Page 1

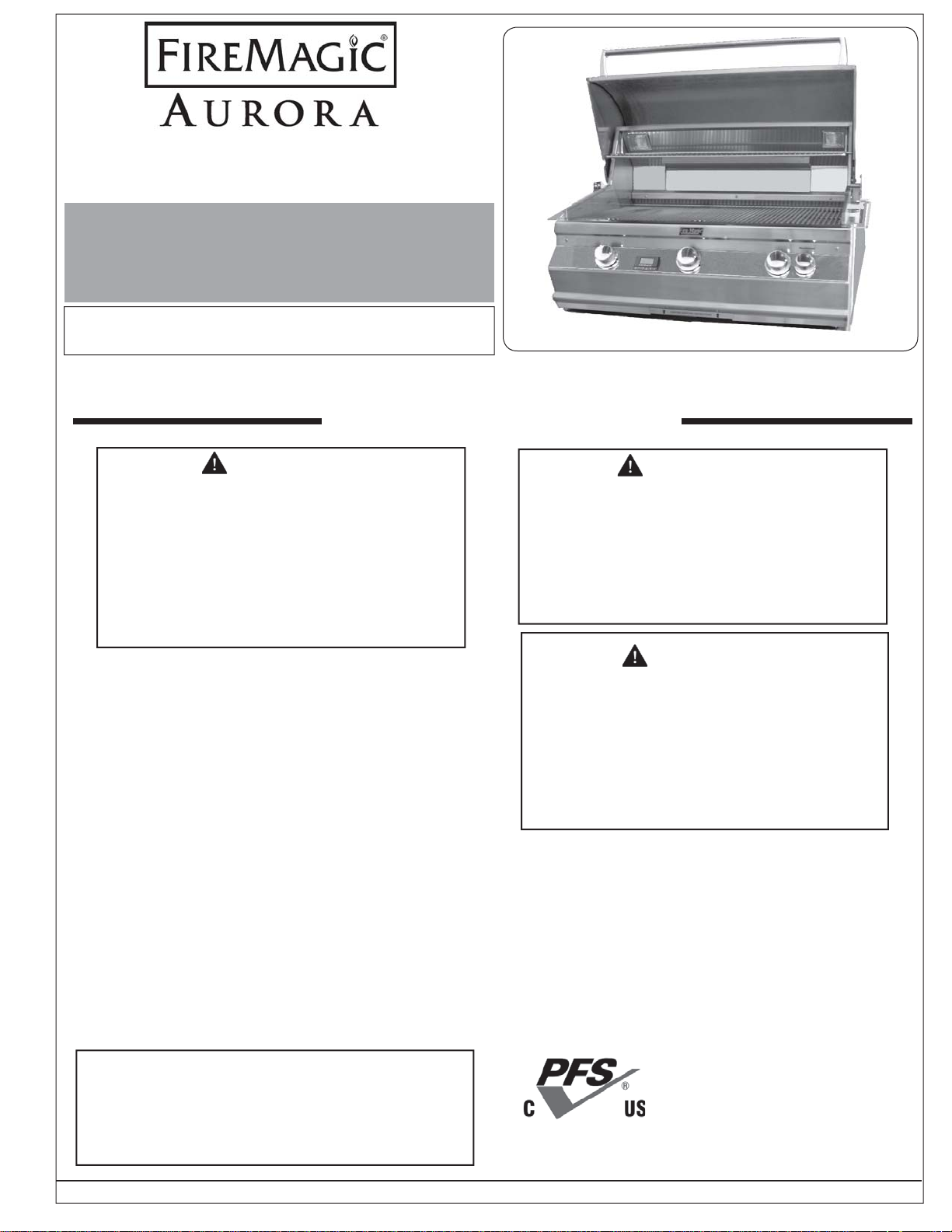

BUILT-IN OUTDOOR GAS GRILLS

A430i, A530i, A540i, A660i, & A790i

INSTALLATION

INSTRUCTIONS AND

OWNER’S MANUAL

INSTALLER: Leave these instructions with consumer.

CONSUMER: Retain for future reference.

IMPORTANT: READ THESE INSTRUCTIONS CAREFULLY BEFORE STARTING INSTALLATION OR USE.

WARNINGS AND SAFETY CODES

A790i shown

DANGER:

IF YOU SMELL GAS:

1. Shut off the gas to the appliance.

2. Extinguish any open fl ame.

3. Open lid.

4. If odor continues, keep away from the

appliance and immediately call your

gas supplier or the fi re department.

CODE AND SUPPLY REQUIREMENTS: This

grill must be installed in accordance with local

codes and ordinances, or, in the absence of local

codes, with the latest National Fuel Gas Code

(ANSI Z223.1/NFPA 54), or Natural Gas and

Propane Storage and Handling Installation Code

(CSA-B149.1).

This appliance and its dedicated manual shutoff

valve must be disconnected from the gas-supply

piping system when testing the system at pressures

in excess of ½ psig (3.5 kPa).

This appliance must be isolated from the gassupply piping system by closing its dedicated

manual shutoff valve during any pressure testing

of the gas-supply system at pressures up to and

including ½ psig (3.5 kPa).

WARNING:

1. Do not store or use gasoline or other

fl ammable vapors and liquids in the

vicinity of this or any other appliance.

2. An LP cylinder not connected for use

shall not be stored in the vicinity of this

or any other appliance.

WARNING:

Improper installation, adjustment, alteration,

service, or maintenance can cause injury

or property damage. For proper installation,

refer to the installation instructions. For

assistance or additional information,

consult a qualifi ed professional installer,

service agency, or the gas supplier.

All electrical outlets in the vicinity of the grill must

be properly grounded in accordance with local

codes, or, in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70, or the

Canadian Electrical Code, CSA C22.1, whichever

is applicable.

Keep all electrical-supply cords and fuel-supply

hoses away from any heated surface.

Proper operation of your grill

requires prompt and periodic

maintenance. See the CARE &

CLEANING section for details.

Robert H. Peterson Co. • 14724 East Proctor Avenue • City of Industry, CA 91746

REV 8 - 1405291355

Certifi ed to: ANSI Z21.58b-2012

11-093

1

CSA 1.6b-2012

L-C2-276

Page 2

INSTALLATION INSTRUCTIONS ET MANUEL DU PROPRIÉTAIRE

GRIL EXTÉRIEUR DE GAZ DU BUILT-IN

IMPORTANT: LISEZ CES INSTRUCTIONS SOIGNEUSEMENT AVANT DE COMMENCER L’INSTALLATION OU L’UTILISATION

SÛRETÉ ET CODES D’AVERTISSEMENT

DANGER:

SI VOUS SENTEZ LE GAZ :

1. Coupez le gaz à l’appareil.

2. Éteignez-vous n’importe quelle fl amme nue.

3. Ouvrez le couvercle.

4. Si l’odeur continue, gardez loin de

l’appareil et appelez immédiatement

votre département de fournisseur ou de

feu de gaz.

CONDITIONS DE CODE ET D’APPROVISIONNEMENT:

Ce gril doit être installé selon des codes et des ordonnances

locaux, ou, en l’absence des codes locaux, avec l’un ou l’autre

le plus défunt Code national de gaz de carburant (norme ANSI

Z223.1/NFPA 54), et Stockage de gaz naturel et de propane

et manipulation du code d’installation (CSA-B149.1).

Cet appareil et ses différents robinets d’isolement doivent être

démontés du gaz-fournissent le système siffl ant en examinant

le système aux pressions au-dessus du ½ psig (kPa 3.5).

Cet appareil doit être isolé dans gaz-fournissent le système

siffl ant par fermeture que ses différents robinets d’isolement

manuels pendant tous les essais sous pression du gazfournissent le système aux pressions jusques et y compris

le ½ psig (kPa 3.5).

• Ce gril est pour ultilisation à l’extérieur seulement.

Si l’appareil est entreposé à l’intérieur, enlever les

bouteilles et les laisser à l’extérieur.

• Ne pas ranger le gril immédiatement aprés l’avoir utilisé.

le laisser refroidir avant de le déplacer ou de la ranger.

Le non respect de cette mesure de sécurité pourrait

entraîner un incendie causant des dommages à la

propriété, des blessures ou la mort.

• Ne pas utiliser cet appareil sous une surface

combustible.

• Ne pas utiliser cet appareil sous un auvent. Le non

respect de cette mesure de sécurité pourrait entraîner

un incendie ou des blessures.

• Dégagement minimal entre les parois latérales et

l’arriére de l’appareil et la construction combustible (45.7

cm à partir des parois latérales et 45.7cm à partir de

l’arriére).

• Le régulareur de pression de gaz prévu avec cet appareil

de cuisson à gaz pour l’extérieur doit être utilisé. Ce

régulateur est réglé pour une pression de sortie de 5

pouces de colonne de l’eau pour le gaz naturel, et 10

pouces pour le propane.

• LE RÉGULATEUR INCLUS D’APPAREILS EST ÉVALUÉ

POUR LE MAXIMUM DE 1/2 (LIVRES PAR POUCE

CARRÉ). SI VOTRE OFFRE DE GAZ EST 1/2 PLUS

GRAND QUE (LIVRES PAR POUCE CARRÉ), UN

AVERTISSEMENT:

1. Ne stockez pas ou n’employez pas

l’essence ou d’autres vapeurs et liquides

infl ammables à proximité de ceci ou

d’aucun autre appareil.

2. Un cylindre de propane non relié pour

l’usage ne sera pas stocké à proximité

de ceci ou d’aucun autre appareil.

AVERTISSEMENT:

L’installation inexacte, l’ajustement, le

changement, le service, ou l’entretien

peuvent causer des dommages ou des

dégats matériels. Référez-vous à ce

manuel. Pour l’aide ou l’information

additionnelle, consultez un installateur

professionnel qualifi é, l’agence de service,

ou le fournisseur de gaz.

Toutes les sorties électriques à proximité du gril doivent être

correctement fondues selon des codes locaux, ou en l’absence

de local code, avec le code électrique national, ANSI/NFPA

70, ou le code électrique canadien, CSA C22.1, celui qui est

applicable.

Maintenez tout électrique-fournissent des cordes et carburantfournissent des tuyaux partis de n’importe quelle surface de

chauffage.

RÉGULATEUR ADDITIONNEL DOIT ÊTRE INSTALLÉ

AVANT LE GRIL. VOIR LA SECTION DE CONDITIONS

D’OFFRE DE GAZ POUR LA PRESSION APPROPRIÉE

D’OFFRE DE GAZ.

• Ne couvrez jamais la surface entière de cuisine ou de

gril de gauffreuses ou de casseroles. La surchauffe se

produira et les brûleurs ne seront pas très performants

quand la chaleur de combustion est emprisonnée audessous de la surface à cuire.

• Ne pulvérisez jamais l’eau sur une unité chaude de gaz,

comme ceci peut endommager des composants de

porcelaine ou de fer de fonte.

• Une fuite de GPL peut causer une incendie ou une

explosion si enflammée entraînant des blessures

corporelles graves ou la mort.

• Communiquez avec le fournisseur de GPL pour les

réparations ou pour disposer de qules bouteille ou du

GPL non utilisé.

Certifi é à la norme: ANSI Z21.58b-2012 / CSA 1.6b-2012

INSTALLATEUR : Laissez ces instructions avec le consommateur.

CONSOMMATEUR : Maintenez pour la future référence.

