Page 1

PN: 51127:C ECN 00-506

Fire Alarm Control Panel

MS-2410B &

MS-2410BE

Document #51127

11/7/00 Rev.

© 2000 Fire•Lite

C

Page 2

Fire Alarm System Limitations

While a fire alarm system may lower insurance

rates, it is not a substitute for fire insurance!

An automatic fire alarm system–typically made up of smoke

detectors, heat detectors, manual pull stations, audible warning devices, and a fire alarm control with remote notification

capability–can provide early warning of a developing fire.

Such a system, however, does not assure protection against

property damage or loss of life resulting from a fire.

The Manufacturer recommends that smoke and/or heat detectors be located throughout a protected premise following the

recommendations of the current edition of the National Fire

Protection Association Standard 72 (NFPA 72),

manufacturer's recommendations, State and local codes, and

the recommendations contained in the Guide for Proper Use

of System Smoke Detectors, which is made available at no

charge to all installing dealers. A study by the Federal Emergency Management Agency (an agency of the United States

government) indicated that smoke detectors may not go off in

as many as 35% of all fires. While fire alarm systems are designed to provide early warning against fire, they do not guarantee warning or protection against fire. A fire alarm system

may not provide timely or adequate warning, or simply may not

function, for a variety of reasons:

Smoke detectors may not sense fire where smoke cannot

reach the detectors such as in chimneys, in or behind walls, on

roofs, or on the other side of closed doors. Smoke detectors

also may not sense a fire on another level or floor of a building. A second-floor detector, for example, may not sense a

first-floor or basement fire.

Particles of combustion or "smoke" from a developing fire

may not reach the sensing chambers of smoke detectors because:

• Barriers such as closed or partially closed doors, walls, or

chimneys may inhibit particle or smoke flow.

• Smoke particles may become "cold," stratify, and not reach

the ceiling or upper walls where detectors are located.

• Smoke particles may be blown away from detectors by air

outlets.

• Smoke detectors may be drawn into air returns before

reaching the detector.

The amount of "smoke" present may be insufficient to alarm

smoke detectors. Smoke detectors are designed to alarm at

various levels of smoke density. If such density levels are not

created by a developing fire at the location of detectors, the

detectors will not go into alarm.

Smoke detectors, even when working properly, have sensing

limitations. Detectors that have photoelectronic sensing

chambers tend to detect smoldering fires better than flaming

fires, which have little visible smoke. Detectors that have ionizing-type sensing chambers tend to detect fast-flaming fires

better than smoldering fires. Because fires develop in different ways and are often unpredictable in their growth, neither

type of detector is necessarily best and a given type of detector may not provide adequate warning of a fire.

Smoke detectors cannot be expected to provide adequate

warning of fires caused by arson, children playing with

matches (especially in bedrooms), smoking in bed, and violent

explosions (caused by escaping gas, improper storage of

flammable materials, etc.).

Heat detectors do not sense particles of combustion and

alarm only when heat on their sensors increases at a predetermined rate or reaches a predetermined level. Rate-of-rise

heat detectors may be subject to reduced sensitivity over time.

For this reason, the rate-of-rise feature of each detector

should be tested at least once per year by a qualified fire protection specialist.

Heat detectors are designed to protect

property, not life.

IMPORTANT!

Smoke detectors must be installed in the

same room as the control panel and in rooms used by the system for the connection of alarm transmission wiring, communications, signaling, and/or power.

cated, a developing fire may damage the alarm system, crippling its ability to report a fire.

Audible warning devices such as bells may not alert people

if these devices are located on the other side of closed or

partly open doors or are located on another floor of a building.

Any warning device may fail to alert people with a disability or

those who have recently consumed drugs, alcohol or medication. Please note that:

• Strobes can, under certain circumstances, cause seizures

in people with conditions such as epilepsy.

• Studies have shown that certain people, even when they

hear a fire alarm signal, do not respond or comprehend the

meaning of the signal. It is the property owner's responsibility to conduct fire drills and other training exercise to make

people aware of fire alarm signals and instruct them on the

proper reaction to alarm signals.

• In rare instances, the sounding of a warning device can

cause temporary or permanent hearing loss.

A fire alarm system will not operate without any electrical

power. If AC power fails, the system will operate from standby

batteries only for a specified time and only if the batteries

have been properly maintained and replaced regularly.

Equipment used in the system may not be technically compatible with the control. It is essential to use only equipment

listed for service with your control panel.

Telephone lines needed to transmit alarm signals from a

premise to a central monitoring station may be out of service

or temporarily disabled. For added protection against telephone line failure, backup radio transmission systems are recommended.

The most common cause of fire alarm malfunction is inadequate maintenance. To keep the entire fire alarm system in

excellent working order, ongoing maintenance is required per

the manufacturer's recommendations, and UL and NFPA standards. At a minimum, the requirements of Chapter 7 of NFPA

72 shall be followed. Environments with large amounts of

dust, dirt or high air velocity require more frequent maintenance. A maintenance agreement should be arranged

through the local manufacturer's representative. Maintenance

should be scheduled monthly or as required by National and/

or local fire codes and should be performed by authorized professional fire alarm installers only. Adequate written records

of all inspections should be kept.

If detectors are not so lo-

LimWarLg.p65 01/10/2000

Page 3

Installation Precautions

Adherence to the following will aid in problem-free

installation with long-term reliability:

WARNING -

nected to the fire alarm control panel.

of power before servicing. Control unit and associated equipment may be damaged by removing and/or inserting cards,

modules, or interconnecting cables while the unit is energized.

Do not attempt to install, service, or operate this unit until this

manual is read and understood.

CAUTION -

Changes.

must be tested in accordance with NFPA 72 Chapter 7 after

any programming operation or change in site-specific software. Reacceptance testing is required after any change, addition or deletion of system components, or after any modification, repair or adjustment to system hardware or wiring.

All components, circuits, system operations, or software functions known to be affected by a change must be 100% tested.

In addition, to ensure that other operations are not inadvertently affected, at least 10% of initiating devices that are not

directly affected by the change, up to a maximum of 50 devices, must also be tested and proper system operation verified.

This system meets NFPA requirements for operation at

0-49° C/32-120° F

condensing) at 30° C/86° F. However, the useful life of the

system's standby batteries and the electronic components

may be adversely affected by extreme temperature ranges

and humidity. Therefore, it is recommended that this system

and all peripherals be installed in an environment with a nominal room temperature of 15-27° C/60-80° F.

Verify that wire sizes are adequate for all initiating and

indicating device loops. Most devices cannot tolerate more

than a 10% I.R. drop from the specified device voltage.

Several different sources of power can be con-

Disconnect all sources

System Reacceptance Test after Software

To ensure proper system operation, this product

and at a relative humidity of 85% RH (non-

Like all solid state electronic devices, this system may

operate erratically or can be damaged when subjected to lightning-induced transients. Although no system is completely

immune from lightning transients and interferences, proper

grounding will reduce susceptibility.

Overhead or outside

aerial wiring is not recommended, due to an increased susceptibility to nearby lightning strikes.

cal Services Department if any problems are anticipated or

encountered.

Disconnect AC power and batteries prior to removing or inserting circuit boards. Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing,

reaming, or punching of the enclosure. When possible, make

all cable entries from the sides or rear. Before making modifications, verify that they will not interfere with battery, transformer, and printed circuit board location.

Do not tighten screw terminals more than 9 in-lbs.

Over-tightening may damage threads, resulting in reduced

terminal contact pressure and difficulty with screw terminal

removal.

Though designed to last many years, system components

can fail at any time. This system contains static-sensitive

components. Always ground yourself with a proper wrist strap

before handling any circuits so that static charges are removed from the body. Use static-suppressive packaging

to protect electronic assemblies removed from the unit.

Follow the instructions in the installation, operating, and

programming manuals. These instructions must be followed

to avoid damage to the control panel and associated

equipment. FACP operation and reliability depend upon

proper installation by authorized personnel.

Consult with the Techni-

FCC Warning

WARNING: This equipment generates, uses, and can

radiate radio frequency energy and if not installed and

used in accordance with the instruction manual, may

cause interference to radio communications. It has

been tested and found to comply with the limits for class

A computing device pursuant to Subpart B of Part 15 of

FCC Rules, which is designed to provide reasonable

protection against such interference when operated in a

commercial environment. Operation of this equipment in

a residential area is likely to cause interference, in which

case the user will be required to correct the interference

at his own expense.

Canadian Requirements

This digital apparatus does not exceed the Class A

limits for radiation noise emissions from digital

apparatus set out in the Radio Interference Regulations

of the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits

radioelectriques depassant les limites applicables aux

appareils numeriques de la classe A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.

LimWarLg.p65 01/10/2000

Page 4

Notes

4

Document #51127 Rev.C 11/7/00 P/N 51127:C

Page 5

Table of Contents

CHAPTER 1: Product Description .........................................................................................................................9

1.1: Product Features..........................................................................................................................................9

1.2: Specifications ..............................................................................................................................................11

1.3: Controls and Indicators ...............................................................................................................................12

1.4: Circuits ........................................................................................................................................................13

1.5: Components ................................................................................................................................................13

1.6: Optional Modules........................................................................................................................................14

1.7: Optional Accessories...................................................................................................................................14

CHAPTER 2: Installation.........................................................................................................................................19

2.1: Mounting Options .......................................................................................................................................19

2.2: Backbox Mounting......................................................................................................................................19

2.3: Transformer Installation ..............................................................................................................................22

2.4: Main Circuit Board Installation...................................................................................................................23

2.5: Operating Power..........................................................................................................................................24

2.6: Input Circuits...............................................................................................................................................25

2.7: Output Circuits ............................................................................................................................................26

2.8: Power-limited Wiring Requirements...........................................................................................................27

2.9: Installation of Optional Modules with Remote Accessories.......................................................................28

CHAPTER 3: Programming Instructions...............................................................................................................34

3.1: Switch Functions .........................................................................................................................................34

3.2: Programmable Features and Options ..........................................................................................................35

3.3: Entering Program Mode..............................................................................................................................36

3.4: Programming Function................................................................................................................................37

3.4.1: Program Feature Selection................................................................................................................37

3.4.2: Programming Options.......................................................................................................................37

3.4.3: Programming Example .....................................................................................................................37

3.5: Program Features and Options ....................................................................................................................41

3.5.1: Program Features ..............................................................................................................................41

3.5.2: Programming Options.......................................................................................................................41

3.6: Default Programming Mode........................................................................................................................46

CHAPTER 4: Operating Instructions..................................................................................................................... 47

4.1: Switch Functions in Normal Mode .............................................................................................................47

4.2: Status LEDs.................................................................................................................................................48

4.3: Operation.....................................................................................................................................................49

4.3.1: Fire Alarm Response.........................................................................................................................50

4.3.2: Fire Alarm Restoral...........................................................................................................................50

4.3.3: System Supervisory Condition Response .........................................................................................50

4.3.4: System Supervisory Restoral Response............................................................................................51

4.3.5: Trouble Condition Response.............................................................................................................51

4.3.6: Trouble Condition Restoral...............................................................................................................51

CHAPTER 5: Servicing ...........................................................................................................................................52

5.1: Walktest Mode.............................................................................................................................................52

5.2: Last Event/History Mode ............................................................................................................................53

5.3: Lamp Test ....................................................................................................................................................54

CHAPTER 6: Power Supply Calculations..............................................................................................................55

6.1: Overview .....................................................................................................................................................55

6.2: Calculating the AC Branch Circuit..............................................................................................................55

6.3: Calculating the System Current Draw.........................................................................................................56

Document 51127 Rev. C 11/7/00 P/N: 51127:C

5

Page 6

Table of Contents

6.3.1: Overview ...........................................................................................................................................56

6.3.2: How to Use Table 6-3 on page 57 to Calculate System Current Draw .............................................56

6.4: Calculating the Battery Size ........................................................................................................................58

6.4.1: NFPA Battery Requirements .............................................................................................................58

6.4.2: Selecting and Locating Batteries.......................................................................................................58

Appendix A: NFPA Requirements ......................................................................................................................59

Appendix B: Wire Requirements .........................................................................................................................60

Appendix C: Slide-in Labels .................................................................................................................................61

6

Document #51127 Rev. C 11/7/00 P/N: 51127:C

Page 7

This control panel has been designed to comply with standards set forth by the following regulatory agencies:

Before proceeding, the installer should be familiar with the following documents.

