Page 1

®

Firepower

FP 125, FP 135, FP165

PORTABLE MIG/FLUX CORED WELDER

Operating

Manual

Révision : AC Issue Date: April 6, 2016 Manual No.: 0-5123

www.firepoweronline.com

Page 2

WE APPRECIATE YOUR BUSINESS!

Congratulations on your new Firepower product. We are proud to have you as our customer and will strive

to provide you with the best service and reliability in the industry. This product is backed by our extensive

warranty and world-wide service network. To locate your nearest distributor or service agency, visit us on

the web at www.firepoweronline.com.

This Operating Manual has been designed to instruct you on the correct use and operation of your Firepower

product. Your satisfaction with this product and its safe operation is our ultimate concern. Therefore please

take the time to read the entire manual, especially the Safety Precautions. They will help you to avoid potential

hazards that may exist when working with this product.

YOU ARE IN GOOD COMPANY!

The Brand of Choice for Contractors and Fabricators Worldwide.

ESAB is a Global Brand of manual and automation Plasma Cutting Products.

We distinguish ourselves from our competition through market-leading, dependable products that have stood

the test of time. We pride ourselves on technical innovation, competitive prices, excellent delivery, superior

customer service and technical support, together with excellence in sales and marketing expertise.

Above all, we are committed to developing technologically advanced products to achieve a safer working

environment within the welding industry.

Page 3

WARNING

!

Firepower FP 125, 135, 165 MIG/Flux Cored Welder

Operating Manual Number 0-5123

Published by:

ESAB

2800 Airport Rd.

Denton, TX 76208

www.Firepoweronline.com

Copyright 2015 by ESAB

All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher

is prohibited.

Read and understand this entire Manual and your employer’s safety practices before installing, operating, or servicing the equipment.

While the information contained in this Manual represents the Manufacturer's best judgement,

the Manufacturer assumes no liability for its use.

The publisher does not assume and hereby disclaims any liability to any party for any loss

or damage caused by any error or omission in this Manual, whether such error results from

negligence, accident, or any other cause.

For Printing Material Specification refer to document 47x1909

Original Publication Date: March 19, 2009

Revision Date: April 6, 2016

Record the following information for Warranty purposes:

Where Purchased:_______________________________ __________

Purchase Date:__________________________________ __________

Power Supply Serial #:___________________________ __________

Torch Serial #:___________________________________ __________

Page 4

Be sure this information reaches the operator.

You can get extra copies through your supplier.

CAUTION

These INSTRUCTIONS are for experienced operators. If you are not fully familiar

with the principles of operation and safe practices for arc welding and cutting equipment, we urge you to read our booklet, “Precautions and Safe Practices for Arc

Welding, Cutting, and Gouging,” Form 52-529. Do NOT permit untrained persons to

install, operate, or maintain this equipment. Do NOT attempt to install or operate this

equipment until you have read and fully understand these instructions. If you do not

fully understand these instructions, contact your supplier for further information. Be

sure to read the Safety Precautions before installing or operating this equipment.

USER RESPONSIBILITY

This equipment will perform in conformity with the description thereof contained in this manual and accompanying labels and/or inserts when installed, operated, maintained and repaired in accordance with the instructions

provided. This equipment must be checked periodically. Malfunctioning or poorly maintained equipment should not be

used. Parts that are broken, missing, worn, distorted or contaminated should be replaced immediately. Should such repair or replacement become necessary, the manufacturer recommends that a telephone or written request for service

advice be made to the Authorized Distributor from whom it was purchased.

This equipment or any of its parts should not be altered without the prior written approval of the manufacturer.

The user of this equipment shall have the sole responsibility for any malfunction which results from improper use,

faulty maintenance, damage, improper repair or alteration by anyone other than the manufacturer or a service facility

designated by the manufacturer.

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR

PROTECT YOURSELF AND OTHERS!

!

OPERATING.

Page 5

TABLE OF CONTENTS

SECTION 1: SAFETY ........................................................................................ 1-1

1.0 Safety Precautions .......................................................................................... 1-1

2.0 Précautions de sécurité .................................................................................. 1-3

SECTION 2:

INTRODUCTION ...................................................................................... 2-1

2.01 How To Use This Manual ................................................................................ 2-1

2.02 Equipment Identification ................................................................................. 2-1

2.03 Receipt Of Equipment ..................................................................................... 2-1

2.04 General ........................................................................................................... 2-1

2.05 Specifications ................................................................................................. 2-2

2.06 Volt - Amp Curves .......................................................................................... 2-3

2.07 Duty Cycle ...................................................................................................... 2-5

2.08 MIG Gun Maintenance ................................................................................... 2-6

2.09 Handle / Feet Assembly ................................................................................... 2-6

SECTION 3:

INSTALLATION ....................................................................................... 3-1

3.01 Location ......................................................................................................... 3-1

3.02 Safety ............................................................................................................. 3-1

3.03 Grounding ...................................................................................................... 3-1

3.04 Electrical Input Requirements ........................................................................ 3-1

3.05 Requirements for Maximum Output .............................................................. 3-1

3.06 Installation of Shielding Gas (GMAW) Process .............................................. 3-2

3.07 Attaching the Gun and Cable Assembly to the Power Source ........................ 3-5

3.08 Polarity Changeover ....................................................................................... 3-6

3.09 Installing Wire Spool ..................................................................................... 3-7

3.10 Feedrolls ......................................................................................................... 3-7

3.11 Install Wire into the Feedhead ........................................................................ 3-7

3.12 Install Wire into the Welding Gun .................................................................. 3-9

SECTION 4:

OPERATION ........................................................................................... 4-1

4.01 General Safety Precautions ............................................................................. 4-1

4.02 Firepower Controls ........................................................................................ 4-1

4.03 Gas Metal Arc Welding (GMAW) .................................................................... 4-3

4.04 Flux Cored Arc Welding (FCAW) .................................................................... 4-3

4.05 Shutdown Procedures .................................................................................... 4-3

4.06 Basic Welding Technique ............................................................................... 4-3

4.07 Welding Gun Positions .................................................................................. 4-5

4.08 MIG Welding (GMAW) Variables .................................................................... 4-6

4.09 Establishing the Arc and Making Weld Beads ................................................ 4-7

4.10 Pre-Weld Procedure ....................................................................................... 4-7

4.11 Welding Procedure ........................................................................................ 4-7

4.12 Reference Tables ............................................................................................ 4-8

4.13 Firepower FP 125 Welding Setting Selection Guide ........................................ 4-9

4.14 Firepower FP 135 Welding Setting Selection Guide ...................................... 4-10

Page 6

TABLE OF CONTENTS

4.15 Firepower FP 165 Welding Setting Selection Guide ...................................... 4-11

4.16 Gas Selection for Gas Metal Arc Welding ...................................................... 4-12

SECTION 5:

SERVICE ............................................................................................... 5-1

5.01 Cleaning of the Unit ....................................................................................... 5-1

5.02 Cleaning of the Feed Rolls ............................................................................. 5-1

5.03 Basic Troubleshooting ................................................................................... 5-1

5.04 Solving Problems Beyond the Welding Terminals .......................................... 5-1

5.05 Welding Problems ......................................................................................... 5-2

APPENDIX 1: OPTIONS AND ACCESSORIES ............................................................ A-1

APPENDIX 2: REPLACEMENT PARTS ................................................................... A-2

APPENDIX 3: FIREPOWER 125 SYSTEM SCHEMATIC ................................................. A-4

APPENDIX 4: FIREPOWER 135 SYSTEM SCHEMATIC ................................................. A-5

APPENDIX 5: FIREPOWER 165 SYSTEM SCHEMATIC ................................................. A-6

REVISION HISTORY ........................................................................................ A-8

INTERNATIONAL CONTACT INFORMATION ................................................. REAR COVER

Page 7

FIREPOWER FP 125,135,165

SECTION 1: SAFETY

1.0 Safety Precautions

Users of ESAB welding and plasma cutting equipment have the ultimate responsibility for ensuring that anyone who works

on or near the equipment observes all the relevant safety precautions. Safety precautions must meet the requirements that

apply to this type of welding or plasma cutting equipment. The following recommendations should be observed in addition to

the standard regulations that apply to the workplace.

All work must be carried out by trained personnel well acquainted with the operation of the welding or plasma cutting

equipment. Incorrect operation of the equipment may lead to hazardous situations which can result in injury to the operator

and damage to the equipment.

1. Anyone who uses welding or plasma cutting equipment must be familiar with:

- its operation

- location of emergency stops

- its function

- relevant safety precautions

- welding and / or plasma cutting

2. The operator must ensure that:

- no unauthorized person stationed within the working area of the equipment when it is started up.

- no one is unprotected when the arc is struck.

3. The workplace must:

- be suitable for the purpose

- be free from drafts

4. Personal safety equipment:

- Always wear recommended personal safety equipment, such as safety glasses, flame proof

clothing, safety gloves.

- Do not wear loose fitting items, such as scarves, bracelets, rings, etc., which could become

trapped or cause burns.

5. General precautions:

- Make sure the return cable is connected securely.

- Work on high voltage equipment may only be carried out by a qualified electrician.

- Appropriate fire extinguishing equipment must be clearly marked and close at hand.

- Lubrication and maintenance must not be carried out on the equipment during operation.

Dispose of electronic equipment at the recycling facility!

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic Equipment and its

implementation in accordance with national law, electrical and/or electronic equipment that has reached

the end of its life must be disposed of at a recycling facility.

As the person responsible for the equipment, it is your responsibility to obtain information on approved

collection stations.

For further information contact the nearest ESAB dealer.

ESAB can provide you with all necessary cutting protection and accessories.

Manual 0-5123 1-1 SAFETY INSTRUCTIONS

Page 8

FIREPOWER FP 125,135,165

WARNING

ELECTRIC SHOCK - Can kill.

- Install and earth (ground) the welding or plasma cutting unit in accordance with applicable standards.

- Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

- Insulate yourself from earth and the workpiece.

- Ensure your working stance is safe.

FUMES AND GASES - Can be dangerous to health.

- Keep your head out of the fumes.

- Use ventilation, extraction at the arc, or both, to take fumes and gases away from your

breathing zone and the general area.

ARC R AYS - Can injure eyes and burn skin.

- Protect your eyes and body. Use the correct welding / plasma cutting screen and filter

lens and wear protective clothing.

- Protect bystanders with suitable screens or curtains.

FIRE HAZARD

- Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

Arc welding and cutting can be injurious to yourself and others. Take

precautions when welding and cutting. Ask for your employer's safety

practices which should be based on manufacturers' hazard data.

NOISE - Excessive noise can damage hearing.

- Protect your ears. Use earmuffs or other hearing protection.

- Warn bystanders of the risk.

MALFUNCTION - Call for expert assistance in the event of malfunction.

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

PROTECT YOURSELF AND OTHERS!

Do not use the power source for thawing frozen pipes.

WARNING

CAUTION

CAUTION

CAUTION

Class A equipment is not intended for use in residential locations

where the electrical power is provided by the public low-voltage

supply system. There may be potential difficulties in ensuring

electromagnetic compatibility of class A equipment in those locations, due to conducted as well as radiated disturbances.

This product is solely intended for metal removal. Any other use may

result in personal injury and / or equipment damage.

Read and understand the instruction manual before

installing or operating.

CUIDADO

SAFETY INSTRUCTIONS 1-2 Manual 0-5123

Page 9

FIREPOWER FP 125,135,165

2.0 Précautions de sécurité

Les utilisateurs du matériel de soudage et de coupage plasma ESAB ont la responsabilité ultime d'assurer que toute personne qui

opère ou qui se trouve dans l'aire de travail observe les précautions de sécurité pertinentes. Les précautions de sécurité doivent répondre aux exigences applicables à ce type de matériel de soudage ou de coupage plasma. Les recommandations suivantes doivent être

observées en plus des règles standard qui s'appliquent au lieu de travail.

