Page 1

FEATURES

3 Transmitter/receiver built into same unit

3 Six user-selectable sensitivity levels

3 5m to 70m (use BEAMLRK beyond 70m) protection range

3 Removable plug-in terminal blocks

3 Digital display – no special tools required

3 Built-in automatic gain control compensates for signal

deterioration from dust buildup

3 Optional remote test station

3 Optional long-range kit (BEAMLRK) for applications in

excess of 70m

3 Optional multi-mount (BEAMMMK) providing ceiling or wall

mount capability with increased angular adjustment

PRODUCT DATA SHEET

SS-BEAM1224

Conventional Beam Detector

Installation Guide

PRODUCT DESCRIPTION

The FireSense SS-BEAM1224 is a conventional projected beam smoke sensor. It is uniquely suited for

protecting open areas with high ceilings where other methods of smoke detection are difficult to install and

maintain. Alignment is quickly accomplished via an optical sight and a 2-digit signal strength meter incorporated

into the product.

Listed for operation from -30ºC to 55ºC, the SS-BEAM1224 can be used in open area applications to provide early

warning in environments where temperature extremes exceed the capability of other types of smoke detection.

The SS-BEAM1224 consists of a transmitter/receiver unit at the head end and a reflector. When smoke enters the

area between the unit and the reflector, it causes a reduction in the signal and when the smoke level reaches the

predetermined threshold, an alarm is activated.

The SS-BEAM1224 has four standard sensitivity selections along with two Acclimate settings. When either of the

two Acclimate settings are selected the detector will automatically adjust its sensitivity using advanced software

algorithms to select the optimum sensitivity for the specific environment.

CABLING REQUIREMENTS

SS-BEAM1244

3 Requires 2 core for 24Vdc

3 Requires 2 core for initiating alarm contact

NSW

18-20 Brookhollow Ave

NORWEST 2153

02 8850 2888

sales@firesense.com.au

VIC

Unit 4, 297 Ingles St

PORT MELBOURNE 3207

03 9646 4557

salesvic@firesense.com.au

QLD

Unit 2, 225 Queensport Rd North

MURARRIE 4172

07 3890 8842

salesqld@firesense.com.au

www.firesense.com.au

Page 2

PRODUCT DATA SHEET

Conventional Beam Detector

TECHNICAL SPECIFICATIONS

Protection range 5m to 70m (70m to 100m long range kit)

Adjustment angle ± 10º horizontal and vertical

Sensitivity

(Refer to Sensitivity Chart on page

6 of Installation Guide)

Alarm indicator Local red LED and remote alarm

Trouble indicator Local yellow LED and remote trouble

Normal indicator Local flashing green LED

Temperature -30ºC to 55ºC

Humidity 10% - 93% Relative humidity non-condensing

Voltage 10.2 to 32Vdc

Average standby current 17mA maximum

Alarm current 38.5mA maximum

Fault current 8.5mA maximum

Detector dimensions 254mm H x 191mm W x 84mm D

Reflector dimensions 5m to 70m 200mm x 230mm

Level 1 – 25% total obscuration

Level 2 – 30%

Level 3 – 40%

Level 4 – 50%

Acclimate Level 1 – 30-50%

Acclimate Level 2 – 40-50%

Over 70m 400mm x 460mm

SS-BEAM1224

Installation Guide

PRODUCT DESCRIPTION

Installation/Alignment

The alignment is divided into four steps: coarse alignment, fine adjustment, final gain adjustment, and final

verification. It is necessary for all four steps to be executed properly to ensure proper alignment of the product.

Pre-Alignment Checklist

3 Ensure that both the detector and reflector are mounted securely to stable surfaces

3 Ensure that all wiring is correct

3 Ensure that terminal blocks are fully seated into their receptacles on the detector

3 Complete any wiring dressing to minimize movement to the detector once the alignment procedure is

completed

3 Ensure that the appropriate number of reflectors are used for the installed distance. Distances between

70 - 100m require additional reflectors (4 total). The BEAMLRK accessory should be used in these cases.

3 Ensure that the line of sight between the detector and reflector is clear and that reflective objects are not

too near.