NFPA Standards

This Fire Alarm Control Panel complies with the following NFPA Standards:

NFPA 72 National Fire Alarm Code for Local Fire Alarm Systems (Automatic, Manual, Waterflow

and Sprinkler Supervisory), Auxiliary Fire Alarm Systems (Automatic, Manual and Waterflow),

Remote Station Fire Alarm Systems (Automatic, Manual and Waterflow) and Proprietary Fire Alarm

Systems (Automatic, Manual and Waterflow).

Underwriters Laboratories Documents:

UL 38 Manually Actuated Signaling Boxes

UL 217 Smoke Detectors, Single and Multiple Station

UL 228 Door Closers - Holders for Fire Protective Signaling Systems

UL 268 Smoke Detectors for Fire Protective Signaling Systems

UL 268A Smoke Detectors for Duct Applications

UL 346 Waterflow Inidicators for Fire Protective Signaling Systems

UL 464 Audible Signaling Appliances

UL 521 Heat Detectors for Fire Protective Signaling Systems

UL 864 Standard for Control Units for Fire Protective Signaling Systems

UL 1481 Power Supplies for Fire Protective Signaling Systems

UL 1638 Visual Signaling Appliances

UL 1971 Signaling Devices for Hearing Impaired

Other:

NEC Article 250 Grounding

NEC Article 300 Wiring Methods

NEC Articla 760 Fire Protective Signaling Systems

Applicable Local and State Building Codes

Requirements of the Local Authority Having Jurisdiction (LAHJ)

Fire•Lite Documents

Fire•Lite Device Compatibility Document Document #15384

Annunciator Modules Document #15390

AFM-16ATF Annunciator Document #15970

AFM-16AF Annunciator Document #15210

FCPS-24F(E) Field Charger/Power Supply Document #50079

LDM Series Lamp Driver Modules Document #50055

LED-10 Annunciator Document #50361

ACM-8RF Annunciator Control Relay Module Document #50362

411 Digital Alarm Communicator/Transmitter Document #50921

411UD Digital Alarm Communicator/Transmitter Document #50759

Document #51127 Rev. C 11/7/00 P/N 51127:C

7

Page 8

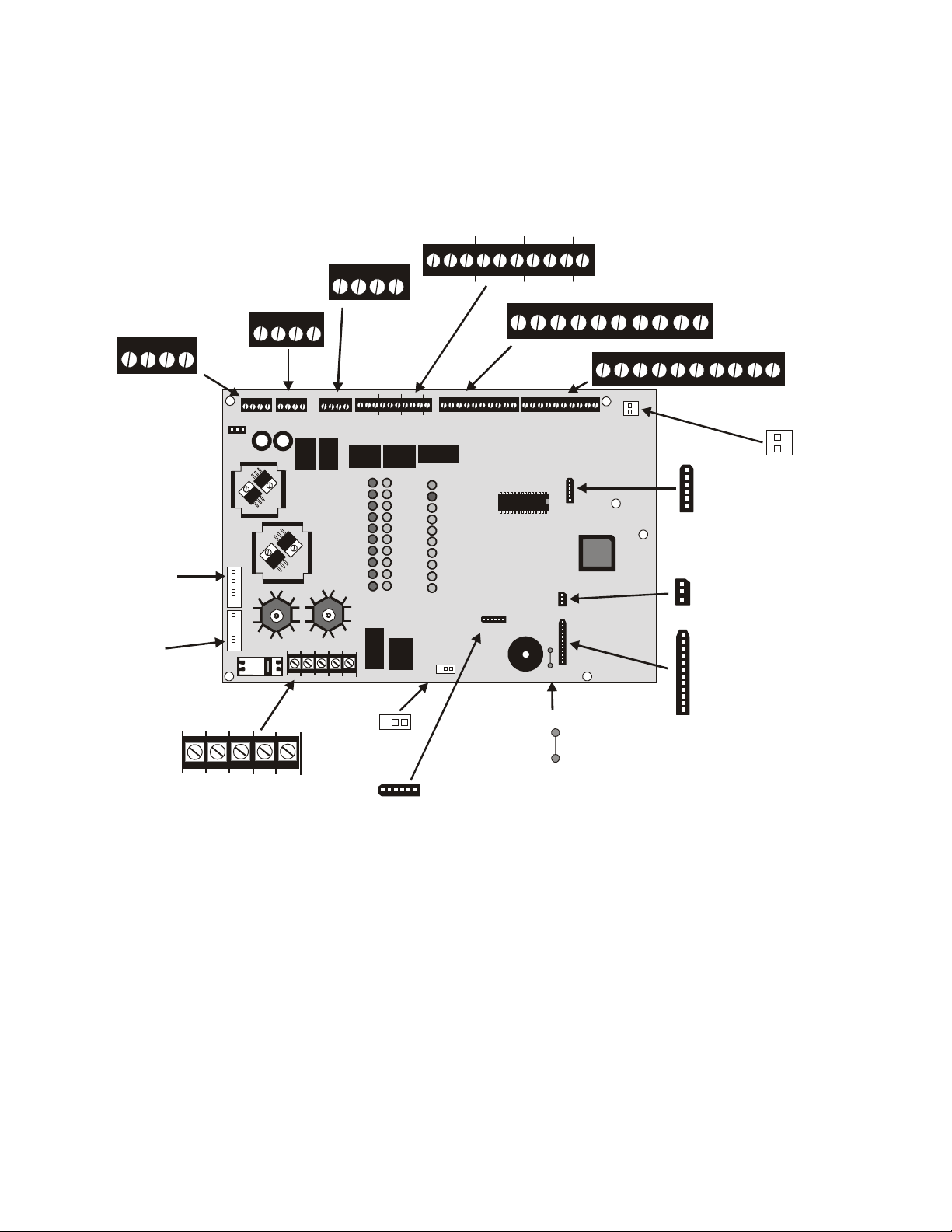

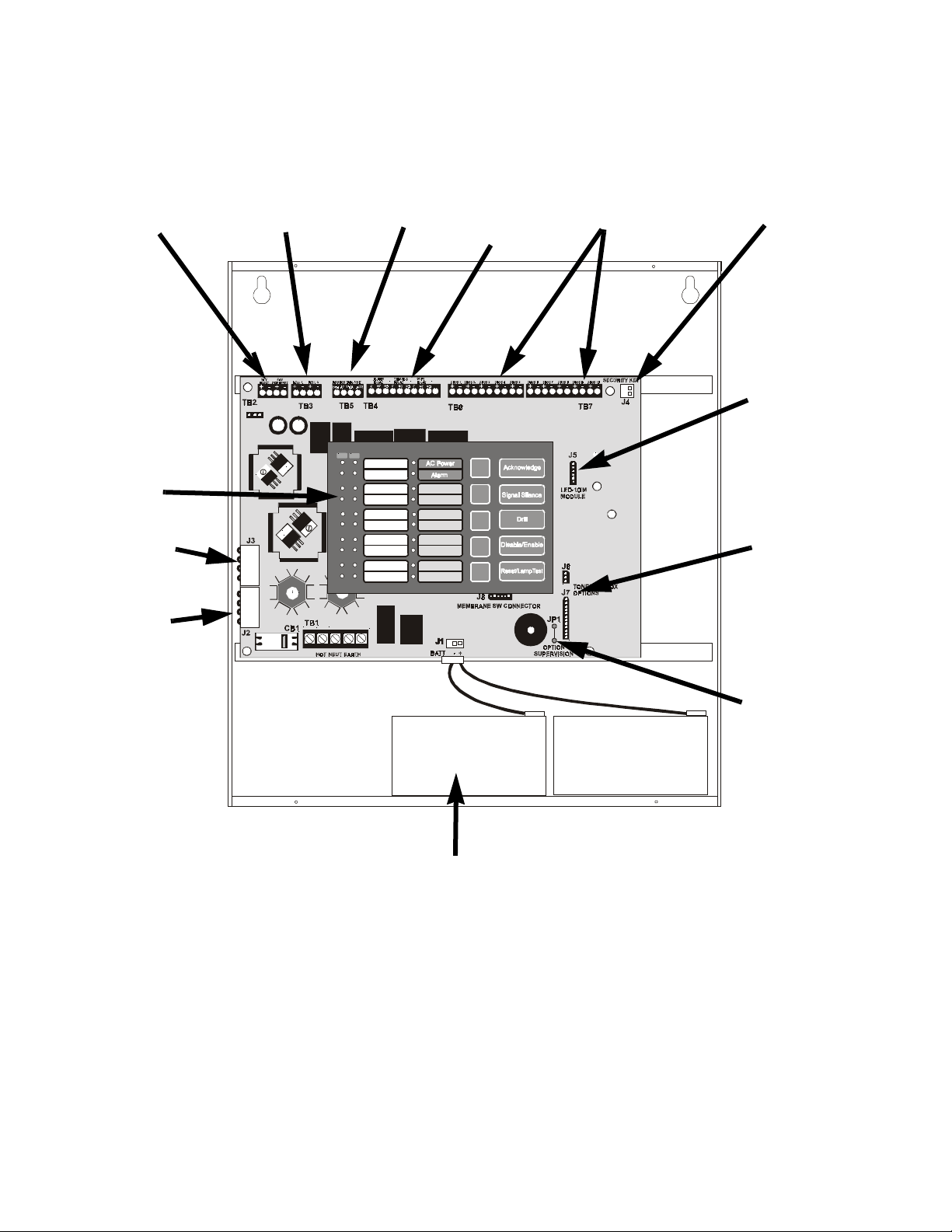

MS-2410B Main Circuit Board

24 V

24 V

NONR ESET

RESET

+ - + -

TB2

J3

PRIMARY

TRANSFO RMER

CONNECTOR

CAUTION!

HIGH VOLTAGE

J2

OPTIONAL

TRANSFO RMER

CONNECTOR

BELL 1

+ - + -

TB3

24 V

RESET

NONRES ET

+ - + -

TB2

J3

J2

NC NO

TROUBLE

RELAY

SUPV

RELAY

NO

C

NC

ZONE 1 ZONE 2 ZONE 3 ZONE 4 ZON E 5

NO

ZO NE 6 ZON E 7 ZO NE 8 ZON E 9 ZO NE 10

BELL 2

REMOTE TRBL UNIT

AC TRBL BUZZ

GND

TB5

ALARM

RELAY

C

TB4

TB6

SUPV

ALARM

24 V

BELL 1

BELL 2

REMOTE TRBL UNIT

AC TRBL BUZZ

GND

+ - + -

TB3

TB5

TB1

CB1

EARTH

HOT

NEUT

TROUBLE

RELAY

RELAY

NC NO

RELAY

CCC

ZONE 1 ZON E 2 Z ONE 3 ZO NE 4 ZO NE 5

NO

NCNCNC

C

NO

+ - + - + - + - + - + - + - + - + - + -

TB4

TB6

ZONE 6 ZONE 7 ZONE 8 ZO NE 9 ZO NE 10

J5

U3

LED-10IM

MODULE

U6

TB7

SECURITY KEY

J4

TB7

J5

LED-10IM

MODULE

J4

SECURITY KEY

J6

J6

MEMBRANE SW CONNECTOR

J1

BAT T - +

TON E/CITY BOX

OPTIONS

J8

J7

JP1

OPTION

SUP ERVIS ION

TO NE/CIT Y BO X

J7

OPTIONS

TB1

H

N

O

E

T

U

T

AC Pow er

J1

JP1

BATT - +

E

A

R

T

H

J8

MEMBRANE SW CO NNECTOR

OPTION

SUPERVISION

MS-2410B Terminals and Connectors

2410layo.cdr

8

Document #51127 Rev.C 11/7/00 P/N 51127:C

Page 9

Product Description

CHAPTER 1 Product Description

The MS-2410B is a 10-zone FACP (Fire Alarm Control Panel), which uses conventional input devices. The panel

accepts waterflow devices, two-wire smoke detectors, four-wire smoke detectors, pull stations and other

normally-open contact devices. Outputs include two Notification Appliance Circuits (NACs), three standard Form-C

relays (alarm, trouble and supervisory) and an EIA-485 port to interface with remote annunciators and optional

remote relay modules. The FACP is field programmable via the panel keypad. It also supervises all wiring, AC

voltage and battery level. The MS-2410BE offers the same features as the MS-2410B but allows connection to 220/