Tous les travaux doivent être effectués par un personnel qualifié possédant de bonnes connaissances par rapport au fonctionnement

du matériel de soudage et de coupage plasma. Un fontionnement incorrect du matériel peut produire des situations dangereuses qui

peuvent causer des blessures à l'opérateur ou des dommages au matériel.

1. Toute personne travaillant avec le matériel de soudage ou de coupage plasma doit connaître :

- son fonctionnement;

- l'emplacement des interrupteurs d'arrêt d'urgence;

- sa fonction;

- les précautions de sécurité pertinentes;

- les procédures de soudage et/ou de coupage plasma.

2. L'opérateur doit assurer que :

- seules les personnes autorisées à travailler sur l'équipement se trouvent dans l'aire de travail lors de la mise en

marche de l'équipement;

- toutes les personnes dans l'aire de travail sont protégées lorsque l'arc est amorcé.

3. Le lieu de travail doit être :

- aménagé convenablement pour acquérir le matériel en toute sécurité;

- libre de courants d'air.

4. Équipement de sécurité personnelle

- Vous devez toujours utiliser un équipement de sécurité convenable tels que les lunettes de protection, les

vêtement ininflammables et des gants de protection.

- Vous ne devez jamais porter de vêtements amples, tels que foulards, bracelets, bagues, etc., qui pourraient

se prendre dans l'appareil ou causer des brûlures.

5. Précautions générales :

- Assurez-vous que le câble de retour est bien branché.

- La réparation d'un équipement de haute tension doit être effectuée par un électricien qualifié seulement.

- Un équipement d'extinction d'incendie approprié doit être à proximité de l'appareil et l'emplacement doit être clairement

indiqué.

- Vous ne devez jamais procéder à la lubrification ou l'entretien du matériel lorsque l'appareil est en marche.

Classe de boîtier

Le code IP indique la classe du boîtier, à savoir le niveau de protection offert contre toute pénétration par des objets solides ou de l’eau.

La protection est fournie contre le contact d’un doigt, la pénétration d’objets solides d’une taille supérieure à 12mm et contre l’eau

pulvérisée jusqu’à 60 degrés de la verticale. L’équipement marqué IP21S peut être stocké mais ne doit pas être utilisé à l’extérieur

quand il pleut à moins d’être sous abri.

ATTENTION

Si l’équipement est placé sur une surface

inclinée de plus de 15°, il y a danger de basculement et en conséquence, des blessures

personnelles et/ou des dommages importants à l’équipement.

Manual 0-5123 1-3 SAFETY INSTRUCTIONS

Inclinaison

maximum

autorisée

15°

Page 10

FIREPOWER FP 125,135,165

LE SOUDAGE ET LE COUPAGE À L'ARC PEUVENT CAUSER DES

BLESSURES À L'OPÉRATEUR OU LES AUTRES PERSONNES SE

TROUVANT DANS L'AIRE DE TRAVAIL. ASSUREZ-VOUS DE

AVERTISSEMENT

CHOC ÉLECTRIQUE - peut être mortel.

- Assurez-vous que l'unité de soudage ou de coupage plasma est installée et mise à la terre conformément

aux normes applicables.

- Ne touchez pas aux pièces électriques sous tension ou les électrodes si vos mains ne sont pas bien

protégées ou si vos gants ou vos vêtements sont humides.

- Assurez-vous que votre corps est bien isolé de la mise à la terre et de la pièce à traiter.

- Assurez-vous que votre position de travail est sécure.

VAPEURS ET GAZ - peuvent être danereux pour la santé.

- Gardez votre tête éloignée des vapeurs.

- Utilisez un système de ventilation et/ou d'extraction à l'arc pour évacuer les vapeurs et les gaz de votre

zone respiratoire.

PRENDRE TOUTES LES PRÉCAUTIONS NÉCESSAIRES LORS D'UNE

OPÉRATION DE SOUDAGE OU DE COUPAGE. DEMANDEZ À

VOTRE EMPLOYEUR UNE COPIE DES MESURES DE SÉCURITÉ QUI

DOIVENT ÊTRE ÉLABORÉES À PARTIR DES DONNÉES DES RISQUE

DU FABRICANT.

RAYONS DE L'ARC - peuvent endommager la vue ou brûler la peau.

- Protégez vos yeux et votre corps. Utilisez un écran de soudage/coupage plasma convenable équipé de

lentilles teintées et portez des vêtements de protection.

- Protégez les personnes se trouvant dans l'aire de travail à l'aide d'un écran ou d'un rideau protecteur

convenable.

RISQUE D'INCENDIE

- Les étincelles (projections) peuvent causer un incendie. Assurez-vous qu'il n'y a pas de matériel

inflammable à proximité de l'appareil.

BRUIT - un bruit excessif peut endommager la capacité auditive.

- Protégez vos oreilles. Utilisez des protecteurs d'oreilles ou un autre type de protection auditive.

- Avertissez les personnes se trouvant dans l'aire de travail de ce risque.

FONCTIONNEMENT DÉFECTUEUX - Dans le cas d'un fonctionnement défectueux demandez l'aide d'une

personne qualifiée.

ASSUREZ-VOUS DE LIRE ET DE COMPRENDRE LE MANUEL D'UTILISATION AVANT

D'INSTALLER OU D'OPÉRER L'UNITÉ. PROTÉGEZ-VOUS ET LES AUTRES !

Ce produit est uniquement destiné à la découpe du plasma. Toute autre

ATTENTION

utilisation peut entraîner des blessures ou endommager l’équipement.

ATTENTION

Pour éviter toute blessure personnelle et/

ou endommagement à l’équipement, soulever à l’aide de la méthode et des points

d’attache indiqués ici.

SAFETY INSTRUCTIONS 1-4 Manual 0-5123

Page 11

SECTION 2:

!

INTRODUCTION

FIREPOWER FP 125,135,165

2.01 How To Use This Manual

This Owner’s Manual applies to just specification or part numbers

listed on page i.

To ensure safe operation, read the entire manual, including the

chapter on safety instructions and warnings.

Throughout this manual, the words WARNING, CAUTION, DANGER,

and NOTE may appear. Pay particular attention to the information

provided under these headings. These special annotations are

easily recognized as follows:

NOTE!

An operation, procedure, or background

information which requires additional

emphasis or is helpful in efficient operation

of the system.

CAUTION

!

!

Additional copies of this manual may be purchased by contacting

ESAB at the address and phone number in your area listed on

back cover of this manual. Include the Owner’s Manual number

and equipment identification numbers.

Electronic copies of this manual can also be downloaded at no

charge in Acrobat PDF format by going to the Firepower web site

listed below

http://www.firepoweronline.com

A procedure which, if not properly followed,

may cause damage to the equipment.

WARNING

A procedure which, if not properly followed,

may cause injury to the operator or others

in the operating area.

WARNING

Gives information regarding possible

electrical shock injury. Warnings will be

enclosed in a box such as this.

DANGER

Means immediate hazards which, if not

avoided, will result in immediate, serious

personal injury or loss of life.

2.02 Equipment Identification

The unit’s identification number (specification or part number),

model, and serial number usually appear on a data tag attached

to the rear panel. Equipment which does not have a data tag

such as torch and cable assemblies are identified only by the

specification or part number printed on loosely attached card or

the shipping container. Record these numbers on the bottom of

page i for future reference.

2.03 Receipt Of Equipment

When you receive the equipment, check it against the invoice to

make sure it is complete and inspect the equipment for possible damage due to shipping. If there is any damage, notify the

carrier immediately to file a claim. Furnish complete information

concerning damage claims or shipping errors to the location in

your area listed in the inside back cover of this manual.

Include all equipment identification numbers as described above

along with a full description of the parts in error.

Move the equipment to the installation site before un-crating

the unit. Use care to avoid damaging the equipment when using

bars, hammers, etc., to un-crate the unit.

2.04 General

The Firepower FP 125, 135, 165 Machines are single-phase input

welding machines and come equipped with the following:

1. Built-in Wire Feeder and Wire Spool Hub

2. Welding Gun and Cable

3. Work Cable and Clamp

4. Regulartor/Flow Meter (FP 125 optional)

5. Input Cord

6. 2 Spare Contact Tips

7. Operational Manual

8. 0.5 lb. Spool of Wire

9. Gas Hose

The welding system is designed for use with the following

processes:

1. GMAW - Gas metal arc welding (MIG). Requires the use of

a shielding gas and regulator.

2. FCAW – Flux-cored arc welding – Does not require the

use of a shielding gas.

Manual 0-5123 2-1 INTRODUCTION

Page 12

FIREPOWER FP 125,135,165

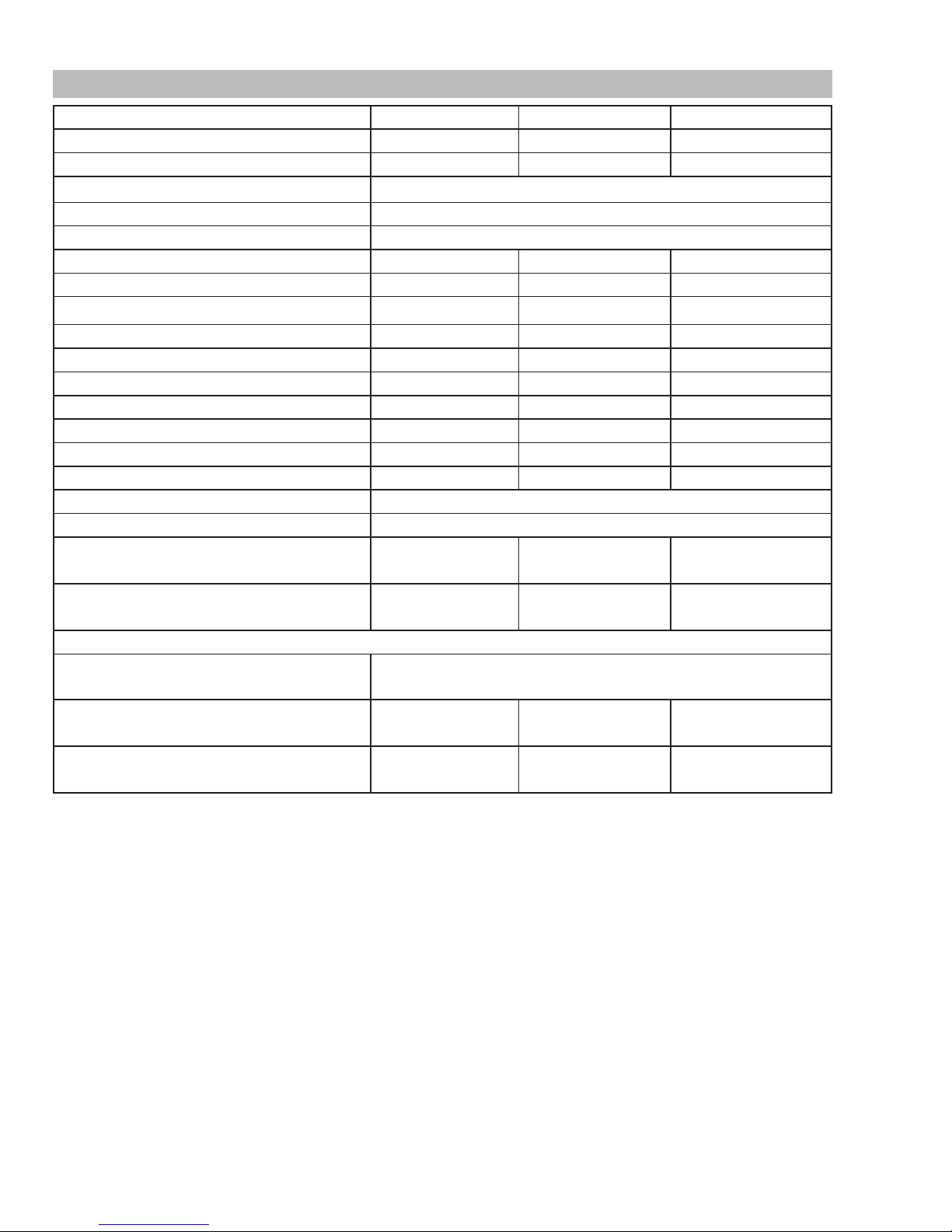

2.05 Specifications

Description FP 125 FP 135 FP 165

Package System Part Number 1444-0324 1444-0326 1444-0328

Power Source Weight 47.4 lb (21.5 kg) 52.9 lb (24.0kg) 58.1 lb (26.4 kg)