NSW

18-20 Brookhollow Ave

NORWEST 2153

02 8850 2888

sales@firesense.com.au

VIC

Unit 4, 297 Ingles St

PORT MELBOURNE 3207

03 9646 4557

salesvic@firesense.com.au

QLD

Unit 2, 225 Queensport Rd North

MURARRIE 4172

07 3890 8842

salesqld@firesense.com.au

www.firesense.com.au

Page 3

PRODUCT DATA SHEET

SS-BEAM1224

Conventional Beam Detector

Installation Guide

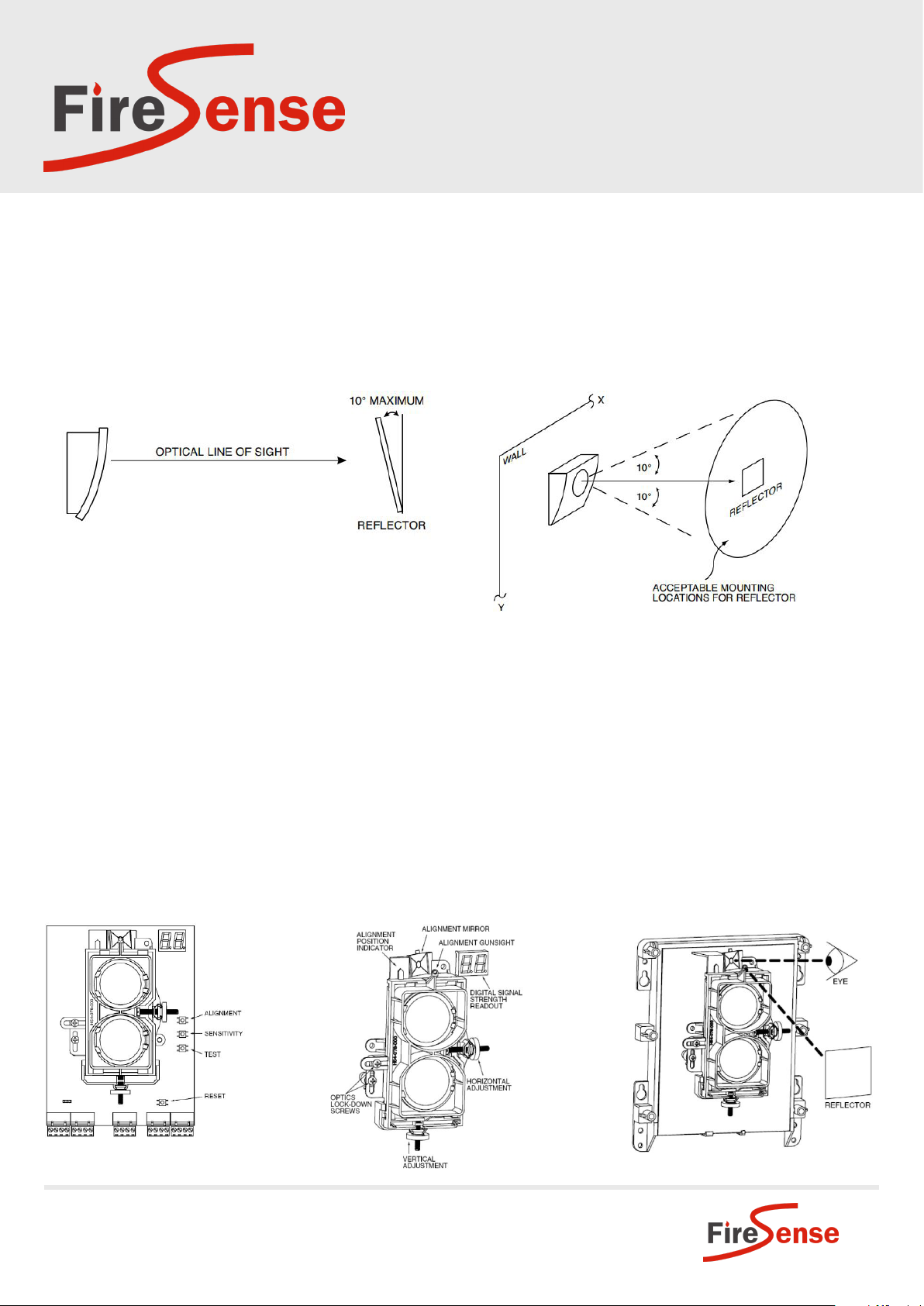

3 Ensure that both the detector and reflector are mounted within their operational parameters for off axis

angles (see below)

3 Disable the zone or system to prevent unwanted alarms before applying power

3 Ensure power to the detector is “ON”

You are now ready to begin the alignment procedure.

Reflector Mounting Guidelines

Step 1. Coarse Alignment

Refer to Figures 2 and 3 for this step.

1. Ensure that both of the optics lock-down screws are loosened so that the optics will move freely.

2. Looking through the alignment mirror, at both the alignment sight and reflector simultaneously, locate the

position of the reflector in the optical sight. This step will require some practice. It is necessary to train your

eyes to shift focus between the reflector and the mirror in order to locate the reflector. If the distance between

the reflector and the detector is large it is helpful to place a brightly coloured object on the wall near the

reflector to aid in seeing the reflector in the alignment mirror.

3. Once the reflector has been located, begin to adjust both the horizontal and vertical alignment knobs so that

the reflector becomes centred in the alignment mirror. Take care in this step. If the optics are incorrectly aligned

in this step, it will not be possible to proceed with the fine adjustment step.

Figure 1: Switch Locations Figure 2: Alignment Adjustment Locations Figure 3: Coarse Alignment Procedure

NSW

18-20 Brookhollow Ave

NORWEST 2153

02 8850 2888

sales@firesense.com.au

VIC

Unit 4, 297 Ingles St

PORT MELBOURNE 3207

03 9646 4557

salesvic@firesense.com.au

QLD

Unit 2, 225 Queensport Rd North

MURARRIE 4172

07 3890 8842

salesqld@firesense.com.au

www.firesense.com.au

Page 4

PRODUCT DATA SHEET

SS-BEAM1224

Conventional Beam Detector

Installation Guide

Step 2. Fine Adjustment

Refer to Figures 1-3 for this step.

In this step you will be fine-tuning the optics to the reflector. To provide feedback of the signal level coming

from the reflector the dual digital display readout will be used. Due to the large distance range that the detector

can operate over it is necessary that the detector operate with many different settings of “electronic amplifier

gain”. The detector is capable of determining the appropriate gain setting and then setting it itself via on-board

processing algorithms. There are no external gain settings on the detector that must be set by the operator.

Periodically throughout the fine adjustment step the detector will need to re-adjust its “electronic amplifier gain”

setting. When this occurs it will be indicated by the dual digital readout as “- -”. When this occurs, cease any further

adjustment until the display again reads a number value.

1. Ensure that neither you nor any other objects are in the line of sight between the detector and the reflector.

2. Depress the Alignment switch once. Both the digital display and the yellow LED should turn on indicating

that alignment mode has been entered. The display should begin reading “- -” signifying an electronic gain

adjustment. After a few moments the display will indicate a numeric value near 20. If the display reads “Lo”

then the detector is not receiving enough light from the reflector. Go back and repeat the coarse alignment step

and verify that the proper number of reflectors is used for the installed distance.

Note: The display will continue to read “Lo” until the detector receives enough light from the reflector to continue

with the fine adjustment step.

Note: In alignment mode (indicated by the yellow LED and the numeric display) the sensitivity select and test

switches are disabled.

3. With the display reading a numeric value, begin adjusting the horizontal and vertical alignment knobs one at

a time in the direction that increases the numeric signal level on the display. Continue adjusting each axis one

at a time going back and forth between them until a peak value is indicated. If a value of 90 is achieved, the

detector will re-adjust the electronic gain once again. This will be indicated by a “- -” reading on the display.

When this happens halt any further adjustment until the display again reads a numeric value. This process may

occur more than once during the fine adjustment step.

Note: Each time the display reads a value of 90 or greater the detector will reduce the electronic gain. Each time

the display reads a value of 10 or less the detector will increase the electronic gain.

4. Once satisfied that it is not possible to achieve a higher reading on the display, depress the alignment switch

to complete the fine adjustment step. The digital display readout will turn “OFF” and the yellow LED will remain

“ON”.

Note: It may not be possible to achieve a value near 90 on the display during the last adjustment iteration. The

final value of the display will not likely be near 90. This is normal. It is due to the detector reducing its electronic

gain each time a value of 90 is achieved. When this occurs the detector resumes with less electronic gain than

previously when 90 was achieved. Less gain makes it more difficult to achieve higher values. Final values anywhere

between 20 and 90 are acceptable if no further increase can be achieved.

Note: The alignment procedure is not complete yet. At this time it is possible to set the sensitivity of the detector

using the sensitivity switch and digital display. See the Sensitivity Selection section of this manual for further

details.

NSW

18-20 Brookhollow Ave

NORWEST 2153

02 8850 2888

sales@firesense.com.au

VIC

Unit 4, 297 Ingles St

PORT MELBOURNE 3207

03 9646 4557

salesvic@firesense.com.au

QLD

Unit 2, 225 Queensport Rd North

MURARRIE 4172

07 3890 8842

salesqld@firesense.com.au

www.firesense.com.au

Page 5

Step 3. Final Gain Adjustment

In this step, the detector will electronically adjust its internal gain

one final time. It is necessary to complete this step with the outer

housing installed since the housing will change the amount of light

received from the reflector.

1. Tighten the optics lock down screws so the optics are secure.

2. Install the outer housing of the detector. The housing is installed

by tightening four screws, one in each corner of the housing. The

screws are captivated in the plastic of the housing and cannot

fall out during assembly.

Note: The housing contains a gasket seal that protects the detector

circuitry from corrosion and moisture sources. To ensure that the

gasket seal performs correctly it is necessary to fully tighten all four

of the screws that hold the outer housing in place.

PRODUCT DATA SHEET

SS-BEAM1224

Conventional Beam Detector

Installation Guide

3. Remove the protective film from the front surface of the outer housing.

4. To initiate the final electronic gain adjustment, the reset switch must be depressed. Once depressed the yellow

LED will begin to blink. This indicates that the detector is adjusting the electronic gain setting. Once complete,

the yellow LED will stop blinking and the green LED will begin blinking. This indicates that the gain adjustment

was successful.

Note: Use caution not to block the line of sight between the detector and reflector in this step.

5. Install the outer aesthetic ring by snapping it onto the outer housing.

Note: If the outer aesthetic ring has been painted ensure that the paint is completely dry before proceeding with

this step.

Step 4. Final Verification

This step is required to ensure the detector has been setup correctly and will detect smoke at the proper sensitivity

level.

1. With the detector functioning (indicated by the green LED blinking), completely block the reflector with an

opaque material. (Due to the high optical efficiency of the reflector, the selection of the opaque material used

to block the reflector is not critical. Acceptable materials include, but aren’t limited to, this manual or the

cardboard packaging inserts.) The detector should enter the trouble condition (indicated by the fault relay and

the yellow LED (see Appendix I). If the detector does not enter the trouble condition there is a problem with the

installation refer to the troubleshooting section in Appendix I for further assistance.

2. Complete a sensitivity test of the detector. Refer to the Sensitivity Testing section of this manual for the

appropriate procedure.

3. If the orange sticky paper was used to aid in the location of the reflector in the alignment mirror it should

be removed now. It is no longer necessary. Congratulations. You have completed the final installation and

alignment procedure.

NSW

18-20 Brookhollow Ave

NORWEST 2153

02 8850 2888

sales@firesense.com.au

VIC

Unit 4, 297 Ingles St

PORT MELBOURNE 3207

03 9646 4557

salesvic@firesense.com.au

QLD

Unit 2, 225 Queensport Rd North

MURARRIE 4172

07 3890 8842

salesqld@firesense.com.au

www.firesense.com.au

Page 6

PRODUCT DATA SHEET

SS-BEAM1224

Conventional Beam Detector

Installation Guide

Sensitivity Selection

The detector has six sensitivity selections. Each of these selections is only acceptable over a specific distance

separation between the detector and the reflector per UL268. The chart below is used to determine which

selections are acceptable for your installed distance. The sensitivity of the detector can be set only when the

housing is removed and the detector is not in the fine adjustment step of the alignment mode, indicated by the

illumination of the dual digital display. To set the sensitivity depress the sensitivity button one time (see Figure

1). Once the switch is pressed the digital display will illuminate and read the current sensitivity setting in percent

obscuration. To change the sensitivity continue to depress the sensitivity switch until the desired setting is achieved.

The digital display will turn off automatically if no further switch presses occur.

In addition to the four standard sensitivity selections the detector has two Acclimate settings. When either of

these settings is chosen the detector will automatically adjust its sensitivity using advanced software algorithms to

select the optimum sensitivity for the environment. The sensitivity will be continuously adjusted within the ranges

specified in the chart below.

Sensitivity Setting Percent Obscuration Display Reading

Acceptable Distance

Between Detector &

Reflector (Feet)

Acceptable Distance

Between Detector &

Reflector (Meters)

Level 1 25 25 16.4 - 120 5.0 - 36.6

Level 2 30 30 25 - 150 7.6 - 45.7

Level 3 40 40 60 - 220 18.3 - 67

Level 4 50 50 80 - 328 24.4 - 100

Acclimate Level 1 30-50 A1 80 - 150 24.4 - 45.7

Acclimate Level 2 40-50 A2 80 - 220 24.4 - 67

Sensitivity

Total obscuration can be converted to percent per foot,

assuming uniform smoke density for the entire length of the

beam. The chart on the right converts total obscuration to

percent per foot for all acceptable sensitivity settings.

Sensitivity Testing

Detectors must be tested after installation and following periodic maintenance. The sensitivity of the BEAM1224/

BEAM1224S may be tested with a calibrated Test Filter (Reflector Test Card) or the local test switch on the

transmitter/receiver unit.

Note: Before testing, notify the proper authorities that the smoke detector system is undergoing maintenance, and

therefore the system will be temporarily out of service. Disable the zone or system undergoing maintenance to

prevent unwanted alarms.

Note: Before testing the detector, check for the presence of the flashing green LED at the receiver, making sure not

to disturb or block the beam. If it does not flash and the detector is not in trouble or alarm, power has been lost to

the detector (check the wiring).

NSW

18-20 Brookhollow Ave

NORWEST 2153

02 8850 2888

sales@firesense.com.au

VIC

Unit 4, 297 Ingles St

PORT MELBOURNE 3207

03 9646 4557

salesvic@firesense.com.au

QLD

Unit 2, 225 Queensport Rd North

MURARRIE 4172

07 3890 8842

salesqld@firesense.com.au

www.firesense.com.au

Page 7

Conventional Beam Detector

APPENDIX I. OPERATION MODES AND TROUBLESHOOTING GUIDE

PRODUCT DATA SHEET

SS-BEAM1224

Installation Guide

Modes Red Yellow Green

Normal Off Off Blink Off

On, Relative amount

Alignment Off On Off

Alarm On Off Off Off

Trouble-Drift

Comp Elevated

Signal

Trouble-Drift

Comp Reduced

Signal

Trouble-Signal

Over Range

Trouble-Beam

Blockage

Response

Initialisation-

Power On

Initialisation-

Alignment Exit

Local Test

(BEAM1224S)

Pass Result

Local Test

(BEAM1224S)

Fail Result

Local Test

(BEAM1224)

Fail Result

Local Test

(BEAM1224)

Pass Result

Off

Off

Off

Off

Off

Off

On

Off

Off

On

3 Quick

Blinks

2 Quick

Blinks

2 Quick

Blinks

4 Quick

Blinks

Blink Until

Complete

Blink Until

Complete

Blinking the

amount of

drift used

On until

reset or

time-out

Per fault

mode

Blinking the

amount of

drift used

of signal 0-99, or - - if

automatic gain reset-

ting, or Lo if signal is

Blink Off

Blink Off

Blink Off

Off Off Beam blockage Open Off Open

Blink Off

Blink Off

Off Off

Blink Off

Blink Off

Off Off

Dual Digital

Dispaly Readout

too low

Initiating Means

Successful completion

of initialisation or

detector reset

Alignment switch Close Off Open

Smoke, test filter,

RTS451/KEY or

RTS151/KEY

Long term drift refer-

ence out of range

Long term drift refer-

ence out of range

Increase of reflected

signal

Apply power from

discharged state

Depressing RESET

switch after alignment

RTS451/KEY or

RTS151/KEY

RTS451/KEY or

RTS151/KEY

RTS451/KEY or

RTS151/KEY

RTS451/KEY or

RTS151/KEY

Alarm Controls

Alarm Remote

Open

Open

Open On Close

Open Off Open

Open Off Open Clean detector and reflector

Open Off Open

Open Off Close

Open Off Close

Close On Close

Open Off Open

Open Off Open

Open On Close

Off Close

Fault

Contacts

Comments &

Troubleshooting Tips

- Sunlight into detector or reflector

- Re-align detector

Inspect line of sight between de-

tector and reflector for reflective

objects in the pathway

- Remove blockage

- Faulty unit

Detector remains in alarm until

reset or time-out

Detector remains in fault until

reset or time-out

If local test fails will already be

in fault

Blinks output by yellow LED and

Remote Trouble Output once the

device has passed a local remote

test (tables to the right):

NSW

18-20 Brookhollow Ave

NORWEST 2153

02 8850 2888

sales@firesense.com.au

VIC

Unit 4, 297 Ingles St

PORT MELBOURNE 3207

03 9646 4557

salesvic@firesense.com.au

Percent the detector has drifted Number of blinks output

<10% None

<20% 1

<30% 2

<40% 3

<50% 4

QLD

Unit 2, 225 Queensport Rd North

MURARRIE 4172

07 3890 8842

salesqld@firesense.com.au

Percent the detector has drifted Number of blinks output

<60% 5

<70% 6

<80% 7

<90% 8

<100% 9

www.firesense.com.au

Loading...

Loading...