLATE AIR SPRINGS Use the blind

nuts for attachment. This is accomplished by bringing bolts

(two or four depending upon air spring size) through the

customer supplied mountIng plate and tightening into the

blind nut. If this bolt is too long, it may fracture the bottom

out of the blind nut.

3

/8-16 UNC

Blind Nut,

5

/8" Deep

5

/8"

5

/8"

To Air Supply

Customer Supplies

Mounting Plates

Bolts & Washers

Customer Supplies

Mounting Plates

Nuts & Washers

Tightening Torque

on the blind nut: 15 to 20 ft.-lbs.

STUD ADAPTER

1

/2-13 UNC Thread

3

/8-16 UNC Thread

1.35

If a protruding bolt rather than a blind nut is preferred to

attach the air spring, a STUD ADAPTER is available from

Firestone:

1.35

Page 8

8

END CLOSURE OPTIONS

CONVOLUTED AIR SPRINGS

(#22 is shown, with bead rings instead of

crimped bead plates)

MOUNTING PLATE is not included. See page 10 for

material, machining recommendations, and installation

instructions.

BEAD RING BOLT May be one of four varieties. See

page 10. Also refer to the data sheet order block on each

individual part for bolt lengths.

NUTS AND LOCKWASHERS are included with the part.

(Except for socket head type bead rings).

BELLOWS Wall gauge is approximately 1/4"

. See page 5

for detailed information.

GIRDLE HOOP Wire wound type shown, molded into the

bellows.

BEAD RING, upper and lower. Countersunk steel type

shown. May also be of a second stamped steel variety or

made of aluminum. See page 10. Also refer to the data

sheet order block on each part for type and material. See

the selection guide on page 32 for bolt circle diameter

and number of bolts (each ring).

REVERSIBLE SLEEVE AIR SPRINGS

(1T15M-6 is shown, with a bead ring

instead of a crimped bead plate)

MOUNTING PLATE is not included. See page 10 for

material, machining recommendations, and installation

instructions.

BEAD RING BOLT May be one of four varieties. See

below. Also refer to the data sheet order block on each

individual part for bolt lengths.

NUTS AND LOCKWASHERS are included with the

part. (Except for socket head type bead rings).

BEAD RING Countersunk steel type shown. See the

selection guide on page 32 for bolt circle diameter and

number of bolts (each ring).

BUMPER STUD A permanent part of the bellows end

closure (and bellows). It has two functions:

1.

The optional rubber bumper snaps over the

outside (of it).

2. The inside is a threaded hole (see data sheets for

thread dimension and depth) used to secure the piston to the bellows.

THREADED HOLE May be used for attachment to

mounting surface. Not included in some pistons (See

individual data sheets for specific part configuration.)

STEEL BEAD RINGS

Page 9

9

All of the parts that are shown with crimped bead plates

are also available with bead rings. (Bead plates are not

suitable for some applications.) Typical examples of

where bead rings are often used follow:

1.

Where parts are stacked to increase stroke

(See page16).

2. Where the air spring is being used as a boot or

flexible connector (See page 29).

3.

When used as an Airmount isolator with an auxiliary

reservoir (See page 24).

4. When air must move in or out of the unit at an extremely

fast rate (and a 3/4" NPT air inlet is too small).

5. When used with an internal shaft, to either guide the

part or to pull (rather than push) a load.

CONVOLUTED AIR SPRINGS

(#203 is shown)

BEAD RING BOLT May be one of four varieties. See

page 10. Also refer to the data sheet order block on each

individual part for bolt lengths.

NUTS AND LOCKWASHERS are included with the part.

(Except for socket head type bead rings).

MOUNTING PLATE is not included. See page 10 for

material, machining recommendations, and installation

instructions.

BEAD RING, upper and lower. (Aluminum)

GIRDLE HOOP Solid steel type shown, molded into the

bellows.

BELLOWS Wall gauge is approximately

1

/4". See page 5

for detailed information.

END CLOSURE OPTIONS

LARGE PAR TS WITH ALUMINUM BEAD RINGS

Page 10

10

When using bead rings, THE CUSTOMER WILL NEED

TO FABRICATE HIS OWN MOUNTING PLATES. Hot or

cold rolled steel provides satisfactory mounting surfaces,

with specific finishes of 32 micro-inches, if machined in a

circular fashion, and 250 micro-inches when ground (side

to side). The thickness of mounting plates depends upon

the application. The plates must be strong enough and

backed by structural members to prevent bowing (of the

plates) when subjected to the forces or loads involved.

The rubber bellows provides its own seal; therefore, ‘O’

rings or other sealants are not needed when installing the

part.

INSTALLATION

Follow this technique for assembling a bead ring style bellows to the mounting plate:

a. Insert the bolts into the bead ring (the bead rings have

been previously attached to the bellows at the factory).

The bolts will be pulled into place by the action of tightening the nuts.

b. Slip all of the bolts (which are protruding through the

bead ring) into the mating holes of the mounting plate

and attach the lockwashers and nuts. FINGER TIGHTEN all nuts to produce a uniform gap between the bead

ring and mounting plate all the way around.

c. At this point, make certain that the bellows bead is prop-

erly seated under the bead ring.

PLEASE NOTE THAT UNIFORM SUCCESSIVE TIGHTENING OF THE NUTS IS IMPORTANT TO SEAT THE

RUBBER BEAD PROPERLY TO THE MOUNTING

PLATE FOR ITS FULL CIRCUMFERENCE.

Continue with the following sequence:

d. Tighten all nuts one turn each, moving around the circle

until continuous contact is made between the bead ring

and mounting plate.

e. Torque all nuts to the torque specifications shown on the

page, going at least two complete turns around the bolt

circle.

MATERIAL

Bead rings are supplied in either steel or aluminum. Steel

bead rings can be of two different types. Both the bead ring

material and type of ring are called out in the description

section of the order block on each individual data page.

Also, the bolt length (for the bolts supplied with that particular order number) is given.

WHERE A BEAD PLATE PART IS SHOWN AND THE

BEAD RING ATTACHMENT IS PREFERRED, PLEASE

REFER TO THE SELECTION GUIDE ON PAGE 32 FOR

BOLT CIRCLE DIAMETERS AND NUMBER OF BOLTS

(EACH RING).

