Page 1

Page 2

TABLE OF CONTENTS

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .i

LIMITATION OF LIABILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .i

SYSTEM COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

HEIGHT SENSOR INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

PROGRAMMING THE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

OPERATION OF THE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

COMMONLY ASKED QUESTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

WARRANTY

What is covered

Firestone Industrial Products Company warrants the IntelliRide system to be free of defects in material and workmanship for a period of one year or 12,000 miles (whichever occurs first) from the date of original purchase.

If the control system or any part of the control system fails because of a manufacturing defect, Firestone will, at

its option, provide replacement part(s) for the consumer, without charge, provided

the customer:

1) Returns the component/system to the original purchase location, an authorized Firestone distributor.

2) Submits proof of original purchase.

What is not covered

1) Installation or service charges for replacement parts.

2) Damage caused by incorrect installation.

3) Parts that have been altered or tampered with.

4) Damage caused by vehicle accident.

5) Damage from misuse or abuse.

6) Damage caused by extraordinary environmental conditions or events, such as fire, flood or

acts of God.

LIMITATION OF LIABILITY

Warrantor is not responsible for consequential damages. Some states do not allow the exclusion or limitation

of incidental or consequential damages, so the above limitation or exclusion may not apply to you. The warranty

gives you specific legal rights, and you may also have other rights, which vary from state to state. To know

what your legal rights are in your state, consult your local or state consumer affairs office or your state’s

Attorney General.

Vehicle Note: Prior to installation of this kit, the air springs must be installed to your vehicle. Air pressure and

air lines should be removed from the air springs prior to the installation of the Intelliride™ system.

i

24-8201 09-04 NAD-32047-2

Page 3

C

C

ongratulations on your purchase of a new IntelliRide system by Firestone. This kit will provide automatic height control and leveling of

your vehicle. The following will introduce you to the system components as well as provide detailed instructions concerning installing the

height sensors and programming the system. Be sure to take all applicable safety precautions during the installation of this kit. Position

the vehicle on a solid level surface and apply the parking brake. Disconnect the negative battery cable from the battery. With the vehicle on a solid,

level surface raise the vehicle and remove the wheels. After the removal of the wheels, lower the vehicle so the suspension rests on jack stands

rated for your vehicle's weight.

TOOLS REQUIRED

> Drill > 1/2” End wrench > Phillips head screw driver

> 3/8” Drill bit > 10mm End wrench > Sharp knife

> 3/16” Drill bit > 8mm End wrench > Pliers

> Center punch > 7mm End wrench > Tape measure

> Hacksaw > 3/8” End wrench > Marker

> 1” Hole saw > 9/16” End wrench

PARTS LIST

ii

Top Box Components Part # Qty

Valve block 9235 1

Pressure Sensor 0002 1

1/4 NPT Straight Fittings 3100 8

Air Compressor 9210 1

Electronic Control Unit 0200 1

Air Dryer 0004 1

Height Sensors 0100 4

Height Sensor Bracket 5342 4

Height Control Rod 3265 4

Height Sensor Template 8252 4

Bottom Layer Components Part # Qty

Air Tank, 3 Gallon 9127 1

Wire Harness & Connections Part # Qty

Variable Leveling Connection (Park Wire) 0008 1

Wire Harness With Switches, Grommet 9238 1

Hardware & Tubing Part # Qty

Separate Plastic Bag with:

Hardware Required for Height Sensor Installation (Figure 2)

10-32 x 1” Machine Screw 8

10-32 Nylon Lock Nut 8

3/16” Flat Washer 8

M5 x 8 mm Machine Screw 8

M6 x 16 mm Machine Screw 4

M6 Nylon Lock Nut 4

Height Control Arm 4

Hardware Required for Height Sensor Linkage Installation (Refer to

Figure 6)

Hose Clamp 4

Axle Mounting Bracket 4

Height Control Linkage 8

M5 Nylon Lock Nuts 8

M5 Jam Nut 8

1/4” Tubing, 18ft. 1

Hardware & Tubing Part # Qty

Separate Plastic Bag with:

Hardware Required for Component Mounting & Air Fittings

Valve Block Mounting Hardware & Exhaust Silencer

Silencer 3271 1

10-32 x 1-3/4” Socket Head Cap Screw 2

10-32 Nylon Lock Nut 2

3/16” Flat Washer 2

Compressor Isolator Mounting Hardware & Air Fitting

1/8 NPT Fitting 1

10-32 x 1” Machine Screw 3

10-32 Nylon Lock Nut 3

3/16” Flat Washer 6

Ground Wire Mounting Hardware

1

0-32 x 1” Machine Screw 1

10-32 Nylon Lock Nut 1

3/16” Flat Washer 1

ECU Mounting Hardware

10-32 x 1” Machine Screw 1

10-32 Nylon Lock Nut 1

3/16” Flat Washer 1

Air Dryer Mounting Hardware and Air Fittings

3/8 NPT Straight Fitting 2

10-32 x 1” Machine Screw 4

10-32 Nylon Lock Nut 4

3/16” Flat Washer 4

Compressor Relay Mounting Hardware

10-32 x 1” Machine Screw 1

10-32 Nylon Lock Nut 1

3/16” Flat Washer 1

Reservoir Mounting Hardware & Air Fittings

3/8” – 16 Flange Lock Nut 4

3/8” Flat Washer 4

3/8” – 16 x 1” Hex Head Bolt 4

1/4” NPT Plug 1

1/4” NPT Fitting 1

Tie Wraps to Securely Mount Wire Harness 30

Thermal Sleeves to Protect Tubing 4

Inflation Valve for Height Sensor Installation 4

(Air Spring Method)

Torque Recommendations - 1/4 NPT Tank Plug: Tighten the fitting securely to engage the orange thread sealant.

