Firegear FPB-25MT/N, FPB-2020MT/N, FPB-2626MT/N, FPB-3232MT/N, FPB-3838MT/N Installation And Operating Instructions Manual

...

MODELS

Match Throw Description Manual Spark

FPB-19MT/N 19” rd. pan & restar FPB-19MSI/N

FPB-25MT/N 25” rd. pan & restar FPB-25MSI/N

FPB-1212MT/N 12”x12” sq. pan & restar FPB-1212MSI/N

FPB-1414MT/N 14”x14” sq. pan & restar FPB-1414MSI/N

FPB-2020MT/N 20”x20” sq. pan & restar FPB-2020MSI/N

FPB-2626MT/N 26”x26” sq. pan & restar FPB-2626MSI/N

FPB-3232MT/N 32”x32” sq. pan & restar FPB-3232MSI/N

FPB-3838MT/N 38”x38” sq. pan & restar FPB-3838MSI/N

FPB-5050MT/N 50”x50” sq. pan & restar 50-inch not available

Outdoor Match Throw/ Manual Spark Fire Pit

Installation and Operating Instructions

IF YOU CANNOT READ OR UNDERSTAND THESE INSTALLATION INSTRUCTIONS DO

NOT ATTEMPT TO INSTALL OR OPERATE THIS APPLIANCE

INSTALLTION PRECAUTION:

This re pit requires a minimum 18-square inches (per side) of cross ventilation.

Failure to provide proper ventilation can void the warranty.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

Warning: For Outdoor Use Only

!! !!!"#$%&!

!

"#!$%&!'()**!+,'-!

!

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. If odor continues, keep away

from the appliance and

immediately call your gas

supplier or fire department.

!!'"&#(#$!

!

.%!/%0!'0%1)!%1!&')!+,'%*2/)!%1!%03)1!

#*,((,4*)!5,6%1'!,/7!*28&27'!2/!03)!

5292/20$!%#!032'!%1!%03)1!,66*2,/9):!

!

;/!<=>9$*2/7)1!/%0!9%//)90)7!#%1!&')!

'3,**!/%0!4)!'0%1)7!2/!03)!5292/20$!%#!032'!

%1!,/$!%03)1!,66*2,/9):!

!!!"#$%&! ! ! )"&*+#,-+#+.(!%,/"00"&!,

,

1234,56673589:,958,6;<=>9:,95;?<8,@<8<A3=:,

B2392,254,8<,<=<;C,

,

D438E,3F,38,58,:897<4:=,4659:,958,G377,H<>C,

,

#:I:;,>4:,F234,56673589:,38,58,:897<4:=,4659:,

4>92,54,5,95@6:;J,F:8FJ,95;,<;,2<@:C,

!

'"&#(#$-!!"#!03)!2/#%1(,02%/!2/!03)')!2/'01&902%/'!2'!/%0!#%**%?)7!)@,90*$A!,!#21)!%1!

)@6*%'2%/!(,$!1)'&*0!9,&'2/+!61%6)10$!7,(,+)A!6)1'%/,*!2/B&1$!%1!7),03:!

!

K+&,L+D&,M"K%1L,

.%!/%!'0%1)!%1!&')!+,'%*2/)!%1!%03)1!#*,((,4*)!5,6%1'!,/7!*28&27'!2/!03)!5292/20$!%#!

032'!%1!,/%03)1!,66*2,/9):!

!! !!'"&#(#$!

"(61%6)1!2/'0,**,02%/A!,7B&'0()/0A!

,*0)1,02%/A!')1529)!%1!(,2/0)/,/9)!9,/!

9,&')!2/B&1$!%1!61%6)10$!7,(,+):!!C),7!

03)!2/'0,**,02%/A!%6)1,02/+!,/7!

(,2/0)/,/9)!2/'01&902%/'!03%1%&+3*$!

4)#%1)!2/'0,**2/+!%1!')15292/+!032'!

)8&26()/0!!!!!!

'"&#(#$,

.%!/%0!*),5)!&/,00)/7)7!7&12/+!&'):!

.%!/%0!&')!#%1!9%%D2/+:!

E%**%?!,**!+,'!*),D!61%9)7&1)'!2/!032'!

(,/&,*!612%1!0%!%6)1,02%/:!

Matchlight Fire Pits

REV. 10-24-12 Page 1

!

"#$%&!#&$'!()!*+&!,(-$'!+..%(+)/$&0!+)'!12$!.-3'#/1&!3,!/345#&1(3)!3,!&#/2!,#$%&0!/3)1+()!

/2$4(/+%&!6)37!13!12$!81+1$!3,!9+%(,3-)(+!13!/+#&$!/+)/$-0!5(-12!'$,$/1&!+)':3-!312$-!-$.-3'#/1(;$!

2+-4<!=2(&!7+-)()*!(&!(&&#$'!.#-&#+)1!13!9+%(,3-)(+!>$+%12!?!8+,$1@!93'$!8$/<ABACD<E!