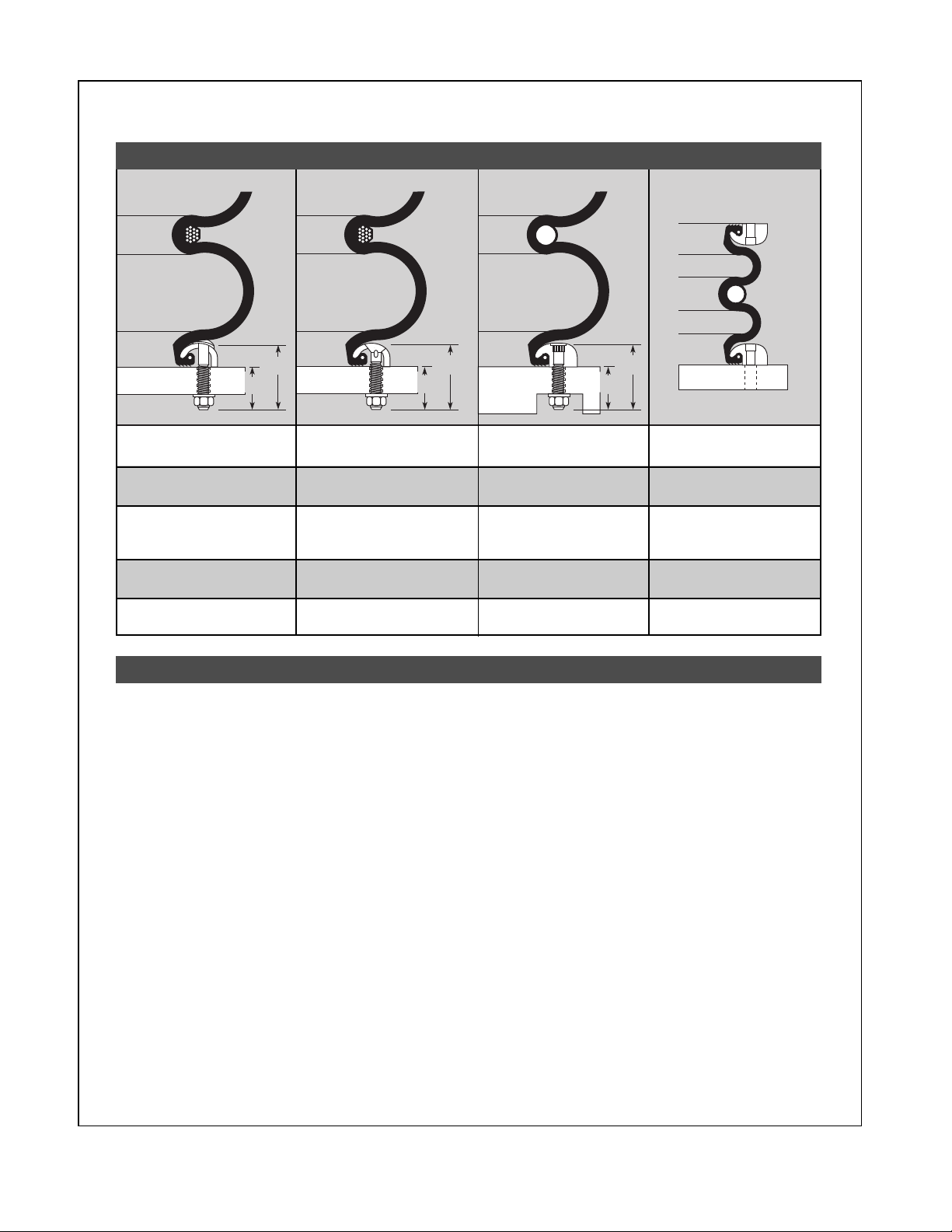

BUTTON HEAD STEEL

BEAD RING

COUNTERSUNK STEEL

BEAD RING

RIBBED NECK

ALUMINUM

BEAD RING

SOCKET HEAD

ALUMINUM BEAD RING*

Optional Shorter Length

Ribbed Neck Bolt

Used on

4.5 in.

Bolt

Circles

Use M6

Cap

Screws,

(Not

Included)

Customer

Supplies Plate

Effective

Length

Bolt

Length

Customer

Supplies Plate

Customer

Supplies

Plate

Customer

Supplies Plate

Effective

Length

Bolt

Length

Effective

Length

Bolt

Length

Standard Bolt Length (in.) Standard Bolt Length (in.) Standard Bolt Length (in.)

1 7/

8

1 5/

8

1 7/

8

Standard Effective Length

(in.)

Standard Effective Length

(in.)

Standard Effective Length

(in.)

1.28 1.22 1.28

Standard Order Number Standard Order Number Standard Order Number

(bolt only) (bolt only) (bolt only)

WC1-358-3607 WC1-358-3625 WC1-358-3620

Thread Thread Thread

5

/16-24 UNF

5

/16-24 UNF

3

/8-24 UNF

Tightening Torque (ft.-lbs.) Tightening Torque (ft.-lbs.) Tightening Torque (ft.-lbs.)

17 to 22 17 to 22 28 to 32

END CLOSURE OPTIONS

THE FOUR TYPES OF BEAD RINGS

BEAD RINGS CONTINUED

*Available only on style #16, #25, and #255-1.5

Page 11

11

AIR INLET 3/4NPT is standard. See the selection guide

on page 32 for location (type 5). A centered 2" NPT air

inlet is also available for some rolled plate parts. (Consult

Firestone).

BLIND NUT

1

/2-13 UNC thread x 3/4" deep (four each

plate). Used for mounting the part. A stud adapter for this

size blind nut is not available.

UPPER BEAD PLATE (9 gauge carbon steel, .149").

Permanently crimped to bellows to form an airtight assembly. Allows for leak testing before the unit leaves the

factory. Zinc/chromate plated for rust protection.

The convoluted parts, with 17, 20, and 22 inch diameter,

are shown with bead rings as standard. We have developed a method for permanently attaching plates to these

larger sized Airstrokes (called rolled plate assembly).

These parts may be an advantage over the bead ring

parts in some cases, because installation is much easier

(they attach the same way as the bead plate parts).

When installing the rolled plate parts, a backup plate as

large in diameter as the bead plate must be used. This

plate should be a minimum of 1/2inch thick.

Again, for the blind nut and air entrance locations of rolled

plate parts (bead rings are shown as standard on the

data pages), please refer to the selection guide on page

32. The static data chart on each individual part may be

used for the rolled plate version; but, two modifications

must be made:

1. Increase the minimum height by .70 inch.

2. Add .70 inch to the height (bottom axis) before

reading loads.

9mm

END CLOSURE OPTIONS

LARGE PAR TS WITH ROLLED PLATES

CLAMP RING This ring is crimped up under the bel-

lows bead to permanently attach the bead plate to the

bellows. It is also zinc/chromate plated for rust

protection.

LOWER BEAD PLATE Usually the same as upper

bead plate, except without air inlet. See the selection

guide on page 32 for diameter (type 5).

LARGE CONV OLUTED AIR SPRINGS

(#203 is shown, with rolled plates instead of bead rings)

Page 12

12

HO W T O USE

THE STATIC D A TA CHART

We also refer to this chart as the load/deflection

(L/D) curve for an air spring. The force [1] is given

on the right hand axis vs. the air spring height [2]

as shown along the bottom axis; thus, load vs.

deflection. The internal volume [3] is also given

along the left hand axis, again vs. height [2]. It is

called static data because the air spring is in a

static, or non-moving, constant pressure condition. In almost all cases the static curves were run

using a two ply bellows; however,

where a four

ply bellows is available, use the two ply chart for it

also.

AIRSTROKE A CTU ATION

The important considerations are minimum

height [4] (3.0 inches) and maximum recommended height [5] (10.1 inches). Subtracting one

from the other gives the stroke potential for this

part (10.1 – 3.0 = 7.1 inches). As an actuator, the

entire stroke may be used,

or any potion thereof

.

Ignore recommended airmount design height

[6]

and the corresponding darkened line

[7]. This

height is important in using the air spring as an

isolator (AIRMOUNT). It has nothing to do with

the concern here of actuation. To determine the

force at any given height, simply move up the

height line to where it intersects any of the static

pressure curves. Then move to the right and

read from the force scale [1].

EXAMPLE: At 80 psig, what is the force using a

#22 from 4.0 to 9.0 inches, or 9.0 – 4.0 = 5.0 inch

stroke? See [8] for force at 4.0 inches (7,180 #)

and [9] for force at 9.0 inches (4,670 #). This

example illustrates the primary difference

between Firestone Airstrokes and conventional

air cylinders. Air cylinders have a constant area

for the pressure to work against, or constant

effective area.

the effective area and force of an

air spring changes as the height changes.(There

is one exception: notice the plateau section of

reversible sleeve 1T type curves.)

Bumper Contact

(4.2 IN.)

MAX. HT.