Power Source Dimensions HxWxD 12 x 9.75 x 17.5" ( 304.8 x 247.7 x 444.5mm)

Number of Phases 1 Ø

Frequency 60Hz

Flexible Supply Cable Size 7 ft (2.2 m) 14AWG 7 ft (2.2 m) 14AWG 7.5 ft (2.5 m) 14AWG

Supply Lead Plug Type 5-15P 5-15P 6-50P

Nominal Input Voltage

Rated kVA @ 100% Duty Cycle 5kVA 6kVA 7kVA

Rated Input Current 15A (60A@40%) 15A (60A@60%) 22.5A (120A@25%)

Maximum Input Current 38A (110A@10%) 50A (120A@13%) 35A (155A@15%)

Generator Requirements # 5kVA # 6kVA # 7kVA

Supply VA @ max. output # 4.6kVA # 5kVA # 6.8kVA

Open Circuit Voltage Range 16 – 30V 16 – 32V 15 – 30V

Output Current Range 40 – 125A 39 – 135A 36 – 165A

Duty Cycle Period 10 Minutes

Number of Output Voltage Values 4

Minimum Mains Circuit to suit factory fitted Plug &

Lead (Weld Current @ Duty Cycle)

120V AC 120V AC 230V AC

15A (60A@40%) 15A (60A@60%) 22.5A (120A@25%)

Maximum Mains Circuit to suit factory fitted Plug &

Lead (Weld Current @ Duty Cycle)

Steel

Stainless Steel

Flux Core

38A (110A@10%) 50A (120A@13%) 35A (155A@15%)

Wire Size Range

.023” - .030” - .035"

(0.6 - 0.8 - 0.9mm)

.030” - .035”

(0.8 - 0.9mm)

.023” - .030” - .035"

(0.6 - 0.8 - 0.9mm)

.030” - .035”

(0.8 - 0.9mm)

.023” - .030” - .035"

(0.6 - 0.8 - 0.9mm)

.030” - .035”

(0.8 - 0.9mm)

Table 2-1: System Specifications

∆ The recommended time delay fuse or circuit breaker size is 20 amp. An individual branch circuit capable of carrying 30 amperes and protected by fuses or circuit breaker is recommended for this application. Fuse size is based on not more than 200 percent

of the rated input amperage of the welding power source (Based on Article 630, National Electrical Code)

Firepower continuously strives to produce the best product possible and therefore reserves the right to change, improve or revise the

specifications or design of this or any product without prior notice. Such updates or changes do not entitle the buyer of equipment

previously sold or shipped to the corresponding changes, updates, improvements or replacement of such items.

The values specified in the table above are optimal values, your values may differ. Individual equipment may differ from the above specifications due to in part, but not exclusively, to any one or more of the following; variations or changes in manufactured components,

installation location and conditions and local power grid supply conditions.