NPT Fittings: Tighten the air fitting so as to make contact with the nylon ring and then tighten 1/4 turn to snug the fitting. No thread sealant is needed.

Pressure Sensor: The pressure sensor is sensitive to over-torque. Carefully install the pressure sensor into the valve block with 7.2 ft-lbs. (9.8 N-m) of torque.

Page 4

Battery Connection

Connections to be made with

vehicle interior

Program button. This is discon-

nected after programming and

replaced with the Park Wire.

Connector to ECU, to be mounted

inside the vehicle.

Service Switch to be used

to turn the system on and

off.

Ignition wire and ground wire.

Ignition wire should be connected

to a source less than 1/2 amp.

Grommet to be used if needed

in the firewall.

Height Control

Switch

Compressor Relay

To be mounted inside engine bay.

Figure 1

Page 5

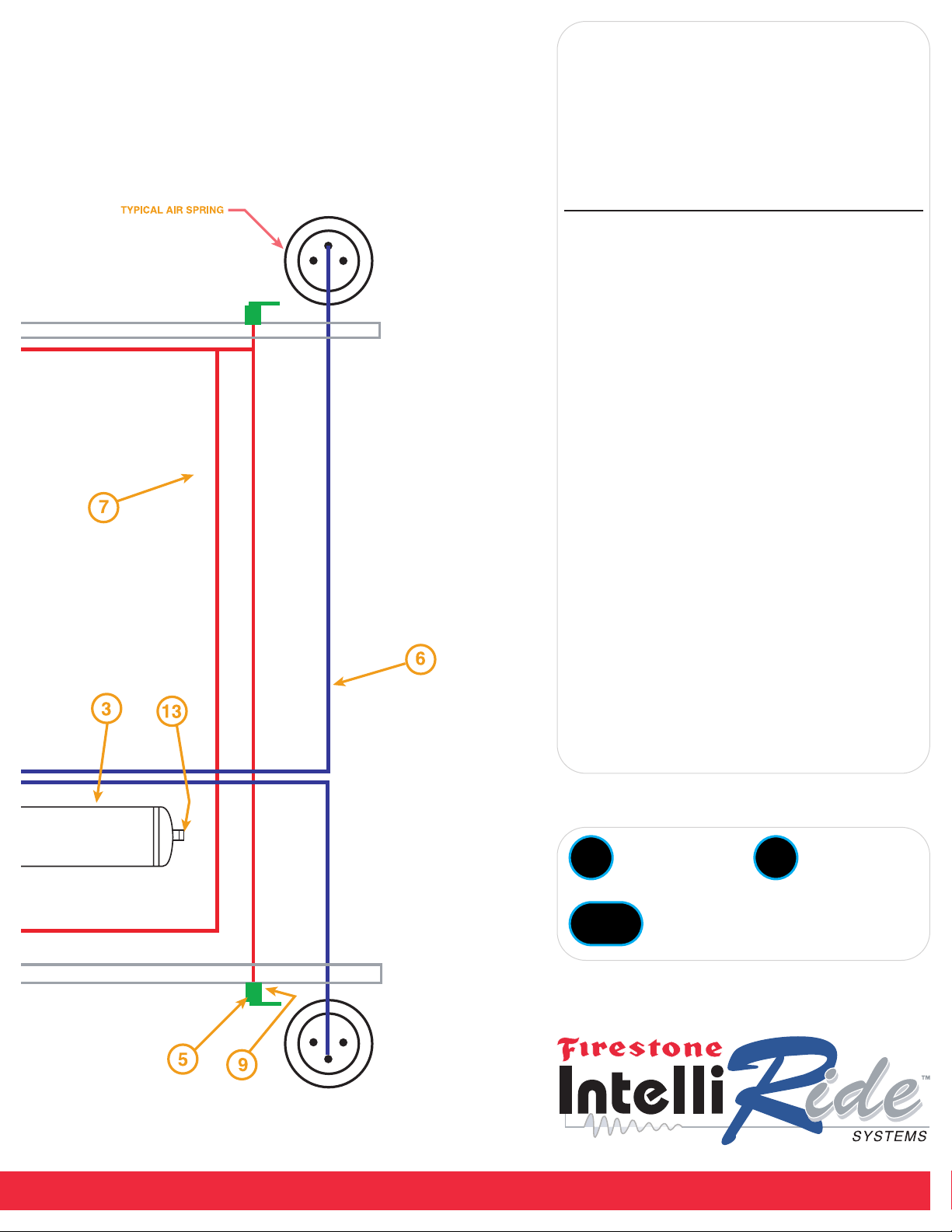

1

IntelliRide

™

Full System Schematic

DET DESCRIPTION

1 FULL SYSTEM VALVE ASSEMBLY

2 AIR COMPRESSOR

3 AIR TANK - 3 GALLON

4 ELECTRIC CONTROL UNIT (ECU)

5 HEIGHT SENSORS

6 1/4 TUBING 18ft.