11

10

9

8

7

6

5

4

3

2

1

11

10

9

8

7

6

5

4

3

2

1

12 11 10 9 8 7 6 5 4 3

MIN. HT.

[16]

[5]

[2]

HEIGHT IN.

VOLUME (WITHOUT BUMPER) CU IN. x 100

[3]

FORCE LBS x 1000

[1]

Static Data

1227

[6]

Recommended

Airmount

Design Height

9.5 Inches

Do not use Airstroke in

shaded area without

consulting Firestone

[13]

752

120

100

80

60

40

20 Psig

Volume

100 Psig

[12]

349

[

1 1

]

4,280

4,670

[

1 4

]

[

1 5

]

[9]

7,180

[10]

[4]

[7]

[8]

Page 13

13

(There is one exception: notice the plateau section of

reversible sleeve 1T type curves). In the example the effective

area of a #22, at 4.0 inches using the 80 psi curve, is:

7,180 lbs.

80 Ibs/in

2

= 89.8 in

2

at 9.0 inches in height it is:

4,670 lbs.

80 Ibs/in

2

= 58.4 in

2

An air cylinder with 89.8 in2of area would have an 80 psi curve

as shown by dotted line [10].

The volume curve [3] may also be of importance:

a. If one needs to know the amount of free air (then com-

pressed by the compressor) to perform a desired operation.

b. If the actuation must be completed quickly and calculations

of flow through the air inlet (orifice) are required.

In each case above, the change in internal volume is required.

Read up from the two heights involved to the intersecting point

with the volume curve. Then move to the left and read from the

volume scale. In the example at 4.0 a #22 (notice most volume

curves are at 100 psig) has an internal volume of 349 in

3

[11]

and at 9.0 the volume is 752 in3[12]. The change in volume is

then 752 in3– 349 in3, or 403 in3. The volume at minimum

height (349 in3) would not be subtracted if exhausting the air

spring to atmospheric pressure.

Notice the shaded area [13]. We do not recommend that an

air spring be used at heights extending into this section. The

“beginning of the shaded area” for a #22 is at 101 inches [5].

SEE PAGE

15

FOR A MORE DETAILED DISCUSSION OF

ACTUATION.

AIRMOUNT ISOLATION

Because of lateral stability considerations (see page 23 for

more details) we recommend that each air spring be used at a

specific height

when used as an

isolator

. This specific height is

called the “Airmount design height” [6]. The vertical line running

through this height [7] is darkened so that it is easy to see

where it intersects the static curves for load readings.

EXAMPLE: Support a 4,100 pound load with an air spring.

Would a #22 be appropriate, and if so, at what height? The

height isn’t much of a problem, as this part SHOULD BE

USED AT 9.5 INCHES. Simply move up the darkened line to

where it intersects 4,100 Ibs [14]. That point falls between the

80 and 60 psig curves. Exactly what pressure would be

required? Use the formula:

Effective Area =

Load (Ibs.)

Pressure (Ibs/in

2

)

Determine the effective area at 9.5 inches (using the 80 psig

curve, since 80 psig would be closer to our exact pressure

than 60 psig), or:

Effective Area =

4,280 Ibs. [15]

= 53.5 in

2

80 Ibs/in

2

Then divide the actual load by the effective area:

4,100 Ibs.

= 76.6 in

2

53.5 in

2

The pressure required to support 4,100 Ibs. with a #22 at a

design height of 9.5 inches is therefore 76.6 PSIG.

Please note that the static data can be converted to dynamic

data (the air spring is in motion) by applying the formulas that

are presented in the Airmount isolation section on page 22.

SEE PAGE 21 FOR A MORE DETAILED DISCUSSION OF

VIBRATION ISOLATION.

INTERNAL RUBBER BUMPERS

Some parts are available with internal rubber bumpers. Where

a bumper is available, it is shown as a dotted line in the cross

sectional view of the air spring. Additionally, please note that:

1. the minimum height is increased to the “bumper contact”

point [16] (this reduces the total available stroke somewhat,

by 4.2 – 3.0 = 12 inches in our #22 example), and

2. the order block contains the proper ordering numbers for

parts with bumpers.

Page 14

14

BASIC P ARAMETERS APPLICABLE T O

BO TH AIRSTROKE

®

A CTU A T ORS AND

AIRMOUNT

®

ISOLATORS

MEDIA

Air springs are designed for use with compressed air. Nitrogen

is also acceptable. Air springs may be filled with water or waterglycol (automotive antifreeze) solutions. If water is to be used,

rust inhibitors should be added to protect the end closures. Two

reasons for liquid filling an air spring are:

1. To reduce the internal volume of air (and therefore,

increase

the natural frequency of the air spring) and,

2.

To use a media which is incompressible. Accurate positioning

would be one reason to do this.

Petroleum base fluids (most hydraulic oils fall into this category)

are NOT RECOMMENDED. Moderately lubricated air will not

harm the bellows.

PRESSURE

Our “rule of thumb” is:

1. 100 psig maximum for 2 ply.

2. 175 psig maximum for high strength.

We recommend that there be a minimum three times safety factor between maximum internal air pressure and burst pressure.

So, as an example, if 100 psig is required, the burst should be at

300 psig or greater. For convoluted air springs, the burst pressure decreases as height increases. Therefore, the determining

factors are twofold: What is the maximum height into extension

and what is the internal pressure at that point? Please see the

Airstroke Inflation Pressure Chart (for single, double, and triple

convoluted air springs) on page 17 for specific pressure vs.

height information.

For AIRMOUNT applications (where the part is used at a

height very close to the shaded area), it is best to stay within

100 psig maximum for a two ply, and 150 psig maximum for a

four ply or high strength cord air spring.

TEMPERA TURE

1. STANDARD BELLOWS. Our standard industrial air springs

should be limited to use in the range:

– 35

° F to + 135° F.

2. ALL NATURAL RUBBER (LOW TEMPERATURE COM-

POUND). A few of our industrial air springs are available in

all natural rubber construction. This increases the acceptable cold or low end of the scale to – 65° F. The range then

becomes – 65° F to +135° F.

3. EPICHLOROHYDRIN (HIGH TEMPERATURE COM-

POUND). Most convoluted parts are available in this

material. The operating temperature range for it is: 0° F to

225° F. Additionally, Epichlorohydrin has very good oil resistance. ALL EPICHLOROHYDRIN APPLICATIONS MUST

BE APPROVED BY FIRESTONE. For more information on

Epichlorohydrin (also known as Herclor), ask for

Technigram number 111.

CONT AMINATES

Shielding should be used to protect the bellows from exposure

to hot metal, sand, petroleum base fluids, acids, etc. Please

consult Firestone if you wish to know how the bellows will withstand a specific contaminant (For liquids such as acids, it is

important to know both concentration and temperature).

STORA GE

The best storage environment is a dark, dry area at normal

room temperature.

W ARNING

DO NOT INFLATE ASSEMBLY WHEN IT IS UNRESTRICTED. ASSEMBLY

MUST BE RESTRICTED BY SUSPENSION OR OTHER ADEQUATE STRUCTURE. DO NOT INFLATE BEYOND PRESSURES RECOMMENDED IN

DESIGN LITERATURE (CONTACT FIRESTONE FOR INFORMATION).

IMPROPER USE OR OVERINFLATION MAY CAUSE ASSEMBLY TO

BURST CAUSING PROPERTY DAMAGE OR SEVERE PERSONAL INJURY.

Page 15

15

AIRSTROKE A CTU ATION

SELECTION

1.

Refer to the selection guide on page 32 for Airstroke force

and stroke capabilities. After your list of possibilities has been

reduced to one or two air springs, then turn to the individual

data page for more detailed information on those parts.