INTRODUCTION 2-2 Manual 0-5123

Page 13

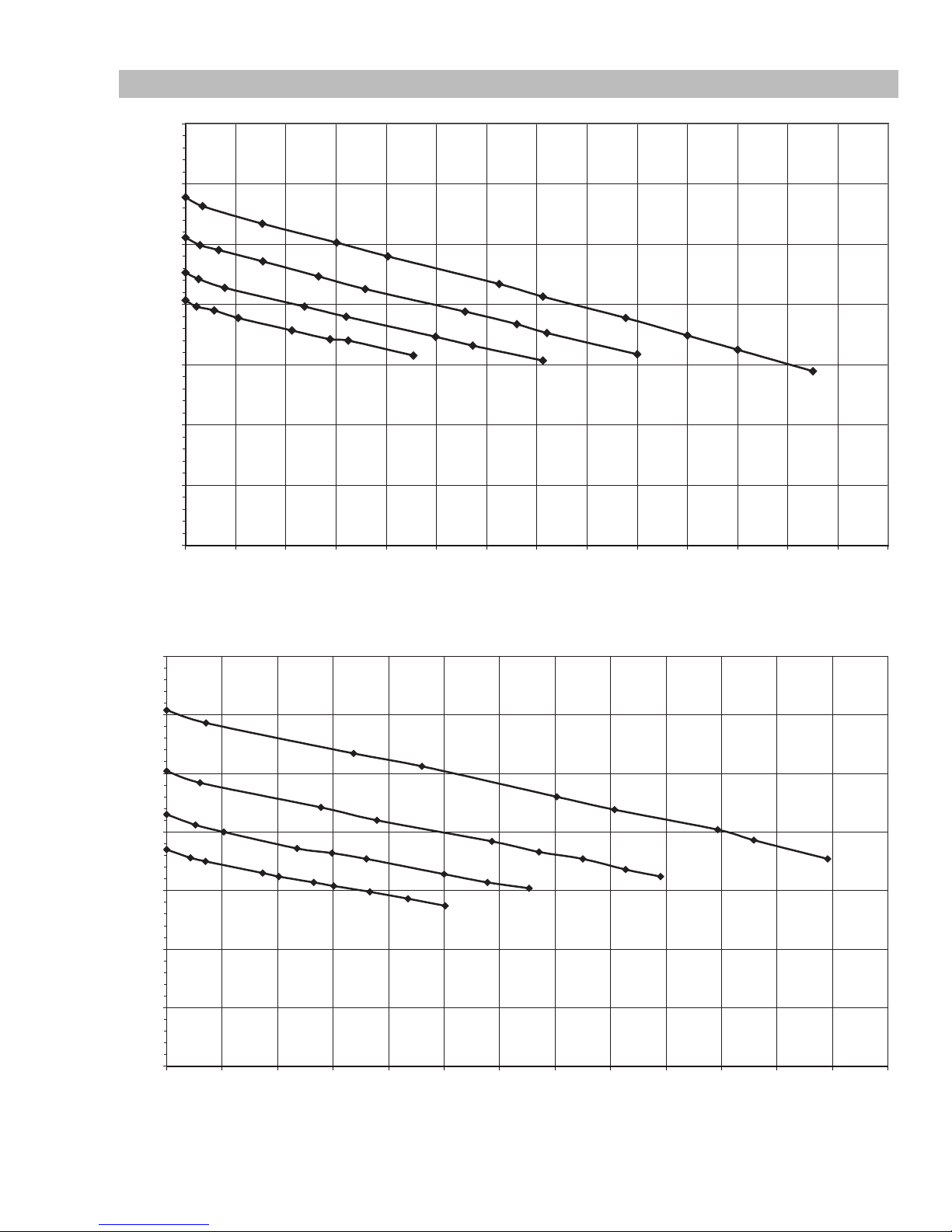

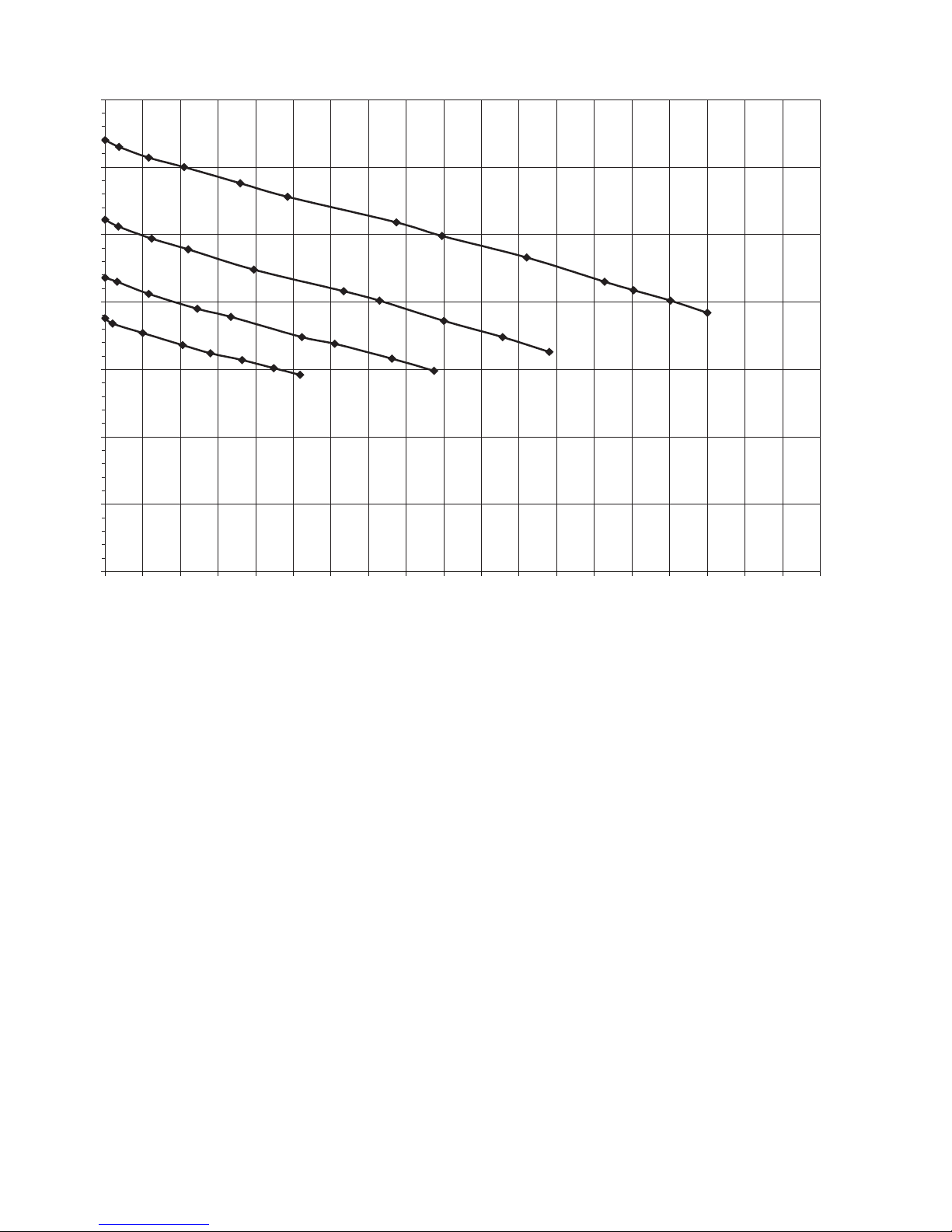

2.06 Volt - Amp Curves

FP 125 FIREPOWER Vin=115V 60Hz

5.0

10.0

15.0

20.0

25.0

30.0

35.0

0102030405060708090 100 110 120 130 140

OUTPUT CURRENT

OUTPUT VOLTAGE

Art # A-09076_AB

FP 135 FIREPOWER Vin=115V 60Hz

OUTPUT CURRENT

OUTPUT VOLTAGE

FIREPOWER FP 125,135,165

Figure 2-1: Volt/Amp curves of the Firepower 125

35

Art # A-09077_AB

30

25

20

15

10

5

0

0102030405060708090 100 110 120 130

Manual 0-5123 2-3 INTRODUCTION

Figure 2-1: Volt/Amp curves of the Firepower 135

Page 14

FIREPOWER FP 125,135,165

FP 165 FIREPOWER Vin=230V 60Hz

OUTPUT CURRENT

OUTPUT VOLTAGE

35

Art # A-09078_AB

30

25

20

15

10

5

0

0102030405060708090100 110 120 130 140 150 160 170 180 190

Figure 2-1: Volt/Amp curves of the Firepower 165

INTRODUCTION 2-4 Manual 0-5123

Page 15

FIREPOWER FP 125,135,165

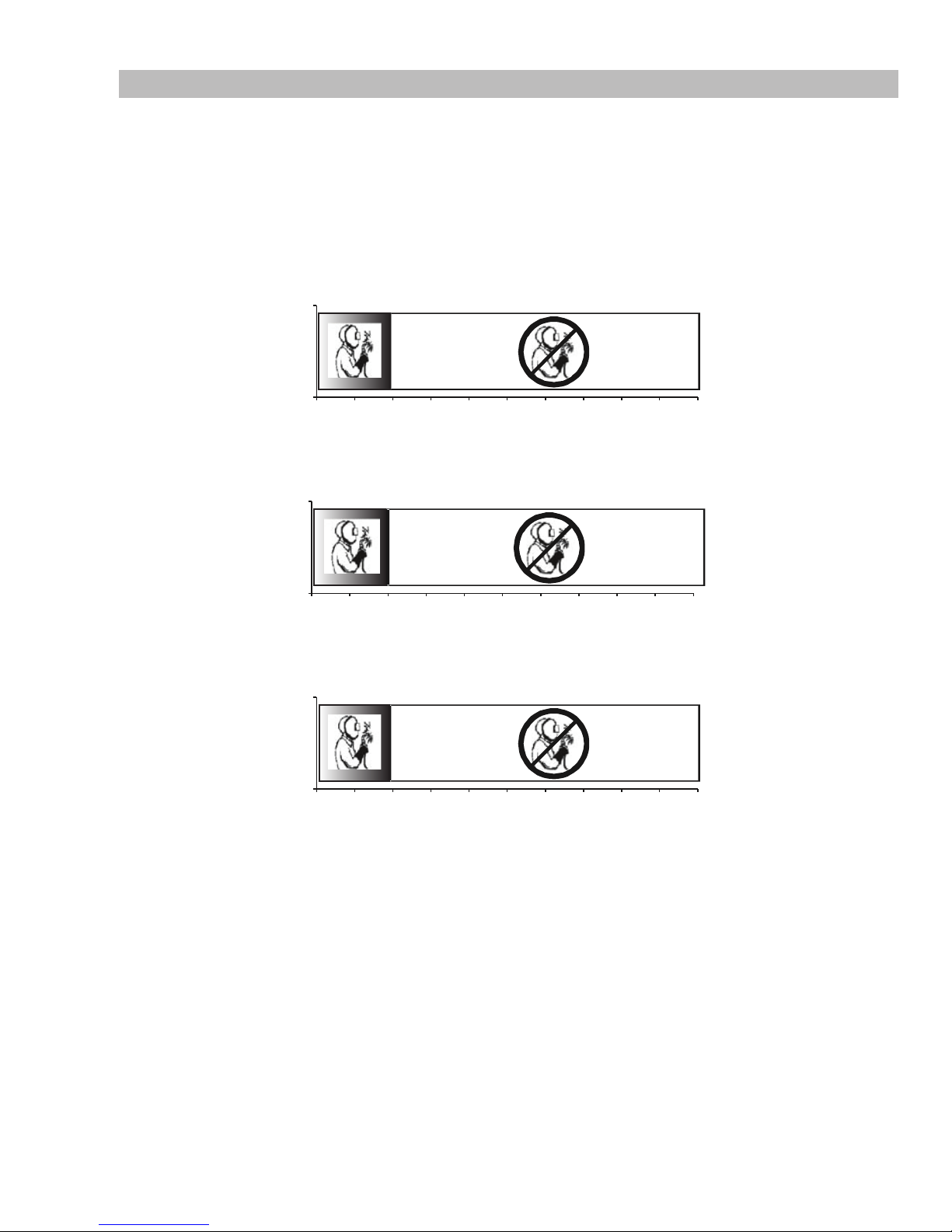

Firepower 125 at Rated Duty Cycle

0

Minutes

910

Firepower 135 at Rated Duty Cycle

0

Minutes

91

Firepower 165 at Rated Duty Cycle

0

Minutes

910

2.07 Duty Cycle

Duty Cycle is the amount of arc-on time (actual welding time) during any 10 minute period that a machine can operate at it’s rated

output without damaging internal components. For example, the Firepower FP 135 is designed for 20% duty cycle at 117 amps. This

means that it has been designed and built to provide the rated amperage, 117 amps, for 2 minutes out of every 10 minute period. During the other 8 minutes of the 10 minute period, the Firepower FP 135 must idle and be allowed to cool. The thermal cutout will operate

if the duty cycle is exceeded.

The Firepower FP 125 is designed for 19% duty cycle at 90 Amps.

The Firepower FP 135 is designed for 20% duty cycle at 117 Amps.

The Firepower FP 165 is designed for 18% duty cycle at 140 Amps.

If the unit overheats and the thermostat opens, wait 15 minutes for unit to cool.

Art # A-09058_AB

1

1

1

23

45678

Figure 2-5: Duty Cycle of Firepower 125

23

45678

Figure 2-6: Duty Cycle of Firepower 135

23

45678

Figure 2-7: Duty Cycle of Firepower 165

Art # A-09059_AB

0

Art # A-09060_AB

Manual 0-5123 2-5 INTRODUCTION

Page 16

FIREPOWER FP 125,135,165

2.08 MIG Gun Maintenance

Remove dust and metallic particles from the gun conduit by forcing clean, dry compressed air into the conduit once a week. This will

minimize wire feeding problems.

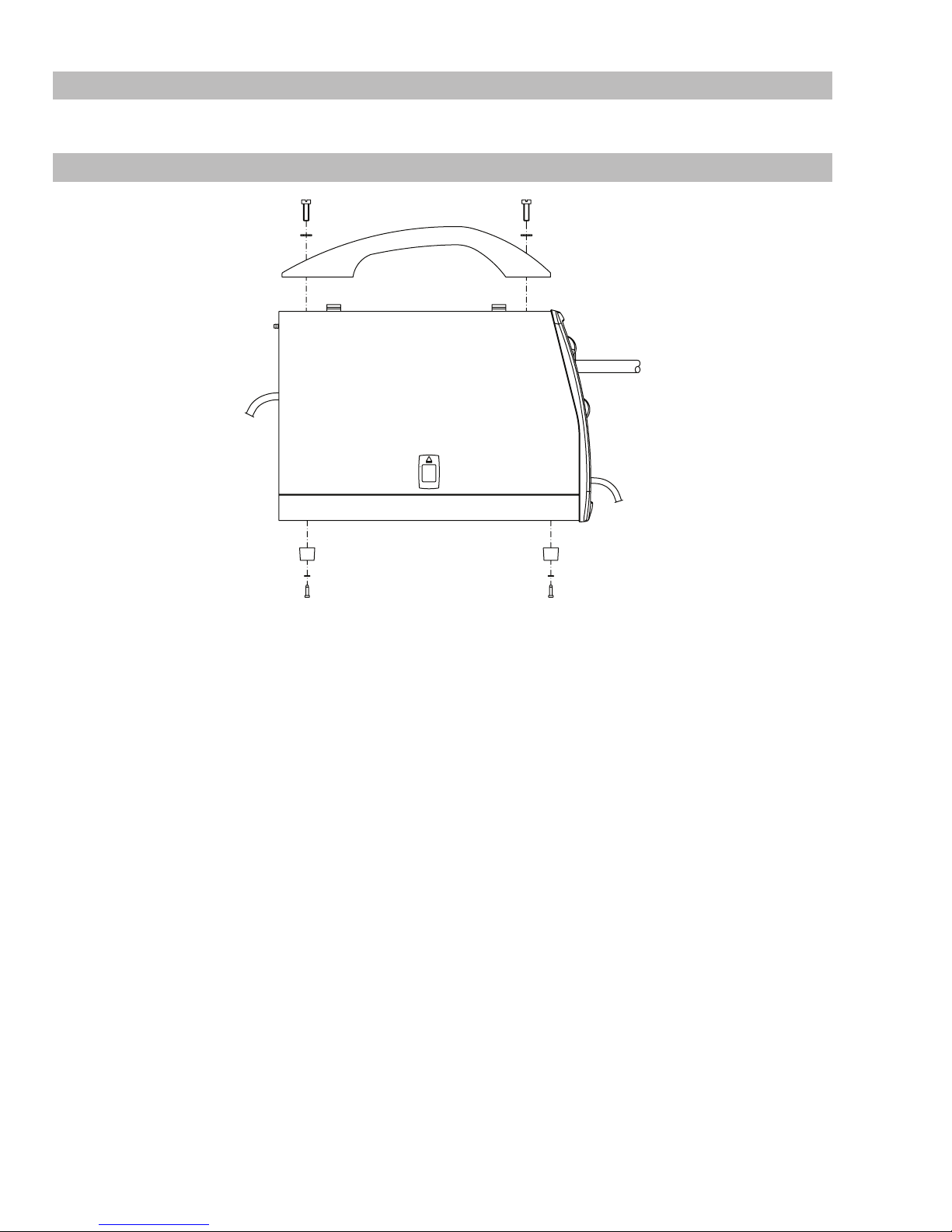

2.09 Handle / Feet Assembly

Art # A-09094

INTRODUCTION 2-6 Manual 0-5123

Page 17

SECTION 3:

INSTALLATION

FIREPOWER FP 125,135,165

3.01 Location

For best operating characteristics and longest unit life, take care

in selecting the installation site. Avoid locations exposed to high

humidity, dust, high ambient temperature, or corrosive fumes.

Moisture can condense on electrical components, causing corrosion or shorting of circuits. Dirt on components will retain this

moisture and also increases wear on moving parts.

Adequate air circulation is needed at all times in order to assure

proper operation. Provide a minimum of 12” (300mm) of free air

space at both the front and rear of the unit. Make sure that the

ventilation openings are not obstructed.

CAUTION

!

These MIG machines are not suitable for

use in rain.

3.02 Safety

Refer to additional installation instructions under the SAFETY

INSTRUCTIONS AND WARNINGS (Section 1) in this manual.

3.03 Grounding

The internal frame of this welding machine should be grounded

for personal safety. Where grounding is mandatory under state or

local codes, it is the responsibility of the user to comply with all

applicable rules and regulations. Where no state or local codes

exist, it is recommended that the National Electrical Code be

followed.

The National Electrical Code (Article 630B) provides standards for

amperage handling capability of supply conductors based on the

duty cycle of the welding power source. The Firepower FP 125

has a 19% duty cycle (1 minute 54 seconds of every 10 minutes

can be used for welding). The Firepower FP 135 has a 20% duty

cycle (2 minutes of every 10 minutes can be used for welding).

The Firepower FP 165 has an 18% duty cycle (1 minute 48 seconds of every 10 minutes can be used for welding). The power

cords supplied with these units comply with these standards.

Ensure that the building supply and receptacle comply with NEC

standards and any additional state and local codes.

NOTE!

The supply wiring for the welding power

source must be capable of handling a minimum of 20 amperes. The welding power

source must be the only load connected to

the supply circuit. Poor unit performance

or frequently opening line fuses or circuit

breakers can result from an inadequate or

improper supply.