7 WIRE HARNESS FULL SYSTEM

8 AIR DRYER - SYSTEMS

9 BRACKET - HEIGHT SENSOR

10 3/8 NPT FITTING, 1/4 TUBE

11 1/8 NPT FITTING, 1/4 TUBE

12 1/4 NPT FITTING, 1/4 TUBE

13 1/4 NPT PLUG

14 1/4 NPT SILENCER

15 PRESSURE SENSOR

3/16” Flat Washer (16)

10-32 Nylon Lock Nut (13)

10-32 x 1” Machine Screw (11)

Miscellaneous Mounting Hardware

Page 6

SYSTEM COMPONENTS

Wire Harness

All necessary electrical wires and connectors have been included with this kit. Review Figure 1 before beginning

installation. You will have to put the major components in a position so that the wire harness will reach all of them.

Route the wire harness loosely throughout the vehicle as indicated in Figure 1. Each end of the wire harness is

marked with the major component that it will connect with.

Route the wire harness loosely throughout the vehicle as indicated in Figure 1, with the spine of the wire harness

installed on the right side of the vehicle.

Compressor Relay

Select a location in the engine compartment to mount the compressor relay. This should be a protected location

to prevent damage from flying rocks, water or debris. The compressor relay is located on the wire harness,

simply pull the compressor relay off the wire harness for mounting. Ensure that a clear access to the electrical

connection on the compressor relay is maintained. Then plug the wire harness marked “relay” back into the

compressor relay connector.

Electronic Control Unit (ECU)

The main electronic unit needs to be mounted in the interior of the vehicle, preferably under the dashboard. The wire

harness was designed to provide enough length so the ECU could be mounted under the dashboard and the harness

ran through the firewall to corresponding corners, valve block and power connections.

Valve Block

The valve block should be placed in a protected location to prevent damage from flying rocks or debris. Ensure that a

clear access to all of the fittings on the valve block is maintained. The valve block should be mounted with solenoids

pointing up or sideways, never pointing down. In order to ease installation, abbreviations for the correct plumbing

connections are scribed into the valve block.

The valve block abbreviated connector notations are:

OD = outflow from dryer LF = left/front air spring PS = pressure sensor EX = exhaust

RF = right/front air spring ID = inflow to dryer LR = left/rear air spring Comp Inlet = compressor inlet

RR = right/rear air spring

2

10-32 x 1-3/4” Socket Head

Cap Screw (2)

Silencer

(1)

Pressure

Sensor (1)

1/4” NPT Straight

Fittings (8)

TIPS

1. Do not run the wire harness near vehicle exhaust system.

2. Secure harness firmly to vehicle with

the provided tie wraps.

3. Make sure wire harness does not interfere with any moving parts of the vehicle.

4. Start with the ECU connectors and

then begin running the harness into the

interior of the vehicle.

5. Many vehicles have a blank hole in the

firewall to run wires through.

6. A grommet has been provided if a 1”

hole must be cut to get the wire harness

to the interior. Before drilling the holes,

make sure all electrical, brake and fuel

lines are cleared from the path of the drill.

Page 7

SYSTEM COMPONENTS (cont.)

Height Sensors

The height sensor connections must go to their corresponding corners for proper sensor operation. THE HEIGHT

SENSORS AND THE WIRE HARNESS CONNECTIONS ARE LOCATION AND POSITION SENSITIVE. The sensor

connectors are laid out so they work with the sensors mounted on the outside of the frame rail, with the arms pointed

toward the rear of the vehicle. If the height sensors are mounted inside of the frame rail, the arms must point toward

the front of the vehicle. The system WILL NOT work if the height sensors are mounted incorrectly or if the wire

harness connector is in the wrong corner.

Compressor

Select a convenient location for mounting the compressor. This location should provide ample air flow and be

protected from most airborne debris. The surface should be rigid to support the unit. Some examples might include

under the hood on a fender well, or in a vented storage compartment.

Using the compressor feet as a template, mark the three 3/16” holes. Remove the compressor and drill the three

3/16” holes. Before drilling the holes make sure all electrical, brake and fuel lines are cleared from the path of the

drill. It is recommended that burrs be removed from the holes so as not to damage the rubber isolator. Mount the

compressor using the 10-32 machine screws, 10-32 nylon lock nuts and 3/16” flat washers located in your hardware

pack. Proper mounting of this compressor will provide maximum isolation. DO NOT OVER TIGHTEN, further

tightening will crush the insert and isolator and reduce vibration isolation. Secure the ring terminal to a grounded

component of the vehicle’s chassis. Find the red wire on your wire harness marked air compressor. Connect the

wiring harness to the female spade terminal on the compressor.

3-Gallon Air Tank

Select a location to mount the air tank. This should be a protected location to prevent damage from flying rocks or

debris. Using the holes in the tank brackets as a template, mark the locations of the mounting holes on the mounting

surface. Use a center punch to mark the center of the holes on the mounting surface.

Before drilling the holes make

sure all electrical, brake and fuel lines are cleared from the path of the drill

. Drill four 3/8” holes on the center

marks. Using the supplied 3/8”-16 x 1” hex bolts and 3/8”-16 nuts and 3/8” washers, attach the air tank to the vehicle. Ensure that a clear access to the fittings on the air tank is maintained.

3

Shown with mounts

and air filter.