REV 8 - 1405291355

2

L-C2-276

Page 3

CONTENTS

4 REPLACEMENT PARTS LIST

6 COUNTERTOP OVERHANG

6 MODEL SPECIFICATIONS

7 SUBSTRATE

7 BUILT-IN GRILL DIMENSIONS TABLE

8 ELECTRICAL CONNECTIONS

8 GRILL MAINTENANCE AND SAFETY INFORMATION

8 LIGHT SWITCH

9 INSTALLATION REQUIREMENTS

10 ENSURING PROPER COMBUSTION AIR AND COOLING AIRFLOW

10 EXHAUST REMOVAL

10 GAS-SUPPLY PLUMBING REQUIREMENTS

11 NATURAL GAS INSTALLS

11 PROPANE GAS INSTALLS (HOUSEHOLD & CYLINDER)

11 WHEN A PROPANE CYLINDER IS USED

11 ENCLOSURE REQUIREMENTS

12 COUNTER PREPARATION

12 CONNECTING THE GAS SUPPLY

12 INSTALLING THE BUILT-IN UNIT

13 ELECTRICAL INSTALLATION

15 SAFE USE & MAINTENANCE OF PROPANE GAS CYLINDERS

16 IDENTIFICATION OF GRILL CONTROLS

17 LIGHTING (IGNITION) INSTRUCTIONS

17 SHUTTING OFF THE UNIT

19 DEFAULT SCREEN

19 DIGITAL THERMOMETER

20 MENU SCREEN

22 OPTIONAL ROTISSERIE

23 INFRARED BURNER OPERATION

24 GRILLING TIPS

25 ACCESSORIES

25 THE ROTIS-A-LIGHT (OPTIONAL)

®

26 FIRE MAGIC

DRIP TRAY

27 CARE & CLEANING

28 REPLACING HALOGEN BULBS

29 REGULATOR CONVERSION

29 GAS ORIFICE CONVERSION

29 CONVERTING THE GAS TYPE

31 BURNER AIR SHUTTER ADJUSTMENT

33 TROUBLESHOOTING

34 WARRANTY

REV 8 - 1405291355

3

L-C2-276

Page 4

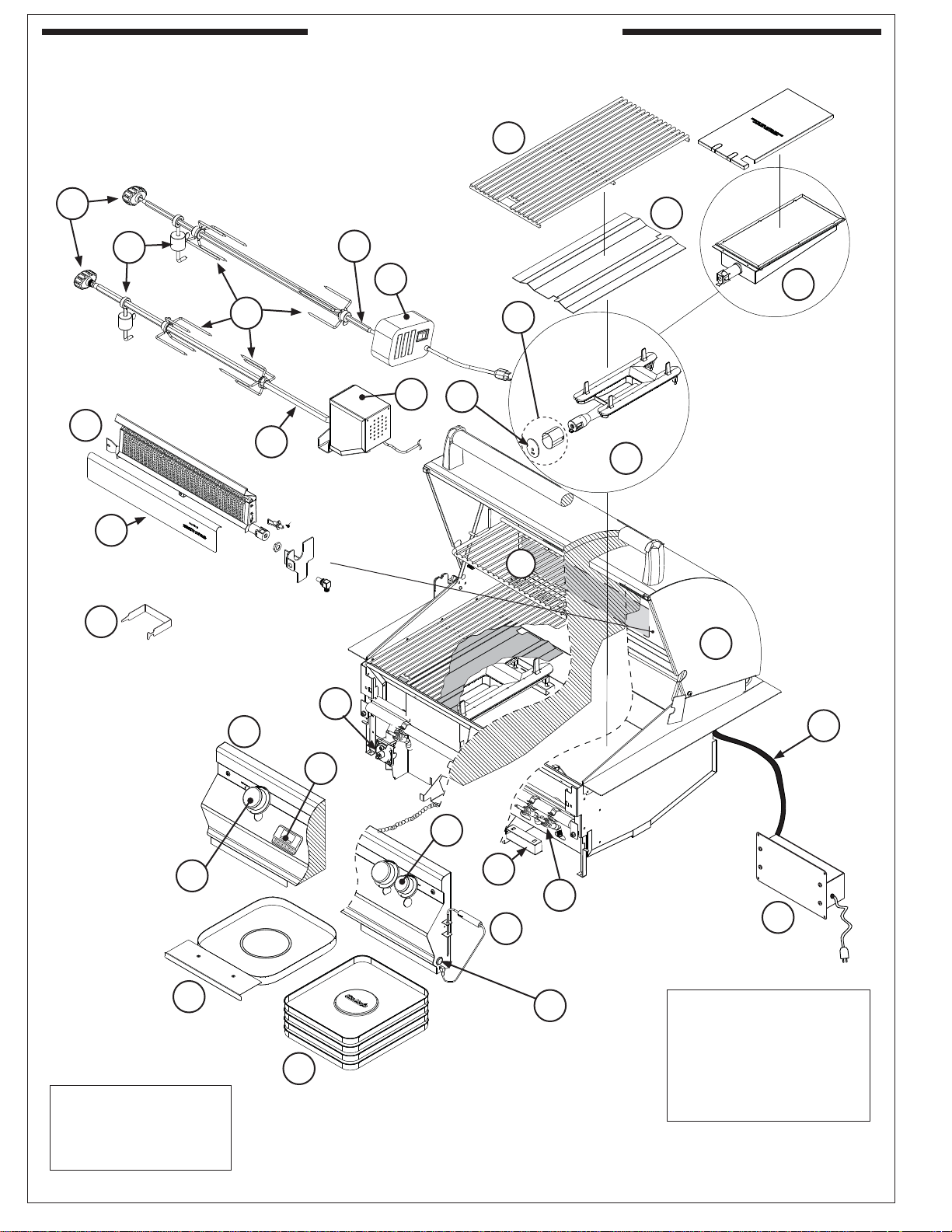

REPLACEMENT PARTS LIST

1

15

2

17

16

13

11

12

6

4

5

9

14

3

10

8

18

7

23

26

To order replacement

parts, contact your

local Fire Magic®

dealer.

21

27

24

19

22

31

25

43

39

20

38

Some items shown

are optional, or are not

available for certain

models. Your model

may vary, refer to parts

table.

REV 8 - 1405291355

4

L-C2-276

Page 5

REPLACEMENT PARTS LIST (cont.)

A430i A530i A540i A660i A790i

Item Description Part No. Qty. Part No. Qty. Part No. Qty. Part No. Qty. Part No. Qty.

Stainless cooking grid (set of 2 or 3) 3542-S-2 1 3539-S-2 1 3543-S-3 1 3544-S-3 1 3539-S-3 1

1.

Flavor grid (set of 2 or 3) 3063-S-2 1 3056-S-2 1 3064-S-3 1 3057-S-3 1 3056-S-3 1

2.

Main burner 3042-50 2 3041-50 2 3042-50 3 3041-50 3 3041-50 3

3.

Heatshield kit 24177-05 2 24177-05 2 24177-05 3 24177-05 3 24177-05 3

4.

Silicone gasket 24177-06 2 24177-06 2 24177-06 3 24177-06 3 24177-06 3

5.

Infrared burner * 3051 1 3049 1 3051 1 3049 1 3049 1

6.

Oven lid 23729-53 1 23736-53 1 23733-53 1 23738-52 1 23745-52 1

7.

Warming rack 3672S-M 1 3672S-M 1 3673S-M 1 3673S-M 1 3675S-M 1

8.

Back burner* 24130-11 1 24130-11 1 24170-11 1 24170-11 1 24180-11 1

9.

Back burner cover* 24148-010 1 24148-010 1 24739-010 1 24739-010 1 24745-010 1

10.

Rotisserie motor* 3600-02 1 3600-02 1 3600-02 1 3600-02 1 3600-02 1

11.

Heavy-duty motor*† N/A N/A 3600-05 1 3600-05 1 3600-05 1

12.

Rotisserie rod* 3603-30 1 3603-30 1 3606-30 1 3606-30 1 N/A

13.

Heavy duty rod*† N/A N/A 3606-40 1 3606-40 1 3609-40 1

14.

Rotisserie knob* 24187-16 1 24187-16 1 24187-16 1 24187-16 1 24187-16 1

15.

Meat holder (pair)* 3613 1 3613 1 3613 1 3613 1 3613 1

16.

Counterbalance* 3620E 1 3620E 1 3620E 1 3620E 1 3620E 1

17.

Grid lifter 3519 1 3519 1 3519 1 3519 1 3519 1

18.

Convertible regulator PR-4 1 PR-4 1 PR-4 1 PR-4 1 PR-4 1

19.

Valve manifold w/ back burner 24130-22 1 24130-22 1 24170-22 1 24170-22 1 24180-22 1

20.

valve manifold w/o back burner 24130-28 1 24130-28 1 24170-28 1 24170-28 1 N/A

or

Control panel w/ back burner 24130-45 1 24130-45 1 24170-45 1 24170-45 1 24180-45 1

21.

Control panel w/o back burner 24130-46 1 24130-46 1 24170-46 1 24170-46 1 N/A

or

Small knob* 3016 1 3016 1 3016 1 3016 1 3016 1

22.

Large knob 3015 2 3015 2 3015 3 3015 3 3015 3

23.

Digital thermometer 24180-12 1 24180-12 1 24180-12 1 24180-12 1 24180-12 1

24.

Meat probe 24187-14S 1 24187-14S 1 24187-14S 1 24187-14S 1 24187-14S 1

25.

Drip tray 3084 1 3084 1 3084 1 3084 1 3084 1

26.

Drip tray liner (set of 4) 3557 1 3557 1 3557 1 3557 1 3557 1

27.

Wire harness assembly‡ 24177-26 1 24177-26 1 24177-26 1 24177-26 1 24177-26 1

28.

Back burner electrode*‡ 4199-70 1 4199-70 1 4199-70 1 4199-70 1 4199-70 1

29.

Electrode & collector box assy‡ 3199-45 2 3199-45 2 3199-45 3 3199-45 3 3199-45 3

30.

Ignitor module 3199-44 1 3199-44 1 3199-46 1 3199-46 1 3199-46 1

31.

Natural gas orifi ce(s)‡ 3001-42-2 1 3001-40-2 1 3001-44-3 1 3001-42-3 1 3001-38-3 1

32.

Natural back burner gas orifi ce(s)‡ 3001-52-1 1 3001-52-1 1 3001-49-1 1 3001-49-1 1 3001-44-1 1

33.

Propane gas orifi ce(s)‡ 3001-54-2 1 3001-53-2 1 3001-55-3 1 3001-54-3 1 3001-53-3 1

34.

Propane back burner gas orifi ce(s)‡ 3001-59-1 1 3001-59-1 1 3001-57-1 1 3001-57-1 1 3001-56-1 1

35.

Fire Magic® cookbook‡ 3595 1 3595 1 3595 1 3595 1 3595 1

36.

Thermometer wire harness‡ 24177-25 1 24177-25 1 24177-25 1 24177-25 1 24177-25 1

37.

Power supply w/ connector 24177-11 1 24177-11 1 24177-11 1 24177-11 1 24177-11 1

38.

Wire harness extension 24177-27 1 24177-27 1 24177-27 1 24177-27 1 24177-27 1

39.

12V / 10 watt halogen light bulb ‡ 24187-15 2 24187-15 2 24187-15 2 24187-15 2 24187-15 2

40.

Light lens ‡ 24187-26 2 24187-26 2 24187-26 2 24187-26 2 24187-26 2

41.

Lamp assembly ‡ 24187-28 2 24187-28 2 24187-28 2 24187-28 2 24187-28 2

42.

Light switch 24182-46 1 24182-46 1 24182-46 1 24182-46 1 24182-46 1

43.

* If equipped

† Not available on A430i or A530i models

‡ Not shown

REV 8 - 1405291355

5

L-C2-276

Page 6

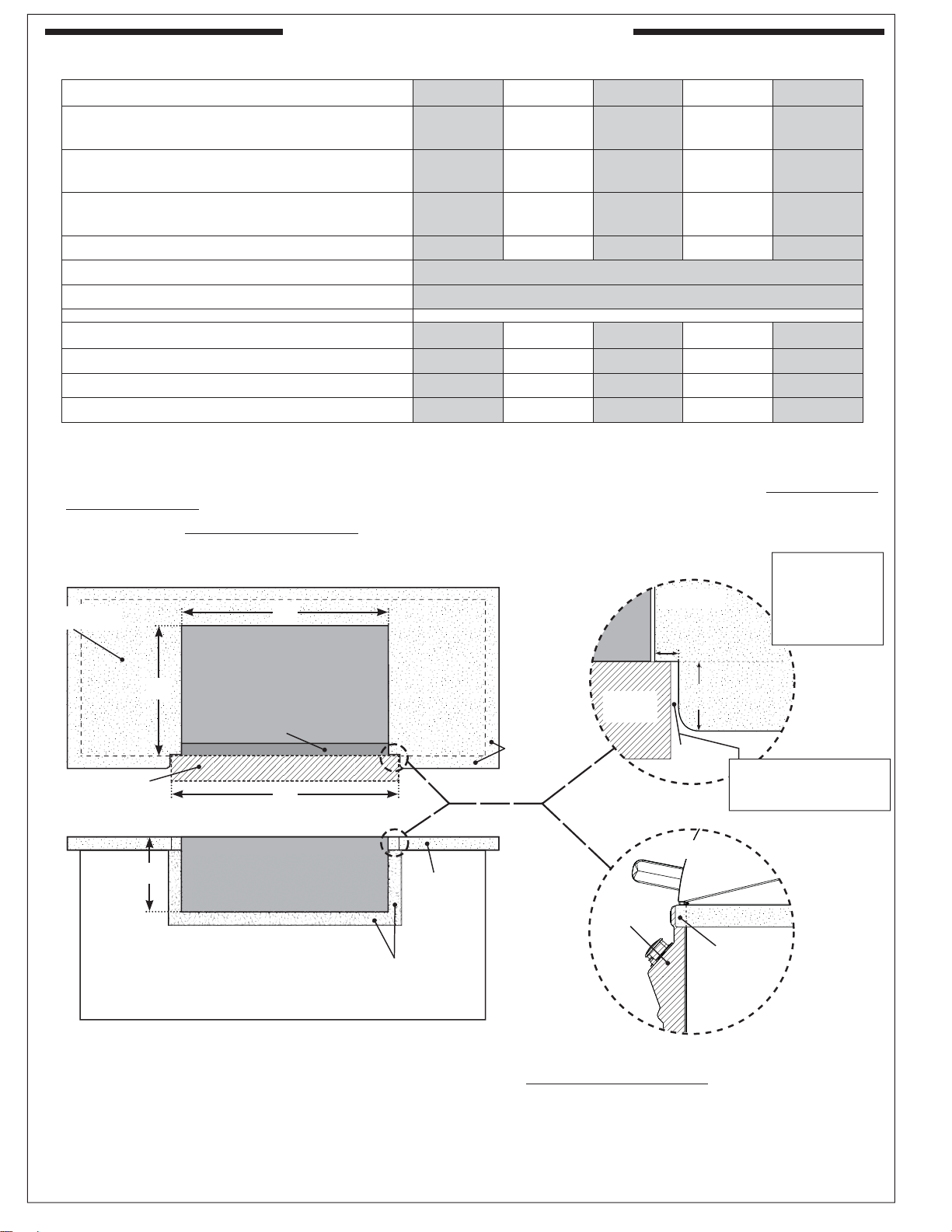

MODEL SPECIFICATIONS

MODEL SPECIFICATIONS TABLE

Table 1

Main burner BTU

N/P orifi ce drill size

Backburner BTU

N/P orifi ce drill size

Infrared searing burner BTU

N/P orifi ce drill size

▲

▲

A430i A530i A540i A660i A790i

25,000 x 2

#42/#54

13,000

#52/#59

17,000

#49/#56

30,000 x 2

#40/#53

13,000

#52/#59

25,000

#45/#55

20,000 x 3

#44/#55

18,000

#49/#57

17,000

#49/#56

25,000 x 3

#42/#54

18,000

#49/#57

25,000

#45/#55

30,000 x 3

#38/#53

20,000

#44/#56

25,000

#45/#55

Optional Aurora insulating liner model # 23130-50 23125-50 23150-50 3176-50 3186-50

Power supply rating

120VAC / 0.5A / 60 Hz

Oven lights rating 12V / 10 watt halogen bulb

A Countertop to unit bottom cut-out* 12" 12" 12" 12" 12"

B Side to side non-combustible cut-out* 25-1/2" 25-1/2" 32" 32" 37-3/4"

C Front to back non-combustible cut-out*† 19-1/2" 23-1/2" 19-1/2" 23-1/2" 23-1/2"

D Control panel width non-combustible cut-out‡ 27" 27" 33" 33" 38-3/4"

▲

If equipped

*Note: If using an insulating liner, consult liner instructions for counter cut-out dimensions and installation.

†

Includes any substrate at front wall of enclosure (in the area the rear of the control panel is to sit fl ush against). See SUBSTRATE

section on next page.

‡

Only applicable for non-combustible enclosures that have countertops with an overhang (see illustration and section below).

Countertop

Control panel

TOP VIEW

B

NON-COMBUSTIBLE

CABINET CUT-OUT

C

DIMENSIONS

Lower support

D

FRONT VIEW

A

Countertop

overhang

See next page

for substrate

considerations

Countertop

overhang

(Control

panel)

Control

panel

TOP VIEW

(Countertop)

X

Y

1

/4"

Clearance

SIDE VIEW

Countertop

overhang

X= D-B÷2

Y= Total

Countertop

Overhang

(Overhang)

Check clearance for

control panel removal

Fig. 6-1

COUNTERTOP OVERHANG

The control panel is designed to sit fl ush against the enclosure front wall. If the non-combustible enclosure countertop extends beyond

the front wall, creating a countertop overhang, it must be cut fl ush with the front wall for the width of the control panel or a gap will be

created exposing the forward portions of the left and right side grill fi re walls. See illustrations above.