TABLE OF CONTENTS

Specications 3

Preparation for Non-Conbustible Structure 4

Hard Piping to Fire Pit 4

Cross Ventilation Requirements 4

High Elevation 4

Installation into an Approved Enclosure 5

Requirements 5

Installing Key Valve & Piezo Ignitor 5

Typical Installation Drawings 6

Installing Battery in Piezo Ignitor 7

Ignitor Alignment 7

Installation of Lava Rock/Media 7

Operation 8

Lighting Instructions 8

Air Shutter Adjustment 8

Replacement Parts 9

Replacement Parts List 10

Fire Pit Maintenance/ Trouble Shooting 11

Optional Accessories/Conversion Kits 11-12

Warranty 13

NOTE: This installation instruction covers both Match Throw and Manual Spark

Igntition systems. Not all sections will be applicable to your particular application.

Matchlight Fire Pits

REV. 10-24-12 Page 2

5” Max.

5” Max.

2” Min.

1” Max.

A

C

B

Most re pits are equipped for Natural gas (NG) however, if you are considering converting to LP gas

use the guidelines below for proper tank storage.

REMOTE PROPANE / LP GAS ENCLOSURES

INSTALLATION GUIDELINES

If this re pit is permanently connected to a gas piping

system from a remote supply tank, installation must be in

accordance with local codes or, in absence of local codes,

with the National Fuel Gas codes ANSI Z223/1/NFPA 54.

If constructing an enclosure to conceal a propane •

tank/LP cyclinder- the enclosure must adhere to the

following construction requirements:

Enclosures may be constructed with one side •

compeletely OPEN or if the enclosure is built with four

(4) sides, a top and a bottom, then as ollows:

A Propane/LP gas cyclinder enclosure requires four •

(4) ventilation openings at the top and bottom of the

enclosure. The openings must adhere to the minu-

mum requirements according to the capacity of the

cyclinder (See diagram 1).

Each opening in the enclosure must be equally sized •

and spaced at a minimum of 180º. Openings must

remain unobstructed.

Top ventilation openings are required on the side walls •

of the enclosure within 5-inches (127mm) of the top

enclosure. They need to be of equal size,

unobstructive and spaced 180º apart. The openings

need to be a total area of 1 in² /lb (14.2 cm²/kg) of fuel

storage capacity.

Every opening must have minmum dimensions to allow •

entrance of a 1/2” (3.2 mm) diameter rod.

Ventilation openings in side walls must not connunicate •

directly with other enclosures of the re pit.

The cyclinder valve must be easily accessible by hand. •

Connections should be easy to leak test inside the

enclosure. A door on the enclosure is acceptable only if

easily opened without the use of tools and is non

locking.

The enclosure needs to be isolate the cylinder from the •

burner compartment and provide protection from

radiation, act as a ame barrier and protect cylinder

from foreign material.

The enclosure needs to allow connection, disconnec-•

tion and inspection of the connection of the LP gas

cylinder.

The enclosure should allow testing of any connetion on •

the LP cylinder that might be distrubed during

installation.

Bottom opening must provide a minimum of 1/2 •

square inches (3.23 cm²) for each pound of propane/

LP

contained in the tank (see example below.

Propane/LP Tank Enclosure Specications

A - Opening 180º apart from each other

B - Min. 2” (50.8mm) from oor/ground to base of tank

C - Max. 1” (25.4mm) from tank base to bottom of opening

Matchlight Fire Pits

Diagram 1.

REV. 10-24-12 Page 3

SPECIFICATIONS

36”

96”

24”

Maximum

Overhang

Center of Flame

!

A

B

C

.875 TYP. (usable flat lip)

*

*

D

Ground Level

Model A

Pan Depth

B Min/Max

Install Opening

C

Inside Pan

Ground Level

FPB-19MT/N (Rd.) 2.625” 19.25”/21.5” 19” 8”

FPB-25MT/N

FPB-1212MT/N

FPB-1414MT/N

FPB-2020MT/N

FPB-2626MT/N

FPB-3232MT/N

FPB-3838MT/N

FPB-5050MT/N

Table1. Fire Pit Dimensions

(Rd.) 2.625” 25.25”/27.5” 25” 8”

(Sq.) 2.625” 12.25”/13.75” 12” 8”

(Sq.) 2.625” 14.25”/15.75” 14” 8”

(Sq.) 2.625” 20.25”/21.75” 20” 8”

(Sq.) 2.625” 26.25”/27.75” 26” 8”

(Sq.) 2.625” 32.25”/33.75” 32” 8”

(Sq.) 2.625” 38.25”/39.75” 38” 8”

(Sq.) 2.625” 50.25”/51.75” 50” 8”

D

Figure 1. Fire Pit dimensions; refer to Table 1. (Dimensions applicable to

round or square pans)

Model

Btu’s

Natural/Propane (LP)

FPB-19MT/N 60,000 Btu’s

FPB-25MT/N 100,000 Btu’s

FPB-1212MT/N 20,000 Btu’s

FPB-1414MT/N 36,000 Btu’s

FPB-2020MT/N 60,000 Btu’s

FPB-2626MT/N 100,000 Btu’s

FPB-3232MT/N 160,000 Btu’s

FPB-3838MT/N 200,000 Btu’s

FPB-5050MT/N 240,000 Btu’s

Table 2: Btu Specications based on 7.0”WC - NG and 10.0”WC -LP

Note: Fire pits are rated at maximum Btu’s which is dependent upon proper gas pipe sizing. Flex line size also affect

Btu’s. As a result your Btu’s will may vary from Table 2 specications listed above.

