Page 1

GETTING STARTED

AUTOMATIC OUTDOOR

INSTALLATION INSTRUCTIONS

AND OWNER’S MANUAL

INSTALLER: Leave these instructions with consumer.

CONSUMER: Retain for future reference.

Important: READ THESE INSTRUCTIONS CAREFULLY BEFORE STARTING INSTALLATION OR USE.

KEEP THIS MANUAL IN A SAFE PLACE AFTER READING IT.

ICE MAKER

Model # 3597

WARNINGS

Do not use where the supply voltage is different from the unit's requirements.

This product is designed for indoor/outdoor use.

The appearance, design, color, and parts of the product are subject to change without notice.

The functions and specifi cations stated in this manual may be changed at anytime without prior notice.

The manual has WARNING and CAUTION marks. The information is impor tant for the safe and effi cient installation

and operation of the ice maker. Two types of cases may be found during installation:

CAUTION: If the instructions are not observed, a situation that may result in minor injury and/or damage to

the product may occur.

WARNING: If the instructions are not observed, serious injury or death may result.

Thank you for purchasing the 3597 Ice Maker (drain pump is optional). The product is a built-in and free-standing

type of ice maker and is designed for use at home. The product produces transparent ice of the highest quality.

Proper installation of the ice maker is of the utmost importance. The product should be installed by a qualifi ed

professional service technician.

Before installing the product, read this installation manual in full. The manual contains detailed instructions to

be observed during installation. If you have any questions about installation, contact your dealer.

Important: When designing or manufacturing the ice maker, safety matters and functions are accorded the

utmost importance. This ice maker is designed and certifi ed according to the UL safety standard.

The company does not bear any responsibility or liability for products that are modifi ed, installed

with parts not supplied or approved, or used incorrectly. R.H. Peterson reserves the right to change

product specifi cations and design at any time without prior notice.

REV 0 - 1608220820

SA32944

Robert H. Peterson Co. • 14724 East Proctor Avenue • City of Industry, CA 91746

1

L-C2-499

Page 2

CONTENTS

GETTING STARTED

WARNINGS .................................................................................................................................................. 1

IMPORTANT INFORMATION

UNPACKING ...........................................................................................................................................3

VENTILATION ........................................................................................................................................3

WATER SUPPLY .....................................................................................................................................3

WATER QUALITY ...................................................................................................................................3

INTERIOR OF UNIT ...............................................................................................................................3

ELECTRICAL SAFETY INFORMATION ..............................................................................................4

SPECIFICA TIONS AND DIMENSIONS ................................................................................................4

PARTS LIST ..................................................................................................................................................7

ITEM CHECK LIST ....................................................................................................................................8

INSTALLATION

INSTALLATION ..........................................................................................................................................9

INSTALL ICE MAKER ............................................................................................................................9

DOOR REVERSAL (if applicable) ........................................................................................................10

.................................................................................................................3

USE, CARE, & SERVICE

OPERATION ...............................................................................................................................................11

INITIAL OPERATION ...........................................................................................................................11

USING THE ICE MAKER .....................................................................................................................11

ICE ........................................................................................................................................................11

ICE CONTAINER ..................................................................................................................................11

OPERATION TIME ...............................................................................................................................11

ICE PRODUCTION ..............................................................................................................................11

SER VICING AND CLEANING ..............................................................................................................12

EXTERIOR ............................................................................................................................................12

ICE CONTAINER ..................................................................................................................................12

CONDENSER ........................................................................................................................................12

ICE REMOVAL CYCLE ........................................................................................................................12

HOW IT MAKES ICE ............................................................................................................................12

ICE-PRODUCTION SYSTEM ..............................................................................................................13

LONG TERM STORAGE OR NON-OPERATION ................................................................................13

NOTES PAGE .............................................................................................................................................14

TROUBLESHOOTING .............................................................................................................................15

WARRANTY ..............................................................................................................................................16

REV 0 - 1608220820

2

L-C2-499

Page 3

IMPORTANT INFORMATION

UNPACKING

After removing the packing materials, check the appearance of the ice maker for possible defects or irregularity.

If the product shows any irregularity in its appearance, contact the dealer to inquire about it.

All the packing materials (strings, box, styrofoam, and wood, etc.) should not be left within reach of children and

should be disposed of responsibly.

For safety, the product should be installed and used with caution in accordance with this manual. Incorrect

installation or careless use of the product may cause damage or injury to the environment, humans, animals,

and/or materials and property. The manufacturer does not bear any responsibility for any damage or injury.

The automatic ice maker performs best at an ambient temperature of 50°~75° F, and with a supply of water at

50° F.

