Page 1

CP350 Plug-in Addressable Ionization Sensor

Installation and Maintenance Instructions

GENERAL DESCRIPTION

Model CP350 is an addressable sensor that uses a state-of-the-art ionization sensing chamber. This sensor is designed to provide open area protection

and is intended for use with compatible control panels only.

Two LEDs on each sensor light to provide a local, visible sensor indication. Remote LED annunciator capability is available as an optional accessory

(Part No. RA400Z).

SPECIFICATIONS

Operating Voltage Range: 15 to 32 VDC

Max. Avg. Standby Current: 300µA @ 24 VDC (one communication every 5 sec. with LED blink enabled)

Max. Alarm Current (LED on): 6.5 mA @ 24 VDC

Operating Humidity Range: 10% to 93% Relative Humidity, noncondensing

Operating Temperature Range 0° to 49°C (32° to 120°F)

Height: 1.7 inches (43 mm) installed in B310LP Base

Diameter: 6.1 inches (155 mm) installed in B310LP Base

Weight: 3.6 oz. (102 g)

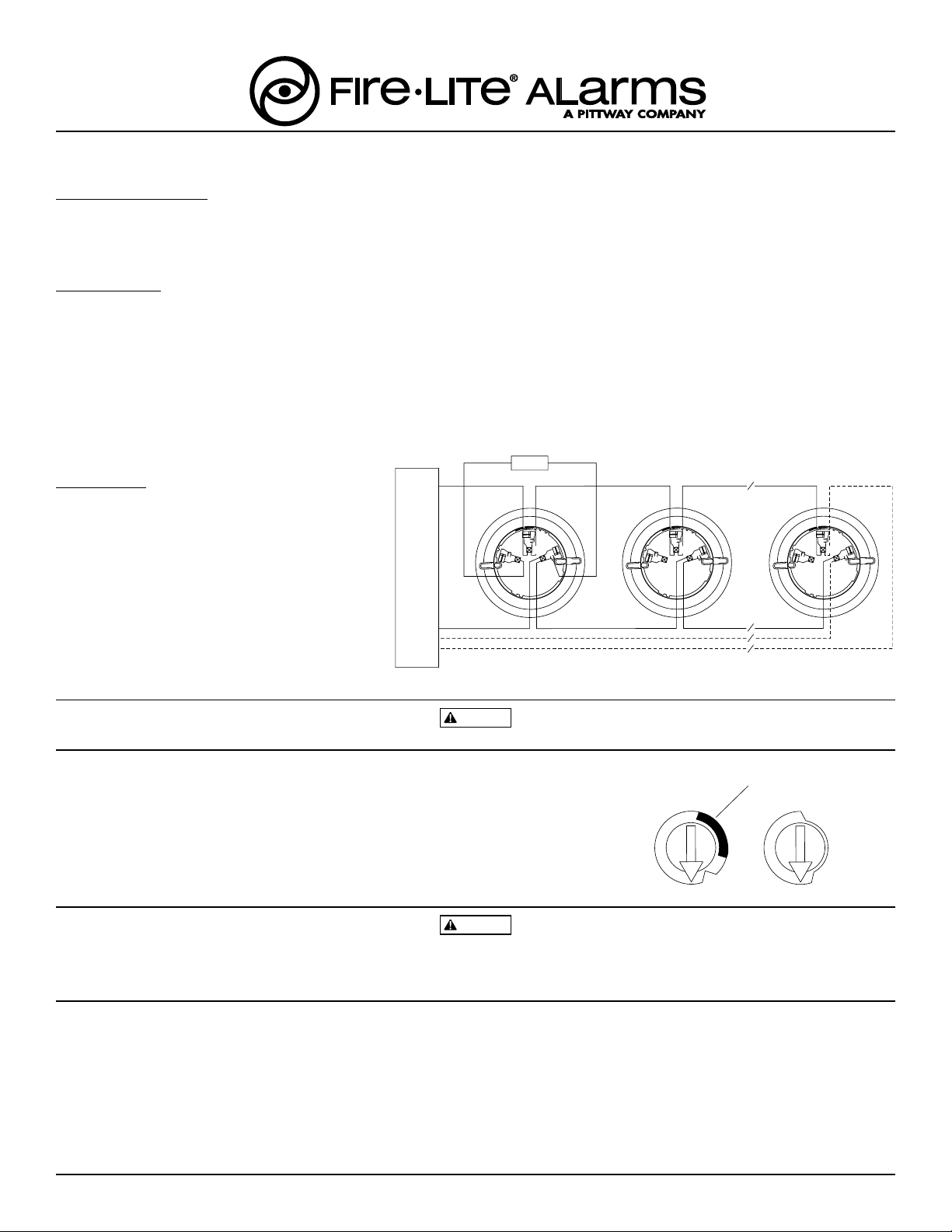

WIRING GUIDE

Refer to the installation instructions for the plug-in

base being used. As indicated in Figure 1, terminals for

power, ground, and the optional RA400Z Remote Annunciator are included in the base.

NOTE: All wiring must conform to all applicable codes,

ordinances, regulations and to the control panel

specifications.

NOTE: Verify that all sensor bases are installed and

that polarity of the wiring is correct at each base.

CONTROL PANEL

U.L. LISTED COMPATIBLE

REMOTE ANNUNCIATOR

+

-

+

+-

2

3

1

CAUTION: Do not loop wire under terminal 1 or 2.

Break wire run to provide supervision of connections.

2

3

1

CLASS A OPTIONAL WIRING

Figure 1.

2

3

1

WARNING

Disconnect loop power before installing sensors.

Before installing the sensor, please read the system wiring and installation manual, I56-407-XX. This manual includes detailed information on sensor

spacing, placement, zoning, and special applications. Copies of this manual are available from Fire•Lite.

1. Sensor Installation

a. Set the address on the sensor per job drawings.

NOTE: Some panels support extended addressing. In order to set

the sensor above address 99 on compatible systems, carefully remove the stop

on the upper rotary switch with thumb or finger as shown in Figure 2.

b. Insert the sensor into the base and rotate it clockwise until it drops into place.

c. Continue to rotate the sensor until it locks into the base.

CAUTION

Figure 2.

7

6

5

4

3

9

8

2

1

BREAKAWAY STOP

10

11

6

12

5

13

4

14

15

0

9

8

7

3

2

0

1

Dust covers are an effective way to limit the entry of dust into smoke detector sensing chambers. However, they may not completely prevent airborne

dust particles from entering the detector. Therefore, Fire•Lite recommends the removal of detectors before beginning construction or other dust producing activity.

Be sure to remove dust covers from any sensors that were left in place during construction as part of returning the system to service.

2.Tamper-Resistance

Model CP350 includes a tamper-resistant capability that prevents its removal from the bracket without the use of a tool. Refer to the base manual for

details on making use of this capability.

3. After all sensors have been installed, apply power to the system.

4. See Figure 3. Test the sensor by positioning a test magnet against the sensor plastic in the magnet test area. The alarm level should be recognized

at the panel and the LED controlled by communication command from the panel.

5. Reset the sensor by communication command from the panel.

F300-15-00 1 I56-036-00R

Fire•Lite, One Fire•Lite Place, Northford, CT 06472-1653, (203) 484-7161

Page 2

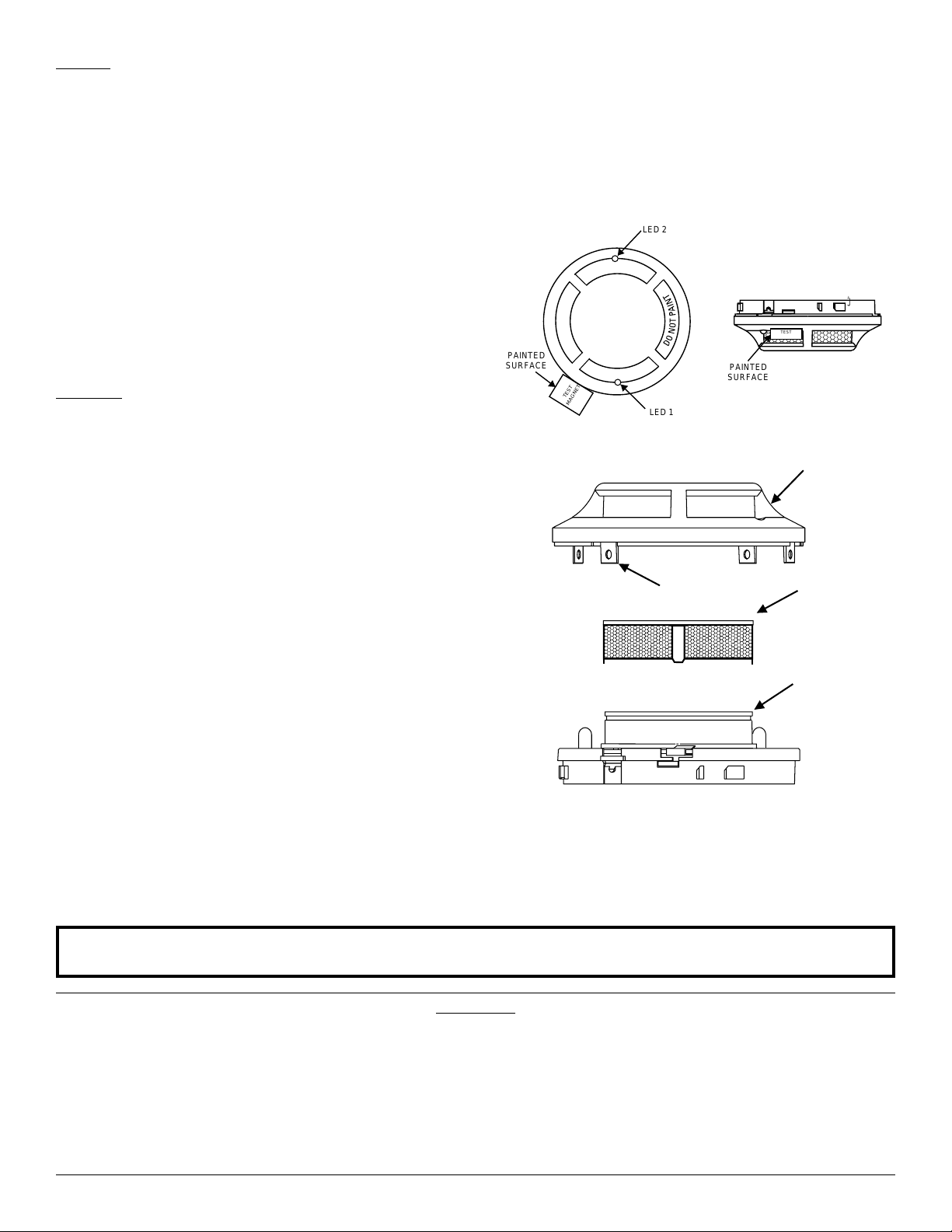

TESTING

Detectors must be tested after installation and following periodic maintenance. However, before testing, notify the proper authorities that the

smoke detector system is undergoing maintenance and the system will

be temporarily out of service. Disable the zone or system undergoing

maintenance to prevent unwanted alarms.

Test the sensors as follows:

A. Test Magnet (P/N M02-04-01 or M02-09-00)

1. Test the sensor by positioning the optional test magnet against the

sensor plastic in the magnet test area, as shown in Figure 3.

2. Two LEDs on the sensor are controlled by the panel to indicate sen-

sor status. Coded signals, transmitted from the panel, can cause the

LEDs to blink, latch on, or latch off. Refer to the control panel technical documentation for sensor LED operation and expected delay to

alarm.

B. Smoke Entry: Aerosol Generator (Gemini 501)

The GEMINI model 501 aerosol generator can be used for smoke

entry testing. Set the generator to represent 4%/ft to 5%/ft obscuration as described in the GEMINI 501 manual. Using the bowl shaped

applicator, apply aerosol until the panel alarms.

CLEANING

Before cleaning, notify the proper authorities that the system is undergoing maintenance and will be temporarily out of service. Disable the system to prevent unwanted alarms.

1. Remove the sensor to be cleaned from the system.

2. Remove the sensor cover, see Figure 4. Use a small standard screw-

driver to release each of the four cover removal tabs that hold the

cover in place.

3. Vacuum the outside of the screen carefully without removing it.

4. Remove the sensor screen. Pull the screen straight away from the

sensing chamber until it snaps out of place. Replacement screens

are available.

5. Use a vacuum cleaner or clean, compressed air to remove dust and

debris from the sensing chamber.

6. Reinstall or replace the sensing chamber screen by sliding the edge

without the tabs over the sensing chamber. Make sure that one of the

screen contacts touches the circuit board contact.

7. Reinstall the sensor cover. Use the LEDs to align the cover with the

sensor. Snap the cover into place.

8. When all sensors have been cleaned, restore power to the system

and test the sensor(s) as described in the TESTING section of this

manual.

LED 2

TEST

MAGNET

PAINTED

SURFACE

TEST

MAGNET

LED 1

PAINTED

SURFACE

Figure 3. Test Magnet Positioning

SENSOR

COVER

COVER REMOVAL

TABS

SENSOR

SCREEN

SENSING

CHAMBER

A78-2463-07

Figure 4. Cleaning

Please refer to insert for the Limitations of Fire Alarm Systems

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

FCC Statement

F300-15-00 2 I56-036-00R

©2000 Fire•Lite

Loading...

Loading...