1/8 NPT Fitting (1)

3/8”-16 x 1 Hex

Head Bolt (4)

3/8”-16 Flat

Washer (4)

3/8”-16 Flange

Lock Nut (4)

1/4 NPT

Fitting (1)

1/4 NPT

Plug (1)

Air Tank Mounting Hardware

M5 Nylon Lock

Nut (8)

M5 x 8mm

Machine Screw (8)

M6 Nylon Lock

Nut (4)

M6 X 16mm

Machine Screw (4)

Axle Mounting Bracket (4)

Hose Clamp (4)

Height Control Linkage (8)

Height Control Arm (4)

Height Sensor Template (4)

Height Sensor Bracket (4) Height Sensor (4)

Page 8

SYSTEM COMPONENTS (cont.)

Air Dryer

Select a location to mount the air dryer. This should be a protected location to prevent damage from flying rocks or

debris and close to the valve block. Ensure that a clear access to all of the fittings on the air dryer is maintained.

Height Selection Switch

The height selection switch may be mounted directly in the dashboard, only if the dashboard material is 1/8” in thickness or less. The height selection switch is located on the wire harness, simply pull the switch off the connector by

depressing the locking clip and pulling the connector off of the switch. To mount the switch to your vehicle, snap the

height selection switch into the open hole with the arrows on the back of the switch pointing up. Then take the wire

harness marked height selection switch and plug the end back into the back of the height selection switch until you

hear it click.

Service and Program Switches

The service switch is basically the ON/OFF switch for the system. It will not operate when RED is showing. When the

switch shows all BLACK the system is functional and will return the vehicle to the height prior to ignition off. The

service switch should be used to disable the system if repairs to the vehicle need to be made. I.E. changing tires,

damper work (such as shock absorber replacements), working under the vehicle or general repairs. The service

switch may be mounted in an area that you can easily access if you need to work on the vehicle’s suspension. The

service switch will mount in panel material that is 1/8” in thickness or less.

The program switch is located on the wire harness. Simply pull the switch off the connector to mount it to your vehicle. After mounting the switch to the vehicle, reconnect the switch to the wire harness. The switch should click into

the harness connector when connecting.

Variable Leveling Response Connection (Park Wire)

As an extra feature, an additional connection wire has been provided that will allow the vehicle to level itself within 5

seconds compared to the standard response time of 40 seconds. This quicker response is desirable when the vehicle

is parked and the payload is increased, providing the user with a more immediate confirmation of leveling. The tan

variable-leveling-response wire with clear connector will be attached to the wire harness in the same location

originally used for the red program switch. Install the park wire after the system has been successfully programmed.

To connect the wire:

1. Unplug the program button. 2. Plug in the park wire connector. 3. Connect the other end of

the park wire to ground or to a switch that will be grounded when the vehicle is NOT in park. This can be done via a

customer supplied switch that will switch out ground for the faster leveling while the vehicle is not moving or the tan

wire can be connected to a vehicle wire/switch that will not be grounded while the vehicle is in park (i.e. parking

brake signal).

Park wire if not grounded = Fast, overly active response

Park wire if grounded = Slow, normal response

Note: If the park wire is not connected, the compressor will be more active than necessary. Install the park wire after the

system has been successfully programmed.

The faster leveling feature is not desirable for normal driving conditions because the system will become too active,

(i.e. - leveling when not desired during cornering).

4

Service

Switch

Program

Switch

Page 9

5

HEIGHT SENSOR INSTALLATION

Step 1

There will be a bag in your kit with all of the hardware that you will

need to put the height sensors on your vehicle. Group a height

sensor from the kit with a height sensor bracket and two M5 x

8mm machine screws as indicated in Figure 2. Attach the bracket

and height sensor template to the sensor using the machine

screws, as shown in Figure 2. Next group a sensor arm and one

M6 x 16mm and one M6 lock nut. Attach the metal arm to the

sensor arm with the M6 x 16mm and the M6 lock nut, refer to

Figure 2. Repeat this procedure for the three other sensors.

Step 2

In the process of installing the height sensors the vehicle suspension must be able to go though the entire suspension movement,

with damper attached, from full jounce to full rebound to mechanically prove height sensor position, refer to Figure 3. This can be

done by either using jack method or the air spring method.

Jack Method

Raise the vehicle using a lift or platform jack rated for your vehicle

weight. Do not use wood or concrete blocks to support the weight

of the vehicle. Lower the vehicle frame onto jack stands rated for

your vehicle’s weight making sure the suspension is fully extended

to damper limit. Then to determine the jounce suspension position

that you will need to mount the height sensors, just jack the suspension up to that point into the jounce stop. Make sure that the

air line is removed and that there is no air in the air springs when

using this method.

Air Spring Method

Cut four sections of air line tubing 3” in length and insert into

each air spring. Install the four inflation valves

(included with sys-

tem)

in the end of each hose. Now you can inflate and deflate the

air springs on suspension to find the location to mount the height

sensors. This will also make calibration easier.

Step 3

Avoid direct heat from the engine and exhaust pipe when installing

height sensors. The height sensor linkage to the suspension

should be as close to 90° from sensor arm at ride height as possible. The sensor arm and sensor linkage should not be inline

throughout the entire travel of the height sensor linkage, from full

jounce to full rebound. An incorrectly mounted height sensor will

result in system not functioning. The height sensor must be

mounted with the electrical connection pointing up and the arm

in the correct position on the sensor.

Note: The best description of a poorly mounted height sensor is shown in Figure 3. Too big of an angle between the height

sensor arm and link may allow the arm to “toggle” over center.

Figure 2

Page 10

6

HEIGHT SENSOR INSTALLATION (cont.)