The ice maker should NOT be installed near heat generators such as heaters, stoves, dish washers, or grills.

VENTILATION

The ice maker sucks air through the left part of the kick plate/grill using a fan and expels hot air through the

right parts of the kick plate/grill. If any material is placed in front of the kick plate/grill, the fl ow of air fl ow will be

disrupted, and can result in reduced performance and/or malfunction. The ice maker should be operated within

a temperature range of 50° F to 100° F.

CAUTION: Do not cover the kick plate/grill parts.

Note: A decoration door may be installed at the front but the ventilation holes of the kick plate/grill should not

be blocked.

WATER SUPPLY

The ice maker requires a continuous supply of drinking water at 20psi or higher pressure. The hydrostatic

pressure should not exceed 80psi.

WATER QUALITY

There is no such thing as “perfectly pure” water. All kinds of water including tap water contain some impurities.

Rainwater absorbs impurities from the atmosphere or when it passes through soil. Some impurities consist of

solid particles called suspended solids and are fi ltered through micro fi lters. Any remaining impurities cannot be

fi ltered because they are chemically combined with water molecules. These impurities are called dissolved solids.

The mineral content of the ice produced by the product is reduced compared to the content in the water before

conversion into ice. Water containing a low level of impurities is rapidly frozen. The reason for this is that the

impurities elevate the temperature of water. Through such an action, most of the impurities condensed in the

water-tank of the ice maker form a hard precipitation called scale.

If a large quantity of mineral scale accumulates, the lifespan of the ice maker may be reduced.

For best operation of the ice maker, impurities and minerals should be decomposed by washing with vinegar

periodically. See the SERVICING AND CLEANING section for details.

In general, it is best to use fi ltered water. Filters may remove not only bad odor but also particles. Dissolved

solids may be treated with a reverse osmosis system. Neutral water is not recommended.

Water softener is not recommended because it exchanges minerals. If the hardness of the water is very high,

softening may lead to the attachment of opaque pieces of ice.

If you have any questions about the purity of your water, contact your local water department.

INTERIOR OF UNIT

This product was thoroughly washed at the factory. However, check the cleanness of the inside before use and

keep it clean during use.

WARNING: Used refrigerators and freezers should be safely stored or disposed of. Ensure that the product’s

door has been removed or permanently closed. If children are able to enter the ice maker, a serious

accident may occur.

REV 0 - 1608220820

3

L-C2-499

Page 4

ELECTRICAL SAFETY INFORMATION

• To protect against electric shock, do not immerse cord or plugs in water or other liquid.

• Unplug from the outlet when not in use and before cleaning.

• CAUTION: Risk of Electric Shock - Switch in OFF postion does not de-energize the unit.

• Do not operate any outdoor appliance with a damaged cord, plug, or after the appliance malfunctions or

has been damaged in any manner. Contact the manufacturer for repair.

• Do not let the cord touch hot surfaces.

• Do not use an outdoor appliance for purposes other than intended.

• Use only a properly wired and inspected 120VAC (15 AMP minimum) Ground Fault Circuit Interrupter

(GFCI) GROUNDED 3-wire receptacle with this outdoor appliance.

• The GFCI receptacle must be a WEATHER-PROOF IN-USE COVERED RECEPTACLE.

• Never remove the grounding plug or use with an adapter of 2 prongs.

• Use only extension cords with a 3 prong grounding plug, rated for the power of the equipment, and approved

for outdoor use with a W-A marking.

• The provisions of the National Electric Code as well as any local codes must be observed when

installing the product.

