Page 1

Digital Alarm

Communicator/Transmitter

411

Document #50921

11/07/2005 Rev.

P/N 50921:D ECN 05-465

© 2005

D

Page 2

Fire Alarm System Limitations

While a fire alarm system may lower insurance

rates, it is not a substitute for fire insurance!

An automatic fire alarm system–typically made up of smoke

detectors, heat detectors, manual pull stations, audible warning devices, and a fire alarm control panel with remote notification capability–can provide early warning of a developing

fire. Such a system, however, does not assure protection

against property damage or loss of life resulting from a fire.

The Manufacturer recommends that smoke and/or heat detectors be located throughout a protected premise following

the recommendations of the current edition of the National

Fire Protection Association Standard 72 (NFPA 72),

manufacturer's recommendations, State and local codes, and

the recommendations contained in the Guide for Proper Use

of System Smoke Detectors, which is made available at no

charge to all installing dealers. A study by the Federal Emergency Management Agency (an agency of the United States

government) indicated that smoke detectors may not go off in

as many as 35% of all fires. While fire alarm systems are designed to provide early warning against fire, they do not guarantee warning or protection against fire. A fire alarm system

may not provide timely or adequate warning, or simply may not

function, for a variety of reasons:

Smoke detectors may not sense fire where smoke cannot

reach the detectors such as in chimneys, in or behind walls, on

roofs, or on the other side of closed doors. Smoke detectors

also may not sense a fire on another level or floor of a building. A second-floor detector, for example, may not sense a

first-floor or basement fire.

Particles of combustion or "smoke" from a developing fire

may not reach the sensing chambers of smoke detectors because:

• Barriers such as closed or partially closed doors, walls, or

chimneys may inhibit particle or smoke flow.

• Smoke particles may become "cold," stratify, and not reach

the ceiling or upper walls where detectors are located.

• Smoke particles may be blown away from detectors by air

outlets.

• Smoke particles may be drawn into air returns before reaching

the detector.

The amount of "smoke" present may be insufficient to alarm

smoke detectors. Smoke detectors are designed to alarm at

various levels of smoke density. If such density levels are not

created by a developing fire at the location of detectors, the

detectors will not go into alarm.

Smoke detectors, even when working properly, have sensing

limitations. Detectors that have photoelectronic sensing

chambers tend to detect smoldering fires better than flaming

fires, which have little visible smoke. Detectors that have ionizing-type sensing chambers tend to detect fast-flaming fires

better than smoldering fires. Because fires develop in different ways and are often unpredictable in their growth, neither

type of detector is necessarily best and a given type of detector may not provide adequate warning of a fire.

Smoke detectors cannot be expected to provide adequate

warning of fires caused by arson, children playing with

matches (especially in bedrooms), smoking in bed, and violent

explosions (caused by escaping gas, improper storage of

flammable materials, etc.).

Heat detectors do not sense particles of combustion and

alarm only when heat on their sensors increases at a predetermined rate or reaches a predetermined level. Rate-of-rise

heat detectors may be subject to reduced sensitivity over

time. For this reason, the rate-of-rise feature of each detector

should be tested at least once per year by a qualified fire protection specialist. Heat detectors are designed to protect

property, not life.

IMPORTANT! Smoke detectors must be installed in the

same room as the control panel and in rooms used by the

system for the connection of alarm transmission wiring, communications, signaling, and/or power. If detectors are not so

located, a developing fire may damage the alarm system,

crippling its ability to report a fire.

Audible warning devices such as bells may not alert people

if these devices are located on the other side of closed or

partly open doors or are located on another floor of a building.

Any warning device may fail to alert people with a disability or

those who have recently consumed drugs, alcohol or medication. Please note that:

• Strobes can, under certain circumstances, cause seizures

in people with conditions such as epilepsy.

• Studies have shown that certain people, even when they

hear a fire alarm signal, do not respond or comprehend the

meaning of the signal. It is the property owner's responsibility to conduct fire drills and other training exercise to

make people aware of fire alarm signals and instruct them

on the proper reaction to alarm signals.

• In rare instances, the sounding of a warning device can

cause temporary or permanent hearing loss.

A fire alarm system will not operate without any electrical

power. If AC power fails, the system will operate from standby

batteries only for a specified time and only if the batteries

have been properly maintained and replaced regularly.

Equipment used in the system may not be technically compatible with the control. It is essential to use only equipment

listed for service with your control panel.

Telephone lines needed to transmit alarm signals from a

premise to a central monitoring station may be out of service

or temporarily disabled. For added protection against telephone line failure, backup radio transmission systems are recommended.

The most common cause of fire alarm malfunction is inadequate maintenance. To keep the entire fire alarm system in

excellent working order, ongoing maintenance is required per

the manufacturer's recommendations, and UL and NFPA standards. At a minimum, the requirements of NFPA 72 shall be

followed. Environments with large amounts of dust, dirt or

high air velocity require more frequent maintenance. A maintenance agreement should be arranged through the local

manufacturer's representative. Maintenance should be

scheduled monthly or as required by National and/or local

fire codes and should be performed by authorized professional fire alarm installers only. Adequate written records of

all inspections should be kept.

PrecauLarge.PMD 01/10/2005

Page 3

Installation Precautions

Adherence to the following will aid in problem-free

installation with long-term reliability:

WARNING - Several different sources of power can be con-

nected to the fire alarm control panel. Disconnect all sources

of power before servicing. Control unit and associated equipment may be damaged by removing and/or inserting cards,

modules, or interconnecting cables while the unit is energized.

Do not attempt to install, service, or operate this unit until this

manual is read and understood.

CAUTION - System Reacceptance Test after Software

Changes. To ensure proper system operation, this product

must be tested in accordance with NFPA 72 after any programming operation or change in site-specific software. Reacceptance testing is required after any change, addition or

deletion of system components, or after any modification,

repair or adjustment to system hardware or wiring.

All components, circuits, system operations, or software functions known to be affected by a change must be 100% tested.

In addition, to ensure that other operations are not inadvertently affected, at least 10% of initiating devices that are not

directly affected by the change, up to a maximum of 50 devices, must also be tested and proper system operation verified.

This system meets NFPA requirements for indoor dry operation at 0-49° C/32-120° F

RH (non-condensing) at 32 ±2° C/90 ±3° F. However, the

useful life of the system's standby batteries and the electronic components may be adversely affected by extreme

temperature ranges and humidity. Therefore, it is recommended that this system and all peripherals be installed in

an environment with a nominal room temperature of 15-27°

C/60-80° F.

Verify that wire sizes are adequate for all initiating and

indicating device loops. Refer to manual Specifications section for maximum allowable I.R. drop from the specified device voltage.

and at a relative humidity of 93 ±2%

Like all solid state electronic devices, this system may

operate erratically or can be damaged when subjected to

lightning-induced transients. Although no system is completely immune from lightning transients and interferences,

proper grounding will reduce susceptibility. Overhead or out-

side aerial wiring is not recommended, due to an increased

susceptibility to nearby lightning strikes. Consult with the

Technical Services Department if any problems are anticipated or encountered.

Disconnect AC power and batteries prior to removing or inserting circuit boards. Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing,

reaming, or punching of the enclosure. When possible, make

all cable entries from the sides or rear. Before making modifications, verify that they will not interfere with battery, transformer, and printed circuit board location.

Do not tighten screw terminals more than 9 in-lbs.

Over-tightening may damage threads, resulting in reduced

terminal contact pressure and difficulty with screw terminal

removal.

This system contains static-sensitive components.

Always ground yourself with a proper wrist strap before handling any circuits so that static charges are removed from the

body. Use static-suppressive packaging to protect electronic

assemblies removed from the unit.

Follow the instructions in the installation, operating, and

programming manuals. These instructions must be followed

to avoid damage to the control panel and associated

equipment. FACP operation and reliability depend upon

proper installation by authorized personnel.

FCC Warning

WARNING: This equipment generates, uses, and can ra-

diate radio frequency energy and if not installed and used

in accordance with the instruction manual, may cause interference to radio communications. It has been tested

and found to comply with the limits for class A computing

device pursuant to Subpart B of Part 15 of FCC Rules,

which is designed to provide reasonable protection against

such interference when operated in a commercial environment. Operation of this equipment in a residential area is

likely to cause interference, in which case the user will be

required to correct the interference at their own

expense.

PrecauLarge.PMD 01/10/2005

Canadian Requirements

This digital apparatus does not exceed the Class A

limits for radiation noise emissions from digital

apparatus set out in the Radio Interference Regulations

of the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits

radioelectriques depassant les limites applicables aux

appareils numeriques de la classe A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.

Page 4

Notes

4 411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D

Page 5

Table of Contents

CHAPTER 1: Product Description ...........................................................................................................................................8

1.1: Product Features..........................................................................................................................................8

FIGURE 1-1: 411 Digital Communicator............................................................................................8

1.2: Specifications ..............................................................................................................................................9

1.3: Circuits ........................................................................................................................................................9

1.3.1: Power Requirements .........................................................................................................................9

1.3.2: Channels/Inputs.................................................................................................................................10

1.3.3: Primary and Secondary Phone Lines ................................................................................................10

1.3.4: Earth Ground.....................................................................................................................................10

1.4: Controls and Indicator.................................................................................................................................10

FIGURE 1-2: 411 Indicator .................................................................................................................10

1.5: Digital Communicator Operation................................................................................................................11

1.6: Telephone Requirements and Warnings ......................................................................................................11

1.6.1: Telephone Circuitry - PH1 & PH2....................................................................................................11

1.6.2: Digital Communicator: .....................................................................................................................11

1.6.3: Telephone Company Rights and Warnings:......................................................................................12

1.6.4: For Canadian Applications................................................................................................................12

1.7: Operational Modes ......................................................................................................................................13

1.7.1: Normal Mode ....................................................................................................................................13

1.7.2: Real Time Clock Mode.....................................................................................................................13

1.7.3: Program Mode...................................................................................................................................13

1.7.4: Troubleshoot Mode...........................................................................................................................13

1.7.5: Default Mode ....................................................................................................................................13

CHAPTER 2: Installation ..........................................................................................................................................................14

2.1: Mounting Options .......................................................................................................................................14

FIGURE 2-1: 411 Enclosure................................................................................................................14

2.2: Operating Power..........................................................................................................................................14

2.3: Input Channels.............................................................................................................................................14

FIGURE 2-2: Typical FACP Connection to 411.................................................................................15

FIGURE 2-3: Style B Channel Connections........................................................................................16

2.4: Telephone Circuits.......................................................................................................................................17

TABLE 2-1: Wiring Phone Jacks ........................................................................................................17

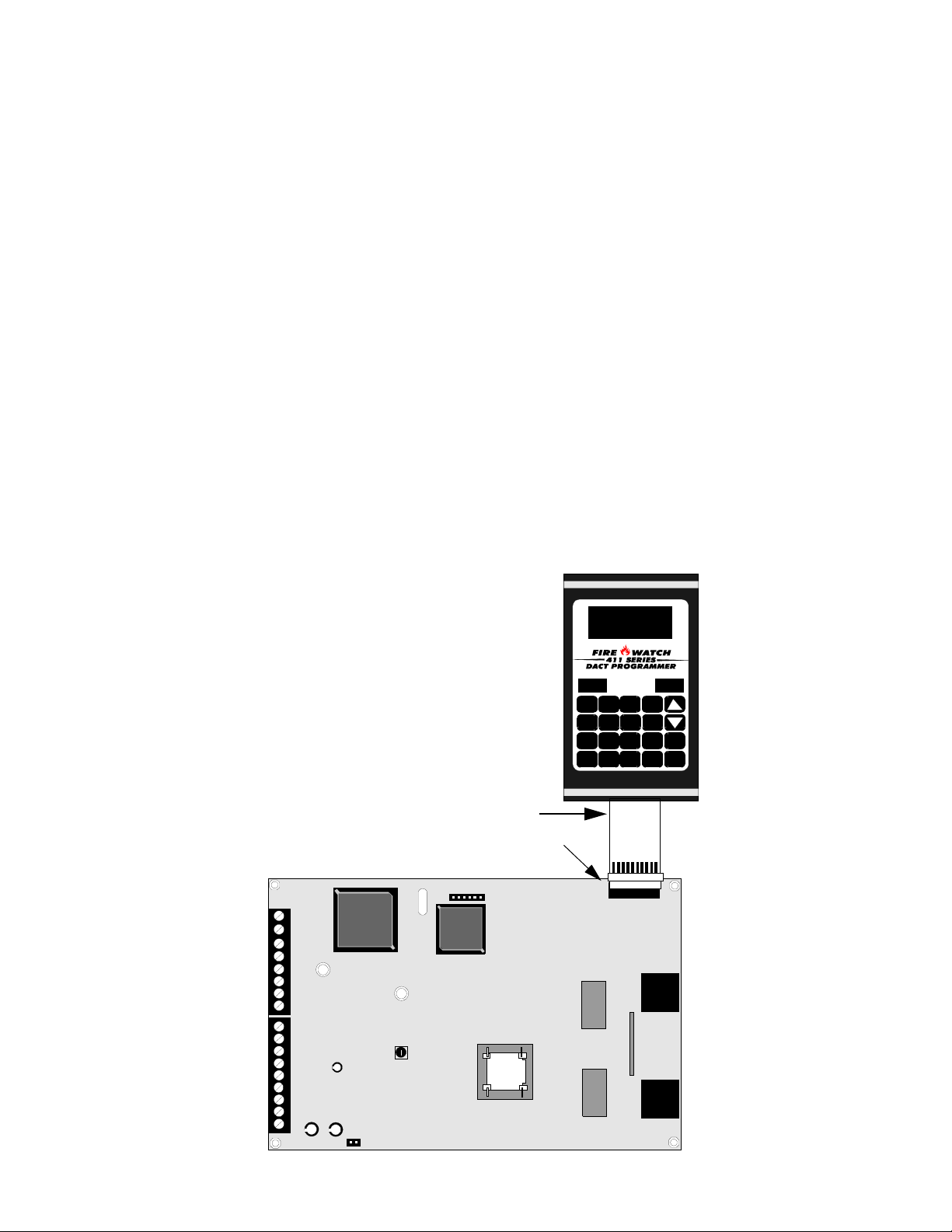

2.5: Optional Programmer..................................................................................................................................18

FIGURE 2-4: Programmer Connection to 411 ....................................................................................18

2.6: UL Power-limited Wiring Requirements ....................................................................................................19

CHAPTER 3: Modes of Operation............................................................................................................................................20

3.1: Normal Mode ..............................................................................................................................................20

3.1.1: Programmer Key Functions ..............................................................................................................21

FIGURE 3-1: Programmer Keypad .....................................................................................................21

3.1.2: Programmer Display .........................................................................................................................22

3.2: Real Time Clock Mode ...............................................................................................................................22

3.3: Program Mode.............................................................................................................................................24

3.3.1: DACT Programming.........................................................................................................................25

TABLE 3-1: Ademco Contact ID Format - Primary ...........................................................................27

TABLE 3-2: 4+2 Standard and 4+2 Express Formats - Primary.........................................................27

TABLE 3-3: All 3+1, 4+1 and 4+2 Expanded Formats - Primary ......................................................28

TABLE 3-4: Ademco Contact ID Format - Secondary .......................................................................30

TABLE 3-5: 4+2 Standard and 4+2 Express Formats - Secondary.....................................................31

TABLE 3-6: All 3+1, 4+1 and 4+2 Expanded Formats - Secondary ..................................................32

3.4: Default Mode...............................................................................................................................................36

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D 5

Page 6

Table of Contents

3.5: Troubleshoot Mode......................................................................................................................................36

FIGURE 3-2: Handset/Speaker Connection ........................................................................................36

CHAPTER 4: Central Station Communications......................................................................................................................37

TABLE 4-1: Format Selection Addresses ( 20 and 50) Programming ................................................38

TABLE 4-2: Format Selection Address Explanation...........................................................................39

4.0.1: Transmittal Priorities.........................................................................................................................40

4.0.2: Ademco Contact ID Format Event Code Description.......................................................................41

TABLE 4-3: Compatible UL Listed Receivers....................................................................................42

Appendix A: Programming Sheets .......................................................................................................................43

A.1: Digital Communicator Options Program Sheets .......................................................................................43

A.2: Digital Communicator Options Program Sheet (Factory Defaults) ..........................................................45

Appendix B: Event Codes/Transmission Format Programming Sheets ..........................................................47

B.1: 4+2 Standard & 4+2 Express Formats Primary

B.2: 4+2 Standard & 4+2 Express Formats Secondary

B.3: 4+2 Standard & 4+2 Express Formats Primary

B.4: 4+2 Standard & 4+2 Express Formats Secondary

B.5: All 3+1, All 4+1 and 4+2 Expanded Formats for Primary

B.6: All 3+1, All 4+1 and 4+2 Expanded Formats for Secondary

B.7: All 3+1, All 4+1 and 4+2 Expanded Formats for Primary

B.8: All 3+1, All 4+1 and 4+2 Expanded Formats for Secondary

B.9: Ademco Contact ID Format Primary

Central Station ................................................................................50

B.10: Ademco Contact ID Format Secondary

B.11: Ademco Contact ID Format Primary

Central Station (Factory Defaults) ...............................................51

B.12: Ademco Contact ID Format Secondary

Central Station ................................................................47

Central Station ............................................................47

Central Station ................................................................48

Central Station ............................................................48

Central Station ...............................................49

Central Station ...........................................49

Central Station (Factory Defaults) ................49

Central Station (Factory Defaults) ...........49

Central Station ..........................................................................50

Central Station (Factory Defaults) ...........................................51

Appendix C: Ademco Contact ID Format Event Code Description .................................................................52

Appendix D: Wire Requirements .........................................................................................................................56

TABLE 4-4: Wire Specifications.........................................................................................................56

Appendix E: Operational Modes ..........................................................................................................................57

TABLE 4-5: Operational Modes..........................................................................................................57

6

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D

Page 7

This digital communicator has been designed to comply with standards set forth by the following regulatory agencies:

• Underwriters Laboratories Standard

• NFPA 72 National Fire Alarm Code

• CAN/ULC - S527-M87 Standard for Control Units for Fire Alarm Systems

Before proceeding, the installer should be familiar with the following documents.