240 VAC input.

1.1 Product Features

• 10 Class B Initiating Device Circuits (IDCs)

✓ All zones accept smoke detectors and any normally open contact device

✓ Zones 1 - 8 configured as general alarm zones

✓ Zones 9 - 10 can be configured as smoke zones or supervisory alarm zones

• Two Class B Notification Appliance Circuits (NACs)

• Form-C Alarm Relay

• Form-C Trouble Relay

• Form-C Supervisory Relay

• 3.6 amps of system power expandable to 6.6 amps

• RTB Remote Trouble Buzzer

• Remote Relay Option Module (ACM-8RF) providing one 5.0 amp relay per zone

• Dress Panel coverplate (DP-2410B)

• Built-in keypad for panel control and programming

• 24 volt operation

• Trouble Reminder

• Alarm Verification (zones 1 through 3 only)

• Interfaces with Fire•Lite annunciators (requires

LED-10IM Option Module)

✓ LED-10 Series Remote Annunciators provide

red alarm and yellow trouble LEDs

✓ LDM-32F Graphic Annunciator Driver

✓ AFM Series LED Annunciators

• Small backbox size 16.9” (42.9 cm) X 14.5” (36.8

cm) X 4.5” (11.43 cm)

• Silence Inhibit Notification Appliance Circuits

• Auto-Silence Notification Appliance Circuits

• Fuseless design

• Low AC voltage sense

• Silent or audible Walktest

FIGURE 1-1:

DP-2410B

DP2410b.cdr

Note: Unless otherwise specified, the term MS-2410B shall be used in this manual to refer to both the MS-2410B and

the MS-2410BE Fire Alarm Control Panels.

Document #51127 Rev. C 11/7/00 P/N 51127:C

9

Page 10

Product Features

24 VDC

Power

Keypad and

LEDs

Standard

Trans former

Notification

Appliance

Circuits

Remote

Trouble

Buzzer

AT

Zone 1

Zone 2

Zone 3

Zone 4

Zone 5

Zone 6

Zone 7

Zone 8

Zone 9

Zone 10

Trouble

Supervisory

Signal Silence

NAC Fault

Ground Fault

Battery Trouble

Zone Disabled

Annc. Trouble

Relays

10 Input

Zones

Security Key

LED-10IM

Interface

Module

Connector

Reverse

Pol arity

Module

Optional

Trans former

Note: Transformers

are mounted to the

backbox, under the

main circuit board.

Holds up to 12 AH Batteries,

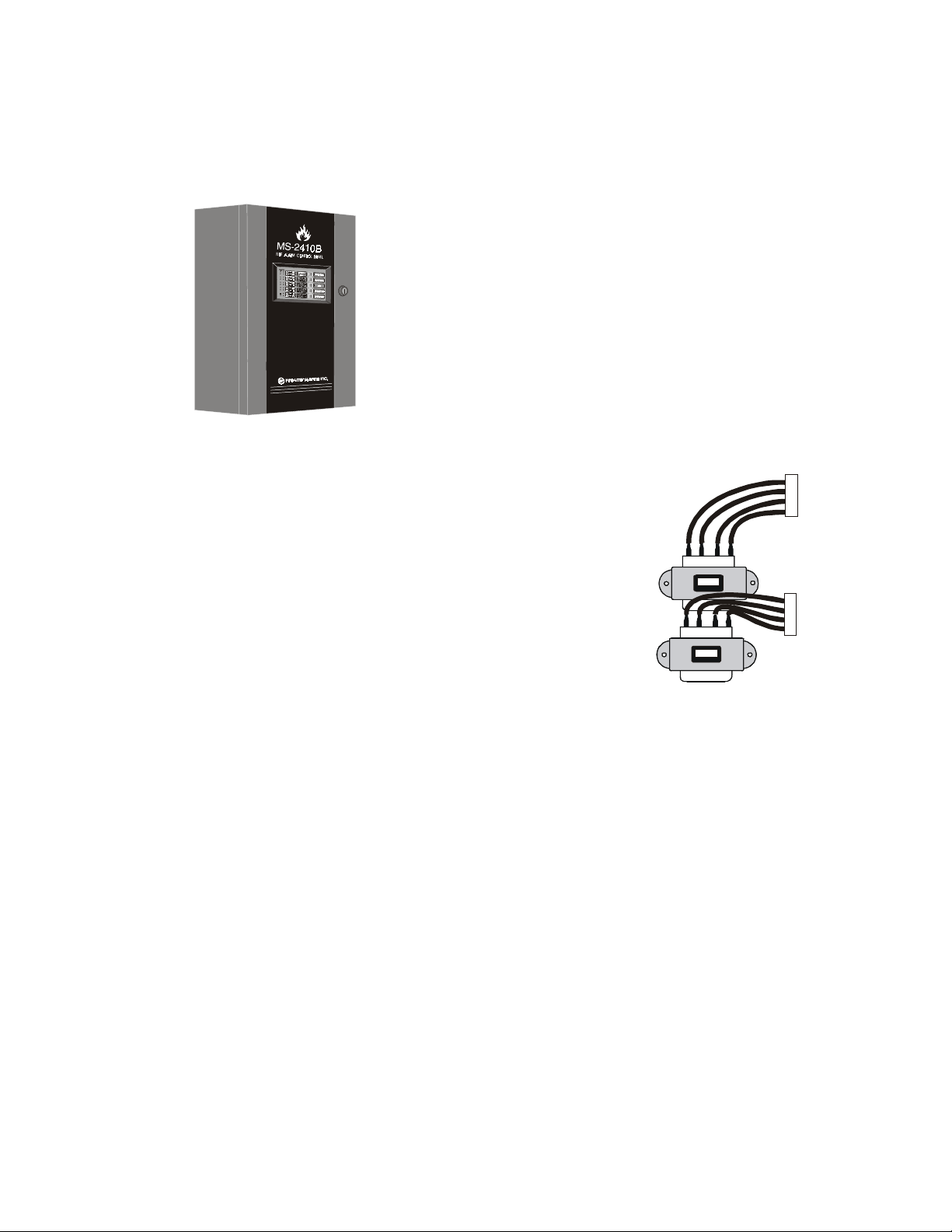

FIGURE 1-2:

MS-2410B Panel

Reverse

Polarity

Module

Supervision

m2410enc.cdr

10

Document #51127 Rev.C 11/7/00 P/N 51127:C

Page 11

Specifications

1.2 Specifications

AC Power - TB1

MS-2410B: 120 VAC, 60 Hz, 2.3 amps

MS-2410BE: 220/240 VAC, 50 Hz, 1.15 amps

Wire size: minimum #14 AWG (2.0 mm

Battery (lead acid only) - J1

Maximum Charging Circuit: Normal Flat Charge—27.6V @ 0.8 amp

Maximum Charger Capacity: 18 Amp Hour battery (MS-2410B cabinet holds maximum 12 Amp Hour battery.

Larger batteries require Fire•Lite BB-17F)

Initiating Device Circuits TB6 and TB7

General Alarm Zones 1 through 8

Smoke Zones or Supervisory Alarm Zones 9 and 10

Operation: All zones Class B

Normal Operating Voltage: Nominal 24 VDC (ripple = 100 mV maximum)

Alarm Current: 15 mA threshold

Short Circuit Current: 42 mA maximum

Maximum Loop Resistance: 100 ohms

End-of-Line Resistor: 4.7K, ½ watt (Part #27072)

Standby Current: 7.26 mA (includes ELR and 2 mA maximum detector current)

Smoke Detector Identifier A

Refer to Fire•Lite Device Compatibility Document for listed compatible devices.

2

) with 600V insulation

Notification Appliance Circuits - TB3

Class B wiring

Operating voltage nominal 24 volts

Current for all external devices: 3.0 amps expandable to 6.0 amps

1

Current Limit: TB3 via PTC

Maximum signaling current/circuit: TB3 = 1.25 amps expandable to 2.5 amps

End-of-Line resistor: 4.7K, ½ watt (Part #71252) for Notification Appliance Circuits

Refer to Fire•Lite Device Compatibility Document for listed compatible devices

Three Form-C Relays - TB4

TB4 relay contact rating: 2.0 amps @ 30 VDC (resistive), 2.0 amps @ 30 VAC (resistive)

Four-wire Smoke Detector Power - TB2 Terminals 3(-) & 4(+)

Maximum ripple voltage: 10 mV

Up to 300 mA is available for powering 4-wire smoke detectors

Recommended maximum Standby current is 50 mA

Operating Voltage nominal 24 volts

RMS

2

1

Refer to Fire•Lite Device Compatibility Document for compatible listed device

1. Total current for nonresettable power, four-wire smoke power, and two Notification Appliance Circuits

amps.

Total system current in excess of 3.6 amps requires the XRM-24 Transformer (XRM-24E for 220/240 VAC applications)

and 12 Amp Hour or 18 Amp Hour batteries.

2. For power supply and battery calculations, refer to “Power Supply Calculations” on page 55.

Document #51127 Rev. C 11/7/00 P/N 51127:C

must not exceed 6.0

11

Page 12

Controls and Indicators

Nonresettable 24 VDC Power - TB2 Terminals 1(-) & 2(+)

Maximum ripple voltage: 10 mV

Total DC current available from this output is up to 500 mA

Operating Voltage nominal 24 volts

RMS

1

Recommended maximum Standby current is 150 mA

Refer to Fire•Lite Device Compatibility Chart for compatible listed devices

Remote Trouble Buzzer - TB5

Operating Voltage: nominal 24 VDC

DC current when RTB Remote Trouble Buzzer is in normal standby (AC Power LED on alone) is 20 mA.

Maximum DC current from this output when RTB Remote Trouble Buzzer is active is 50 mA.

