Page 1

12 Clintonville Road, Northford, CT, 06472

THE SENSISCAN 2000

I

NSTALLATION

, O

PERATION, AND PROGRAMMING

M

ANUAL

Document # 15017

10/8/96 Rev:

P/N 15017:H ECN 96-200

H

Page 2

Installation Precautions - Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of power can be connected to the fire alarm

control panel. Disconnect all sources of power before servicing. Control unit and

associated equipment may be damaged by removing and/or inserting cards,

modules, or interconnecting cables while the unit is energized. Do not attempt to

install, service, or operate this unit until this manual is read and understood.

CAUTION - System Reacceptance Test after Software Changes: To ensure

proper system operation, this product must be tested in accordance with NFPA 72-

1993 Chapter 7 after any programming operation or change in site-specific software.

Reacceptance testing is required after any change, addition or deletion of system

components, or after any modification, repair or adjustment to system hardware or

wiring.

All components, circuits, system operations, or software functions known to be

affected by a change must be 100% tested. In addition, to ensure that other

operations are not inadvertently affected, at least 10% of initiating devices that are

not directly affected by the change, up to a maximum of 50 devices, must also be

tested and proper system operation verified.

This system meets NFPA requirements for operation at 0-49O C/32-120O F

and at a relative humidity of 85% RH (non-condensing) at 30O C/86O F.

However, the useful life of the system's standby batteries and the electronic

components may be adversely affected by extreme temperature ranges and

humidity. Therefore, it is recommended that this system and its peripherals be

installed in an environment with a nominal room temperature of 15-27O C/60-80

F.

Verify that wire sizes are adequate for all initiating and indicating device loops.

Most devices cannot tolerate more than a 10% I.R. drop from the specified device

voltage.

Like all solid state electronic devices, this system may operate erratically or can

be damaged when subjected to lightning induced transients. Although no system is

completely immune from lightning transients and interferences, proper grounding will

reduce susceptibility. Overhead or outside aerial wiring is not recommended, due to

an increased susceptibility to nearby lightning strikes. Consult with the Technical

Services Department if any problems are anticipated or encountered.

Disconnect AC power and batteries prior to removing or inserting circuit boards.

Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing, reaming, or punching

of the enclosure. When possible, make all cable entries from the sides or rear.

Before making modifications, verify that they will not interfere with battery,

transformer, and printed circuit board location.

Do not tighten screw terminals more than 9 in-lbs. Over tightening may damage

threads, resulting in reduced terminal contact pressure and difficulty with screw

terminal removal.

This system contains static-sensitive components. Always ground yourself with a

proper wrist strap before handling any circuits so that static charges are removed

from the body. Use static suppressive packaging to protect electronic assemblies

removed from the unit.

O

Follow the instructions in the installation, operating, and programming manuals.

These instructions must be followed to avoid damage to the control panel and

associated equipment. FACP operation and reliability depend upon proper

installation.

Fire Alarm System Limitations

An automatic fire alarm system - typically made up of smoke detectors, heat

detectors, manual pull stations, audible warning devices, and a fire alarm control

with remote notification capability can provide early warning of a developing fire.

Such a system, however, does not assure protection against property damage or

loss of life resulting from a fire.

Any fire alarm system may fail for a variety of reasons:

Smoke detectors may not sense fire where smoke cannot reach the detectors such

as in chimneys, in walls, or roofs, or on the other side of closed doors. Smoke

detectors also may not sense a fire on another level or floor of a building. A second

floor detector, for example, may not sense a first floor or basement fire. Further-

more, all types of smoke detectors - both ionization and photoelectric types, have

sensing limitations. No type of smoke detector can sense every kind of fire caused

by carelessness and safety hazards like smoking in bed, violent explosions,

escaping gas, improper storage of flammable materials, overloaded electrical

circuits, children playing with matches, or arson.

IMPORTANT! Smoke detectors must be installed in the same room as the

control panel and in rooms used by the system for the connection of alarm

transmission wiring, communications, signaling, and/or power. If detectors are

not so located, a developing fire may damage the alarm system, crippling its

ability to report a fire.

While installing a fire alarm system may make lower insurance

rates possible, it is not a substitute for fire insurance!

FCC Warning

Audible warning devices such as bells may not alert people if these devices are

located on the other side of closed or partly open doors or are located on another

floor of a building.

A fire alarm system will not operate without any electrical power. If AC power fails,

the system will operate from standby batteries only for a specified time.

Rate-of-Rise heat detectors may be subject to reduced sensitivity over time. For

this reason, the rate-of-rise feature of each detector should be tested at least once

per year by a qualified fire protection specialist.

Equipment used in the system may not be technically compatible with the control.

It is essential to use only equipment listed for service with your control panel.

Telephone lines needed to transmit alarm signals from a premise to a central

monitoring station may be out of service or temporarily disabled.

The most common cause of fire alarm malfunctions, however, is inadequate

maintenance. All devices and system wiring should be tested and maintained by

professional fire alarm installers following written procedures supplied with each

device. System inspection and testing should be scheduled monthly or as required

by National and/or local fire codes. Adequate written records of all inspections should

be kept.

WARNING: This equipment generates, uses, and can radiate radio frequency

energy and if not installed and used in accordance with the instruction manual, may

cause interference to radio communications. It has been tested and found to comply

with the limits for class A computing device pursuant to Subpart B of Part 15 of FCC

Rules, which is designed to provide reasonable protection against such interference

when operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the user will be required

to correct the interference at his own expense.

Technical Publishing Document PRECAULG.PM6 12/31/96

Canadian Requirements

This digital apparatus does not exceed the Class A limits for radiation noise

emissions from digital apparatus set out in the Radio Interference Regulations of the

Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits radioelectriques depassant les

limites applicables aux appareils numeriques de la classe A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le ministere des Communica-

tions du Canada.

Page 3

TABLE OF CONTENTS

SECTION ONE: GENERAL INFORMATION ............................................................. 4

Introduction ...........................................................................................................................4

Key Features .........................................................................................................................4

Related Documentation ........................................................................................................5

Minimum System Configurations ..........................................................................................6

SECTION TWO: INVENTORY ............................................................................... 7

The BE-2000 Basic Equipment Package..............................................................................8

Power Supplies .....................................................................................................................9

Modules............................................................................................................................... 10

Equipment for the Sensiscan 2000 .....................................................................................12

Cabinets .............................................................................................................................. 13

SECTION THREE: INSTALLATION ....................................................................... 14

Mount the cabinet backbox .................................................................................................16

Install a CHS-4 ....................................................................................................................16

Install the Main Power Supply .............................................................................................16

Install the AVPS ..................................................................................................................16

Mounting Modules............................................................................................................... 17

Mounting the CPU-2000 .....................................................................................................18

Connecting Row Ribbon Cables to Modules ......................................................................19

Mounting the RS-1459 in the CHS-4 ..................................................................................19

SECTION FOUR: FIELD WIRING THE MODULES ................................................. 20

UL Power-Limited Wiring Requirements .............................................................................2 1

The EIA-485 Interface .........................................................................................................24

NFPA Style B Field Wiring of Initiating Zone Modules ........................................................25

NFPA Style D Field Wiring of IZ-8F with IZE-A Expander................................................... 26

NFPA Style Y/Z Field Wir ing of the IC-4F and ICE-4F ........................................................27

Field Wiring of the CR-4F and the CRE-4F ........................................................................28

SECTION FIVE: THE POWER SUPPLIES............................................................. 29

The MPS-24AF/MPS-24AFE Main Power Supply...............................................................30

The MPS-24BF/MPS-24BFE Main Power Supply...............................................................33

Field Wiring of the Optional Audio Visual Power Supplies..................................................36

The R45-24/R45-24E Remote Battery Charger..................................................................37

SECTION SIX: APPLICATIONS ......................................................................... 38

Waterflow Alarm..................................................................................................................38

Supervisory Ser vice............................................................................................................ 38

Central Station ....................................................................................................................38

Digital Alarm Communicator Transmitters (DACT) .............................................................. 38

Tee-Tapping.........................................................................................................................44

Four-Wire Smoke Detectors................................................................................................45

Notification appliance circuit Power Configurations ............................................................ 46

Remote Command Inputs for the Sensiscan 2000 ............................................................. 48

SECTION SEVEN: PROGRAMMING .................................................................... 51

System Programming (Password 123-1232) ......................................................................52

Extended Programming Features (Password 123-3211)....................................................56

SECTION EIGHT: OPERATION.......................................................................... 58

CPU-2000 Circuits ..............................................................................................................59

Disabling/Enabling Circuits ................................................................................................. 61

SECTION NINE: SENSISCAN 2000 TESTING ....................................................... 62

Acceptance Test ..................................................................................................................62

Periodic Testing and Service...............................................................................................62

Operational Checks .............................................................................................................62

Battery Checks and Maintenance .......................................................................................63

Walk Testing the Sensiscan 2000 ....................................................................................... 63

APPENDIX A: SUPPLY CALCULATIONS ............................................................. 64

The Fire Alarm Circuit ......................................................................................................... 64

The Main Power Supply ......................................................................................................64

Sensiscan 2000 Programming Log.....................................................................................69

S2000 15017 Rev H 10/08/96 P/N 15017:H

3

Page 4

SECTION ONE: GENERAL INFORMATION

1.1 INTRODUCTION

The System 2000 is an expandable multi-zone Fire Alarm Control Panel designed with maximum flexibility and modularity

as a basic requirement. The heart of the system is the Central Processor Unit (CPU-2000) module which monitors and

directs the actions of all other modules in the system. Up to seven additional modules may be installed in various configurations. Internal communications are accomplished over a high-speed serial bus.

The CPU-2000 is provided with the Basic Equipment package. This module provides two Style Z and/or Style Y notification appliance circuits, Form-C alarm and trouble contacts, Remote Station alarm and trouble outputs, and a Municipal

Master Box output. A main power supply (MPS-24AF/MPS-24AFE or MPS-24BF/MPS-24BFE) and an initiating zone

module (IZ-4F or IZ-8F) must be added to make the basic system functional.

The basic system can be expanded using one or more of the following optional modules or boards:

IZ-8F Initiating Zone Module

IZ-4F Initiating Zone Module

IZE-AF Initiating Zone Expander

IC-4F Notification Circuit Module

ICE-4F Notification Circuit Expander

CR-4F Control Relay Module

AVPS-24F/AVPS-24FE Audio-Visual Power

Supply

CRE-4F Control Relay Expander

TC-2F Time Control Module

System expansion must comply with:

The physical limitations of the cabinet configuration.

The electrical limitations of the system power supplies (see Appendix A).

The capacity of the standby batteries (see Appendix A).

TC-4F Time Control Module

AFM-16ATF Annunciator Fixed Module

AFM-32AF Annunciator Fixed Module

AFM-16AF Annunciator Fixed Module

AFM-16ATX Annunciator Fixed Module

AFM-32AX Annunciator Fixed Module

UDACT-F Universal Digital Alarm Communicator Trans-

mitter

1.2 KEY FEATURES

Distributed microprocessor electronics.

Field programmable in nonvolatile memory.

Alarm and trouble resound.

Plug-in terminal blocks for ease of field wiring and service.

On/Off status indicators on all notification appliance circuits and control relays.

4

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 5

1.3 RELATED DOCUMENTATION

Before proceeding, the installer should be familiar with the following documents.

NFPA STANDARDS:

NFPA 12 Installation, Maintenance, and Use of Carbon Dioxide Extinguishing Systems

NFPA 12A Installation, Maintenance, and Use of Halon 1301 Extinguishing Systems

NFPA 12B Installation, Maintenance, and Use of Halon 1211 Extinguishing Systems

NFPA 2001 Clean Agent Fire Extinguishing Systems

NFPA 72-1993 Installation, Maintenance, and Use of Central Station Signaling Systems.

NFPA 72-1993 Local Protective Signaling Systems

NFPA 72-1993 Auxiliary Protective Signaling Systems

NFPA 72-1993 Use of Remote Station Protective Signaling Systems

NFPA 72-1993 Use of Proprietary Protective Signaling Systems

NFPA 72-1993 Automatic Fire Detectors

NFPA 72-1993 Installation, Maintenance, and Use of Notification Appliances for Protective Signaling Systems

NFPA 72-1993 Testing Procedures for Signaling Systems

UNDERWRITERS LABORATORIES DOCUMENTS:

UL 38 Manually Actuated Signaling Boxes

UL 217 Smoke Detectors, Single and Multiple Station

UL 228 Door Closers - Holders for Fire Protective Signaling Systems

UL 268 Smoke Detectors for Fire Protective Signaling Systems

UL 268A Smoke Detectors for Duct Applications

UL 346 Waterflow Indicators for Fire Protective Signaling Systems

UL 464 Audible Signaling Appliances

UL 521 Heat Detectors for Fire Protective Signaling Systems

UL 864 Standard for Control Units for Fire Protective Signaling Systems

UL 1481 Power Supplies for Fire Protective Signaling Systems

UL 1638 Visual Signaling Appliances

UL 1971 Signaling Devices for the Hearing Impaired

UNDERWRITERS LABORATORIES OF CANADA (ULC) LISTED

Standard CAN/ULC-S527-M87

OTHER:

EIA-485 Serial Interface Standards

NEC Article 300 Wiring Methods

NEC Article 760 Fire Protective Signaling Systems

** Applicable Local and State Building Codes

** Requirements of the Local Authority Having Jurisdiction

S2000 15017 Rev H 10/08/96 P/N 15017:H

5

Page 6

1.4 MINIMUM SYSTEM CONFIGURATIONS

At a minimum, the following Sensiscan components are required for compliance with NFPA standards 12, 12A, 12B and 72-

1993.

BE-2000 Basic Equipment Package which includes:

CPU-2000 Central Processor Module, Vented Dress Panel, CHS-4F Chassis, and connecting

cables.

An IZ-4F or IZ-8F Initiating Zone Module for up to eight Style B initiating device circuits.

The Main Power Supply (MPS-24AF/MPS-24AFE or MPS-24BF/MPS-24BFE)

Standby Batteries - refer to Standby Power Requirements, Appendix A.

A Sensiscan 2000 Cabinet (CAB-A3F or CAB-B3F)

In addition, the following equipment is required for the specific NFPA standards listed below.

An NFPA 72-1993 Proprietary Protected Premises Control Unit requires:

Potter Electronic Signal Co. Transmitter (Model EFT-C) with transformer (Model ULT, Stock. Number 1000391).