CAUTION

!

Do not connect the Firepower FP 125 or

135 to an input power supply with a rated

voltage that is greater than 120 +10%

VAC. Do not remove the power cord ground

prong.

3.04 Electrical Input Requirements

Plug the input cord into a properly grounded and protected (by

fuse or circuit breaker) mains receptacle capable of handling a

minimum of 20 Amperes. Firepower FP 125 & FP 135 requires

a 120VAC supply voltage and the Firepower FP 165 requires a

230VAC supply voltage.

The Firepower FP 125 & FP 135's power cord is equipped with

a NEMA 5-15P plug and will only connect to a NEMA 5-15P

receptacle.

Except for some early models, the Firepower FP 165's power

cord is equipped with a NEMA 6-50P plug and will only connect

to a NEMA 6-50P receptacle.

CAUTION

!

Consult the nameplate for proper input

voltage and input amperage. The method

of installation, conductor size, and overcurrent protection shall conform to the requirements of the local electrical code. All

installation wiring and machine connection

shall be done by a competent electrician.

CAUTION

!

Do not connect the Firepower FP 165 to

an input power supply with a rated voltage

that is greater than 230 + 10% VAC. Do not

remove the power cord ground prong.

3.05 Requirements for Maximum Output

In order to obtain the maximum output capability of the Firepower FP 125 a branch circuit capable of 40 amperes at 115 to 125

Volts 60 Hz is required. In order to obtain the maximum output

capability of the Firepower FP 135 a branch circuit capable of 50

amperes at 115 to 125 Volts 60 Hz is required. In order to obtain

the maximum output capability of the Firepower FP 165 a branch

circuit capable of 30 amperes at 208 to 230 Volts 60 Hz is required. This generally applies when welding steel that is equal to

or greater than 12 gauge (0.105” 2.5mm) in thickness.

Manual 0-5123 3-1 INSTALLATION

Page 18

FIREPOWER FP 125,135,165

3.06 Installation of Shielding Gas (GMAW) Process

Refer to Figure 3-1.

NOTE!

Shielding Gas is not required if the unit is using self-shielded FCAW (flux cored arc welding) wires.

1. Cylinder Positioning: Chain the cylinder to a wall or other support to prevent the cylinder from falling over. If an optional portable mounting arrangement is used, follow the instructions that are provided with it.

2. Remove Cylinder Cap: Remove the large metal cap on top of the cylinder by rotating counter clockwise. Next remove the dust

seal.

3. Cracking: Position yourself so the valve is pointed away from you and quickly open and close the valve for a burst of gas. This

is called “Cracking” and is done to blow out any foreign matter that may be lodged in the fitting.

CAUTION

!

4. Fit Regulator/Flowmeter to Cylinders:

Screw the regulator into the appropriate cylinder. The nuts on the regulator and hose connections are right hand (RH) threaded and

need to be turned in a clockwise direction in order to tighten. Tighten with a wrench.

!

KEEP FACE WELL AWAY FROM THE CYLINDER VALVE DURING “CRACKING”. Never “crack” a fuel gas cylinder

valve near other welding works, sparks or open flames. Ensure that the surrounding area is well ventilated.

CAUTION

Match regulator to cylinder. NEVER CONNECT a regulator designed for a particular gas or gases to a cylinder containing any other gas.

5. Attach Supplied Gas Line: Attach supplied gas line between the regulator output and the desired input at the rear of the

power supply depending on Spool Gun or MIG Gun use.

INSTALLATION 3-2 Manual 0-5123

Page 19

1

FIREPOWER FP 125,135,165

Cap

2

Shielding

Gas

3

“Cracking”

Shielding

Gas

5

Gas Hose

Regulator and

Flow Meter

1 1/8”

Shielding

Gas

4

Shielding

Gas

Art # A-07965

Manual 0-5123 3-3 INSTALLATION

Figure 3-1 Gas Cylinder Installation for Reference Only!

Page 20

FIREPOWER FP 125,135,165

Adjusting Regulator

Adjust control knob of regulator to the required flow rate, indicated on gauge dial. (Refer to Figure 3-2 and data charts. Approx. 20 CFH)

The gas flow rate should be adequate to cover the weld zone to stop weld porosity. Excessive gas flow rates may cause turbulence and

weld porosity.

Argon or argon based gas flow rates:

- Workshop welding: 20-30 CFH

- Outdoors welding: 30-40 CFH

Helium based or CO2 gas flow rates:

- Workshop welding: 30-40 CFH

- Outdoors welding: 40-50 CFH

NOTE!

All valves downstream of the regulator must be opened to obtain a true flow rate reading on the outlet

gauge. (Welding power source must be triggered) Close the valves after the pressure has been set.

Art # A-07280

Figure 3-2: Adjusting flow rate. Illustration for Reference Only.

Refer to section 4.15 for suggested gas / filler metal combinations.

NOTE!

The regulator/flowmeters used with argonbased and carbon dioxide shielding gases are different. The

regulator/flow meter supplied is for argon based shielding gases. If carbon dioxide is to be used a suitable

carbon dioxide regulator/flow meter will need to be fitted.

Two types of gas are generally used with Gas Metal Arc Welding (GMAW) of thin gauge sheet steel. A mixture of 75% Argon and 25%

Carbon Dioxide (CO2) is recommended, Carbon Dioxide (CO2) can also be used.

INSTALLATION 3-4 Manual 0-5123

Page 21

3.07 Attaching the Gun and Cable

Assembly to the Power Source

The Firepower FP 125, FP 135, FP 165 are supplied with a 80A

MIG gun. The 80A MIG gun is designed with an ergonomic handle

and fewer parts to eliminate performance problems. The 80A MIG

gun uses standard readily available Firepower consumable parts.

1. Open the door to the machine.

2. Connect the gun cable to the power source by first routing

the switch lead through the access hole in the front panel

followed by the gun cable (see Figure 3-3).

NOTE!

Turn the cable end to align the gas hose

nipple on the connector plug with the

keyway located in the bottom of the front

panel access hole.

FIREPOWER FP 125,135,165

3. Loosen the screws and insert the gun cable end as far as

it will go. Tighten thumbscrew (see Figure 3-3).

4. Insert the gun switch plug into the gun switch socket (see

Figure 3-3).

5. If shielding gas is being used, push the gas hose on to the

gas hose nipple and secure it with the hose clamp.

6. To remove the gun, simply reverse these directions.

CAUTION

!

When disconnecting gun switch leads from the

machine, grab the connectors and pull. Do not

pull on the wires..

Gas Tube

Art # A-09079

Gun Switch Plug/Socket

Figure 3-3: Attaching Gun and Cable

Manual 0-5123 3-5 INSTALLATION

Page 22

FIREPOWER FP 125,135,165

Polarity

T

Leads

Gas Hose

Connected

Gas Tube

Leads

Polarity

T

Knobs

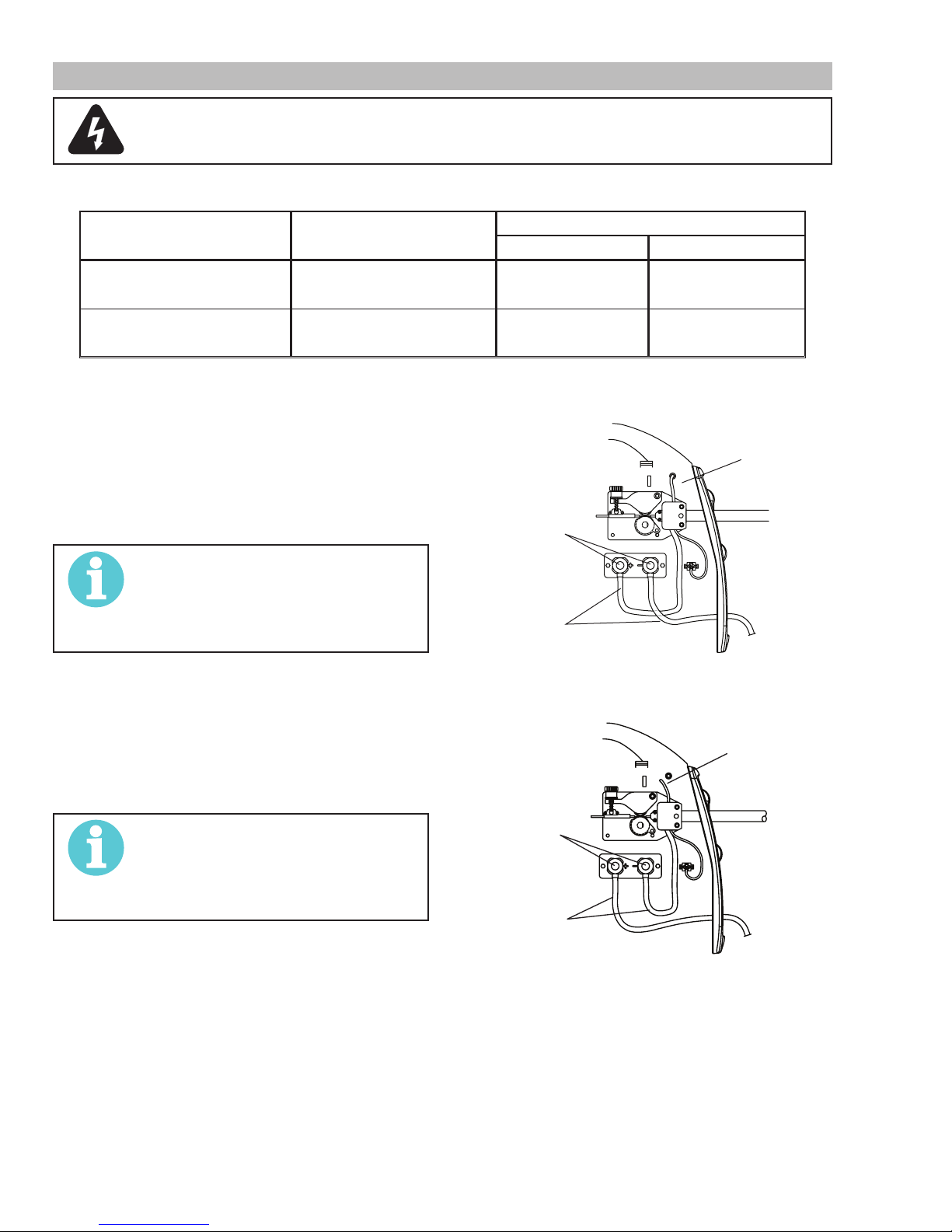

3.08 Polarity Changeover

WARNING

ELECTRIC SHOCK CAN KILL! Make certain the machine is unplugged from the power receptacle. Do not

plug machine in until told to do so in these instructions

As delivered from the factory, the output polarity is set to the polarity which matches the welding wire supplied with the unit. The output

terminals are located on the interior panel of the welding power source if you need to change polarity.

PROCESS POLARITY CABLE CONNECTIONS

CABLE TO GUN CABLE TO WORK

1. GMAW – Solid Wire 1. DCEP – Reverse Polarity 1. Connected to (+) Pos.

output terminal

1. Connected to (-) Neg.

output terminal

2. FCAW – Self-shielding Wire – no

2. DCEN – Straight Polarity 2. Connected to (-) Neg.

Shielding Gas

Table 3-1: Process Cable Connections

Connection for GMAW (reverse polarity DCEP)

1. Open the door to the machine.

2. Remove the polarity terminal knobs.

3. Set up the polarity (as per Table 3-1 above) by removing the leads from the terminals and reversing them if

necessary. Refer to Figure 3-4.

4. Replace the polarity terminal knobs.

NOTE!

Ensure that the polarity terminal knobs

are tightly secured and that there is no

connection between positive and negative

terminals.