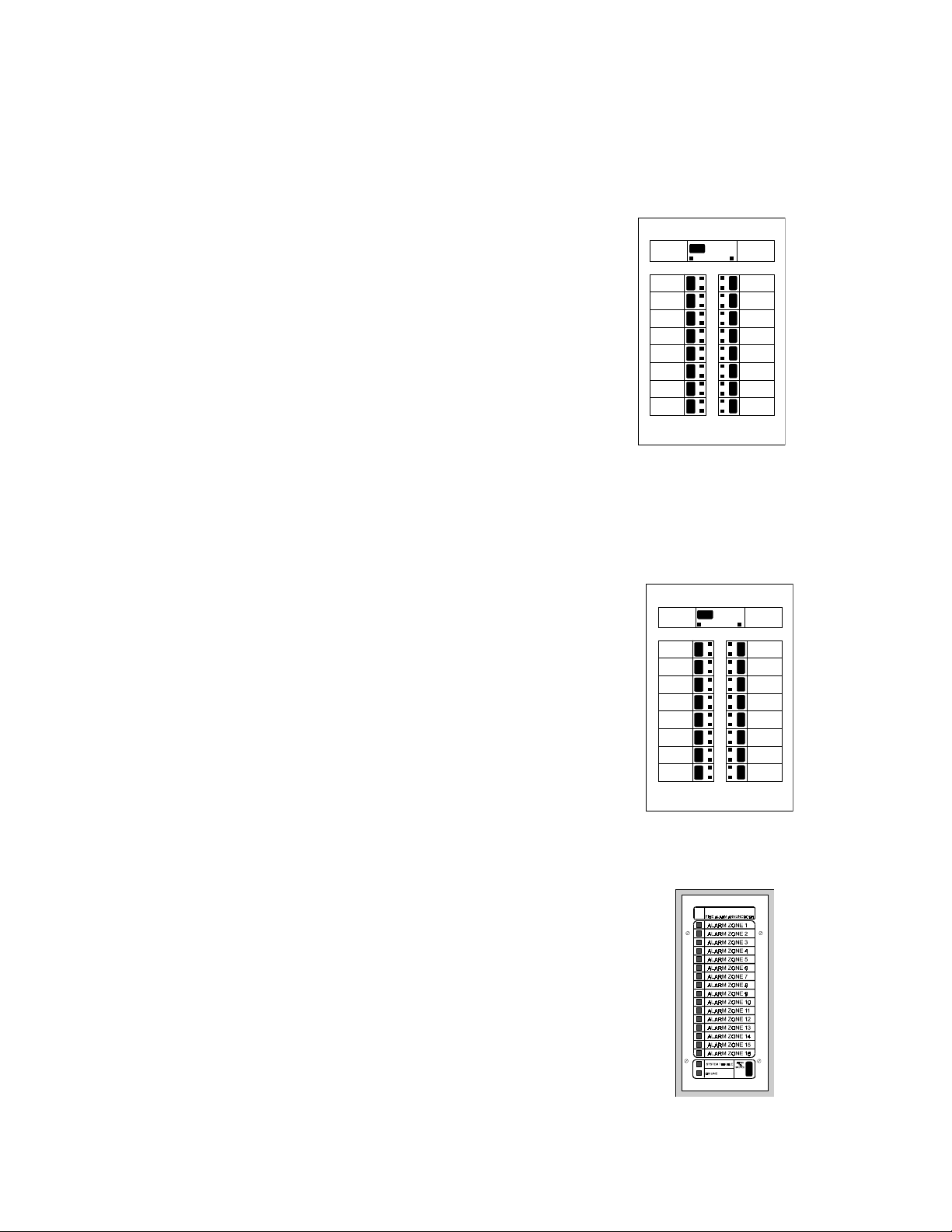

1.3 Controls and Indicators

Front Panel Membrane Keys in Normal Mode

Acknowledge

Signal Silence

Drill

Disable/Enable

Reset/Lamp Test

Note that programming keys function slide-in-labels and

option/feature slide-in labels are also provided and should

be inserted while in Program Mode to view the altered key

functions. Refer to Figure 4-1, “LED Indicators and Keypad,” on page 47 and “Slide-in Labels” on page 61.

LEDs

AC Power - green LED

Alarm - red LED

Trouble - yellow LED

Supervisory - yellow LED

Signal Silence - yellow LED

NAC Fault - yellow LED

Ground Fault - yellow LED

Battery Trouble - yellow LED

Zone Disabled - yellow LED

Annunciator Trouble - yellow LED

Zone Fire Alarm - Zones 1 through 10 - red LEDs

Zone Supervisory Alarm - Zones 9 and 10 only - red LEDs

Zone Trouble - Zones 1 through 10 - yellow LEDs

AT

Zone 1

Zone 2

Zone 3

Zone 4

Zone 5

Zone 6

Zone 7

Zone 8

Zone 9

Zone 10

FIGURE 1-3:

Trouble

Supervisory

Signal Silence

NAC Fault

Ground Fault

Battery Trouble

Zone Disabled

Annunc. Trouble

LEDs and Keypad

2410disp.cdr

2410DISP

Note: A blank slide-in label is provided for circuits 1 through 10 which may be customized by the customer. In

addition, slide-in-labels listing the programming features/options and programming key functions are provided and

should be inserted while in Program Mode.

1. Total current for nonresettable power, four-wire smoke power, and two Notification Appliance Circuits

amps.

Total system current in excess of 3.6 amps requires the XRM-24 Transformer (XRM-24E for 220/240 VAC applica-

tions) and 12 Amp Hour or 18 Amp Hour batteries.

12

Document #51127 Rev.C 11/7/00 P/N 51127:C

must not exceed 6.0

Page 13

Circuits

Local Sounder

A piezo sounder provides separate and distinct sounds for alarm, trouble and supervisory conditions:

• Alarm - on steady

• Alarm Verification - pulse 1 second On and 1 second Off

• Trouble - pulse 1 second On and 1 second Off

• Supervisory - pulse ½ second On and ½ second OFF

1.4 Circuits

Input Circuits

Ten input circuits provide Class B configuration. Input circuits 1 through 10 may be used as standard fire alarm

control panel zones and circuits 9 and 10 may be used as supervisory alarm zones. All ten Initiating Device Circuits accept normally-open contact devices and two-wire smoke detectors.

Output Circuits

• 24 Volt Resettable Power Output 300 mA

• 24 Volt Nonresettable Power Output 500 mA

• 24 Volt Remote Trouble Buzzer Output 50 mA maximum

• 24 Volt Battery Charger (up to 18 AH batteries)

• EIA-485 Port (interfaces to LED-10 Series Annunciators, AFM Series and LDM Graphic Series Annunciators

and ACM-8RF Remote Relay Module)

Notification Appliance Circuits

Two Notification Appliance Circuits Class B.

Relays

Three dry Form-C relays for system alarm, system trouble and supervisory are provided standard. Contacts are

rated 2.0 amps @ 30 VDC (resistive) and 2.0 amps @ 30 VAC (resistive).

EIA-485 Port (Requires LED-10IM Module)

EIA-485 compatible port on the LED-10IM option module supports up to 10 different device addresses which can

consist of LED-10 Series Remote Annunciators, ACM-8RF Relay Modules, AFM Series Annunciators or LDM

Graphic Series Annunciators or any combination of the four modules.

Battery Charger

Battery Charger will charge up to 18 AH batteries. The MS-2410B cabinet holds a maximum of 12 AH batteries.

The Fire•Lite BB-17F is required to hold 18 AH batteries. The charger is rated for 800 mA maximum current.

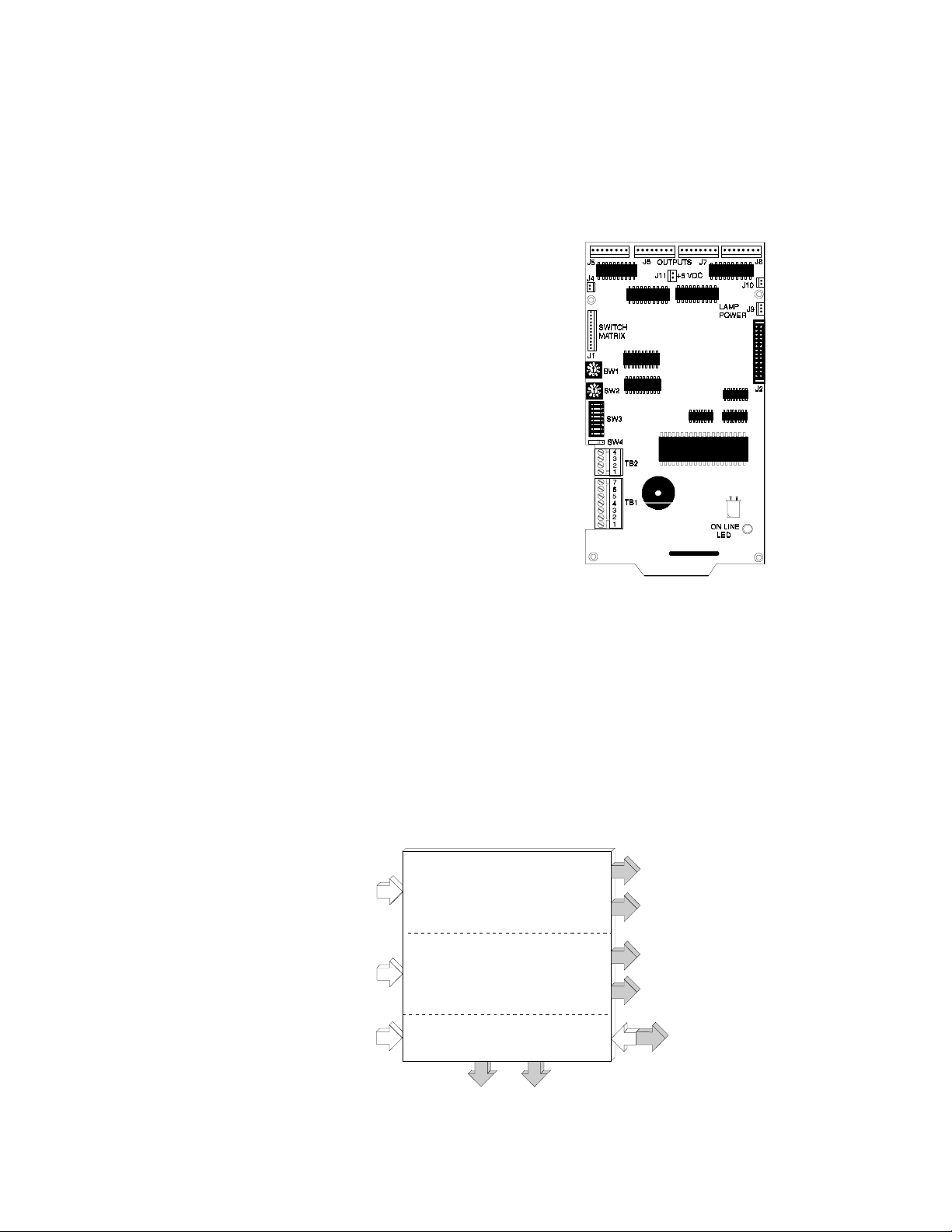

1.5 Components

Main Circuit Board

The main circuit board contains the system's

CPU, power supply, other primary components and wiring interface connectors.

Optional modules plug in and are mounted to

the main circuit board. The main circuit board

is delivered premounted in the cabinet.

24 V

24 V

BELL 1 BELL 2

RESET

NONRESET

REMOTE TRBL BUZZER

GRD

+ - + -

+ - + -

TB2

TB3

J3

TB1

CB1

J2

HOT

AC TRBL BUZZ

TB5

EARTHNEUT

SUPV

TROUBLE

ALARM

RELAY

ZONE 1 ZONE 2 ZONE 3 ZONE 4 ZONE 5 ZONE 6 ZONE 7 ZONE 8 ZONE 9 ZONE 10

RELAY

RELAY

NC

CCCNONONC NO

NC

+ - + - + - + - + - + - + - + - + - + -

TB6

TB4

MEMBRANE SW CONNECTOR

J1

BATT - +

SECURITY KEY

J4

TB7

J5

U3

LED-10IM

MODULE

U6

J6

TONE/C ITY BOX

OPTIONS

JP1

OPTION

SUPERVISION

J7

2410brd.cdr

J8

FIGURE 1-4:

Document #51127 Rev. C 11/7/00 P/N 51127:C

Main Circuit Board

13

Page 14

Optional Modules

Cabinet

The cabinet is red and the backbox measures 16.90” (42.9 cm) long X 14.50” (36.8 cm) high X 4.5” (11.43 cm)

deep and provides space for two batteries (up to 12 Amp Hours). Also available is an optional dress panel,

DP-2410B, which mounts inside the cabinet.

ms2410bcdr

FIGURE 1-5:

MS-2410B Cabinet

Transformer Assembly

One 100VA transformer is provided standard with the panel.

An optional 100VA transformer XRM-24 (XRM-24E for

220/240 VAC applications) is available to provide maximum

accessory power.

Batteries

Standard XRM-24(E)

The cabinet provides space for 12 Amp Hour batteries (larger

batteries up to 18 Amp Hour batteries, use the listed Fire•Lite

BB-17F battery box). Batteries must be ordered separately.

Optional XRM-24(E)

FIGURE 1-6:

Transformer Assemblies

1.6 Optional Modules

LED-10IM

The LED-10IM Interface Module provides an EIA-485 port to support the LED-10 Series Remote Annunciator,

LDM Series Annunciator, AFM Series Annunciator and ACM-8RF Relay Modules. EIA-485 wiring is

supervised for short, open and grounded circuits by this module. The LED-10IM mounts to connector J5 on the

main circuit board.

4XTMF Transmitter Module

The 4XTMF provides a supervised output for local energy municipal box transmitter and alarm and trouble

reverse polarity. It includes a disable switch and disable trouble LED. A module jumper option allows the reverse

polarity circuit to open with a system trouble condition if no alarm condition exists.