Matchlight Fire Pits

Factory Orice

NG LP

#31 #44

#22 #34

#50 #55

#42 #51

#31 #44

#22 #34

#8 #28

#2 #22

#0 #18

Figure 2. Clearance to Combustibles

(Not to be used in an enclosed space)

NG LP

Min.

5.0”WC 11.0”WC

Inlet

Max.

10.5”WC 13.0”WC

Inlet

Table 3. Gas Pressures

REV. 10-24-12 Page 4

WARNING: Proper clearances from combustible, construction and materials must be maintained from all sides, top and

Fire Pit

Enclousure

2”x3”

Fire Pit

Examples of Cross Ventilation

3 - 2”x3” Slots Per Side or

2- 1” x 9” Slots Per Side

Cross Flow Ventilation

(Min. 18 Sq. In. Per Side)

bottom of this appliance. This appliance should never be placed on any combustible surface. This appliance should

never be placed under any combustibles closer then 96-inches. This appliance should never be placed closer than

36-inches from any side to any combustible construction or materials (See g. 2, pg. 3).

PREPARING A NON-COMBUSTIBLE STRUCTURE

The Fire Pit is to be installed on a at, stable surface, away from any combustible materials. Install Fire Pit on any level,

outdoor non-combustible surface. NOTE: Do not place re pit directly on grass, dirt, or rocks this may prevent proper ventilation (Fig. 1, pg. 3). Ensure proper water drainage is also incorporated into the re pit enclosure.

HARD PIPING TO FIRE PIT WITHOUT GAS PROXIMITY

NOTE: We recommend using 3/4” black iron pipe however please refer to the NFPA54 (National Fuel Gas Code) for

proper pipe sizing when exceeding 20-feet in length for re pits rated above 100,000 Btu’s.

1. Turn OFF gas supply system. NOTE: All gas connections (except for brass to brass) require the following. Clean pipe

threads using either a wire brush or steel wool. Apply Teon tape or pipe sealant to the steel ttings before making any

connection. BE CAREFUL! Ensure all gas connections are snug, but not over tighten!

2. Extend the gas supply system using minimum of ¾” black iron pipe or an approved exible gas line from existing house

supply. This can be accomplished by teeing off or tapping into a convenient gas line connection. Install necessary pipe

for the distance required and then install a manual shut-off valve at the exterior house wall. If pipe is to pass through a

foundation or house wall, make sure to re-seal the area around the pipe with weather sealant.

3. From manual valve, extend gas pipe to the Fire Pit location. NOTE: If pipe is to be placed in an underground trench,

check with local codes for required depth and materials needed.

4. Install a ¾” female x ½” male ared brass tting to the end of the ¾” black iron pipe. Be sure to clean the pipe threads

and use Teon tape or pipe sealant.

5. Connect the ½” female ared ex connector from the Fire Pit to the ½” male ared brass tting secured to the black iron

pipe. Note: Flare to are connections do not require Teon tape or pipe sealant.

IMPORTANT

Installation of Natural or LP gas should be done by a qualied installer, service agency or gas supplier.

The appliance and its manual shutoff valve must be disconnected from the gas supply piping system during any

pressure testing of the system at test pressure testing of the system at test pressures in excess of ½ psig (3.5kPa).

This appliance must be isolated from the gas supply piping system by closing its manual shutoff valve during any

pressure testing of the gas supply piping system at test pressures equal to or less than ½ psig (3.5kPa)

NOTE: LP conversion kits are available in the Accessory/Conversion Kit section of this manual. When converting a Fire Pit

ensure you follow the instructions supplied with the

conversion kit.

VENTILATION FOR NON-COMBUSTIBLE ENCLOSURE

Fire pits are subjected to many outdoor elements such as

rain, snow, wind, heat or cold. A minimum of 18 square

inches of cross ventilation (2 sides) is required to keep the

components in good working order. Use gure 3 as guide

to assist to incorporate proper ventilation. NOTE: Ventilation is

not required at the bottom and may also be incorporated in the

upper portion of an enclosure.

HIGH ELEVATION INSTALLATION

This appliance is listed for elevations from 0-4500 feet in

Canada and the U.S. If elevation exceeds 4500 feet it may be

necessary to decrease the input rating by changing the existing burner orice to a smaller size. Input should be reduced

4% for each 1000 feet beyond the 4500 feet above sea level.