An NFPA 72-1993 Central Station Protected Premises Control Unit requires:

UDACT-F, 911A Digital Communicator or an Ademco No. 678 UL-F Digital Communicator

Sprinkler Supervisory and/or Waterflow Alarm Service requires a Control Relay Module.

An NFPA-12 Minimum Carbon Dioxide Extinguishing Control Unit, NFPA-12A Halon 1301 Fire Extinguishing Control

Unit, NFPA-12B Halon 1211 Fire Extinguishing Control Unit requires:

TC-2F or TC-4F Time Control Module.

NOTE

For wiring diagrams and more information on these applications, refer to Section6.

6

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 7

SECTION TWO: INVENTORY

The Sensiscan 2000 is offered under a Basic Equipment (BE-2000) package which provides the CPU-2000 module, the

VP-1F Vented Dress Panel, one CHS-4F Chassis, interconnecting cables and instruction manuals.

Other Components include modules and devices not provided in the Basic Equipment package. These components also

include several items necessary to complete a basic system, such as the main power supply, initiating modules, notification

modules, and control relay modules. See Section One for minimum system requirements.

This installation manual covers a basic system. For information on other devices, refer to the installation manuals of the

following products:

The AFM Annunciator Fixed Module, Document 15970

The AFM-16ATF Annunciator Fixed Module, Document 15210

The AFM-X Series Annunciator Modules, Document 15390

The TC-2F Time Control Module, Document 15971

The TC-4F Time Control Module, Document 15972

The FireLite Device Compatibility Document, Document 15384

The UDACT-F Manual, Document 50049

S2000 15017 Rev H 10/08/96 P/N 15017:H

7

Page 8

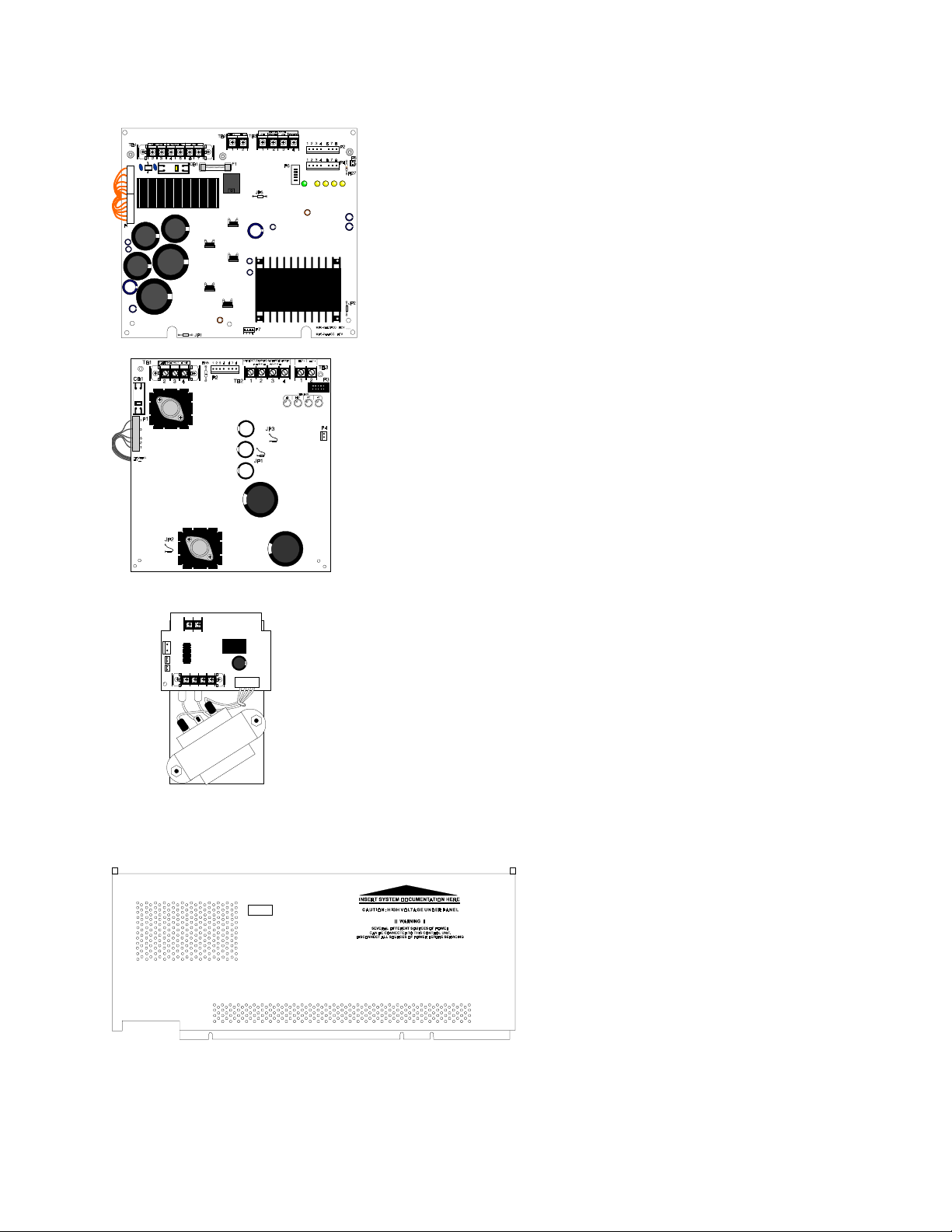

2.1 THE BE-2000 BASIC EQUIPMENT PACKAGE

CPU-2000 CENTRAL PROCESSOR MODULE

This module is the heart of the system. It controls and monitors the system modules

and provides a full accounting of system status. In addition, the CPU contains two

notification appliance circuits, a Remote Signaling Municipal Tie Circuit, and FormC alarm and trouble contacts. Field programming of the system is accomplished from

this module via the use of the Programming Key. Slide-in labels for programming,

control, and system operation are provided with the CPU, as well as end-of-line and

dummy load resistors.

Power Ribbon

(71085)

Main Bell Power Harness

(71093)

End-of-Line Resistor

(ELR)

4.7K, 1/2 watt (71252)

Power Harness

(71086)

Dummy Load Resistor

4.7K, 1/2 watt (71245)

First-Row Ribbon Cable

(71087)

VP-1F Vented Dress Panel

Covers the top row of modules in the

cabinet.

KEY #___ PWD#___

Programming

Key (PKB)

CHS-4 Chassis

For the mounting of up to four modules or four AVPS-24F

Audio-Visual Power Supplies. The CHS-4 occupies one

row in the CAB-A3F or CAB-B3F cabinet.

8

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 9

2.2 POWER SUPPLIES

MPS-24AF/MPS-24AFE

The MPS-24AF supplies the regulated power needed to run system modules. It

also supplies up to 3 amps of regulated notification appliance power, permitting

the use of a variety of standard UL-listed 24 VDC Notification Appliances

(refer to the FireLite Device Compatibility Document, Document 15384 for a

complete list of notification appliances). Up to one amp of resettable power is

available for four-wire smoke detectors. The MPS-24AF contains an integral

battery charger for 9.5 to 55 AH batteries.

MPS-24BF/MPS-24BFE

The MPS-24BF supplies the regulated power needed to run the system's modules. It also supplies up to 2.0 amps of RMS-regulated notification appliance

power, permitting the use of a variety of standard UL-listed 24 VDC notification appliances (see Document 15384 for a complete list). Up to 200mA of

resettable power is available for four wire smoke detectors. The MPS-24BF

contains an integral battery charger capable of charging batteries in the 6.5 to

17 AH range. Includes two sets of battery cables, one with 1/4" lug-type connectors for larger batteries and one set with 3/16" lug-type connectors.

AVPS-24F/AVPS-24FE AUDIO VISUAL POWER SUPPLY

Supplies power to notification appliance circuits only. Unfiltered, unregulated, 3.0 amps

maximum. Assumes one position on the CHS-4 Chassis. Provided with a trouble cable

for connection to the main power supply. See Document 15384 for a list of compatible,

UL-listed notification appliances. The AVPS-24F may be installed under any module

except the CPU or modules with expander board installed.

BP-3F BATTERY DRESS PANEL

Covers the main power supply and the batteries in the

cabinet (provides dead-front where required).

S2000 15017 Rev H 10/08/96 P/N 15017:H

9

Page 10

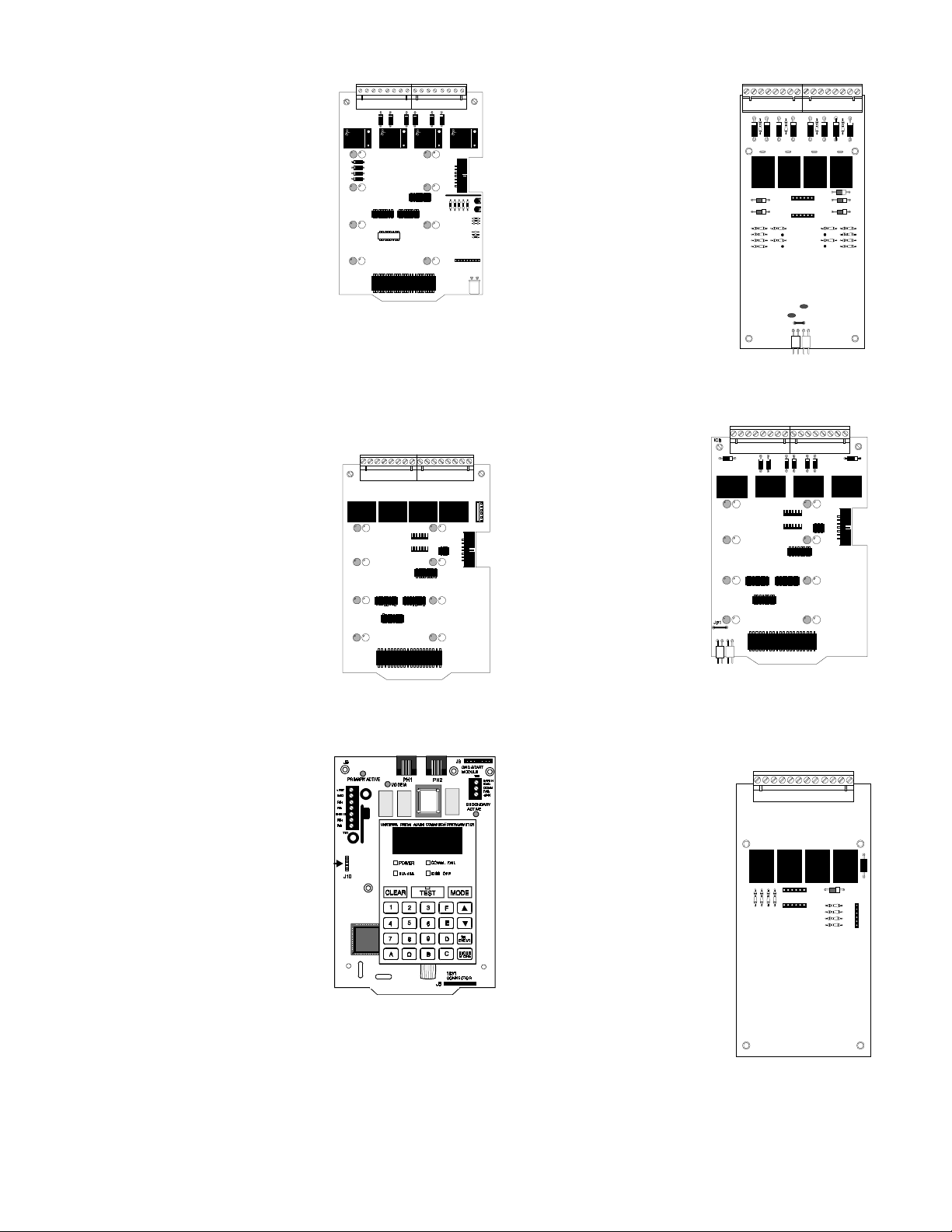

2.3 MODULES

IZ-8F INITIATING

ZONE MODULE

This module provides eight

Style B initiating device circuits. Circuits are power limited and can be programmed for

standard fire, Waterflow Alarm,

Supervisory service, Non

Alarm or Command Inputs.

Also provided are eight end-ofline and eight dummy load resistors.

IZ-4F INITIATING

ZONE MODULE

This module provides four

Style B initiating device circuits. Circuits are power limited and user programmable for

standard fire, Waterflow Alarm

or Supervisory service. Also

provided are four end-of-line

and four dummy load resistors.

IZE-AF INITIATING

ZONE EXPANDER

Converts the eight initiating device circuits on the Initiating

Zone Module (IZ-8F) to Style

D operation. The expander

plugs into the bottom of the IZ8F.

Note: This module will not support an IZE-AF Expander.

