Page 1

DOOR, DRAWER, & PANTRY

INSTALL SPECIFICATIONS

Model # 53830SC Shown

Model # 53930SC Shown

GENERAL INFORMATION

WARNING

INSTALLER: Leave these instructions with consumer.

CONSUMER: Retain for future reference.

Important: READ THESE INSTRUCTIONS CAREFULLY BEFORE STARTING INSTALLATION

• When installing this unit directly below another unit, only install with Fire Magic built-in products.

• For proper installation, be sure to use the correct cutout dimensions as specifi ed for your specifi c

model number.

• It is recommended that silicon caulking (not supplied) is applied around the back of the unit’s

trim before sliding the cabinet assembly into the opening.

• Some models may include an additional owner’s manual.

This unit is to be installed by a qualifi ed,

professional service technician.

• When used for propane cylinder storage, a louvered door model is required.

CAUTION: Make sure the enclosure is properly vented. See your grill owner’s manual for venting

requirements, or consult your local codes.

WHEN USING A PROPANE TANK CYLINDER:

• Never locate a cylinder under or near a grill unless suffi cient ventilation and shielding is

provided to prevent any heating of the cylinder regulator and hose. Refer to any additional

instructions included with your door (and/or your grill owner’s manual) for the required installation

method of propane tank cylinders.

• FOLLOW ALL THE SAFETY WARNING AND INFORMATION FOUND IN THESE

INSTRUCTIONS, ON YOUR PROPANE CYLINDER, AND IN YOUR GRILL OWNER’S MANUAL

ABOUT SAFE STORAGE AND USE OF PROPANE GAS.