2. STROKE: The maximum STROKE CAPABILITY is the dif ference between the height corresponding to the “start of

the shaded area” minus the minimum height. This entire

stroke,

or any portion thereof

, may be used. If an internal

rubber bumper is required, please note that the minimum

height is increased, and therefore, the total stroke is

decreased.

3. FORCE: Read the forces directly from the static data chart,

or, use the force table located under the chart. Notice that

the force generally decreases as height increases. This feature is discussed in detail on page 12 in the section entitled

“How to Use the Static Data Chart.”

4. SELECT THE END CLOSURES AND AIR INLET SIZE:

Most Airstroke actuators are available with permanently

attached plates or bead ring attachments. If an alternate end

closure option is available, it is so stated under the cross

sectional view of the part. Please refer to page 6 for a

detailed discussion of end closure options.

DOWN AND UP STOPS

Positive stops in both directions (compression and extension) should always be used with Airstroke actuators .

1.

In COMPRESSION, the minimum height shown for each air

spring is at, or slightly above the PINCH POINT of the bellows.

Here is a #22 shown in the collapsed or “pinch point” condition:

The bellows can be damaged if allowed to constantly bottom out as shown above; therefore, a downstop is required

to prevent this. An external downstop can be something as

simple as a steel block and should be sized at or slightly

greater than the minimum height of the Airstroke. In our #22

example, the block would need to be at least 3.0 inches

high. If an external downstop cannot be used, many parts

are available with internal rubber bumpers (shown as a

dotted line in the cross-sectional view of the air spring

where available).

2.

In EXTENSION, an upstop is required to prevent the air

spring from overextending at heights into the shaded area of

the graph. The reasons for this are twofold: a) the life of the

bellows may be reduced and b) the crimp may open up,

allowing the bellows bead to blow out of the metal end closure. There are many ways to design-in an upstop, including

a. a chain,

b. a cable,

c. contacting a metal stop, etc.

RETURN

An Airstroke actuator is a

single acting

device. To return the

Airstroke to its minimum height (for another cycle or stroke),

some return force must be used. Gravity acting on the load

may be all that’s required. The force to collapse the convoluted

type Airstrokes to minimum height is given in the order block

section for each part. If the load is not sufficient, then a second

Airstroke or coil spring may be required.

GUIDING

An Airstroke follows the path of least resistance

; therefore, the

actuator should be guided in most instances. This is often easily accomplished in the mounting geometry.

ANGULAR CAPABILITY

An Airstroke actuator can stroke through an arc (without a clevis). Angular motion of up to 30 degrees is possible. When

using an actuator with the mounting plates at an angle to each

other, observe the following:

a. Measure force at the height between the plate centers.

b. Measure maximum height at the side separated

the furthest.

c. Measure minimum height at the side collapsed the most.

3.0

Page 16

16

Angular Capability continued

These measurements must fall within the guide lines for that

particular part. Consider style #22 in the following scissors

arrangement:

Reversible sleeve Type 1T parts may also stroke through an

arc. In this case, care must be taken to prevent the bellows from

rubbing (internally) against itself where it rolls over the piston:

HORIZONT AL MISALIGNMENT

The upper and lower bead plate centers (or mounting plate

centers in the case of a bead ring type attachment) may be out

of line somewhat without injury to the bellows. Our “rule of

thumb” for convoluted type Airstrokes is one inch misalignment

allowed per convolution. So, a single convoluted air spring

may be out of line by as much as 1 inch, a double by 2 inches,

and a triple convoluted air spring by 3 inches.

DESIGN ENVELOPE

Adequate clearance should be provided around the Airstroke

to prevent puncturing or rubbing of the bellows. The maximum

diameter @ 100 psig for each Airstroke (bellows) is located

just above the cross-sectional view of the air spring.

ST A CKING

It is permissible to stack Airstrokes (one on top of another) to

increase stroke; however, the center plate (or plates) connecting the two or more Airstrokes MUST BE GUIDED.

Please note that the air spring forces are

not

additive in this

configuration. A method for guiding, which also illustrates one

center ring concept for mounting the two parts together at the

middle, is illustrated below:

FAIL SAFE DEVICES

Some applications require the use of fail safe mechanisms

(such as a mechanical lock-out on a scissors lift) to prevent

damage or injury in the event of an air system failure.

VACUUM

An Airstroke can withstand a small amount of vacuum without

injury to the bellows. The maximum amount of acceptable vacuum is dependent upon the bellows’ size, the height in use, and

whether it is a two ply or high strength (fabric) air spring. (A high

strength Airstroke bellows has a “stiffer” wall than a two ply;

therefore, it is less susceptible to dimpling and deformation

inward). It is generally best to use only single convoluted air

springs under vacuum.

An Airstroke Design Parameter Worksheet

can be found on page 103.

Max Ht

(Must be ≤ 10.1)

Bellows must

not rub against

itself here.

Max Ht

(Must be ≥ 3.0)

Calculate

Force Here

Pivot

Point

#22

Center Ring

Customer Must

Supply Button

Head-Socket Head

Cap Screws

Page 17

17

AIRSTROKE

INFLATION PRESSURE CHART

MAXIMUM RECOMMENDED INTERNAL PRESSURES FOR CONV OLUTED

TYPE AIRSTROKE

®

ACTU ATOR APPLICATIONS

BASED ON APPRO XIMATEL Y

1

/3 NORMAL BURST V ALUES

APPLICATIONS WHICH EXCEED THESE LIMITS SHOULD BE REVIEWED WITH FIRESTONE.

18 16.5 15 13.5 12 10.5 9 7.5 6 4.5

12 11 10 9 8 7 6 5 4 3

6.5 6 5.5 5 4.5 4 3.5 3 2.5 2

TRIPLE CONVOLUTED

DOUBLE CONVOLUTED

SINGLE CONVOLUTED

OVERALL AIRSTR OKE HEIGHT (INCHES)

FOUR PLY BEAD PLATE AND

BEAD PLATE AND BEAD RING STYLE

ROLLED PLATE STYLE

BEAD RING STYLE

TWO PLY

250

200

150

100

50

0

PRESSURE (PSIG)