End-of-Line Resistor (ELR)

4.7K, 1/2 watt (71252)

Dummy Load Resistor

4.7K, 1/2 watt (71245)

10

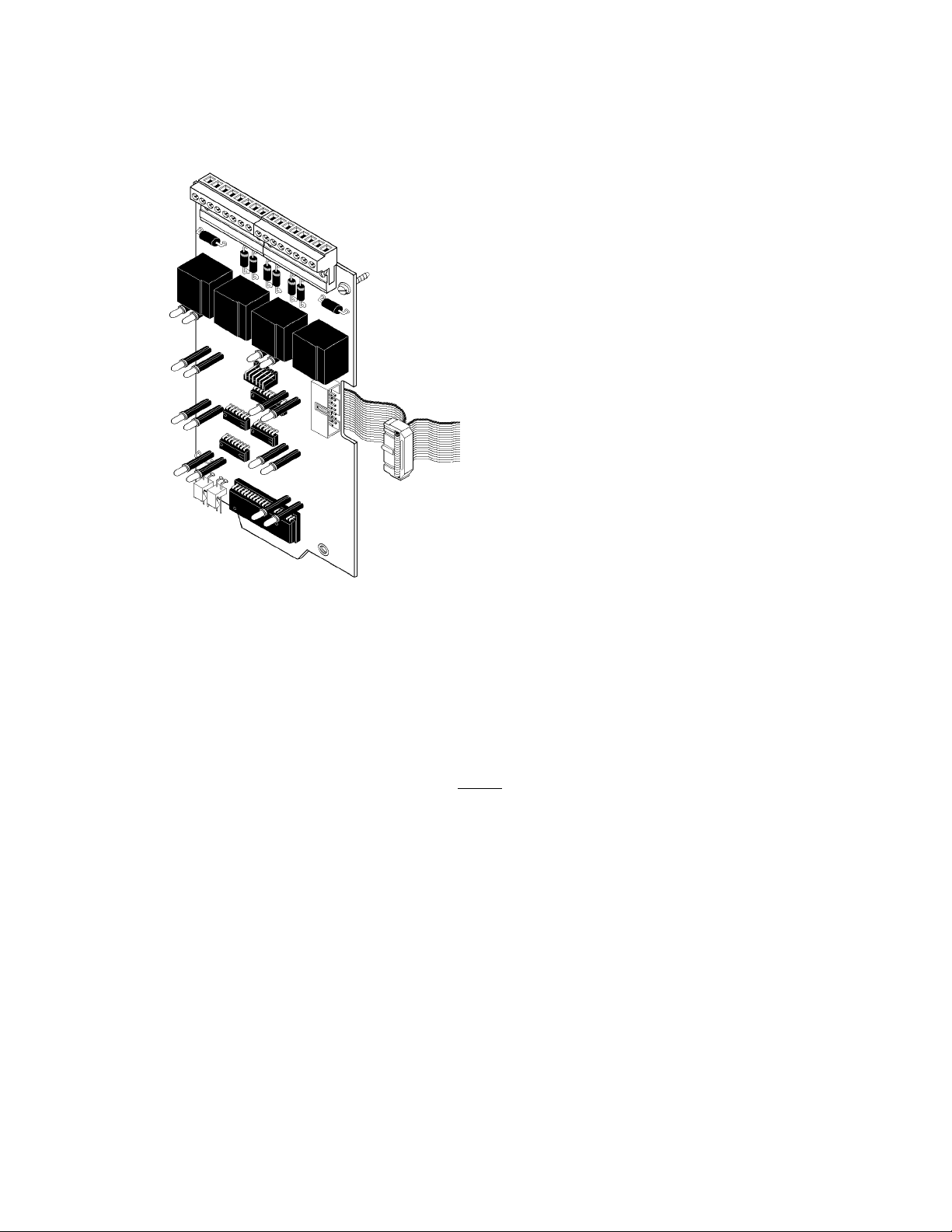

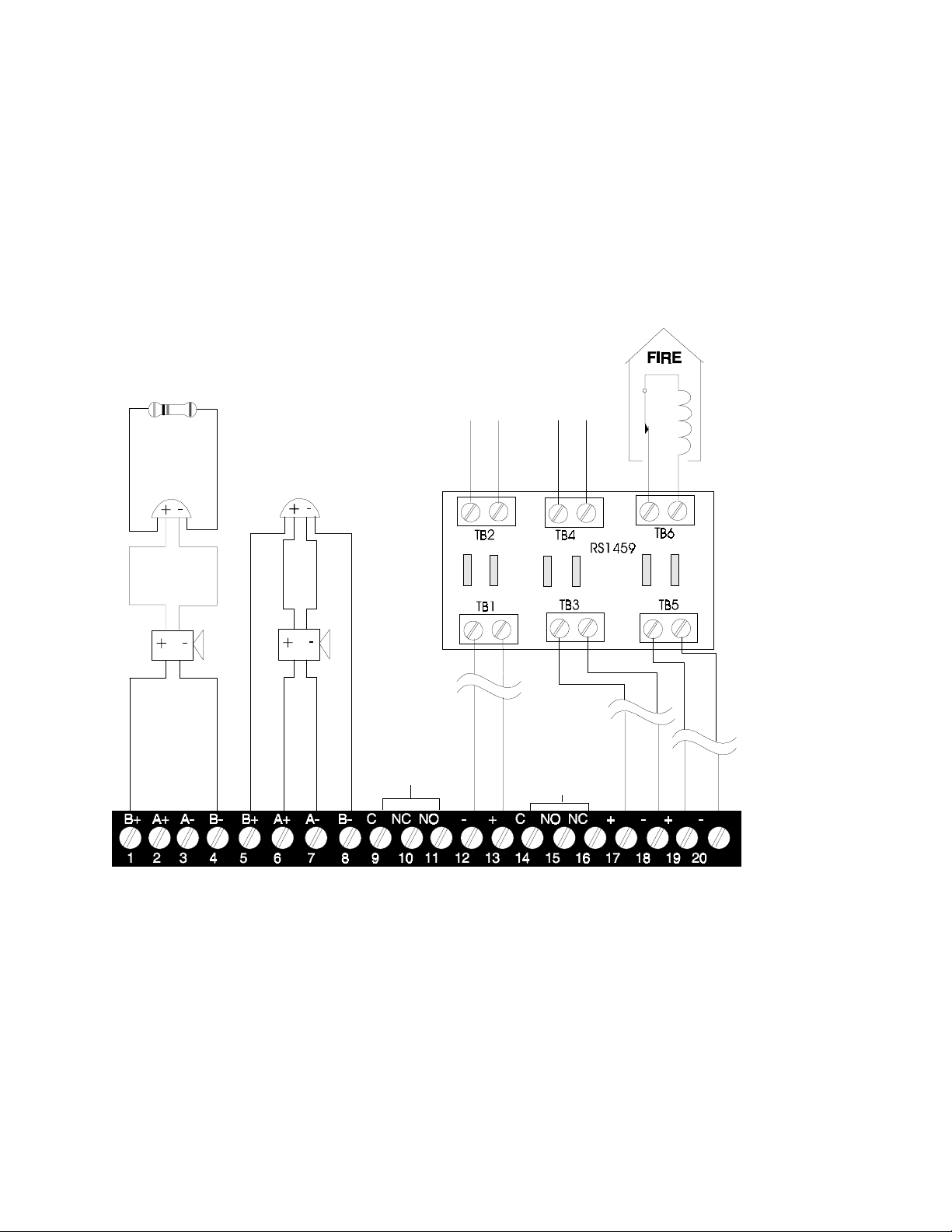

RS-1459 MODULE

The RS-1459 module is used in conjunction with

the Remote Station or Municipal Box Output. The

RS-1459 is NOT required for the Municipal Box

Circuit if wiring remains in conduit, wire length is

less than 1000 meters, and wiring does not cross

any power lines. All conditions must be met according to page 23 of this manual (refer to Figure

4-3). For more information on the RS-1459 module, refer to the RS-1459 Product Installation Drawing, Document 50519.

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 11

IC-4F INDICATING CIR-

CUIT MODULE

ICE-4F INDICATING CIR-

CUIT EXPANDER

Provides four notification appliance

circuits for Style Y or Style Z operation. Maximum signaling current is

3.0 amps (3 amps max per circuit).

Circuits are field programmable to

respond to a single initiating zone, a

group of zones, or all initiating

zones. End-of-line resistors, dummy

load resistors, and an Auxiliary Bell

Power Harness are provided with

each module. For California Code see Figure 4-7.

CR-4F CONTROL RELAY

MODULE

Provides four standard dry FormC alarm contacts rated for 5 amps

@ 120 VAC or 30 VDC (resistive).

Each relay is field programmable

to respond to a single device circuit, a group of circuits, or all initiating device circuits.

Expands the IC-4F to a total of eight

notification appliance circuits (either

Style Y or Style Z). Circuit ratings

are identical to those of the IC-4F.

An Auxiliary Bell Power Harness is

provided with each expander. The

expander plugs into the back of the

IC-4F.

TC-2F/TC-4F TIME

CONTROL MODULE

The TC-2F module can be

configured for one of five

functions. Pre-signal evacuation or dual code evacuation,

and standard release service,

triple-coded release, or IRI release. For more information,

refer to the TC-2F Manual.

The TC-4F can provide either

four releasing circuits or four

power-limited dual code

evacuation circuits. For more information, refer to the TC4F Manual.

THE UNIVERSAL DIGITAL

ALARM COMMUNICATOR/

TRANSMITTER

The UDACT-F may be used with

the FireLite MS-9200 and

Sensiscan 2000 control panels.

The UDACT-F transmits system

status to UL-Listed Central Station

Receivers via the public switched

telephone network. The UDACTF is compact in size and may be

mounted inside the host control

panel or may mount externally in

a separate enclosure. EIA-485 annunciator communications bus

and 24 volt (nominal) connections are required. The UDACT-F

is capable of reporting 198 points or 56 zones when used with

the MS-9200 and 56 zones when used with the Sensiscan 2000.

S2000 15017 Rev H 10/08/96 P/N 15017:H

CRE-4F CONTROL

RELAY EXPANDER

Expands the capacity of the

Control Relay Module (CR4F) to eight Form-C alarm relays. Relays are identical to

those on the CR-4F. The expander plugs into the back of

the CR-4F or IC-4F.

11

Page 12

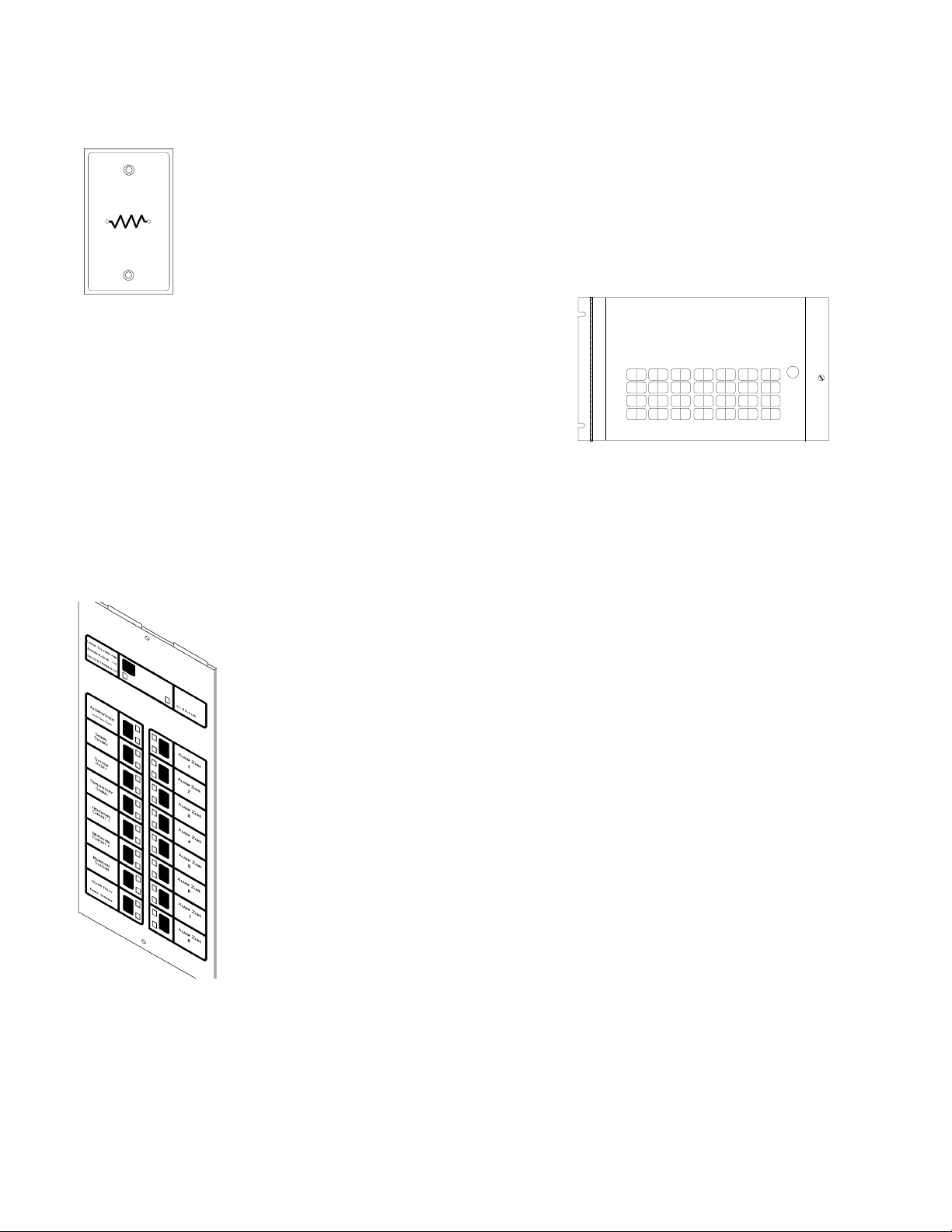

2.4 EQUIPMENT FOR THE SENSISCAN 2000

F-ELR

The F-ELR Resistor Assortment is required for use in Canada. It includes a variety of ELR

values for supervising IZ or IC circuits. The desired resistor mounts to a single ELR plate (illustrated). Included with the F-ELR:

47K, 27K, 10K, 6.8K, 4.7K, 2.2K, 1.8K, 470 and 120 ohm resistors.

CHS-4F

The CHS-4F expansion chassis package is required for all CAB-B3F installations. The CHS-4F includes the CHS-4 Chassis, the MP-1F Module Dress

Panel (illustrated), and an Expander Ribbon Cable.

AFM-16ATX

The AFM-16ATX Annunciator Control Module contains 16 red alarm and 16 yellow trouble LEDs, 16 momentary touchpad switches for controlling each point, a system trouble LED, an ON LINE/POWER LED, and a local piezo sounder with

a silence/acknowledge switch for audible indication of alarm and trouble conditions at each annunciator. The AEM-16ATF

Annunciator Expander Module expands the AFM-16ATX by 16 system points. One to three of these expander modules

can be supported by an AFM-16ATX to a maximum of 64 system points.

MP-1F Module Dress Panel

AFM-32AX

The AFM-32AX Annunciator Control Module contains 32 red alarm LEDs, a System Trouble LED,

an ON LINE/POWER LED, and a local piezo sounder with a silence/acknowledge switch for audible indication of alarm and trouble conditions at each annunciator. The AEM-32ATF Expander

Module expands the AFM-32AX by 32 system points. One expander module can be supported by

an AFM-32AX, providing a maximum of 64 points.

AFM-16ATF

The AFM-16ATF Annunciator Fixed Module contains 16 red alarm and 16 yellow trouble LEDs,

16 momentary touch-pad switches, a system trouble LED, an ON LINE/POWER LED, and a local

piezo sounder with a silence/acknowledge switch for audible indication of alarm and trouble conditions at each annunciator. Only One annunciator may be used in a system.

AFM-32AF

The AFM-32AF Annunciator Fixed Module contains 32 red alarm LEDs, a System Trouble LED,

an ON LINE/POWER LED, and a local piezo sounder with a Local Silence/Acknowledge switch

for audible indication of alarm and trouble conditions. Only one annunciator may be used in a

AFM-16ATX

system.

AFM-16AF

The AFM-16AF Fixed Annunciator module is intended for use in systems that require 16 alarm annunciator points or less.

Only one annunciator may be used in a system.