Step 4

To install the height control sensor, refer to Figure 4a, 4b and 5, to

become familiar with the mounting geometry and hardware. Be

sure that the area above and below the sensor location on the axle

is clear of obstructions for the arm to move.

Step 5

Take the sensor under the vehicle and find a location where the

sensor may be attached to the vehicle so that the arm extends

over the suspension. The arm of the sensor must be able to travel

from full jounce to full rebound for the system to work properly.

Looking at the table below pick out a hole on the sensor arm that

will work on your suspension attachment point. The use of the

provided template will show minimum and maximum arm movement as shown in Figure 3. At ride height the height sensor arm

should be as horizontal as possible.

Hole location Approx. Working range

(from sensor out) (of sensor)

First hole on the sensor arm 2”

itself (6mm)

Second hole 3”

Third hole 4”

Fourth hole 5”

Fifth hole 6”

Notice that the maximum working range of the sensor is 6”, even

with the linkage placed in the fifth hole of the sensor arm. If your

suspension provides more than 6” of travel, you will have to position the sensor so that operates within the yellow portion of the

sensor installation template. For example, if you have a 4-link type

rear suspension, you can simply locate the linkage a bit closer to the pivot of the 4-link arm on one of the 4-link bars. By attaching the linkage a bit

closer to the pivot of the 4-link arm, the sensor “sees” less suspension movement than if it were attached directly at the axle location. The object is

to make sure that the suspension movement does not move the sensor arm out of its range of authority as outlined in Figure 3. On an independent

front suspension, simply place the linkage somewhere inboard of the ball joint to effectively lessen the travel of the sensor. If the sensor arm

exceeds it range of authority, the IntelliRide™ system will not respond. See page 12 & 13 for diagnostic information.

What direction do the height sensors need to be mounted with the

WR8-760-2230 IntelliRide system?

If provided with a wire harness the power and ground to each vehicle corner

expects the height sensor arm to be in a certain position relative to the body of

the sensor. If mounted backwards the system would act in reverse, or not at

all. The height sensors on the right side of the vehicle need to be mounted with

the arm in the 9:00 position. The height sensors on the left side of the vehicle

need to be mounted with the arm in the 3:00 position.

Page 11

HEIGHT SENSOR INSTALLATION (cont.)

Step 6

Once the sensor positions have been found, mark the locations of

the mounting holes on the vehicle frame using the holes in the

height sensor bracket as a template, refer to Figure 3 and Figure

5. Use a center punch to mark the center of the holes on the

mounting surface. Before drilling the holes make sure all electrical, brake and fuel lines are cleared from the path of the drill. Drill

two 3/16” holes on the center marks. Mount the height sensor

bracket using the 10-32 X 1” machine screws, 10-32 nylon lock

nuts and 3/16” flat washers located in your hardware pack. Ensure

that a clear access to the electrical contact on the top of the height

sensor is maintained.

Step 7

Place the axle bracket on the suspension below the height sensor

arm. This bracket does not have to be on top of the suspension.

This bracket can be mounted to the suspension with provided 1032 x 1” machine screw and 10-32 Nylon lock nut or by clamping

the bracket to the suspension with the provided hose clamp.

Step 8

To install the linkage from the suspension to the height sensor

arm. Put suspension at either full rebound or full jounce; mark off

link from suspension position ball joint and to corresponding sensor link ball joint according to template as per Figure 3. That position is now set. Slowly move suspension to the opposite end of its

travel ensuring that the sensor arm stays within the limits of the

template. The parts that you will need for the linkage are M5

threaded rod, two M5 jam nuts, two M5 linkages and two M5

Nylon lock nuts. Layout the linkage with the same distance measured as shown in Figure 3. If the threaded rod is too long it can be

cut to length using a hacksaw. Install the M5 jam nut over both

ends of the threaded rod, cut if needed, and then install the linkages on both ends as shown in Figure 6. Install the finished linkage on the axle bracket and the height sensor arm using the two

M5 Nylon lock nuts. The linkages can be screwed up or down on

the shaft for fine adjustment to insure that you are not out of sensor range as explained in Height Sensor Installation: Step 5.

Adjustment of linkage can be used to adjust sensor arm to achieve

centered arm travel as depicted in Figure 3. The height sensor

template can be removed if desired.

7

Figure 6

How much travel should I have?

The amount of travel is dependent upon the working range of the

height sensor arm and linkages. The system will perform if the sensor arm operates within the yellow section of the sensor template.

The height sensor arm needs to be in the specified working range

(yellow area of the template) throughout the entire suspension

travel, not only through the travel for the selected lowered and

raised heights. Allowing travel outside of this working range will

result in a system fault.

Page 12

8

PROGRAMMING THE SYSTEM

For the system to operate properly the vehicle suspension travel will need to be programmed into the ECU.

Reconnect the negative terminal on the battery.

Step 1: Programming Setup

Plug the program switch into the wire harness that is labeled program switch. Turn the system off using the service switch. When the system is off

the side of the switch will be red. Turn on the vehicle’s ignition and leave it on until the entire programming of the vehicle’s heights is done. There

should be no lights on the height selection switch at this time. Push the program switch three times within six seconds. The lower light on the

height selection switch should start blinking. This will be indicating that jounce height (lowest) needs to be programmed into the ECU.