REFER TO EA CH

INDIVIDUAL D ATA

PA GE FOR MAXIMUM

USABLE HEIGHT

RESTRICTIONS

Page 18

AIRSTROKE®ACTUA T OR PROBLEM SOLVERS

18

GATE VALVE OPERATOR

GLUING PRESS

WEB TENSIONING DEVICE

DIE STRIPPER

KNIFE SPRING ACTUATOR

QUENCH TANK ACTUATOR

PAPER SIZING PRESS

PICKLING TANK ACTUATOR

QUICK LOCK DEVICE

PRESSURE ROLL FOR CALENDER

AIRSTROKE ACTUATORS

QUENCH TANK

UPPER & LOWER POSITIVE STOPS

KNIFE

AIR LINES

ACID TANK

WIRE COILS

ACID

FRAME

PRESS

PIVOT

LOG

ROTATION

PAPER

AIRSTROKE

ACTUATOR

Page 19

AIRSTROKE®ACTU A TOR PROBLEM SOLVERS

19

MISSILE ASSEMBLY FIXTURE

CORE STRAIGHTENER

BELT TAKE UP

ROLLER FRICTION BRAKE

PIPE INDEXING THREADING

OSCILLATING DOCTOR FOR PAPER

CALENDER ROLL

CABLE TENSIONING DEVICE

BAG FLATTENER

TORSIONAL FRICTION BRAKE

FORMING PRESS

AIRSTROKE

ACTUATOR

AIRSTROKE

ACTUATOR

END VIEW OF PIPE

DOCTOR

PRESS

PLATEN

AIRSTROKE

ACTUATORS

BAG OF

MATERIAL

TO BE

FLATTENED

POWERED

ROLLER

DRIVE

BELT

LINESHAFT

TORQUE TUBE

BRAKE BUSHING

AIRSTROKE

ACTUATOR

ROLLER

SUPPORT

FRAME

CYLINDER

FRICTION PAD

Page 20

20

AIRSTROKE®ACTU A TOR PROBLEM SOLVERS

HINGED GATE

HOT FOIL STAMPING PRESS

ACTUATED HEAVY DUTY SEALER PIVOTED CLAMPING DEVICE

AIRSTROKE ACTUATED ROLLER STOP HINGED ACTUATED GRAVITY GATE

VERTICAL ACTUATED DRIVE TABLE

SCISSOR LIFT

CASE PACKER

CONVEYOR TRANSFER ACTUATOR

AIRSTROKE

ACTUATOR

AIRSTROKE

ACTUATOR

AIRSTROKE

ACTUATOR

AIRSTROKE

ACTUATOR

RETURN TENSION

SPRING

RUBBER

STOP

ADJUSTABLE

COLLAPSE

HEIGHT

TOP OF CHAIN IN HIGH POSITION

TOP OF CHAIN IN LOW POSITION

FIXED STOP

AIRSTROKE

ACTUATOR

AIR

FITTING

COMPRESSED POSITION

EXTENDED POSITION

TORSION

SPRING

HINGE

OPEN

CLOSED

WEIGH

HOPPER

AIRSTROKE

ACTUATOR

Page 21

21

AIRMOUNT®VIBRATION ISOLA TION

SELECTION AND ISOLA TION FORMULA

Refer to the selection guide on page 33 for Airmount load and

isolation capabilities. Follow this procedure:

1. LOAD CAPACITY

Select one or two Airmounts that can support the load at each

mounting point. It is normally best to design for pressures in

the 60 to 80 psig range. Consider only the 1M1A-0 and the

single and double convoluted types at first. Please notice that

in the range of 210 to 63,890 pounds you will, in most cases,

find both a single and double convoluted style part which will

support the load.

2. DETERMINE ISOLA TION EFFECTIVENESS

Select the disturbing frequency that is closest to the actual

forced frequency (400, 800, or 1500 cpm). Then check the percentage of isolation for the parts that were selected in 1 above.

3. DETERMINE DESIGN HEIGHT

THE AIR SPRING SHOULD BE USED AT THE DESIGN

HEIGHT GIVEN. The double convoluted part is used at a

design height somewhat higher than its single convolution

equivalent. Make sure that the design height falls within the

height restrictions. Also, the double convoluted part will show a

higher percentage of isolation (less transmitted vibration) than

the single convoluted air spring. The reason for this is that the

double convoluted part has a greater internal volume of air

than the single convoluted version of the same size. At disturbing frequencies in the 400 to 800 cpm range, the double

convoluted part is a significantly better vibration isolator than

the single convoluted part. At disturbing frequencies of 800 to

1500 cpm, the gap closes considerably. At frequencies of

1500 cpm and above, the difference is negligible.

4. DETERMINE EXACT INTERNAL PRESSURE

AND ISOLA TION EFFECTIVENESS

The chances are that your specific vibration problem does not

fall neatly into the load and disturbing frequency criteria as presented in the selection guide.

Therefore, once a preliminary part selection has been made,

turn to the individual data page for that part in order to determine the specific internal pressure required and the

percentage of isolation attainable.

CONSIDER THIS EXAMPLE:

Isolate a vibrating screen which weighs a total of 16,400

pounds, preferably with

one

isolator at each corner. The vibrating mechanism is rotating at a speed of 850 rpm (cpm) with a

total stroke of 5/16inch.

a. Determine the load at each mounting point:

Scan down the 80 psig load column in the selection guide. It

appears that either a #19 or a #22 will support the load at a

pressure between 60 and 80 psig.

b. Determine Isolation Effectiveness.

Read the % of Isolation at 800 cpm for the #19 and #22

(since 800 is closest to our machine speed of 850 cpm). A #19

is at 96.0% and a #22 is at 98.2%. Looking at isolation effectiveness in terms of % TRANSMISSION, the #19 will transmit

100 – 96.0, or 4.0% of the vibrations. A #22 will transmit

100 – 98.2, or 1.8% of the vibrations. So, even though there

does not seem to be much difference between 96.0% and

98.2% isolation, the #22 is in fact a better isolator by approximately a factor of two when comparing transmitted vibration.

c. Determine Design Height.

Let’s say we have chosen the #22 because 96.0% isolation for

a #19 is considered to be too low. A #22 should be used at 9.5

inches as shown in the second column on page 33.

d. Determine Exact Internal Pressure and Isolation Percentage.

Turn to page 61 for detailed information on the #22.

a) What exact pressure will be required to support the load

of 4,100 Ibs? Refer to the information in the block entitled

“Dynamic Characteristics at 9.5 in Design Height.”

Divide the actual load by the effective area:

4

= 4,100 lbs.

4,280 lbs.

80 lbs/in

2

53.5 in2effective area @ 9.5 inches

@ 80 psig

=

=

4,100 lbs.

53.5 in

2

76.6 psig required to support

4,100 lbs. at 9.5 inches

=

16,400

Page 22

22

AIRMOUNT®VIBRATION ISOLA TION

b) What exact isolation will be attained?

Use the formula:

Where: ff= Forced Frequency

fn= Natural Frequency

The forced frequency is 850 cpm Read the natural frequency

from the line at the load and pressure closest to the actual situation, or 106 CPM (@ 80 psig and 4,280 Ibs.):

% Transmission = 1.6%

% Isolation = 100 – % Transmission

% Isolation = 100 – 1.6

% Isolation = 98.4%

Notice that the natural frequency of an Airmount changes only

slightly with variations in pressure and load. Therefore, when

working at pressures other than 40, 60, 80, or 100 psig, % isolation can be calculated quite accurately using the “closest”

natural frequency and the formula above.

DYNAMIC SPRING RATE FORMULA

Spring rate is a different matter. Unlike most conventional

springs, the rate of an Airmount is not constant. It is a function

of the change in effective area, volume, and pressure from

design height. To determine the rate of an Airmount, use the

following formula:

K=[Pg+14.7] A

c

1.38

–A

e

1.38

–14.7(Ac–Ae)

WHERE:

K = Vertical Spring Rate in Ibs./inch

Pg= Gauge Pressure at design height

Ac= Effective Area at 1/2inch below design height (in2)

Ae= Effective Area at 1/2inch above design height (in2)

V1= Internal Volume at design height (in3)

Vc= Internal Volume at 1/2inch below design height (in3)

Ve= Internal Volume at 1/2inch above design height (in3)

Consider the same #22 example: What is the vertical spring

rate with a load of 4,100 pounds at a design height of 9.5

inches? Refer to the static data chart on page 61. Again,

our “closest" pressure is 80 psig, so we'll need to read the

appropriate data from the 80 psig curve.