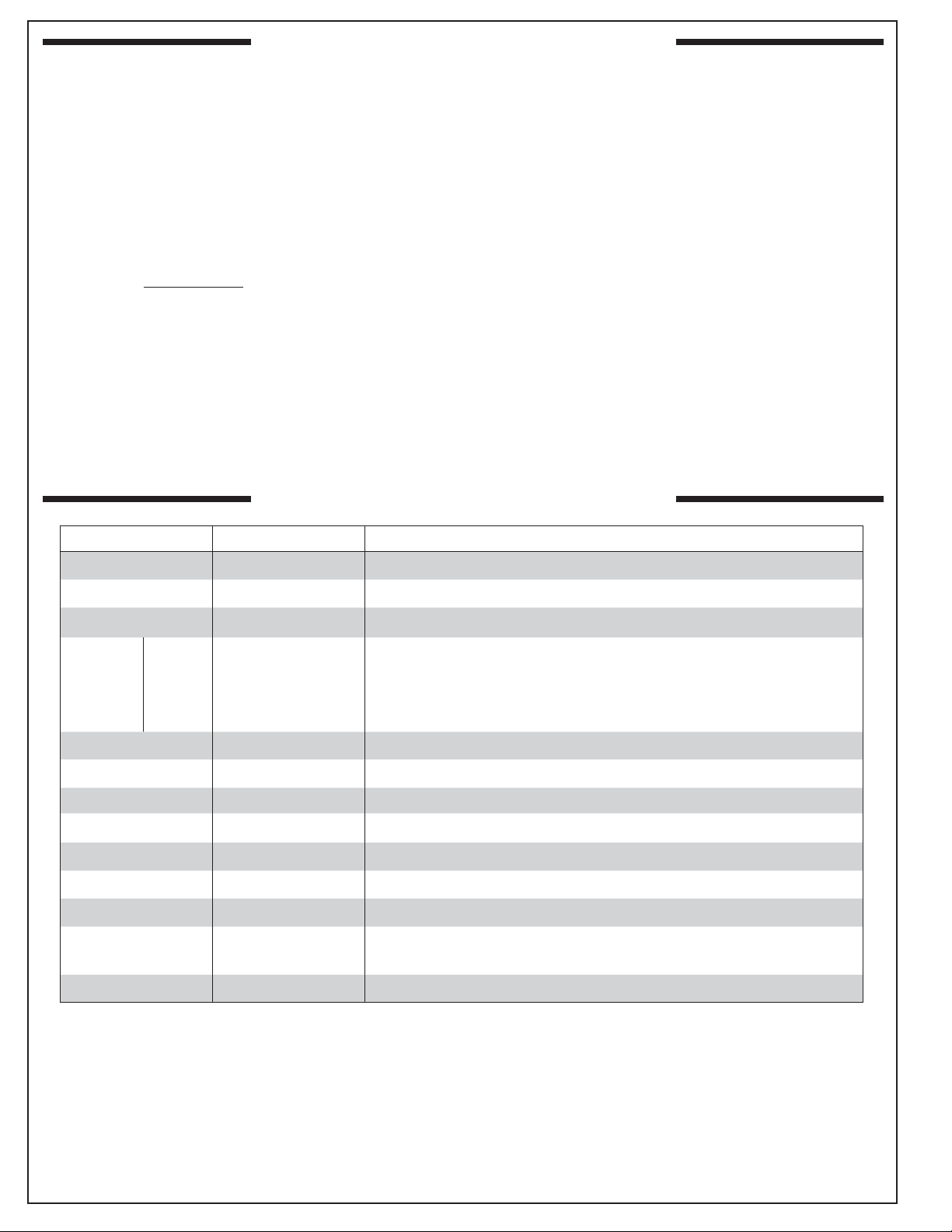

SPECIFICATIONS AND DIMENSIONS

Description Measurement Specifi cation

Rated power

Power

Overall dimension

Net

Weight

Gross

Exterior

Quantity of ice

Maximum product

Ice storage

Refrigerant

Evaporator design

Condenser

Water supply

condition

V / A / Hz 120V / 9 A Max / 60Hz

W MAX 500

W x D x H (inch) 15 x 25 1/4 x 34-35

lb 110

lb 140

-- Top, side, front: durable stainless steel

EA 24 cubes per cycle

lb / day 63.9

lb 26.5

-- R134a

-- Spray type (cube)

-- Air-cooled

°F (°C) 50 ~ 86 (10 ~ 32)

Remark

REV 0 - 1608220820

-- Self-container type

Table 1 - Product Specifi cations

4

L-C2-499

Page 5

SPECIFICATIONS AND DIMENSIONS (cont.)

When moving the ice maker, ensure the cut-out dimensions, electric power, and piping position requirements

are met. Refer to the INSTALLATION section for complete details.

This product is a gravity drain model that requires a drain tube to run from the back of the product to an appropriate

drain pipe. The optional drain pump routes water to a drainage point such as a neighboring sink.

Important: The ice maker should be leveled.

Important: When moving the product using a hand truck or dolly, place the dolly at the side of the product and

shut or fi x the door tightly to avoid possible opening during movement.

CAUTION: The fi nished bottom should be protected with a suitable material to avoid possible damage when

moving the product.