Connection for FCAW (straight polarity DCEN)

1. Open the door to the machine.

2. Remove the polarity terminal knobs.

3. Set up the polarity (as per Table 3-1 above) by removing the leads from the terminals and reversing them if

necessary. Refer to Figure 3-5.

4. Replace the polarity terminal knobs.

NOTE!

Ensure that the polarity terminal knobs

are tightly secured and that there is no

connection between positive and negative

terminals.

2. Connected to (+) Pos.

output terminal

Polarity

Terminal

Knobs

erminal

output terminal

Normally

Art # A-09080

Figure 3-4: Connection for GMAW (reverse polarity DCEP)

Normally

Disconnected

erminal

Polarity

Terminal

Art # A-09081

INSTALLATION 3-6 Manual 0-5123

Figure 3-5: Connection for FCAW (straight polarity DCEN)

Page 23

FIREPOWER FP 125,135,165

3

Art # A-09082

3.09 Installing Wire Spool

As delivered from the factory, the unit is set for an 4” (102mm)

spool.

Installation of Wire Spool

Assemble parts in sequence (shown in Figure 3-6 from right to

left).

1. Spool 4” (102mm)

2. External Ring

3. Retaining Spring

4. Nut

NOTE!

Nut is tightened until a slight force is required to turn the spool.

1

2

4

3.10 Feedrolls

A feedroll consists of two different sized grooves, .023” (0.6mm)

and .030” / .035” (0.8mm / 0.9mm).

The branding inside at the end of the feedroll refers to the size

nearest to the mark

This also applies to optional feedrolls which are available for this

machine.

.030

0.8

Art # A-07963

Figure 3-7 : Feedroll Example

3.11 Install Wire into the Feedhead

WARNING

ELECTRIC SHOCK CAN KILL! Make certain

the machine is unplugged from the power

receptacle. Do not plug machine in until

told to do so in these instructions.

1. Loosen the nut of the spool holder (brake drum). Remove the spring and the external ring.

2. Remove the plastic protection from the spool. Place it

on the spool holder again. Mount the external ring , the

spring and the plastic lock nut again. These parts form

the braking system for the wire spool. Tighten nut to

appropriate tightness. Excessive pressure strains the

wire feeding motor. Too little pressure does not allow the

immediate stop of the wire spool at the end of the welding.

CAUTION

!

Use care in handling the spooled wire as it

will tend to “unravel” when loosened from

the spool. Grasp the end of the wire firmly

and do not let go of it. Make sure that the

end of the wire is free of any burrs and is

straight.

Figure 3-6: 4" Spool Installation

Manual 0-5123 3-7 INSTALLATION

Page 24

FIREPOWER FP 125,135,165

Pressure Arm

Pressure Arm

Pressure Adjust Device

Pressure Arm

Wire Guide

Gun Cable End

Pressure Adjust Device

Gun Cable End

Wire

Wire Spool Inlet Wire Guide Feedroll

Art # A-09083

Figure 3-8: Wire Feeder Components

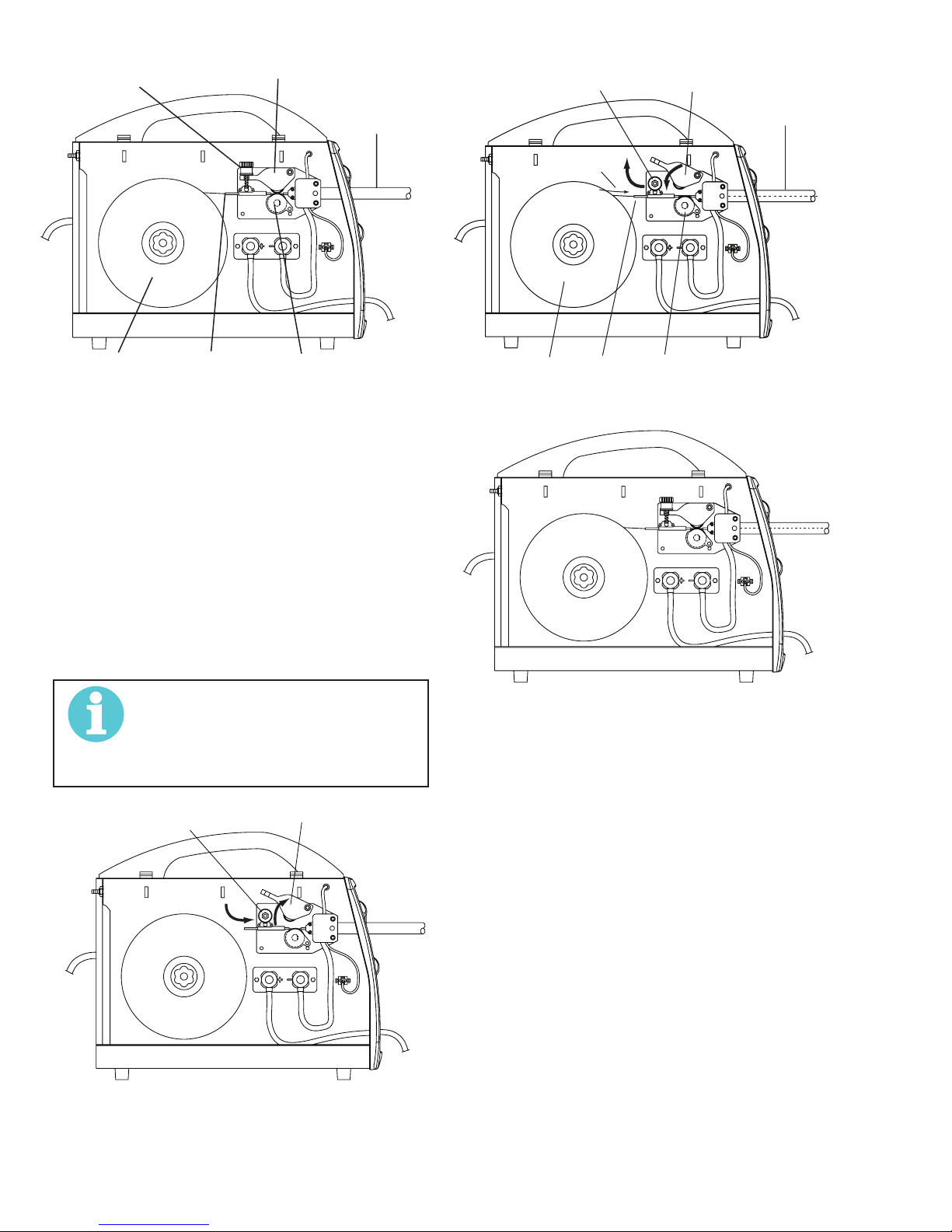

Route the Wire Through the Feedhead

1. Loosen Pressure Adjust Device (Fig. 3-9).

2. Open Pressure Adjust Device (Fig. 3-9).

3. Open Pressure Arm (Fig. 3-9).

4. Place the end of the wire into the Inlet Wire Guide,

feeding it over the Feedroll. Make certain that the proper groove

is being used (Fig. 3-10).

5. Pass the wire into the Gun Liner of the Gun Cable End

(Fig. 3-10).

6. Close the Pressure Arm (Fig. 3-10).

7. Close the Pressure Adjust Device. Tighten it to a “snug”

condition (Fig. 3-10).

8. Figure 3-11 shows the result with the wire installed.

NOTE!

If there is too much pressure on the drive

roll the wire gets locked and the motor

could get damaged, If it is too loose the

wire will not feed properly.

Spool

Feedroll

Figure 3-10: Inserting Wire

Figure 3-11: Wire Installed

Art # A-09085

Pressure Adjust Device

Art # A-09084

Figure 3-9: Opening Pressure Arm

INSTALLATION 3-8 Manual 0-5123

Page 25

3.12 Install Wire into the Welding Gun

2

HIGH

V

Switch

OFF Switch

Art # A-09062_AB

V

Switch

OFF Switch

2

HIGH

V

Switch

OFF Switch

Art # A-09062_AB

V

Switch

OFF Switch

Contact Tip

Nozzle

1. Plug the Welding Power Source into the 120VAC receptacle for the Firepower FP 125 and FP 135, and into the

230VAC receptacle for the Firepower FP 165.

WARNING

ELECTRIC SHOCK CAN KILL! With the gun

switch (located on the gun) activated,

welding power is applied to the output

terminals, feedroll, ground clamp, gun cable

connection and welding wire. Do not touch

these parts with the gun switch activated. .

2. Turn the welding machine ON with the front panel Voltage Control Switch set to "1".

Wire Feed

Speed

Art # A-09061_AB

v

oltage Control

COARSEFINE

LOW1

Power ON

FIREPOWER FP 125,135,165

Wire Feed

Speed

Power ON

oltage Control

Figure 3-15: FP 135, 165 Wire Speed Half-way

4. Straighten the gun cable. Remove the nozzle and contact tip from the MIG welding gun (see Section 2.08).

WARNING

If ground connection clamp is in place

on the workpiece the electrode wire is

electrically “hot” when the gun switch is

activated.

5. Activate the gun switch until the wire feeds out past the

gun nozzle.

Figure 3--12: FP 125 Power ON

Wire Feed

Speed

oltage Control

Figure 3--13: FP 135, 165 Power ON

3. Set the wire feed speed to half-way or "5".

Wire Feed

Speed

oltage Control

v

Art # A-09061_AB

COARSEFINE

LOW1

Power ON

Power ON

Wire

Gun Switch

Art # A-09087

Figure 3-15: Feed Wire Through Gun

6. Deactivate the gun switch and set the Power Control

Switch to "0 / OFF" and unplug the supply cord.

7. Replace the contact tip and nozzle. Cut the wire within

¼” (6mm) from the nozzle.

Figure 3-14: FP 125 Wire Speed Half-way

Manual 0-5123 3-9 INSTALLATION

Page 26

FIREPOWER FP 125,135,165

This Page Intentionally Blank

INSTALLATION 3-10 Manual 0-5123

Page 27

FIREPOWER FP 125,135,165

!

!

SECTION 4:

OPERATION

4.01 General Safety Precautions

Read and understand the safety instructions at the beginning of this manual prior to operating this machine.

WARNING

Be sure to put on proper protective clothing and eye safeguards (welding coat, apron, gloves, and welding

helmet, with proper lenses installed). See Safety Instructions and Warnings chapter included in this manual.

Neglect of these precautions may result in personal injury.

WARNING

Make all connections to the power source including electrode and work cables, as well as remote control

cables, with the power source turned off. These connections could be electrically live with the power switch

ON.

WARNING

ELECTRIC SHOCK CAN KILL! Do not operate the machine with the door open.

CAUTION

!

Do not pull the machine with the gun. Damage can occur to the gun, gun liner and machine. Avoid bending

the gun cable with a sharp radius. Damage can occur to the gun liner.

4.02 Firepower Controls

Refer to Figure 4-1 and 4-2.

1. Power ON / OFF switch turns the power on and off. It also lights when the power supply has gone into overtemp.

2. The Wire Speed Control knob controls the welding current via the electrode wire feed rate (i.e. the speed of the wire feed motor).

3. The Voltage Control Switch(s) sets the voltage level to the welding terminals. There are 4 positions available.

CAUTION

!

!

4. MIG Gun cable end and Gun Switch Leads are routed through this opening.

5. The Work Cable & Clamp connects to the item being welded (not shown).

6. The gas inlet nipple is used to connect the gas hose to the gas regulator for GMAW. Use the hose clamp to secure the hose to

7. The moveable tension knob applies pressure to the grooved roller via screw-adjustable spring pressure. The adjustable spring

8. The Gun Adaptor connects the MIG Gun to the feedhead assembly.

9. The Gun Switch Connector is provided for connection of the Gun Switch Leads.

10. Negative (-) Welding Terminal.

11. Positive (+) Welding Terminal.

The Voltage Control Switch MUST NOT BE SWITCHED during the welding process. Some internal electrical

components are at Mains voltage potential with this switch in the OFF position.