Step 2: Programming the Lowest Vehicle Height

Set the lowest height of your vehicle’s suspension by either using inflation valves at each corner or jack stands. Note: Lowest height cannot be fully

deflated. When all four corners of the vehicle are at the jounce height that you determine, hold the program switch in for eight seconds. Both lights

on the height selection switch should start blinking indicating that the ride height needs to be programmed into the ECU.

The full jounce position should be a minimum of 1/4” from where the jounce bumper stops. This small gap is required to allow for a tolerance as

the suspension height is controlled by the ECU. Without this small tolerance, the ECU will not achieve the lowered height if the suspension is

stopped before the ECU believes the lowest vehicle height is reached.

STEP 3: Programming the Vehicle Design Height

Set the ride height of your vehicle’s suspension by either using inflation valves at each corner or jack stands. When the vehicle is at the ride height

that you determine, hold the program switch for eight seconds. The top light on the height selection switch should start blinking. This will indicate

that the highest height needs to be programmed into the ECU.

STEP 4: Programming Highest Height

Set the highest height of your vehicle’s suspension by either using inflation valves at each corner or jack stands. The rebound position should be a

minimum of 1/2” from where the rebound stops.

This small gap is also required to allow for a tolerance as the suspension height is controlled by the ECU. Without this small tolerance, the ECU

may not achieve the highest height if the suspension is stopped before the ECU believes the highest vehicle height is reached. When the vehicle is

at the rebound height that you determine, hold the program switch in for eight seconds. Both lights on the height selection switch should start

blinking back and forth. This will indicate that the calibration height needs to be programmed into the ECU.

STEP 5: Programming Calibration Height

This calibration step teaches the relative suspension reaction to the IntelliRide system. Specifically this sets the internal tolerance bands and provides a relationship between the voltage that the ECU reads and the suspension height. Lower the height of each corner one inch by either using

inflation valves at each corner or jack stands. When the vehicle is at the calibration height, hold the program switch for eight seconds, and then

release. Both lights in the height selection switch should be on at the completion of programming. Turn off the vehicle’s ignition, and switch the

service switch so that it is all black and not showing red. After the proper airlines are installed and the vehicle’s ignition is turned back on, the system will put the vehicle at standard ride height and pressurized the air tank.

Note: Highest height cannot be fully extended, as this will generate a rough ride and may damage the dampers.

Note: When you choose your jounce height, ensure there is a small gap between travel stops and suspension.

Lowered HeightStandard HeightRaised Height

Page 13

OPERATION OF THE SYSTEM

Once height programming has been completed, the system is ready for use. The height selection switch

is how you will be able to select your height. The switch has two green lenses with arrows printed on

them. This is the primary user interface of the air leveling system. If the switch is mounted correctly,

pressing up will make the height go up and pressing down will make the height go down. When a

height selection is made up or down, the lights will toggle fast during the height change. Corresponding

lights will tell you which height you are at. *If the lights toggle slow or both of them blink slow, a fault

has occurred, see the Trouble Shooting section for a more detailed description.

The system has four modes of operation:

Lowered Height - Indicated by a illuminated lower switch lens

Ride Height (or standard height) - Indicated by no illuminated switch lenses

Raised Height - Indicated by a illuminated upper switch lens

Currently achieving Height - Indicated by both illuminated switch lenses flashing alternately.

Lowered Height is designed to be used for show, or ease of ingress and egress from the vehicle. The

vehicle should not be driven in this mode.

Ride Height is designed to be the primary operating position of the vehicle. This mode allows maximum

up and down travel of the suspension. A full air suspension can be set flat and level. This mode offers

the best ride and handling.

Raised Height is designed to allow maximum ground clearance. This mode offers slightly reduced ride

and handling.

Currently Achieving Height is designed to indicate when the system is actively trying to achieve your

last mode change request. This will typically occur when vehicle has first been started and on

driver selection.

Notes:

> Caution should be taken when vehicle is changing heights that the vehicle does not come in

contact with any object or person during the height change.

> Never have any part of your body under vehicle during height change.

> Never lift a running vehicle by the frame without first disabling the system.

MAINTENANCE

Periodically check all parts for defects. Also check all filters to make sure they are clean and debris free.

It is wise to check reservoir for water, which indicates the air dryer may need to be changed as the

system may have a leak.

9

Page 14

COMMONLY ASKED QUESTIONS

What is the lifetime expectancy of the Firestone dryer?

If there are no system leaks it should be for good for system life.

What type of accuracy is available with our system?

The height sensors that we use are capable of an accuracy of 0.67% of 1 degree. Our system with ECU programming is designed to work with 1/4

of a degree of accuracy. For comparison sake, a pneumatic leveling valve can have a dead band of approximately 3/8”.

How do electronics help increase the life of the compressor?

Mechanical valves waste air when the vehicle goes around corners or stops with a wheel in a hole or on a curb. The ECU recognizes these situations and responds accordingly, not allowing unnecessary air consumption. The situations when mechanical valves cause unnecessary compressor

use can be approximately 15% of trip time.

Are the valves environmentally protected?

The valves are plated for corrosion protection.

Are the connectors environmentally protected?

Firestone uses connectors that have IP68 moisture protection. This means they can withstand 1/2-meter water depth.

Why do the height sensors need to be mounted with the arms in a certain direction?

If provided with a wire harness the power and ground to each vehicle corner expects the height sensor arm to be in a certain position relative to

the body of the sensor. If mounting backwards, the system would act in reverse, or may not work at all.

Does the ECU have to be reprogrammed if the power source is removed?

No, the memory is nonvolatile.