Check with your local gas utility for assistance in determining

the proper orice in your location. In some cases the heating

value may already be reduced and downsizing the orice may

not be necessary.

Matchlight Fire Pits

Figure 3. Cross Ventilation Example

REV. 10-24-12 Page 5

INSTALLATION OF FIRE PIT INTO AN APPROVED ENCLOSURE

Primary Gas

Supply

ON

OFF

REQUIREMENTS

1. Only non-combustible materials should come in direct contact with any part of the Fire Pit. Underneath area should

be non-combustible as well.

2. Only use ¾” gas supply line to the Fire Pit. Based on the selection of the re pit size, the proper brass ttings should

be used to ensure a proper installation.

3. Determine the size of the round or square Fire Pit you are preparing to install (Refer to page 3).

4. You must provide a round or square opening out to place the re pit into the non-combustible enclosure surround.

Do not exceed the maximum opening from Table 1, dimension B.

5. Follow the local code requirements for the gas type being used. This Fire Pit should be installed in accordance with

local codes and ordinances or in the absence of local codes, with the latest National Fuel Gas Code, ANSI Z223.1

NFPA54 or CSA B149.1, Natural and Propane Installation Code in Canada.

6. Fire Pits create high temperatures, it is very important to have any combustibles at a safe distance.

7. CAUTION: A minimum of 18 square inches of cross ventilation (per side) is required to keep the enclousure

dry.

8. These products are designed for outdoor use only. Not approved for any indoor use.

9. This Fire Pit is designed to have Lava Rock/Media completely covering the re star burner, so that the re star is

invisible. Do not cover more than 1” above the top of the covered re star burner. When purchasing Lava Rock it

is recommended to use minimum of 1” diameter as a base to ll the burner pan. Decorative glass covering may

be loosely scattered on top of the rock if desired or non-combustible logs may be added for a campre look. If logs

are chosen, do not place on decorative glass base, use only Lava Rock as the base. NOTE: If using all glass

media, glass must be a minimum of 1/4-inch diameter or larger.

10. Gas lines and ttings must be installed in to the non-combustible structure. All gas connections must be leak tested

before installation of the re pit. Soapy water leak detection is required before regular use of the re pit.

11. Do not use material that will absorb moisture over time and will not release this moisture quickly. Moisture can boil

in this material and can rapidly break apart and cause damage or personal injury.

12. Never leave any other combustible material on top of the re pit. This could cause unsafe operation of this system

and damage to the component that will not be covered under our warranty.

13. Cover the complete burner with lava or decorative Rock material (min. 1-inch diameter). Completely cover the

star burner, no more than 1-inch above the restar burner.

INSTALLING KEY VALVE AND PIEZO IGNITOR

The key valve contents: 1- key valve, 1- key and 1- ange. (See gure 4). The valve requires a 1 1/4” round clearance

hole in the non-combustible enclousure wall. See the instructions supplied with the key valve for more specic details.

Note: Be sure to leak test all tting before operation. Figure 5 shows an example of a typical installation.

After the re pit pan is installed run the piezo ignitor wires into the electrical junction box. Piezio wires are 24-inches in

length; ensure your installation does not exceed the wire length for proper connection.

Fig. 4 Key valve components.

Matchlight Fire Pits

REV. 10-24-12 Page 6

Manual Spark

Piezo Ignitor

Key Valve

Gas Supply

Fire Pit Pan

Non-Combustible

Fire Pit Enclousure

Shut-O

Key Valve Flange

NonCombustible

Wall Material

Non-

Combustible

Wall Material

Key Valve

Primary Gas

Supply

NonCombustible

Wall Material

NonCombustible

Wall Material

Securing Tab

Securing Tab

Self-Securing

Junction Box

Piezo Ignitor

Mounting Plate

Piezo Wires

NOTE: Gas supply shut-off and ex

line to the key valve are not supplied.

i

d

S

e

v

l

a

V

y

e

K

e

V

g

I

o

z

e

i

n

o

t

i

P

i

e

w

D

e

t

a

i

l

d

i

S

r

e

V

i

e

w

D

e

t

a

i

l

Matchlight Fire Pits

Fig. 5 Typical installation.

REV. 10-24-12 Page 7

+

-

AAA

Plastic Mounting Nut

Module Red

Button Cap

Fire Star Burner

Ignitor Aligned Over

Top Port Hole

Lava Rock

Lava Rock

Lava Rock

Ignition Hood

Screen Cover

INSTALLATION OF BATTERY INTO PIEZO IGNITOR (Manual Spark Ignition only)

Fig. 6 Piezo ignitor cap.

Fig. 7 Piezo ignitor battery installation.

Unscrew (counter-clockwise) the piezo ignitor module red button cap and the plastic mounting nut. Slide the module on

the back side of the module cover plate and secure with the plastic mounting nut. Insert the positive end of (1) AAA

battery into the ingitor module and carefully screw the red button cap to the ignitor module until snug. Careful not to overtighten the cap. Attach the extension wires (PIEZO23WH/25WH) to the 2-probe spark ignitor. Careful not to overtighten

the cap. Test the ignitor by pushing and holding the red button to ensure the ignitor probes inside the re pit are sparking. The spark should be located diectly overtop of the burner port

hole for proper ignition of the gas (See g.8). Spacing between the

probes should be approximatel 1/8-inch for proper spark.