1.7 Optional Accessories

Dress Panel

A dress panel (DP-2410B) is available as an option. The dress panel restricts access to the system wiring while

allowing access to the membrane switch panel. Refer to Figure 1-1, “DP-2410B,” on page 9.

14

Document #51127 Rev.C 11/7/00 P/N 51127:C

Page 15

Optional Accessories

Battery Box

The Fire•Lite BB-17F battery box may be used to house

two batteries greater than 12 Amp Hour to a maximum of

18 Amp Hour. The battery box mounts directly below the

MS-2410B cabinet, centered to the main circuit board. The

BB-17F is red and is provided with knockouts.

bb17.cdr

Remote Trouble Buzzer

One Remote Trouble Buzzer can be connected to the

MS-2410B control panel using four wires. The remote unit

includes an AC LED, System Trouble LED and piezo

sounder which are controlled by the MS-2410B. It mounts

to a single-gang electrical box.

ACM-8RF Relay Module

The ACM-8RF option module provides eight Form-C relays

rated at 5.0 amps each. The Relay Module connects to the

EIA-485 port off of the LED-10IM option module. Relays

are assigned to each of the 10 Initiating Device Circuits.

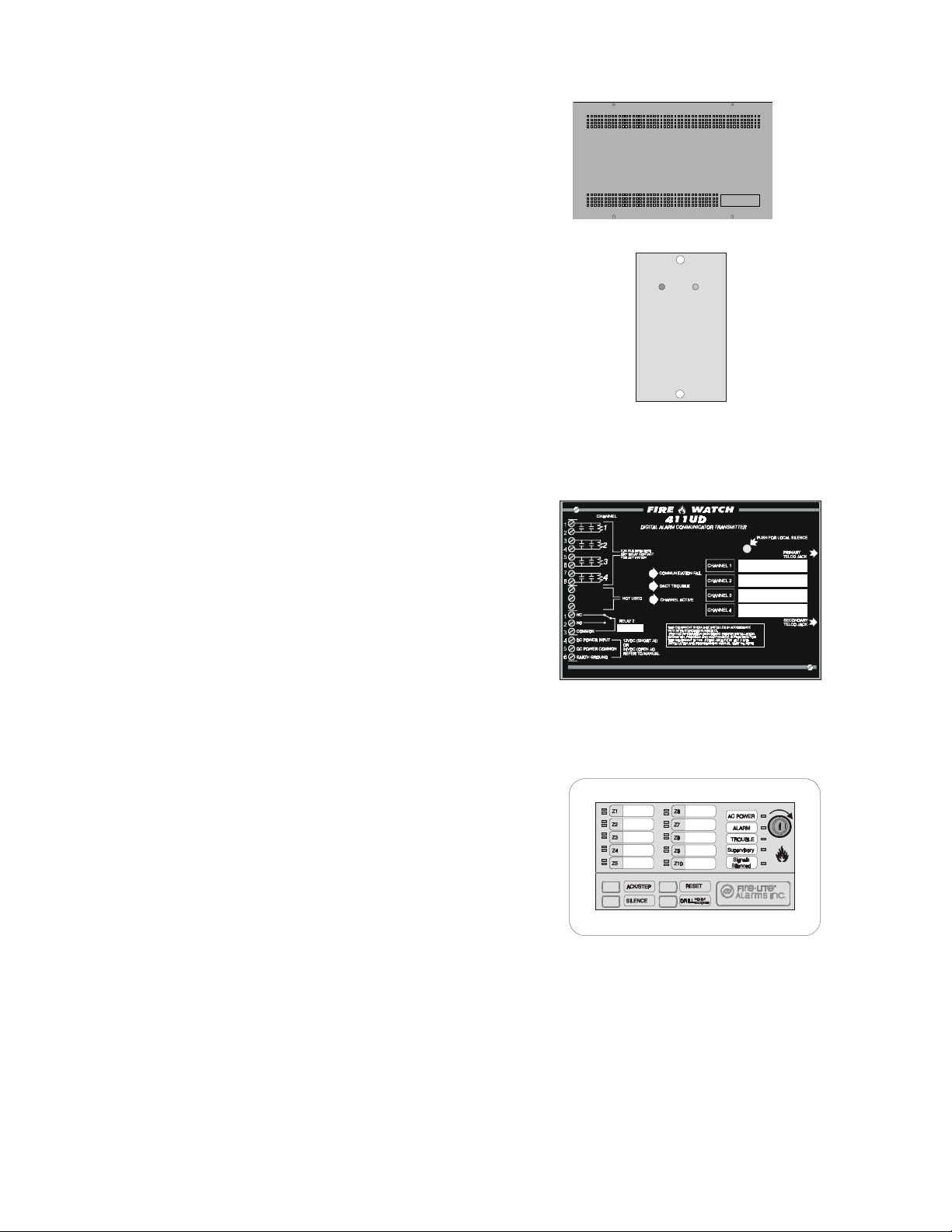

411 and 411UD Digital Alarm Communicator/Transmitter

The three input/channel 411 and the four input/channel 411UD

are dual line, digital alarm communicator transmitters which

can be used as slave communicators with the MS-2410B. The

inputs/channels are compatible with normally open relay contacts, require End-Of-Line (EOL) resistors, are supervised and

are fully programmable. The communicators interface with

the public switched telephone network and are compatible

with most central station receivers. Power supplied must be 12

or 24 volts, filtered and nonresettable. The communicators are

mounted in a small metal enclosure, providing a variety of

mounting options. Refer to the 411 or 411UD manual for

detailed information on installation, wiring and programming.

FIGURE 1-7:

FIGURE 1-8:

FIGURE 1-9:

BB-17F Battery Box

rtbbuzz.cdr

RTB Remote Trouble Buzzer

411udcvr.cdr

411UD Communicator

LED-10 Series Annunciator (LED Zone Type Annunciator)

The LED-10 Series is a 10 zone LED annunciator which

mounts on a 3-gang electrical box and provides LED

indication of the following:

• Alarm Zones 1 through 10

• Supervisory Zones 9 and 10 (LED-10LS2 only)

• Trouble Zones 1 through 10

FIRE ANNUNCIATOR

• AC Power (green)

• System Alarm (red)

• System Trouble (yellow)

FIGURE 1-10:

LED-10 Series Annunciator

• System Supervisory (yellow)

• Alarm Silence (yellow)

A local trouble sounder is standard and switches for remote Acknowledge, Silence, Drill and Reset are also provided on the LED-10 only. Wiring is inherently supervised by the FACP. Slide-in paper labels permit an easy

change of zone information. DIP switches allow the enabling and disabling of the local piezo sounder (with

approval of local AHJ), enabling and disabling of the mechanical keyswitch which may be used to prevent unauthorized use of the function switches and selection of annunciator receive/transmit mode.

Note that the LED-10 Series Remote Annunciators require the use of the LED-10IM Interface Module.

Document #51127 Rev. C 11/7/00 P/N 51127:C

led10.cdr

15

Page 16

Optional Accessories

AFM Series Annunciators (LED Zone Type)

The AFM Series Annunciators remotely display system status. The AFM/AEM-16AT annunciators display zone

alarm and trouble status. In addition, they provide remote Acknowledge, Silence, Reset and Drill functions. The

AFM Series Annunciators require the use of the LED-10IM Interface Module. For more detailed information,

refer to the appropriate AFM Annunciator manual.

✓ AFM-16ATX - The Annunciator Fixed Module-16ATX contains

16 red alarm and 16 yellow trouble LEDs, a system trouble LED,

an ON LINE/POWER LED and a local piezo sounder with

switches for Acknowledge, Silence, Reset and Drill. The

AFM-16ATX is fixed at address '1' and will accept up to 3

AEM-16ATF Expanders. The AFM-16ATX can be mounted in a

Fire•Lite ABS-1F or ABF-1F backbox. Refer to the AFM-16ATX

Manual for detailed information.

Note that only one AFM-16ATX

is required to annunciate 10 zones of alarm and trouble, provided '8

Point Shift' function is selected. Refer to Annunciator Manual P/N

15390 for additional information.

✓ AFM-16ATXCS4 - This module is the same as the AFM-16ATX

except with four yellow supervisory LEDs in place of the four red

FIGURE 1-11:

AFM-16ATX

LEDs at points 13 through 16.

✓ AFM-16ATXCS8 - This module is the same as the AFM-16ATX except with eight yellow supervisory

LEDs in place of the eight red LEDs at points 9 through 16.

✓ AFM-16ATXCS16 - This module is the same as the AFM-16ATX except with sixteen yellow

supervisory LEDs in place of the sixteen red LEDs at points 1 through 16.

✓ AEM-16ATF - The Annunciator Expander Module-16ATF con-

nects to the AFM-16ATX and adds 16 sets of red alarm LEDs

and yellow trouble LEDs. Up to three AEM-16ATFs may be

added to an AFM-16ATX but only one is required.

Note that one

AEM-16ATF is required with an AFM-16ATX to annunciate 10

zones of alarm and trouble as well as general system status provided '8 Point Shift' function is not selected. Refer to Annunciator Manual P/N 15390 for additional information.

✓ AFM-16ATF - The Annunciator Fixed Module-16ATF contains

16 red alarm and 16 yellow trouble LEDs, a system trouble LED,

an ON LINE/POWER LED and a local piezo sounder with

switches for Acknowledge, Silence, Reset and Drill. The

AFM-16ATF is fixed at address '1' and communication is via the

EIA-485 data line. The AFM-16ATF can be mounted in a

Fire•Lite ABS-1F or ABF-1F backbox. Refer to the AFM-16AT

FIGURE 1-12:

AFM-16ATF

Manual for detailed information.

✓ AFM-16AF - The Annunciator Fixed Module-16AF has 16 red

alarm LEDs. Multiple annunciators may be used by setting all

annunciators to Receive Only, except the last AFM-16AF in

line. Each annunciator's address is internally fixed at '1' and

communication is via the EIA-485 data line. The Local

Silence/Acknowledge switch functions as local lamp test and

silence for annunciator piezo. LEDs include On-Line and System Trouble indicators. The AFM-16AF Annunciator can be

mounted in a standard 4-gang electrical box. Refer to the

AFM-16AF Manual for detailed information.

afm16atx.cdr

afm16atx.cdr

16

Document #51127 Rev.C 11/7/00 P/N 51127:C

FIGURE 1-13:

afm-16a.cdr

AFM-16AF

Page 17

Optional Accessories

LDM Series Lamp Driver Modules (Graphic Annunciator)

The LDM Series Lamp Driver Modules, which consist of the LDM-32F master and LDM-E32F expander modules, are used to provide an interface to a custom graphic LED annunciator. The master module provides power

and control for a maximum of three expander modules (expander modules are not required when interfacing to the

MS-2410B). The LDM-32F and LDM-E32F have output connectors which are used to drive lamps or LEDs and

input connectors which are used for remote switch functions. The LDM Series requires the use of the LED-10IM

Interface Module. Refer to the LDM Series Lamp Driver Modules Manual for a complete description.

✓ LDM-32F - The Lamp Driver Module has 32

alarm lamp/LED driver outputs which sink current to system common (-) on activation. A single

positive (+) voltage is required to supply total

operating power for all lamps or LEDs when all

drivers are activated. The LDM-32F provides a

separate driver for system trouble and inputs for a

local lamp test switch. A maximum of 16 external control switches may be wired to the

LDM-32F. DIP switch SW3 is used to enable or

disable the onboard piezo sounder, enable remote

switch functions, select a flashing LED function

for new alarms and troubles and other functions.

Switch SW4 is used to configure the module to

annunciate 32 alarms or 16 alarms and 16 troubles. A green ON-LINE LED flashes to indicate

ongoing communications with the host FACP.

One LDM-32F supports up to three LDM-E32F

modules. The LDM-32F is supplied with four

standoffs and screws for mounting to a CHS-4L

FIGURE 1-14:

LDM-32F Module

ldm-32f.cdr

chassis or custom backbox.