12

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 13

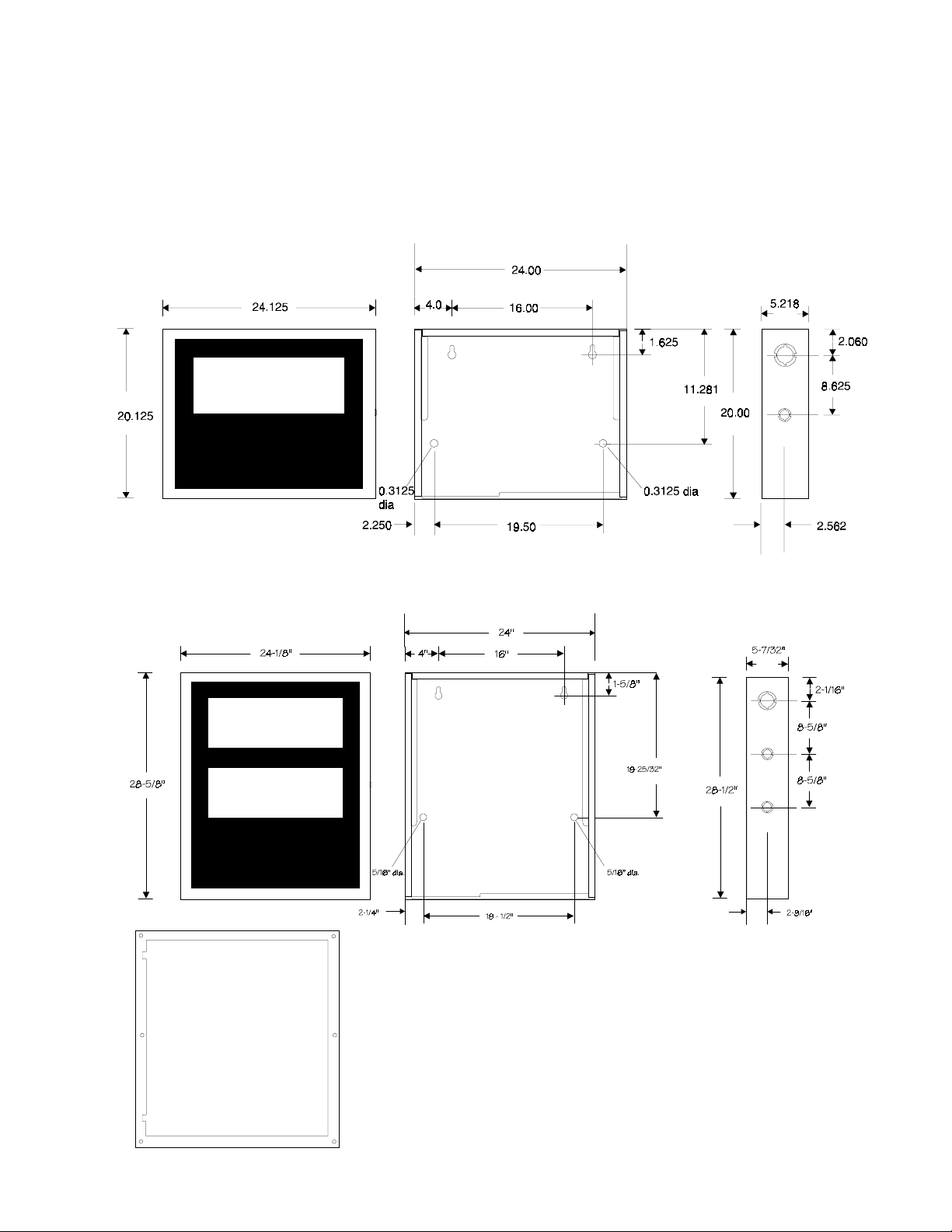

2.5 CABINETS

The CAB-A3F and CAB-B3F cabinet assemblies consist of a backbox and a locking door with two keys. The backbox and

door can be ordered separately or as a complete package.

CAB-A3F

CAB-B3F

TR-A3R/TR-B3R TRIM RING

For semi-flush mounting of the cabinet

S2000 15017 Rev H 10/08/96 P/N 15017:H

13

Page 14

SECTION THREE: I NSTALLATION

The control panel's modules communicate with the CPU

through a common ribbon cable connection.

The following procedures, diagrams, and instructions must be followed precisely to avoid damage to the control panel and

its associated equipment. Reliability depends to a great extent upon proper installation and maintenance.

Cabinet - Mount the cabinet and draw all field wiring through the knockouts provided. If the door is left-hanging,

❏❏

❏

❏❏

mount door hardware now, due to the main power supply resting on lower hinge.

NOTE

Do not draw wiring into the bottom nine inches of the cabinet or conflict with the power

supply and batteries may result.

Main Power Supply - Mount the main power supply to the cabinet as illustrated in Figure 3-3. Do not wire anything

❏❏

❏

❏❏

at this time!

Chassis- Mount all chassis. Refer to Figure 3-2 for installation of the CHS-4 chassis.

❏❏

❏

❏❏

Audio Visual Supplies - If any optional audio visual power supplies are to be employed, mount them to the chassis.

❏❏

❏

❏❏

Refer to Figure 3-4 for mounting of the AVPS-24F/AVPS-24FE to the CHS-4.

Audio Visual Cables - Connect the trouble cable(s) and Auxiliary Bell Power Harness to the audio visual power

❏❏

❏

❏❏

supply as illustrated in Figure 5-4.

❏❏

❏

❏❏

Preliminary System Wiring- The main power supply and any audio visual power supplies should be wired at this

time while the terminals are readily accessible. Refer to Section Five to wire the main power supply, audio visual

power supplies or the R45-24.

14

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 15

Module Ribbon Cables - Connect the 1st Row Ribbon Cable to the CPU as illustrated in Figure 3-8. For each

❏❏

❏

❏❏

additional row of modules installed in the cabinet, connect an Expander Row Ribbon Cable to the CPU.

CPU - Install the CPU module in the top left cabinet position as illustrated in Figure 3-7. Connect the Power Ribbon

❏❏

❏

❏❏

and Power Harness between the CPU and the main power supply as illustrated in the respective figure in Section Four.

Module Expander Boards - If expander boards are to be used with a module, install as illustrated in Figure 3-5.

❏❏

❏

❏❏

Modules - Mount each module in its respective chassis position as illustrated in Figure 3-6. Connect the CPU Row

❏❏

❏

❏❏

Ribbon Cable and the Expander Row Ribbon (in CAB-B3F installations) to the modules. Field-wire each module,

using the following figures for reference:

CPU-2000 Figure 4-3, 4-4

IZ-8F or IZ-4F (Style B) Figure 4-5

IZ-8F requires IZE-AF (for Style D) Figure 4-6

IC-4F/ICE-4F Figure 4-7 (ICE-4F Optional)

CR-4F/CRE-4F Figure 4-8 (CRE-4F optional)

TC-2F (Refer to the TC-2F Manual)

TC-4F (Refer to the TC-4F Manual)

AFM-16ATF, AFM-32AF,AFM-16AF,

AFM-16ATX,AFM-32AX (Refer to respective manual.)

UDACT-F Figure 6-1

Power-on-check - Apply AC power to the control panel. Do not connect the batteries at this time! To silence the

❏❏

❏

❏❏

audible trouble sounder, push the ACKNOWLEDGE switch on the CPU. The system should reflect the following

status.

On the CPU

Green AC POWER indicator should be on.

The BATTERY FAIL indicator will be on due to the absence of batteries.

SYSTEM TROUBLE and POWER FAILURE indicators should be on due to the absence of batteries.

MODULE FAILURE indicator may light shortly after AC power is applied (applies only to a system that has

not been previously configured).

On each module

The yellow trouble indicators may come on approximately ten seconds after AC power is applied (applies

only to a system that has not previously been configured).

On each AVPS

The yellow trouble indicators will light due to the absence of batteries.

On the main power supply

Failure of the AC POWER indicator, or the presence of indications not mentioned above may suggest an installation

problem. Carefully review the installation instructions to isolate the source.

Programming - To configure and program the system, refer to field programming in Section Seven.

❏❏

❏

❏❏

Batteries - Once the system has been programmed and is functional, connect the batteries. Ensure that all indicators

❏❏

❏

❏❏

except AC POWER are extinguished.

Testing - Fully field test the system by conducting the test procedure in Section Nine.

❏❏

❏

❏❏

Dress Panels - Complete installation of the system by installing the cabinet door first, followed by the dress panels

❏❏

❏

❏❏

(VP-1F and MP-1F).

S2000 15017 Rev H 10/08/96 P/N 15017:H

15

Page 16

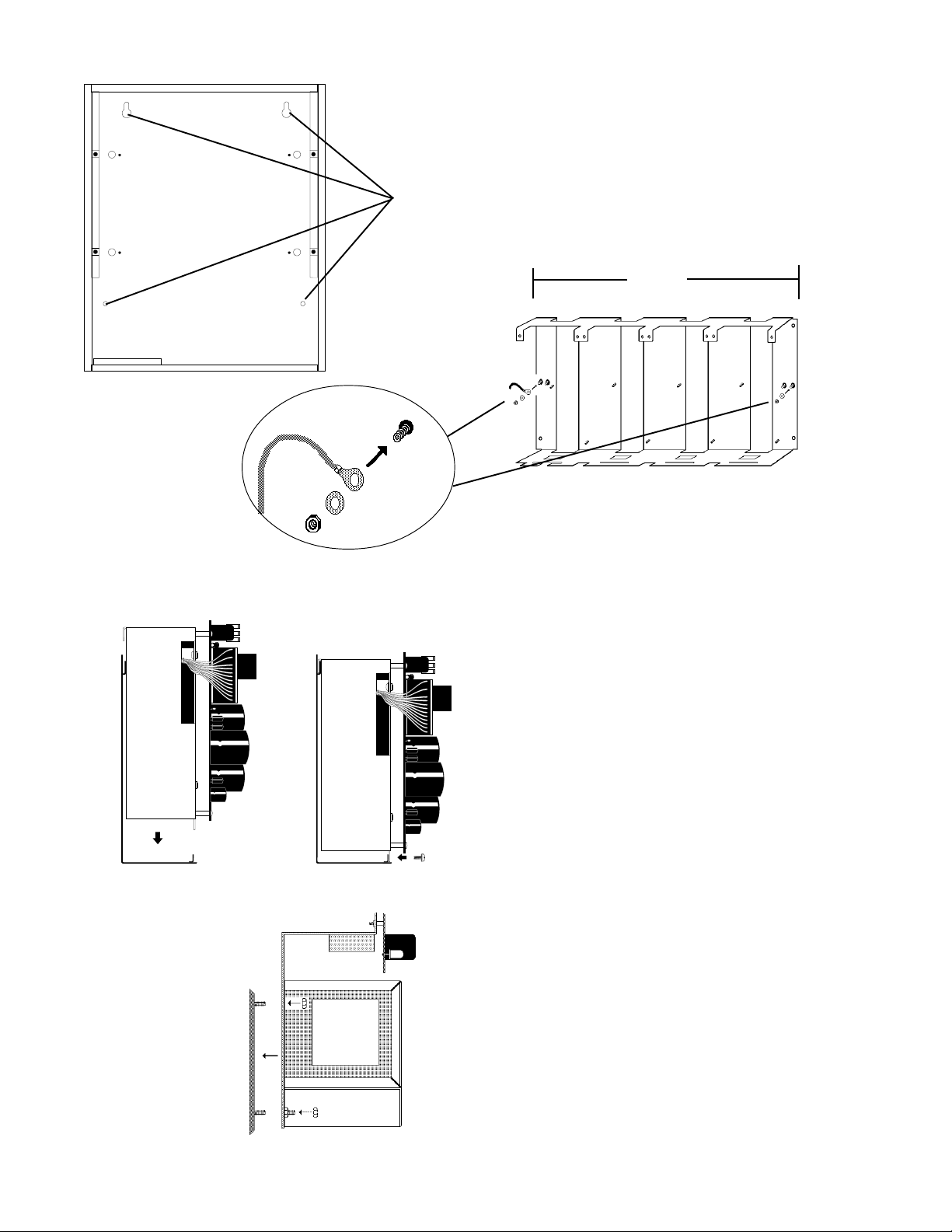

FIGURE 3-1 : MOUNT THE CABINET BACKBOX

Mount the backbox in a clean, dry, vibration free area, using the four

holes provided in the back surface of the cabinet.

Grounding Cable

17-15/16

FIGURE 3-2: INSTALL A CHS-4

Install a CHS-4 in each row of the cabinet that will employ Sensiscan 2000 modules. For proper grounding of

the modules to the cabinet, connect a grounding cable to

one of the chassis mounting screws as illustrated.

FIGURE 3-3: INSTALL THE MAIN POWER

SUPPLY

Place the MPS-24AF/MPS-24AFE (shown) or MPS-24BF/

MPS-24BFE into the bottom of the cabinet, ensuring that

the upper bracket engages the support bracket on the cabinet. Secure the bottom of the power supply to the bottom

cabinet support with the provided screws.

FIGURE 3-4: INSTALL THE AVPS

16

CHS-4

Install any optional AVPS-24F/AVPS-24FE over the screw

AVPS

S2000 15017 Rev H 10/08/96 P/N 15017:H

mounts on the CHS-4 and secure with the two provided nuts.