ROBERT H. PETERSON CO. • 14724 East Proctor Avenue • City of Industry, CA 91746

REV 4 - 1710261125

1

L-C2-358

Page 2

INSTALLATION GUIDELINES

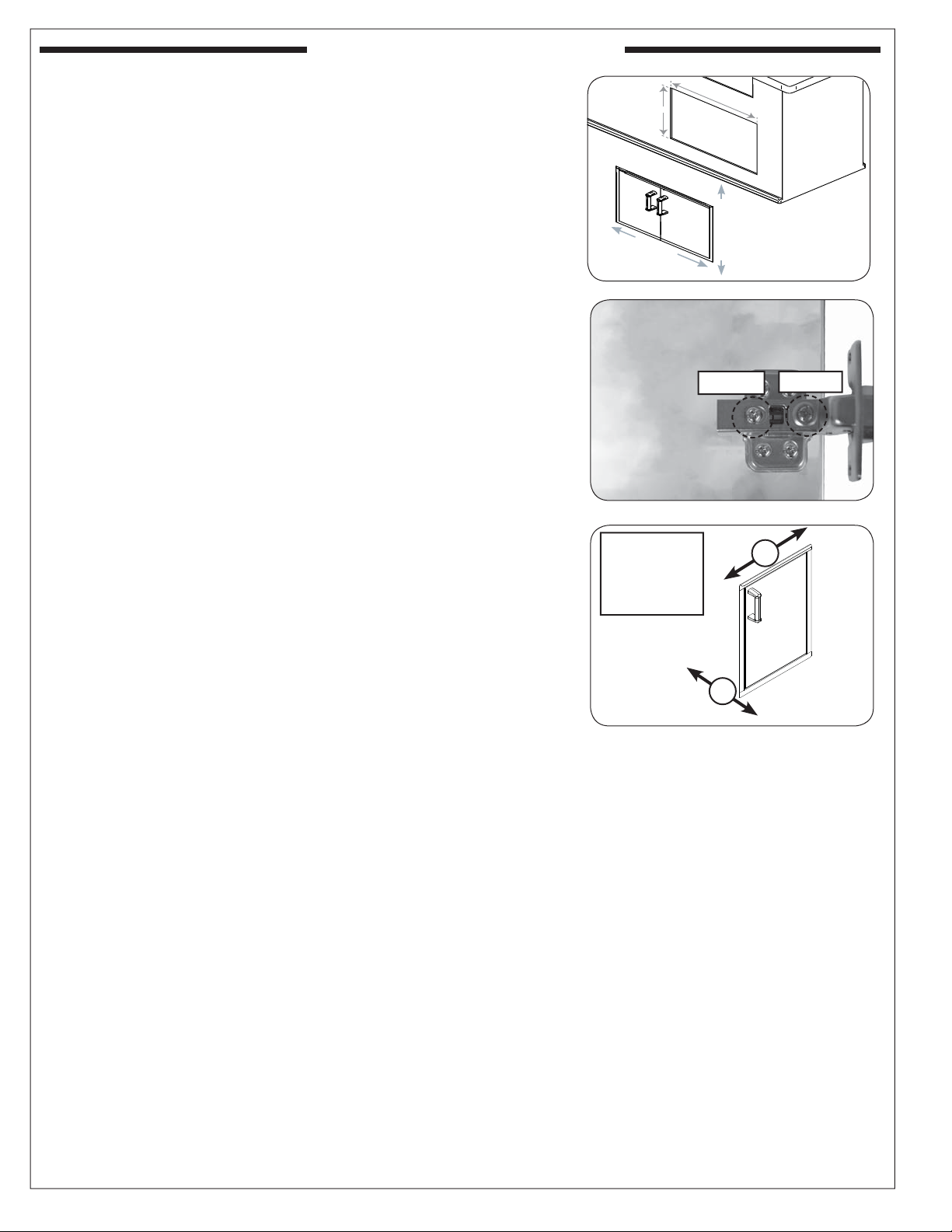

For proper installation, be sure to use the correct cutout

dimensions as specifi ed for your specifi c model number.

Locate your model on the following pages for dimensions,

and reference the cut-out diagram of your unit for proper

orientation.

DOOR

Slide in and fasten the unit securely into the island enclosure

using the appropriate hardware for your enclosure (not supplied)

through the installation screw slots or holes in the top and bottom

of the unit.

For doors with soft-close hinge:

Soft-close hinges have two door adjustment screws per hinge.

Screw "A" adjusts the door left or right. Turn clockwise to move

right and counterclockwise to move left, on both hinges. See Fig.

2-2. Screw "B" allows for the door to adjust inward or outward.

First loosen screw "B", adjust door as needed, then re-secure.

See Fig. 2-2.

For doors with propane tank trays:

To use, simply open the door, pull out the sliding cylinder tray,

place your cylinder on the tray and push the tray back in. The

cylinder is now ready for connection to your grill.

Important: Refer to any additional instructions included

with your door for the required installation

method of propane tank cylinders.

H

E

I

WIDTH

G

H

T

Fig. 2-1 Door cut-out diagram

Screw B Screw A

Fig. 2-2 Adjust door

Screw A: adjust

left/right

Screw B: adjust

inward/outward

A

B

Fig. 2-3 Adjust door

REV 4 - 1710261125

2

L-C2-358

Page 3

Drawer

support

Side View

Drawer

front

INSTALLATION GUIDELINES (cont.)