How durable is the Firestone height sensor arm?

The height sensor arm of the Firestone system is designed to withstand the most severe vehicular environments. The sensor has been used on

high-mileage and off-road applications. The tensile load that the arm has withstood approximately 600lbs in an application. Although the arm is

designed for durability, this durability is a function of proper installation. Offset, shear loading has the potential to damage the arm. While it is true

that the shear loading can be corrected using a strong, metal arm the force will then be exerted elsewhere in the sensor. The result is typically

cracking the sensor body or pivot point leading to the introduction of moisture, corrosion and failure.

Is the ECU certified for electromagnetic interference (EMI)?

The Firestone ECU has been certified to E11 standards, far exceeding the base requirements for EMI. This means that the Firestone IntelliRide system does not emit an electromagnetic disturbance that will affect other electronic systems.

What is electromagnetic interference (EMI)?

Any electromagnetic disturbance that interrupts, obstructs, or otherwise degrades or limits the effective performance of electronics/electrical equipment. It can be induced intentionally, as in some forms of electronic warfare, or unintentionally, as a result of spurious emissions and responses,

intermodulation products, and the like.

How much travel should I have with my WR8-760-2230 IntelliRide system?

The amount of travel is dependent upon the working range of the height sensor as well as the position of the height sensor arm and linkages

(mechanical advantage). The system will perform if the sensor arm operates within the yellow section of the sensor template. Refer to Step 5 of

Height Sensor Installation in the 2230 Installation Instructions.

Is the ECU environmentally protected?

The ECU has a conformal coating agent which protects it from moisture.

10

Page 15

COMMONLY ASKED QUESTIONS (cont.)

In the WR8-760-2230 system, which port from valve block goes to & from the dryer?

Each port on the valve block is labeled for the designated connector. Using the air line tubing, measure the distance from each port of the dryer

back to the valve block. The air line tubing should be routed from the I.D. (inflow to dryer) port on the valve block to the in port on the dryer. The

next air line tubing should be routed from O.D. (outflow from dryer) port on the valve block to output side of the dryer. Cut the air line tubing

accordingly, as squarely as possible. Push the air line tubing into the fittings as far as possible.

What do all of the abbreviations on the valve block refer to in the WR8-760-2230 IntelliRide System?

O.D. = outflow from dryer R.F. = right/front air spring L.F. = left/front air spring I.D. = inflow to dryer P.S. = pressure sensor L.R. = left/rear air

spring R.R. = right/rear air spring EX. = exhaust COMP. INLET = compressor inlet

What do I do with the park wire if I have a manual transmission in the WR8-760-2230 IntelliRide system?

The park wire needs to be connected to a ground or to a customer supplied switch that will be grounded when the vehicle is NOT in park. One

potential input is the parking brake.

In step 3 of Height Sensor Installation of the WR8-760-2230 Installation Instructions it mentions that the sensor arm and linkage

should not be inline. What does that mean?

The best description is shown in the upper right-hand corner on page 6 of the 2230 Installation Instructions, Figure 3. Too big of an angle between

the height sensor arm and link will pull the sensor and may allow the arm to toggle over center.

Why should I use the thermal sleeves provided within the WR8-760-2230 IntelliRide system?

Thermal sleeves have been provided for to protect tubing from direct heat from the engine and exhaust pipe. If a thermal sleeve is required simply

slide the sleeve over the air line tubing to the location requiring protection.

How does the system indicate that the programming portion of the installation is complete in the WR8-760-2230

IntelliRide system?

In step 5 of programming the vehicles heights there is an indication that the process is completed. Please proceed with the instructions as specified in the included 2230 Installation Instructions. When the vehicle is at the calibration height, hold the program switch for eight seconds, and

then release. Both lights on the height selection switch should be on at the completion of programming. FYI: The lights will not turn on immediately at the completion of programming. Please allow a maximum of 30 seconds.

Are the height sensors environmentally protected?

The height sensors are IP68 rated, meaning they can withstand a water depth of 1/2-meter. These height sensors have survived severe off road

driving conditions in water, snow and mud.

Where should the ignition wire on the WR8-760-2230 aftermarket IntelliRide system be connected?

The purple ignition wire should be connected to a source with less than 1/2 amps. Typically a standard ignition wire under the dash of the vehicle

is suitable. A source with more than 1/2 amps can potentially damage the ECU.

What type of dryer is used with our system?

The dryer is regenerative. This means that the dryer is maintenance free assuming that there is not a leak in the system. A leak would not allow the

system to exhaust enough air through the dryer to adequately dry the air.

How much current does the IntelliRide electronic air spring system pull?

When the system is off the ECU draws less than a battery powered watch. When the system is on the max draw is dependant on how many valves

are in operation, i.e. when no valve activity then we draw less than 1 amp but for each valve up to 1.5/2.0 amps, three valves being the most open

at one time. The height indicator lights are LED’s and draw very little current.

Why does the compressor relay need to be mounted inside the engine compartment?

The relays are not sealed units. This is why it is recommended that they are installed inside the engine compartment.

11

Page 16

TROUBLESHOOTING

The height change works, but the WR8-760-2230 system will not level. The left-rear corner is exhausted fully. The LED height

display shows the current height.

The right-front valve is switched with the left-rear valve. Correct the air line connection with the corresponding air spring location and the solenoid

valve connection.

The height change works, but the WR8-760-2230 system will not level. The right-rear corner is exhausted fully. The LED light display shows the current height.