IGNITOR ALIGNMENT (Manual Spark Ignition only)

For proper ignition it is important that the ignitor probes be properly aligned overtop of the burner port holes. Use the Fig.8 as

a guide. Before lighting remove the screen cover of the ignition

hood to burner and ensure the spark probes are directly overtop of

a burner port hole. The sparking probes must be in the path of a

ame to ignite the gas for

proper ignition of the ame.

Replace the screen cover and follow the operating instructions.

Fig. 8 Proper ignitor probe location.

INSTALLATION OF LAVA ROCK/MEDIA INTO BURNER PAN

Install lava rock/media into the burner pan. Ensure the media is a minimum of

1-inch diameter for proper operation. Note: Do not pour Lava Rock directly from

bag. Media should be placed naturally and NOT packed in tight. Loose tting is

important to ensure robust ames. Be sure rocks are free of any excessive dust.

This prevents the burner pan weep holes from being plugged and holding water.

IMPORTANT: Do not place media over top or under the screen cover. The

screen must be free of any debris to ensure proper lighting of burner and good

ame rectication (See g. 8).

Cover the burner completely with media but do not make the depth greater than

1-inch overtop of the burner portholes.

Decorative glass may be loosely scattered on top of the lava rock. Do NOT

cover the stainless steel screen cover with any rock or glass. It must be free an

any debris to operate properly.

Matchlight Fire Pits

Fig. 9 Keep screen cover exposed

REV. 10-24-12 Page 8

OPERATION

To Close

CAUTION: Children and adults should be alerted to the hazards on high surface temperatures and should stay away to

avoid burns or clothing ignition. Young children should be carefully supervised when they are in the area of the appliance.

WARNING: Do not use this appliance if any part has been under water. Immediately call a qualied service technician

to inspect the appliance and to replace any part of control system and any gas control, which has been under water.

SAFETY WARNINGS

1. Never leave the Fire Pit unattended during operation.

2. Clothing or other ammable materials should not be placed on or near the appliance.

3. Any guard or other protective device removed for servicing the appliance must be replaced prior to operating the

appliance.

4. Installation and repair should be done by a qualied service person. The appliance should be inspected before

use and at least annually by a qualied service person. More frequent cleaning may be required as necessary. It

is imperative the control compartment, burners and circulating air passageways of the appliance be kept clean.

5. Inspect the fuel supply connection before each use of the appliance.

6. Temporary storage of this appliance indoors is permissible only if it has been disconnected from its fuel supply

(Natural or L.P. gas line).

WARNING

1. This appliance is hot when operated and can cause sever burns if contacted.

2. Do not burn any solid fuels in this appliance.

MANUAL SPARK IGNITION LIGHTING INSTRUCTIONS

READ ALL LIGHTING INSTRUCTIONS BEFORE ATTEMPTING TO LIGHT FIRE PIT

CAUTION: Ensure you have leak tested the re pit before operating.

1. Insert key into gas valve.

2. Push and hold the red button on the manual Piezo ignitor and ensure sparking is

occurring at the probes inside the re pit.

3. Rotate the key counter-clockwise in gas valve to allow gas to ow.

4. Gas should ignite within 10 seconds or less. If re pit does not light within

10 seconds turn key clockwise to turn OFF the gas supply. Check igiitor probe

loc ation (Fig. 8), ensure there is an 1/8” gap between the probes with a good stong

spark then repeat steps 2 through 4.

Once re pits lights ame color adjustment can be made turning the air shutter nut

under the burner pan. It is recommended that the nut be OPENED until the gas/air

mixture makes a rushing sound (like a blow torch); then slowly CLOSE until the rushing

sound diminishes. A desirable ame is bright yellow with little or no brown at the tips.

Too yellow ame can create excessive sooting (See g. 10).

Fig. 10 Air shutter adjustment

MATCH THROW LIGHTING INSTRUCTIONS

READ ALL LIGHTING INSTRUCTIONS BEFORE ATTEMPTING TO LIGHT THE FIRE PIT

CAUTION: Ensure you have leak tested the re pit before operating.

1. Insert key into gas valve.

2. Light a long match or butane lighter and hold it near the burner.

3. Rotate the key counter-clockwise in gas valve to allow gas to ow and simultaneously apply the burning match as

close to burner as possible to light the re pit.

4. Gas should ignite within 10 seconds or less. If re pit does not light within

10 seconds turn key clockwise to turn OFF the gas supply. Ensure there is not too much media on top of restar that

my inhibit gas ow and try again.

Matchlight Fire Pits

REV. 10-24-12 Page 9

REPLACEMENT PARTS

ON

OFF

8

3

1

9

5

10

6

7

11

2

12

14

Side View

13

17

Matchlight Fire Pits

REV. 10-24-12 Page

REPLACEMENT PARTS

Item

1 19-inch Round Stainless Burner Pan

1 25-inch Round Stainless Burner Pan

2 12-inch Square Stainless Burner Pan

2 14-inch Square Stainless Burner Pan

2 20-inch Square Stainless Burner Pan

2 26-inch Square Stainless Burner Pan

2 32-inch Square Stainless Burner Pan

2 38-inch Square Stainless Burner Pan

2 50-inch Square Stainless Burner Pan

3 9-inch restar (used on 12” Sq. Pan)

3 12-inch restar (used on 14” Sq. Pan)

3 18-inch restar (used on 19” Rd. & 20” Sq. Pans)

3 24-inch restar (used on 25” Rd. & 26” Sq. Pans)

3 30-inch restar (used on 32” Sq. Pans)

3 36-inch restar (used on 38” Sq. Pans)

3 48-inch restar (used on 50” Sq. Pans)

4 1 x 2 1/4” Blank Cover Plate (not shown)

5 1/2” NPT Conduit Lock Nut

6 7/8” Flat Washer/Spacer

7 3/8” Flex Gas Line (28-inch Length)

7 1/2” Flex Gas Line (46-inch Length)

8 Air Shutter Orice NG #50 (Used on 12” Fire Pits)

8 Air Shutter Orice NG #42 (Used on 14” Fire Pits)

8 Air Shutter Orice NG #31 (Used on 19/20” Fire Pits)

8 Air Shutter Orice NG #34 (Used on 25/26” Fire Pits)

8 Air Shutter Orice NG #2 (Used on 38” Fire Pits)

9 Manual Spark Ignitor Module

10 Manual Spark Ignitor Module Cover Plate (w/Screws )

11 Ignition Hood

12 Ignition Hood Screen Cover

13 2-Probe Manual Spark Ignitor

14 Junction Box - With Self Securing Tabs

15 AAA Battery

16 Stainless Steel Thread Cutting Screws - (Not Shown)

17 Manual Key Valve - Valve, Key and Flange

Description

Qty.

Part Number

1 OD-FPBOWL/19

1 OD-FPBOWL/25

1 OD-FPPAN/12x12

1 OD-FPPAN/14x14

1 OD-FPPAN/20x20

1 OD-FPPAN/26x26

1 OD-FPPAN/32x32

1 OD-FPPAN/38x38

1 OD-FPPAN/50x50

DFS-9

1 DFS-12

1 DFS-18

1 DFS-24

1 DFS-30

1 DFS-36

1 DFS-48

1 ST3-100-1030

1 ST3-113-1027

1 ST3-113-1026

1 T-100-9898-28

1 T-200-9898-46

1 FPB-12NGCK

1 FPB-14NGCK

1 FPB-19NGCK

1 FPB-25NGCK

FPB-38NGCK

1 ST3-040-1020

1 ST3-100-1035

1 ST3-100-1031

1 ST3-100-1027

1 1823-106

1 FG-Junction Box

1 ST1-060-1004

6 ST3-113-1028

1 FG-KVHC-PC

Note: No orice is used with the 48-inch re pit.

Matchlight Fire Pits

REV. 10-24-12 Page 11

FIRE PIT MAINTENANCE

1. The Fire Pit should be inspected and cleaned before initial use at least annually by a qualied eld service person.

2. Any component that is found faulty must be replaced with an approved component.

3. Any tampering or modifying with the Fire Pit is dangerous and voids all warranties.

4. During winter months in cold climates and various seasons operation the Fire Pit may be affected by weather condi

tions. It is recommended to use a ventilated cover overtop of your Fire Pit to protect it from humid/rainy weather condi

tions when not in use. Heavy rains/downpours could affect the Fire Pit operation if not covered; if this occurs ensure

you allow the Fire Pit time to dry out before attempting to operate. NOTE: If a combustible type cover is used over the

Fire Pit when not in use be sure to remove it before operation to prevent a severe safety hazard.

5. Carbon (soot) may build up on the surface of logs (if installed) during heavy use. Sooting may also occur periodically

on the screen of the ignitor hood. To clean, brush off with a dry bristle brush or cloth. Keep soot away from clothing or

furniture.

6. Over time stainless steel parts discolor when heated, usually a golden or brown hue. This discoloration is normal and

does not affect the performance of the appliance.

TROUBLE SHOOTING

Sympton Remedy

Piezo won’t spark 1. Be sure battery is installed properly.

2. Check battery voltage. Min. 1.2 VDC needed.

3. Check ignitor gap at probes inside re pit. Gap should be at 1/8”.

4. Double check wires to ensure they are plugged in and secured to the spark ignitor and the

spark ignitor module.

Fire pit won’t light 1. Ensure ignitor is aligned properly overtop of burner port hole. See page 7, gure 8.

2. Bleed gas line.

3. Ensure all gas supply lines are turned ON.

4. Ensure there is not too much media overtop of burner; it can inhibit gas from owing.

Low Flame 1. Ensure the base media is at least 1-inch in diameter and top media is no more than 1-inch over

top of burner.

2. Adjust air shutter at bottom of re pit pan.

3. Ensure all shut-off valves and key valve is fully open. See page 8; gure 10.

Water in my Fire Pit 1. Excess dust/sand material from media may be blocking the weep holes to relieve water.

Remove all media and unplug weep holes. Clean or install new media free of dust and dirt.

2. Ensure re pit enclosure has proper drainage for water and proper ventilation to dry out.

Matchlight Fire Pits

REV. 10-24-12 Page 12

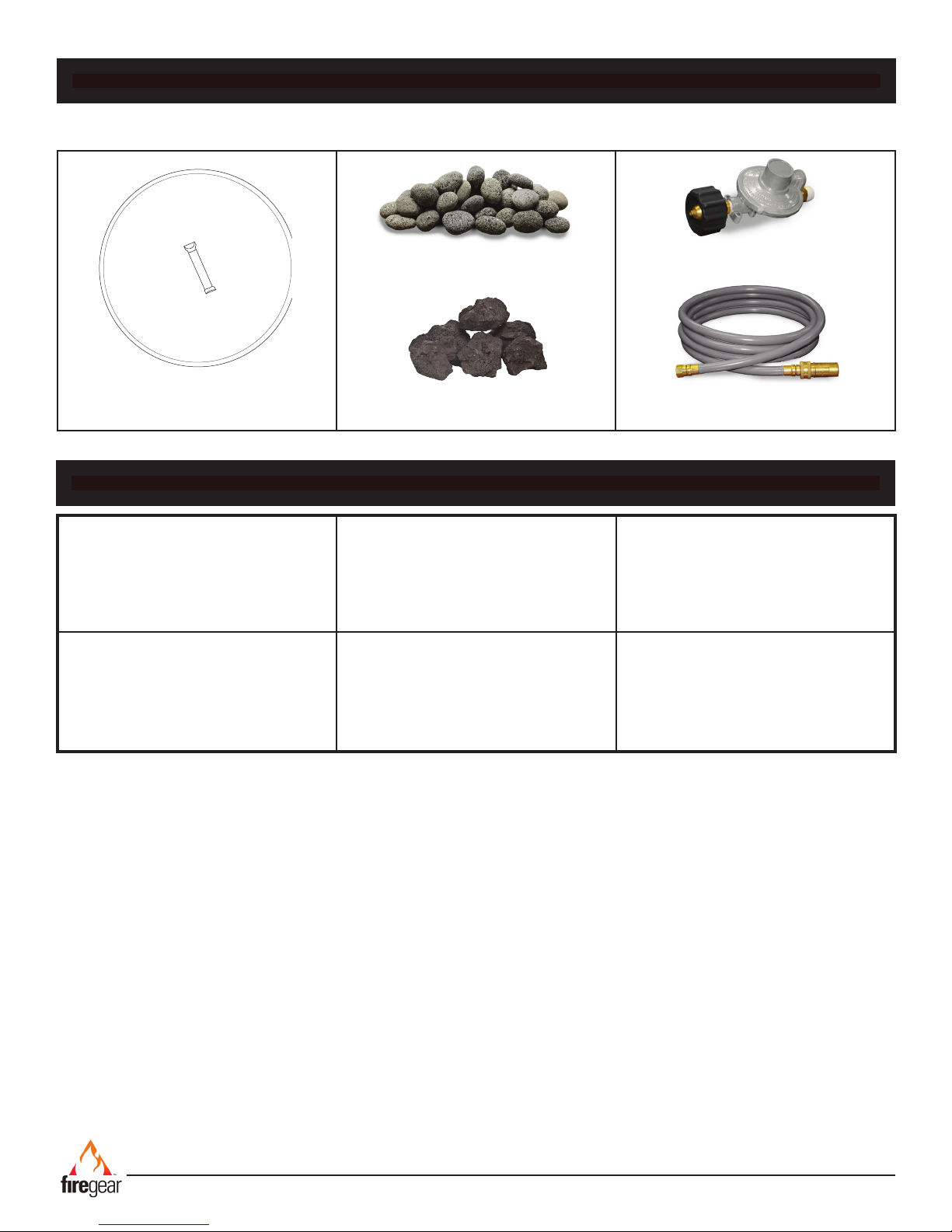

OPTIONAL ACCESSORIES

The following accessories are available from your local regear dealer/distributor. Each accessory comes with a separate

installation manual. Read each instruction thoroughly before installing.

Stainless lid for 19” or 25” round re

pits. Models: FG-19LID or FG-25LID

MODEL: FPB-12LPK

Brass orice/air mixer #56 for

12”x12” re pits using (12-inch restar)

LP Conversion Kit

MODEL: FPB-25LPCK

Brass orice/air mixer #34 for

25” & 26” pits (24-inch restar)

LP Conversion Kit

Lava Stones 1” to 2” size. (20lbs.)

Model: FG-LS20

Lava Boulders 6” to 12” size (30lbs.)

Model: FG-LB30

CONVERSION KITS

MODEL: FPB-14LPK

Brass orice/air mixer #51 for

14”x14” re pits using (14-inch restar)

LP Conversion Kit

MODEL: FPB-32LPK

Brass orice/air mixer #28 for

32”x32” re pit using (30-inch restar)

LP Conversion Kit

LP regulator with 3/8” MPT adapter

Model: FG-LPRK

3/8” Quick connect 12’ hose for NG or

LP gas Model: FG-12QDK

MODEL: FPB-19LPCK

Brass orice/air mixer #44 for

19” & 20” pits using (18-inch restar)

LP Conversion Kit

MODEL: FPB-38LPK

Brass orice/air mixer #22 for

38”x38” re pit using (36-inch restar)

LP Conversion Kit

NOTE: THE MANUFACTURER IS NOT RESPONSIBLE FOR ANY RADIO OR TV INTERFER ENCE CAUSED BY

UNAUTHORIZED MODIFICATIONS TO THIS EQUIPMENT. SUCH MODIFICATIONS COULD VOID THE USER’S

AUTHORITY TO OPERATE THE EQUIPMENT.

FOR TECHNICAL SERVICE, CALL:

Matchlight Fire Pits

FCC REQUIREMENTS

regear, LLC

PO Box 871250

Canton, MI 48187

(888) 220-4333 Ext. #3

Fax (888) 431-0585

WEB SITE: www.regearusa.com

REV. 10-24-12 Page 13

LIMITED WARRANTY

Fire Gear LLC hereby warrants to the ORIGINAL

PURCHASER of this Fire Pit System, that it will be free

from material and workmanship defects that prevent

safe and correct operation of the product commencing

from date of purchase from Fire Gear LLC.

Consumer/Non-Commercial Applications

Stainless Steel Fire Pit Burner Bowl/Pan 5 Years

Stainless Steel - Fire Star 5 Years

Stainless Steel – Valve Box 5 Years

Manual Valve & Spark Ignitor Assembly 1 Year

Commercial Applications

Stainless Steel Fire Pit Burner Bowl/Pan 1 Year

Stainless Steel - Fire Star 1 Year

Stainless Steel – Valve Box 1 Year

Manual Valve & Spark Ignitor Assembly 1 Year

When assembled, installed and operated in accordance

with the accompanying printed instructions.

The Owner must provide a bill of sale, cancelled

check, or payment record to verify purchase date

and establish warranty period. Travel, diagnostic

cost, service labor to repair the defect and freight

charges on warranty parts to and from the factory

will be responsibility of the owner. Fire Gear LLC

will not be responsible for labor charges and/or

damage incurred in installation, repair, and replacement or for incidental or consequential damages.

This Limited Warranty does not cover any failures

or operating difculties due to accident, abuse,

misuse, alteration, misapplication, vandalism,

improper installation or improper maintenance or

service, or failure to perform normal and routine

maintenance.

Damage due to severe weather conditions such as

hail, hurricanes, earthquakes, tornadoes,

discoloration due to over heating, exposure to

chemicals (including salt), either directly or in the

atmosphere, or very high humidity, is not covered

by this Limited Warranty.

Fire Gear LLC may require reasonable proof of your

date of purchase. YOU SHOULD RETAIN YOUR

SALES SLIP OR INVOICE AND RETURN THE

WARRANTY REGISTRATION CARD WITHIN 30 DAYS

OF PURCHASE.

This Limited Warranty shall be valid and limited to,

the original purchaser only, within the connes of

the original site installation.

WARNING: Any modication to this product will

void the warranty!

This Limited Warranty shall be limited to the repair

and/or replacement of parts that prove defective

under normal use and service and which on

examination shall indicate, to Fire Gear LLC’s

satisfaction, that they are defective. Before

returning any parts, contact Fire Gear LLC

Customer Service Center. If Fire Gear LLC conrms

the defect and approves the claim, Fire Gear LLC

will replace such parts without charge.

There are no other express warranties except as

set forth herein and any applicable implied

warranties of merchantability and tness are limited

in duration to the period of coverage of this express

written Limited Warranty. Some states do not allow

limitation on how long an implied warranty lasts, so

this limitation may not apply to you.

Fire Gear LLC is not liable for any special, indirect

or consequential damages. Fire Gear LLC’s liability

is limited to the purchase price of this Fire Gear

LLC Fire Pit System. Some states do not allow the

exclusion or limitation of incidental or consequential

damages, so this limitation or exclusion may not

apply to you.

Fire Gear LLC does not authorize any person or

company to assume for it any other obligation or

liability in connection with the sale, installation, use,

removal, return, or replacement of its equipment;

and no such representations are binding on Fire

Gear LLC.

Matchlight Fire Pits

This Warranty applies only to products sold at retail

and manufactured by:

REV. 10-24-12 Page 14

Loading...

Loading...