Important: FOR YOUR SAFETY, you must provide openings in the island enclosure for drainage, replacement air, and cross-

ventilation of any storage area exposed to possible leakage from gas connections, the unit, or propane bottles. See

the ENCLOSURE REQUIREMENTS section for details.

REV 8 - 1405291355

6

L-C2-276

Page 7

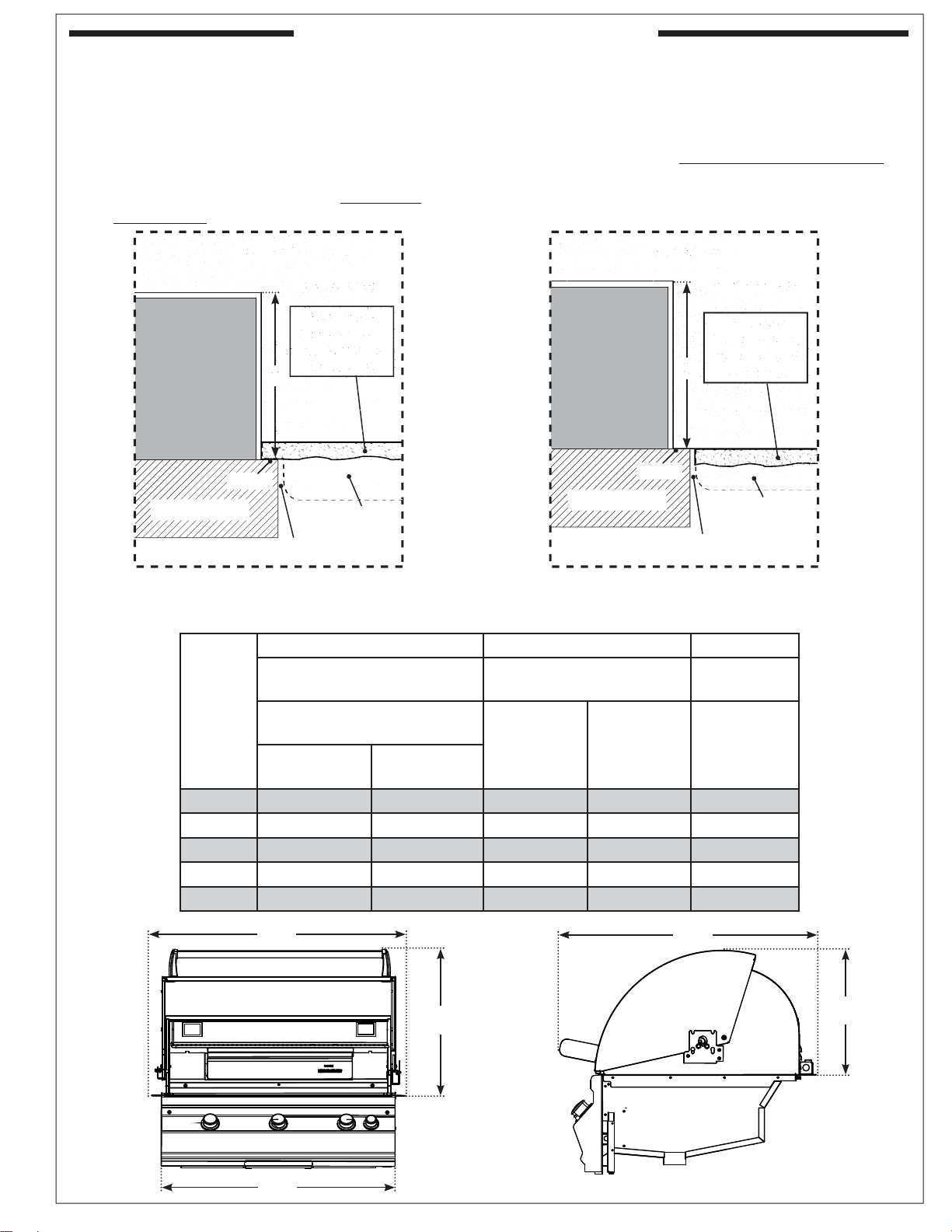

MODEL SPECIFICATIONS (cont.)

SUBSTRATE

When adding any substrate to the enclosure front wall (including tiles, stone, etc.), consider the following:

Substrate Behind Control Panel

Substrate + countertop "front to back" cutout

must equate to Dim. C (see previous page)

when the substrate sits fl ush behind the

control panel.

TOP VIEW TOP VIEW

(Countertop)

Substrate

(includes tiles,

etc. at front of

enclosure)

Grill liner

(Control panel)

C

Flush

Countertop

overhang

(if applicable)

1

/4"

Clearance

Fig. 7-1 Fig. 7-2

Substrate Alongside Control Panel

Any additional substrate alongside the control panel

does not need to be considered in Dim. C (see previous

page), however a

overhang) and below is required.

(Control panel)

1

/4" clearance on each side (same as

(Countertop)

Substrate

(includes tiles,

Grill liner

Flush

etc. at front of

C

1

/4"

Clearance

enclosure)

Countertop

overhang

(if applicable)

Model

A430i

A530i

A540i

A660i

A790i

BUILT-IN GRILL DIMENSIONS TABLE

Height Width Depth

(Top to bottom) (Left to right) (Front to

Upper hanger to top

Hanger to

hanger

(G)

Open

(E)

(with oven)

Closed

(F)

20 1/4" 13 1/4" 30" 26 1/2" 26 3/4"

23 5/8" 15" 30" 26 1/2" 29 3/4"

20 1/4" 13 1/4" 36 1/2" 32 1/2" 26 3/4"

23 5/8" 15" 36 1/2" 32 1/2" 29 3/4"

23 5/8" 15" 42 1/4" 38 1/4" 29 3/4"

G

E

Control

panel

width

(H)

Maximum

I

back)

depth

(I)

F

REV 8 - 1405291355

H

Fig. 7-3

7

L-C2-276

Page 8

GRILL MAINTENANCE AND SAFETY INFORMATION

1. The outdoor grill and surrounding area MUST

remain clear of fl ammable substances such as

gasoline, yard debris, wood, etc.

2. The airfl ow through the vent space located below

the control panel must remain unobstructed.

and clean the orifi ce and burner/venturi tubes

for insects and insect nests. A clogged tube can

lead to a fi re beneath the grill. A proper fl ame

pattern will ensure safe operation and optimal

performance. Adjust the air shutter as needed

(see AIR SHUTTER ADJUSTMENT).

3. When using propane gas:

5. The in-line gas valve or gas cylinder valve must

a. The required ventilation openings in the

always be shut OFF when the grill is not in use.

enclosure must be clear of debris.

6. The drip collector holes must be clear and

b. The propane cylinder, regulator, and

rubber hose must be in a location not

unobstructed. Excessive grease deposits can

result in a grease fi re.

subject to temperature above 125° F (51°

C).

7. The backburner or IR burner cover must be

removed before using the burner.

4. The fl ames on each burner burn evenly along

the entire burner with a steady fl ame (mostly

blue). If burner fl ames are not normal, check

8. Whenever reconnecting any wires, apply a

small amount of dielectric grease to the male

connector, then make the connection.

WARNING: NEVER cover the entire cooking or grill surface with griddles or pans. Overheating will occur, and

burners will not perform properly when combustion heat is trapped below the cooking surface.

CAUTION: NEVER spray water on a hot gas unit.

The grill serial identifi cation number is located on the underside of the drip tray handle. It

is recommended that the drip tray fi rst be removed and cleaned / emptied of its contents,

then turned over to view.

Important: When reviewing this units wiring connections; please refer to the wiring diagram

label affi xed to the inside of the control panel.

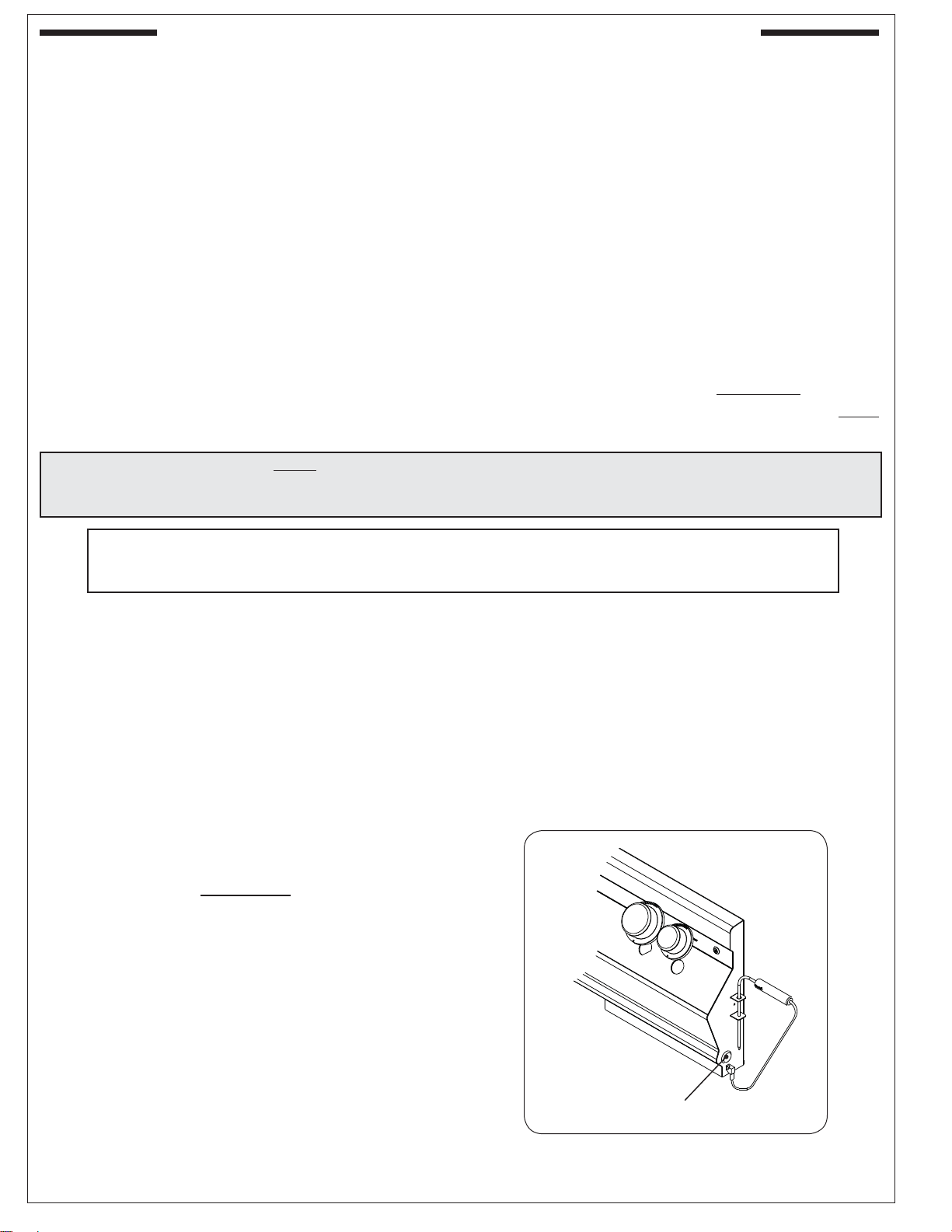

ELECTRICAL CONNECTIONS

This grill requires 120VAC power to operate.

LIGHT SWITCH

The light switch is push button operated, and is

located on the right side of the control panel (see

Plug the power supply cord into a properly wired

Fig. 8-1). It controls the power to all lights.

and inspected GFCI electrical receptacle (15

AMP minimum). Use a heavy-duty grounded

extension cord if necessary.

WARNING

Electrical Grounding Instructions

For your protection against shock hazard, this

outdoor-cooking gas-appliance is equipped with

a three-pronged (grounding) electrical connector.

This appliance should be connected to a properly

grounded three-prong receptacle using a grounding

extension cord rated for outdoor use. Do not cut or

remove the grounding prong from the connector.

Important: ONLY REPLACE THE OVEN LIGHTS

WITH 12V / 10 WATT HALOGEN BULB(S).

REV 8 - 1405291355

Light

switch

8

Fig. 8-1

L-C2-276

Page 9

INSTALLATION REQUIREMENTS

This grill is designed for outdoor use only. DO NOT use this grill

inside a building, garage, enclosed area, or under an unprotected

overhead combustible construction. See the EXHAUST REMOVAL

section on the following page for details on installing under a patio

roof. DO NOT use this grill in or on a recreational vehicle or boat.

Important: If installing this grill in a combustible surround, the

correct R.H. Peterson insulating liner must be used.

Important: Refer to the information below to ensure all

required clearances are met.

The grill must have a minimum clearance of 18" from

combustible materials/items AT ALL TIMES.