NFPA Standards

This digital communicator complies with the NFPA 72 National Fire Alarm Code for:

Central Station Signaling Systems Protected Premises Unit (Automatic, Manual and Waterflow)

Local Fire Alarm Systems (Automatic, Manual, Waterflow and Sprinkler Supervisory)

Proprietary Fire Alarm Systems (Protected Premises Unit)

Remote Station Fire Alarm Systems

Automatic Fire Detectors

Installation, Maintenance and Use of Notification Appliances for Fire Alarm Systems

Inspection, Testing and Maintenance for Fire Alarm Systems

Underwriters Laboratories Documents:

UL 217 Smoke Detectors, Single and Multiple Station

UL 268 Smoke Detectors for Fire Protective Signaling Systems

UL 346 Waterflow Indicators for Fire Protective Signaling Systems

UL 464 Audible Signaling Appliances

UL 521 Heat Detectors for Fire Protective Signaling Systems

UL 864 Standard for Control Units for Fire Protective Signaling Systems

UL 1076 Proprietary Burglar Alarm Units and Systems

UL 1481 Power Supplies for Fire Protective Signaling Systems

UL 1635 Digital Alarm Communicator System Units

UL 1638 Visual Signaling Appliances

UL 1971 Signaling Devices for Hearing Impaired

CAN/ULC - S524-M91 Standard for Installation of Fire Alarm Systems

Other:

NEC Article 250 Grounding

NEC Article 300 Wiring Methods

NEC Article 760 Fire Protective Signaling Systems

Applicable Local and State Building Codes

Requirements of the Local Authority Having Jurisdiction (LAHJ)

This product has been certified to comply with the requirements in the Standard for Control Units and Accessories for Fire Alarm Systems, UL

864, 9th Edition. Operation of this product with products not tested for UL 864, 9th Edition has not been evaluated. Such operation requires the

approval of the local Authority Having Jurisdiction (AHJ).

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D 7

Page 8

Product Description

CHAPTER 1 Product Description

The 411 is a three input/channel, dual line, digital alarm communicator transmitter which can be used as a slave communicator with UL listed fire and nonfire control panels. The three inputs are compatible with normally open relay

contacts, require End-Of-Line (EOL) resistors, are supervised and are fully programmable. The 411 interfaces with

the public switched telephone network and is compatible with most central station receivers. A total of fifteen popular communications formats are supported, including Ademco Contact ID. The communicator also contains a unique

DACT option that eliminates 'dialer runaway'. It restricts the transmission of any trouble event to 10 attempts in a 24

hour period. Power supplied must be 12 or 24 volts, filtered and nonresettable. The Fire-Watch 411 Series DACT

Programmer is available for 411 programming. The 411 comes in a small 6.841" (17.376 cm) X 4.595" (11.671 cm)

X 1.00" (2.54 cm) metal enclosure, providing a variety of mounting options.

1.1 Product Features

FIGURE 1-1: 411 Digital Communicator

• Three input channels

• Dual telephone lines

Dual telephone line voltage detect

Alternating phone lines for 24 hour

test messages

1

2

3

4

5

6

1

2

3

• Program locations for entering up to

20-digit central station and service terminal

telephone numbers

• Surface mount technology

• Compact in size

• Separate external keypad and display

1

2

3

FI RE-WATCH 4 11

provides means of programming dig-

ital communicator in program mode

provides means of testing phone circuits in troubleshoot mode

• 6.841" (17.376 cm) X 4.595" (11.671 cm) X 1.0" (2.54 cm) metal enclosure facilitates internal and external

control panel mounting

• Communicates vital status of monitored control panel:

fire alarm

host control panel trouble

fire supervisory

AC (mains) power loss (programmable)

411COVER.CDR

other

• Communicates vital status of 411 digital communicator:

digital communicator troubles

telephone Line 1 and 2 voltage fault

Primary Central Station number communication fault

Secondary Central Station number communication fault

system off-normal (local Program Mode entered)

24 Hour normal test

24 Hour abnormal test (24 hour test message with previously reported alarm or trouble still active)

• Trouble Resound - if a trouble is silenced and the cause of the trouble is not cleared, the panel will resound the

trouble buzzer every midnight, until the trouble is cleared.

8

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D

Page 9

Specifications

• LED for Communication Fail (visible with cover on)

• Piezo sounder

• Local piezo silence switch which silences onboard piezo sounder (accessible without removing cover)

• Real time clock

• Extensive transient protection

• Option that prevents 'dialer runaway'

1.2 Specifications

Operating Power

The 411 may be powered from UL listed control panels that output nonresettable and power-limited 12 or 24 VDC

power. The configuration of Jumper J4 determines whether 12 VDC power is to be supplied directly to the 411

circuit board or 24 VDC power is to be supplied and then internally regulated down to 12 VDC.

DC Power - TB1 Terminals 1(+) and 2(-), Terminal 3 is Earth Ground

• J4 Jumper removed - Filtered, nonresettable and power-limited 24 VDC (nominal) power must be supplied at

TB1 Terminals 1(+) and 2(-). Operating voltage provided must be within 21.3 to 24.0 VDC (UL tested range:

-15%, +10%). Current requirements are 78 mA in standby and 126 mA

• J4 Jumper installed - Filtered, nonresettable and power-limited 12 VDC (nominal) power must be supplied at

TB1 Terminals 1(+) and 2(-). Operating voltage provided must be within 11.2 to 12.4 VDC (UL tested range:

-15%, +10%). Current requirements are 78 mA in standby and 126 mA

1

while communicating.

1

while communicating.

2

Channels/Inputs

- TB2 Terminals 1 through 6

Programmable Channels 1 through 3

Power-limited circuitry

Fully supervised

Operation: All channels NFPA Style B (Class B). Requires Normally Open contact to trigger

Normal Operating Voltage: 12 VDC

Maximum Line Resistance: 100 ohms per channel

Alarm Current: 3.34 mA

End-of-Line Resistor: 2.2K ohms, ½ watt (P/N 27070)

Short Circuit Current: 3.8 mA per channel/input

1.3 Circuits

The 411 circuit board utilizes surface mount technology and contains a MicroController Unit (MCU), dual modular

phone line jacks, piezo sounder and two connectors for input, output and power wiring.

1.3.1 Power Requirements

Voltage for the digital communicator may be a power-limited, filtered, nonresettable nominal 12 VDC [11.2 to

12.4 VDC (UL tested range: -15%, +10%)] or nominal 24 VDC [21.3 to 24.0 VDC (UL tested range: -15%,

+10%)]. Jumper J4 is used to select the power source.

1. A maximum of 240 mA is possible with all input channels active, the 411 communicating, the Programmer connected and

Lamp Test active.

2. Channels/inputs do not support 2-wire smoke detectors.

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D 9

Page 10

Controls and Indicator

1.3.2 Channels/Inputs

Three input channels are provided on the 411 digital communicator which are used for connection to the control

panel being monitored. Each input can be programmed to monitor the control panel for:

• fire alarm activation

• trouble activation

• fire supervisory activation

• AC loss activation

Each input channel is configured as a Class B circuit and must be wired to a Normally Open contact.

1.3.3 Primary and Secondary Phone Lines

Modular jacks are used to interface the primary and secondary phone lines to the public telephone network.

1.3.4 Earth Ground

Connect a separate earth ground wire to TB1 terminal 3 for transient protection.

Note: If zero ohms impedance exists between the 411 circuitry and earth ground, a ground fault will be indicated

at the host FACP.

1.4 Controls and Indicator

FIGURE 1-2: 411 Indicator

Comm. Fail

LED

1

2

3

4

5

6

1

2

3

1

2

3

FI RE-WATCH 4 11

Front Panel Switch

• Silence Switch - press to silence local 411 piezo sounder

411 Piezo Sounder

• The 411 piezo sounder is used to locally annunciate DACT troubles. DACT troubles include input channel

open circuit, phone line 1 or 2 voltage fault, phone number 1 or 2 communication fault, total communication

failure and communications disabled.

Piezo Silence

Switch

411COVER.CDR

Front Panel Indicator

• Communication Fail - yellow LED

10

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D

Page 11

Digital Communicator Operation

1.5 Digital Communicator Operation

The 411 has been designed to be compatible with a wide variety of fire alarm, nonfire and combination control

panels. Numerous formats are also available for communication to a central station. Two modular phone jacks allow

easy connection to telephone lines. Modular jacks are labeled PH1 and PH2 for the Primary and Secondary phone

lines. The digital communicator provides the following functions:

• Line Seizure- takes control of the phone lines, disconnecting any premises phones using the same lines

• Off/On-Hook - perform on and off-hook status to phone lines

• Listen for dial tone - 440 hertz tone typical in most networks

• Dialing the Central Station(s) phone number - default is Touch-Tone®, programmable to rotary

• Discern proper Central Station 'ACK' and 'Kiss-off' tone(s)

• Transmit data to the Central Station(s)

• Verify data has been accepted by the Central Station(s)

• Hang-up and release phone lines

• Communicate in a variety of formats (Refer to Table 4-1, “Format Selection Addresses ( 20 and 50) Programming,” on page 38).

1.6 Telephone Requirements and Warnings

1.6.1 Telephone Circuitry - PH1 & PH2

DC Ringer Equivalence Number (REN) = 0.5B

AC Ringer Equivalence Number = 1.3

Complies with FCC Part 68

Mates with RJ31X Male Connector

Supervision Threshold: less than 4.0 volts for 2 minutes

The REN is used to determine the quantity of devices which may be connected to the telephone line. Excessive

RENs on the telephone line may result in the devices not ringing in response to an incoming call. In most, but not all

areas, the sum of the RENs should not exceed five (5.0). To be certain of the number of devices that may be connected to the line, as determined by the total RENs, contact the telephone company to determine the maximum REN

for the calling area.

1.6.2 Digital Communicator:

Before connecting the 411 to the public switched telephone network, the installation of two RJ31X jacks is necessary.

The following information is provided if required by the local telephone company:

Manufacturer: Fire•Lite Alarms Inc./Notifier

One Fire-Lite Place

Northford, CT 06472

Product Model Number: 411

FCC Registration Number: OAAUSA-25431-AL-E

Ringer Equivalence 0.5B

Note: The FCC ID label is located on the inside cover.

Important! The DACT must not

9th Edition.

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D 11

be used to dial a phone number that is call-forwarded per requirements of UL 864

Page 12

Telephone Requirements and Warnings

1.6.3 Telephone Company Rights and Warnings:

The telephone company, under certain circumstances, may temporarily discontinue services and/or make changes in

its facilities, services, equipment or procedures which may affect the operation of this digital communicator. However, the telephone company is required to give advance notice of such changes or interruptions. If the digital communicator causes harm to the telephone network, the telephone company reserves the right to temporarily

discontinue service. Advance notification will be provided except in cases when advance notice is not practical. In

such cases, notification will be provided as soon as possible. The opportunity will be given to correct any problems

and to file a complaint.

DO NOT CONNECT THIS PRODUCT TO COIN TELEPHONE, GROUND START OR PARTY LINE SERVICES.

When the digital communicator activates, premise phones will be disconnected.

Two separate phone lines are required. Do not connect both telephone interfaces to the same telephone line.

The digital communicator must be connected to the public switched telephone network upstream of any private telephone system at the protected premises.

An FCC compliant telephone cord must be used with this equipment. This equipment is designed to be connected to

the telephone network or premises wiring using a compatible RJ31X male modular plug which is Part 68 compliant.

1.6.4 For Canadian Applications

The following is excerpted from CP-01 Issue 5:

“NOTICE: The Industry Canada (IC) label identifies certified equipment. This certification means that the equipment meets certain telecommunications network protective, operational and safety requirements as prescribed in the

appropriate Terminal Equipment Technical Requirements document(s). The Department does not guarantee the

equipment will operate to the user’s satisfaction.”

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the local

telecommunications company. The equipment must also be installed using an acceptable method of connection. The

customer should be aware that compliance with the above conditions may not prevent degradation of service in some

situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated by the

supplier. Any repairs or alterations made by the user to this equipment, or equipment malfunctions, may give the

telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power utility, telephone

lines and internal metallic water pipe system, if present, are connected together. This precaution may be particularly

important in rural areas.

CAUTION

Users should not attempt to make such connections themselves, but should contact the appropriate electric inspection

authority, or electrician.

“The Ringer Equivalence Number

number of terminals allowed to be connected to a telephone interface. The termination of an interface may consist of

any combination of devices subject only to the requirement that the sum of the REN of all devices does not exceed 5.”

(REN) assigned to each terminal device provides an indication of the maximum

12

Representative: NOTIFIER, CANADA

10 Whitmore Road

Woodbridge, Ontario L4L 7Z4

IC Certificate Number: 2132 9028 A

Ringer Equivalence Number (REN): 0.2

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D

Page 13

Operational Modes

1.7 Operational Modes

1.7.1 Normal Mode

Normal Mode is the standard mode of operation in which the 411 digital communicator monitors the host control

panel status as well as telephone line voltage and other internal circuits. In addition to locally annunciating communication fail, the digital communicator transmits system status information to UL listed central station receivers.

Transmitted data includes fire alarm, fire alarm trouble, supervisory alarm and AC loss information. Specific digital

communicator troubles are also transmitted.

1.7.2 Real Time Clock Mode

Real Time Clock Mode allows the user to change the digital communicator’s internal 24 hour clock. Connecting an

external Programmer allows access to the various Modes of operation. While the communicator is in Real Time

Clock Mode, it does not monitor channel inputs.

1.7.3 Program Mode

Program Mode is used to change the programmed functions of the 411 digital communicator. While the communicator is in Program Mode, it does not monitor channel inputs.

1.7.4 Troubleshoot Mode

Troubleshoot Mode may be used for testing the telephone line interconnect wiring. Connection from the 411’s modular jacks, through the RJ31X jacks and into the telephone network may be easily checked. In this mode, the Programmer keypad acts similar to a telephone touchpad. While the communicator is in Troubleshoot Mode, it does not

monitor channel inputs.

1.7.5 Default Mode

Default Mode may be used to return all 411 programming back to the factory default settings.

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D 13

Page 14

Installation

CHAPTER 2 Installation

2.1 Mounting Options

The 411 with enclosure may be mounted in the cabinet of the Fire•Lite/Notifier control panel which is being

monitored or in any enclosure UL listed for fire protective use. When using with other than Fire•Lite/Notifier control

panels, the 411 may be mounted in any enclosure UL listed for fire protective use. Mounting tabs are provided for

ease of mounting.

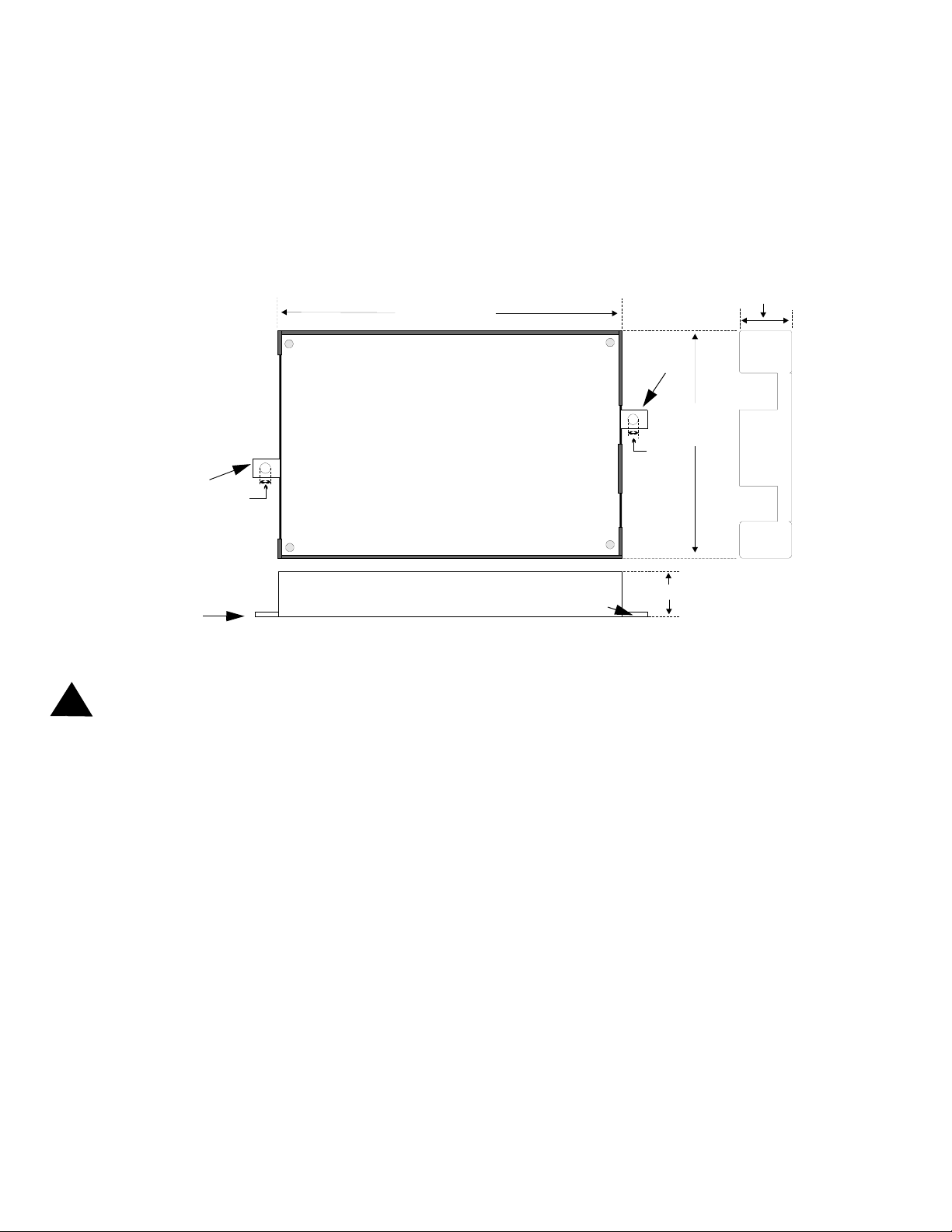

FIGURE 2-1:411 Enclosure

Mounting bracket

0.187“

(0.475 cm)

6.841“ (17.376 cm)

Mounting

bracket

(11.671 cm)

0.187“

(0.475 cm)

4.595“

1.000“

(2.54 cm)

411BKBOX.CDR

1.000“ (2.54 cm)

Mounting bracket

Bottom

Mounting bracket

2.2 Operating Power

CAUTION: Disconnect all power before servicing the 411. The digital communicator may be damaged by removing

!

and/or inserting components or interconnecting cables while the unit is energized.

12VDC or 24VDC nominal power connections are made to TB1 on the 411 circuit board. When jumper J4 is

installed, the 11.2 to 12.4 VDC operating voltage range (UL tested range: -15%, +10%) for the digital communicator

must be power-limited, filtered, nonresettable. This 12 VDC nominal operating power can be supplied directly to the

411 by a UL listed 12 VDC power supply listed for fire protection or by a nonresettable 12 VDC output from a

control panel. Alternatively, removing J4 Jumper on the digital communicator circuit board allows the 411 to be

supplied by a power-limited, nonresettable 21.3 to 24.0 VDC (UL tested range: -15%, +10%). This 24 VDC nominal

operating power can be supplied by a UL listed 24 VDC power supply, which, in order to comply with UL 864 must

be listed for Fire Protective Signaling Systems or by a nonresettable 24 VDC output from a control panel. This nominal 24 VDC power is then internally regulated by the digital communicator to 12 VDC operating power.

Note that upon power-up, the 411 will immediately annunciate a DACT trouble since the communicator is factory

defaulted to 'communicator disabled' at program location 64.

2.3 Input Channels

The 411 digital communicator has three channel inputs. Each channel is supervised for opens (trouble) and shorts

(alarm) by the digital communicator. Each channel is a Style B (Class B) Initiating Device Circuit designed to accept

any normally-open contact device. Since channels do not latch, a reset switch is not provided by the 411. The communicator transmissions to a central station track the state of the inputs. Refer to Figure 2-3, “Style B Channel Connections,” on page 16 for information on wiring Style B circuits.

14

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D

Page 15

Input Channels

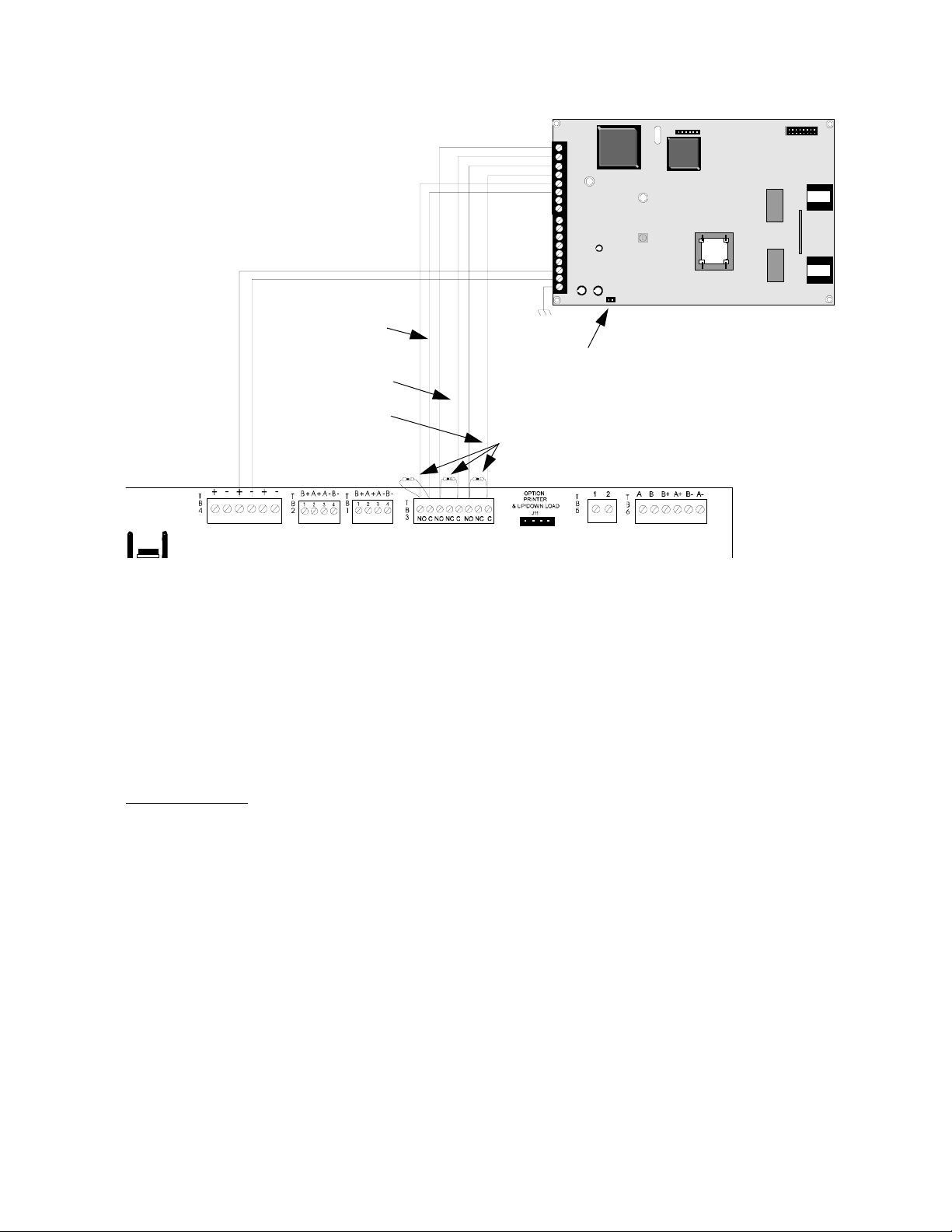

FIGURE 2-2:Typical FACP Connection to 411

24 VDC nonresettable power

Supervisory

Relay

Alarm Relay

Trouble Relay

+ -

Channel 1

Channel 2

Channel 3

2.2K EOLS

P/N 27070

TB2

TB1

J4 Not Installed

J1

U10

U8

R41

J4

J2

PH1

PH2

411

9200-411.CDR

Typical FACP MS-9200

Each input channel monitors a normally open device and may be programmed as follows:

• fire alarm

• host control panel trouble

• fire supervisory

•AC Loss

Programming the input channel automatically programs the transmitted event code, however, the event code can be

changed since it is fully programmable. Event code transmissions can be tailored to the specific application and

requirements of the Central Station.

AC Loss Reporting:

Any channel programmed for AC Loss, will transmit a specific AC loss signal only if the assigned

Normally Open contact provides this function. Some panels provide an option that will automatically delay the trigger of their system trouble relays upon loss of AC. If this is provided by the host panel, program no additional delay

in the 411. Be certain to verify the method employed by the host panel to be monitored.

The factory default programming for each channel is as follows:

Channel 1 - fire alarm

Channel 2 - host control panel trouble

Channel 3 - fire supervisory

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D 15

Page 16

Input Channels

2

Channel Labels

Note that space is provided for labeling the function of each channel. Write the function that has been programmed

for each channel in the white boxes located to the right of the channel designator.

FIGURE 2-3:Style B Channel Connections

Channel/Input Labels

Inputs are power-limited,

supervised

Normally Open Contact Device

2.2K EOL Resistor

P/N 27070

1

2

3

4

5

6

1

2

3

1

3

FI RE-WATCH 4 11

411_CHL.CDR

16

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D

Page 17

Telephone Circuits

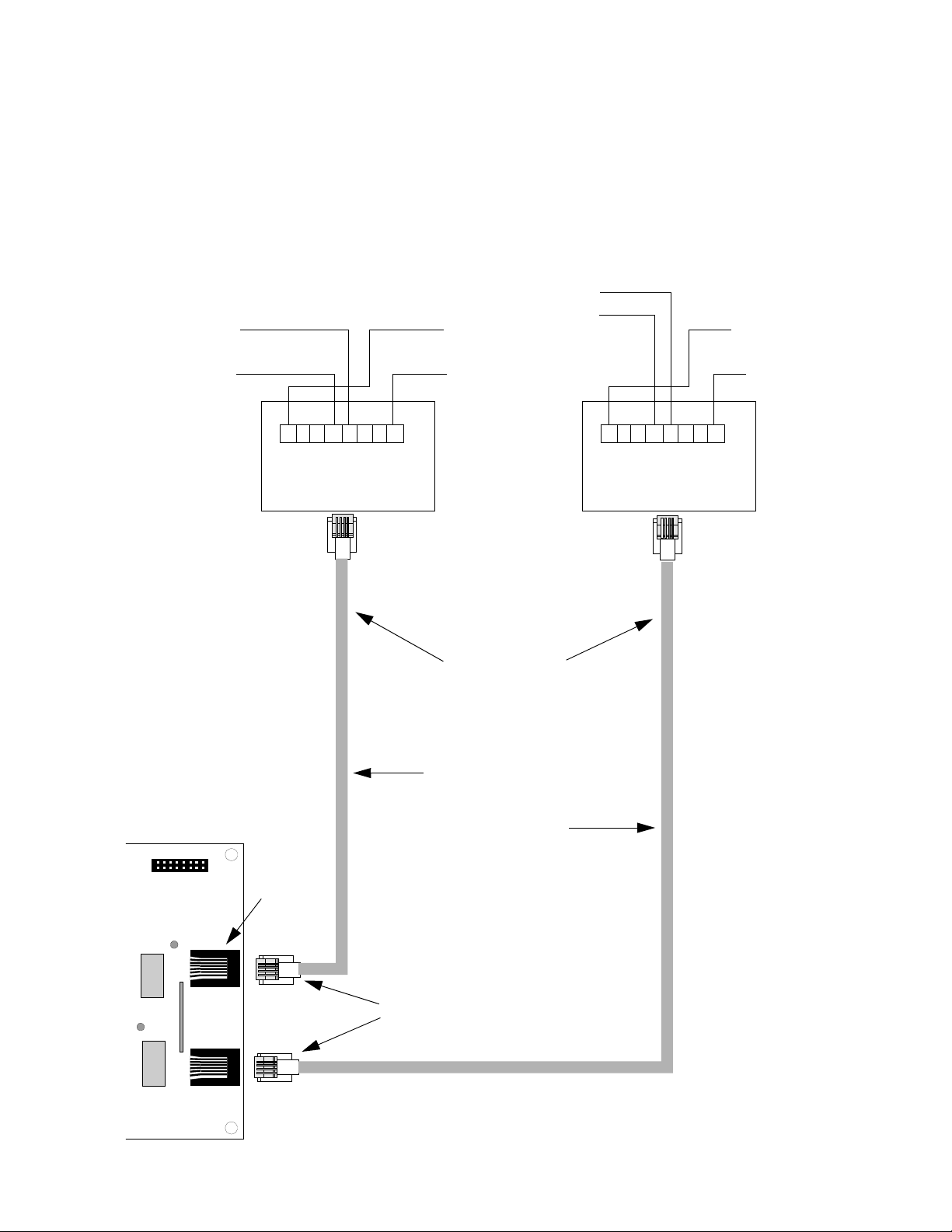

2.4 Telephone Circuits

Provision to connect two independent telephone lines is available via two telephone jacks labeled PH1 (Primary)

and PH2 (Secondary). Telephone line control/command is possible via double line seizure as well as usage of an

RJ31X style interconnection. (RJ31X jacks must be ordered separately).

CAUTION: It is critical that the 411 be located as the first device on the incoming telephone circuit to properly

function.

TABLE 2-1: Wiring Phone Jacks

Incoming Telco Phone

Tip

Ring

Green Wire

Red Wire

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

(Primary Lines)

Lines

Ring

To Premises Phone

Tip

(Secondary Lines)

Incoming Telco Phone

Green Wire

Tip

Red Wire

Ring

Lines

Ring

To Premises

Phone

Tip

RJ31X

JACK

Note: Shorting bars

inside RJ31X Jack

removed during male

plug insertion

7 foot Cable (MCBL-7)

Not supplied - Order

Separately

Primary Phone Line PH1

411

J2

Modular

Female Con-

nector

Secondary Phone Line

PH2

RJ31X

JACK

PH1

Male Plug Connectors

PH2

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D 17

411JACK.CDR

Page 18

Optional Programmer

A

8888

2.5 Optional Programmer

The optional Fire-Watch 411 Series DACT Programmer is used to:

switch between the digital communicator's five Modes of operation

set the digital communicator's 24 hour internal clock in Real-Time Clock Mode

program the 411 digital communicator in Program Mode

test the telephone lines interconnect in Troubleshoot Mode

return all digital communicator programming to the factory default settings in Default Mode

To use the 411 Series DACT Programmer:

1. Remove all power from the 411

2. Remove the two screws holding the 411 cover in place and remove the cover

3. Connect the Programmer cable to connector J2 located in the upper right corner of the 411. Note that the key

on the connector must align with the slot in the J2 connector

4. Reapply power to the 411

5. Operate the Programmer by pressing the MODE key. Enter the appropriate four digit Mode code and then

press the [ENTER/STORE] key.

Note that it is not possible to switch from Normal Mode to any other mode if any of the four Channels is programmed

for fire alarm or fire supervisory, and is active, that is, in alarm (shorted).

FIGURE 2-4: Programmer Connection to 411

TB2

Programmer

Cable attached to Programmer

J2 connector

J1

U10

U8

LAMP

TEST

123 F

456 E

0BC

J2

PH1

MODE

D987

1ST

EVENT

ENTER

STORE

18

411

R41

TB1

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D

J4

411-PRO.CDR

PH2

Page 19

UL Power-limited Wiring Requirements

2.6 UL Power-limited Wiring Requirements

The three 411 input channels are power-limited circuits. Power supplied to the 411 must be power-limited 12 or 24

volts, filtered and nonresettable. Do not

connect nonpower-limited wiring to any circuits on the 411.

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D 19

Page 20

Modes of Operation

CHAPTER 3 Modes of Operation

The 411 digital communicator has five operational modes:

• Normal Mode

• Real Time Clock Mode

•Program Mode

• Troubleshoot Mode

• Default Mode

The operational mode for the digital communicator is Normal Mode. The operator is able to switch between any

modes of operation provided no alarm events are active in the system. It should be noted that the digital communicator will not respond to input activations while in any mode except Normal Mode.

Access to any other Mode requires connection of the optional Fire-Watch 411 Series DACT Programmer which

consists of a keypad and display. Refer to Figure 3-1, “Programmer Keypad,” on page 21:

3.1 Normal Mode

Normal Mode is the standard (default) mode of operation for the 411 digital communicator. The communicator

continuously monitors and reports to a central station, the status of the three input channels as well as the status of the

digital communicator itself. If no activity is detected on the three input channels (no shorts or opens) and the communicator is operating free of internal troubles, the digital communicator will display the following conditions:

Communication Fail LED is off

Onboard piezo sounder is off

Communicator is not transmitting to the Central Station

The 411 digital communicator transmits system status reports to a central station via the public switched telephone

network. Two supervised telephone line connections are made to interface the digital communicator to the telephone

lines. Both telephone lines are supervised by the 411 for proper voltage.

The 411 is capable of line seizure on both the primary and secondary telephone line interfaces. Any time the digital

communicator detects the necessity to call the Central Station, line seizure will disconnect any local premises phones

sharing the same telephone line. Sharing of phone lines, for fire systems, must be approved by the Local Authority

Having Jurisdiction. All transmissions to the Central Station will be sent over the Primary phone line. In the event of

a noisy or faulty phone line, transmissions will be sent over the backup Secondary phone line.

Transmission options exist to:

• send reports to the secondary phone number as backup only

• send reports to both the primary and secondary phone numbers

• send reports to the first available central station phone number

If 10 total attempts to communicate are unsuccessful, the digital communicator will turn on the Communication Fail

LED.

The 411 meets NFPA 72 requirements for Remote Station Protective Signaling Service and Central Station Signaling

Service reporting requirements for: (a) the type of signal, (b) condition and (c) location of the reporting premises.

See “Central Station Communications” on page 37, for additional information.

20

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D

Page 21

Normal Mode

The 411 can be switched from Normal Mode to any other Mode, provided no channel programmed for fire alarm or

fire supervisory is active, that is, in alarm (shorted). The Fire-Watch 411 Series DACT Programmer must be connected to the 411 in order to change from mode to mode.

3.1.1 Programmer Key Functions

FIGURE 3-1:Programmer Keypad

PR411KEY.CDR

Select operating mode

Increment memory address

Address entry keys are 0 to 9

Data entry keys are 0 to 9 and A to F

Decrement memory address

One press = first memory address

Two presses = type any address

Save data, go to next address

MODE KEY

Pressing the MODE key followed by a valid 4-digit numerical code and the [ENTER/STORE] key selects one of

the five modes of operation. To enter Normal Mode from any other mode, press the MODE key followed by

6676 and then [ENTER/STORE].

6676 spells NORM on a Touch-Tone® phone.

If an incorrect key is entered, reenter the proper 4-digit code before

pressing the [ENTER/STORE] key. Note that as

information is entered into the 411, the digits will scroll across the Programmer display from right to left.

___6

__66

_667

6676

A pause of up to 10 seconds between each number is allowed while entering the code.

LAMP TEST KEY

Pressing the Lamp Test key on the Programmer, while the digital communicator is in Normal Mode, will cause the

front panel LED and all segments of the four 7-segment display on the programmer to light. Lamp Test works

only in Normal Mode.

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D 21

Page 22

Real Time Clock Mode

1st EVENT KEY

This key, along with the UP and DOWN arrow keys, are used only in Program Mode. Press the 1st EVENT key

at any time to display the first program memory address and its content. The following may be displayed on the

Programmer:

00_F

(data)

(address)

If the 1st EVENT key is pressed a second time, the following will be displayed on the Programmer display:

0.

Digit to be programmed

The contents of any address can be viewed by entering the digits of the desired address. For example, to view the

contents of address 86, press the '8' key on the keypad. '8' will appear as the first digit in the display, a blank will

appear in the position of the second digit and the decimal point will move one position to the right, indicating that

the next digit can now be entered.

8_.

Digit to be programmed

Press the '6' key on the keypad. '6' will appear as the second digit on the display and the decimal point will move

one position to the right. Press the [ENTER/STORE] to view the contents of address 86.

86_.

DOWN ARROW

Use the DOWN arrow key to decrement the memory address and view its content.

UP ARROW

Use the UP arrow key to increment the memory address and view its content.

[ENTER/STORE]

Stores entry into nonvolatile E

2

memory located on the 411 printed circuit board, then increments to the next

higher address.

3.1.2 Programmer Display

Four 7-segment red LED characters provide visual display of information in the various modes of operation.

3.2 Real Time Clock Mode

Real Time Clock Mode is entered by pressing the MODE key followed by the 4-digit entry code 2525 and pressing

the [ENTER/STORE] key.

2525 spells CLCK on a Touch-Tone® phone.

22

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D

Page 23

Real Time Clock Mode

If an incorrect key is entered, reenter the proper 4-digit code before pressing the [ENTER/STORE] key. Note that as

information is entered into the 411, the digits will scroll across the Programmer display from right to left.

___2

__25

_252

2525

A pause of up to 10 seconds between each number is allowed while entering the code. After pressing the [ENTER/

STORE] key, the digital communicator will be in Real Time Clock Mode. A maximum of 10 minutes idle time is

allowed at this point before beginning program entries and between each key stroke, otherwise, the digital communicator will return to Normal Mode. Note that the time is not stored until the fourth and final digit is selected and the

[ENTER/STORE] key is pressed. If the 411 returns to Normal Mode prior to entering the fourth digit, no changes

will be stored and the original time is retained.

On entering Real Time Clock Mode, 0.001 will appear on the Programmer display:

0.001

Digit to be programmed

The time is displayed in military time. Note the position of the decimal point in the display. This indicates that the

first digit to be programmed is the one to the left of the decimal point. To program the first hour digit, press the corresponding number on the Programmer keypad and then press the [ENTER/STORE] key. For example, to program

2:00 PM (1400 in military time), press '1' on the keypad and then the [ENTER/STORE] key. The number '1' will

appear as the far left digit and the decimal point will move one position to the right indicating that the second digit

from the left is now ready for programming.

10.01

Digit to be programmed

Enter the second hour digit (4 in this example) and press the [ENTER/STORE] key. The number '4' will appear as

the digit second from the left and the decimal point will move one position to the right indicating that the third digit

from the left is now ready for programming.

140.1

Digit to be programmed

Enter the first minute digit (0 in this example) and press the [ENTER/STORE] key. The number '0' will appear as

the digit third from the left and the decimal point will move one position to the right indicating that the fourth digit

from the left is now ready for programming.

1400.

Digit to be programmed

Enter the second minute digit (0 in this example) and press the [ENTER/STORE] key. The number '0' will appear as

the digit fourth from the left. Following the entry of the fourth and final digit, the operating mode will immediately

switch to Normal Mode, indicating that programming of the time is now completed.

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D 23

Page 24

Program Mode

To exit Real Time Clock Mode before completing clock programming, press the MODE key, followed by the 4-digit

code for an alternate mode and then the [ENTER/STORE] key. During Real Time Clock Mode, if no key is pressed

within 10 minutes, the communicator will revert to Normal Mode.

Note that upon power-up, the internal clock starts running at 00:00 midnight. It must be changed so that the 411 can

accurately call in test signals to the Central Station. Upon power loss, the clock reverts to 00:00 midnight and must

be reset.

3.3 Program Mode

NOTICE TO USERS, INSTALLERS, AUTHORITIES HAVING JURISDICTION

AND OTHER INVOLVED PARTIES

This product incorporates field-programmable software. In order for the product to comply with the requirements in the

Standard for Control Units and Accessories for Fire Alarm Systems, UL 864, certain programming features or options must

be limited to specific values or not used at all as indicated below:

Program feature

or option

Trouble Call Limit N

Permitted in

UL 864? (Y/N)

Possible settings

Program Address 89 = 0 (factory default): unlimited

calling to Central Station for any trouble condition

Program Address 89 = 1: limits call for each unique

trouble to 10 within a 24 hour period

Settings permitted

in UL 864

Program Address 89

= 0 for unlimited

Central Station

trouble calls

All programming selections made during Program Mode are stored in nonvolatile Electrically-Erasable Programmable Read-Only Memory (EEPROM). This ensures that the 411 will retain all entries made in Programming Mode

even if power is removed.

The user must program the primary and secondary phone numbers, account numbers, 24-hour test report times and

verify event codes for each Central Station account. The 411 is shipped with the program options/features already

factory programmed. Alternative options/features may be programmed if desired. If all factory default settings are

acceptable, programming is complete.

Program Mode is entered by pressing the MODE key followed by the 4-digit program mode entry code 7764 and

pressing the [ENTER/STORE] key.

7764 spells PROG on a Touch-Tone® phone.

If an incorrect key is entered, reenter the proper 4-digit code before

pressing the [ENTER/STORE] key. Note that as

information is entered into the 411, the digits will scroll across the Programmer display from right to left.

___7

__77

_776

7764

A pause of up to 10 seconds between each number is allowed while entering the code. After pressing the [ENTER/

STORE] key, the digital communicator will be in Program Mode. A maximum of 10 minutes idle time is allowed at

this point before beginning program entries and between each key stroke, otherwise, the digital communicator will

return to Normal Mode. All entries made prior to the 10 minute time-out are valid and are stored.

24

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D

Page 25

Program Mode

Once in Program Mode, the digital communicator will:

Ignore all other keys other than those mentioned in this section

Display 00_F on the Programmer display

Continue to communicate any events not previously acknowledged at a central station prior to entering

Programming Mode

While in Program Mode, the first three locations on the left of the Programmer display represent the memory address

and the last location (farthest right) represents the contents of the memory address. The first address displayed is

shown below:

00_F

(data)

(address)

When desired changes have been completed, exit Programming Mode by pressing the MODE key, followed by the

4-digit code for an alternate mode and then the [ENTER/STORE] key. During Program Mode, if no key is pressed

within 10 minutes, the communicator will revert to Normal Mode.

The Programmer cable should not be removed from the 411 unless the communicator is in Normal Mode. If the Programmer cable is removed while the 411 is in a Mode other than Normal Mode, the communicator will automatically

revert to Normal Mode following a 10 minute

when the cable is removed, the 411 will revert to Normal Mode following a 20 minute

time-out period. Note that if the Programmer is in Troubleshoot Mode

time-out period.

3.3.1 DACT Programming

Primary Central Station Phone Number (00 - 19)

The first twenty addresses (00 - 19) are factory set to 'F' (00_F to 19_F). Programming is done as follows:

If your phone number is 484-7161, press 4.

The display will read 00_4.

Press [ENTER/STORE] to save the entry to memory and increment to the next address 01_F.

Enter the remaining numbers in their respective addresses as shown below:

Entry

4 8 4 7 1 6 1 F F F F F F F F F F F F F

Address

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19

Valid entries for both the primary and secondary phone numbers are 0 to 9 and A to F with the numeric digits as

dialed numbers and the hexadecimal digits representing the following functions:

• A = * on a Touch-Tone phone keypad

• B = # on a Touch-Tone phone keypad

• C = look for secondary dial tone for up to two seconds (then dial anyway)

• D = three second pause

• E = five second pause

• F = end of phone number (Note: F must remain in all unused phone number addresses)

New FCC regulations allow extra digits to the carrier ID code, to identify the long distance carrier. The expanded

phone number field of 20 digits facilitates this function. Simply enter the digits required by the telephone company if

desired.

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D 25

Page 26

Program Mode

Primary Central Station Number Communication Format (20)

One location is needed to select the Communication Format to the primary phone number. Address 20 is used for

this purpose. The factory default setting for this address is 'E', which is Contact ID Format. You may enter '0'

through 'D' in place of the default, then press [ENTER/STORE]. Choose from the list of formats below:

0: 4+1 Ademco Express Standard, DTMF, 1400/2300 ACK

1: 4+2 Ademco Express Standard, DTMF, 1400/2300 ACK

2: 3+1 Standard 1800 Hz Carrier, 2300 Hz ACK

3: 3+1 Expanded 1800 Hz Carrier, 2300 Hz ACK

4: 3+1 Standard 1900 Hz Carrier, 1400 Hz ACK

5: 3+1 Expanded 1900 Hz Carrier, 1400 Hz ACK

6: 4+1 Standard 1800 Hz Carrier, 2300 Hz ACK

7: 4+1 Expanded 1800 Hz Carrier, 2300 Hz ACK

8: 4+1 Standard 1900 Hz Carrier, 1400 Hz ACK

9: 4+1 Expanded 1900 Hz Carrier, 1400 Hz ACK

A: 4+2 Standard 1800 Hz Carrier, 2300 Hz ACK

B: 4+2 Expanded 1800 Hz Carrier, 2300 Hz ACK

C: 4+2 Standard 1900 Hz Carrier, 1400 Hz ACK

D: 4+2 Expanded 1900 Hz Carrier, 1400 Hz ACK

E: Contact ID, DTMF, 1400/2300 ACK

F: Future use

Consult the Central Station for proper Format selection. For any Format chosen, all event codes are automatically programmed by the 411. Refer to Table 3-2, “4+2 Standard and 4+2 Express Formats - Primary,” on page

27, Table 3-3, “All 3+1, 4+1 and 4+2 Expanded Formats - Primary,” on page 28 and Table 3-1, “Ademco Contact ID Format - Primary,” on page 27.

Event Codes - Setting Entries

The Format selected in address 20 will cause the digital communicator to automatically program addresses 138 - 201

with the factory default settings. Any of the Event Code settings may be altered. Consult your Central Station prior

to altering the event code settings. An entry of all zeros for any event code will cause the communicator to NOT

transmit the report. Transmission of reports to either or both Central Station phone numbers may be disabled.

Upon accessing the first address (address 138) shown in Table 3-2 , the following may be displayed on the Programmer 7-Segment Display, if the corresponding Format was selected in address 20.

1381

(data)

(address)

The first three locations on the left of the Programmer display represent the memory address 138 of the Format previously selected in address 20. The last location 1 (farthest right) represents the contents of memory address 138

(which is the first digit of the event code).

The following Tables list the data which is automatically programmed for each Format that can be selected in address

20. The addresses shown in each Table contain the Setting data which is automatically programmed by the 411. To

change the value, key in the new digit and then press the [ENTER/STORE] key to save the new value. Use the Up

and Down Arrow keys to increment to the next address or decrement to the previous address.

26

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D

Page 27

Program Mode

Ademco Contact ID Format Primary Central Station Event Codes

If 'E' is entered for address 20, the following data is automatically programmed for the Primary Central Station

phone number event codes. Enter '000' for the Setting to disable the report to the Central Station. The Channel #

is not programmable.

TABLE 3-1: Ademco Contact ID Format - Primary

Channel/

Address Description Setting

138 - 140 Primary # Input Channel 1 Active Event Code 110 001

141 - 143 Primary # Input Channel 2 Active Event Code 373 002

144 - 146 Primary # Input Channel 3 Active Event Code 200 003

147 - 149 not used

150 - 152 Primary # Input Channel 1 Fault Event Code 380 001

153 - 155 Primary # Input Channel 2 Fault Event Code 380 002

156 - 158 Primary # Input Channel 3 Fault Event Code 380 003

159 - 161 not used

162 - 164 Primary # Phone Line 1 Voltage Fault Event Code 351 000

165 - 167 Primary # Phone Line 2 Voltage Fault Event Code 352 000

168 - 170 Primary # Phone Number 1 Comm. Fault Event Code 354 001

171 - 173 Primary # Phone Number 2 Comm. Fault Event Code 354 002

174 - 176 Primary # System Off Normal Fault Code 308 000

177 - 179 Primary # System Test Message 602 000

180 - 182 Primary # System Abnormal Test Message 608 000

183 - 185 not used

186 - 188 not used

189 - 191 not used

192 - 194 not used

Input #

4+2 Standard and 4+2 Express Formats Primary Central Station Event Codes

If 1, A or C is entered for address 20, the following data is automatically programmed for the Primary Central Station phone number event codes. Enter '00' for the Setting to disable the report to the Central Station.

TABLE 3-2: 4+2 Standard and 4+2 Express Formats - Primary

Address Description Setting

138 - 139 Primary # Input Channel 1 Active Event Code 11

140 - 141 Primary # Input Channel 2 Active Event Code FF

142 - 143 Primary # Input Channel 3 Active Event Code 83

144 - 145 not used

146 - 147 Primary # Input Channel 1 Fault Event Code F1

148 - 149 Primary # Input Channel 2 Fault Event Code F2

150 - 151 Primary # Input Channel 3 Fault Event Code F3

152 - 153 not used

154 - 155 Primary # Phone Line 1 Voltage Fault Event Code 64

156 - 157 Primary # Phone Line 2 Voltage Fault Event Code 65

158 - 159 Primary # Phone Number 1 Comm. Fault Event Code 6A

160 - 161 Primary # Phone Number 2 Comm. Fault Event Code 6B

162 - 163 Primary # System Off Normal Fault Code 6F

164 - 165 Primary # Input Channel 1 Active Restoral Code E1

166 - 167 Primary # Input Channel 2 Active Restoral Code E2

168 - 169 Primary # Input Channel 3 Active Restoral Code E3

170 - 171 not used

172 - 173 Primary # Input Channel 1 Fault Restoral Code D1

174 - 175 Primary # Input Channel 2 Fault Restoral Code D2

176 - 177 Primary # Input Channel 3 Fault Restoral Code D3

178 - 179 not used

180 - 181 Primary # Phone Line 1 Restoral Code A4

182 - 183 Primary # Phone Line 2 Restoral Code A5

184 - 185 Primary # Phone Number 1 Restoral Code AA

186 - 187 Primary # Phone Number 2 Restoral Code AB

188 - 189 Primary # System Off Normal Restoral Code AF

190 - 191 Primary # System Test Message 99

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D 27

Page 28

Program Mode

TABLE 3-2: 4+2 Standard and 4+2 Express Formats - Primary

Address Description Setting

192 - 193 Primary # System Abnormal Test Message 91

194 - 195 not used

196 - 197 not used

198 - 199 not used

200 - 201 not used

All 3+1, 4+1 and 4+2 Expanded Formats Primary Central Station Event Codes

If 0, 2, 3, 4, 5, 6, 7, 8 ,9, B or D is entered for address 20, the following data is automatically programmed for the

Primary Central Station phone number event codes. Enter '0' for the Setting to disable the report to the Central

Station.

TABLE 3-3: All 3+1, 4+1 and 4+2 Expanded Formats - Primary

Address Description Setting

138 Primary # Input Channel 1 Active Event Code 1

139 Primary # Input Channel 2 Active Event Code F

140 Primary # Input Channel 3 Active Event Code 8

141 not used

142 Primary # Input Channel 1 Fault Event Code F

143 Primary # Input Channel 2 Fault Event Code F

144 Primary # Input Channel 3 Fault Event Code F

145 not used

146 Primary # Phone Line 1 Voltage Fault Event Code 6

147 Primary # Phone Line 2 Voltage Fault Event Code 6

148 Primary # Phone Number 1 Comm. Fault Event Code 6

149 Primary # Phone Number 2 Comm. Fault Event Code 6

150 Primary # System Off Normal Fault Code 6

151 Primary # Input Channel 1 Active Restoral Code E

152 Primary # Input Channel 2 Active Restoral Code E

153 Primary # Input Channel 3 Active Restoral Code E

154 not used

155 Primary # Input Channel 1 Fault Restoral Code D

156 Primary # Input Channel 2 Fault Restoral Code D

157 Primary # Input Channel 3 Fault Restoral Code D

158 not used

159 Primary # Phone Line 1 Restoral Code A

160 Primary # Phone Line 2 Restoral Code A

161 Primary # Phone Number 1 Restoral Code A

162 Primary # Phone Number 2 Restoral Code A

163 Primary # System Off Normal Restoral Code A

164 Primary # System Test Message 9

165 Primary # System Abnormal Test Message F

166 not used

167 not used

168 not used

169 not used

Primary Central Station Number Account Code (21 - 24)

The four locations at addresses 21 - 24 default to all '0's. Valid entries are 0 - 9 and A - F. The number of digits

entered must match the format selection. If programming '2, 3, 4 or 5' into address 20, enter three digits (one digit

each in locations 21, 22 and 23 - location 24 is ignored). If programming '0, 1, 6, 7, 8, 9, A, B, C, D or E' into

address 20, enter four digits (one each in locations 21, 22, 23 and 24).

28

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D

Page 29

Program Mode

Primary Central Station Number 24 Hour Test Time (25 - 28)

Use military time when entering the 24 hour 'test' time. The 24 hour test report to phone number 1 takes up four

locations, from addresses 25 - 28. The default is 00:00 (12:00 midnight). The limits for each location are as follows (do not use values of A - F as entries).

25: enter 0, 1 or 2

26: enter 0 - 9

27: enter 0 - 5

28: enter 0 - 9

Primary Central Station Number 24/12/8/6 Hour Test Time Interval (29)

The test report sent to the Primary phone number may be sent every 6, 8, 12 or 24 hours. If the message is to be

sent every 24 hours, leave the factory default entry of '0'. If other test report times are needed, enter 1 = 12 hour,

2 = 8 hour or 3 = 6 hour.

Secondary Central Station Phone Number (30 - 49)

Addresses 30 - 49 are factory set to 'F' (30_F to 49_F). Programming is typically done as follows:

If your phone number is 484-7161, press 4.

The display will read 30_4.

Press [ENTER/STORE] to save the entry to memory and increment to the next address 31_F.

Enter the remaining numbers in their respective addresses as shown below:

Entry

4 8 4 7 1 6 1 F F F F F F F F F F F F F

Address

30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49

Valid entries for both the primary and secondary phone numbers are 0 to 9 and A to F with the numeric digits as

dialed numbers and the hexadecimal digits representing the following functions:

• A = * on a Touch-Tone phone keypad

• B = # on a Touch-Tone phone keypad

• C = look for secondary dial tone for up to two seconds (then dial anyway)

• D = three second pause

• E = five second pause

• F = end of phone number (Note: F must remain in all unused phone number addresses)

411 Communicator Document #50921 Rev. D 11/07/2005 P/N 50921:D 29

Page 30

Program Mode

Secondary Central Station Number Communication Format (50)

One location is needed to select the Communication Format to the secondary phone number. Address 50 is used

for this purpose. The factory default setting for this address is 'E', which is Contact ID Format. You may enter '0'

through 'D' in place of the default, then press [ENTER/STORE]. Choose from the list of formats below:

0: 4+1 Ademco Express Standard, DTMF, 1400/2300 ACK

1: 4+2 Ademco Express Standard, DTMF, 1400/2300 ACK

2: 3+1 Standard 1800 Hz Carrier, 2300 Hz ACK

3: 3+1 Expanded 1800 Hz Carrier, 2300 Hz ACK

4: 3+1 Standard 1900 Hz Carrier, 1400 Hz ACK

5: 3+1 Expanded 1900 Hz Carrier, 1400 Hz ACK

6: 4+1 Standard 1800 Hz Carrier, 2300 Hz ACK

7: 4+1 Expanded 1800 Hz Carrier, 2300 Hz ACK

8: 4+1 Standard 1900 Hz Carrier, 1400 Hz ACK

9: 4+1 Expanded 1900 Hz Carrier, 1400 Hz ACK

A: 4+2 Standard 1800 Hz Carrier, 2300 Hz ACK

B: 4+2 Expanded 1800 Hz Carrier, 2300 Hz ACK

C: 4+2 Standard 1900 Hz Carrier, 1400 Hz ACK

D: 4+2 Expanded 1900 Hz Carrier, 1400 Hz ACK

E: Contact ID, DTMF, 1400/2300 ACK

F: Future use

The Format selected in address 50 will cause the digital communicator to automatically program addresses 202 - 265

with the factory default settings. Any of the Event Code settings may be altered. Consult your Central Station prior

to altering the event code settings. An entry of all zeros for any event code will cause the communicator to NOT