Cut-out dimensions

A Height (top to bottom) min. cut-out 34"

B Width (side to side) cut-out 15 1/4"

C Depth (front to back) min. cut-out 25 1/4"

Unit dimensions

D Width (door closed) 15"

E Width (maximum, door fully open) 25 1/2"

F Height 34"

G Levelers maximum height 1"

H Depth (maximum, door closed) 25 1/4"

I Depth (body only) 21 1/4"

J Depth (body and door w/o handle) 22 3/4"

K Depth (door open 90° ) 36

3

/4"

L Depth (door open maximum 105°) 34 3/4"

Table 2 - Dimensions diagram

A

B

C

Fig. 5-1 Cut-out dimensions

Note: If using a trim kit (purchased separately),

cut-out dimensions remain the same.

D

F

G

Fig. 5-2 Unit dimensions

H

I

J

L

K

105° max.

open

90° max.

outer depth

E

REV 0 - 1608220820

5

L-C2-499

Page 6

SPECIFICATIONS AND DIMENSIONS (cont.)

PLUMBING REQUIREMENTS

Plan for the setup of the water supply pipes.

Connect the unit to a cold water source using the supplied water inlet hose.

Install a shut-off valve between the tap water pipe and the product so that the user can operate the valve. Do

not install the shut-off valve at the rear of the product.

Do not use a self-piercing valve. If the tap water has a high level of minerals, a pipeline fi lter will be required.

The pressure of the tap water should be maintained at a level between 20psi and 80psi. An electric outlet

installed behind the ice maker will make installation easier. Installation of the outlet, tap water pipe, and drain

pipeline should meet all provisions under local laws and regulations. Refer to the INSTALLATION section for

complete details.

Important: The unit must remain removable for servicing. Do not install any material at the front, upper

or lower end of the product which may prevent removal of the unit.

Important: Piping should be setup in accordance with all the provisions of local laws and regulations.

REV 0 - 1608220820

6

L-C2-499

Page 7

PARTS LIST

Z

X

Y

YY

Y[

Y\

Y]

ZW

Y^

ZX

\_

YZ

Z[

ZZ

Z]

Y_

Z^

Z`

Z_

[W

[\

[[

]

\

[Z

Y`

[X

[Y

Z\

\X

\Z

\[

\Y

ZY

\^

YX

X\

X[

]W

XY

REV 0 - 1608220820

XZ

X`

XX

X]

^

X^

X_

YW

[_

[^

[]

[

]W

XW

`

[`

_

7

\]

\\

\W

L-C2-499

Page 8

PARTS LIST (cont.)

Item Description Code No. Qty.

Top cover

1.

Foam top cover

2.

Hinge plug

3.

Top hinge block

4.

Top cover bracket

5.

Ice scoop hanger

6.

Safety TC shaft

7.

Door hinge -

8.

bottom

Door stop bracket

9.

Door stopper bolt

10.

Upper door hinge

11.

Door - front panel

12.

Handle bar

13.

Handle bar sup-

14.

port

Logo plate

15.

Door gasket

16.

Door magnet

17.

Cover magnet

18.

Door bottom

19.

bracket

Door bearing

20.

Door top plug

21.

Cover EVA sheet

22.

EVA plating assy

23.

EVA sensor (N)

24.

Bracket EVA

25.

Bracket fl ow ice

26.

Pin fl ow ice

27.

Flow ice front

28.

Flow ice back

29.

Button support

30.

3171006-10 1 -

3060191-00 1 -

3030182-00 1 -

3210030-00 1 -

3210025-00 1 -

3011446-00 1 -

3160040-00 1 -

3210027-00 1 -

3980092-00 1 -

2140170-00 1 -

3210028-10 1 -

4470118-00 1 -

3020057-00 1 -

3020058-00 2 -

3280156-00 1 -

6560010-03 1 -

3220039-00 3 -

3170907-00 1 -

3980093-00 1 -

3270075-00 1 -

3180194-00 1 -

3170909-00 1 -

4090344-01 1 -

6550072-00 1 -

3010596-00 1 -

3010677-00 1 -

3150037-00 1 -

3170728-00 13 -

3170766-00 14 -

3180194-00 2 -

Replacement

Part No.

Item Description Code No. Qty.

Hand screw

31.

Cover vessel

32.

Rubber EVA pipe

33.

Ice guide

34.

Vessel

35.

Over fl ow pipe

36.

Packing over fl ow

37.

Bolt vessel IN

38.

Packing nipple

39.

Strainer

40.

Bolt/vessel IN/

41.

OUT

Packing nipple

42.

Hose nozzle

43.

Nozzle frame

44.

Cover nozzle

45.

Rocker switch

46.

Cover S/W

47.

Front cover plate

48.

Leveling foot

49.

Power cord assy

50.

Water valve

51.

water valve socket

52.

Packing nipple (L)

53.

Drain hose con-

54.

nection

Back down base

55.