For the minimum clearances between the grill and any side or rear

walls, your setup must fall within one (or more) of the following:

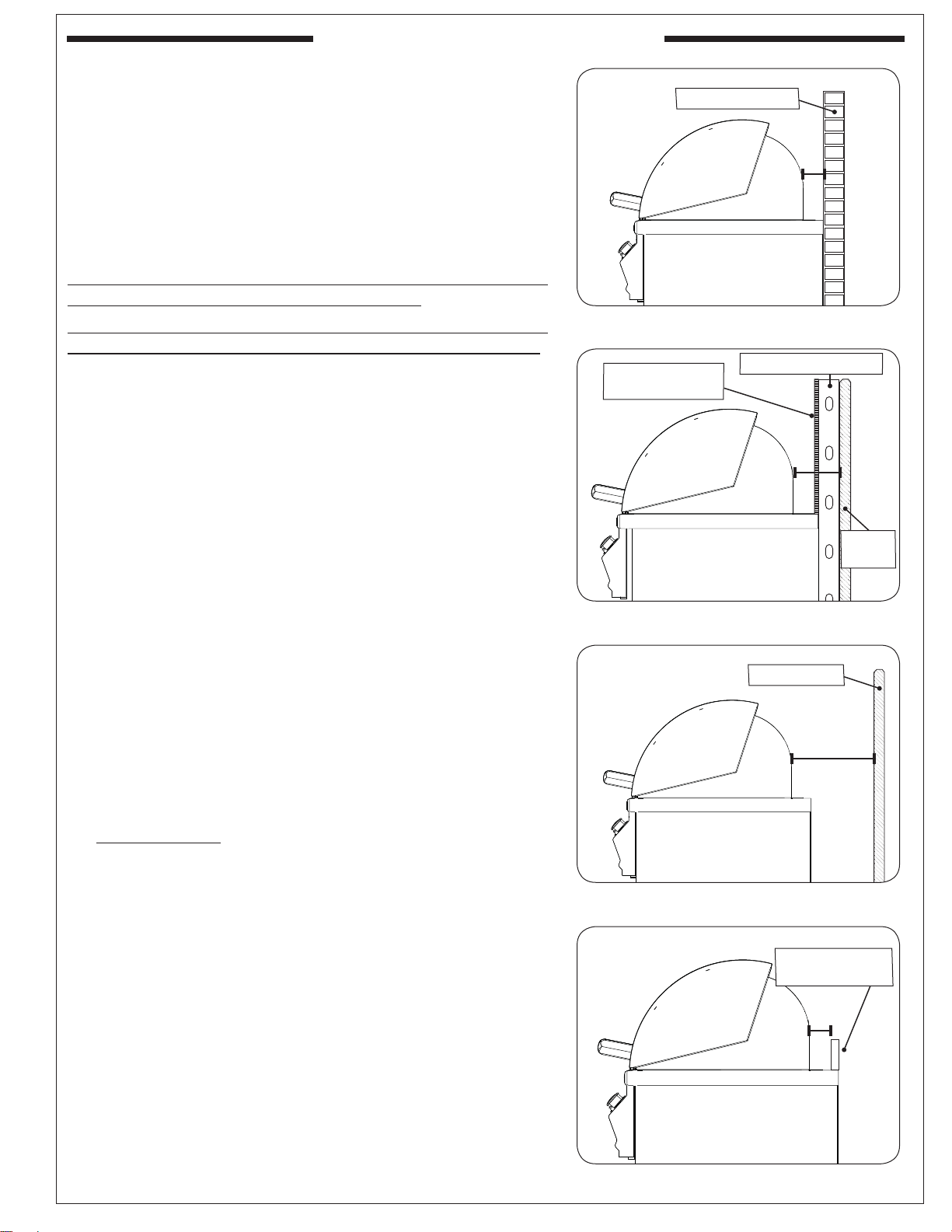

A. Clearance between grill and strictly non-combustible wall

(i.e. brick wall, see Fig. 9-1)

Non-combustible

Min.

4"

(Clearance required for

right, left, and rear)

Fig. 9-1 Clearance 'A' Diagram

Non-combustible

substrate

Non-combustible 4"

• The grill must have a minimum of 4" right, left, and rear

clearance from any non-combustible wall.

(To allow for proper ventilation and prevent dangerous

overheating.)

B. Clearance between grill and a protected combustible wall

(i.e. a non-combustible wall in front of a combustible wall to

serve as a barrier. This can be accomplished by brick, or

a metal stud fi nished with non-combustible substrate, see

Fig. 9-2)

• The grill must have a minimum of 14" right, left, and rear

clearance from the protected combustible wall.

(The 4" non-combustible material plus an additional 10"

clearance between the grill and protected wall.)

C. Clearance between grill and combustible wall

• The grill must have a minimum of 18" right, left, and rear

clearance from any combustible wall (see Fig. 9-3).

Backsplash (if applicable)

If a non-combustible backsplash exists, it must have a minimum

of a 4" clearance from the rear of the grill (to allow for proper

ventilation and prevent dangerous overheating). See Fig. 9-4.

Important: This 4" backsplash clearance must fi rst be met prior

to any non-combustible walls beginning behind it.

Min.

14"

(Clearance required for

right, left, and rear)

Fig. 9-2 Clearance 'B' Diagram

Combustible

Min.

18"

(Clearance required for

right, left, and rear)

Fig. 9-3 Clearance 'C' Diagram

Com-

bustible

REV 8 - 1405291355

Non-combustible

Backsplash

Min.

4"

Fig. 9-4 Backsplash clearance

9

L-C2-276

Page 10

INSTALLATION REQUIREMENTS (Cont.)

The control panel MUST remain removable for servicing

(see PARTS LIST).

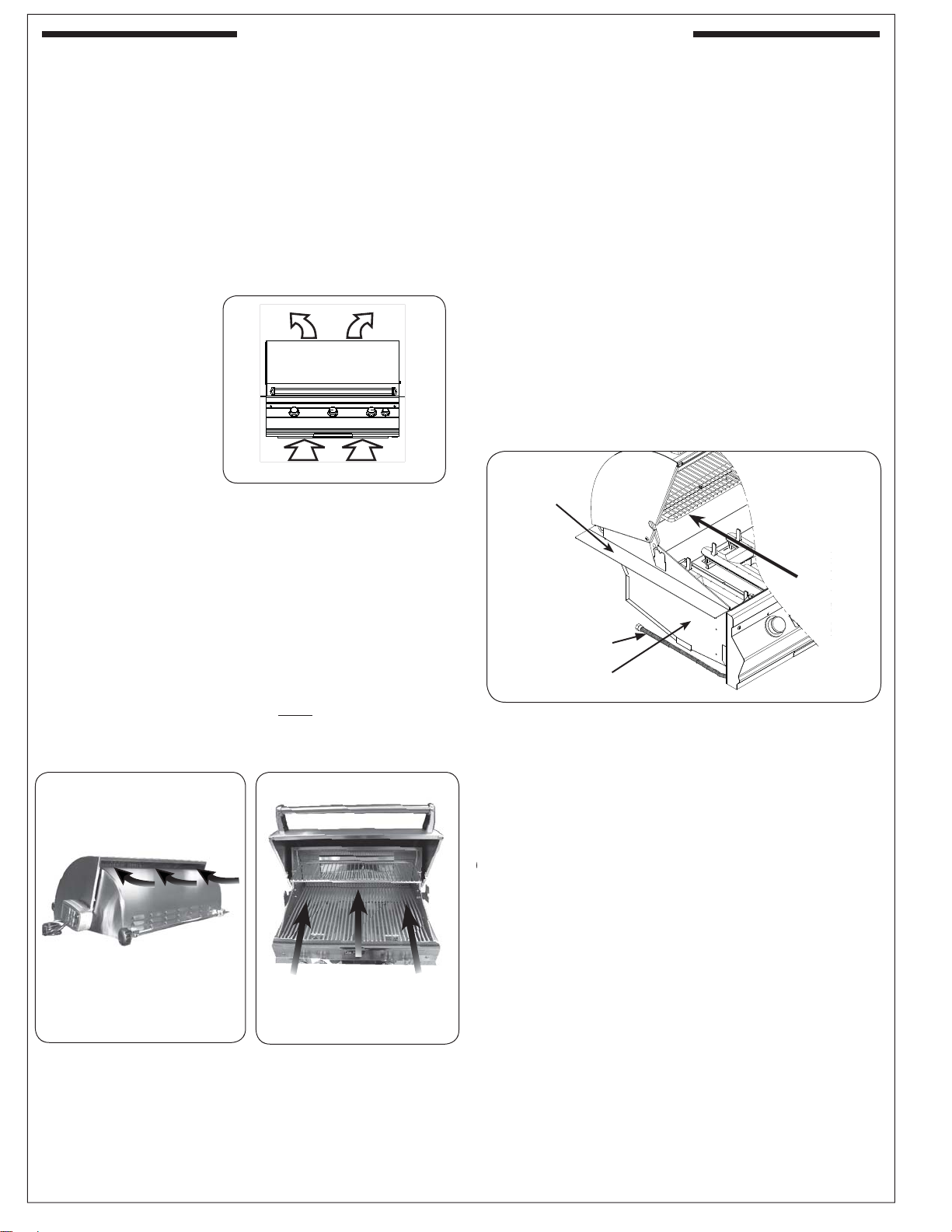

ENSURING PROPER COMBUSTION AIR AND

COOLING AIRFLOW

Proper airfl ow (Fig. 10-1) MUST be maintained for the

grill to perform as it was designed. If airfl ow is blocked,

overheating and poor combustion will result. Do not

block the 1" (2.5 cm) front air inlet along the bottom of

the control panel or more than 75% of the cooking grid

surface with pans or griddles.

Note: The 1" (2.5 cm)

front air space

also allows

access to the

drip tray.

Fig. 10-1 - Ventilation diagram

EXHAUST REMOVAL

If installed or used under a patio roof, the cooking grid

area must be fully covered by an exhaust hood with a vent.

An exhaust fan with a rating of 1,000 CFM (cubic feet per

minute) (472 liters per second) or more may be necessary

to effectively remove smoke and other cooking by-products

from the area under the hood. Fire Magic Vent Hoods

are available to meet this requirement. This grill must

not be used under unprotected overhead combustible

construction. THIS UNIT MUST NOT BE LOCATED IN

A FULLY ENCLOSED AREA OF ANY KIND.

INCORRECT

Rear oven lid vent

YOU MUST PROTECT

REAR OVEN VENT FROM

PREVAILING WIND

Fig. 10-2

CORRECT

PLACE GRILL SO PREVAILING

WIND BLOWS TOWARD FRONT

OF GRILL

Fig. 10-3

GAS-SUPPLY PLUMBING REQUIREMENTS

1

For natural gas or a household propane system, rigid

/2"

(1.3 cm) or 3/4" (1.9 cm) black steel pipe or local codeapproved pipe is required to conduct the gas supply to

the unit. Contact your local gas supplier. Connect this

pipe to the required C.S.A.-approved stainless-steel fl ex

connector (attached). An NPT adapter has been provided

1

for

/2" pipe. DO NOT use a rubber hose within the grill

enclosure. Apply only joint compounds that are resistant

to all gasses to all male pipe fi ttings except fl are fi ttings.

Make sure to tighten every joint securely.

1

Note: If

/2" (1.3 cm) pipe is used with natural gas,

it should be no longer than 20' (6.1 meters).

Important: An external valve (with a removable

key) in the gas line is necessary for

safety when the grill is not in use. It also

provides for convenient maintenance.

Left-side

hanger

Orient grill

so prevailing

wind blows

this way.

Flex connector

Left-side

support wall

CAUTION: Wind blowing into or across the rear

oven lid vent (Fig. 10-2) can cause

poor performance and/or dangerous

overheating. Orient the grill so that the

prevailing wind blows toward the front of

the grill (Fig. 10-3).

GAS SUPPLY AND MANIFOLD PRESSURES:

For natural gas - normal 7" (17.78 cm) water column

(w.c.), minimum 5" (12.7 cm), maximum 10

cm). For propane gas - normal 11" w.c., minimum 10"

(25.4 cm), maximum 13" (33 cm).

Fig. 10-4

1

/2" (26.7

REV 8 - 1405291355

10

L-C2-276

Page 11

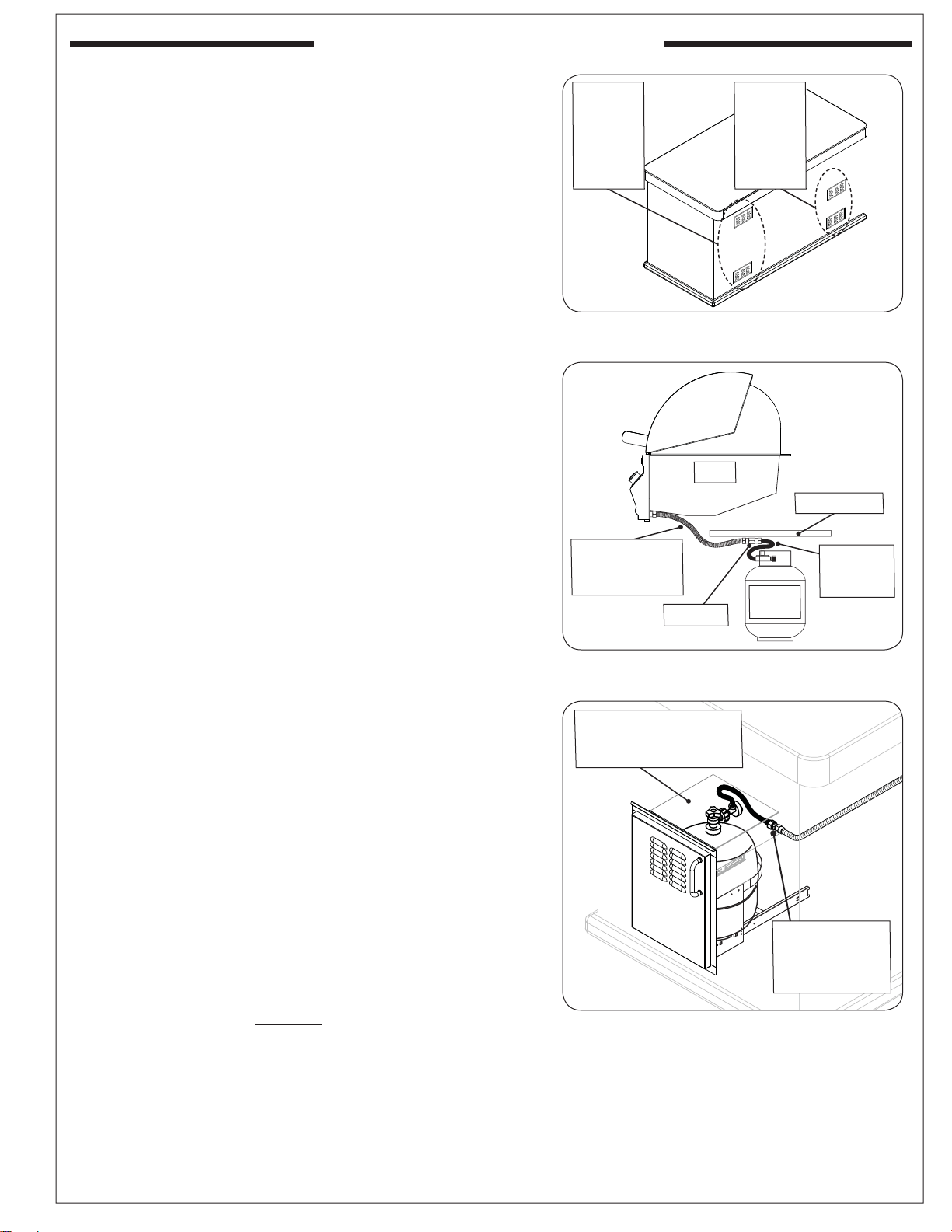

ENCLOSURE REQUIREMENTS

FOR YOUR SAFETY, you must provide the openings listed

below for drainage, replacement air, and cross-ventilation

of any storage area exposed to possible leakage from gas

connections, the unit, or propane cylinders.

One side of the enclosure can be left completely open to

the outside, OR 4 ventilation openings must be created:

NATURAL GAS INSTALLS

Two of the openings are to be at the top level (approx.