Page 17

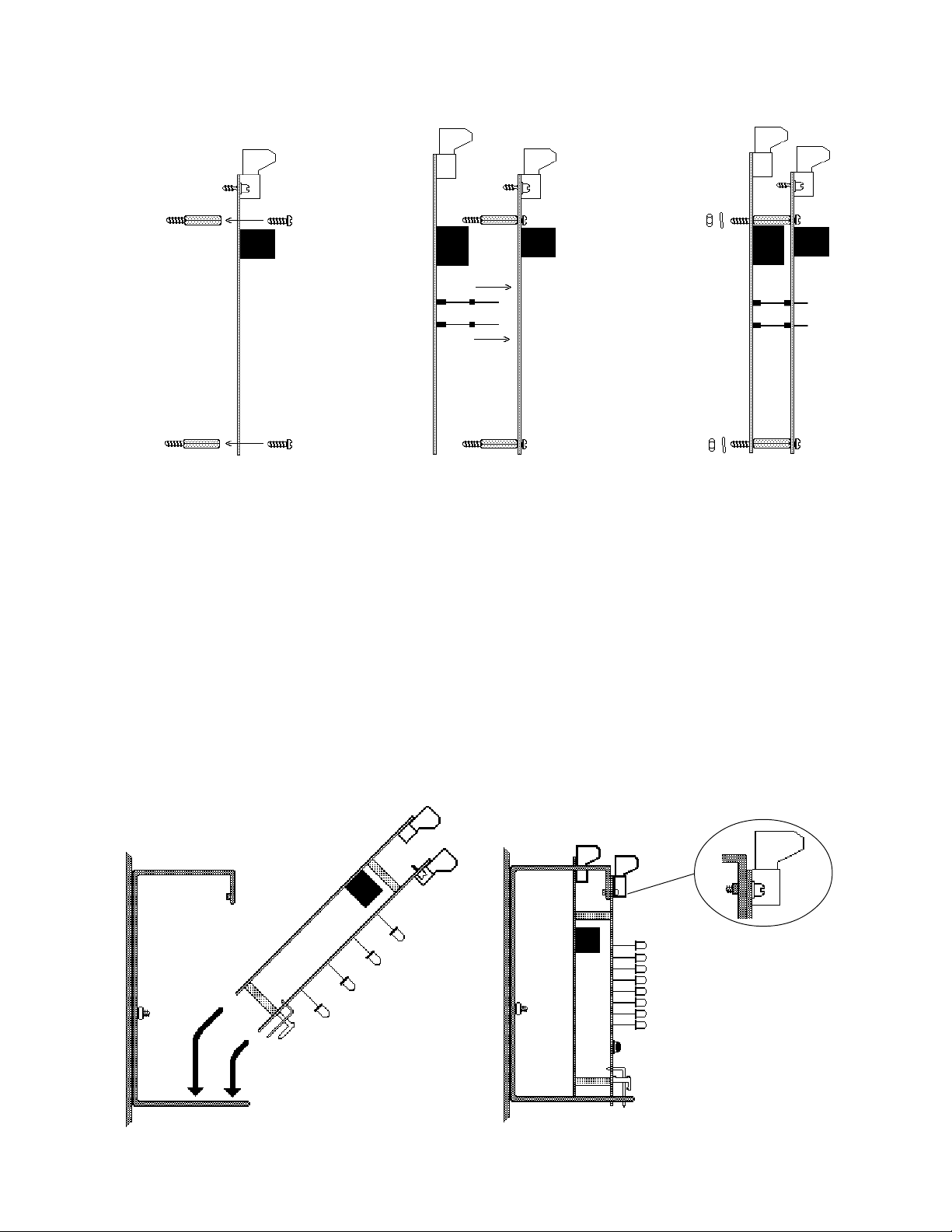

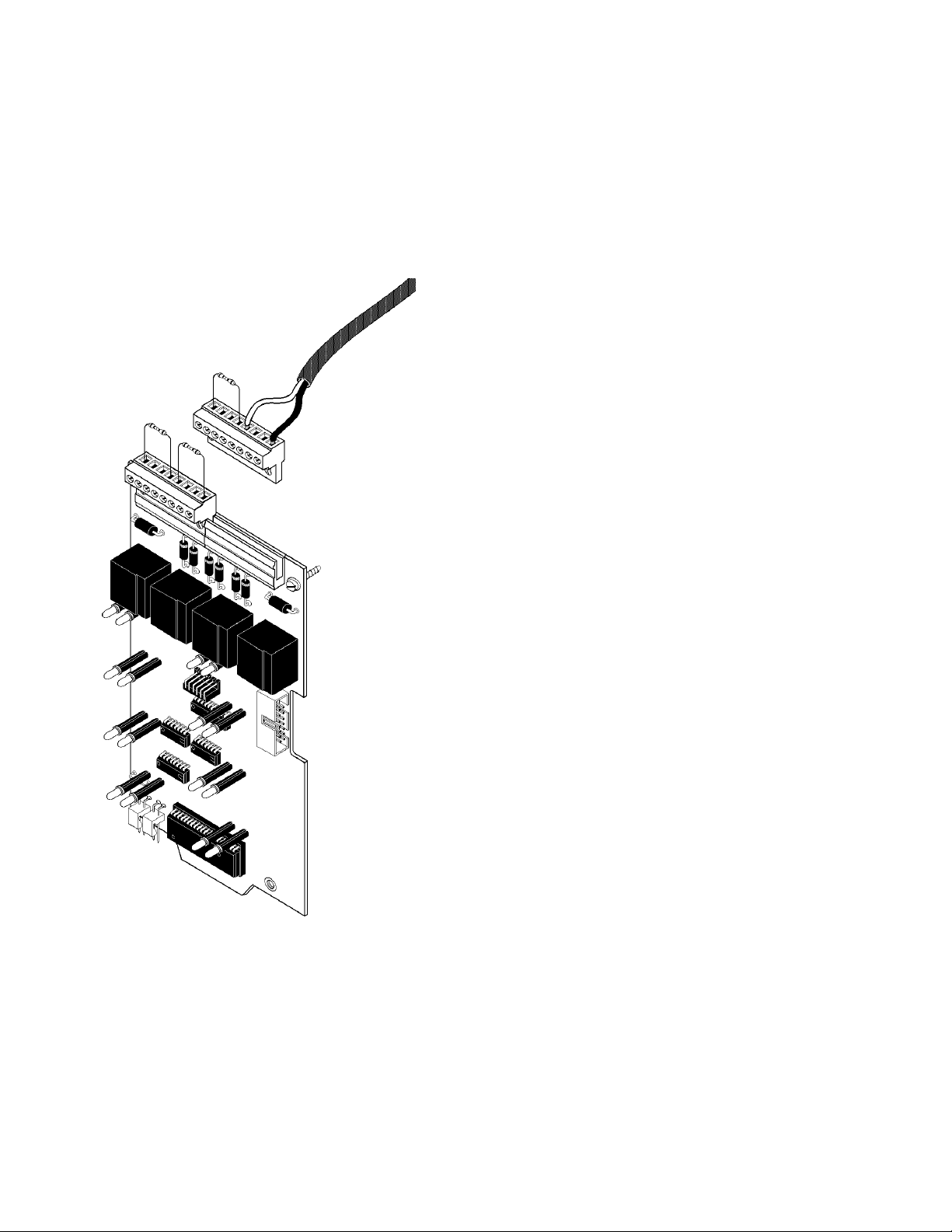

FIGURE 3-5: MOUNTING MODULE EXPANDERS

Module

Step 1:

Attach four standoffs to the

module using the four screws

provided.

Expander Module

Step 2:

Insert the pins on the expander board into

the connector on the module and press the

two boards together, ensuring that the pins

are properly aligned.

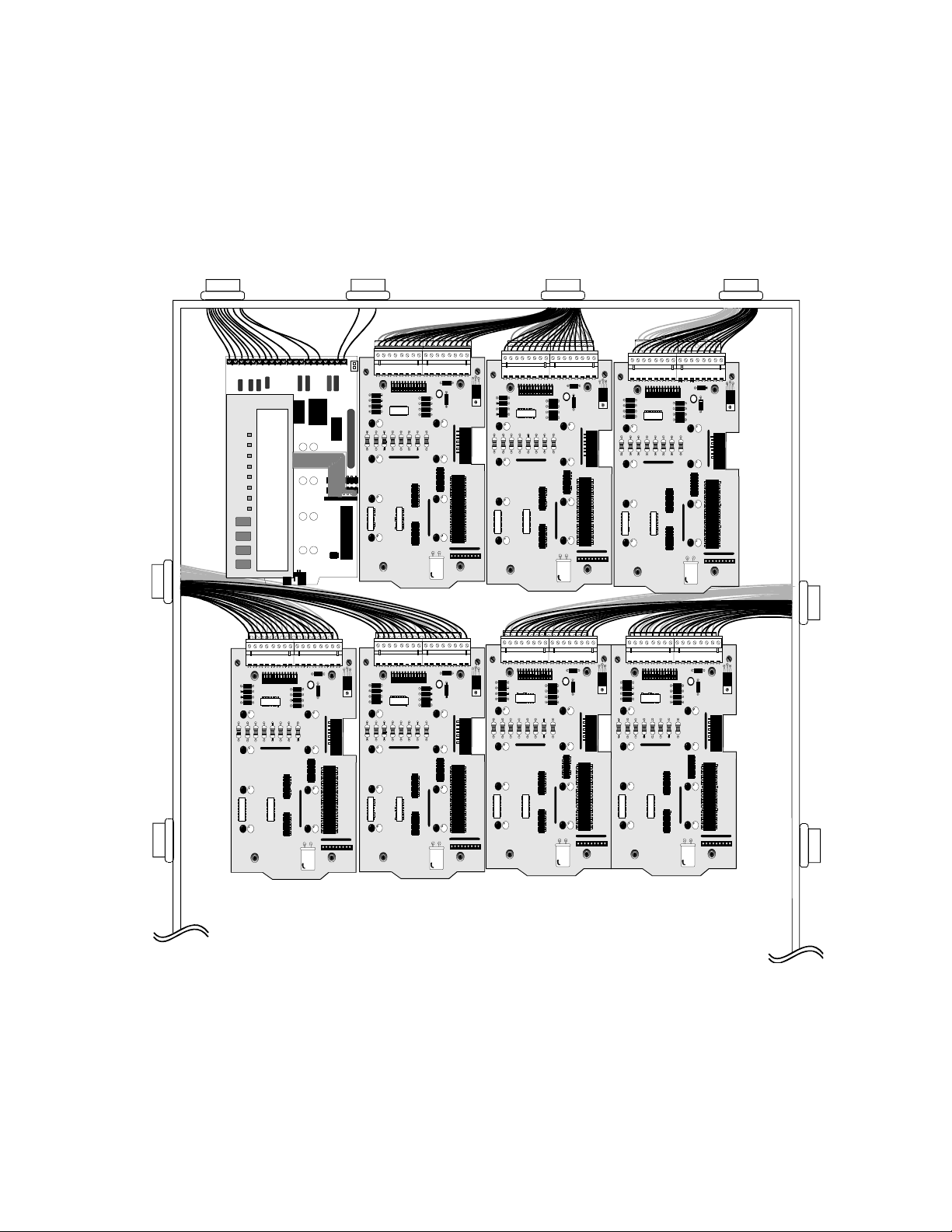

FIGURE 3-6: MOUNTING MODULES IN THE CHASSIS

Step 1:

Angle the module into the cabinet so that the upper

board edge slips into the cabinet slot as shown.

Step 2:

Push the upper end of the module into the cabinet and secure

with two module screws. Straighten LEDs so that they extend

from the board at a 90 degree angle.

Expander/Module

Step 3:

Secure the module/expander assembly with the four nuts and lock

washers provided.

Cabinet

Cabinet

S2000 15017 Rev H 10/08/96 P/N 15017:H

17

Page 18

FIGURE 3-7: MOUNTING THE CPU-2000

Step 1:

Insert the CPU Module into the left-most

cabinet slot, angling the front end of the

module into position as shown.

Step 2:

Push the back end of the module down into the

cabinet and pull down until the upper board

engages the slot on the chassis as shown.

Bottom View

18

Step 3:

Align the module screws with the

thread-holes on the chassis and secure

in place.