Back down cover

56.

Back cover

57.

Ice scoop

58.

Door assy w/

59.

handle

Kick plate

60.

2108045-01 2 -

3170906-00 1 -

2110033-00 1 -

3410090-00 1 -

6040014-00 1 -

3030174-00 1 -

3030166-00 1 -

6100180-00 1 -

3030055-01 1 -

6050011-00 1 -

2140155-00 1 -

3030055-01 1 -

2290114-00 1 -

3480081-00 1 -

3030221-00 2 -

3550133-00 1 3597-12

3550089-00 1 -

3170894-01 1 -

3020029-00 1 -

7220094-00 1 -

3400280-0 1 -

3400118-00 1 -

3030071-00 1 -

3360094-00 1 -

3490546-10 1 -

3490629-10 1 -

3490598-10 1 -

6070011-00 1 3597-11

- 1 3597-10

- 1 3597-13

Replacement

Part No.

ITEM CHECK LIST

Prior to installation, check that all the following items have been included with your unit. If any items listed below

are missing, contact your dealer.

• Ice maker

• Inlet hose

• Outlet hose

• Ice scoop

REV 0 - 1608220820

8

L-C2-499

Page 9

INSTALLATION

INSTALLATION

INSTALL ICE MAKER

This installation method is for a gravity drain pipe setup. If

the optional drain pump kit is purchased, follow the installation

instructions provided with the pump.

Refer to plumbing codes when connecting the ice maker to a

drain connection.

Before connecting the drain tube and the water inlet hose to

the ice maker, pipes [including shut-off valve and water fi lter (if

needed)] should be properly setup. The drain tube should slope

1

/4" for every foot. An air gap is required between the drainage

tube of the ice maker and the drain pipe.

Important: Incorrect installation of the drainage pipe will

cause the ice in the ice container to melt rapidly.

1. Locate the ice maker at the front of the enclosure cut-out

opening.

2. Connect the supplied water inlet hose to the ice maker

using the supplied fl are adapter (see Fig. 9-3).

3. Connect the other end of the water inlet hose to the water

supply shut-off valve. (see Fig. 9-3).

Note: If a water fi lter (not included) is installed between the

shut-off valve and the ice maker, connect the water

inlet hose to the water fi lter, and the water fi lter to the

shut-off valve. See Fig. 9-3.

Locate drain within 2" diameter

area 23" back from front of unit

Drain

tube

25 1/4" min.

15 1/4"

Fig. 9-1 Top view

Water inlet hose

Shut-off valve

(not included)

Water fi lter

(if applicable,

not included)

4. Cut the required length of drain tube.

5

5. Connect the drain tube (with a diameter of

/8") to the drain

pipe at the rear of the product and secure them together

using a hose clamp. See Fig. 9-1 for orientation.

6. Turn on the shut-off valve and check for leaks.

7. Insert the plug into the electrical receptacle.

8. Adjust the leveling legs: turn counterclockwise to raise the

unit, or clockwise to lower it.

The user does not need to fi ll the container with water.

The fi rst batch of ice should be discarded. Ice production

takes 1-2 hours.

Flare

adapter

(Ice maker)

34" min.

Water inlet hose

Fig. 9-2 Front view

Water shut-off valve

(not included)

REV 0 - 1608220820

(If applicable)

Water fi lter

(not included)

Filter connections

(not included)

Fig. 9-3 Water connection diagram

9

L-C2-499

Page 10

INSTALLATION (cont.)

DOOR REVERSAL (if applicable)

The direction in which the door opens can be changed. The hinges are attached to the right-hand side of the

door when the product is shipped from the factory. The ice maker is designed so that the hinges may be installed

on either side. If the hinges are moved to the holes on the left-hand side, the door will open to the left.

Remove

upper door

hinge

Remove

door

A

B

1. Remove the upper door

hinge, then carefully lift and

remove the door.

Remove and

install top

cover bracket

to right side

Remove and

install hinge

block to left

side

Remove

upper hinge

plug

Remove

top cover

screw

2. Remove the upper hinge plug

and the top cover screw.

Re-install

3 rear

screws

A

Re-install

upper hinge

plug to right

side

B

A

Remove

top cover

Remove 3

screws

B

3. Remove the 3 top cover

screws at the rear of the unit,

then remove the top cover.

Remove and install

bottom hinge to left side

Front panel

Move

screws to

right side

A

4. Remove and install the top

cover bracket to the right

side and the hinge block to

the left side.

(Bottom view of door)

Install door

bottom bracket

as shown

7. Remove and install the door

bottom bracket and plastic

insert to the right side of the

door bottom.

REV 0 - 1608220820

Re-install top cover

screw to right side

5. Re-install the top cover using

the 3 rear screws and 1 front

screw. Install the upper hinge

plug to the right side.

Move plug to right side

(Top view of door)

8. Remove and install the door

top plug to the right side.

10

Flip stop

B

plate to face

outward

6. Remove and install bottom

hinge to the left side. Remove

bottom screw and fl ip the door

stop plate as shown.

Note: The front panel may need

to be removed in order to

hold the channel in place

when re-securing the hinge.

Install top

B

door hinge

Install

door

A

9. Re-install the door to the

bottom hinge. While holding

the door in place, install the

top door hinge.

L-C2-499

Page 11

ICE

OFF

WASH

USE, CARE, & SERVICE

OPERATION

INITIAL OPERATION

1. Open the water supply shut-off valve connected to the

ice maker.

2. Open the door and turn the switch at the lower end of the

product to the “ICE” position.

3. Discard the fi rst batch of ice.

4. Good-quality ice is produced 1-2 hours later.

USING THE ICE MAKER

Turn the switch at the lower end of the product to the “ICE”

position. The product automatically starts ice production, which

continues until the ice container has been fi lled with ice. Remove

the ice using the supplied ice scoop found on the inside left

wall of the ice maker. (If you place the ice scoop on the ice, it

may be covered over by ice.)

The ice maker produces 24 pieces of ice every 30 minutes.

Important: Do not put anything other than ice in the ice

container. Wine or beer bottles are unsanitary

and a detached label may block the drain pipe.

Fig. 11-1 Switch

ICE

The ice has a top hat shape (see Fig. 11-2). Newly produced

ice is clear and transparent. The inside of the ice is sometimes

cracked; however, such cracks commonly occur in the production

process and disappear with time. Ice stored in the container

for a long time may gather frost on the outside and look cloudy.

This is normal and once water is poured on the ice, the frost

disappears.

ICE CONTAINER

The product continues making ice until the level of ice reaches the

temperature sensing tube (right side). It then ceases operation.

Models with a drain pump drain away melted ice when the ice

maker is turned off. The pump works for only several seconds.

OPERATION TIME

It takes about 20-35 minutes to produce a set of 24 ice pieces.

The length of one cycle of the ice maker (ice production and

ice removal) differs depending upon the cleanness of the ice

maker, the surrounding temperature, and the temperature of

the water supplied to the ice maker. It takes about 10-12 hours

to fi ll the empty ice container with ice.

ICE PRODUCTION

The ice production process largely consists of two cycles – ice

production and ice removal. 24 pieces of ice are produced with

each cycle of ice production and ice removal.

Fig. 11-2 Ice cube

When water is sprayed on to the surface of the frozen iceforming mold, the ice production cycle is started. When ice is

removed and water is supplied to ice maker, the ice removal

cycle is started.

REV 0 - 1608220820

11

L-C2-499

Page 12

OPERATION (cont.)

ICE REMOVAL CYCLE

The compressor works during the progression of the ice removal cycle, but the pump motor and fan motor are

stopped. The hot gas valve and water supply valve work. When the two valves are opened and the frozen surfaces

are heated, ice drops down into the container. Then the ice removal cycle is stopped and the ice production

cycle is started again by the program installed in the ice maker.

HOW IT MAKES ICE

The ice maker starts its work with the fi xed quantity that has been fed into the water container. When water

is sprayed on to the surface of the ice-forming mold, the water not containing mineral impurities freezes and

attaches to the ice-forming mold. The water containing impurities drops down into the water container. During

the progression of the ice production cycle, the mineral impurity level of the water in the water container rises.

During the progression of the ice removal cycle, water is fed to the ice maker, thereby diluting the water in the

container, and washes a part of the concentrated minerals through the drain pipe.

SERVICING AND CLEANING

All the exterior parts, door, ice container, condenser, circulatory parts for iceproduction water, and ice scoop of the product should be kept clean.

The ice maker should be cleaned periodically. If the ice maker is kept clean, its

lifespan will be extended. Regular cleaning should be performed at least once a

year; twice a year is recommended. The frequency of cleaning the ice-production

system should be increased depending upon the water quality.

CAUTION: Before service or cleaning is performed, ensure the switch is in the

OFF position, the power supply is disconnected, and all components

of the unit are completely cool.

Wipe with

grain

EXTERIOR

The exterior of the appliance should be cleaned by fi rst using stainless steel

cleaner to remove grease and dirt. Always wipe with the grain (see Fig. 12-1).