4" below the countertop) and on opposite walls of the

enclosure. 2 more openings must be at the fl oor level (no

more than 5" above the fl oor) and on opposite sides of the

enclosure. Each opening must have a minimum of 10 sq.

in. of free area. To achieve the proper ventilation, you may

drill a series of holes, omit the grout from masonry joints,

or replace a brick with a hardware cloth screen. If the fl oor

in the cabinet is raised and the space beneath the cabinet

is open to the outside, the lower ventilation openings may

be in the fl oor. Reference Fig. 11-1.

PROPANE GAS INSTALLS

(HOUSEHOLD & CYLINDER)

Two of the openings are to be at the cylinder valve level

(approx. 16" above the fl oor) and on opposite walls of the

enclosure. 2 more openings must be at the fl oor level (no

more than 5" above the fl oor) and on opposite sides of

the enclosure. Each opening must have a minimum of 10

sq. in. of free area. To achieve the proper ventilation, you

may drill a series of holes, omit the grout from masonry

joints, or replace a brick with a hardware cloth screen. If

the fl oor in the cabinet is raised and the space beneath

the cabinet is open to the outside, the lower ventilation

openings may be in the fl oor. Reference Fig. 11-1.

Nat. gas

installs

(repeat for

opposite

side)

L.P. gas

installs

(repeat for

opposite

side)

Fig. 11-1 Ventilation detail

Grill

Heatshield

C.S.A. listed

stainless steel

fl ex connector

Adapter

L.P.

cylinder

Regulator/

hose

assembly

Fig. 11-2 Propane cylinder orientation

Cylinder & regulator/

hose assembly

protected by heatshield

WHEN A PROPANE CYLINDER IS USED

When a propane cylinder is installed inside of the enclosure,

the guidelines below MUST be followed. FAILURE TO

DO SO MAY CAUSE DAMAGE TO YOUR UNIT AND/OR

PERSONAL INJURY. Reference Fig. 11-2 for an example.

• Only a C.S.A. listed stainless steel connector can be

connected to the grill.

• The regulator/hose assembly coming from the propane

cylinder can only be connected to the above mentioned

grill fl ex connector. DO NOT connect the regulator/

hose assembly directly to the grill. An adapter will

be required.

• A heatshield must be installed to protect the regulator/

hose assembly and propane cylinder valve.

• Fire Magic offers a propane cylinder door with tank

tray to meet the cylinder install requirements. See

Fig. 11-3.

REV 8 - 1405291355

11

Equipped with

adapter for hose

assembly and

fl ex connector

Fig. 11-3 Optional Fire Magic door w/tank tray

L-C2-276

Page 12

INSTALLING THE BUILT-IN UNIT

OFF

Dedicated manual shut-off valve

To gas

system

Cut-out

Countertop

Hanger

Flex

connector

Gas inlet pipe

COUNTER PREPARATION

Consult Table 1 for non-combustible enclosure cut-out

dimensions. A Robert H. Peterson insulating liner must

be used if the counter or any supporting construction is

combustible. Consult the instructions that come with the

liner for dimensions and additional installation information

before beginning the installation.

This outdoor built-in grill must be supported by the

stainless-steel hanger extending from the upper portion

of the grill. The hanger rests on the left, right, and back

of the countertop and on the two front structural supports

with attached adjustable screws located below the control

panel on the left and right sides (see Fig. 12-3).

The control panel is designed to sit fl ush against the

enclosure front wall (see Fig. 12-2). If the non-combustible

enclosure countertop extends beyond the front wall,

creating a countertop overhang (see Fig. 12-1), it must

be cut fl ush with the front wall for the width of the control

panel or a gap will be created exposing the forward

portions of the left and right side grill fi re walls. Reference

the MODEL SPECIFICATIONS section.

Note: It is not necessary to remove the control panel

or knobs to install this unit.

CONNECTING THE GAS SUPPLY

For propane cylinders:

For connecting a propane unit to a portable propane tank,

read the safety warnings and follow the instructions in the

section SAFE USE AND MAINTENANCE OF PROPANE

GAS CYLINDERS.

control panel

stops here

Countertop Countertop

Proposed cutout in overhang

GAP CREATED

Fig. 12-1

Overhang

IDEAL

Flush-mounted

control panel

Fig. 12-2

Note: When a propane cylinder is installed inside

of the enclosure, the guidelines found in the

ENCLOSURE REQUIREMENTS section

MUST be followed.

For household propane or natural gas units:

CAUTION: Use only C.S.A. listed stainless-steel fl ex

connectors within the enclosure.

WARNING

A rubber or plastic connector will rupture or leak,

resulting in an explosion or serious injury if used

inside the appliance enclosure.

a. Run the attached fl ex connector routed under the

left side of the grill out of the enclosure and to the

gas stub.

b. Turn OFF the gas supply at the source. Then

1

connect the

the stainless-steel fl ex connector to the gas-supply

stub. Use pipe joint compound that is resistant to all

gasses on the male pipe fi tting and tighten securely.

DO NOT use pipe joint compound to connect

fl are fi ttings.

d. Turn all burner control knobs to the OFF position.

Turn the gas supply on. Then carefully check all gas

connections for leaks with a brush and half-soap/

half-water solution before lighting. NEVER USE A

MATCH OR OPEN FLAME TO TEST FOR LEAKS.

e. Close the dedicated gas-supply shut-off valve, then

slide the grill into place. Do not to pinch, kink, or

damage the gas connector line.

f. Rotate the adjustable support screws to the left to

raise and to the right to lower the respective side

of the appliance grill. Use a

as needed.

Important: Do not extend the support screws so

/2" pipe adapter fi tting supplied with

7

/16" open-end wrench

far that any part of the hanger is raised

off the counter top.

Bottom

of control

panel

REV 8 - 1405291355

Adjustable

support

screw

Bottom

of cut-out

opening

Fig. 12-3

12

Fig. 12-4

L-C2-276

Page 13

ELECTRICAL INSTALLATION

POWER SUPPLY HOOKUP

CAUTION: IMPROPERLY CONNECTED WIRES

WILL CAUSE DAMAGE TO THE GRILL

AND MAY RESULT IN PROPERTY

DAMAGE AND/OR PERSONAL INJURY.

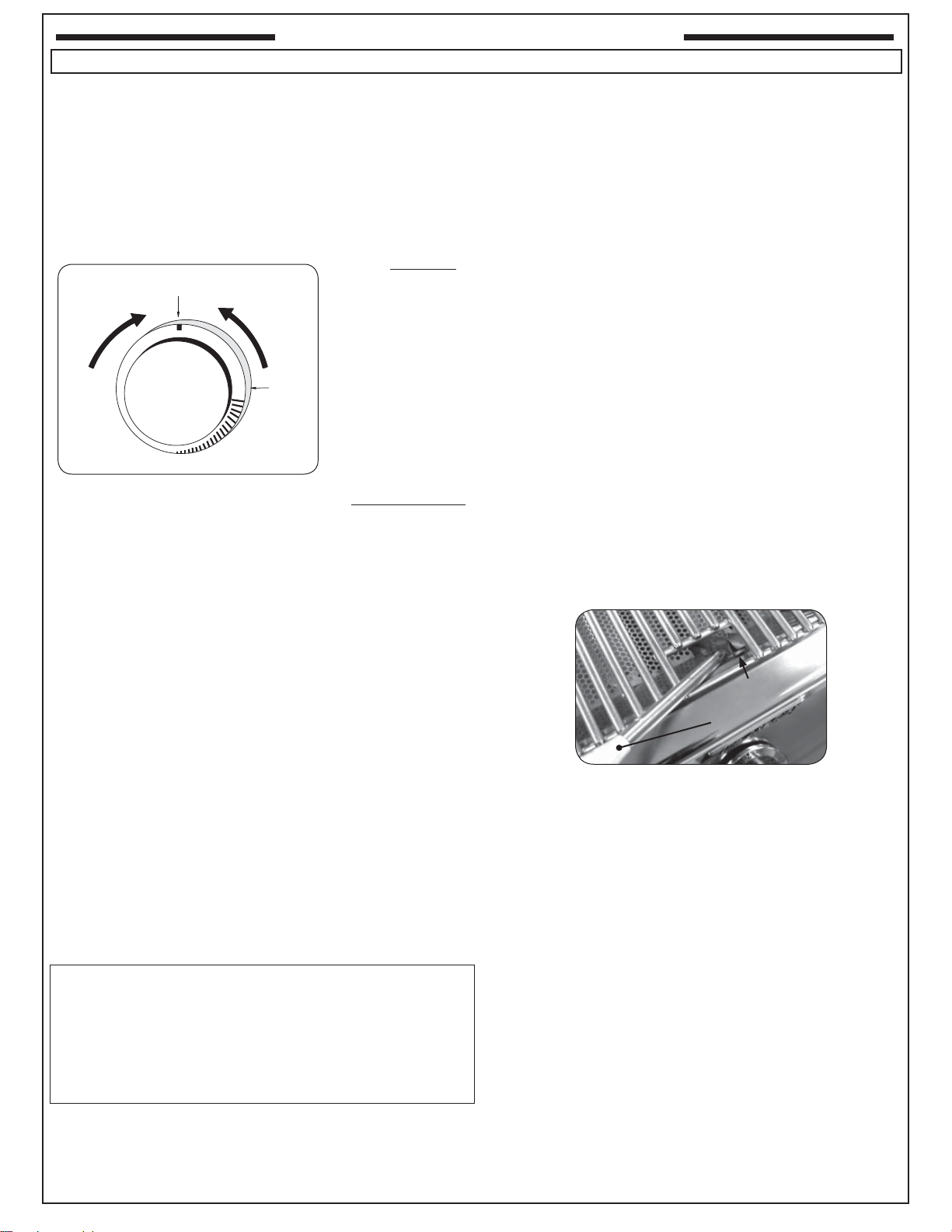

This grill includes a power supply box. When installing

the power supply box:

• It MUST be located at least 12 inches below the

bottom of the grill (see Fig. 13-3).

• The wire extension that exits from the control panel

MUST be routed directly downward. This will prevent

overheating. DO NOT route the wire extension

below the grill (see Fig. 13-3).

Note: For enclosures with a solid area beneath the

grill, a cutout must me made near the wire

extension to allow for the above requirement.

If an insulating liner is installed, route the wire

down through the nearest hole possible.

• DO NOT block the vent holes found on the box.

Required

Required

GFI electrical

GFCI electrical

receptacle

receptacle (not

(not included)

included)

Grounded

plug

Grounded

plug

Fig. 13-1 Power supply detail

Fasten the power supply box to the inside of the

Fig. 13-2 Wire connections

enclosure using appropriate hardware for your enclosure.

The electrical connections from the power supply box to

the grill electrical systems come pre-connected.

WARNING

Electrical Grounding Instructions

This outdoor-cooking gas appliance is equipped with a

three-pronged (grounding) plug. Do not cut or remove

the grounding prong from the plug.

CONNECTING THE POWER SUPPLY TO LINE

Route wires

directly downward

(to prevent

overheating)

12"

Min.

POWER

Plug the power supply cord into a properly wired

and inspected GFCI electrical receptacle (15 AMP

Fig. 13-3 Power supply clearance

minimum). Use a heavy-duty grounded extension cord

if necessary.

ELECTRICAL SAFETY

To protect against electric shock, do not immerse cord or plugs in water or other liquid;

Unplug from the outlet when not in use and before cleaning. Allow to cool before putting on or taking off parts;

Do not operate any outdoor cooking gas appliance with a damaged cord, plug, or after the appliance malfunctions

or has been damaged in any manner. Contact the manufacturer for repair;

Do not let the cord hang over the edge of a table or touch hot surfaces;

Do not use an outdoor cooking gas appliance for purposes other than intended;

When connecting, fi rst connect plug to the outdoor cooking gas appliance then plug appliance into the outlet;

Use only a Ground Fault Circuit Interrupter (GFCI) protected receptacle with this outdoor cooking gas appliance;

Never remove the grounding plug or use with an adapter of 2 prongs.

Use only extension cords with a 3 prong grounding plug, rated for the power of the equipment, and approved

for outdoor use with a W-A marking.

13

Page 14

U

L

UTILISATION SÛRE ET ENTRETIEN DES CYLINDRES DE GAZ DE PROPANE

IMPORTANT POUR VOTRE SÛRETÉ

LISEZ ET SUIVEZ TOUS LES AVERTISSEMENTS ÉQUIPÉS DE VOTRE CYLINDRE DE GAZ DE PROPANE.

En actionnant cet appareil avec un cylindre de gaz de propane ON DOIT observer ces instructions et avertissements.

LE MANQUE DE FAIRE AINSI PEUT AVOIR COMME CONSÉQUENCE UNE INCENDIE OU UNE EXPLOSION SÉRIEUSE.

CYLINDRE ET CONDITIONS ET

CARACTÉRISTIQUES DE CONNECTEUR

a. Des cylindres et les valves de gaz de propane doivent être

maintenus en bon état et doivent être remplacés s’il y a

des dommages évidents au cylindre ou à la valve.

b. Ce gril, une fois utilisé avec un cylindre, devrait être relié à

un gallon de la norme 5 (20lb.) cylindre de gaz de propane

équipé d’un OPD (remplissez au-dessus du niveau le

dispositif d’empêchement). L’OPD a été exigé sur tous les

cylindres vendus depuis octobre 1.1998 pour empêcher le

remplissage excessif.

c. Les dimensions de cylindre devraient être approximativement

12"(30.5cm) de diamètre et 18" (45.7cm) hauts. Des

cylindres doivent être construits et marqués selon les

caractéristiques pour des cylindres de gaz de propane du

département des ETATS-UNIS du transport (D.O.T.) ou

le niveau national du Canada, du CAN/CSA-B339, des

cylindres, des sphères et des tubes pour le transport des

marchandises dangereuses.

d. Le cylindre doit inclure un collier pour protéger la valve

de cylindre et le circuit d’alimentation de cylindre doit être

assuré le retrait de vapeur.

e. Le montage du régulateur de pression et le fl exible (Fig. 14-1)

e. Le régulateur de pression et l’ensemble de tuyau utilisé

fourni avec cet appareil au gaz en plein air (modèles au

doivent assortir les spécifi cations pour le type I par ANSI

propane seulement) doit être utilisé. Assemblées d'origine et

Z 21.58-2005/CGA 1.6-2005 (voir la fi gue. 14-1).

régulateur de pression et le tuyau de remplacement doivent

être ceux spécifi és par le fabricant pour le raccordement d'un

dispositif de cylindre de liaison identifi ée comme de type I par

le 21.58-2005/CGA ANSI Z 1.6 à 2005 (voir liste des pièces

pour les informations de commande).

f. La valve de cylindre de gaz de propane doit être équipée

d’un dispositif d’accouplement de raccordement de

cylindre, décrit comme type I dans la norme défi nie dans le

e. de paragraphe ci-dessus. Ce dispositif est généralement

décrit comme coupleur rapide de fi l de point culminant.

g. Si votre cylindre de gaz de propane vient avec une prise

de la poussière, placez le bouchon anti-poussière sur la

sortie de valve de cylindre toutes les fois que le cylindre

n’est pas en service.