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 19

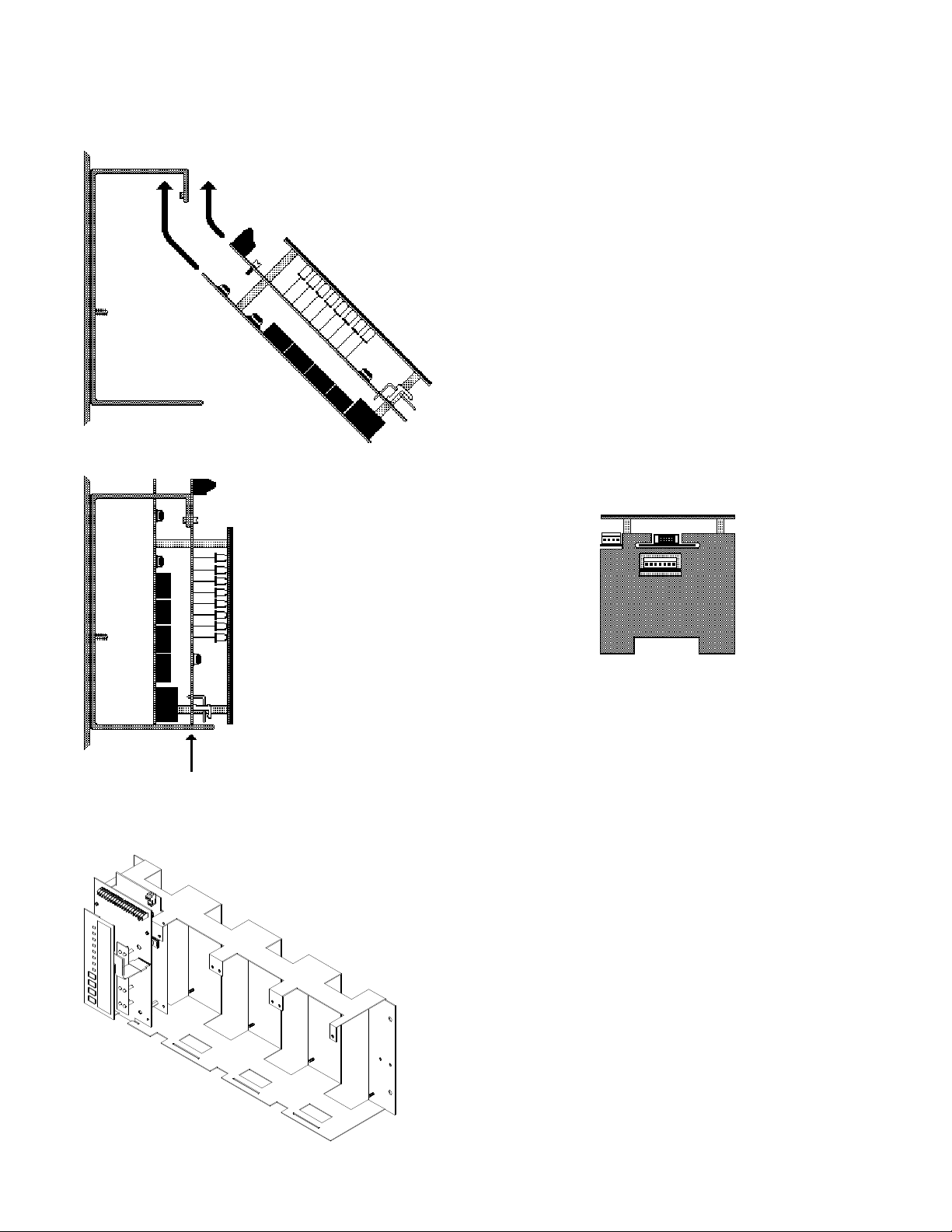

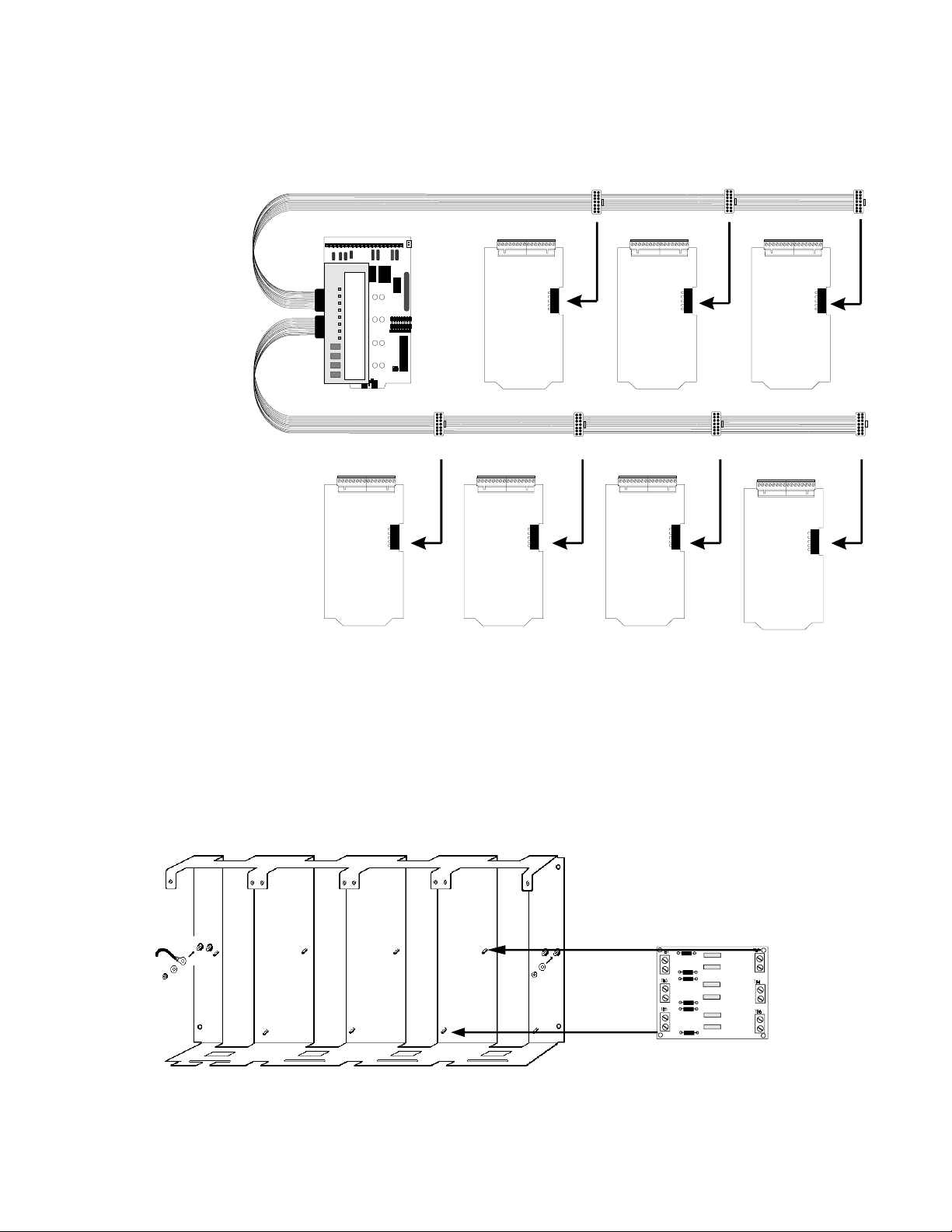

FIGURE 3-8: CONNECTING ROW RIBBON CABLES TO MODULES

The ribbon cable is notched at the module ends.

First Row

Ribbon

(71087)

Connect to upper-

most connector on

CPU.

Expander

Ribbon

(71088)

FIGURE 3-9: MOUNTING THE RS-1459 IN THE CHS-4

Mount the RS-1459 to two studs in any position on the back of the CHS-4. Use the provided standoffs and screws to mount

the module. Refer to Figure 4-3 for information on wiring the module.

RS-1459

CHS-4

S2000 15017 Rev H 10/08/96 P/N 15017:H

19

Page 20

SECTION FOUR: FIELD WIRING THE MODULES

The IC-4F Notification Circuit Module, as well

as the IZ, CR and TC modules feature removable

terminal blocks that ease installation and servicing of the control panel.

20

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 21

4.1 UL POWER-LIMITED WIRING REQUIREMENTS

Power-limited and nonpower-limited circuit wiring must remain separated in the cabinet. All power-limited circuit wiring

must remain at least 0.25" away from any nonpower-limited circuit wiring. Furthermore, all power-limited and nonpowerlimited circuit wiring must enter and exit the cabinet through different knockouts and/or conduits. A typical wiring diagram

for the Sensiscan 2000 is shown below.

Nonpowerlimited

circuits

Power-limited

circuits

Nonpower-limited

circuits

Power-limited

circuits

Power-limited

circuits

Po werlimited

circuits

Power supplies in bottom of cabinet - see Figure 4-2

Figure 4-1: Typical Wiring Diagram for UL Power-limited Wiring Requirements

S2000 15017 Rev H 10/08/96 P/N 15017:H

21

Page 22

4.2 UL POWER-LIMITED WIRING REQUIREMENTS - POWER SUPPLIES

The diagram below shows a typical Sensiscan 2000 installation and is provided as a guide for proper wiring placement. The

AC and battery wiring are not power-limited. A separation of at least 0.25" must be maintained between power-limited and

nonpower-limited wiring. Install the tie wraps and adhesive squares as indicated below.

Adhesive square and tiewrap on back of cabinet

affixing power-limited

wiring.

22

Adhesive square and

tie-wrap on back of

cabinet and on top of

power supply chassis

affixing nonpowerlimited wiring.

Figure 4-2: Power-limited and Nonpower-limited Wiring for Power Supplies

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 23

Typical Supervised Power-limited

Notification Appliance Circuits

Use only compatible, UL-listed notification appliances (see the Device Compatibility Document, 15378). Max current per circuit is 3.0

amps, subject to the limitations of the power

supply.

Style Y

4.7K, 1/2 watt ELR,

Part # 71252.

Non-Supervised

Remote Station Outputs

Non-Supervised, Power-limited

(Standby polarity shown)

24 VDC (nominal). 10 mA max rated

current. Internal resistance = 1360 ohms

(nominal).

Intended for connection to the polarity

reversal circuit of a remote station receiving unit (Fire-Lite Model RS-82) having

compatible ratings.

Remote Station

Trouble Output

Remote Station

Alarm Output

Municipal Box Output

Nonpower-limited, supervised for

open circuits. Max. Current (short

circuit) = 0.6 amps. Max. Voltage

(open circuit) = 27.6 VDC. Max.

Wire Resistance = 5 ohms.

Municipal Box Ratings

Trip current = 0.25 Amps (min)

Coil voltage = 3.65 VDC (min)

Coil resistance = 14.6 ohms (max)

UL-listed

24 VDC

Polarized Bell

UL-listed

24 VDC

Polarized Horn

Style Z

System

Trouble

Contacts

(power-limited

source only)

2A @ 30VDC

1A @ 120VAC

(resistive)

Programmable

Alarm

Contacts

(power-limited

source only)

5A @ 30VDC

5A @ 120VAC

(resistive)

Figure 4-3: Field Wiring the CPU

Municipal box wiring

must be run in conduit.

Municipal Box Output

Nonpower-limited and supervised (for open circuits). Wiring can leave the building.

1) The Remote Station Alarm Output and the Municipal Box Output must not be used simultaneously.

2) Notification appliance circuits, Remote Station Trouble output, and the Remote Station Alarm output are power-

limited and may be connected to limited-energy cable.

3) Wire notification appliances according to the manufacturer's instructions packaged with each device.

4) Terminal blocks will accept #12 to #22 AWG wire.

5) Size notification circuit wire for a maximum drop of 2 volts DC at the last device on the circuit.

6) The RS-1459 module is required when the Remote Station or Municipal Box Output is connected to a circuit that

exits the protected premises. Exception - The RS-1459 module is not required for the Municipal Box Circuit if

ALL of the following conditions exist: (1) wiring is in conduit, (2) wire length is less than 1000 meters, and (3)

wiring does not cross any power lines.

S2000 15017 Rev H 10/08/96 P/N 15017:H

23

Page 24

DUMMY-LOADING UNUSED CIRCUITS ON THE CPU

An unused notification circuit must be terminated with

one dummy load resistor.

If the Municipal Box Output is not to be used,

it must be terminated with a dummy load resistor.

4.7K, 1/2-watt Resistor

Part # 71245

4.7K, 1/2-watt Resistor

Part # 71245

THE EIA-485 INTERFACE

The Sensiscan 2000 communicates with the AFM serial annunciators through the EIA-485 interface on the CPU. Maximum

distance is 6000 feet and maximum resistance is 100 ohms.

EIA-485 Interface

Supervised and Power-limited

EIA-485 (+)

EIA-485 (-)

24

TB2

Figure 4-4: Connecting the EIA-485 Interface

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 25

FIGURE 4-5 NFPA STYLE B FIELD WIRING OF INITIATING ZONE MODULES

ABCD E*F*G*H*

b+ b- b+ b- b+ b- b+ b- b+ b- b+ b- b+ b- b+ b-

AE

BF

C G

4.7K, 1/2 watt ELR, Part # 71252.

Manual Pull Station

UL-listed two-wire

Photo smoke detector

2

5

DH

*NOTE: IZ-4F contains only circuits A, B, C and D.

1) Initiating device circuits are supervised, power limited and may be connected to limited-energy cable, except for initiating devices that require

24 VDC power.

2) Use only the compatible, UL-listed two-wire smoke detectors that are

listed in FireLite Document 15384.

3) For connection of four-wire smoke detectors, refer to Section Six.

4) Wire initiating devices according to the manufacturer's instructions pack-

aged with each device.

5) For Canada, model F-ELR End-of-Line Resistor Assembly required.

6) Maximum line resistance is 100 ohms.

UL-listed two-wire

Ion smoke detector

2

Typical NFPA Style B

Initiating Device Circuit

Supervised and Power-limited

Dummy load all unused circuits

with 4.7K ELR (71245).

S2000 15017 Rev H 10/08/96 P/N 15017:H

25

Page 26

FIGURE 4-6: STYLE D FIELD WIRING OF IZ-8F INITIATING ZONE MODULE WITH IZE-AF

EXPANDER

ABCD E FGH

a+ a- a+ a- a+ a- a+ a- a+ a- a+ a- a+ a- a+ a-

b+ b- b+ b- b+ b- b+ b- b+ b- b+ b- b+ b- b+ b-

Manual Pull Station

AE

Two-wire Photo smoke detector

BF

C G

DH

IZ-8F/IZE-AF

1) Initiating device circuits are supervised, power limited and may be

connected to limited-energy cable, except for initiating devices that

require 24 VDC power.

2) Use only the compatible, UL-listed two-wire smoke detectors that

are listed in FireLite Document 15384.

3) For connection of four-wire smoke detectors, refer to Section Six.

4) Wire initiating devices according to the manufacturer's instructions

packaged with each device.

5) The IZ-4F does not support the IZE-AF expander module and therefore cannot be wired for Style D circuits.

6) Maximum line resistance is 100 ohms.

two-wire Ion smoke detector

2

Typical NFPA Style D

Initiating Device Circuit

Supervised and Power-limited

26

Dummy load all unused circuits

with a 4.7 ELR (71245).

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 27

FIGURE 4-7: NFPA STYLE Y/Z FIELD WIRING OF THE IC-4F INDICATING CIRCUIT MOD-

ULE AND ICE-4F EXPANDER

E F G H

b+ a+ a- b- b+ a+ a- b- b+ a+ a- b- b+ a+ a- b-

A B C D

b+ a+ a- b- b+ a+ a- b- b+ a+ a- b- b+ a+ a- b-

A E

Optional ICE-4F Indicating Circuit Expander. Positions E, F, G, and H

are active only with this board installed.

Typical

NFP A Style Y

Notification Appliance

Circuit

4.7K, 1/2 watt ELR,

Part # 71252.

5

Typical

NFPA Style Z

Notification Appliance

Circuit

UL-listed

24 VDC

Polarized Bells

UL-listed

24 VDC

Polarized Horns

Jumper

unused

circuits

B F

Jumper

unused

circuits

CG

D35

DH

JP2

J5 J6

Cut this diode for California Code

IC-4F/ICE-4F

1) Notification appliance circuits are supervised, power limited and may be connected to limited-energy cable.

2) Use only compatible, UL-listed notification appliances that are listed in Document 15384.

3) Wire notification appliances according to the manufacturer's instructions packaged with each device.

4) Max current per circuit is 3.0 amps, subject to the limitations of the source of power (MPS-24AF/MPS-24AFE, MPS24BF/

MPS-24BFE, or AVPS-24F/AVPS-24FE).

5) For Canada, model F-ELR End-of-Line Resistor Assembly is required.

6) Size wiring for a maximum voltage drop of two volts at the last device on the circuit.

7) The IC-4F is California Code programmable (microprocessor Rev. B or higher of IC-4F). To program for California Code, cut

diode D35.

8) Cut jumper JP1 and JP2 to separately power notification appliance circuits 1 & 2 or 3 & 4. Separate 3 amps max. power

supplies must be tied to J5 & J6.

S2000 15017 Rev H 10/08/96 P/N 15017:H

27

Page 28

FIGURE 4-8: FIELD WIRING OF THE CR-4F CONTROL RELAY MODULE AND THE CRE-4F

CONTROL RELAY EXPANDER

EFGH

no nc c no nc c no nc c no nc c

* Optional CRE-4F Control Relay Expander. Positions E, F, G and H

are active only with this board installed.

ABCD

no nc c no nc c no nc c no nc c

AE

★

These Form-C gold-plated, silver alloy relay contacts are for

medium duty switching and are not intended for Motor Control or Pilot Duty.

UL contact ratings are 5 amps @ 125 volts AC (resistive) or

30 volts DC (resistive) and 2 amps @ 125 volts AC (inductive).

Activation of a CR-4F or CRE-4F relay occurs automatically when an alarm is detected on a selected (programmed)

Initiating Device Circuit.

Note: Refer to the power-limited label located on the FACP door.

Make a notation on the label for each circuit being employed as

a nonpower-limited circuit. (Refer to the example on the label).

★

★

★

Nonpower-limited and power-limited wiring must have a minimum

BF

CG

D H

distance of 0.25" wire to wire and must enter and exit from different

knockouts. If this module is used to drive nonpower-limited and

power-limited circuits, please follow the instructions below.

1) Skip a set of dry contacts to maintain the 0.25" required space

Relay 1

Relay 2

Relay 3

Relay 4

NO

NC

NO

NC

NO

NC

NO

NC

Power-limited

C

C

C

C

Circuit

Power-limited

Circuit

no connection

Nonpower-limited

Circuit

Nonpower-limited

Circuit

between power-limited and nonpower-limited circuits. The wiring

of this module must follow UL Power-limited Wiring Requirements.

2) If this module is needed to drive power-limited and nonpowerlimited relays that are next to each other, refer to the figure to the left

showing a typical connection.

Typical Form-C Contr ol Rela y in Standb y P osition

OR

28

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 29

SECTION FIVE: THE POWER SUPPLIES

Main Power Suppl y Bell

Power Harness

(71093)

Blue to Bell Pow er (+)

Black to Bell P o w er (-)

Three cables complete the electrical connection between the CPU and the main power supply.

CPU

(Bottom

View)

Power Ribbon

(71085)

Connects to P3

on the main

power supply

Main Power Harness

(71086)

to P2 on the main power

supply

S2000 15017 Rev H 10/08/96 P/N 15017:H

29

Page 30

5.1 THE MPS-24AF/MPS-24AFE MAIN POWER SUPPLY

The MPS-24AF/MPS-24AFE Main Power Supply is capable of powering the control panel continuously during standby and

alarm conditions. A total of 3.0 amps (internal0 @ 24 VDC regulated is available from the main power supply for operating

the system during Standby conditions. No more than 6 amps @ 24 VDC can be drawn from the MPS-24AF.

Figures 5-1 and 5-2 illustrate connections for primary and secondary power to the MPS-24AF Main Power Supply, as well

as terminal and harness connections for the control panel.

CONNECTING THE PRIMARY POWER SOURCE

Primary power required for the MPS-24AF is 120 VAC, 50/60 Hz, 1.8 amps and primary power for the MPS-24AFE is 220/

240 VAC, 50/60 Hz, 0.9 amps. With the breaker at the main power distribution panel turned off, remove the plastic insulating cover from Terminal Block TB1 on the main power supply and connect the system primary power source. Connect the

service ground to TB1 Terminal 2 and ground the power supply assembly to the cabinet with a Chassis Ground cable (71073)

to TB1 Terminal 1. Connect the primary Neutral line to TB1 Terminal 4 and the primary Hot line to TB1 Terminal 6. After

completion of these connections reinstall the plastic insulating cover over the terminal strip. Leave the main power breaker

off until installation of the entire system is complete.

CONNECTING THE SECONDARY POWER SOURCE (24 VDC)

Secondary power (batteries) is required to support the system during loss of primary power. These batteries reside in the

control panel cabinet, or in a separate R45-24 Remote Battery Charger cabinet which can be mounted up to 20 feet away

from the control panel (for connection of an R45-24, refer to Figure 5-6).

Connect the Battery Positive Cable (71071) to TB2 Terminal 1 (+) and the Battery Negative Cable (71072) to TB2 Terminal

2 (-). Do not connect the Battery Interconnect Cable (Part Number 71070) at this time. This connection will be made just

after initial primary system power-up.

FOUR-WIRE SMOKE DETECTOR POWER (24 VDC)

Up to one amp of current for four-wire smoke detectors can be drawn from TB3 Terminals 1 (+) and 2 (-). Power is removed

from these terminals during system reset. This 24 VDC regulated four-wire smoke detector power is power limited but must

be supervised via an UL-listed end-of-line power supervision relay. The power supervision relay is energized by the fourwire power circuit and its contact must be connected in series with an initiating device circuit.

NOTIFICATION APPLIANCE POWER (24 VDC)

Up to 3 amps of regulated power-limited current for powering notification appliances can be drawn from TB3 Terminals

3(+) and 4(). Power is not removed from these terminals during system reset. If a resettable power circuit is desired, cut

JP5 on the MPS-24AF (Note that a maximum of 2 amps is available with JP5 cut.) Note: On the Main Power Supply Bell

Power Harness, the fork lugs must be cut off and wires stripped for connection to the MPS-24AF.

ANNUNCIATOR POWER (24 VDC)

AFM Annunciators can be powered either from the four-wire smoke detector output or the notification appliance power

output. Both outputs provide filtered, regulated, power-limited source required by the annunciators. The power run to the

annunciators is supervised by the annunciator (Loss of Communications error).

SYSTEM HARNESS CONNECTIONS

Internal power for the system is provided via the power harness. Connect this harness from P2 on the main power supply to

the CPU. This same power can be fed to other boards or modules requiring internal power. Signaling between the CPU and

the main power supply is accomplished through connection of the Power Ribbon (71085) to P3 on the MPS-24AF.

30

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 31

FIGURE 5-1: FIELD WIRING THE MPS-24AF/MPS-24AFE POWER SUPPLY

Four-Wire Smoke Detector/Annunciator Power

24 VDC (20.4-26.4, 200 mV ripple), 1 amp max. Filtered, regulated and resettable.

Power-limited but must be supervised via a UL approved Power Supervision Relay.

+ -

Secondary Power

27.6 VDC, supervised and power-limited.

Fast charge = 2 amps, trickle charge = 20 mA.

Battery Battery +

Notification Appliance/Annunciator Power

+

Power-limited, filtered, regulated,

-

non-resettable , 3 amps (in alarm)

max. P ow er is supervised by output

module (such as an ICM-4F) in the

Sensiscan 2000.

120 VAC, 50/60 Hz, 1.8 amps for MPS-24AF

Primary Power

220/240 VAC, 50/60 Hz, 1.8 amps for MPS-24AFE

Neutral Out Hot In

Earth

Ground

Connect to

chassis via a

Grounding Cable

Assembly.

Neutral In Hot Out

Ground

Battery Fuse

Power Ribbon Connector

Power Harnesses (P2, P4)

Cut R27 to disable

Earth Fault

Detection.

AVPS-24F

Supervisory Cable

Connector

LED Indicators

Ground Fault

Battery Fail

AC Power Fail

(not used)

When employing an

R45-24/R45-24E

Remote Battery

Charger, remove

Jumper JP-1.

S2000 15017 Rev H 10/08/96 P/N 15017:H

* Cut JP5 to convert

Notification Appliance

power

(TB3 Terminals 3-4)

to a resettable,

2-amp maximum

circuit.

DO NOT CUT JP2.

31

Page 32

FIGURE 5-2 HARNESS CONNECTIONS FOR THE MPS-24A

If powering a notification circuit module from the

main power supply, connect the Auxiliary Bell Power

Harness (71091) from J6 on the CPU to J5 on the ICM4F or ICE-4F. See Section 6.9 for more information.

Bottom

view

of ICM-4F

or ICE-4F

(ICM-4F)

(ICE-4F)

Connector orientation

CPU

(bottom view)

7-position end

Main Pwer

Supply Bell

Power

Harness (71093)

Blue wire

+ -

Power Ribbon

(71085)

Wire at 8-position end

Power Harness

(71086)

Connect to P2 or P4.

MPS-24AF/

MPS-24AFE

Note position of Red

32

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 33

5.2 THE MPS-24BF/MPS-24BFE MAIN POWER SUPPLY

Note: The MPS-24BF has been designed to support single-cabinet row systems only.

This amounts to enough power for the CPU and up to three other modules as a maximum.

The MPS-24BF Main Power Supply is a supply capable of powering the system continuously during standby and alarm

conditions. A total of 750 mA @ 24 VDC regulated is available for operating the system during Standby conditions.

Figures 5-3 and 5-4 illustrate connections for primary and secondary power to the MPS-24BF Main Power Supply, as well

as terminal and harness connections.

CONNECTING THE PRIMARY POWER SOURCE

The MPS-24BF requires 120 VAC, 50/60 Hz, 1.8 amps primary power and the MPS-24BFE requires 220/240 VAC, 50/60

Hz, 0.9 amps. With the breaker at the main power distribution panel turned off, remove the plastic insulating cover from

Terminal Block TB1 and connect the system primary power source. Ground Cable per NEC requirements. Ground the

power supply assembly to the cabinet with a Chassis Ground cable (71073) to TB1 Terminal 2. Connect the primary Neutral

line to TB1 Terminal 3 and the primary Hot line to TB1 Terminal 4. Do not route 120 VAC wiring in the same conduit as

other control panel circuits. After completion of these connections reinstall the plastic insulating cover over the terminal

strip. Leave the main power breaker off until installation of the entire control panel is complete.

CONNECTING THE SECONDARY POWER SOURCE (24VDC)

Secondary power (batteries) is required to support the system during loss of primary power. These batteries reside in the

control panel cabinet. Connect the Battery Positive Cable to TB3 Terminal 1 (+) and the Battery Negative Cable to TB3

Terminal 2 (-). Do not connect the Battery Interconnect Cable at this time. This connection will be made just after initial

primary system power-up.

EARTH FAULT DETECTION

The MPS-24BF automatically employs detection of earth faults in the system (unless Resistor R55 is removed).

FOUR-WIRE SMOKE DETECTOR POWER (24VDC)

Up to 200mA of current for 24 VDC four-wire smoke detectors can be drawn from TB2 Terminals 1 (+) and 2 (-). Power is

removed from these terminals during system reset (unless Jumper JP1 is removed). This regulated four-wire smoke detector

power is power-limited but must be supervised via a UL-listed Power Supervision Relay. The power supervision relay is

energized by the four-wire power circuit and its contact must be connected in series with an initiating device circuit.

ANNUNCIATOR POWER (24VDC)

Up to 200mA of current suitable for powering an AFM-16ATF or AFM-32AF Annunciator can be drawn from TB2 Terminals 1 (+) and 2(-). The power is regulated, power-limited and is supervised by the annunciator.

NOTIFICATION APPLIANCE POWER (24 VDC)

Up to 2.0 amps of regulated power-limited current for powering Notification appliances can be drawn from TB2 Terminals

3 (+) and 4 (-). Power is not removed from these terminals during system reset. Do not connect any type of serial

annunciator (such as an AFM) or any device requiring filtered 24 VDC power to this circuit or damage may result!

SYSTEM HARNESS CONNECTIONS

Internal power for the system is provided via the Power Harness (71086). Connect this harness from P2 on the MPS-24BF

to the CPU. Signaling between the CPU and the main power supply is accomplished through connection of the Power

Ribbon (71085) to P3 on the MPS-24BF.

S2000 15017 Rev H 10/08/96 P/N 15017:H

33

Page 34

FIGURE 5-3 THE MPS-24BF MAIN POWER SUPPLY

Four-Wire Smoke Detector/Annunciator Power

+

+ 24 VDC (20.4-26.4, 200 mV ripple), 200 mA max.

Filtered, regulated and resettable*. Power-limited b ut

-

when used for four-wire detectors, must be supervised by a UL-listed Power Supervision Relay.

+

Primary Power

120 VAC, 1.8 amps max for MPS-24BF

220/240 VAC, 0.9 amps max for MPS-24BFE

Neutral Hot

Earth Ground

Chassis Ground

Connect to chassis with

a Grounding Cable Assembly (Cable # 71073).

Cut R55 to disable

Earth Fault Detection

-

Notification Appliance power (see Caution below)

+ 24 VDC power-limited, RMS-regulated, non-resettab le,

2.0 amps (in alarm) max. Power is super vised by output

module such as an IC-4.

powering annunciators.

CAUTION: The +24 VDC provided on TB2 Terminal 3 is

power-limited only when used with the minus return on

TB2 T erminal 4.

minal 2 with the +24 VDC power on TB2 Terminal 3.

27.6 VDC, 6.5 to 17 AH. Supervised and power-limited.

Fast charge =750mA max., trickle charge = 20 mA (typ).

Do not use the minus return on TB2 Ter-

Secondary Power

This output is not suitable for

Battery +

Battery -

AC Circuit

Breaker

Cut JP2 to disable the battery

charger when employing the R4524 Remote Battery Charger.

LED Indicators

Ground Fault

Battery Fail

AC Power Fail

Supervisory Cable to

optional AVPS

* Cut JP1 to make Four-Wire

Smoke Detector/Annunciator

Power on TB2 Ter minals 1 and 2

a non-resettable circuit.

34

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 35

FIGURE 5-4 MPS-24BF/MPS-24BFE HARNESS CONNECTIONS

Power Harness Connector Orientation

7-position end

CPU

(bottom view)

Note position of Red

Wire at 8-position end.

Power Harness

(71086)

Connect to P2

Red Wire

Blue wire

Black wire

Main Power

Supply Bell

Power

Harness (71093)

Connect to J5 on

the CPU-2000.

Power Ribbon

(71085)

+

-

S2000 15017 Rev H 10/08/96 P/N 15017:H

35

Page 36

Figure 5-5 Field Wiring of the Optional Audio Visual Power Supplies (AVPS-24F/

AVPS-24FE)

24 VDC Bell Power

Unfiltered, unregulated, power-limited (3.0 amps max). Use Auxiliary

Bell Power Harness to provide power to notification circuit modules

(connect to J5 on IC-4F or ICE-4F).

+ -

1 2

Auxiliary Bell

Power Harness

Black wire

Blue wire

For the first or only A VPS-24F in a Sensiscan

2000, connect the AVPS-24F Trouble Cable

(71033) to P5 on the MPS-24AF or P4 on the

MPS-24BF for supervision. Otherwise connect as illustrated below.

P3

Trouble

LED

TB2

TB1

Earth Ground In

Connect to chassis or Earth

Ground Terminal on the

main power supply.

Secondary Power

(24 VDC Batteries)

Connect to:

MPS-24AF: TB2-1 (+) and TB2-2 (-)

MPS-24BF: TB3-1 (+) and TB3-2 (-)

For multiple

Audio Visual

Power Supplies

Earth Ground Out

Connect to TB1 Terminal 1

on next AVPS-24F.