Next, apply stainless steel polish and wipe down using polish wipes to restore

the stainless steel color.

If the gasket has spots/stains on its surface, remove and clean using soap and

warm water. Use non-abrasive cloths or pads.

ICE CONTAINER

The ice container should be cleaned regularly. Mix 1 ounce of home bleaching

agent and 2 gallons of warm water at 95°-115° (35-45° C) for use as the cleansing

fl uid. Moisten clean cloths with the cleansing fl uid and scrub the inside of the ice

container with the cloths. Pour a small quantity of the fl uid into the drain pipe.

See Fig. 12-2. Thoroughly rinse with clean water and dry the interior.

CONDENSER

The condenser should be cleaned 2-3 times a year to remove

any lint that has penetrated the condenser. When cleaning the

condenser, remove the front lower panel and the kick plate using

a screwdriver. Then, remove any dust and lint from the condenser

using a soft bristle brush. See Fig. 12-3.

Important: To avoid possible bending of the condenser pins,

clean the condenser in the direction of the pins (up

and down).

Condenser

Fig. 12-1 Wipe with grain

Fig. 12-2 Clean ice container

Front

panel

and kick

plate

CAUTION: If the condenser is not cleaned, the temperature

may drop or the machine may experience technical

problems or sustain damage.

REV 0 - 1608220820

12

(View from

behind panels)

Fig. 12-3 Clean condenser

L-C2-499

Page 13

ICE-PRODUCTION SYSTEM

SERVICE AND CLEANING (cont.)

1. Open the door and turn off the switch at the lower end of the front.

2. Re-connect the power supply.

3. Take out all the ice and dispose of it or store it in an ice chest or refrigerator.

4. Pour 4 ounces of a washing agent (neutral detergent for dishwashing

or equivalent) into the water container of the ice maker.

5. Press the switch to the “WASH” position. The process by which water

is supplied for 2 minutes and the circulation pump works for 4 minutes

is repeated three times.

6. Repeat the above process 2-3 times. Add the washing agent to the

water container if necessary, depending upon the washing process.

7. Clean the ice container (1), ice curtain (2), nozzle frame (3), spray

nozzle (4), connective hose (5), the inside of the water container (6),

slide grill (7), and ice scoop (8) using a mixture of washing agent and

water. See Fig. 13-1.

8. Thoroughly rinse all components with clean water.

9. Replace the removed ice. Regularly wash the ice scoop. It may be

washed together with other food containers.

This procedure is for purposes of cleaning the ice-production system

only. To treat the ice-production system for scaling, follow the same

procedure above using equal parts vinegar and water instead of

detergent.

WARNING: When using detergents and cleaning agents, the safety

precautions and instructions labeled on those products

must be observed.

7

8

2

1

6

5

3

Fig. 13-1 Ice-production

system components

4

Important: Disconnect the power supply if other services will be performed

to the appliance.

LONG TERM STORAGE OR NON-OPERATION

1. Clean the ice-production system (see previous section).

2. Disconnect the power supply.

3. Empty the water container. Remove the back panel from the ice maker.

Remove the pump hose.

4. Disconnect the inlet hose from the water supply shut-off valve.

5. Remove the plug from underneath the water container (see Fig. 13-2).

6. Reconnect the power and turn the switch to the “WASH” position to

open the water supply valve and to remove the water from the inlet

pipe inside the ice maker.

7. Turn off the ice maker and disconnect the power supply.

8. Re-insert the reservoir plug once water is completely removed and the

unit is completely dry.

9. Leave the door open to allow for circulation and to prevent mold and

mildew.

10. Leave water supply line and power supply disconnected until ready to

reuse.

Fig. 13-2 Remove plug

When using the ice maker in the future, re-install all components removed

during this procedure. Repeat the steps in the INITIAL OPERATION section.

REV 0 - 1608220820

13

L-C2-499

Page 14

NOTES PAGE

REV 0 - 1608220820

14

L-C2-499

Page 15

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTION

Ice maker does not

operate

Ice cubes are too

large

Ice cubes are too

small

Ice cubes are

partially formed –

ragged sides

1. Ice maker is unplugged

2. Breaker tripped

3. Switch turned to “OFF”

4. Storage bin full, keeping ice maker off

5. Drain pipe blocked (drain pump model)

6. Drain pump malfunction (drain pump model)

1. Cube size control set too cold 1. Contact dealer.

1. Not enough water

2. Cube size control set too warm

1. Spray jets partially clogged 1. Clean ice making system.

1. Plug the ice maker in.

2. Reset breaker - if it happens again, call an authorized

service center.