OPÉRATION DE COUPLEUR RAPIDE

Pour relier le regulator/hose à l’ajustage de précision de

valve de cylindre de gaz de propane: Serrez l’écrou de main

sur le régulateur au-dessus de l’ajustage de précision de fi l

de point culminant sur la valve de cylindre. Tournez l’écrou de

main dans le sens des aiguilles d’une montre pour engager les

fi ls et pour serrer jusqu’à ce que douillettement. L’utilisation des

pinces ou de la clé ne devrait pas être nécessaire. Seulement

le propane marqué par cylindres doit être employé.

Pour débrancher: Tournez l’écrou de main dans le sens

contraire des aiguilles d’une montre jusqu’à isolé (fi g. 14-1).

Important: Avant d’employer le gril, et ensuite chaque

fois que le cylindre est enlevé et rattaché,

examinez tous les raccordements pour déceler

les fuites. Arrêtez les valves de gril et ouvrez

la valve principale de cylindre, puis vérifi ez

les raccordements avec de l’eau savonneux.

Réparez toutes les fuites avant d’allumer le gril.

ATTENTION: Tournez toujours la valve principale de cylindre

de propane au loin après chaque utilisation,

et avant de déplacer le gril et le cylindre, ou

débrancher l’accouplement. Cette valve doit

rester fermée et le cylindre a débranché alors

que l’appareil n’est pas en service, quoique

l’écoulement de gaz soit arrêté par un dispositif

de sûreté quand le coupleur est débranché.

Inspectez soigneusement l’ensemble de tuyau chaque fois

avant que le gaz soit allumé. Un tuyau fi ssuré ou effi loché doit

être immédiatement remplacé.

Si l'appareil est stocké à l'intérieur, le cylindre doit être disconnected

et a enlevé. Des cylindres Disconnected doivent être stockés

dehors, hors de la portée des enfants, avec les prises de valve

fi letées étroitement installées, et ne doivent pas être stockés dans

un bâtiment, le garage, ou n'importe quel autre secteur inclus.

POUR VOTRE SÛRETÉ

a. Ne stockez pas un cylindre de gaz disponible de propane

dessous ou ne vous approchez pas de cet appareil.

b. Ne remplissez jamais cylindre au delà de 80 pour cent de

plein.

c. SI L’INFORMATION DANS “A” ET “B” N’EST PAS SUIVIE

EXACTEMENT, UN FEU CAUSANT LA MORT OU DES

DOMMAGES SÉRIEUX PEUT SE PRODUIRE.

Fig. 14-1 type coupleur rapide de fi l de point culminant d’I

Volant de commande

QCC

Type 1

Valve

Valve

de

décompression

1

Ajustage de précision

en laiton de fi l de

point culminant

4

Indicateur

de niveau

de liquide

(facultatif)

3

2

Écrou de main avec le

fi l de point culminant.

Régulateur

Passage

Tuy au

Pour la ventilation de propane, voir la section sur les exigences de boîtier.

14

Page 15

U

L

SAFE USE & MAINTENANCE OF PROPANE GAS CYLINDERS

IMPORTANT FOR YOUR SAFETY

READ AND FOLLOW ALL WARNINGS PROVIDED WITH THE PROPANE-GAS CYLINDER.

When operating this appliance with a propane-gas cylinder, these instructions and warnings MUST be observed.

FAILURE TO DO SO MAY RESULT IN A SERIOUS FIRE OR EXPLOSION.

CYLINDER/CONNECTOR REQUIREMENTS

a. Propane-gas cylinders, valves, and hoses must be

maintained in good condition and must be replaced if

there is visible damage to either the cylinder or valve. If the

hose is cut or shows excessive abrasion or wear, it must

be replaced before using the gas appliance (see e.).

b. This unit, when used with a cylinder, should be connected

to a standard 5-gallon (20 lb.) propane-gas cylinder

equipped with an OPD (Overfi ll Prevention Device).

The OPD has been required on all cylinders sold since

October 1,1998, to prevent overfi lling.

c. Cylinder dimensions should be approximately 12" (30.5

cm) in diameter and 18" (45.7 cm) high. Cylinders must

be constructed and marked in accordance with the

Specifi cations for Propane Gas Cylinders of the U.S.

Department of Transportation (D.O.T.) or the National

Standard of Canada, CAN/CSA-B339, Cylinders,

Spheres, and Tubes for Transportation of Dangerous

Goods.

d. The cylinder used must include a collar to protect the

cylinder valve, and the cylinder supply system must be

arranged for vapor withdrawal.

e. The pressure regulator and hose assembly used must

e. The pressure regulator and hose assembly (Fig. 15-1)

match the specifi cation for Type I by ANSI Z 21.58-2005/

supplied with this outdoor gas appliance (L.P. models

CGA 1.6-2005 (see Fig. 15-1).

only) must be used. Original and replacement pressure

regulator and hose assemblies must be those specifi ed

by the manufacturer for connection with a cylinder

connecting device identifi ed as Type I by the ANSI Z

21.58-2005/CGA 1.6-2005 (see PARTS LIST for ordering

information).

f. The propane-gas cylinder valve must be equipped with a

cylinder connection coupling device, described as Type I

in the standard defi ned in paragraph e. above. This device

is commonly described as an Acme thread quick coupler.

g. If the propane-gas cylinder comes with a dust plug, place

the dust cap on the cylinder valve outlet whenever the

cylinder is not in use.

QUICK COUPLER OPERATION

To connect the regulator/hose assembly to the propanegas cylinder valve fi tting: Press the hand nut on the regulator

over the Acme thread fi tting on the cylinder valve. Turn the hand

nut clockwise to engage the threads and tighten until snug.

The use of pliers or a wrench should not be necessary. Only

cylinders marked “propane” may be used.

To disconnect: Turn the hand nut counterclockwise until

detached (Fig. 15-1).

Important: Before using the unit, and after each time the

cylinder is removed and reattached, check

the hose for wear (see a.) and check all

connections for leaks. Turn off the unit valves

and open the main cylinder valve, then check

connections with soapy water. Repair any

leaks before lighting the unit.

CAUTION: Always turn the propane cylinder main valve

off after each use, and before moving the unit

and cylinder or disconnecting the coupling.

This valve must remain closed and the

cylinder disconnected while the appliance

is not in use, even though the gas fl ow is

stopped by a safety feature when the coupler

is disconnected.

Carefully inspect the hose assembly each time before the

gas is turned on. A cracked or frayed hose must be replaced

immediately.

If the appliance is stored indoors, the cylinder must be

disconnected and removed. Disconnected

cylinders must be

stored outdoors, out of the reach of children, with threaded

valve plugs tightly installed, and must not be stored in a

building, garage, or any other enclosed area.

FOR YOUR SAFETY

a. DO NOT store a spare propane-gas cylinder under or

near this appliance.

b. NEVER fi ll the cylinder beyond 80-percent full.

c. IF THE INFORMATION IN a. AND b. IS NOT FOLLOWED

EXACTLY, A FIRE CAUSING DEATH OR SERIOUS

INJURY MAY OCCUR.

Fig. 15-1 Type I Acme thread quick coupler

QCC

Type 1

valve

Pressure

relief

valve

Hand wheel

Brass Acme

thread fi tting

Liquid level

indicator

(optional)

Hand nut with Acme

thread

Regulator

Vent

Hose

For propane ventilation requirements, see the ENCLOSURE REQUIREMENTS section.

15

Page 16

IDENTIFICATION OF GRILL CONTROLS

Right

Control panel

screw(s)

Left

main burner

control knob

Digital

Thermometer

Drip

tray

Light switch

A430i and A530i controls

To remove the control panel:

Turn off the gas shutoff valve.

•

• Pull off the control knobs. Unscrew and remove the control panel

screws and washers.

• Lift the control panel up and outward, allowing it to rest on the

internal chain(s).

main burner

control knob

Backburner

control knob

(if equipped)

Meat probe

Fig. 16-1

Important: During reinstallation;

valve, be sure the control knobs are in the OFF position.

Center main burner

Control panel

screw(s)

Left

main burner

control knob

Digital

thermometer

Drip

tray

A540i, A660i, and A790i controls

prior to opening the gas shutoff

control knob

Light switch

Right

main burner

control knob

Backburner

control knob

(if equipped)

Meat probe

Fig. 16-2

16

Page 17

LIGHTING (IGNITION) INSTRUCTIONS

Read all instructions before lighting, and follow these instructions each time you light the unit.

ELECTRONIC LIGHTING

Note: Grill must be connected to 120VAC power for

Note: Electronic lighting requires an installed 9-volt

electronic lighting.

battery with a good charge.

1. Open lid(s) or remove cover(s) from burner(s) to be lit.

2. Turn all gas control knob(s) to their OFF position(s).

3. Turn on the gas at its source.

Read setting here

Read setting

(OFF position shown)

TURN OFF

To Turn OFF

TO

Press

knob in

to turn

Fig. 17-1 - Control knob

here

OFF

LOW

To Turn ON

TO TURN ON

LIGHT

HI

HIGH to

Use

LIGHT

HI (high)

to light

4. Depress the desired control knob for 5 seconds,

then, while pressing turn it counterclockwise to the

HI LIGHT position. Once the burner lights, release

the knob.

Note: DO NOT

turn on more

than one valve at

a time for either

electronic or

manual lighting.

MANUAL LIGHTING

CAUTION: Always wait fi ve (5) minutes for gas to

clear after any unsuccessful lighting

attempt.

1. Follow steps 1 through 3 (left).

2. Insert either a burning long-barrel butane lighter or

a burning long-stem match through the cooking grid

opening to the top of the lighting tube. (Fig. 17-2).

For backburners, hold the flame

against the surface of the backburner.

For sideburners, hold the fl ame against the burner.

3. While holding the match or lighter fl ame at the top of

3. While holding the match or lighter fl ame at the top

the lighting tube or next to the burner (backburner

of the lighting tube or next to the burner (sideburner

only), depress the desired control knob and while

and backburner only), depress the desired control

pressing turn it counterclockwise to the HI LIGHT

knob and while pressing turn it counterclockwise to

position. Remove the lighter or match when the

the HI LIGHT position. Remove the lighter or match

burner lights, and release the control knob.

when the burner lights, and release the control

knob.

4. If the burner does not light, immediately depress

the knob and turn the valve to OFF. WAIT FIVE

(5) MINUTES before repeating steps 2 through 4

of the MANUAL LIGHTING instructions.

CAUTION: If a burner does not light within fi ve (5)

seconds of turning on the control knob,

depress the knob and turn it to the OFF

position. WAIT FIVE (5) MINUTES

before repeating step 4. If you smell

gas, follow the instructions on the cover

of this manual. If the burners still do not

light after several attempts, refer to the

instructions for manual lighting.

5. Repeat step 4 for each additional burner to be lit.

WHEN USING A PORTABLE PROPANE TANK

Propane tanks are equipped with a safety shutdown

device that may cause low or no gas pressure/fl ame

at the burners if operating and lighting instructions

are not followed exactly (See important note in the

TROUBLESHOOTING section for more details.)

Lighting

tube

Lighter

Fig. 17-2 - Manual lighting

SHUTTING OFF THE UNIT

To shut off the unit, depress each valve control knob

and, and while pressing turn it clockwise to the OFF

position.

Always close the valve from the gas supply after each

use of the unit.

17

Page 18

ALLUMAGE DES INSTRUCTIONS (D’ALLUMAGE)

Lisez toutes les instructions avant l’allumage, et suivez ces instructions chaque fois vous lumière le unité.

ÉCLAIRAGE ÉLECTRONIQUE

Note: Le unité doit être relié à la puissance 120VAC pour

Note: L’éclairage électronique exige une batterie installée

l’éclairage électronique.

de 9 volts avec une bonne charge.

1. Ouvrez les couvercles ou enlevez les couvertures des brûleurs

pour être Lit.

2. Tournez tous les boutons de commande de gaz à leurs

positions de repos.

3. Allumez le gaz à sa source.

Lisez l’établissement ici

Read setting

(OUTRE de montrer)

here

TURN OFF

OUTRE DE

TO

Enfoncez

le bouton

pour

tourner

Fig. 18-1 - bouton de commande

OFF

LOW

TO TURN ON

LIGHT

HI

SUR

HIGH to

Utilisation

LIGHT

SALUT

(haute)

à la lumière

4. Diminuez le bouton de commande désiré pendant 5

secondes, puis, et tout en pressant le tour il dans le sens

contraire des aiguilles d’une montre dans la position

LÉGÈRE de HI. Une fois que le brûleur s’allume, libérez

le bouton.

Note: N’ouvrez

pas plus d’une

valve à la fois

pour l’éclairage

électronique ou

manuel.

ÉCLAIRAGE MANUEL

ATTENTION: Attendez toujours cinq (5) minutes le gaz

pour se dégager après que n’importe quelle

tentative non réussie d’éclairage.

1. Suivez les étapes 1 à 3 (à gauche).

2. Passez un allumeur brûlant de butane de long-baril ou

une allumette brûlante de long-tige dans la grille à cuire

s’ouvrant au dessus du tube d’éclairage. (Fig. 18-2). Pour

des backburners, tenez la fl amme contre le surface du

backburner. Pour des sideburners, tenez la fl amme contre

le brûleur.

3. Tout en tenant l’allumette ou la flamme plus légère

3. Tout en tenant l’allumette ou la flamme plus légère

au dessus du tube d’éclairage ou à côté du brûleur

au dessus du tube d’éclairage ou à côté du brûleur

(sideburner et backburner seulement), diminuez le

(backburner seulement), diminuez le bouton et tout en

bouton et tout en pressant le tour de commande désirés

pressant le tour de commande désirés il dans le sens

il dans le sens contraire des aiguilles d’une montre

contraire des aiguilles d’une montre dans la position

dans la position LÉGÈRE de HI. Enlevez l’allumeur ou

LÉGÈRE de HI. Enlevez l’allumeur ou assortissez quand

assortissez quand le brûleur s’allume, et libérez le bouton

le brûleur s’allume, et libérez le bouton de commande.

de commande.

4. Si le brûleur ne s’allume pas, enfoncez immédiatement

le bouton et tournez la valve à AU LOIN. ATTENDEZ

CINQ (5) MINUTES avant de répéter les étapes 2 à 4

des instructions manuelles d’éclairage.

ATTENTION : Si un brûleur ne s’allume pas dans cinq

(5) secondes d’allumer le bouton de

commande, enfoncez le bouton et tournezle à la position de repos. ATTENDEZ CINQ

(5) MINUTES avant de répéter l’étape 4. Si

vous sentez le gaz, suivez les instructions

sur la couverture de ce manuel. Si les

brûleurs ne s’allument toujours pas après

que plusieurs tentatives, se rapportent aux

instructions pour l’éclairage manuel.

5. Répétez l’étape 4 pour que chaque brûleur additionnel soit Lit.

EN EMPLOYANT UN RÉSERVOIR DE PROPANE PORTATIF

Des réservoirs de propane sont équipés d’un dispositif

d’arrêt de sûreté qui peut ne pas causer le bas ou aucunes

pression de gaz/fl amme aux brûleurs si le fonctionnement

et l’allumage des instructions ne sont pas suivis exactement

(voir la note importante dans la section de dépannage pour

plus de détails.)

Tube

d’éclairage

Plus léger

Fig. 18-2 - Éclairage manuel

ARRÊT DU UNITÉ

Pour couper le unité, diminuez chaque bouton de commande

de valve et, et tout en pressant tour il dans le sens des

aiguilles d’une montre à la position de repos.

Fermez toujours la valve de la fourniture de gaz après chaque

utilisation du unité.

18

Page 19

DIGITAL THERMOMETER

MENU

SET

®

MENU

SET

®

078

080170

350

TEMP

SET ACT

°F

MEAT

OVEN

TIMER

00:00

MENU

SET

®

OVEN

ACTUAL: 078

SET TEMP: 350

Your grill comes with a digital thermometer for oven and

meat probe temperature monitoring, and timed cooking.

Pressing the power button will turn on the thermometer. The

thermometer will automatically shut off after 5 minutes if no

temperature change is detected.

The thermometer is located on the control panel between

the control knobs.

Plug in the meat probe on the right side of the control panel

as shown in Fig. 19-1.

Meat probe plug

Meat probe handle

MEAT

PROBE

FOR BEST PERFORMANCE, GENTLY PRESS THE

BUTTONS. When turned on, accurate temperature readings

will begin after the thermometer has initialized. When turned

off, allow 5 seconds prior to turning back on.

Read the following sections completely regarding

thermometer operation. Refer to Fig. 19-2 for thermometer

orientation and button locations.

DEFAULT SCREEN

Press the power button to turn the thermometer ON. The

default screen will be displayed. Temperatures for the oven and

meat probe will be shown (Fig. 19-3). See below for options

under the default screen.

Setting a Location Temperature

1. Press the up/down arrow to switch to the desired location

(oven or meat probe). Location will be highlighted when

selected. Press SET.

2. The selected location’s temperature screen will be

displayed. Use the arrows to set the desired temp. The

actual temp. will also be shown. (See Fig. 19-4)

Timer

button

Menu

button

Power

button

Time set via Timer

Oven temp.

info

Meat probe

temp. info

Fig. 19-1 Meat probe detail

Display screen

Fig. 19-2 Orientation

Arrows for

adjusting digits

SET button

for selecting &

confi rming

Note: PRESSING the arrows will adjust the desired

temp. by increments of one degree. HOLDING

them down (for several seconds) will adjust the

temp. rapidly.

3. Press SET to return to the default screen. Repeat as

necessary for other location.

The display will fl ash red and the alarm will sound (if set

to do so) when the oven / meat probe reaches its set

temperature. The alarm is silenced by pressing any button

on the thermometer.

Fig. 19-3 Default screen detail

Current location

Use arrows

to set

Set this temp. as desired

Fig. 19-4 Location temp. screen (oven shown)

19

Page 20

DIGITAL THERMOMETER (cont.)

MENU

SET

®

SETUP

GRILL GUIDE

ALARM

BACKLIGHT

MENU

SET

MED

RARE

WELL

DONE

170

170

180

160

N/A

160

150

N/A

150

140

N/A

140

BEEF

PORK

LAMB

PROBE

TEMP

MEDRARE

®

MENU

SET

05:00

TIMER

®

Setting the Timer

1. Press the timer button. Use the arrows to set the desired

amount of time (see Fig. 20-1.)

Set time as desired

2. Press SET to return to the default screen.

The time remaining will be shown on the default screen. Once

the time reaches zero; the display will fl ash red and the alarm

will sound. The alarm is silenced by pressing any button on the

thermometer.

MENU SCREEN

Press the power button to turn the thermometer ON. The

default screen will be displayed. Press the MENU button to

display its screen. Press the up/down arrow to scroll through

the options. (See Fig. 20-2.) See below for options under the

menu screen.

Note: The menu screen will return to the default screen after

approximately 30 seconds of no activity. Press the

MENU button to manually return to the default screen.

Changing temperature units (°C/°F)

1. Under the menu screen select SETUP. Press SET.

2. Press the up/down arrow to select SETUP FC. Press SET.

3. Press the up/down arrow to select the desired temperature

unit (°C/°F).

Use arrows

to set

Timer button

Fig. 20-1 Timer screen

Fig. 20-2 Menu screen

4. Press SET to return to the menu screen.

Grill Guide and Meat Probe

The grill guide displays recommended ready temperatures for

various meats.

1. Under the menu screen select GRILL GUIDE. Press SET.

2. Press the up/down arrow to view the desired meat.

3. Note the temp. and press SET. This will take you to the

meat probe temperature screen.

4. Use the arrows to set the noted temp.

5. Press SET to return to the default screen.

Putting the meat probe into the cooking meat will give an actual

temp. reading. The display will fl ash red and the alarm will sound

(if set to do so) when the actual temp. reaches the set temp. The

alarm is silenced by pressing any button on the thermometer.

Note: Do not leave the meat probe in the meat for a

prolonged period of time, or with the hood closed.

Note: The meat probe is calibrated specifi cally for use at

temperatures between 130°F and 180°F.

Use arrows

to view

desired

meat

Fig. 20-3 Grill Guide screen

20

Page 21

MENU

SET

®

OFF

OFF

ON

BACKLIGHT

RED

GREEN

BLUE

MENU

SET

®

OFF

ON

OVEN

PROBE

DIGITAL THERMOMETER (cont.)

Setting the Alarm

The alarm can be individually set (ON or OFF) for the meat

probe and oven temp. The default setting has the alarm OFF

for the meat probe and oven temp. The alarm always alerts

for the TIMER.

1. Under the menu screen select ALARM. Press SET.

Use arrows

to select

desired

alarm

2. Use the up/down arrow to select the desired alarm,

and press the power button to turn the alarm ON/OFF.

3. Press SET to return to the menu screen.

Setting the Thermometer Backlight

The default color for the thermometer backlight is blue. The

color may be changed as desired by turning the three base

colors ON/OFF. Various combinations will result in different

colors.

1. Under the menu screen select BACKLIGHT. Press SET.

2. Use the up/down arrow to select the desired color, and

press the power button to turn the color ON/OFF.

3. Press SET to return to the menu screen. The new color

will be displayed.

Note: Turning all colors OFF will result in no backlight.

Press power button

to turn ON/OFF

Fig. 21-1 Alarm screen

Use arrows

to select

desired

color

Press power button

to turn ON/OFF

Fig. 21-2 Backlight screen

21

Page 22

OPTIONAL ROTISSERIE

FIREMAGIC

FIREMAGIC

Rotisserie

rod bracket

B

1

Fig. 22-1

Heavy-duty

Rotisserie motor

2

Rotisserie motor

slots (4)

Fig. 22-4

Backburner

(unlit)

Drip tray

liner

A

Rod drive socket

1

Rocker

switch

Fig. 22-2

loosen/

tighten

Backburner cover

Rotisserie

motor

bracket

Meat

holders

Rotisserie

motor bracket

Warming rack

Counterbalance

Rotisserie motor

Fig. 22-5

Arm

slide

Rotisserie rod

rear bracket

Rotisserie

rod

and

knob

Rotisserie

motor

Rod drive socket

Fig. 22-3

CAUTION: WHEN USING THE BACKBURNER; KEEP

THE OVEN LID CLOSED TO PREVENT HEAT

LOSS, PROVIDE PROPER CONVECTION,

AND PROVIDE PROPER VENTING. THIS WILL

ENSURE EVEN COOKING TEMPERATURES.

DO NOT KEEP YOUR OVEN LID OPEN DURING

ROTISSING, AS THIS MAY CAUSE PERSONAL

INJURY, OR IN SOME CASES, IN WINDY

CONDITIONS, DAMAGE TO THE GRILL.

DO NOT USE THE ROTISSERIE MOTOR IN THE

RAIN. DO NOT LEAVE THE MOTOR ON THE

GRILL WHEN NOT IN USE.

1. Remove warming rack, backburner cover, and cooking grids.

Leave the fl avor grids on if possible.

2. Slide rotisserie motor fully onto motor bracket (right side,

Fig. 22-2 or Fig. 22-3, and Fig. 22-1).

3. Remove rotisserie rod from rear bracket (Fig. 22-1) and

attach knob if necessary.

4. Slide the left meat holder onto the rod (and tighten), the

meat onto the rod and into the holder, followed by the right

meat holder onto the rod and into the meat as shown in

Fig. 22-4. Tighten the right meat holder. Be sure the meat

is centered and balanced as well as possible.

7. Hold both ends of the rod so it settles freely (do not grip

tightly). Allow the rod to rotate until the heavy side of the

meat rests downward.

8. The counterbalance may then be attached to even weight

distribution. Slide counterbalance onto rod next to the meat

holder. Loosen the arm and point it upward opposite the

heavy side of the meat. Tighten the arm.

9. Slide the counterbalance weight up or down the arm until

the rod rotates most evenly then tighten thumb screw (Fig.

22-5 and Fig. 22-6).

10. Insert the pointed end of the rod into the motor drive socket

and the groove next to the knob into the left support bracket.

11. To keep drippings off the burners and simplify cleanup,

place Fire Magic® drip tray liners under the meat, if desired

(Fig. 22-4).

12. Plug-in the rotisserie motor and press the rocker switch to

start.

13. Light backburner per lighting instructions in this manual (or

on drip tray handle) and close oven lid.

Important: Turn the backburner to low or off when stopping

the rotisserie to prevent overcooking.

Fig. 22-6

Backburner

(lit)

Thumb

screw

Weight

Left support bracket

22

Page 23

O

FF

HI

LIGHT

LOW

OFF

HI

LIGHT

L

O

W

OPTIONAL INFRARED BURNER OPERATION

The infrared (IR) searing burner (optional) cooks with

a powerful radiant heat.

Cover

Cut-out for

Flash tube

Ignitor

Flash tube

electrode

Fig. 23-1

Light the infrared burner following the LIGHTING

INSTRUCTIONS in this manual or printed on the

drip tray. Follow these guidelines when operating the

Infrared burner:

• DO NOT place food on the cooking grid until

the IR burner glows orange (Fig. 23-3). Drippings

are heated and evaporate instead of sticking to and

impairing burner function.

• For cleaning purposes; always leave your burner

on (after cooking) for an additional 5 minutes, to

allow for a burnoff period. This is important to

keep your burner clean and operating properly.

WARNING

Only handle the infrared burner cover when the

grill is cold or with a well-insulated long-handled

tool or heat resistant gloves.

SIDE VIEW (with cover on)

Ignitor

Cover

Food

particles

or debris

electrode

Flash

tube

Fig. 23-2

NO foreign

objects

Airborne

dust or

grease

Drippings

and other

liquids

Burner ceramic must be protected with cover when

burner is not in use.

SIDE VIEW

(burner on HI LIGHT

and glowing orange)

Ignitor

electrode

Flash

tube

As the burner is self cleaning (at full temperature);

avoid the use of cleaners or abrasives.

• When not in use, always cover the infrared burner

with the stainless-steel cover. This protects the

burner from drippings (from other cooking), airborne

particles, and foreign objects (Fig. 23-2).

• Do not strike or scratch the burner ceramic as it

may chip, crack, or break (Fig. 23-2).

Note: Digital thermometer does not give accurate

readings for infrared burners.

Important: When grilling with the infrared burner,

always place a cooking grid above it.

The cooking grid must be removed for

rotisserie cooking.

CAUTION: DO NOT operate your IR burner with the

oven hood closed.

CAUTION: Never attempt to operate the IR burner

with the protective cover in place.

Fig. 23-3

Drips and particles evaporate before hitting infrared

burner when cooking at the maximum setting.

Note: Flavor grids are not to be used with infrared

burners.

To ensure proper operation, all infrared burners

(back and main) must be operated on the HI setting

for a minimum of 10 minutes. Thereafter, the fl ame

may be lowered as desired.

CAUTION: Always monitor the infrared burner fl ame

when operated on low, as it may blow

out in high-wind conditions.

23

Page 24

GRILLING TIPS

The art of grilling involves learning the nuances of your

grill and knowing how various cuts of meat and other

foods cook on it under different settings and conditions.

Each grill will be unique due to its configuration

and how it is positioned or installed. This section

contains information about how Fire Magic grills were

engineered, which will help you in learning how your

grill responds to the way you use it.

WIND CONSIDERATIONS

Wind direction can have an effect on the grill,

especially with the oven open. For maximum stability

and convenience, position the grill so that the oven

opens toward any prevailing wind (Fig. 24-1).

GRILL HEAT DISTRIBUTION - MAIN BURNERS

The heat level at each part of the grill has been

engineered for specifi c purposes. Knowing the heat

distribution for each burner will allow you the best

possible food positioning when grilling.

CAUTION: Even the coolest part of the grill is too

hot to be touched during operation of

the grill.

The front of the grill is designed, for safety reasons,

to be the coolest part of the grill. If you look directly

down on the grill top, while it is off and cool, you can

see this portion of the grill, where the front end of each

burner stops and the slope of the inner grill fi re wall

begins. This area also loses heat most rapidly when

the oven lid is opened (see Fig. 24-2).

From the front of the grill moving toward the back, the

heat rises gradually until just above the burner’s front

edge, where it rises rapidly to a fairly even temperature

refl ected by the thermometer. The heat continues to

rise gradually until it reaches a maximum directly

above the place where the two lobes of each burner

connect (see Fig. 24-2). From there to the back of

the grill, heat diminishes moderately. This supports

the desired temperature for the warming rack and

prevents heat from becoming excessive at the back

fi re wall of the grill.

Fig. 24-1

Orient barbecue so prevailing

wind blows in this direction

Fig. 24-2

Medium heat

High heat

Medium heat

Low heat

GRILL HEAT DISTRIBUTION - IR BURNER

Infrared burners are designed for even, searing

heat across their whole surface. Because the heat

is radiant, it tends to heat the food you are cooking

directly without heating the air around it as much as

a conventional burner.

24

Page 25

ACCESSORIES

THE GRILL BRUSH (optional)

Purchase a Fire Magic® stainless-steel grill brush (sold

separately) to keep your grill cleaner. It comes with

scraper for large particles and a replaceable head with

brass bristles for overall cleaning.

Fig. 25-1

Grill brush with replacement head

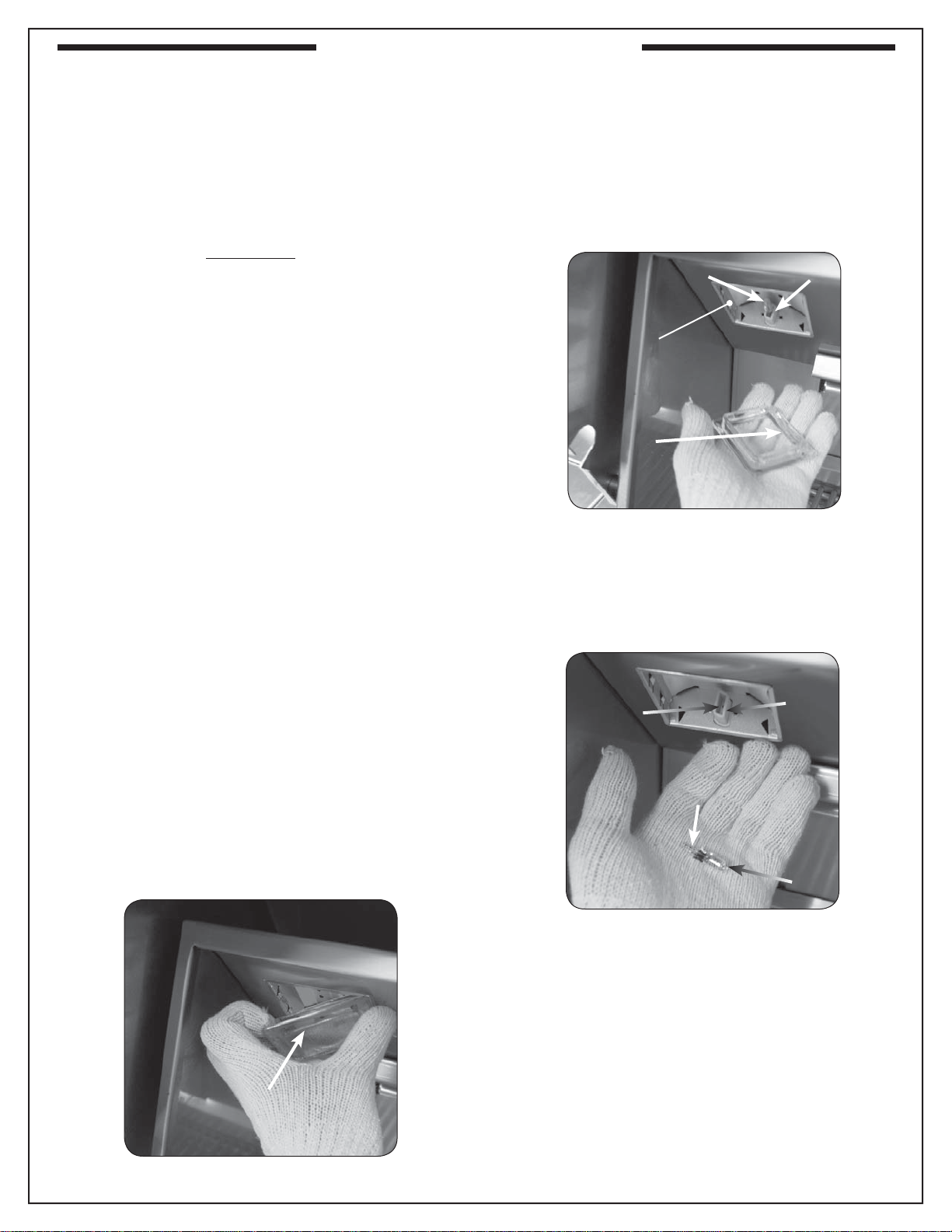

THE COOKING GRID LIFTER

Hold the grid lifter by gripping the center section with the

prongs pointing down (use an oven mitt or heavy glove

if the grill is hot). Insert the notched end of the grid lifter

into the cooking grid, in front of the midway point (front

to back; Fig. 25-3), and central (left to right; Fig. 25-4).

Twist the grill lifter (clockwise or counterclockwise) so

the handle is parallel to the grill rods. This “seats” the

spiked end of the grid lifter between two rods, enabling

you to safely lift out the grid. Lift slowly and adjust the

grid lifter, if necessary, for balance.

THE WARMING RACK

The warming rack (Fig. 25-2) is packed separately.

To install the warming rack, lift the front of the rack up

slightly and insert the rack hangers into the two holes

in the back of the inner oven hood. Then lower the front

of the rack into a level position to lock the rack in place.

To remove the warming rack, lift up on the front of the

rack until the rack hangers pull free from their supporting

holes.

Note: Removing the warming rack before using the

rotisserie will leave more clearance for the

meat being cooked. (if applicable)

Fig. 25-2 Warming rack in place inside oven

THE DRIP TRAY

The drip collection system allows you to brush or scrape

excess dried residue from the grilling area directly into

the drip tray (see PARTS LIST for drip tray location).

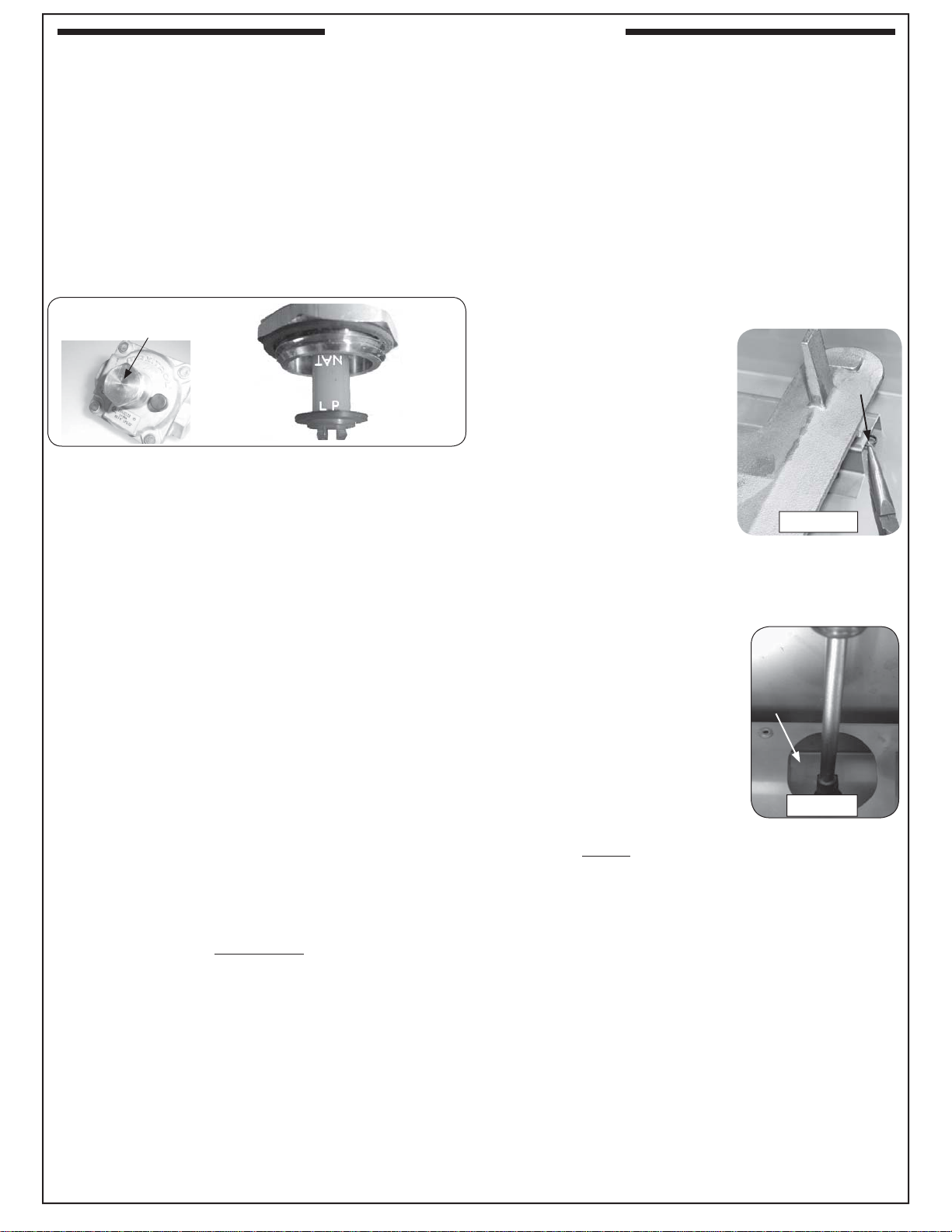

THE FLAVOR GRID(S)

Place each fl avor grid directly over a burner. The solid

areas of the grid should rest over the tabs found on the

burner. See Fig. 25-5. The slightly larger grids are

designed to be placed over the outside burners,

and the slightly smaller grid(s) are designed to be

placed over the interior burner(s).

Note: This allows heat from the burners to be evenly

distributed throughout the cooking area. The

fl avor grids heat and cool quickly, making the

grill very responsive to changes in heat from

the burners.

Fig. 25-5

Flavor grid

Fig. 25-3

Placement of the grid lifter in cooking grid

Fig. 25-6 Optional Rotis-A-Light

Fig. 25-4

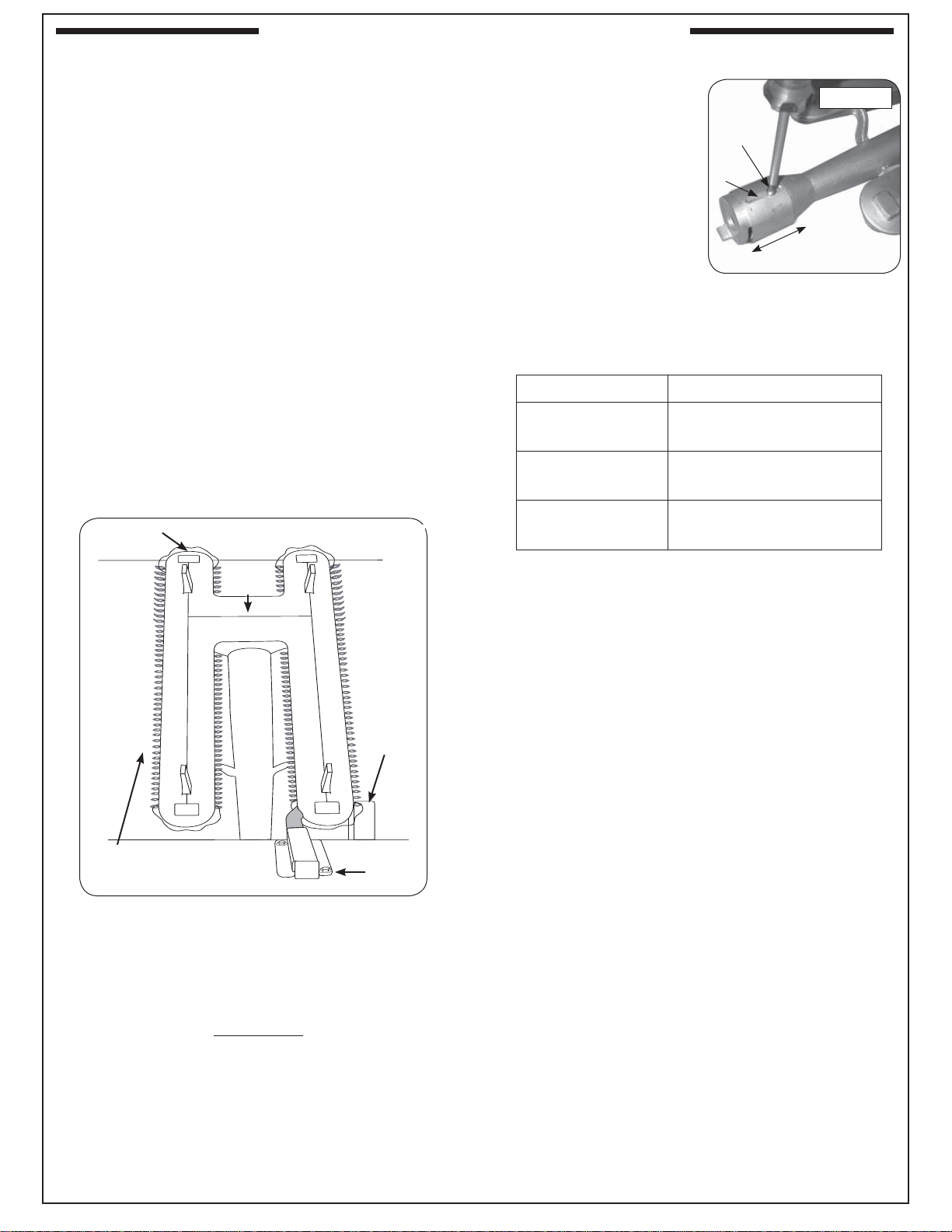

THE ROTIS-A-LIGHT (OPTIONAL)

This fl exible grill lighting solution

(sold separately)

will enhance your outdoor cooking experience by

enabling you to continue cooking long after the sun

has set. The Rotis-A-Light has two multi-directional

fl exi-angles, making this a completely versatile and

indispensable light suitable for any grilling location.

25

Page 26

Fig. 26-2

Pull out the drip tray and place liner

FIRE MAGIC® DRIP TRAY

Drippings from grilling flow through specially

designed channels and collect in the drip tray . Check

the drip tray regularly and empty when required.

Fig. 26-1

Fig. 26-3

Be sure liner fi ts under lighting instruction plate

Your grill includes a pack of four (4) Fire Magic

®

drip tray liners (Fig. 26-1). For your convenience

in cleanup, place a liner into the drip tray before

grilling.

To fi t a liner into the drip tray, pull out the tray and