FCPS-24F(E) Remote Power Supply (System Power Expansion)

The FCPS-24F(E) is a compact, remote power supply and battery charger. This remote power supply consists of a

filtered 24 VDC output that may be configured to drive up to four Notification Appliance Circuits (four Class B or

two Class A and two Class B). Alternately, the four Notification Appliance Circuits may be used as auxiliary

power configured for resettable or nonresettable operation.

The FCPS-24F(E) may be used in a number of different applications. It may be used as a remotely mounted power

supply and battery charger powering up to four, coded or noncoded, Notification Appliance Circuits. Alternately,

any or all of these circuits may be used as 24 VDC output circuits capable of powering four-wire smoke detectors

or any device that requires filtered power. These circuits may be configured as resettable or nonresettable outputs

to expand FACP auxiliary system power.

Class B/Class A Notification Appli-

Notification Appliance Circuit

Control Input #1 (from FACP)

Notification Appliance Circuit

Control Input #2 (from FACP)

FIGURE 1-15:

AC Power

FCPS-24F(E)

Specific Application

Power

FCPS Trouble

Contact Output

ance Circuit or 24 VDC Output #1

Class B Notification Appliance

Circuit or 24 VDC Output #2

Class B/Class A Notification Appli-

ance Circuit or 24 VDC Output #3

Class B Notification Appliance

Circuit or 24 VDC Output #4

Battery Charger

fcpsblok.cdr

Document #51127 Rev. C 11/7/00 P/N 51127:C

17

Page 18

Optional Accessories

One of the most common applications for the FCPS-24F(E) remote power supply utilizes the NAC expander

mode. In this application, one or two Notification Appliance Circuits (NACs) are connected from the main FACP

NAC output(s) to the remote power supply Control Input circuits. When these Control Input circuits activate (due

to reverse polarity of the NAC output), the power supply will activate its corresponding outputs. NAC Control

Input #1 controls power supply output circuits #1 and #2. NAC Control Input #2 controls output circuits #3 and

#4.

During the inactive state, the remote power supply supervises its NAC field wiring for short and open circuits. If

a fault is detected, the supply will enter a trouble condition and illuminate the corresponding NAC trouble LED

(Output Circuits 1-4), however, once the Notification Appliance Circuits are activated, the supervision is disabled

and the circuits are no longer supervised. Supervision of other power supply faults such as low battery, Earth

Fault, AC loss and battery charger failure will continue and may be monitored via the independent trouble relay

contact.

If a specific application requires that all four outputs activate at the same time, only one NAC control input from

the FACP is necessary. For this application, The Notification Appliance Circuit from the FACP is wired into NAC

Control Input #1 of the remote supply and then a pair of wires are connected from NAC Control Output #1 to

NAC Control Input #2. Refer to the FCPS-24F(E) Installation, Operation and Application Manual for a complete

description and examples of applications.

18

Document #51127 Rev.C 11/7/00 P/N 51127:C

Page 19

Installation

CHAPTER 2 Installation

2.1 Mounting Options

The cabinet may be either semi-flush or surface mounted. The door

is removable during the installation period by opening and lifting off

the hinges. The cabinet mounts using two key slots and two additional 0.250" (6.35 mm) diameter holes located in the backbox. The

key slots are located at the top of the backbox and the two securing

holes at the bottom.

Carefully unpack the system and check for shipping damage. Mount

the cabinet in a clean, dry, vibration-free area where extreme temperatures are not encountered. The area should be readily accessible

with sufficient room to easily install and maintain the panel. Locate

the top of the cabinet approximately five feet above the floor with the

hinge mounting on the left. Determine the number of conductors

required for the devices to be installed. Sufficient knockouts are provided for wiring convenience. Select the appropriate knockout(s)

and pull the required conductors into the box. All wiring should be

in accordance with the National and/or Local codes for fire alarm

systems.

FIGURE 2-1:

ms2410b.cdr

MS-2410B Mounting

2.2 Backbox Mounting

✓ Open the door and lift the door off the pin hinges.

✓ Remove the main PC board assembly and transformer(s) which are packaged with the backbox. Set the

board and transformer aside in a safe, clean place. Avoid static discharge which may damage the board.

✓ Mark and predrill holes for the top two keyhole mounting bolts using the dimensions illustrated.

✓ Install two upper fasteners in the wall with the screw heads protruding.

✓ Using the upper 'keyholes', mount the backbox over the two screws.

✓ Mark and drill the lower two holes.

✓ Mount backbox, install remaining fasteners and tighten.

✓ When the location is dry and free of construction dust, install the transformer and main circuit board as

described in the following sections.

Document #51127 Rev. C 11/7/00 P/N 51127:C

19

Page 20

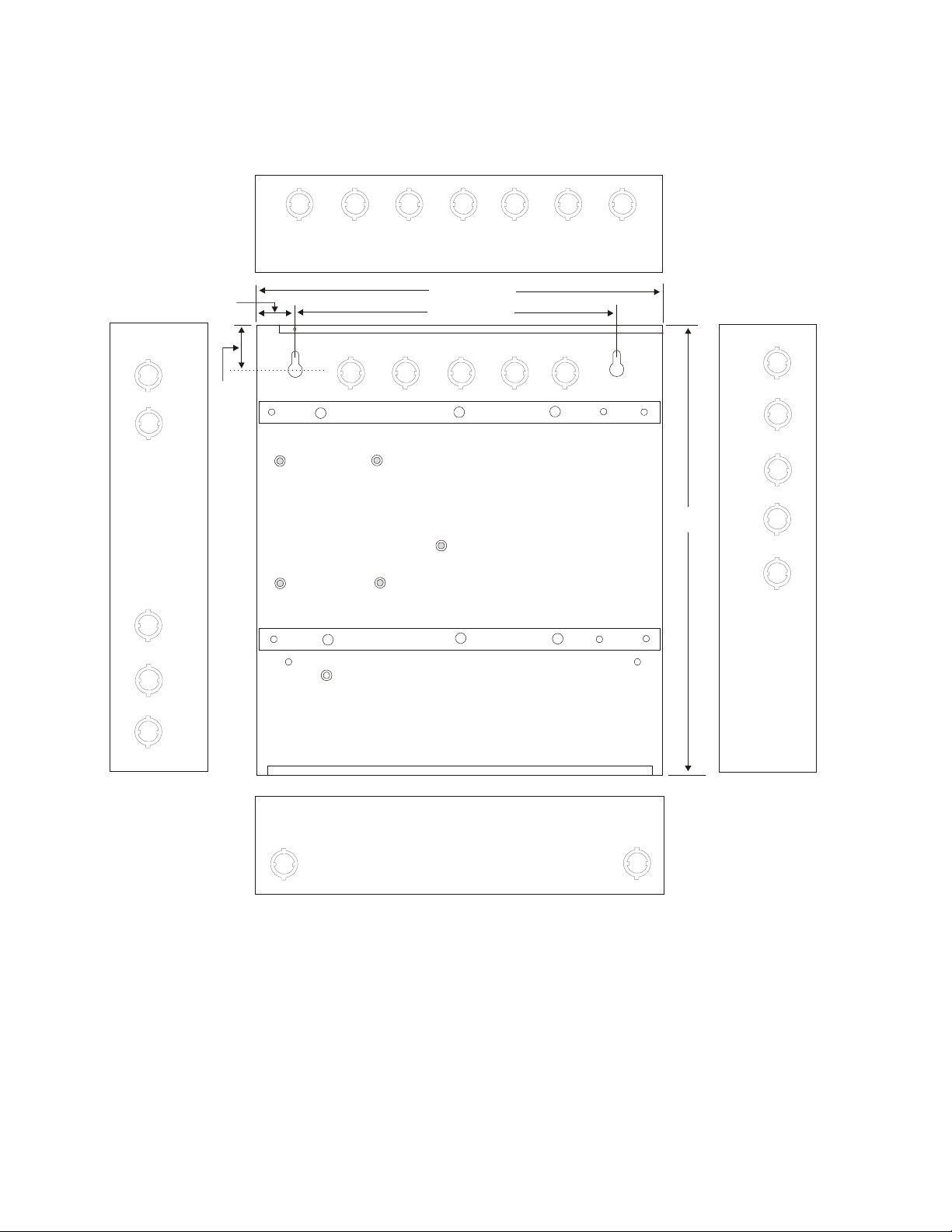

Backbox Mounting

Draw wires through the respective knockout locations.

To p

Left Side

1.5”

(3.81 cm)

1.55”

(3.94 cm)

14.5” (36.83 cm)

11.5” (29.21 cm)

Right Side

16.9””

(42.93 cm)

20

Bottom

FIGURE 2-2:

Document #51127 Rev.C 11/7/00 P/N 51127:C

Cabinet Dimensions and Knockout Locations

5210bkbx.cdr

Page 21

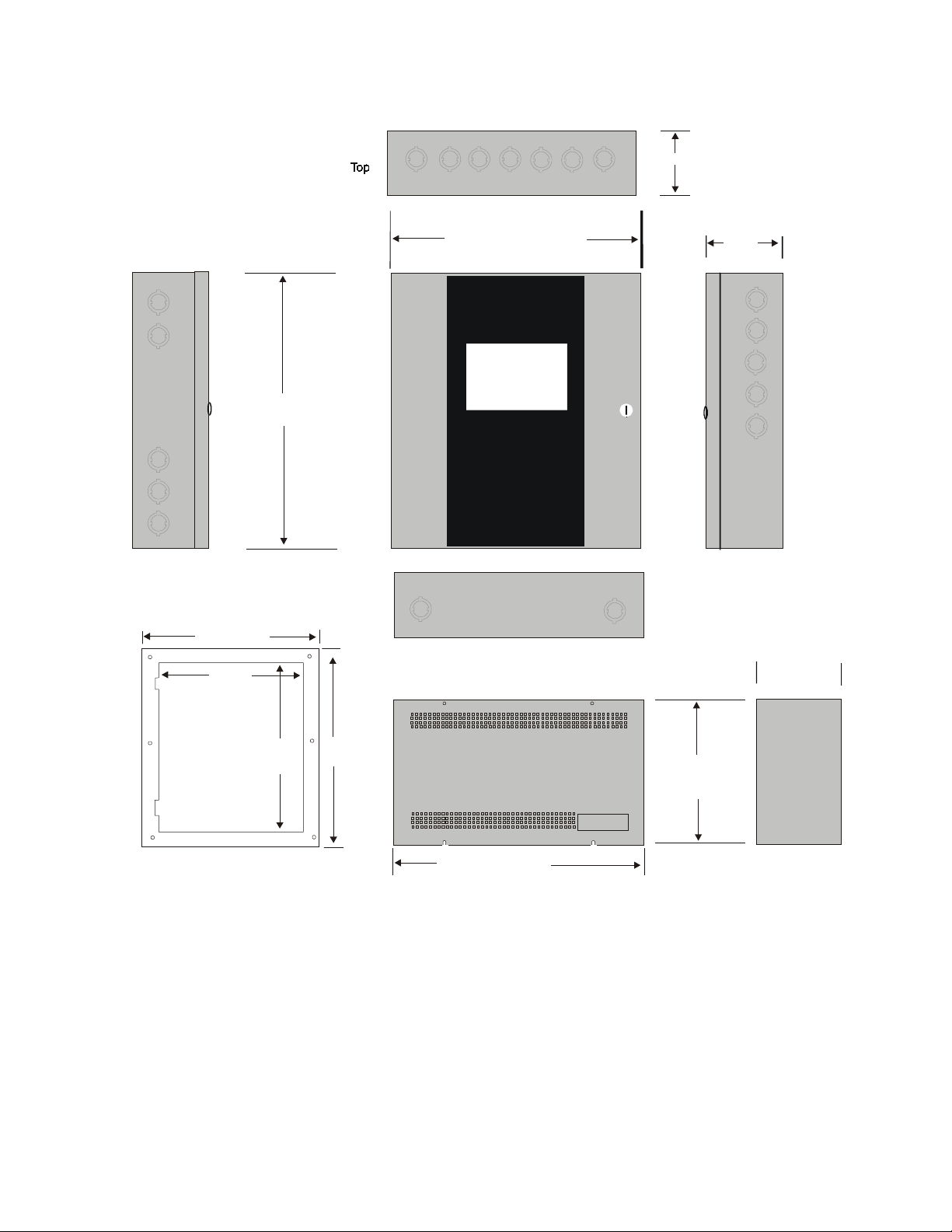

Backbox Mounting

Depth = 4.5" (11.43 cm)

Left Side

Door = 17.114" (43.37 cm)

Backbox = 16.9" (42.9 cm)

17.620"

(44.75 cm)

14.620"

(37.14 cm)

Bottom

Door = 14.714" (37.37 cm)

Backbox = 14.5" (36.8 cm)

Depth =

4.695"

11.93 cm)

2410bcab.cdr

Right Side

Depth = 4.75"

(12.07 cm)

17.020"

(43.23 cm)

TR-4-R Trim Ring

20.020"

50.85 cm)

Battery Box=8.5"

(21.59 cm)

(Optional BB-17F)

Battery Box=14.5" (36.8 cm)

(Optional BB-17F)

When batteries larger than 12 Amp Hour are being used, the BB-17F battery box (or equivalent) must be

installed. To install the BB-17F:

Mount the FACP cabinet to the wall.