CAUTION

The Voltage Control Switch MUST NOT BE SWITCHED during the welding process. Some internal electrical

components are at Mains voltage potential with this switch in the OFF position.

the gas nipple.

screw should be adjusted to a minimum pressure that will provide satisfactory wire feed without slippage. If slipping occurs,

and inspection of the wire contact tip reveals no wear, distortion or burn-back jam, the conduit liner should be checked for

kinks and clogging by metal flakes and slag. If this is not the cause of slipping, the feedroll pressure can be increased by rotating the adjustable spring screw clockwise. The use of excessive pressure may cause rapid wear of the feed roller, motor shaft

and motor bearings.

Manual 0-5123 4-1 OPERATION

Page 28

FIREPOWER FP 125,135,165

4

CAUTION

!

13. The wire reel hub incorporates a friction brake which is adjusted during manufacture for optimum braking. If it is considered

!

Loose welding terminal connections can cause overheating and result in the cables being fused to the

welding terminals.

necessary, adjustment can be made by turning the large nut inside the open end of the wire reel hub. Clockwise rotation will

tighten the brake. Correct adjustment will result in the wire reel circumference continuing no further than ¾” (20mm) after

release of the Torch Trigger Switch. The wire should be slack without becoming dislodged from the reel.

CAUTION

Excessive tension on the brake will cause rapid wear of mechanical wire feed parts, overheating of electrical components and possibly an increased incidence of wire burnback into the contact tip.

2

6

3

8

9

Art # A-09065_AB

3

1

13

12 11

10

Figure 4-1: Firepower FP 125 Controls

2

6

4

7

Figure 4-2: Firepower FP 135 and 165 Controls

OPERATION 4-2 Manual 0-5123

8

1

3

Art # A-09066_AB

12

11 10

9

Page 29

FIREPOWER FP 125,135,165

!

4.03 Gas Metal Arc Welding (GMAW)

See Welding Guidelines included in this manual.

Make all necessary connections as instructed in the INSTALLATION chapter.

Place the WELD VOLTAGE RANGE SWITCH at the desired setting.

CAUTION

!

Plug the supply cord into a 120 VAC 40 Ampere receptacle for the FP 125, 120 VAC 50 Ampere receptacle for the 135 and into a 230

VAC 30 Ampere receptacle for the FP 165.

Open the gas cylinder valve to supply shielding gas to the gun. (optional gas regulator required on the FP 125)

Connect the WORK CLAMP to the workpiece (material to be welded).

Rotate the WIRE SPEED control to the desired setting.

Extend wire from the gun, and cut to proper stick-out for that type of wire (when welding always maintain this distance).

Position gun to where it is at approximately right angles to the workpiece with proper wire stick-out. Lower your welding helmet and

pull the gun trigger switch.

Do not turn the WELD VOLTAGE RANGE SWITCH clockwise past position 4, as damage to the switch may

occur.

WARNING

Be sure to put on proper protective clothing and eye safeguards (welding coat, apron, gloves, and welding

helmet with proper lenses installed). See Safety Instructions and Warnings chapter included in this manual.

Neglect of these precautions may result in personal injury.

Travel at a speed necessary to maintain a bead width from 1/8" to ¼" (3mm to 6mm) depending on the thickness of the material. For

material that may require larger weldments, either change to a larger diameter filler wire or use multi pass beads. On some applications, it may be necessary to adjust the voltage range to stabilize the arc.

Upon completion of the weld, release the gun trigger switch, raise the welding helmet, and visually examine the weld.

NOTE!

To help you overcome any problems that might arise, you will find useful information in section 4.06 Basic Welding

Techniques..

4.04 Flux Cored Arc Welding (FCAW)

Follow the same general procedure as with the GMAW process above. Shielding gas is not required for self shielded type wires. For

differences in the process see section 4.06 Basic Welding Techniques. Also included is information to solve any problem related to the

FCAW process.

4.05 Shutdown Procedures

Close the cylinder valve (GMAW process only). Press gun switch to vent gas line (GMAW process only). Place the POWER ON/OFF

SWITCH in the OFF position.

WARNING

!

After releasing the gun switch, the electrode wire will remain electrically “hot” for several seconds.

4.06 Basic Welding Technique

General

Two different welding processes are covered in this section, with the intention of providing the very basic concepts in using the semiautomatic mode of welding. In this mode, the welding gun is hand-held. The electrode (welding wire) is then fed into a weld puddle and

the arc is shielded by a gas or gas mixture.

Setting of the Power Supply

The settings of the Firepower requires some practice by the operator in that the welding Power Supply has two control settings that

need to balance. These are the Wire Speed control and the Voltage Control switches. The welding current is determined by the Wire

Speed control (i.e., the current will increase with increased wire speed, resulting in a shorter arc). Slower wire speed will reduce the

current and lengthen the arc. Increasing the welding voltage hardly alters the welding current level, but lengthens the arc. By decreasing the voltage, a shorter arc is obtained with little change in welding current.

Manual 0-5123 4-3 OPERATION

Page 30

FIREPOWER FP 125,135,165

Art: A-05104

!

When changing to a different electrode wire diameter, different control settings are required. A thinner electrode wire needs more wire

speed to achieve the same current level.

A satisfactory weld cannot be obtained if the wire speed and voltage switch settings are not adjusted to suit the electrode wire diameter and dimensions of the work piece.

If the wire speed is too high for the welding voltage, “stubbing” will occur as the wire dips into the molten pool and does not melt.

Welding in these conditions normally produces a poor weld due to lack of fusion. If however, the welding voltage is too high, large drops

will form on the end of the electrode wire, causing spatter. The correct setting of voltage and wire speed can be seen in the shape of

the weld deposit and heard by a smooth regular arc sound.

GAS METAL ARC WELDING (GMAW)

This process, also known as MIG welding, CO2 welding, Micro Wire Welding, short arc welding, dip transfer welding, wire welding etc.,

is an electric arc welding process which fuses together the parts to be welded by heating them with an arc between a solid, continuous, consumable electrode and the work. Shielding is obtained from an externally supplied gas or gas mixture. The process is normally

applied semi-automatically; however the process may be operated automatically and can be machine operated. The process can be

used to weld thin and fairly thick steels, and some non-ferrous metals in all positions.

Shielding Gas

Weld Metal

Solidified Weld

Metal

Nozzle

Electrode

Arc

Base Metal

Art: A-05103

Figure 4-3: GMAW Process

FLUX CORED ARC WELDING (FCAW)

This process also known as Open arc, Innershied, FAB Shield, etc., is an electric arc welding process which fuses together the parts

to be welded by heating them with an arc between a continuous flux filled electrode wire and the work. Shielding is obtained through

decomposition of the flux within the tubular wire. The process is normally applied semi-automatically; however the process may be

applied automatically or by machine. It is commonly used to weld large diameter electrodes in the flat and horizontal position and small

electrode diameters in all positions. The process is used to a lesser degree for welding stainless steel and for overlay work.

Gas (optional)

Molten Metal

Solid Weld

Metal

Slag

Molten

Slag

Nozzle (optional)

Flux Cored

Electrode

Arc

WARNING

Follow these instructions only after referring to the Safety Instructions and Warnings chapter of this manual,

and the instructions in the Installation chapter. .

Check List Before Starting

POLARITY – DCEP (Direct Current Electrode Positive) or DCEN (Direct Current Electrode Negative)

WIRE FEED SPEED – 1 to 10

VOLTAGE RANGE SWITCH SETTING – 1 to 4 for FP 135, 165 an two switches and1-2 and Low-High for FP 125.

GAS FLOW RATE – 15 to 25 CFH (If shielding gas is required)

ELECTRODE WIRE STICK-OUT – approx 3/8” (10mm)

OPERATION 4-4 Manual 0-5123

Figure 4-4: FCAW Process

Page 31

FIREPOWER FP 125,135,165

30 to 60º

T

Angle

Direction of

T

4.07 Welding Gun Positions

The welding gun should be held at an angle to the weld joint (see Secondary Adjustment Variables in Section 4.08). Hold the gun so that

the welding seam is viewed at all times. Always wear the welding helmet with proper filter lenses.

CAUTION

!

The electrode wire is not energized until the gun trigger switch is depressed. The wire may therefore be placed on the seam or joint

prior to lowering the helmet.

Do not pull the welding gun back when the arc is established. This will create excessive wire extension

(stickout) and make a very poor weld.

5º to 15º

Longitudinal

Angle

Direction of

90º

Transverse

Angle

Travel

Art: A-05105

Figure 4-5: Butt and Horizontal Welds

10º Longitudinal Angle

ransverse

Figure 4-6: Vertical Weld

5 to 15º

Longitudinal Angle

ravel

Figure 4-7: Horizontal Fillet Weld

10 to 20º Longitudinal

Angle

Direction of Travel

30 to 60º

Transverse Angle

Art: A-05107

Direction of Travel

30º

to 60º

Transverse

Angle

Art: A-05106

Manual 0-5123 4-5 OPERATION

30 to 60º

Transverse Angle

Figure 4-8: Overhead

5 to 15º

Longitudinal

Angle

Art: A-05108

Page 32

FIREPOWER FP 125,135,165

Actual Stickout

Transverse

4.08 MIG Welding (GMAW) Variables

Most of the welding done by all processes is on carbon steel. The following items describe the welding variables in short-arc welding of 24 gauge (0.024”, 0.6mm) to ¼” (6.4mm) mild sheet or plate. The applied techniques and end results in the GMAW process are

controlled by these variables.

Pre-selected Variables

Pre-selected variables depend upon the type of material being welded, the thickness of the material, the welding position, the deposition rate and the mechanical properties. These variables are:

1. Type of electrode wire

2. Size of electrode wire

3. Type of gas (not applicable to self-shielding wires FCAW)

4. Gas flow rate (not applicable to self-shielding wires FCAW)

Primary Adjustable Variables

These control the process after Pre-selected Variables have been found. They control the penetration, bead width, bead height, arc

stability, deposition rate and weld soundness. They are:

1. Arc Voltage

2. Welding Current (wire feed speed)

3. Travel Speed

Secondary Adjustable Variables

These variables cause changes in primary adjustable variables which in turn cause the desired change in the bead formation. They are:

1. Stickout—distance between the end of the contact tube (tip) and the end of the electrode wire. Keep this at about 3/8” (10mm)

stickout (as shown in Figure 4-8).

Gas Nozzle

Tip to Work

Distance

Average Arc Length

Contact Tip (Tube)

Electrode Wire

Art: A-05109

Figure 4-9: Electrode Stick-Out

2. Wire Feed Speed. Increase in wire feed speed increases weld current. Decrease in wire feed speed decreases weld current.

3. Nozzle Angle. (Figures 4-9 and 4-10) This refers to the position of the welding gun in relation to the joint. The transverse angle

is usually one half the included angle between plates forming the joint. The longitudinal angle is the angle between the center

line of the welding gun and a line perpendicular to the axis of the weld. The longitudinal angle is generally called the Nozzle

Angle and can be either trailing (pulling) or leading (pushing). Whether the operator is left-handed or right-handed has to be

considered to realize the effects of each angle in relation to the direction of travel.

Angle

Longitudinal

Angle

Axis of Weld

Figure 4-10: Transverse and Longitudinal Nozzle Axes

OPERATION 4-6 Manual 0-5123

Art: A-05110

Page 33

FIREPOWER FP 125,135,165

Direction of Gun Travel

Art # A-05111

Leading or "Pushing"

Angle (Forehand)

90º

Figure 4-11: Nozzle Angle, Right-Handed Operator

4.09 Establishing the Arc and Making Weld Beads

Before attempting to weld on a finished piece of work, it is recommended that practice welds be made on a sample metal of the same

material as that of the finished piece.