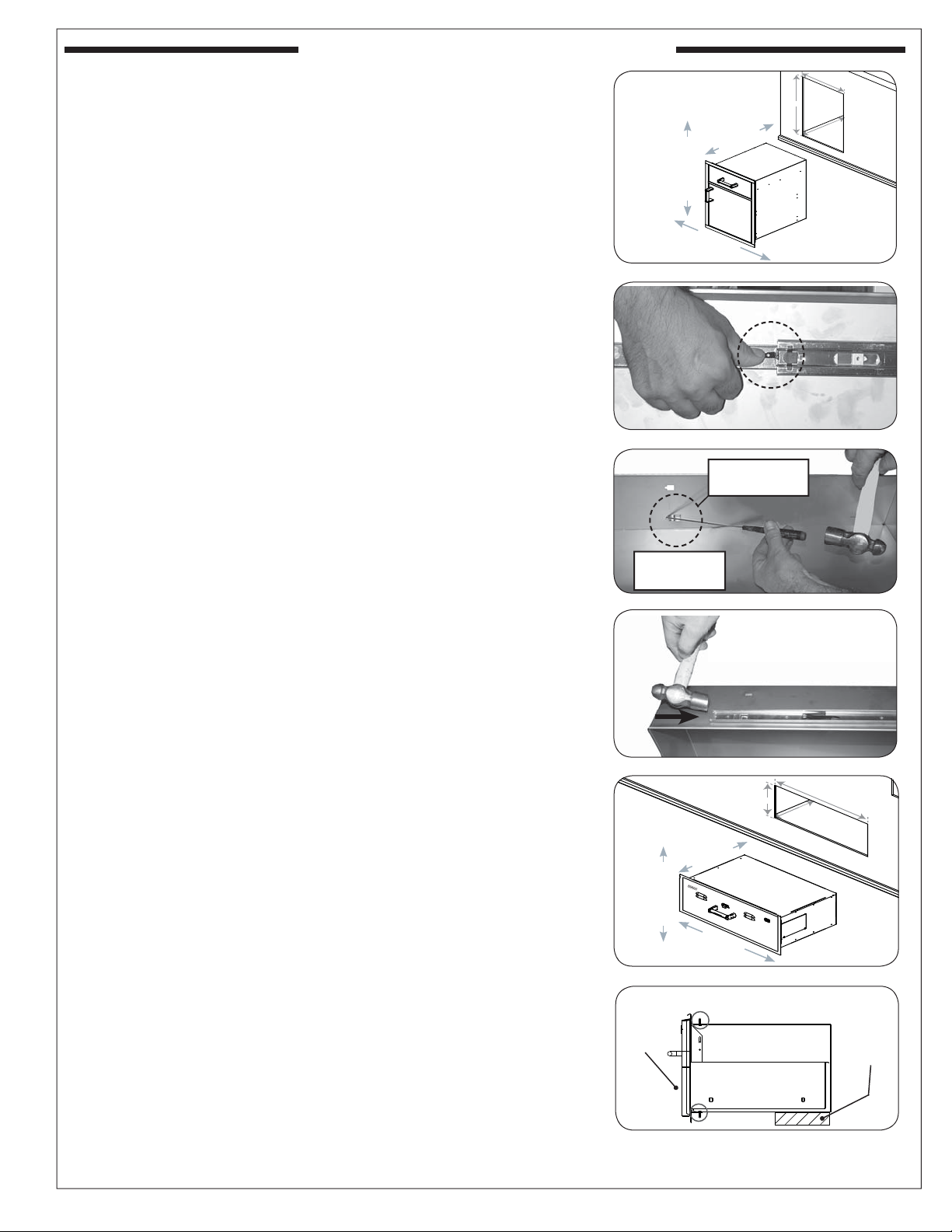

PANTRY

Installation Guidelines

Before installing your pantry, remove the drawer from its

base by completely pulling it out. Release the drawer from

the drawer slides by pressing the black lever down on the

right side, and up on the left side

on the drawer until it comes free of the runners.

1. Slide in and fasten the unit securely into the island

enclosure using the appropriate hardware for your

construction (not supplied) through the installation holes

in the top, sides, and bottom of the unit.

Important: Install using

3

screws are fl ush.

2. To re-attach the drawer; extend the drawer slides

completely and align the drawer into the slides, pushing

the drawer closed. Open the drawer to verify that it has

locked in place.

Note: DO NOT damage gasket while installing the screws.

Inner Drawer Height Adjustment

The top inner-drawer height can be adjusted (lowered) by

raising the drawer runners.

1. Pull out the drawer completely (see above section).

2. From the interior of the drawer, use a fl at head

screwdriver and a hammer to tap the runners free

(through the notches). See Fig. 3-3.

3. Align each runner over the alternate notches and use

the hammer to gently tap into place (see Fig. 3-4).

4. Reinstall the drawer.

DRAWER

Before installing your drawer, remove the drawer from its

base by completely pulling it out. Release the drawer from

the drawer slides by pressing the black lever down on the

right side, and up on the left side

on the drawer until it comes free of the runners.

1. In order to properly support the weight of your drawer, it

is necessary to provide a secure, level surface in the rear

of the unit (see

using bricks, 2 X 4’s, etc. Be sure that the height of this

rear support is 1/8" higher than that of the front opening

support, so that your drawer sits level.

2. Slide in and fasten the unit securely into the island

enclosure using the appropriate hardware for your

construction (not supplied) through the installation screw

slots in the top and bottom of the unit.

3. To re-attach the drawer; extend the drawer slides

completely and align the drawer into the slides, pushing

the drawer closed. Open the drawer to verify that it has

locked in place.