3. Turn switch to “ICE”.

4a. Ice on sensor tube – it is normal for ice maker to be

off.

4b. Ice maker in location below 50° (10° C) – location

must be warmer for ice maker to operate.

5. Clean the interior of drain pipe.

6a. Check the drain pump.

6b. Contact dealer.

1a. Check water supply – fi lter may be restricted.

1b. Check inlet water valve – inlet screen may be

restricted.

2. Contact dealer.

Ice maker makes

ice, but storage bin

does not fi ll with

ice

Ice cubes are

partially formed –

white at the bottom

Unit operates but

no ice falling in

storage bin

1. Storage bin should fi ll with ice and ice maker

shut off in 12~16 hours – if not, condenser

may be dirty

2. Storage bin drain may be partially restricted

3. Air fl ow to ice maker may be obstructed

1. Not enough water in reservoir 1a. Check water supply – fi lter may be restricted.

1. Ice may be stuck in the evaporator and the

unit is “frozen up”

2. Too much heat load

3. No water spray

4. No airfl ow

5. Compressor does not operate properly or

at all

6. Not enough refrigerant

7. Hot gas valve leaks through

1. Clean condenser.

2. Clean out drain, check installation.

3. Check installation – kick plate/grill must be free of

obstructions.

1b. Check inlet water valve – inlet screen may be

restricted.

1c. Check for water leak in reservoir.

1a. Check water supply – fi lter may be restricted.

1b. Check inlet water valve – inlet screen may be

restricted or valve does not operate.

1c. Hot gas valve may not operate – check and repair

or replace.

2. Inlet water valve leaks through, must be replaced.

3. Water pump does not operate, must be replaced or

check for water leak in reservoir.

4a. Fan motor does not operate or fan blade is broken,

must be replaced.

4b. Condenser completely blocked, must be cleaned.

5. Contact dealer.

6. Contact dealer.

7. Contact dealer.

REV 0 - 1608220820

15

L-C2-499

Page 16

WARRANTY

ONE-YEAR WARRANTY - Fire Magic

®

electric accessories are warranted for one year

from the date of purchase.

A COPY OF YOUR SALES SLIP FOR PROOF OF PURCHASE IS REQUIRED

This warranty applies to the original purchaser for products which are installed in the United States or Canada and which are operated and maintained

as intended for single family residential usage. This warranty is valid only with proof of purchase, shall commence on the date of purchase, and shall

terminate (both as to original and any replacement products) on the anniversary date of the original purchase of the product stated on the above schedules.

This warranty covers defects in material and workmanship. This warranty does not cover parts which become defective as a result of negligence, misuse,

use not in compliance with the Owner’s Manual/Installation Instructions, accidental damage, improper handling, improper storage, improper installation,

lack of required routine maintenance (as specifi ed in the Owner’s Manual/Installation Instructions), electrical damage, local gas impurities or failure to

protect against combustibles. Product must be installed (and gas must be connected) as specifi ed in the Owner’s Manual/Installation Instructions by

a qualifi ed professional installer. Modifi cations to products which are not specifi cally authorized will void this warranty. Accessories, parts, valves,

remotes, etc. when used must be Peterson products or this warranty is void. Warrantied items will be repaired or replaced at Peterson’s sole discretion.

This warranty does not apply to rust, corrosion, oxidation, or discoloration unless the affected part becomes inoperable.

This warranty does not cover labor or labor related charges, except as provided by separate specifi c written programs from the Peterson Co. All repair

work must be performed by a qualifi ed professional service person and requires prior approval of Peterson.

Peterson may require the defective product or part to be returned to the factory to determine the cause of failure. Peterson will pay freight charges if

the product or part is determined to be defective. This warranty does not cover breakage in shipment from our (Independent) distributor to its customer

if the damage is determined to have occurred during that shipment.

This warranty specifi cally excludes liability for indirect, incidental, or consequential damages. Some states and provinces do not allow the exclusion

or limitation of incidental or consequential damages, so the above exclusion may not apply to you. This warranty gives you specifi ed legal rights, and

you may have other rights that vary from state to state or province.

For additional information regarding this warranty, or to place a warranty claim, contact the R. H. Peterson dealer where the product was purchased.

TO REGISTER YOUR PRODUCT ONLINE GO TO: WWW.RHPETERSON.COM,

AND CLICK ON PRODUCT REGISTRATION. THANK YOU FOR YOUR PURCHASE.

Robert H. Peterson Co. • 14724 East Proctor Avenue • City of Industry, CA 91746

16

Loading...

Loading...