+

-

Hot

Neutral

Primary Power

120 VAC for AVPS-24F

220/240 VAC for AVPS-24FE

MPS-24AF: TB1-5 (Neutral) and TB1-7 (Hot)

MPS-24BF: TB1-3 (Neutral) and TB1-4 (Hot).

Connect to:

36

To P5 on MPS-24AF;

or to P4 on the MPS24BF.

Last AVPS-24FFirst AVPS-24F

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 37

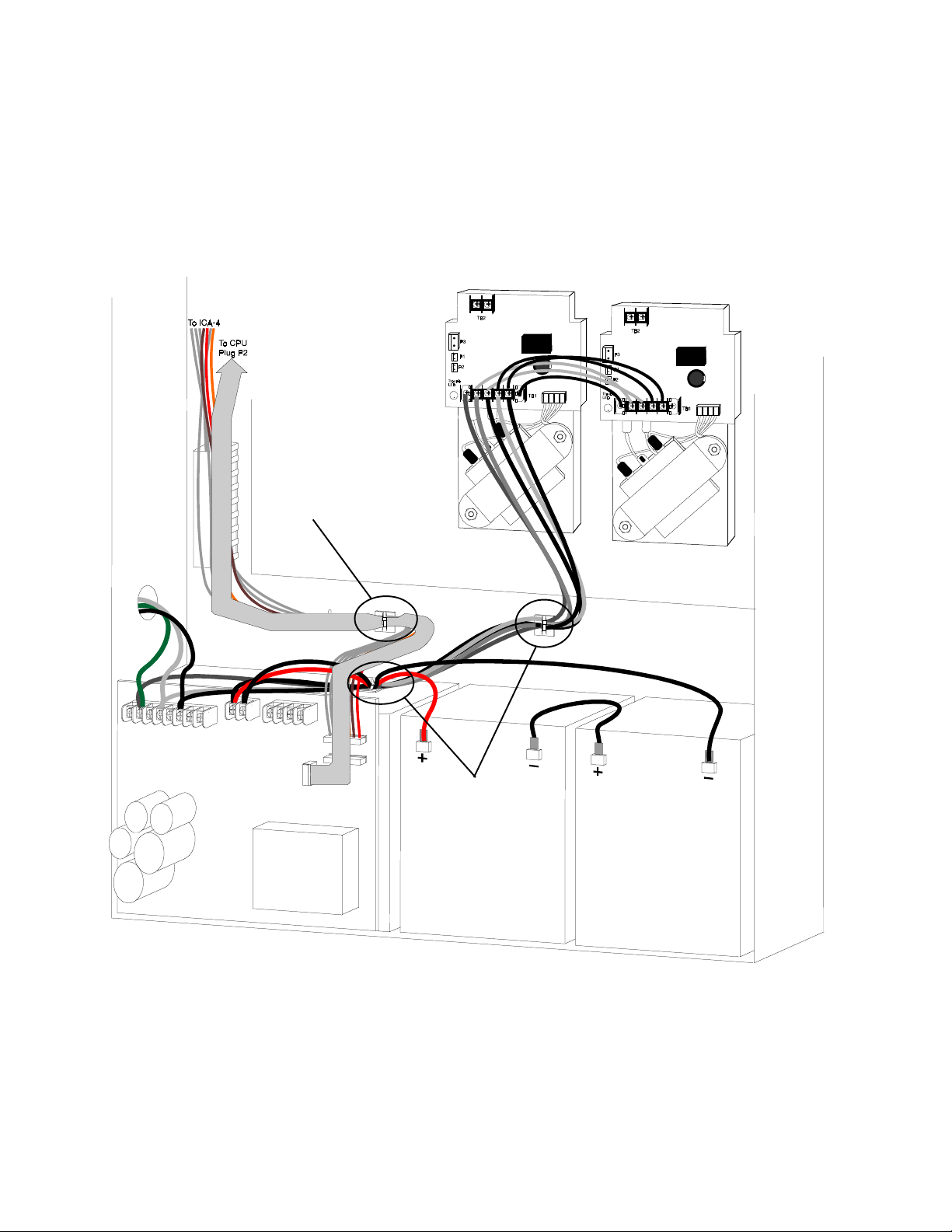

THE R45-24/R45-24E REMOTE BATTERY CHARGER

When the secondary requirements demand batteries that cannot be adequately charged by the main power supply employed,

an R45-24 Remote Battery Charger must be used. The R45-24 mounts in its own cabinet, up to 20 feet away (must be in the

same room as the control panel). The R45-24 is capable of charging 55 AH PS-12550 batteries, which are also contained in

the charger cabinet. For more information refer to the R45-24 Product Installation Drawing packaged with each unit.

CONNECTING THE PRIMARY POWER SOURCE

The R45-24 requires 120 VAC, 50/60 Hz primary power and the R45-24E requires 220/240 VAC, 50/60 Hz primary power.

With the breaker at the main power distribution panel turned off, connect the primary Hot line to Terminal 1 on the R45-24

and the primary Neutral line to Terminal 2. All connections between the Sensiscan 2000 and the R45-24 must be made in

conduit, using #12 AWG wire. Do not route VAC wiring in the same conduit as other Sensiscan 2000 circuits. Leave the

main power breaker off until installation of the entire system is complete.

CONNECTING THE SECONDARY POWER SOURCE (24VDC)

Do not connect AC power or batteries until the system is completely wired and ready for testing. Refer to Wiring Diagram

and instructions for the Fire-Lite R45-24 remote Battery Charger.

24 VDC. (supervised). Maximum charge current for standby batteries is 2 amps

Primary Power Sour ce

Hot Neutral

(fast charge) or 20mA (trickle charge). Use #12 AWG wire in conduit (20 feet or

less, in same room).

-

+

1 2 3 4

+ -

R45-24

MPS-24AF MPS-24BF

- +

PS-12550

12 VDC

55-AH

Battery

- +

PS-12550

12 VDC

55-AH

Battery

PS-12550

Battery

PS-12550

Battery

IMPORTANT!

1) Cut JP1 to disable on-board charger on the MPS-24AF.

2) Cut JP2 to disable on-board charger on the MPS-24BF.

TB2-2

TB2-1

Figure 5-6 Connecting the R45-24 Remote Battery Charger

TB2-6

TB2-5

S2000 15017 Rev H 10/08/96 P/N 15017:H

37

Page 38

SECTION SIX: APPLICATIONS

6.1 WATERFLOW ALARM

A waterflow alarm device may be connected to an IZ Series Initiating Zone Module circuit provided that the circuit is

programmed to activate at least one notification appliance circuit and one of the following conditions are met:

The initiating Device Circuit is programmed for waterflow operation

OR

the notification appliance circuit is programmed as non-silenceable.

6.2 SUPERVISORY SERVICE

Normally open supervisory devices may be connected to any Initiating Zone Module circuit provided that the circuit is

programmed for supervisory operation. This circuit must be dedicated to supervisory devices.

6.3 CENTRAL STATION

The Sensiscan 2000 can be employed as a protected premises Control Unit when used in conjunction with a compatible,

UL- listed electrically-activated transmitter or when used in conjunction with a compatible, UL-listed digital alarm communicator such as the 911A. (See Figure 6-1)

6.4 DIGITAL ALARM COMMUNICATOR TRANSMITTERS (DACT)

The Fire Alarm Control Panel (FACP) will support a Digital Alarm Communicator Transmitter (DACT) provided that the

panel is configured and programmed for DACT operation. Software P/N 73452 (or higher) will support DACTs that are

activated via relay contacts (911A), while Software P/N 73611 (or higher) will support the UDACT-F via the EIA-485

Annunciator Port.

The FACP must be programmed for DACT operation (see the Extended Programming Section). Programming the FACP for

DACT operation will delay the reporting of an AC loss condition for approximately eight hours (Software P/N 73452 or

higher) and modify the EIA-485 Annunciator Port protocol (Software P/N 73611 or higher) for UDACT-F operation.

The modified protocol is compatible with the AFM and LDM Annunciators. Annunciators and a UDACT-F can be connected to the EIA-485 Annunciator Port simultaneously. However, the modified EIA-485 protocol alters the assignment of

the first eight yellow annunciator LED's as shown in the table on the following page.

38

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 39

Annunciators and a UDACT-F can be connected to the EIA-485 Annunciator Port simultaneously. However, the modified

EIA-485 protocol alters the assignment of the first eight yellow annunciator LEDs as follows:

elbuorT

tnioP

wolleY(

)DEL

1elbuorTmetsyS

N/PerawtfoS

dna25437

rewol

tuohtiW

F-TCADU

elbuorTmetsyS

)ssolCAssel(

rehgihdna11637N/PerawtfoS

F-TCADUhtiW

elbuorTmetsyS

)ssolCAssel(

2decneliSlangiSdecneliSlangiSdecneliSlangiS

3desUtoNdesUtoNdesUtoN

4yrosivrepuSyrosivrepuSyrosivrepuS

5

6

7

tiucriCgnitacidnI

elbuorT1

tiucriCgnitacidnI

elbuorT2

eiTlapicinuM

elbuorT

tiucriCgnitacidnI

elbuorT1

tiucriCgnitacidnI

elbuorT2

eiTlapicinuM

elbuorT

tiucriCgnitacidnI

elbuorT1

tiucriCgnitacidnI

elbuorT2

dnG/yrettaBwoL

tluaF

8elbuorTlenaPliaFCAliaFCA

The FACP must be programmed for an annunciator whenever it's connected to a UDACT-F since the UDACT-F receives the

FACP status on the EIA-485 Annunciator Port. If the FACP is connected to both annunciators and a UDACT-F, all devices

except one must be configured as receive only. Refer to the table below for configuration and supervision arrangements.

seciveD

dellatsnI

F-TCADU

ylnO

F-TCADU

dna

rotaicnunnA

noitarugifnoCnoisivrepuSnoitarugifnoCnoisivrepuS

ylnOevieceR

F-TCADU)1etoN(rotaicnunnA

timsnarT/evieceR584-AIEaiV

timsnarT/evieceR584-AIEaiV

F-TCADUaiV

liaFmmoC

timsnarT/evieceR584-AIEaiV

1sserddA

ylnOevieceR

1sserddA

)2etoN(tuptuO

timsnarT/evieceR

1sserddA

ylnOevieceR

desivrepuS-nU

584-AIEaiV

584-AIEaiV

)3etoN(

1) Additional annunciators may be employed in the Receive Only Mode. The wiring to these annunciators will be

supervised only if the power and the EIA-485 circuits are wired sequentially and the Receive/Transmit device is

connected last.

2) The UDACT-F's Comm Fail Output (TB3, pin #2) must be connected to the AUX Trouble Input on the main power

supply (P5, pin #1 on MPS-24AF or P4, pin #1 on MPS-24B). See connection diagrams.

3) The power and the EIA-485 circuits are wired sequentially (the FACP connects to the annunciator and the annunciator connects to the UDACT-F).

S2000 15017 Rev H 10/08/96 P/N 15017:H

39

Page 40

INSTALLING THE UDA CT-F

Remove all power from the control panel by disconnecting AC and batteries. Install the three supplied nylon support posts

for the top and bottom left of the UDACT-F, one aluminum/nylon and one aluminum standoff in the CHS-4 chassis slot in

which the UDACT-F is to be installed (refer to Figure 6-1). Position the UDACT-F on the standoffs and secure on aluminum standoff with a #6-32 screw. Alternatively, the UDACT-F may be mounted remotely using an ABS-8RF enclosure.

Ferrite cores are required for this application. Refer to the UDACT-F Manual, Document 50049 for more information.

Connect the communication line between the EIA-485 terminal block on the CPU-2000 and TB1 terminals 3 and 4 on the

UDACT-F being certain to observe polarity (refer to the Document 50049). Recommended wire is 12 AWG to 18 AWG

twisted pair. If no other devices are connected to the EIA-485, install a 120 ohm end-of-line resistor across UDACT-F TB1

terminals 3 and 4.

Connect the supplied Ground Strap from the UDACT-F Earth Ground terminal on TB3 to the CHS-4 chassis. Connect

24VDC filtered, regulated, non-resettable power to TB1 terminals 1 and 2 on the UDACT-F (refer to Document 50049).

CPU-2000

CHS-4

Aluminum Standoff

and screw

Figure 6-1: UDACT-F Mounting in CHS-4

UDACT-F

Nylon

Support

Posts

Ground

Strap

Nylon &

Aluminum

Standoff

40

S2000 15017 Rev H 10/08/96 P/N 15017:H

Page 41

6.5 CONNECTION OF A 911A DIGITAL COMMUNICATOR

The Noti-Fire 911A Digital Alarm Communicator Transmitter (DACT) is a three-zone module designed for use with the

Sensiscan 2000 to provide for off-premises monitoring of this fire alarm control panel. For stand-alone installations, use the

911AC kit that includes a transformer and an enclosure(s) for both the 911A and the transformer. The 911A is self-powered

in this mode and is triggered by the alarm and/or trouble contacts received from the control panel. It communicates with a

digital receiver by means of one of two transmission formats, BFSK or Pulsed Fast Single Round format.

Power Requirements: 26.6VDC minimum, 30 mA in Normal; 138 mA while communicating; 166.8 mA with alarm &

trouble relays while communicating.

Retard time and Reset time must be programmed for zero second when connecting the alarm initiating circuit to an existing

control panel.

For more detailed instructions and connection and power information, refer to the Noti-Fire 911A manual, Document #7406200-005-A.

Trouble

Common

(+) 24 VDC

(+) 27.6 VDC

CPU

Alarm

911A

Wiring between the F A CP

and 911A must be in conduit.

mralA

yllamron

nepo

stcatnoc

elbuorT

yllamron

nepo

stcatnoc

CDV42+

nommoC

UPCA119SPM

41-1BT7dna6

51-1BT9dna8

9-1BT01

11-1BT11

23-2BT

44-2BT

MPS-24AF

S2000 15017 Rev H 10/08/96 P/N 15017:H

41

Page 42

6.6 MS-5012 AS A DAC T

Secondary

CPU

The MS-5012 may be used as a slave communicator to a master FACP. In slave configuration, five channels may be

triggered by the relay outputs of the master panel. Zone 1 is used for General Alarm, Zone 2 is used for general trouble, Zone

4 is used for supervisory. Zone 3 and 5 may be programmed to match the FACP relay function.

Phone Line

Modular Cable

P/N MCBL-6

Primary

Phone Line

120 VAC

HOT

Neutral

Ground

White

Green

Black

yellow

1 2

Primary

Active

yellow

Black

Secondary

Active

J2

Kissoff

AC POWER TROUBLE

ALARM

RESET SILENCE MODE

Red

+

-