Fig 3-6

(Fig 3-2). Then pull outward

/16" countersink screws. Ensure

(Fig 3-2). Then pull outward

). This may be accomplished by

H

DEPTH

E

I

G

H

T

WIDTH

Fig. 3-1 Pantry cut-out diagram

Fig. 3-2 Releasing drawer from slides

Hammer

through notch

(Interior of

the drawer)

Fig. 3-3 Release tracking from drawer

Fig. 3-4 Reinstall runners

DEPTH

H

E

I

G

H

T

WIDTH

Fig. 3-5 Drawer cut-out diagram

REV 4 - 1710261125

Fig. 3-6 Drawer Installation (Side View)

3

L-C2-358

Page 4

FLUSH-MOUNTED DOORS, DRAWERS, & PANTRY

Cut-out is height x width x depth

DOUBLE DOORS WITH DUAL DRAWERS

MODEL:

CUT-OUT:

53930SC-22

21” x 30 ½” x 20 ½”

ELECTRIC WARMING DRAWER

MODEL:

CUT-OUT:

53830-SW

14 ½” x 32 ¼” x 22”

DOUBLE DOORS WITH TRASH

TRAY & DUAL DRAWERS

MODEL:

CUT-OUT:

TRIPLE ENCLOSED DRAWERS

MODEL:

CUT-OUT:

53930SC-12

21” x 30 ½” x 20 ½”

53803SC

26 ¼” x 14 ½” x 20 ½”

MASONRY DRAWER

MODEL:

CUT-OUT:

DOUBLE ENCLOSED DRAWERS

MODEL:

CUT-OUT:

(53802SC model shown)

53830SC

14 ½” x 32 ¼” x 22”

53802(H)SC

16” x 14 ½” x 20 ½”

SINGLE ACCESS DOOR*

MODEL:

CUT-OUT:

DOUBLE ACCESS DOORS

MODEL:

CUT-OUT:

(53938SC model shown)

REV 4 - 1710261125

53924SC-L

25” x 17 ½”

53938(H)SC

16” x 39”

DOUBLE ACCESS DOORS

MODEL:

CUT-OUT:

SINGLE DOOR WITH DUAL DRAWERS*

MODEL:

CUT-OUT:

53934SC

15” x 30”

53820SC-R

21” x 14 ½” x 20 ½”

Available in left or right hinge

*

4

ACCESS DOOR W/ DOUBLE

DRAWERS

MODEL:

CUT-OUT:

SINGLE ENCLOSED DRAWER

MODEL:

CUT-OUT:

53810SC

18 ½” x 30” x 26”

53801SC

5 ¼” x 14 ½” x 20 ½”

L-C2-358

Page 5

FLUSH-MOUNTED DOORS, DRAWERS, & PANTRY (cont.)

Cut-out is height x width x depth

DOUBLE ACCESS DOORS

MODEL:

CUT-OUT:

SINGLE ACCESS DOOR*

MODEL:

CUT-OUT:

53930SC

21” x 30”

53914SC-R

15” x 20 ½”

SINGLE ACCESS DOOR*

MODEL:

CUT-OUT:

(53920SC-L model shown)

DOUBLE ACCESS DOORS

WITH LOUVERS

MODEL:

CUT-OUT:

53920(H)SC-L

21” x 14 ½”

53930SC-1

21” x 30”

SINGLE ACCESS DOOR*

MODEL:

CUT-OUT:

ACCESS DOORS W/ PLATTER STORAGE

AND DOUBLE DRAWERS

MODEL:

CUT-OUT:

53816SC

18 ½” x 36½” x 26”

53917SC-R

18” x 24 ½”

PANTRY W/ TOP DRAWER

AND SINGLE DOOR W/ DUAL

DRAWERS (INSULATED)

MODEL:

CUT-OUT:

REV 4 - 1710261125

54020S

33 ½” x 20” x 26”

Also available: (not shown)

MODEL: 54018S

MODEL: 53820SC-L

MODEL: 53820(H)SC-TL or TR

MODEL: 53914SC-L

MODEL: 53917SC-L

MODEL: 53920(H)SC-R

MODEL: 53924SC-R

MODEL: 53930SC-12T

Available in left or right hinge

*

5

CUT-OUT: 25” x 17 ½” x 26”

CUT-OUT: 21” x 14 ½” x 20 ½”

CUT-OUT: 21” x 14 ½” x 20 ½”

CUT-OUT: 15” x 20 ½”

CUT-OUT: 18 ½” x 24 ½”

CUT-OUT: 21” x 14 ½”

CUT-OUT: 25” x 17 ½”

CUT-OUT: 21” x 30 ½” x 20 ½”

L-C2-358

Page 6

SELECT DOORS & DRAWERS

Cut-out is height x width x depth

ELECTRIC WARMING DRAWER

MODEL:

CUT-OUT:

TRIPLE DRAWERS

MODEL:

CUT-OUT:

33803

26 ¼” x 14 ½” x 20 ½”

33830-SW

13” x 31” x 20 ½”

MASONRY DRAWER

MODEL:

CUT-OUT:

DOUBLE DRAWERS

MODEL:

CUT-OUT:

33802

16” x 14 ½” x 20 ½”

33830-S

13” x 31” x 20 ½”

DOUBLE ACCESS DOORS

MODEL:

CUT-OUT:

DOUBLE DOORS WITH TANK TRAY

AND LOUVERS

MODEL:

CUT-OUT:

33930S

21” x 30”

33930S-12T

21” x 30 ½” x 20 ½”

REV 4 - 1710261125

SINGLE DOOR WITH DUAL DRAWERS*

MODEL:

CUT-OUT:

33820-SR

21” x 14 ½” x 20 ½”

*

Available in left or right hinge

ACCESS DOORS W/ PLATTER STORAGE

AND DOUBLE DRAWERS

MODEL:

CUT-OUT:

6

33816S

18 ½” x 36½” x 26”

L-C2-358

Page 7

SELECT DOORS & DRAWERS (cont.)

Cut-out is height x width x depth

SINGLE ACCESS DOOR*

MODEL:

CUT-OUT:

33914-SR

15” x 20 ½”

SINGLE ACCESS DOOR WITH TANK

TRAY AND LOUVERS*

MODEL:

CUT-OUT:

DOUBLE DOORS WITH 2 DRAWERS

MODEL:

CUT-OUT:

33820-TSL

21” x 14 ½” x 20 ½”

33930S-22

21” x 30 ½” x 20 ½”

SINGLE ACCESS DOOR*

MODEL:

CUT-OUT:

SINGLE ACCESS DOOR*

MODEL:

CUT-OUT:

33917-SR

18” x 24 ½”

33920-SR

21” x 14 ½”

REV 4 - 1710261125

SINGLE DRAWER

MODEL:

CUT-OUT:

33801

5 ¼” x 14 ½” x 20 ½”

ACCESS DOOR W/ DOUBLE DRAWERS

MODEL:

CUT-OUT:

Also available: (not shown)

MODEL: 33914-SL CUT-OUT: 15” x 20 ½”

MODEL: 33917-SL CUT-OUT: 18” x 24 ½”

MODEL: 33920-SL CUT-OUT: 21” x 14 ½”

MODEL: 33924-SR or SL CUT-OUT: 25” x 17 ½”

MODEL: 33920-1-SR or SL CUT-OUT: 21” x 14 ½”

MODEL: 33938S CUT-OUT: 16” x 39”

MODEL: 33820-SL CUT-OUT: 21” x 14 ½” x 20 ½”

MODEL: 33820-TSR CUT-OUT: 21” x 14 ½” x 20 ½”

MODEL: 33930S-12 CUT-OUT: 21” x 30 ½” x 20 ½”

Available in left or right hinge

*

7

33810S

18 ½” x 30” x 26”

L-C2-358

Page 8

LEGACY DOORS & DRAWERS

Cut-out is height x width x depth

MASONRY DRAWER

MODEL:

CUT-OUT:

SINGLE ACCESS DOOR (RIGHT OR LEFT)

WITH TANK TRAY AND LOUVERS

MODEL:

CUT-OUT:

23830-S

13” x 31” x 20 ½”

23920-1T-S

20 ½” x 14 ½” x 20 ½”

SINGLE ACCESS DOOR

MODEL:

CUT-OUT:

SINGLE ACCESS DOOR WITH LOUVERS

MODEL:

CUT-OUT:

23917-S

17 ½” x 24 ½”

23920-1-S

20 ½” x 14 ½”

SINGLE ACCESS DOOR

MODEL:

CUT-OUT:

DOUBLE ACCESS DOORS

MODEL:

CUT-OUT:

23920-S

20 ½” x 14 ½”

23930S

20 ½” x 30”

DOUBLE DOORS WITH DUAL DRAWERS

AND TRASH TRAY

MODEL:

CUT-OUT:

VENTING PANEL, LOUVERED STAINLESS STEEL

MODEL:

CUT-OUT:

OUTER DIMENSIONS:

REV 4 - 1710261125

23930S-12

21” x 30 ½” x 20 ½”

5510-01

5” x 12 ¾”

6” x 14”

Available in left or right hinge

*

SINGLE DOOR WITH DUAL DRAWERS

MODEL:

CUT-OUT:

23820-S

20 ½” x 14 ½” x 20 ½”

Also available: (not shown)

MODEL: 23912-S CUT-OUT: 12 ½” x 18 ½”

MODEL: 23918-S CUT-OUT: 18 ½” x 12 ½”

MODEL: 23924-S CUT-OUT: 24 ½” x 17 ½”

MODEL: 23914-S CUT-OUT: 14 ½” x 20 ½”

MODEL: 23912 CUT-OUT: 12 ½” x 18 ½”

MODEL: 23918 CUT-OUT: 18 ½” x 12 ½”

MODEL: 23924 CUT-OUT: 24 ½” x 17 ½”

MODEL: 23914 CUT-OUT: 14 ½” x 20 ½”

MODEL: 23917 CUT-OUT: 17 ½” x 24 ½”

MODEL: 23920 CUT-OUT: 20 ½” x 14 ½”

MODEL: 23920-1T CUT-OUT: 20 ½” x 14 ½” x 20 ½”

MODEL: 23920-1 CUT-OUT: 20 ½” x 14 ½”

8

L-C2-358

Page 9

CARE & CLEANING

By following these recommendations, you will enjoy the

beauty and convenience of your unit for many years to

come.

STAINLESS STEEL

Clean your unit by fi rst using stainless steel grill cleaner

to remove grease and dirt. Always wipe with the grain

(See Fig. 9-1). Next, apply stainless steel polish and

wipe down using polish wipes to restore the stainless

steel color.

If your unit is installed in a seaside (salt air) or poolside

(chlorine) location, it will be more susceptible to corrosion

and must be maintained/cleaned more frequently. Do not

store chemicals (such as chlorine or fertilizer) near your

stainless steel unit.

Due to the nature of stainless steel, surface iron oxide

deposits may appear. Do not be alarmed – these deposits

are removable with stainless-steel cleaner through prompt

and periodic maintenance. If not attended to promptly,

permanent pitting may occur.

Stainless

steel shown

Wipe with grain

Fig. 9-1

PORCELAIN

Doors that are porcelainized provide many years of

trouble-free service. These surfaces may be cleaned with

non-corrosive oven/grill cleaner, following manufacturer’s

instructions. For any stainless steel see above.

9

Page 10

U

L

SAFE USE & MAINTENANCE OF PROPANE GAS CYLINDERS

IMPORTANT FOR YOUR SAFETY

READ AND FOLLOW ALL WARNINGS PROVIDED WITH THE PROPANE-GAS CYLINDER.

When operating this appliance with a propane-gas cylinder, these instructions and warnings MUST be observed.

FAILURE TO DO SO MAY RESULT IN A SERIOUS FIRE OR EXPLOSION.

CYLINDER/CONNECTOR REQUIREMENTS

a. Propane-gas cylinders, valves, and hoses must be

maintained in good condition and must be replaced if

there is visible damage to either the cylinder or valve. If the

hose is cut or shows excessive abrasion or wear, it must

be replaced before using the gas appliance (see e.).

b. This unit, when used with a cylinder, should be connected

to a standard 5-gallon (20 lb.) propane-gas cylinder

equipped with an OPD (Overfi ll Prevention Device).

The OPD has been required on all cylinders sold since

October 1,1998, to prevent overfi lling.

c. Cylinder dimensions should be approximately 12" (30.5

cm) in diameter and 18" (45.7 cm) high. Cylinders must

be constructed and marked in accordance with the

Specifi cations for Propane Gas Cylinders of the U.S.

Department of Transportation (D.O.T.) or the National

Standard of Canada, CAN/CSA-B339, Cylinders,

Spheres, and Tubes for Transportation of Dangerous

Goods.

d. The cylinder used must include a collar to protect the

cylinder valve, and the cylinder supply system must be

arranged for vapor withdrawal.

e. The pressure regulator and hose assembly used must

e. The pressure regulator and hose assembly (Fig. 10-1)

match the specifi cation for Type I by ANSI Z 21.58/CGA

supplied with this outdoor gas appliance (L.P. models

1.6 (see Fig. 10-1).

only) must be used. Original and replacement pressure

regulator and hose assemblies must be those specifi ed by

the manufacturer for connection with a cylinder connecting

device identifi ed as Type I by the ANSI Z 21.58/CGA 1.6

(see PARTS LIST for ordering information).

f. The propane-gas cylinder valve must be equipped with a

cylinder connection coupling device, described as Type I

in the standard defi ned in paragraph e. above. This device

is commonly described as an Acme thread quick coupler.

g. If the propane-gas cylinder comes with a dust plug, place

the dust cap on the cylinder valve outlet whenever the

cylinder is not in use.

QUICK COUPLER OPERATION

To connect the regulator/hose assembly to the propanegas cylinder valve fi tting: Press the hand nut on the regulator

over the Acme thread fi tting on the cylinder valve. Turn the hand

nut clockwise to engage the threads and tighten until snug.

The use of pliers or a wrench should not be necessary. Only

cylinders marked “propane” may be used.

To disconnect: Turn the hand nut counterclockwise until

detached (Fig. 10-1).

Important: Before using the unit, and after each time the

cylinder is removed and reattached, check

the hose for wear (see a.) and check all

connections for leaks. Turn off the unit valves

and open the main cylinder valve, then check

connections with soapy water. Repair any

leaks before lighting the unit.

CAUTION: Always turn the propane cylinder main valve

off after each use, and before moving the unit

and cylinder or disconnecting the coupling.

This valve must remain closed and the

cylinder disconnected while the appliance

is not in use, even though the gas fl ow is

stopped by a safety feature when the coupler

is disconnected.

Carefully inspect the hose assembly each time before the

gas is turned on. A cracked or frayed hose must be replaced

immediately.

If the appliance is stored indoors, the cylinder must be

disconnected and removed. Disconnected

cylinders must be

stored outdoors, out of the reach of children, with threaded

valve plugs tightly installed, and must not be stored in a

building, garage, or any other enclosed area.

FOR YOUR SAFETY

a. DO NOT store a spare propane-gas cylinder under or

near this appliance.

b. NEVER fi ll the cylinder beyond 80-percent full.

c. IF THE INFORMATION IN a. AND b. IS NOT FOLLOWED

EXACTLY, A FIRE CAUSING DEATH OR SERIOUS

INJURY MAY OCCUR.

Fig. 10-1 Type I Acme thread quick coupler

QCC

Type 1

valve

Pressure

relief

valve

Hand wheel

Brass Acme

thread fi tting

Liquid level

indicator

(optional)

Hand nut with Acme

thread

Regulator

Vent

Hose

ENCLOSURE REQUIREMENTS

FOR YOUR SAFETY, you must provide the openings listed below for replacement air and ventilation of the unit enclosure. One

side of the enclosure shall be left completely open to the outside; OR 4 (minimum) ventilation openings MUST be created:

• Each opening must have a minimum of 10 sq. in. of free area. The openings must be equally sized.

• Two openings must be in the side walls of the enclosure, at the top level, and spaced at a minimum of 90 degrees. The openings

must begin 1" or less below the countertop level and end no more than 5" below the countertop level.

• Two openings must be in the side walls of the enclosure, at the fl oor level, and spaced at a minimum of 90 degrees. The openings

must begin 1" or less above the fl oor level and end no more than 5" above the fl oor level.

• The openings must remain unobstructed: The clearance between the openings and any items outside of the enclosure is

a minimum of 6". The clearance between the openings and any items within the enclosure is a minimum of 2".

It is acceptable to use RHP venting panels (PN 5510-01). Contact your dealer.

KEEP THE REQUIRED VENT OPENINGS AND SURROUNDING AREA OF THE ENCLOSURE CLEAR AND FREE AT ALL TIMES.

WARNING: Ventilation openings in side walls shall not communicate directly with other enclosures of the outdoor cooking gas appliance.

10

Loading...

Loading...