The 80 psig information at

1

/2inch above design height

would fall at the 10.0 inch height line, and 1/2inch below

design height would fall at the 9.0 inch height line. (In this

example, we can read loads from the force table). The

information at design height is located in the “Dynamic

Characteristics Block.” So,

K = Unknown

Pg= 76.6 psig (see page 13)

V1= 782 in

3

Vc= 752 in

3

Ve= 809 in

3

K=[Pg+14.7] A

c

1.38

–A

e

1.38

–14.7(Ac–Ae)

K=[76.6+14.7] 58.4

1.38

–47.6

1.38

–14.7

(58.4–47.6)

K = 1,324 lbs/inch

NA TURAL FREQ UENCY FORMULA

Once the spring rate is determined, calculate the Airmount

natural frequency (for an

undamped

system) as follows:

Where:

fn= Natural Frequency in cycles per minute (cpm)

K = Rate (Ibs/inch)

L = Load (pounds)

in our example:

f

n

= 106.8 cpm

( )

% Transmission =

100

f

f

f

n

– 1

2

( )

% Transmission =

100

106

– 1

2

850

[ ( ) ( ) ]

V

1

V

c

V

1

V

e

[ ( ) ( ) ]

V

1

V

c

V

1

V

e

[ ( ) ( ) ]

782

752

782

809

( )

lbs

in

2

n

A = 58.4 in

2

c

( )

4,670 lbs.

80 lbs/in

2

A = 47.6 in

2

e

( )

3,810 lbs.

80 lbs/in

2

f = 188

√

K

L

n

f = 188

√

1,324

4,100

Page 23

23

AIRMOUNT®VIBRATION ISOLA TION

Up to this point, only the weight and disturbing frequency have

been discussed. THERE ARE MANY OTHER IMPORTANT

CONSIDERATIONS:

CENTER OF GRA VITY

An Airmount isolation system is inherently soft (easily deflected); therefore, precautions must be taken to insure that the

system is stable. First, consider the location of the center of

gravity (c.g.). Ideally, the Airmounts should be located on the

same plane (parallel to the ground) as the center of gravity.

Where this is not possible, follow this guideline: The distance

between the most narrow mounting points should be at least

twice the height of the center of gravity.

In the above example, the most narrow distance between two

Airmounts is 46 inches The height to the c.g. is 48 inches;

therefore, this system does not meet our guideline. Two possible solutions would be:

1. Increase the base dimensions to meet our guideline by

increasing both the width and length to at least 48 x 2 or

96 inches.

2. Locate the Airmounts at the c.g. as shown above (in the

next column).

LA TERAL RATES AND ST ABILITY

Single and double convoluted air springs SHOULD BE USED

AT THE DESlGN HEIGHTS GIVEN, because that is the point

of maximum lateral rate or stability. The lateral rate

decreases

as the Airmount height

decreases

. Consider a #22 again at

80 psig:

Notice that the #22 becomes unstable in the horizontal or lateral

direction when moving down only two inches from design height.

Height Lateral Rate Vertical Rate

9.5 inch (design height) 325 lbs/in 1,373 lb/in

8.5 inch 212 lbs —

7.5 inch Unstable —

Height 48"

Width 46"

Length 50"

Page 24

24

AIRMOUNT®VIBRATION ISOLA TION

At design height and without an auxiliary reservoir, the single

and double convoluted parts follow this pattern; i.e., the lateral

rate varies from 1/5 to 1/2 of the vertical rate (only the larger

high strength parts get as high as 1/2). Notice the #22 is

approximately 1/4( ). Going back to the original example of

a vibrating screen which weighs 16,400 Ibs. mounted on four

#22’s (@ 9.5 inches), a side load of 1,300 pounds (325 x 4)

would deflect the entire suspended mass by one inch.

TRIPLE CONV OLUTED AND

REVERSIBLE SLEEVE TYPE PARTS

Both of these types are unstable laterally (except for the

1M1A). Due to low natural frequencies, both can be excellent

isolators; however, do not use these two types as Airmount

isolators without consulting Firestone (for special guidelines

and precautions).

DESIGN ENVELOPE

Adequate clearance should be provided around the Airmount to

prevent puncturing or rubbing of the bellows. The maximum

diameter @ 100 psig for each Airmount (bellows) is shown just

above the cross sectional view of the air spring.

SAFETY STOPS

It is normally recommended that positive stops be installed

in all

directions

; i.e., into compression, extension, and laterally.

Positioning of the vertical stops depends upon the amplitude of

movement, both during normal operation and startup and shutdown. A good “rule of thumb” is ±1/2inch from design height for

vertical stops and also ±1/2inch (horizontally) for lateral stops.

INITIAL INSTALLATION

NEVER use Airmounts to lift equipment into place, due to the lateral instability at lower air spring heights as discussed

previously. Equipment should be rested on stops set

slightly

below design height and raised into position for isolation.

ST AR TUP AND SHUTDO WN/

RESONANCE AND AMPLIFICATION

Resonance is the condition where the forced frequency of the

vibrating system is at the natural frequency of the suspension.

When this happens, AMPLIFICATION of movement occurs.

Going back to our vibrating screen example again, if the normal stroke is 5/16of an inch, during startup and shutdown (as

the machine goes through resonance), the amplitude of

movement will be multiplied somewhat. So, while the machine

is building up to speed and slowing down, the stroke may be

amplified in the range of 1/2to 11/2inches. The longer the

machine takes to go through resonance (to build up to, or

slow down from full operating speed), the larger the amplitude

of movement.

ISOLA TING AN UNB ALANCED MASS

The primary concern in this case is the amplitude of movement. It is dependent on:

1) The ratio of the unbalanced moving mass to the total

suspended mass, and

2)

The ratio of the speed of the unbalanced moving mass

(forced frequency) to the natural frequency of the Airmounts.

The addition of damping to the isolation system (shock

absorbers) will reduce the large amplitude of movement

experienced during resonance.

If the amplitude of movement is too great, one possible solution would be to add an inertia base in order to increase the

ratio of the total suspended mass to the moving unbalanced

mass. A good “rule of thumb” is 10:1, respectively.

LOW PRESSURE OPERATION

The lateral rate of a single and double convoluted style

Airmount

decreases

with decreasing internal air pressure

(becomes unstable). Consult Firestone if you plan on operating an Airmount at less than 40 psig.

EFFECT OF AN A UXILIAR Y RESER V OIR

There is a direct relationship between natural frequency

and isolation effectiveness. Generally, the lower the natural

frequency, the better the isolator (or higher percentage of

isolation). As previously mentioned, a double convoluted

Airmount has a lower natural frequency than a single convoluted type (of the same size) because it has more

internal air volume. We can use this principle to lower the

natural frequency of an air spring by adding an auxiliary

reservoir (pressure vessel) externally to the Airmount. This

effectively increases the air spring volume and reduces its

natural frequency.

In order for the reservoir to work properly, there must be a

free flow of air between the Airmount and reservoir.

Therefore, it should be mounted as close as possible to the

Airmount. Additionally, a bead ring attachment is the best

end closure choice as the hole in the upper mounting plate

can be sized as large as the inside diameter of the bellows

(at the top). A 3/4" NPT air inlet will restrict the flow of air

somewhat, but can be used as long as it is understood that

there is some throttling effect.

Going back to the #22 example, an auxiliary reservoir of

three times the internal volume of the air spring at design

height (approximately 10 gallons) will reduce the natural

frequency from 106.8 cpm to 90.2 cpm. The spring rate

also decreases, from 1,324 Ibs./inch to 944 Ibs./inch.

325

1,373

Page 25

25

AIRMOUNT®VIBRATION ISOLA TION

DAMPING

Damping is defined as the ratio:

WHERE: C = System Damping

Cc= Critical Damping

The damping ratio inherent in an Airmount is in the order of

.03. This damping number is so small that the formulas presented in this section assume it to be zero.

PLUMBING SYSTEMS

There are three basic ways of controlling an air suspended

isolation system:

1. With a TANK VALVE in each Airmount. Each air spring is

then inflated individually. The pressure in each must be

checked periodically, because air will permeate through

the bellows.

For an idea of the permeation rate, a #116 will lose approximately 30 psig over a period of one year (from 100 psig to

70 psig). Please see page 7 for a picture of a 1/4" NPT tank

valve.

2. Three Point Regulated System The Airmounts can be

connected directly to the factory compressed air system

using pressure regulating valves. This eliminates the

need for periodic inspections. The air springs should always

be connected in clusters so the mass is supported with only

THREE REGULATORS. This is illustrated below (in the

previous column) for both a four and eight Airmount system:

3. Three Point Leveled System Height control can be provided by adding height control valves to the system.

Again, there should be only THREE POINTS OF CONTROL, or in this case, three leveling valves. Attempting

to use more than three control points often results in the

valves hunting or fighting one another. There are sensing

systems available to control heights within ±.001 inch.

Truck type leveling valves can provide accuracy to ±

1

/

16

inch. A three point, eight air spring, leveled system is

illustrated below:

Firestone supplies height control valves and the accompanying linkages from the valve to the supported system.

An Airmount Design Parameter Worksheet

can be found on page 105.

C

C

c

AIR

SPRING

AIR

SPRING

AIR

SPRING

AIR

SPRING

AIR

SPRING

AIR

SPRING

AIR

SPRING

AIR

SPRING

AIR

SPRING

AIR

SPRING

TO AIR

SUPPLY

TO AIR

SUPPLY

CHECK

VALVE

LEVELING

VALVE

LEVELING

VALVE

LEVELING

VALVE

TO AIR

SUPPLY

REGULATORS

REGULA-

TORS

REGULATORS

AIR

SPRING

AIR

SPRING

AIR

SPRINGS

AIR

SPRINGS

AIR

SPRINGS

AIR

SPRINGS

CHECK

VALVES

CHECK

VALVES

Description Order No.

Immediate Response Valve WC1-358-3597

Immediate Response Valve Linkage WC1-358-3594

Time Delay Valve WC1-358-3599

Time Delay Valve Linkage WC1-358-3598

Page 26

26

AIRMOUNT®VIBRATION ISOLA TION

ISOLA TION CHAR T

50

41.7

33.2

25

16.7

15

13.3

11.7

10

8.3

6.7

5.0

4.2

CPMHERTZ

3000

2500

2000

1500

1000

900

800

700

600

500

400

300

250

)

f

FORCED FREQUENCY (f

3.3

200

2.5

150

Percent

Isolation

98 97 969599.5 99 708090 6099.9

Amplification

Resonance

1.7

100

30

0.50400.67500.83601.0801.33

100

1.67

150

2.50

200

3.33

300

5.00

400

6.67

500

8.33

NA TURAL FREQUENCY (fn)

600

10.0

800

13.3

1000

16.7

CPM

HERTZ

Page 27

27

AIRMOUNT®ISOLATION PROBLEM SOLVERS

COMMERCIAL LAUNDRY MACHINE

BIN HOPPER

VIBRATING PACKER

COMPRESSOR

Page 28

28

AIRMOUNT®ISOLATION PROBLEM SOLVERS

CONTROL BOOTH

VIBRATING SCREEN

BLOWER AND MOTOR

CONTROL PANEL

Page 29

29

MISCELLANEOUS APPLICATIONS

The air spring provides a unique solution for many actuation

and isolation applications the world over. Besides the common

applications, there are many that are not readily recognized

because of the air spring’s unique construction. Listed below

are some miscellaneous applications.

SHOCK IMPACT ISOLA TION

The air spring is frequently used in shock impact isolation

applications. This air spring application is commonly found in

saw mills as the means to both absorb the shock of a falling

log, and then by actuating the air spring, to lift and transfer a

log onto a conveyor. Because of the properties of both air and

rubber, the air spring is an ideal solution to this problem.

Without it, the mechanism and surrounding structure would

suffer fatigue and fail prematurely due to the intensity of the

shock from the falling log. Refer to the problem solver section

on the following pages for miscellaneous applications.

PRO TECTIVE BOO T AND

FLEXIBLE CONNECTOR

An air spring bellows, with a bead ring type attachment, can be

used as a protective boot or flexible connector. Due to the flexible construction of the air spring and the ability to handle both

misalignment and angular movement, the air spring is a suitable solution to this problem. To protect the inner surface from

the flow of material, an inner sleeve may be required. Refer to

the problem solver section on the following pages for miscellaneous applications.

VACUUM PUMP

It is possible to drive an air spring mechanically in order to create a vacuum. The air spring can withstand a small amount of

acceptable vacuum without injury to the bellows. The maximum amount of tolerable vacuum is dependent upon the

bellows’ size, height and whether it is a 2 ply or high strength

air spring. It is generally best to use only the single convoluted

air spring for this purpose. Refer to the problem solver section

on the following pages for miscellaneous applications.

INFLA TABLE CHUCK

By restricting the height internally of a bead ring style air spring,

the rubber walls will extend in an outward fashion. In this

arrangement the air spring can be used as an inflatable chuck.

The air will need to be introduced via the same mechanism that

restrains the air spring’s height. Refer to the problem solver

section on the following pages for miscellaneous applications.

CAM FOLLO WER

The introduction of an air spring as the cam follower can

extend the life of the cam greatly. Surface wear is reduced by

removing the rigidity and friction of typical cam followers. With

this reduction of wear comes continually smooth operations

and overall minimization of fatigue. Refer to the problem solver

section on the following pages for miscellaneous applications.

AIRSPRING

ROTA TING

CAM

HEATING

PLATEN

INDEXING CONVEYOR

SYSTEM

EXTENDED

COLLAPSED

VACUUM CYLINDER

SPRING RETURN

PREPRINTED LABELS

INDEXED IN

RETURN

SPRING

PA CKA GE

OF MEAT

For more information, call your local stocking distributor or the

Firestone applications engineer at the phone number on the

back cover of this design guide.

CHECK

VALVE

AIRMOUNT

CARRIAGE

CONVEYOR RAIL

AIRSTROKE

ROTATING

SHAFT

AIR ENTRANCE

TUBE

AIRSTROKE

PIPE

HYDALON

SLEEVE

Page 30

30

AIRSTROKE

END VIEW

MISCELLANEOUS PROBLEM SOLVERS

ROBOTIC COUPLING CONVEYOR END STOP

SHOCK ABSORBER TEST SYSTEMMOUNTAIN/TRAIL BIKE

SCREENING MACHINE COVER CLAMP

PIPE CRAWLER

VIBRATING SCREENDELICATE ELECTRONIC EQUIPMENT

Page 31

31

MISCELLANEOUS PROBLEM SOLVERS

SHEET WELDING CLAMP

PERFECT BOUND MAGAZINE CUTTER

CHECK VALVE LAPPING

AIR BLAST GENERATOR

SWASH PLATE MOTOR

WAVE POWER MODULE

SELF ALIGNING DEVICE

SOLAR TRACKER

Page 32

Maximum

1 Inch 3 Inches

Stroke

(pounds) (pounds)

(pounds)

1 1.75 4 4.50 6

3 3.50 1.75

•

4 6.31 8

3 3.50 1.75

•

4 6.31 8

3 3.50 1.75

•

4 6.31 8

3 6.20 2.88 4 9.00 12

3 6.20 2.88 4 9.00 12

3 6.20 2.88 4 9.00 12

3 6.20 2.88 4 9.00 12

3 6.20 2.88 4 9.00 12

3 6.20 2.88 4 9.00 12

3 6.20 2.88 4 9.00 12

3 6.20 2.88 4 9.00 12

2 6.25 4 11.31 12

2 6.25 4 11.31 12

1X84D-1 5.2 DO NOT USE 1X84D-1 AS AN AIRSTROKE ACTUATOR

4001 3.1 3.6 3.6 7.2 280 310 310

7002 4.2 3.5 2.5 6.0 710 660 660

7010 4.0 5.75 4.25 10.0 570 600 640

7012 5.0 5.0 4.5 9.5 690 750 760

1T12E-3 5.0 6.0 7.6 13.6 750 600 540

1T14C-1 9.1 5.0 7.7 12.7 2,790 2,570 1,720

1T14C-3 9.0 5.8 8.2 14.0 2,930 2,550 1,780

1T14C-7 9.0 8.0 9.4 17.4 3,040 2,610 1,630 1T28C-7

1T15T-1 11.2 4.0 6.7 10.7 5,010 4,370 2,910

1T15S-6 11.1 6.0 10.0 16.0 5,070 4,420 2,830

1T15L-4 11.7 6.0 9.9 15.9 5,690 5,500 3,680

1T15M-0 12.8 4.3 7.0 11.3 5,700 5,550 3,840

1T15M-2 12.6 5.0 8.3 13.3 6,080 5,930 4,060

1T15M-4 12.6 6.0 10.5 16.5 6,270 5,730 4,020

1T15M-6 12.6 7.0 12.2 19.2 6,280 5,730 3,950

1T15M-9 12.7 8.5 15.1 23.6 6,450 5,850 4,210

1T19L-7 14.2 6.0 12.8 18.8 8,800 7,300 4,700

1T19L-11 14.2 8.0 15.4 23.4 8,600 7,300 5,100

352 13.1 4.5 11.2 15.7 8,030 7,340 4,080

313 15.1 4.5 10.5 15.0 10,650 9,700 5,460 39

333 15.2 4.5 12.0 16.5 10,921 10,033 5,800

312** 18.2 4.5 10.4 14.9 15,700 14,200 8,740 314

323** 20.5 4.5 10.9 15.4 21,200 19,500 12,420 324

320** 22.4 4.5 11.8 16.3 28,700 26,700 17,390 328

321 27.9 4.5 14.2 18.7 43,300 41,200 26,420

348-3 37.4 5.5 13.8 19.3 77,000 74,000 53,600 348-3 is 4Ply

25 6.4 2.8 3.3 6.1 1,380 780 660

255-1.5 6.5 3.0 4.0 7.0 2,039 1,786 1,198

224 8.0 2.8 4.9 7.7 2,350 1,760 1,030

26 8.6 3.0 5.7 8.7 2,700 2,230 1,420

20 9.9 3.0 6.1 9.1 3,790 3,180 1,770 202

20-2 10.4 3.0 8.0 11.0 4,125 3,753 2,122

22 12.9 3.0 7.1 10.1 7,180 6,470 3,700 210

22-1.5 13.7 3.0 7.8 10.8 7,680 6,990 3,830

21 15.1 3.0 7.1 10.1 10,300 9,310 5,670 205

21-2 16.0 3.0 8.7 11.7 11,330 10,670 5,850

233-2 15.5 3.0 10.4 13.4 10,966 10,564 5,900

28** 17.4 3.3 6.8 10.1 15,000 13,200 8,530 201

203** 20.0 3.3 7.2 10.5 21,400 19,200 12,910 218

29** 22.7 3.3 7.5 10.8 26,900 24,400 17,280 207

200 26.0 3.3 7.3 10.6 35,700 33,300 24,250

215 27.9 3.3 8.8 12.1 42,500 40,000 28,160

248-2 37.4 4.2 9.1 13.3 78,200 74,100 53,990 248-2 is 4 Ply

16 6.0 1.9 1.4 3.3 960 620

16ST 5.4 1.5 1.8 3.3 1,330 780

131 6.5 2.0 2.1 4.1 1,350 850

110 8.3 2.0 3.1 5.1 2,090 1,030 940

116 9.1 2.0 3.1 5.1 2,690 1,370 1,300 117

116-1 9.6 2.0 4.2 6.2 2,980 2,240 1,460

115 10.1 2.0 3.1 5.1 3,550 1,730 1,620 124

19 12.9 2.0 3.5 5.5 6,720 4,500 3,400

19-.75 13.5 2.0 3.9 5.9 7,040 5,000 3,250

113 15.2 2.0 3.8 5.8 9,900 6,890 4,650 128

113-1 15.9 2.0 4.6 6.6 10,860 8,800 5,500 128-1

153-2 18.1 2.5 4.8 7.3 13,135 10,604 6,422

119** 17.4 2.0 4.2 6.2 14,030 11,450 7,850

121** 20.3 2.0 3.6 5.6 19,600 14,450 11,350

126** 22.4 2.0 4.4 6.4 25,990 22,460 16,000

138-1 .5 27.9 2.0 5.3 7.3 43,430 38,230 22,700

148-1 37.4 2.5 4.8 7.3 78,300 67,690 52,500 148-1 is 4Ply

Maximum

Minimum Maximum

Maximum 80 PSI Force* at Stroke of High

Style Diameter

Height Stroke

Usable Strength

Number

at100 PSIG

(inches) (inches)

Height Style

(inches) (inches) Number

AIRSTROKE®ACTU ATORS

3 6.20 2.88 N/A N/A N/A

2 6.25 4 11.31 12

2 6.25 4 11.31 12

5 9.00 13.79 4 13.81 18

5 12.00 16.50 4 16.50 24

5 15.00 19.00 4 19.00 24

4 23.50 32

4 32.68 40

1 1.75 4 4.50 6

1 1.75 N/A N/A N/A

1 1.75 4 4.50 6

1 1.75 4 4.50 6

1 2.75 4 5.31 6

1 2.75 4 5.31 6

3 3.50 1.75

•

4 6.31 8

3 6.20 2.88 4 9.00 12

3 6.20 2.88 4 9.00 12

2 6.25 4 11.31 12

2 6.25 4 11.31 12

2 6.25 N/A N/A N/A

5 9.00 13.79 4 13.81 18

5 12.00 16.50 4 16.50 24

5 15.00 19.00 4 19.00 24

4 23.50 32

4 32.68 40

1 1.75 4 4.50 6

1 1.75 4 4.50 6

1 2.75 4 5.31 6

1 2.75 4 5.31 6

3 3.50 1.75

•

4 6.31 8

3 3.50 1.75 4 6.31 8

3 6.20 2.88 4 9.00 12

3 6.20 2.88 4 9.00 12

2 6.25 4 11.31 12

2 6.25 4 11.31 12

2 6.25 4 11.31 12

5 9.00 13.79 4 13.81 18

5 12.00 16.50 4 16.50 24

5 15.00 19.00 4 19.00 24

4 22.00 24

4 23.50 32

4 32.68 40

Bead

Dim. A

Bead

Dim. C Number

Plate

(blind nut Dim. B

Ring

(bolt circle of Bolts

Type

centers)

(inches)

Type

diameter) (each

(inches) (inches) ring)

END CLOSURE OPTIONS

SELECTION GUIDE

* To determine Airstroke force at other pressures, divide force shown by 80 PSIG and multiply result by new pressure.

** When using the rolled plate end closure option, add .7 inch to heights shown.

•

On plates with a 3/4 inch NPT air inlet, B dimension is 1.50 inch.

SEE INDIVIDUAL

DATA PAGE

SEE INDIVIDUAL

DATA PAGE

➧

➧

➧

➧

➧

➧

➧

TRIPLE CONVOLUTION

SINGLE CONVOLUTION

DOUBLE CONVOLUTION

REVERSIBLE SLEEVE