1.

Remove knockouts on the bottom of the FACP cabinet and top of the BB-17F.

2.

Using conduit, hang the BB-17F from the FACP cabinet making sure there is at least ½" of

3.

clearance between the two cabinets.

Anchor the BB-17F to the wall.

4.

FIGURE 2-3:

FACP Backbox

Document #51127 Rev. C 11/7/00 P/N 51127:C

21

Page 22

Transformer Installation

2.3 Transformer Installation

One 100 VA transformer P/N: XRM-24 (XRM-24E for 220/240 VAC applications) is supplied standard with the

FACP. An optional second XRM-24(E) transformer can be ordered and installed to supply additional system power.

To install the transformer(s):

✓ Position the supplied transformer over the top set of mounting studs as illustrated below

✓ Secure to the studs with the supplied nuts

✓ If a second optional transformer has been ordered, position it over the bottom set of mounting studs as

illustrated below

✓ Secure the optional transformer with the supplied nuts

✓ Before installing the main circuit board, be sure to plug the transformer connector into J3 Primary

Transformer Connector on the main circuit board, and the optional transformer connector into J2

Optional Transformer Connector on the main circuit board.

Primary (standard) XRM-24(E) Transformer

Primary (Standard)

Transformer Mounting Studs

Optional XRM-24(E) Transformer

Optional

FIGURE 2-4:

Transformer Installation

MS-2410B Backbox

22

Document #51127 Rev.C 11/7/00 P/N 51127:C

Page 23

Main Circuit Board Installation

2.4 Main Circuit Board Installation

The circuit board contains static-sensitive components. Always ground yourself with a proper wrist strap before han-

!

dling any boards so that static charges are removed from the body. Use static suppressive packaging to protect electronic assemblies.

Install the supplied standoffs in the backbox as follows (refer to Figure 2-5 for locations):

1.

• Install large plastic standoff in center of box by screwing threaded female end onto the pem stud

• Install four metal standoffs on mounting rails by screwing male threaded ends into threaded holes on rails

• Install six short plastic standoffs by pressing into holes on mounting rails

Position the main circuit board near the installed transformer(s) and plug the transformer connector(s) into J3

2.

(Primary) and J2 (Optional) located on the main circuit board

Position the main circuit board over the installed standoffs on the backbox rails as illustrated below

3.

Secure the main circuit board to the standoffs with the supplied screws

4.

Metal Standoff

metal standoff

metal standoff

Primary Transformer

Optional Transformer

small plastic standoffs

small plastic standoffs

MS-2410B Backbox

24 V

24 V

BELL 1 BELL 2

RESET

NONRESET

+ - + -

+ - + -

TB2

TB3 TB5

J3

TB1

CB1

J2

HOT

REMOTE TRBL BUZZER

GRD AC T RBL BUZZ

EARTHNEUT

metal standoff

large plastic standoff

metal standoff

SUPV

TROUBLE

ALARM

RELAY

ZONE 1 ZON E 2 ZONE 3 ZO NE 4 ZONE 5 ZONE 6 ZON E 7 ZON E 8 ZO NE 9 ZONE 10

RELAY

RELAY

NC

CCCNONONC NO

NC

+ - + - + - + - + - + - + - + - + - + -

TB6

TB4

MEMBRANE SW CONNECTOR

J1

BATT - +

SECURITY KEY

J4

TB7

J5

U3

LED-10IM

MODULE

U6

J6

TONE/CITY BOX

OPTIONS

JP1

OPTION

SUPERVISION

J7

J8

MS-2410B Main Circuit Board

Metal Standoff

Grounding Stud

FIGURE 2-5:

Metal Standoff

MS-2410B Backbox

Main Circuit Board Installation

Document #51127 Rev. C 11/7/00 P/N 51127:C

23

Page 24

Operating Power

2.5 Operating Power

WARNIN G:

!

before servicing. The panel and associated equipment may be damaged by removing and/or inserting cards, modules

Several different sources of power can be connected to this panel. Disconnect all sources of power

or interconnecting cables while this unit is energized.

Primary Power Source (AC) and Earth Ground Connections

AC power connections are made inside the control panel cabinet. The primary power source for the MS-2410B is

120 VAC, 60 Hz, 2.3 amps and the MS-2410BE is 220/240 VAC, 50 HZ, 1.15 amps. Run a pair of wires (with ground

conductor) from the protected premises main breaker box to TB1 of the main circuit board. As per the National Electrical Code, use 14 AWG (2.00 mm

2

, 1.6 mm O.D.) or heavier gauge wire with 600V insulation. No other equipment

may be connected to this circuit. In addition, this circuit must be provided with overcurrent protection and may not

contain any power disconnect devices. A separate Earth Ground connection must be made to ensure proper panel

operation and lightning and transient protection. Connect the Earth Ground wire [minimum 14 AWG (2.00 mm

the mounting stud located on the cabinet near TB1.

Do not use conduit for the Earth Ground connection since this

does not provide reliable protection.

Secondary Power Source (Batteries)

Observe polarity when connecting the battery. Connect the battery cable to J1 on the main circuit board using the

plug-in connector and cable provided. The battery charger is current-limited and capable of recharging sealed lead

acid type batteries. The charger shuts off when the system is in alarm. See “Wire Requirements” on page 60 for calculation of the correct battery rating.

WARNIN G:

!

If contact is made with sulfuric acid, immediately flush the skin or eyes with water for 15 minutes and seek immediate

Battery contains sulfuric acid which can cause severe burns to the skin and eyes and can destroy fabrics.

medical attention.

2

)] to

24

VAC In p ut

AT

Zone 1

Zone 2

Zone 3

Zone 4

Zone 5

Zone 6

Zone 7

Zone 8

Zone 9

Zone 10

Earth

Hot

Ground

Neutral

FIGURE 2-6:

Document #51127 Rev.C 11/7/00 P/N 51127:C

Trouble

Supervisory

Signal Silence

NAC Fault

Ground Fault

Battery Trouble

Zo ne Dis abled

Annc. Trouble

24 VDC Batteries

Operating Power Connections

J1

+ - + -

TB1

2410pwrl.cdr

Page 25

Input Circuits

2.6 Input Circuits

The control panel has 10 zone input circuits. The maximum loop resistance limit for each input circuit is 100 ohms.

All field wiring of each zone is supervised for opens and ground faults. Both conditions are visually and audibly

annunciated.

Each zone is a Class B Initiating Device Circuit (IDC) designed to accept any normally-open contact devices and conventional 2-wire, 24 volt smoke detectors.

All zones may be configured for general fire alarm applications. In addition, zones 9 and 10 can be configured as fire

alarm zones or supervisory alarm zones.

Four-wire smoke detectors may be connected to any zone. Resettable power is provided via TB2 Terminals 3 and 4.

Refer to the Fire•Lite Device Compatibility Document for a list of compatible smoke detectors.

It is allowable to mix an assortment of device types (i.e. smoke detectors, heat detectors, pull stations, etc.) on any

zone. If, however, alarm verification is employed on zones 1, 2 and 3, only smoke detectors should be installed on

these three zones.

Class B Initiating Device Circuit (supervised and power-limited). 4.7K,

UL listed compatible 2-wire smoke detector

Heat Detector

P/N: 71252

½watt,

UL listed compatible 2-wire smoke detector

Manual Pull StationManual Pull Station

Heat Detector

Dummy Load all unused circuits (P/N: 71245)

TB6

B+ B- B+ B- B+ B - B + B - B + B - B + B- B+ B- B+ B- B+ B- B+ B-

ZONE 1 ZONE 2 ZONE 3 ZONE 4 ZONE 5 ZONE 6 ZONE 7 ZONE 8 ZONE 9 ZONE 10

FIGURE 2-7:

Class B Initiating Device Circuit Connections

Document #51127 Rev. C 11/7/00 P/N 51127:C

TB7

2410tb6.cdr

25

Page 26

Output Circuits

2.7 Output Circuits

DC Power Output Connections

.

4-Wire Smoke Detector Power (300 mA) 24

VDC filtered, resettable power for 4-wire

smoke detectors can be obtained from TB2

Nonresettable Power (500 mA) 24 VDC

filtered, nonresettable power can be

obtained from TB2 Terminals 1(-) and 2(+).

Terminals 3(-) and 4(+)

TB2

4 3 2 1

FIGURE 2-8:

Auxiliary Power Connections

Notification Appliance Circuits

The MS-2410B provides two Notification Appliance Circuits standard as Class B. Each circuit is capable of a

maximum of 2.5 amps of current. Total current drawn from these as well as other DC power outputs cannot

exceed 3.6 amps with the standard transformer, 6.6 amps if an optional XRM-24(E) Transformer is installed.

Circuits are supervised. Refer to the Fire•Lite Device Compatibility Document for a listing of compatible notification appliances.

Class B Notification Appliance Circuit (supervised). 4.7K ohm,

P/N: 71252

2410tb2.cdr

½ watt.

Polarized Horn

Polarized Horn

Note: Notification Appliance Circuit polarity

shown in alarm

state.

FIGURE 2-9:

+

+

+

Polarized BellPolarized Bell

Polarized Horn

Polarized Horn

+

+

+

TB3

2410bell.cdr

Notification Appliance Circuit Connections

Dummy Load all unused circuits (P/N: 71245)

26

Document #51127 Rev.C 11/7/00 P/N 51127:C

Page 27

Power-limited Wiring Requirements

Standard Relays

The control panel provides three Form-C relays rated for 2.0 amps @ 30 VDC (resistive) and 2.0 amps @ 30 VAC

(resistive).

Relay connections may be power-limited or nonpower-limited, provided that a minimum of

0.25" is maintained between conductors of power-limited and nonpower-limited circuits.

ALARM

RELAY

TROUBLE

RELAY

1 2 3 4 5 6 7 8 9

Relay contacts shown with no power applied to panel

SUPV

RELAY

TB4

FIGURE 2-10:

ALARM

RELAY

TROUBLE

RELAY

C NC NO C NC NO C NC NOC NC NO C NC NO C NC NO

1 2 3 4 5 6 7 8 9

Relay contacts shown with

no active troubles, alarms or supervisories

Relay Terminals

SUPV

RELAY

TB4

m2410rel.cdr

power applied to panel and

2.8 Power-limited Wiring Requirements

Power-limited and nonpower-limited circuit wiring must remain separated in the cabinet. All power-limited circuit

wiring must remain at least 0.25" (6.35 mm) away from any nonpower-limited circuit wiring. Furthermore, all

power-limited and nonpower-limited circuit wiring must enter and exit the cabinet through different knockouts and/or

conduits. A typical wiring diagram for the MS-2410B is illustrated in Figure 2-11.

AC Power

Power-limited Circuits

FIGURE 2-11:

Nonpower-limited

Power-limited Circuits

Circuit

AT

Zone 1

Zone 2

Zone 3

Zone 4

Zone 5

Zone 6

Zone 7

Zone 8

Zone 9

Zone 10

Trouble

Supervisory

Signal Silence

NAC Fault

Ground Fault

Battery Trouble

Zone Disabled

Annc. Trouble

+ - + -

TB1

J1

2410pwrl.cdr

Typical Wiring Diagram for Power-limited Requirements

Power-limited Circuits

Nonpower-limited Circuit

Document #51127 Rev. C 11/7/00 P/N 51127:C

27

Page 28

Installation of Optional Modules with Remote Accessories

U

2.9 Installation of Optional Modules with Remote Accessories

CAUTION: Remove all power (AC and DC) before installing or removing modules or wiring.