The left-front valve is switched with the right-rear valve. Correct air line connection with air spring location and solenoid valve block.

On the WR8-760-2230 IntelliRide system the height change works but leveling is confused. The system is very active and unable

to achieve level. The LED switch displays the current height.

The left-front valve is switched with right-rear valve, or left-rear valve is switched with right-rear valve. Another possibility is the left-front height

sensor is switched with the right-front height sensor, or left-rear height sensor is switched with right-rear height sensor. Correct air line connection

with air spring location and solenoid valve block; or position height sensor locations according to the wire harness labels.

On the WR8-760-2230 IntelliRide system the height change and leveling is confused. System will detect if a height change is

made but can take up to 2 minutes. The LED lights toggle slow.

There are a couple possible causes and related solutions. (1) A possible cause is the left-front valve is switched with left-rear valve. Correct air line

connection with air spring location and solenoid valve block. (2) Another possible cause is the front height sensors are switched with the rear

height sensors. Correct the location of the height sensors to the corresponding corners as indicated on the wire harness.

On the WR8-760-2230 IntelliRide system the height change up will not work; will not level up. The current height is displayed on

the LED lights.

The possible cause is the inlet valve is removed. Check for pinched airlines and check wire connections to valve block.

On the WR8-760-2230 IntelliRide system the height change down will not work; will not level down. The current height is displayed on the LED lights.

The possible cause is the exhaust valve is removed. Check for pinched airlines and check wire connections to valve block.

On the WR8-760-2230 IntelliRide system the height change will not work properly; system will attempt to height change and will

go back to previous height. Will not be able to level corner. The LED lights show that the current height is displayed.

The possible cause is any corner valve is removed. Check for pinched air lines and check wire connections to valve block.

The WR8-760-2230 IntelliRide system cannot make a height change; the compressor will not run. The LED lights toggle slowly.

There are a few possible causes: (1) The possible cause is the compressor fuse is blown. (2) Compressor power not connected. (3) Ground on

relay connector not connected. (4) Compressor not grounded. Solution: Check the compressor ground, compressor fuse and relay connections.

The WR8-760-2230 IntelliRide system will not level or height change to the set height. The LED lights show the current height.

Calibration height set too far from the highest vehicle height. Redo calibration height so that it is approximately 1-inch below the highest vehicle

height.

The WR8-760-2230 IntelliRide system is very active at one height. The LED lights show that the current height is displayed.

A possible cause is that the park wire is not connected, meaning the system is looking to level the vehicle every 5 seconds instead of every 40 seconds. Please install the park wire as described in the installation manual.

12

Page 17

TROUBLESHOOTING (cont.)

The diagnostic lights on the WR8-760-2230 aftermarket IntelliRide system toggle fast as though it is attempting to change

heights, and the valve block clicks trying to pass air. However no height change occurs and there is no air pressure within the

reservoir tank.

(1) There is a potential blockage in the air dryer.

(2) The compressor connections are not sufficient.

(3) The pressure sensor is not connected.

The WR8-760-2230 system is locked down, with no functions. Both of the lights on the LED switch flash slowly.

There are a few different causes and solutions:

(1) The pressure sensor is unplugged. Insure that the pressure sensor is torqued into the valve block at the recommended torque

value of 7.2 ft-lbs (9.8 N-m). Make sure pressure sensor is plugged in firmly.

(2) The height sensor(s) is/are unplugged. Insure that each height sensors is securely connected into the wire harness.

(3) The height sensor(s) is/are out of range.

Insure that the height sensor arm travels within the recommended yellow area of the height sensor template. It is also important that the height

sensor are mounted correctly with the wire connection pointing up. (4) The pressure sensor is out of range. Insure the pressure sensor connector

is fully inserted and wires into the connector are not exposed (5) +5Volts removed. Ensure sensor power wire is inserted on the ECU connector.

The WR8-760-2230 is locked down, no function. The system will not level or change height. The lights toggle slowly.

The ground is removed from the valve block. Check grounding on valve block wire.

The WR8-760-2230 system is locked down, no function without any indication from control switch.

There are few potential causes and related solutions. (1) System is off due to the main ground removed. Check all fuses, power, ignition and

ground connections (2) The system is off due to the voltage battery is removed. Check all fuses, power, ignition and ground connections. (3) The

ignition connection is removed. Check all fuses, power, ignition and ground connections. (4) The service switch is showing red. Turn the service

switch so that it is showing all black. (5) Make sure the ignition wire is connected to a source of less than 1/2 amps.

The WR8-760-2230 system will not function. The leveling and ability to change height is disabled. Both lights flash slowly.

The pressure sensor low limit failure caused by grounding out. Insure the pressure sensor connector is fully inserted and wires into the connector

are not exposed.

The vehicle will attempt to raise the vehicle, but after an extended period of time the attempt is unsuccessful and the vehicle

returns to its previous height.

The 2230 IntelliRide system is designed to time-out if a height is not achievable. Common reasons for an unachievable height change include:

1) the air springs are too large and have air volume requirements that exceed the capabilities for this specific air system or, 2) the air springs do

not have enough load capacity to lift the vehicle.

13

Page 18

For the latest technical information and support

questions/answers, please visit: www.fsip.com/ir

14

Page 19

TECHNICAL

15

Page 20

Firestone Industrial Products Company

12650 Hamilton Crossing Blvd.

Carmel, IN 46032-5400

www.fsip.com/Intelliride

Loading...

Loading...