The easiest MIG welding procedure for the beginner to experiment with, is the flat position. This equipment is capable of flat, vertical

and overhead positions.

For practicing MIG welding, secure some pieces of 16 or 18 gauge (0.06” 1.5mm or 0.08” 2.0mm) mild steel plate 6” x 6” (150 x

150mm). Use 0.024” (0.6mm) wire and 75% Argon / 25% CO2 shielding gas.

Trailing or "Pulling"

Angle (Backhand)

4.10 Pre-Weld Procedure

1. Check the OPERATION chapter of this manual for details on this equipment.

2. Set the welding voltage range switch at position 1 or 2.

3. Set the wire feed speed control to about the 2.5 setting. Readjust as necessary.

4. Adjust the gas flow rate to about 20 cubic feet per hour (15 - 20 lpm).

5. Review standard safe practice procedures in ventilation, eye and face protection, fire, compressed gas and preventative maintenance. See Safety Instructions and Warnings chapter included in this manual.

4.11 Welding Procedure

1. Maintain the tip to work distance (stickout) at 5/16” to 3/8” (8 to 9mm) at all times.

2. For transverse and longitudinal nozzle angles, see section 4.07 Welding Gun Positions.

3. Hold the gun about 3/8” (9mm) from the work, lower the helmet by shaking your head and squeeze the trigger to start the wire

feeding, and establish the arc.

NOTE!

Get in the habit of shaking the helmet down, rather than using the hands. One hand must hold the gun, and

the other is often needed to hold pieces to be tacked or positioned.

4. Make a single down-hand (pulling) stringer weld bead.

5. Practice welding beads. Start at one edge and weld across the plate to the opposite edge.

NOTE!

When the equipment is properly adjusted, a rapidly cracking or hissing sound of the arc is a good indicator

of correct arc length.

6. Practice stopping in the middle of the plate, restarting into the existing weld crater and continuing the weld bead across the

plate.

NOTE!

When the gun trigger is released after welding, the electrode forms a ball on the end. To the new operator,

this may present a problem in obtaining the penetration needed at the start of the next weld. This can be

corrected by cutting the ball off with wire cutters.

Manual 0-5123 4-7 OPERATION

Page 34

FIREPOWER FP 125,135,165

4.12 Reference Tables

The following tables are provided as user aids when performing MIG or FLUX CORED welding.

Type of Gas Typical Mixtures Primary Uses

Carbon Dioxide (CO2) Mild and low alloy steels

Argon (Ar) - Carbon Dioxide (CO2) 75% Ar – 25% CO2 Mild and low alloy steelsStainless Steel

Argon (Ar) Aluminum

Table 4-1: Type of Gas

Result Desired Welding Variable

Arc

Voltage

Deeper Penetration 1Increase 3Trailing Max 25° 2Decrease

Shallower

Penetration 1Decrease 3Leading 2Increase 5Larger

Larger Bead 1Increase 2Decrease 3Increase (*)

Smaller Bead 2Decrease 2Increase 3Decrease (*)

Higher Narrower

Bead 1Decrease 2Trailing 3Increase

Flatter Wider Bead 1Increase 290° or Leading 3Decrease

Faster Deposition

Rate 1Increase 2Increase (*) 3Smaller

Slower Deposition

Rate 1Decrease 2Decrease (*) 3Larger

Key: (1) First Choice, (2) Second Choice, (3) Third Choice, (4) Fourth Choice, (5) Fifth Choice

Welding Current

(wire speed)

Travel

Speed Nozzle Angle Stick out Wire size Gas Type

5Smaller

(*) 4CO2

Table 4-2: Welding Variables

NOTE!

Same adjustment is required for wire feed speed.

4Ar CO2

mix

* When these variables are changed, the wire feed speed must be adjusted so that the welding current remains constant. See DEPOSITION RATE in the WELDING VARIABLES section. This change is especially helpful on materials of 20 gauge (.04” 1mm approximately)

and smaller in thickness.

OPERATION 4-8 Manual 0-5123

Page 35

FIREPOWER FP 125,135,165

Art # A-09030_AB

Steel

Flux Core

E71T-GS

None

Required

.030" (0.8mm)

.035" (0.9mm)

Steel

ER70S-6

Solid

(or hard)

100% CO

2

25cfh

.023" (0.6mm)

.030" (0.8mm)

.035" (0.9mm)

.023" (0.6mm)

.030" (0.8mm)

.035" (0.9mm)

75% Ar

25cfh

CO

2

25%

L1

L1

L1

5

L1

3.5

L1

3.5

5

3.5

L1

L1

L1

566 7.5

5

4

8

5

6

4.5

3

7

4

4

4

7

4

3

5

3.5

L2 L2 H1

H1

H1

H1

H1

H1

8

6

5

8.5

7.5

6.5

H2

H2

H2

H2

H2

H2

6

7.5

6.5

H2

H2

H2

H1

L2

L2

L1

L1

L2

3

L2

L2

L1

L1

564

L1

3

L1

7.5

643

H1

6.5

H2L1L1

L2

L2

H2

H2

8.5

7.5

H2

24 ga. (0.6mm)

22 ga. (0.7mm)

20 ga. (0.9mm)

18 ga. (1.2mm)

16 ga. (3mm)

1/8" (3.2mm) 3/16" (4.8mm)

Wire

Speed

Voltage

Step

THICKNESS

FINE

1

2

COARSE

LOW

HIGH

Material Type Wire Type Shielding Gas

and Flow Rate

Wire Size

(Diameter)

4.13 Firepower FP 125 Welding Setting Selection Guide

Manual 0-5123 4-9 OPERATION

Figure 4-12: FP 125 Selection Guide

Page 36

FIREPOWER FP 125,135,165

4.14 Firepower FP 135 Welding Setting Selection Guide

Material Type Wire Type Shielding Gas

and Flow Rate

100% CO

25cfh

Solid

Steel

(or hard)

ER70S-6

75% Ar

25%

CO

Wire Size

(Diameter)

.023" (0.6mm)

2

.030" (0.8mm)

.035" (0.9mm)

.023" (0.6mm)

2

.030" (0.8mm)

25cfh

.035" (0.9mm)

Steel

Stainless

Steel

3

2

1

4

Voltage

Step

Wire

Speed

Flux Core

E71T-GS

Stainless

Steel

ER 308L

THICKNESS

None

Required

98% Ar

2% CO

35cfh

.030" (0.8mm)

.035" (0.9mm)

.023" (0.6mm)

2

.030" (0.8mm)

.035" (0.9mm)

Art # A-09031_AB

24 ga. (0.6mm)

2

3.5

2

2.5

1

3

1

2

1

2

1

3

22 ga. (0.7mm)

2

2

20 ga. (0.9mm)

3.54.5 5.56

2.5

223

2

1

1

3

1

2

1

1

1

1

2

1

2.5

2.5

3

3

2.5

18 ga. (1.2mm)

2

3

2

2.5

2

5

2

3.5

2

3

2

462.5

16 ga. (3mm)

2

3

2

2

2

3

3

1

3355.5

1

2

122

3

2.5

2

3.5

1

2.5

1

1

2

2

Figure 4-13: FP 135 Selection Guide

1/8" (3.2mm) 3/16" (4.8mm) 1/4" (6.4mm) 5/16" (7.9mm)

4

7.5

4.5

5

7.5

5.5

5

7 8.5

7

7.5

5.5

5.5

8

4

6

4

4.5

4

8

4

7

4

7

4

4

8

4

8

4

7

4

6.5

4

7

4

7

4

8.5

421

8

4

7

4

6.5

3

3.5

5.5

4

3.5

53.51.5

4

4

4

3

4

3

3

3

4

4

3

3

3

4

6.5

OPERATION 4-10 Manual 0-5123

Page 37

FIREPOWER FP 125,135,165

57

4.15 Firepower FP 165 Welding Setting Selection Guide

3

2

1

24 ga. (0.6mm)

1

3

1

3

1

1

1

4

1

3

1

1.5

Voltage

4

Step

22 ga. (0.7mm)

1

1

1

1

1

1

1.5

Material Type Wire Type Shielding Gas

Solid

Steel

(or hard)

ER70S-6

and Flow Rate

100% CO

2

25cfh

75% Ar

CO

2

25%

.023" (0.6mm)

.030" (0.8mm)

.035" (0.9mm)

.023" (0.6mm)

.030" (0.8mm)

25cfh

.035" (0.9mm)

Steel

Stainless

Steel

Flux Core

E71T-GS

Stainless

Steel

ER 308L

Wire

Speed

20 ga. (0.9mm)

333.55

122

1

1

3

1

1

1

1

1

4445.5

3

112

1

1

18 ga. (1.2mm)

1

2

1

3

2

1.5

1.51.5 3.5

3

1.5

2

1

1.5

2

4

1

2

2

2.5

1

1

3

1

2

None

Required

98% Ar

2% CO

35cfh

THICKNESS

16 ga. (3mm)

2

3

2

2

2

5

2

3.5

2

3

2

2

32.52.5

2

4

2

3

.030" (0.8mm)

.035" (0.9mm)

.023" (0.6mm)

2

.030" (0.8mm)

.035" (0.9mm)

1/8" (3.2mm) 3/16" (4.8mm) 1/4" (6.4mm) 5/16" (7.9mm)

3

3

3

3

3

3

3

3

3

3

3

Wire Size

(Diameter)

4

6

4

5

4

4

4

7

4

5.5

4

4.5

3

5 6

3

4

4

7

4

5.5

4

4

7

6.5

6

7.5

7

6.5

5

7.5

7

6

Art # A-09032_AB

4

6

4

8

4

6.5

4

422

4

4

4

7.

7

7.5

7

6

4

.5

4

7.5

4

6

Manual 0-5123 4-11 OPERATION

Figure 4-14: FP 165 Selection Guide

Page 38

FIREPOWER FP 125,135,165

4.16 Gas Selection for Gas Metal Arc Welding

Metal Type

Carbon

Steel

Low Alloy

and

High Alloy

Steel

Base Plate

Thickness Filler Metal

Greater than

22 gauge

(.030”)

Greater than

22 gauge

(.030”)

Greater than

22 gauge

(.030”)

Greater than

10 gauge

(1/8”)

Greater than

22 gauge

(.030”)

Greater than

22 gauge

(.030”)

ER70S-X Short Circuit 100% CO2All Position

ER70S-X Short Circuit 75% Argon

ER70S-X Short Circuit 92% Argon

ER70S-X Spray

See Note 1 Short Circuit

See Note 1 Short Circuit 92% Argon

Transfer

Mode

Transfer

Globular

Suggested

Shielding Gas

25% CO2

8% CO2

92% Argon

8% CO2

75% Argon

25% CO2

8% CO2

Welding

Positions Comments

High welding speeds. Good penetration and pool

Welding

All Position

Welding

All Position

Welding

Flat & HV

Fillet

All Position

Welding

All Position

Welding

Suitable for high-current and high-speed welding.

Higher deposition rates without melt-through.

Minimum distortion and spatter. Good pool control

for out-of-position welding.

Good arc stability, weld soundness, and increasing

High welding speeds. Good penetration and pool

control. Applicable for out-of-position welds.

Suitable for high-current and high-speed welding.

Good coalescence and bead contour. Good

control.

width of fusion.

mechanical properties.

Greater than

3/32”

Greater than

14 gauge

(.075”)

Stainless

Steel

Aluminum Greater than

Greater than

22 gauge

(.030”)

Greater than

3/32”

18 gauge

(.045”)

See Note 1 Spray

transfer