!

RTB - Remote Trouble Buzzer

The RTB is a Remote Trouble Buzzer which provides a green AC Power LED and a yellow Trouble LED along

with a piezo sounder, all of which mimic the condition of the control panel. The RTB can be mounted remotely in

a single-gang electrical box. Four wires are required to connect the RTB to the MS-2410B control panel as

illustrated in Figure 2-12.

RTB Remote Trouble Buzzer

(-) return (GND)

Trouble LED (TRBL)

AC Power LED (AC)

rtbbuzz.cdr

Buzzer (BUZZ)

SUPV

RELAY

NC

CCC

NONC NO

NC

NO

TB4

ZONE 1 ZONE 2 ZONE 3 ZONE 4 ZONE 5 ZONE 6 ZONE 7 ZONE 8 ZONE 9

+ - + - + - + - + - + - + - + - + -

TB6

TB2

24 V

24 V

NONRES ET

RESET

+ - + -

BELL 2

BELL 1

+ - + -

TB3

GND AC TRBL BUZZ

TB5

ALARM

RELAY

TROUBLE

RELAY

J5

U3

LED-10IM

MODULE

m2410rtb.cdr

J3

MS-2410B

28

FIGURE 2-12:

Document #51127 Rev.C 11/7/00 P/N 51127:C

RTB Remote Trouble Buzzer

Page 29

Installation of Optional Modules with Remote Accessories

CAUTION: Remove all power (AC and DC) before installing or removing modules or wiring.

!

LED-10IM - EIA-485 Interface Module

The LED-10IM Interface Module provides an EIA-485 port to support the LED-10 Series Remote Annunciator,

LDM Series Annunciator, AFM Series Annunciator and the ACM-8RF Relay Module. EIA-485 wiring is supervised for open circuits by this module. The LED-10IM mounts to connector J5 on the MS-2410B main board.

SUPV

TROUBLE

AC TRBL BUZZ

TB5

ALARM

RELAY

RELAY

RELAY

NC

CCC

NONC NO

ZONE 1 ZON E 2 Z ON E 3 ZO NE 4 ZON E 5 ZON E 6 ZO NE 7 ZON E 8 ZO NE 9 ZO NE 1 0

NC

NO

+ - + - + - + - + - + - + - + - + - + -

SECURITY KEY

J4

TB4

TB6

TB7

TB2

24 V

24 V

RESET

NONRESET

+ - + -

BELL 1 BELL 2

+ - + -

TB3

REMOTE TRBL BUZZER

GRD

MS-2410B

LED-10IM

U3

J5

LED-10IM

MODULE

J1

TB1

metal standoff

FIGURE 2-13:

LED-10IM Installation

U6

LED-10 Series Remote LED Annunciator

The LED-10 Series Annunciator connects to the MS-2410B via the LED-10IM Interface Module. It is recommended that overall foil/braided-shielded, twisted pair cable with a maximum length of 6,000 feet (1,800 m) @ 18

AWG ( 0 . 7 5 mm

2

) be used. Filtered power can be supplied by the MS-2410B or a remote UL listed filtered, power

supply such as the Fire•Lite FCPS-24F(E).

SW1

1

2

3

4

5

6

7

8

TB2

U1

U3

J1

J3

SW2

2

1

Top View

LED-10 Series Annunciator

TB1

J2

m2410led.cdr

+ - + -

Earth Ground

-24 VDC

+24 VDC

J1

TB1

+ EIA-485

-

Earth

Ground

- 24 VDC

+ 24 VDC

Shield

FIGURE 2-14:

Document #51127 Rev. C 11/7/00 P/N 51127:C

Wiring LED-10IM to LED-10 Series

led10ckt.cdr

LED-10 Series Annunciator

TB2

LED-10IM

29

Page 30

Installation of Optional Modules with Remote Accessories

CAUTION: Remove all power (AC and DC) before installing or removing modules or wiring.

!

ACM-8RF Remote Relay Module

The ACM-8RF Module provides eight Form-C relays with contacts rated for

5.0 amps. Relays can be assigned to each of the ten Initiating Device Circuits (two ACM-8RF relay modules are required). The module is installed

on the EIA-485 line using the LED-10IM Interface Module. Communication

wiring is supervised by the FACP. Power for the module must be power-limited. Refer to the ACM-8RF Manual for power-limited wiring requirements

and switch SW4 receive/transmit selection option.

Removable terminal blocks are provided for ease of installation and servicing. DIP switch SW3 allows assignment of relays to FACP IDCs. The

ACM-8RF module can be mounted remotely in an ABS-8RF annunciator

surface-mount backbox.

ACM-8RF Address and SW3 DIP Switch Settings Each of the ten MS-2410B IDCs can be assigned to an ACM-8RF relay. Two relay modules are required, with

both set to the same address. Use the decade rotary switches to set the address (i.e. for address '01', position the

first [left] switch so the arrow points to '0' and the second [right] switch so the arrow points to '1'). Refer to Table

3-10, “Annunciator Addressing - Zone 8 Alarm LED,” on page 45.

✓ To assign the first eight relays of the first ACM-8RF Relay Module to FACP IDCs 1 through 8, set

ACM-8RF SW3 DIP switches 2 and 5 ON and 1, 3, 4, 6, 7 and 8 OFF.

✓ To assign the first two relays of the second ACM-8RF Relay Module to FACP IDCs 9 and 10, set

ACM-8RF SW3 DIP switches 3 and 5 ON and 1, 2, 4, 6, 7 and 8 OFF.

FIGURE 2-15:

ACM-8RF

acm8pwrl.cdr

ABS-8RF

NO

C

NC

To Next Device

Power-limited 24 VDC

12

Left

Decade

Switch

12345678

Right

Decade

Switch

acm-8r.cdr

30

LED-10IM

Document #51127 Rev.C 11/7/00 P/N 51127:C

FIGURE 2-16:

Wiring LED-10IM to ACM-8RF

Page 31

Installation of Optional Modules with Remote Accessories

CAUTION: Remove all power (AC and DC) before installing or removing modules or wiring.

!

LDM-32F Lamp Driver Module

The Lamp Driver Module is used to provide an interface to a custom graphic annunciator. The LDM-32F has 32

alarm lamp/LED driver outputs which sink current to system common (-) on activation. A single positive (+) voltage is required to supply total operating power for all lamps or LEDs when all drivers are activated. The

LDM-32F provides a separate driver for system trouble and inputs for a local lamp test switch. A maximum of 16

external control switches may be wired to the LDM-32F. DIP switch SW3 is used to enable or disable the onboard

piezo sounder, enable remote switch functions, select a flashing LED function for new alarms and troubles and

other functions. A green ON LINE LED flashes to indicate ongoing communications with the host FACP. The

LDM-32F is supplied with four standoffs and screws for mounting to a CHS-4L chassis or custom backbox.

The LDM-32F is installed on the EIA-485 line using the LED-10IM Interface Module. Communications wiring is

supervised by the FACP. Power for the module must be power-limited.

LDM-32F Switch Settings - Use the decade rotary switches to set the address (i.e. for address '01', position switch

SW1 [top] so the arrow points to '1' and switch SW2 [bottom] so the arrow points to '0'). Refer to Table 3-10,

“Annunciator Addressing - Zone 8 Alarm LED,” on page 45

EIA-485

+

-

To Next Device

J5

J4

KEYSWITCH

SWITCH

MATRIX

J1

SW1

SW2

SW3

SW4

4

3

TB2

2

1

7

-

+

6

5

TB1

4

3

2

1

J6 J7 J8

J11

LAMP

POWER

ON LINE

J10

J9

J2

LED-10IM

Power-limited

24 VDC Source

FIGURE 2-17:

Document #51127 Rev. C 11/7/00 P/N 51127:C

Wiring LED-10IM to LDM-32F

LDM-32F

ldm-32.cdr

31

Page 32

Installation of Optional Modules with Remote Accessories

CAUTION: Remove all power (AC and DC) before installing or removing modules or wiring.

!

AFM-16ATX and AFM-16ATF Annunciators

The Annunciator Fixed Modules-16ATX and 16ATF each contain 16 red alarm and 16 yellow trouble LEDs, a

system trouble LED, an ON LINE/POWER LED and a local piezo sounder with switches for FACP Acknowledge, Silence, Reset and Drill. The AFM-16ATX is fixed at address '1' and is installed on the EIA-485 line using

the LED-10IM Interface Module.

AFM-16AF Annunciator

The Annunciator Fixed Module-16AF has 16 red alarm LEDs. The annunciator address is fixed at '1' and communication is via the EIA-485 line using the LED-10IM Interface Module. The Local Silence/Acknowledge switch

functions as a local lamp test and silence for the annunciator piezo sounder. LEDs include ON LINE/POWER and

System Trouble.

87

6543 2 1

OPEN

EIA-485

TB1

J1

LED-10IM

To Next Device

-

+

Po we r -l im i te d

24 VDC Source

FIGURE 2-18:

TB2 EIA-485

In Out Out +

In +

-

+

In Out In +24V

Out +24 V

Earth

PowerTB1

Wiring LED-10IM to AFM-16ATX

afm16atx.cdr

32

Document #51127 Rev.C 11/7/00 P/N 51127:C

Page 33

Installation of Optional Modules with Remote Accessories

CAUTION: Remove all power (AC and DC) before installing or removing modules or wiring.

!

4XTMF Transmitter Module

Push the disconnect switch to the down position to prevent accidental activation of the municipal box during testing of the control panel. The Disconnect LED will remain illuminated while the municipal box is disconnected.

The System Trouble LED will indicate disconnected and/or open circuit conditions on the municipal box. During

trouble conditions, it is possible to obtain the circuit condition on the alarm reverse polarity output. If this operation is desired, cut the TBL jumper on the 4XTMF module.

For Local Energy Municipal Box Service (NFPA 72 Auxiliary Fire Alarm Systems):

Supervisory Current: 5.0 mA.

Trip Current: 350 mA (subtracted from notification appliance power).

Coil Voltage: 3.65 VDC.

Maximum Coil Resistance: 14.6 ohms.

Maximum allowable wire resistance between panel and trip coil: 3 ohms.

Municipal Box wiring can leave the building.

For Remote Station Service (NFPA 72 Remote Station Fire Alarm Systems) - Intended for connection to a

polarity reversal circuit or a Remote Station receiving unit having compatible ratings:

Maximum load for each circuit: 10 mA.

Reverse polarity output voltage: 24 VDC.

Remote Alarm and Remote Trouble wiring can leave the building.

ZO NE 1 ZO NE 2 Z ON E 3 ZO NE 4 Z ON E 5 ZO NE 6 ZON E 7 ZO NE 8 ZO N E 9 Z ON E 10

+ - + - + - + - + - + - + - + - + - + -

SECURITY KEY

J4

TB6

TB7

TBL Jumper

Install 4XTMF Module by

plugging into connector

on MS-2410B main board

J6

and

J7

J8

MEMBRANE SW CONNECTOR

U3

JP1

J5

4XTMF Module

Note: This module is not suitable

for transmitting reverse polarity

supervisory signal.

Polarities are shown for

module activation

1 (+)

2 (-)

3 (+)

4 (-)

5

6 (+)

7 (-)

* Wiring from these terminals can

exit the protected premises.

Dummy load terminals 6 and 7

(4.7KΩ, ¼ watt resistor) if Municipal

Box is not connected.

Remote Alarm (power-limited)*

}}}}

Remote Trouble (power-limited)*

}}}}

no connection

Municipal Box (nonpower-limited)*

}}}}

Disconnect Switch

Disconnect LED

- +

MS-2410B Main Circuit Board

OPTION

SU PE RVISION

Cut JP1 for 4XTMF module placement supervision

FIGURE 2-19: